Method for treating surface of high-strength fastener

A processing method and technology for fasteners, which are applied to devices, chemical instruments and methods, cleaning methods and utensils for coating liquids on surfaces, etc. Ease of use, no loss of metal, no cracking or damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

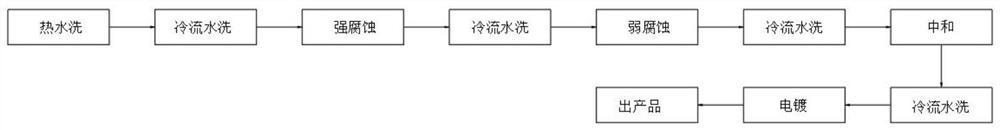

[0029] see figure 1 , an embodiment provided by the present invention: a method for treating the surface of a high-strength fastener, comprising the following steps:

[0030] Step 1: Degreasing;

[0031] Step 2: Laser removal of scale;

[0032] Step 3: electroplating treatment;

[0033] Step 4: Reduce hydrogen embrittlement processing;

[0034] Step five: chromate passivation treatment;

[0035] Step six: drying process;

[0036] Step 7: apply grease;

[0037] Step 8: Remove and drain.

[0038] Further, in step 1, place high-strength fasteners in organic solvents, such as kerosene, light diesel oil, gasoline, acetone, alcohol, and trichloroethylene, and then u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com