A flat combined drag chain cable and its preparation method

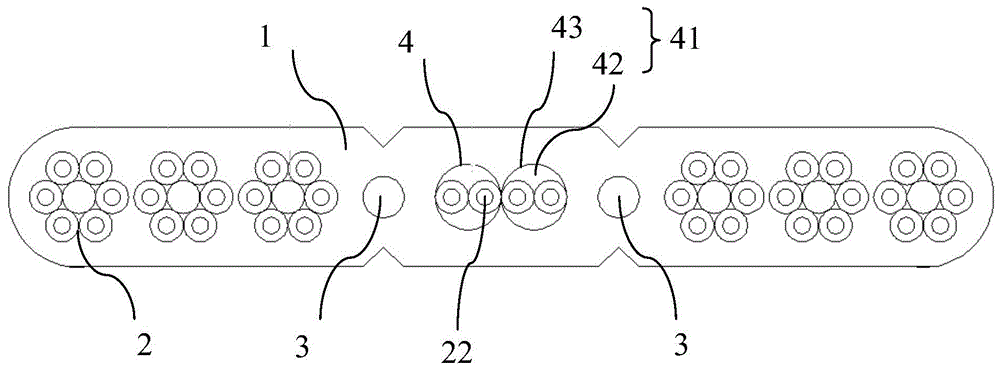

A towline cable, flat technology, applied in the field of flat combined towline cable and its preparation, can solve the limitation of the drag chain system wire and cable adaptability and scope of application, service life, limited bending and tearing resistance, wire Problems such as the inability to make adaptive adjustments to the cables, so as to achieve the effect that the physical and electrical properties are not affected, the installation and operation problems are reduced, and the bending ability is enhanced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present application also provides a preparation method of the towline cable. Since the process control conditions in the preparation process of the towline cable are in the prior art, details will not be repeated here. Wherein, the preparation method comprises the following steps:

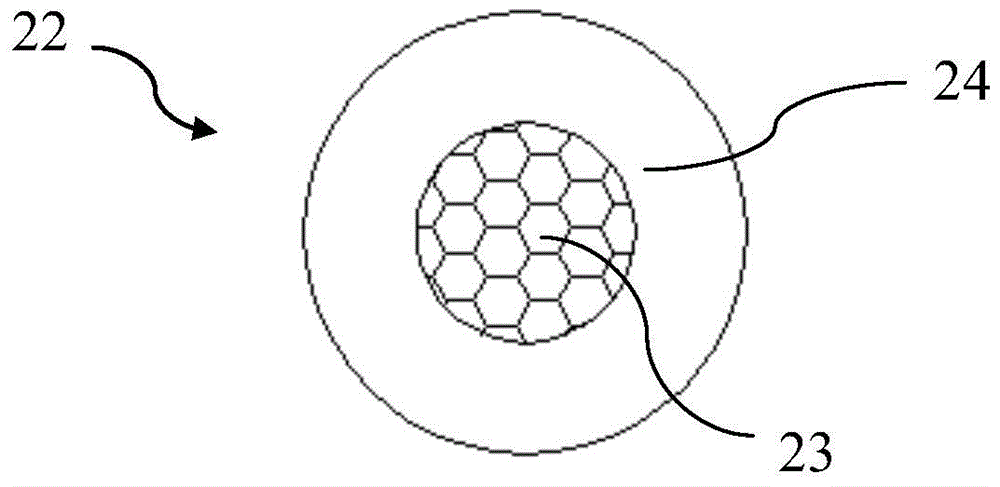

[0048] S1. Conductor preparation: the conductor material is drawn and twisted to obtain the conductor 23 .

[0049] Specifically, conductor preparation includes three sub-steps: material selection, wire drawing and stranding. Material selection: Select the conductor material used according to the requirements of preparing different cables, such as choosing an electrical round copper rod as the conductor material; wire drawing: draw and anneal the conductor material to obtain annealed oxygen-free copper wire, the diameter of the annealed oxygen-free copper wire 0.15 mm; Stranding: The annealed oxygen-free copper wires obtained by wire drawing are twisted into conductors 23 by harness twi...

