Method for electroplating high-strength corrosion-proof cadmium-tin-titanium alloy on 304 or 316 L stainless steel surface

A technology of tin-titanium alloy and stainless steel, which is applied in the field of metal electroplating to achieve the effect of reducing cathodic hydrogen permeation, weak acidity, and reducing hydrogen embrittlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

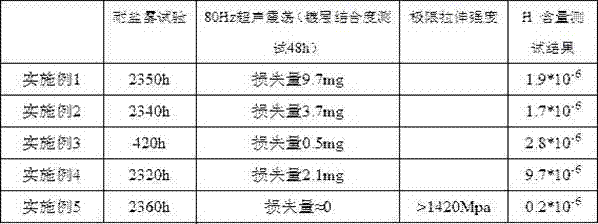

Examples

Embodiment 1

[0023] In this treatment process, conventional chemical degreasing fluid and no anodic oxidation treatment are used. The specific treatment steps are:

[0024] (1) heating to relieve stress; (2) sand blasting; (3) chemical degreasing to use NaOH, Na 2 CO 3 , Na 3 PO4 Ultrasonic immersion in an alkaline degreasing agent composed of an emulsifier for 2 to 5 minutes to clean the surface of stainless steel; (4) high-current impact cyanide-free electroplating of cadmium; (5) low-current cyanide-free electroplating of cadmium-tin-titanium; (6) Heating to remove hydrogen; (7) passivation - hot water cleaning; (8) aging, natural cooling.

Embodiment 2

[0026] In this process, there is no high current cadmium plating, and cadmium tin titanium is directly electroplated. The specific processing steps are:

[0027] (1) Stress relief by heating; (2) Sand blasting; (3) Chemical degreasing; (4) Anodizing treatment; (5) Small current cyanide-free electroplating of cadmium-tin-titanium; (6) Heating dehydrogenation; (7) ) passivation - hot water cleaning; (8) aging, natural cooling.

Embodiment 3

[0029] In this treatment process, the electroplating solution does not contain titanium and tin, and the specific treatment steps are:

[0030] (1) Stress relief by heating; (2) Sand blasting; (3) Chemical degreasing; (4) Anodizing treatment; (5) After high current cyanide-free electroplating of cadmium, small current electroplating of cadmium; (6) Heating dehydrogenation; (7) Passivation - hot water cleaning; (8) Aging, natural cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com