Patents

Literature

51results about How to "Will not disconnect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

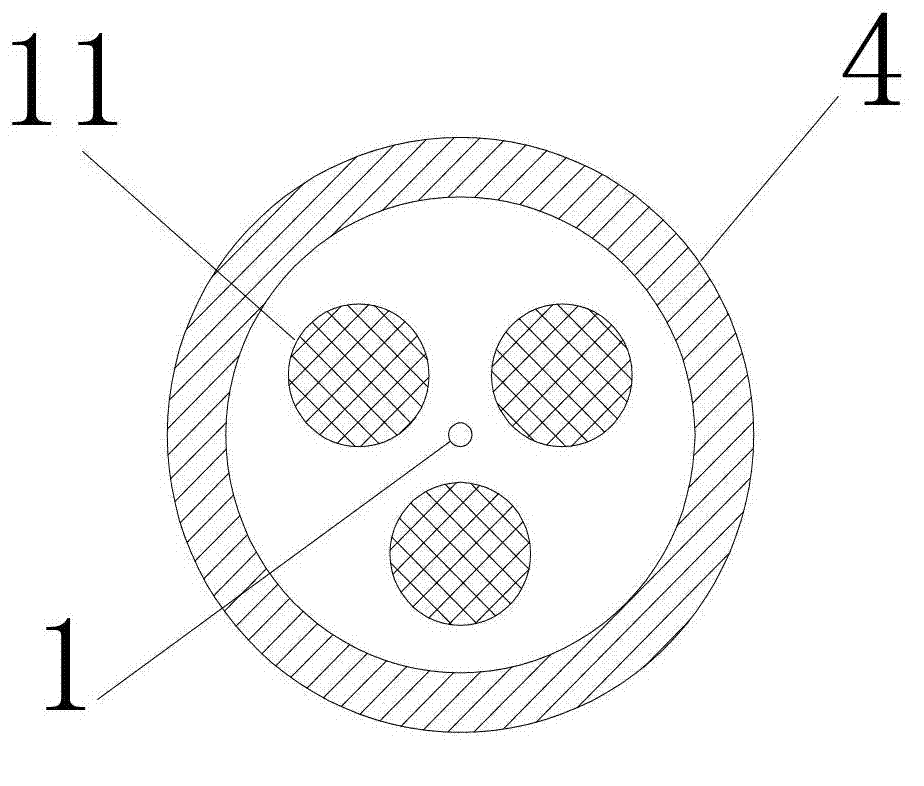

Preparation method of copper covered steel woven wire special for communication cable shielding layer

InactiveCN1913046AWill not disconnectGood flexibilitySingle bars/rods/wires/strips conductorsExtrusion cleaning devicesCopper wireThin wire

This invention relates to a preparation method for special steel woven filaments for communication cable shield layers including rough drawing, plating, mid-drawing, fine-drawing and annealing of copper-wrapped steel filaments with the mechanical performance approaching to copper wires, the extension rate of which reaches to 20% and the tensile strength reaches to that of copper wires, so it will not be broken when used in weaving cable shield layers and the product will not be hard and keep fine flexibility.