Embodiment 1

[0055] S1. Conductor preparation: the conductor material is drawn and twisted to obtain the conductor 23;

[0056] S2. Extruding the insulation layer: using an extrusion mold to coat the insulation layer 24 made of nitrile polyvinyl chloride composite material on the outside of the conductor 23 to obtain the insulated core wire 22;

[0057] Among them, the nitrile polyvinyl chloride composite material includes in parts by mass: 15 parts of nitrile rubber, 105 parts of polyvinyl chloride, 3 parts of zinc oxide, 1 part of anti-aging agent RD, 3 parts of stearic acid, 30 parts of clay and diphthalic acid 20 parts of octyl;

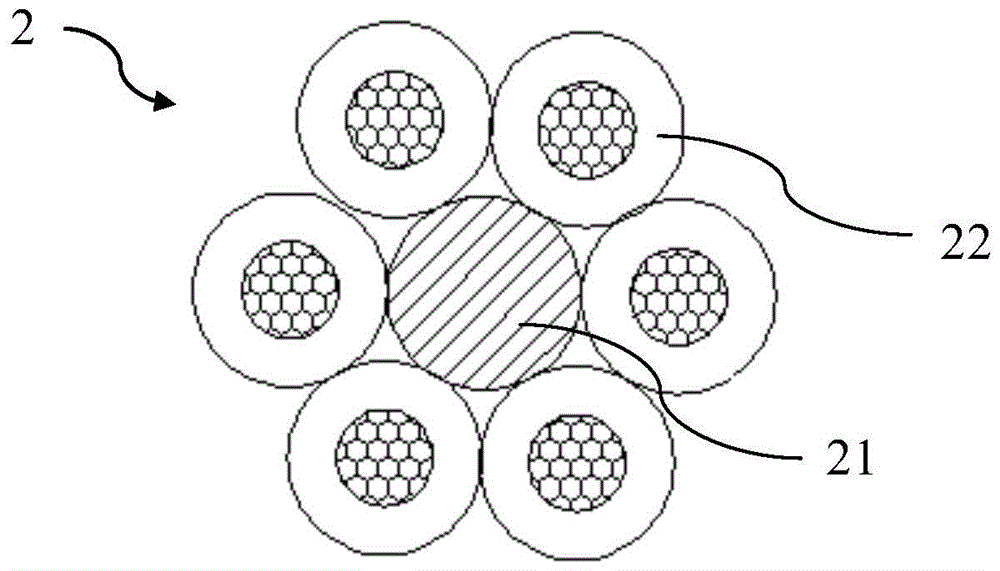

[0058] S3. Wire core preparation: multiple insulating core wires 22 and at least one rubber strip 21 are twisted into a wire core 2, the number of insulating core wires 22 is six, and the number of rubber strips 21 is one;

[0059] S4. Extruded sheath layer: the sheath layer 1 made of nitrile polyvinyl chloride composite material is evenly coated on the outs...

Embodiment 2

[0062] S1. Conductor preparation: the conductor material is drawn and twisted to obtain the conductor 23;

[0063] S2. Extruding the insulation layer: using an extrusion mold to coat the insulation layer 24 made of nitrile polyvinyl chloride composite material on the outside of the conductor 23 to obtain the insulated core wire 22;

[0064] Among them, the nitrile polyvinyl chloride composite material includes in parts by mass: 35 parts of nitrile rubber, 85 parts of polyvinyl chloride, 5 parts of zinc oxide, 1 part of anti-aging agent RD, 3 parts of stearic acid, 45 parts of clay and diphthalic acid 30 parts of octyl;

[0065] S3. Wire core preparation: multiple insulating core wires 22 and at least one rubber strip 21 are twisted into a wire core 2, the number of insulating core wires 22 is six, and the number of rubber strips 21 is one;

[0066] S4. Extruded sheath layer: the sheath layer 1 made of nitrile polyvinyl chloride composite material is evenly coated on the outsi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com