Continuous chrome plating device and method for large rods

A rod and large-scale technology, which is applied in the field of continuous chrome plating device for large hydraulic cylinder piston rod, can solve the problems that the surface of the rod is easy to oxidize and affect the bonding force of the electroplating coating, so as to reduce hydrogen embrittlement, avoid floating rust and passivation layer , The process is simple and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

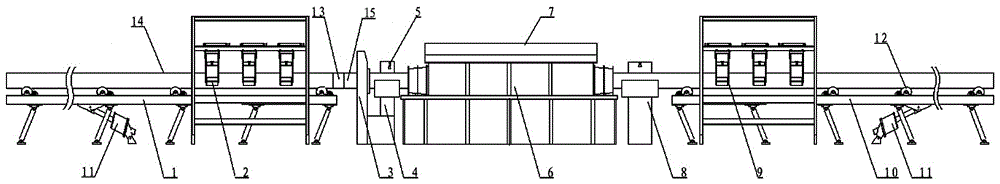

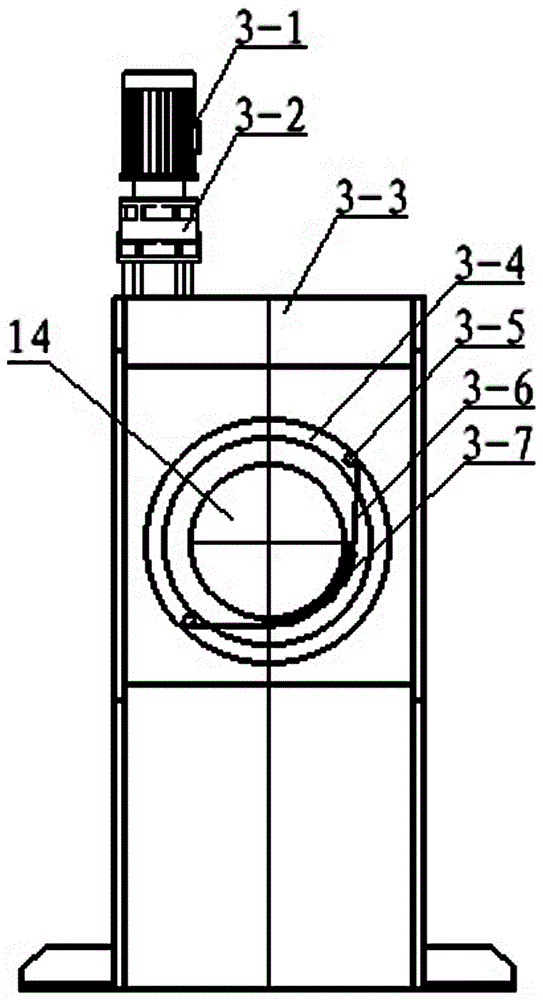

[0029] Such as figure 1 , 2 Among them, a large continuous chrome plating device for rods comprises an electroplating tank 6, which is provided with a through hole for the rods to pass through, and a front bracket 1 and a rear bracket 10 are arranged at both ends of the electroplating tank 6, and the front bracket 1 And the rear support 10 is provided with multiple groups of driving rollers 12, and every group of driving rollers 12 is driven by independent motors and reducers, and then all motors are regulated by frequency converters. A screw lifter 11 is also provided on the front support 1 and the rear support 10 . A front follow-up conductive frame 2 is provided above the front support 1, a rear follow-up conductive frame 9 is provided above the rear support 10, and a conductive element that rotates with the rod is provided on the front follow-up conductive frame 2 and the rear follow-up conductive frame 9. . A rotary sanding device 3 is provided between the front follow...

Embodiment 2

[0035] On the basis of embodiment 1, a kind of method that adopts above-mentioned large bar continuous chrome plating device to carry out continuous chrome plating may further comprise the steps:

[0036] 1. The processed rods are directly cleaned and degreased without pickling;

[0037] Use alcohol or gasoline to clean and degrease the rod as a whole;

[0038] 2. Sanding directly after cleaning and degreasing;

[0039] 3. Spray transition protection fluid after sanding;

[0040] 4. Enter the electroplating tank for continuous electroplating;

[0041] Through the above steps, the continuous chrome plating of the piston rod of the large hydraulic cylinder is realized.

[0042] In the sanding step, use a scouring pad to rotate along the circumferential direction of the rod at a speed of 20-30r / min, and continuously rinse with water at 60-70°C during the sanding process.

[0043] In the step of spraying the transitional protection liquid, use the protection liquid prepared by...

Embodiment 3

[0048] On the basis of Examples 1 and 2, the piston rod specification is 200mm in diameter × 8105mm in length, and the chrome plating process is as follows:

[0049] 1. Degreasing and cleaning: Use alcohol to clean and degrease the surface of the rod as a whole. Alcohol is preferably anhydrous alcohol. Avoid the risk of increased floating rust formation caused by cleaning with water-based degreasers.

[0050]2. Sanding: Use a scouring pad to rotate and sand along the circumference of the rod, and press it on the surface of the piston rod through the compression spring 3-6, the speed is 30r / min, and the washing water temperature is 60°C.

[0051] 3. Transition protection: use 6g / L anhydrous sodium carbonate solution, which is prepared from anhydrous sodium carbonate and distilled water. Spray the surface of the rod with a flat nozzle to ensure that the anhydrous sodium carbonate solution is not missed and evenly distributed on the surface of the rod.

[0052] 4. Chromium pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com