Owner:仲庆

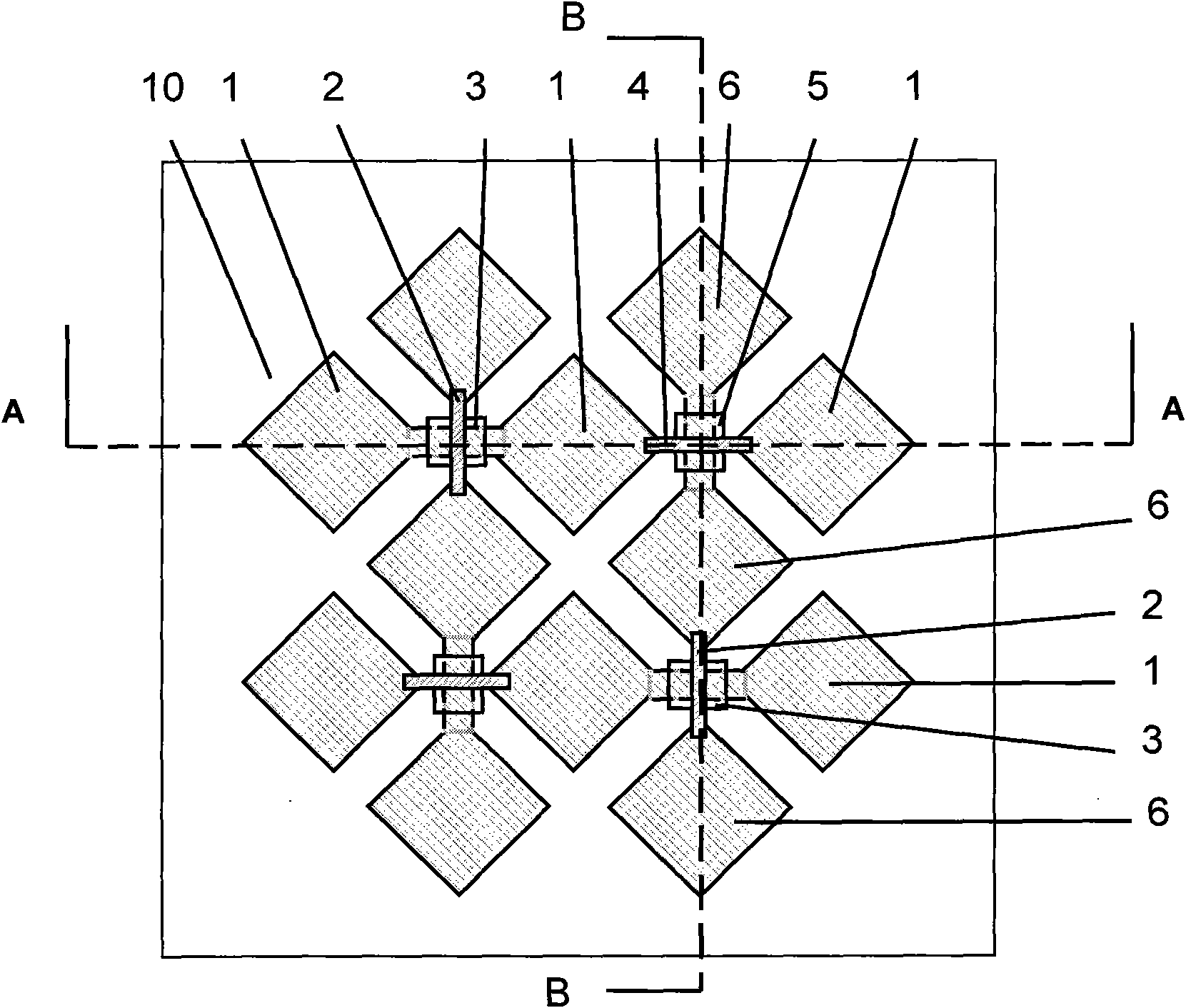

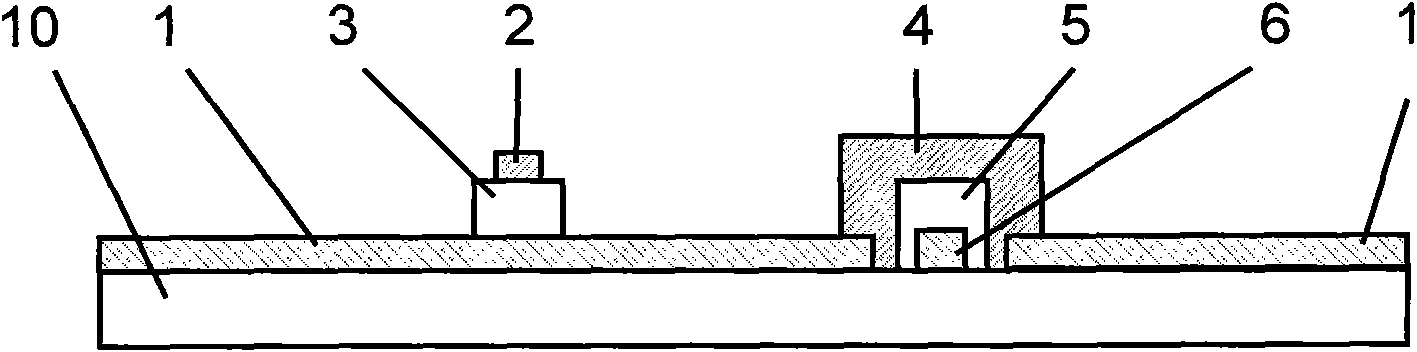

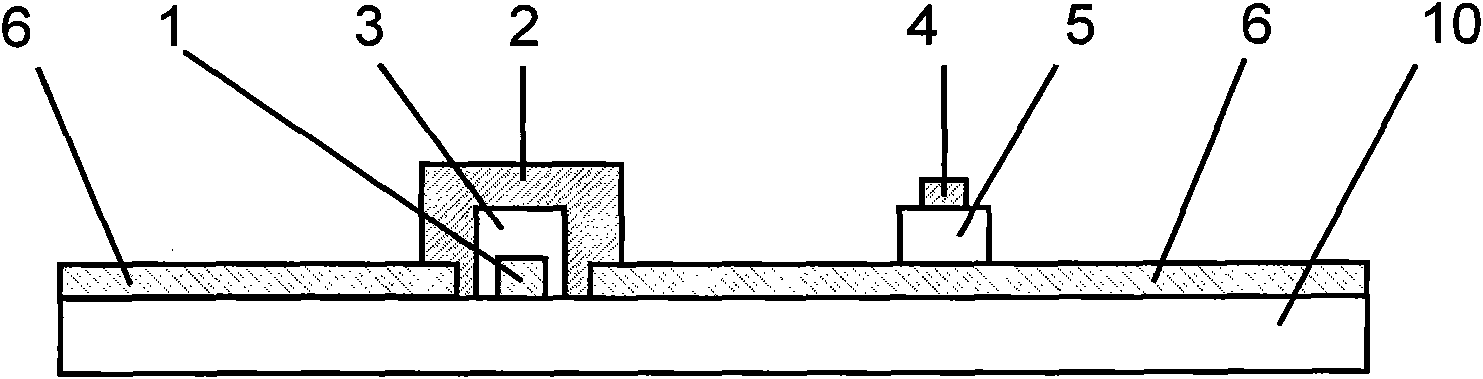

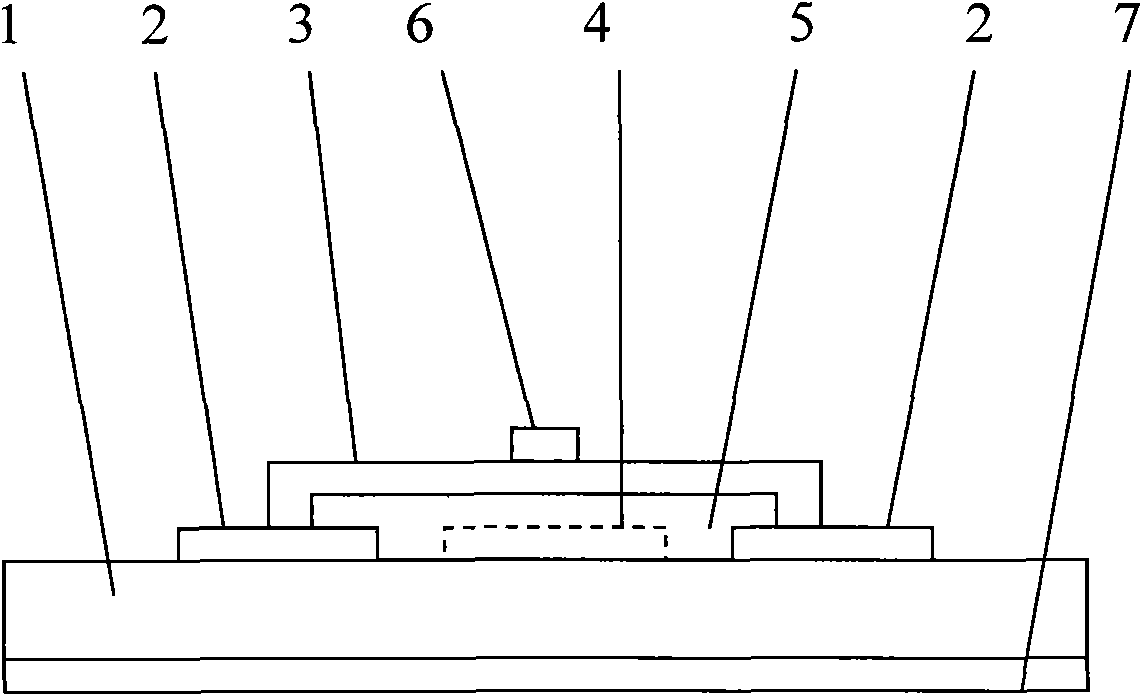

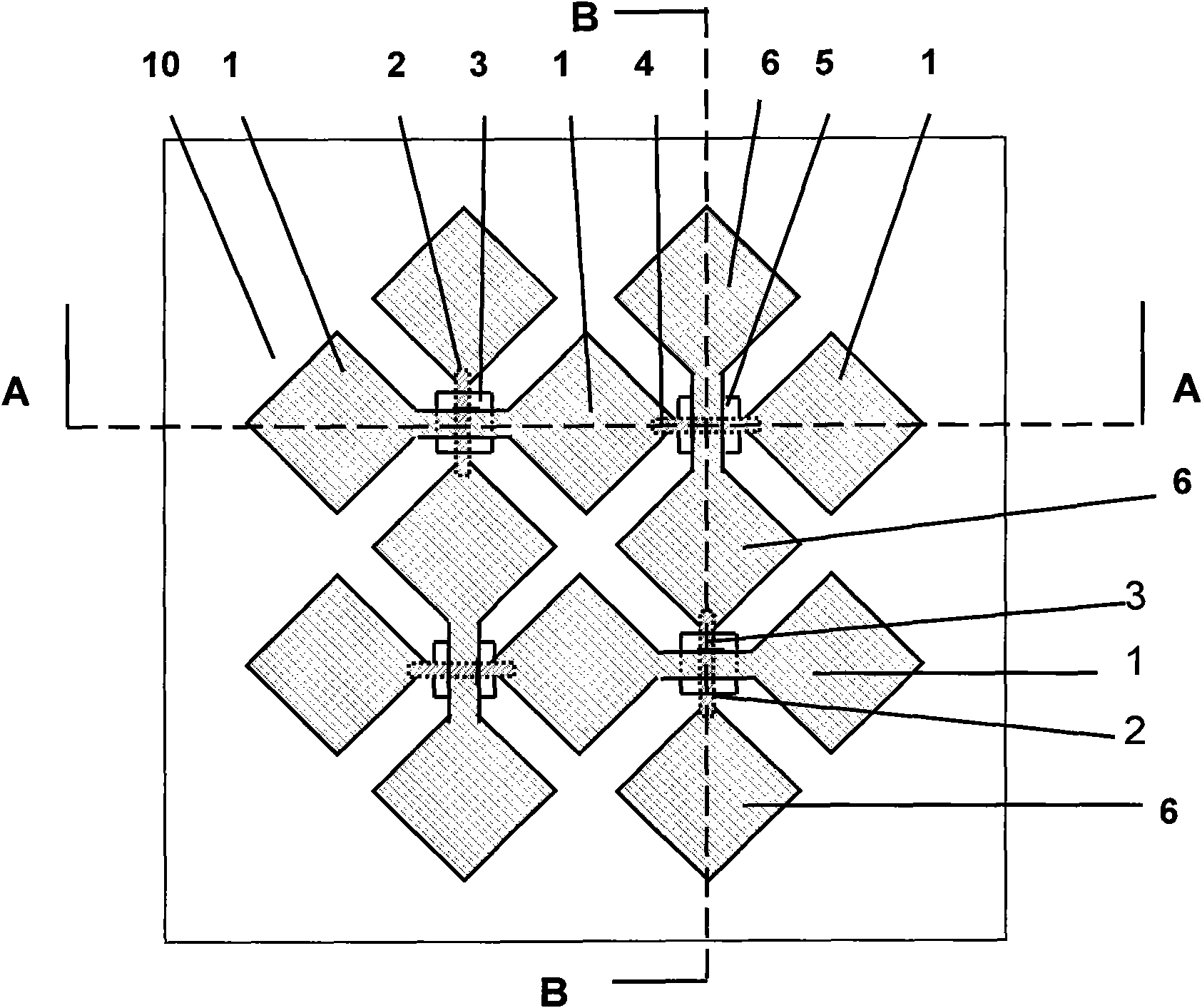

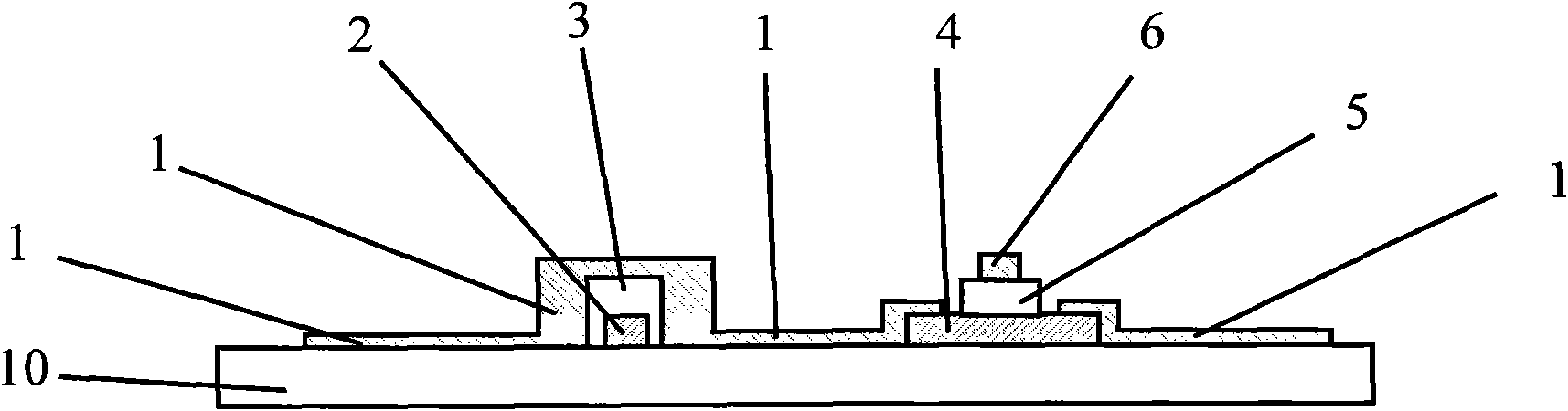

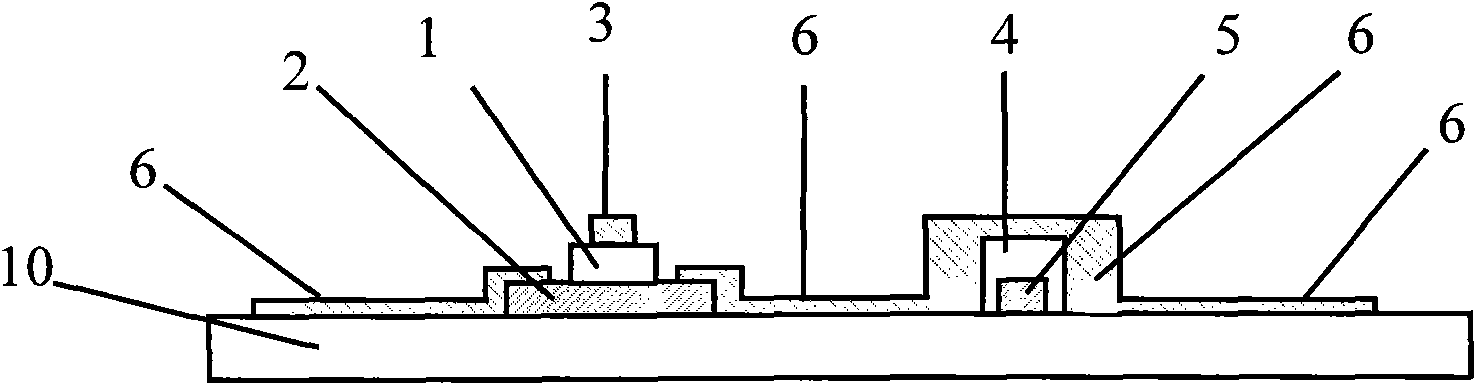

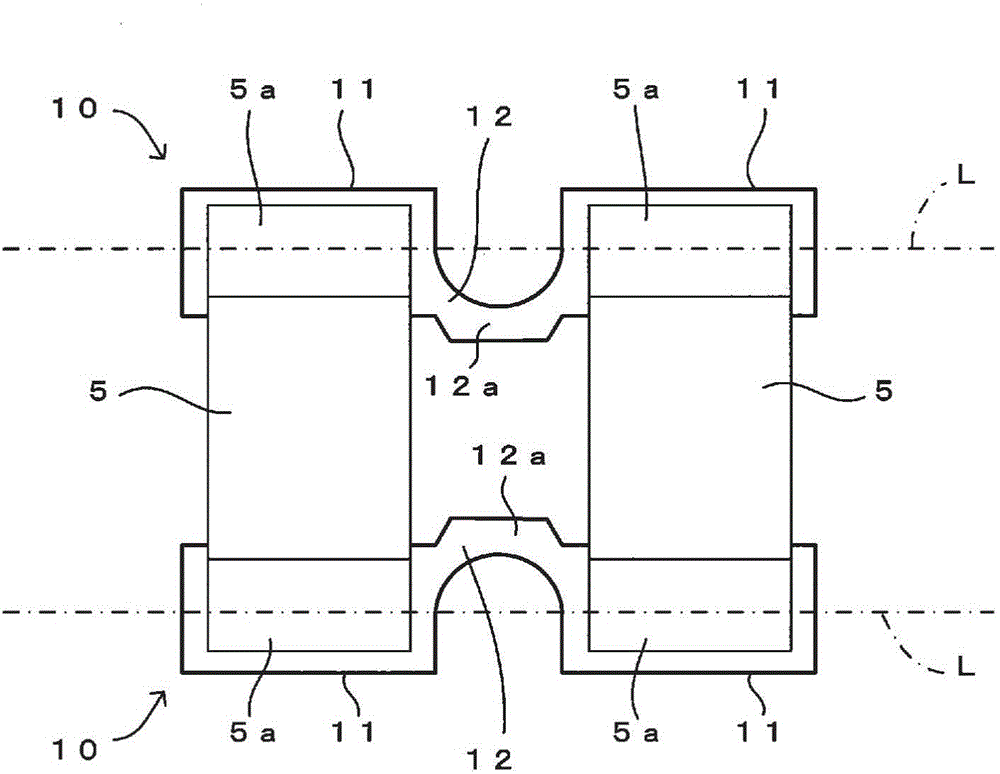

Wiring method and manufacturing method of capacitive touch screen

ActiveCN101634922AImprove product qualityAvoid chromatic aberrationInput/output processes for data processingElectrical resistance and conductanceEngineering

The invention relates to a wiring method and a manufacturing method of a capacitive touch screen, wherein the wiring method comprises the step of arranging two groups of wire transparent conducting films in X and Y directions, an insulating film and a bridging film on a basal plate, wherein the surface resistance of the bridging film is lower than the surface resistance of the transparent conducting films, an intersection structure of the transparent conducting films in the two directions comprises continuous connection and bridging connection, wherein the continuous connection structure is a continuation of transparent conducting film material at two sides of the intersection point, and the bridging connection structure has the structures that the transparent conducting film in X or Y direction is continuously connected and positioned on the basal plate at the intersection point, the transparent conducting film in the other direction is disconnected at the intersection point, the insulating film is covered on the transparent conducting films that are continuously connected at the intersection part, and the bridging film stretches over the transparent conducting films that are continuously connected at the intersection point and is covered on the insulating film and connected with the transparent conducting film disconnected at the intersection point; and the method comprises the step of manufacturing two groups of wire conducing film, the insulating film and the bridging film. The invention can avoid color difference and improve the sensitivity, the standard ratio and the quality of the touch screen.

