Heat treatment process of high-wear-resistance antirust gear steel

A high wear resistance, gear steel technology, applied in heat treatment furnaces, hot dip plating processes, heat treatment equipment, etc., can solve the problems of uneven heat dissipation, low structural integration, affecting the service life of gear steel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

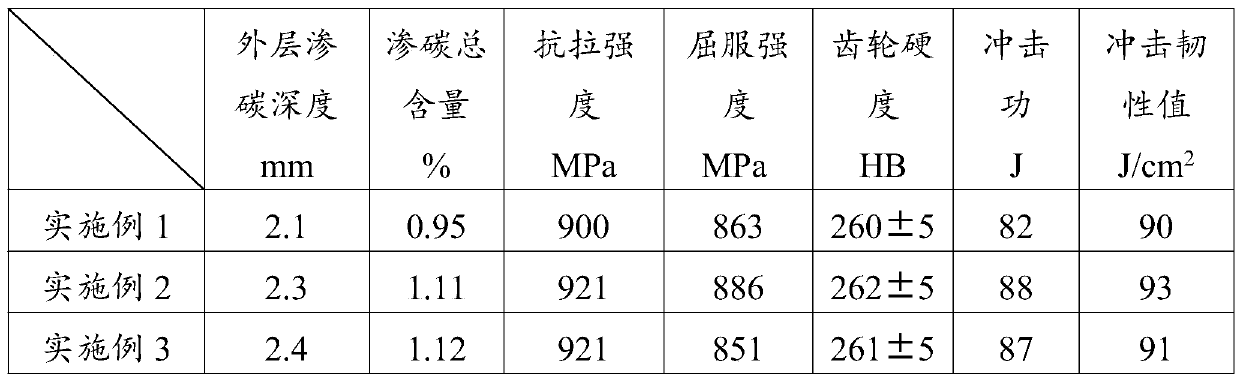

Examples

Embodiment 1

[0031] The invention provides a high wear resistance antirust gear steel heat treatment process, the specific operation steps are:

[0032] Step 1: Use medium alloy steel raw material 30Mn 2 MoW hot die forging gear blanks, pre-heating the gear blanks, performing sub-temperature secondary normalizing to refine the structure, and periodically supplying oxygen to the normalizing furnace at a uniform speed when the gear blanks are heated by the secondary normalizing, And fully pyrolysis combustion dehydrogenation, sub-temperature secondary normalizing process are as follows:

[0033] The first normalizing heating temperature is 930°C, after heating for 30 minutes, keep warm for 20 minutes, and air cool to 500°C;

[0034] The second normalizing heating temperature is 870°C. After heating for 30 minutes, keep it warm for 20 minutes, and then take it out of the oven and air cool to room temperature;

[0035] Excellent strength and toughness are obtained through sub-temperature sec...

Embodiment 2

[0053] The invention provides a high wear resistance antirust gear steel heat treatment process, the specific operation steps are:

[0054] Step 1: Use medium alloy steel raw material 30Mn 2 MoW hot die forging gear blanks, pre-heating the gear blanks, performing sub-temperature secondary normalizing to refine the structure, and periodically supplying oxygen to the normalizing furnace at a uniform speed when the gear blanks are heated by the secondary normalizing, And fully pyrolysis combustion dehydrogenation, sub-temperature secondary normalizing process are as follows:

[0055] The first normalizing heating temperature is 950°C, after heating for 30 minutes, keep warm for 20 minutes, and air cool to 500°C;

[0056] The second normalizing heating temperature is 900°C. After heating for 30 minutes, keep it warm for 20 minutes, and then take it out of the oven and air cool to room temperature;

[0057] Excellent strength and toughness are obtained through sub-temperature sec...

Embodiment 3

[0075] The invention provides a high wear resistance antirust gear steel heat treatment process, the specific operation steps are:

[0076] Step 1: Use medium alloy steel raw material 30Mn 2 MoW hot die forging gear blanks, pre-heating the gear blanks, performing sub-temperature secondary normalizing to refine the structure, and periodically supplying oxygen to the normalizing furnace at a uniform speed when the gear blanks are heated by the secondary normalizing, And fully pyrolysis combustion dehydrogenation, sub-temperature secondary normalizing process are as follows:

[0077] The first normalizing heating temperature is 980°C, after heating for 30 minutes, keep warm for 20 minutes, and air cool to 500°C;

[0078] The second normalizing heating temperature is 920°C. After heating for 30 minutes, keep it warm for 20 minutes, and then take it out of the oven and air cool it to room temperature;

[0079] Excellent strength and toughness are obtained through sub-temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com