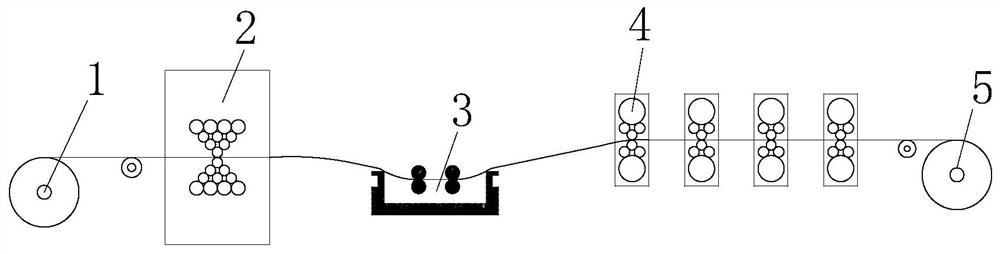

Ferritic stainless steel cold-rolled strip steel production device

A technology for cold-rolled strip steel and production equipment, which is applied in the directions of grinding drive devices, grinding machines, grinding machine parts, etc. Improve quality and efficiency, increase reaction rate, protect strip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

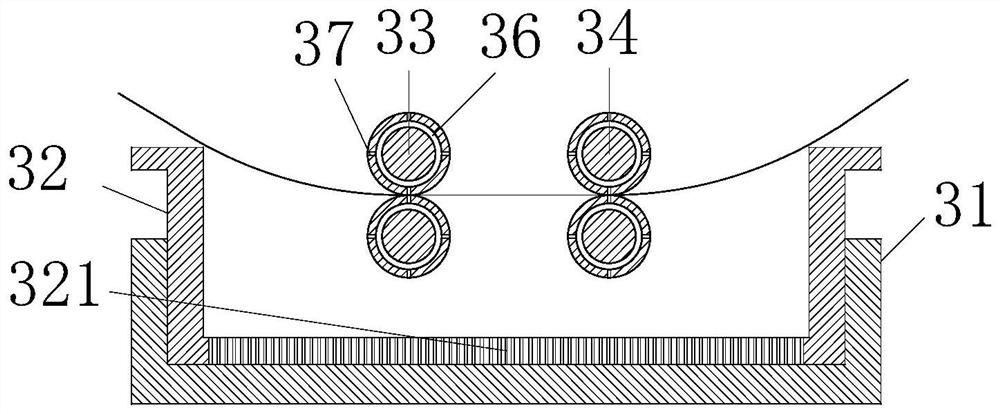

[0026] As a specific embodiment of the present invention, the No. 1 grinding roller 33 and the No. 2 grinding roller 34 are provided with a booster hole 37 , and the booster hole 37 communicates with the cavity 36 .

[0027] When the No. 1 grinding roll 33 and the No. 2 grinding roll 34 were grinding the strip, the cavity 36 provided by the No. 1 grinding roll 33 and the No. 2 grinding roll 34 was compressed and rebounded when the grinding roll rotated, and the No. 1 grinding roll 33 And the booster hole 37 on the No. 2 grinding roller 34 squeezes out and inhales the pickling solution in the cavity 36 while the cavity 36 compresses and rebounds, so that the pickling solution around the strip steel is accelerated to flow, and the strip is enlarged. The reaction rate of steel and pickling solution, the hydrogen gas produced during the pickling process, also accelerates the overflow when the pickling solution accelerates to flow, reducing the occurrence of hydrogen embrittlement c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com