Owner:SHENZHEN LAIBAO HI TECH

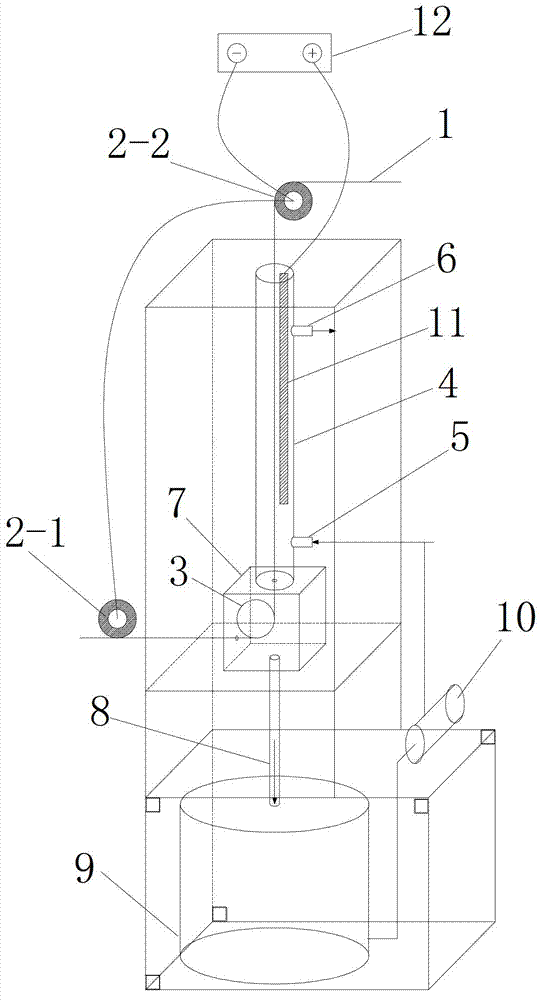

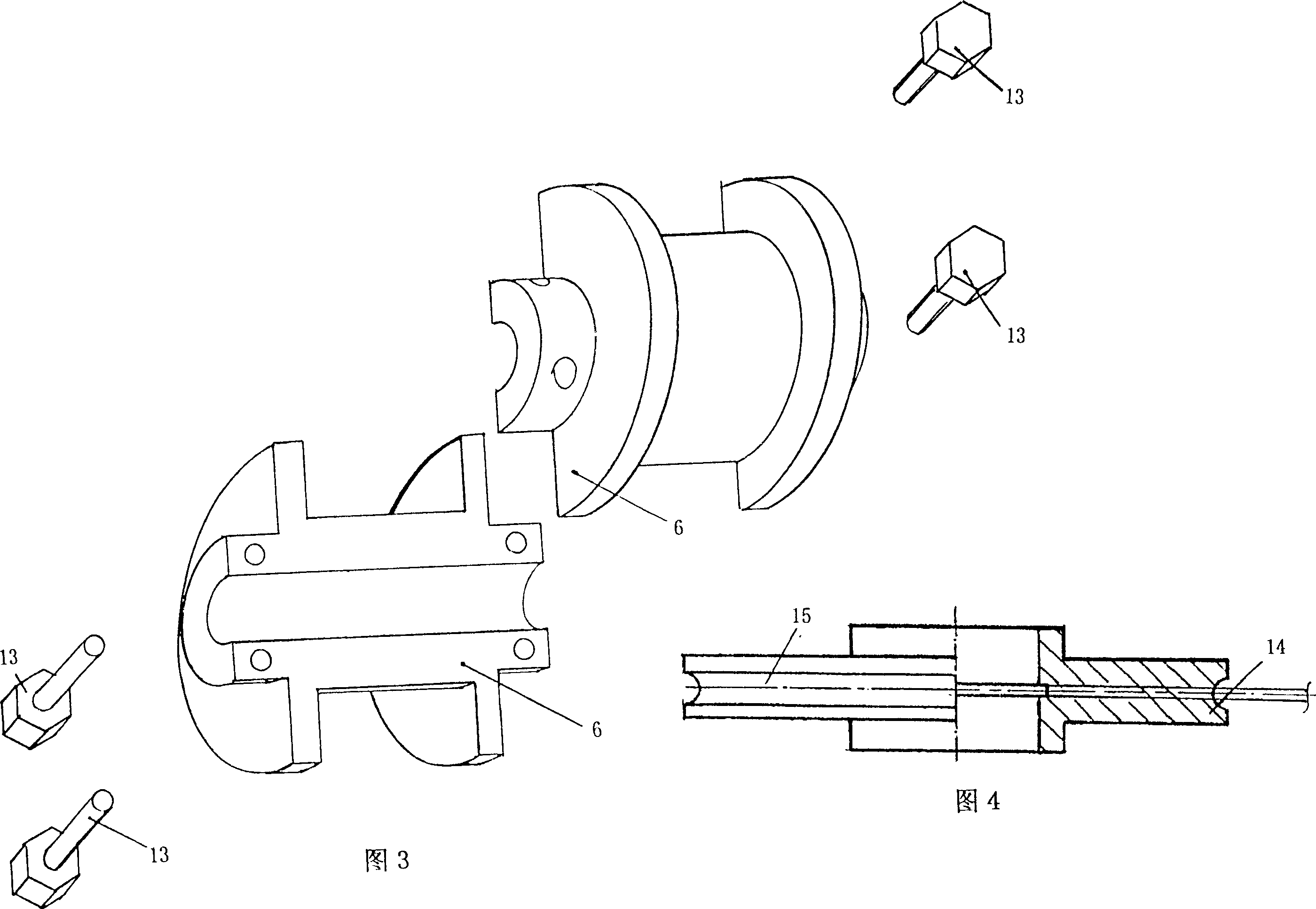

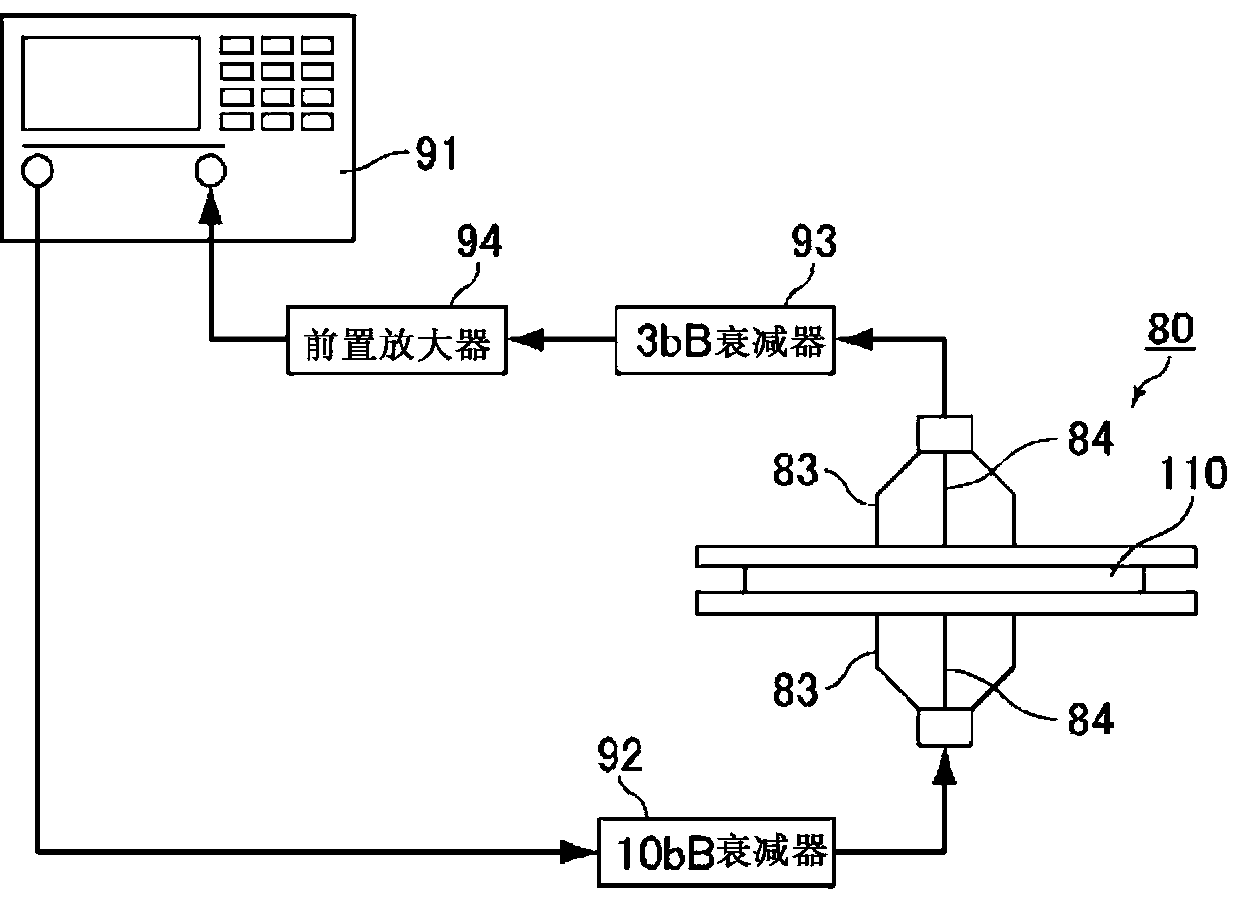

Electroplated diamond wire saw sand-applying device

The invention discloses an electroplated diamond wire saw sand-applying device. The device sequentially comprises the components, from top to bottom: a vertical tubular sand-applying sub tank, a liquid-returning box, and a plating solution master tank. A guide wheel is fixed in the liquid-returning box. A core wire is sequentially wound on a wire-feeding conductive wheel on the bottom of the vertical tubular sand-applying sub tank and the guide wheel. The core wire then penetrates the vertical tubular sand-applying sub tank, and is finally wound on a wire-discharging conductive wheel on the top of the vertical tubular sand-applying sub tank. The wire-feeding conductive wheel and the wire-discharging conductive wheel are connected in parallel, and are then connected to the negative electrode of an electroplating power supply. Metal anodes are arranged around the core wire in the vertical tubular sand-applying sub tank. The metal anodes are connected with positive electrodes of the electroplating power supply. Through a water pump above the plating solution, the plating solution is lifted from the plating solution master tank into the vertical tubular sand-applying sub tank. With the device provided by the invention, sand-application of produced diamond wire is uniform and good. During the production process, current density is high, efficiency is high, internal stresses of the plating and the substrate are small, plating solution application amount is low, and wire breakage probability is low.

Owner:无锡超亚环保设备有限公司

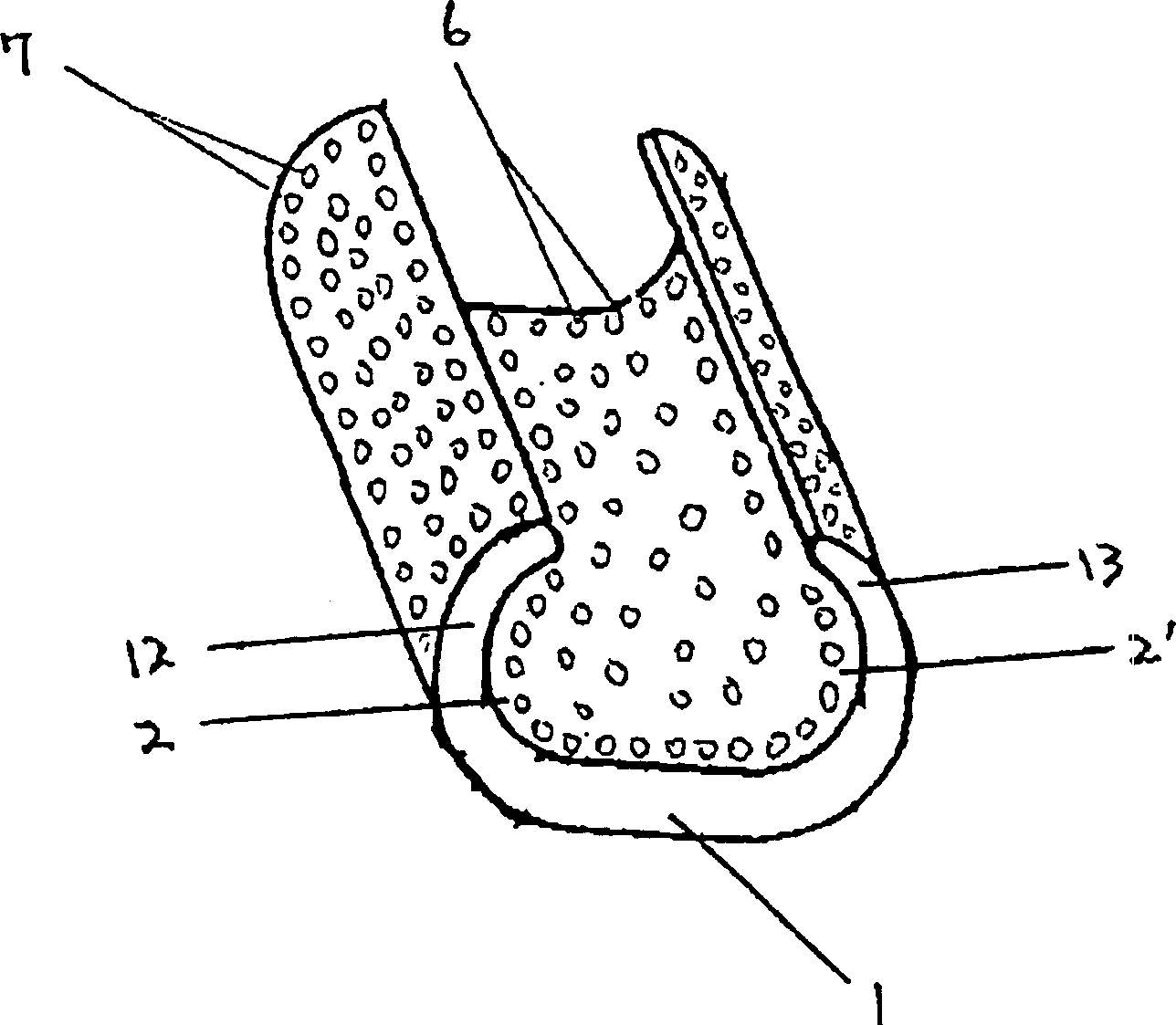

Wire-cutting wire of structural electrodeposited abrasive material

The invention relates to a wire-cutting wire of a structural electrodeposited abrasive material, comprising a structural metal blank wire, superhard abrasive material granules and a coating. The superhard abrasive material granules and the coating are plated on the surface of the structural metal blank wire which uses the axis of the structural metal blank wire as a basic wire, and a plurality of segments of S-shaped or Z-shaped curves are distributed in a range of 360 degrees along the axis of the structural metal blank wire; the structural metal blank wire has the projection diameter of 0.1-0.6 mm; and the abrasive material granules are selected from diamond granules or cubic boron nitride granules with the grain sizes of 10-50 microns. In the invention, the wire-cutting wire is prepared by using the structural metal blank wire as the basic wire and using a composite galvanization method, has favorable scrap containing and retreating functions, and is beneficial to effective prevention of the obvious problem of broken wire; meanwhile, the formed stable and high-efficiency cutting state improves the use efficiency of the wire-cutting wire of the structural electrodeposited abrasive material, and the wire-cutting wire is suitable for industrial application.

Owner:CHANGSHA DIAT NEW MATERIAL SCI & TECH

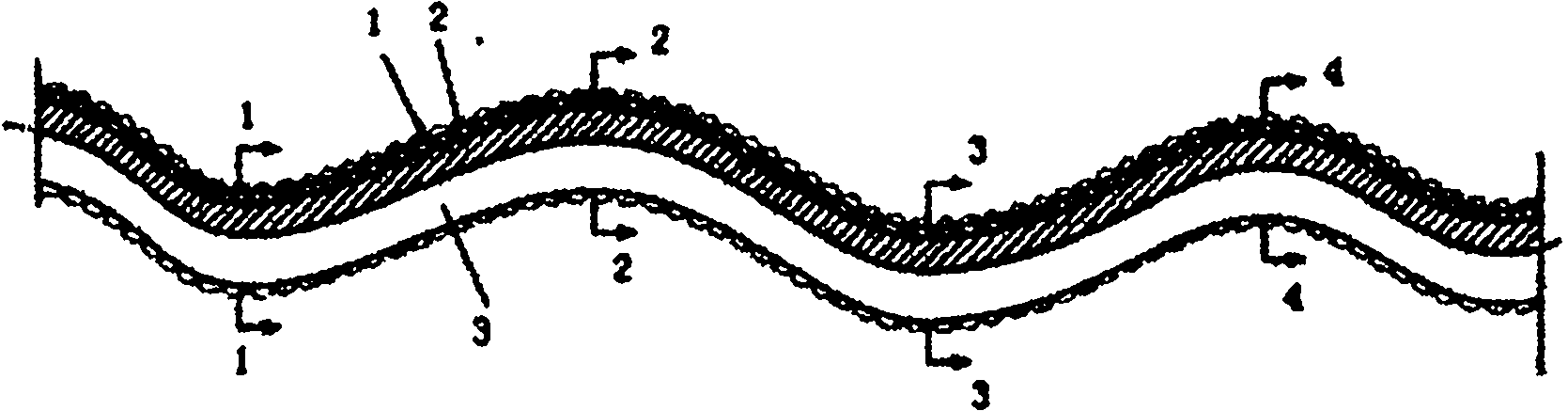

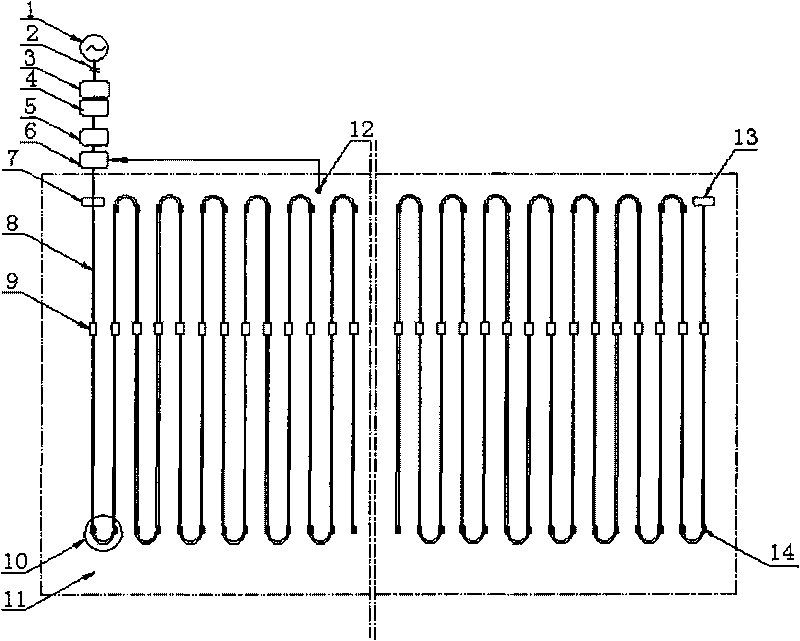

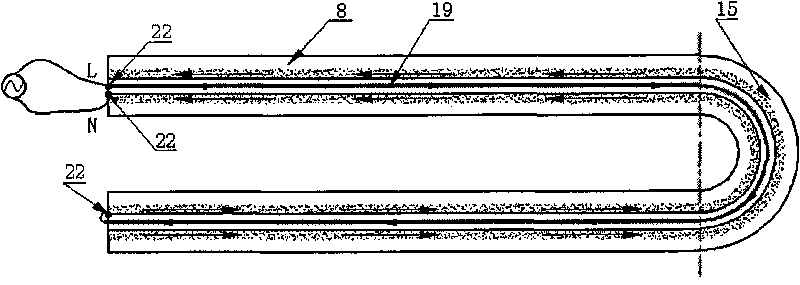

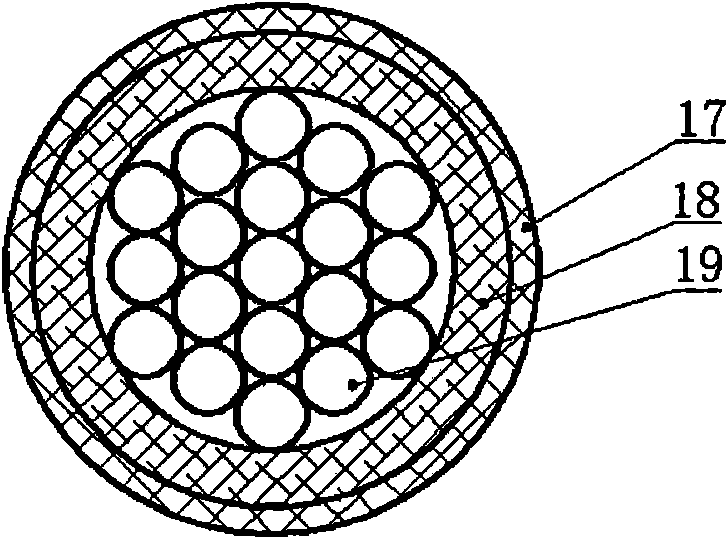

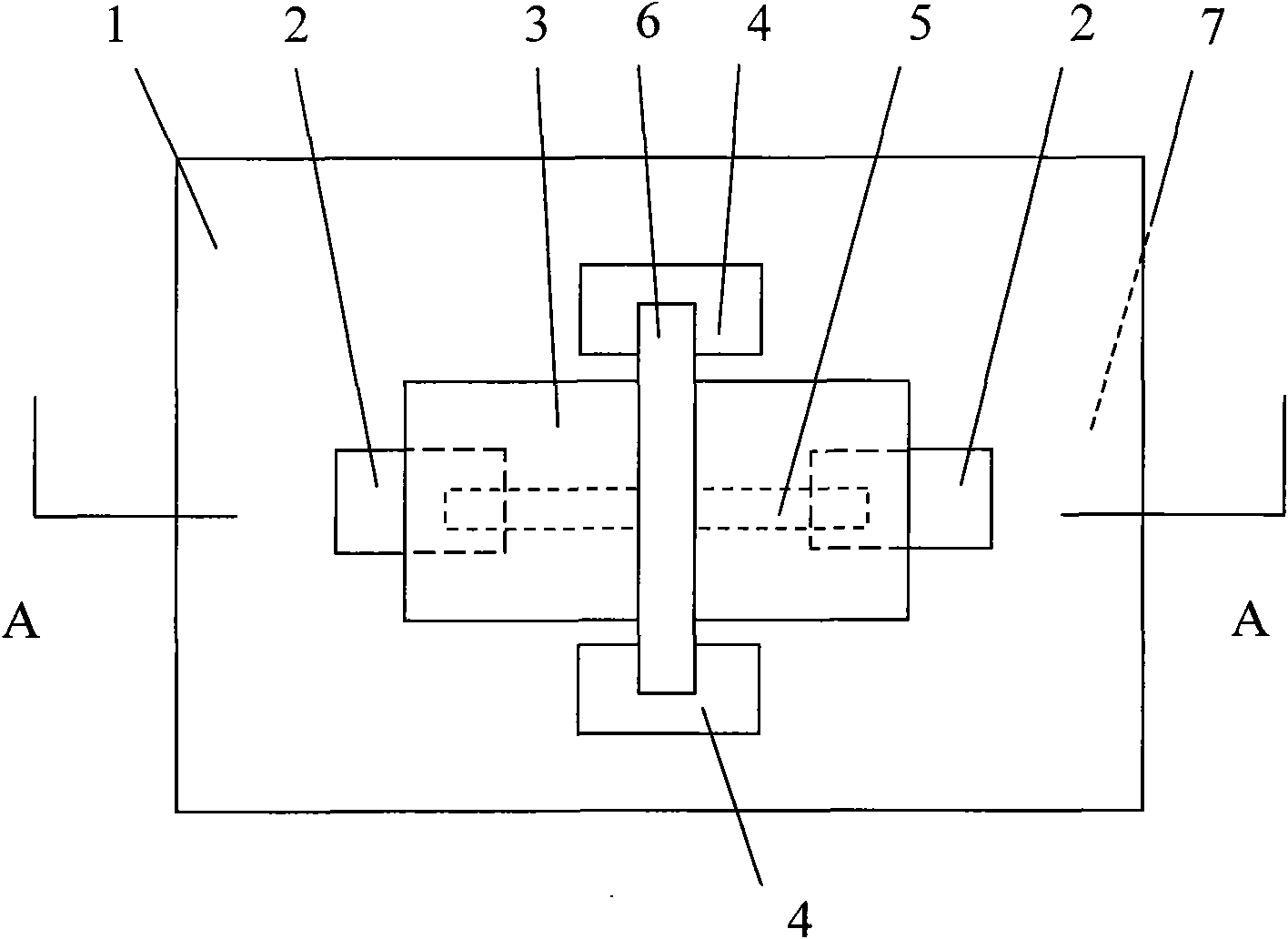

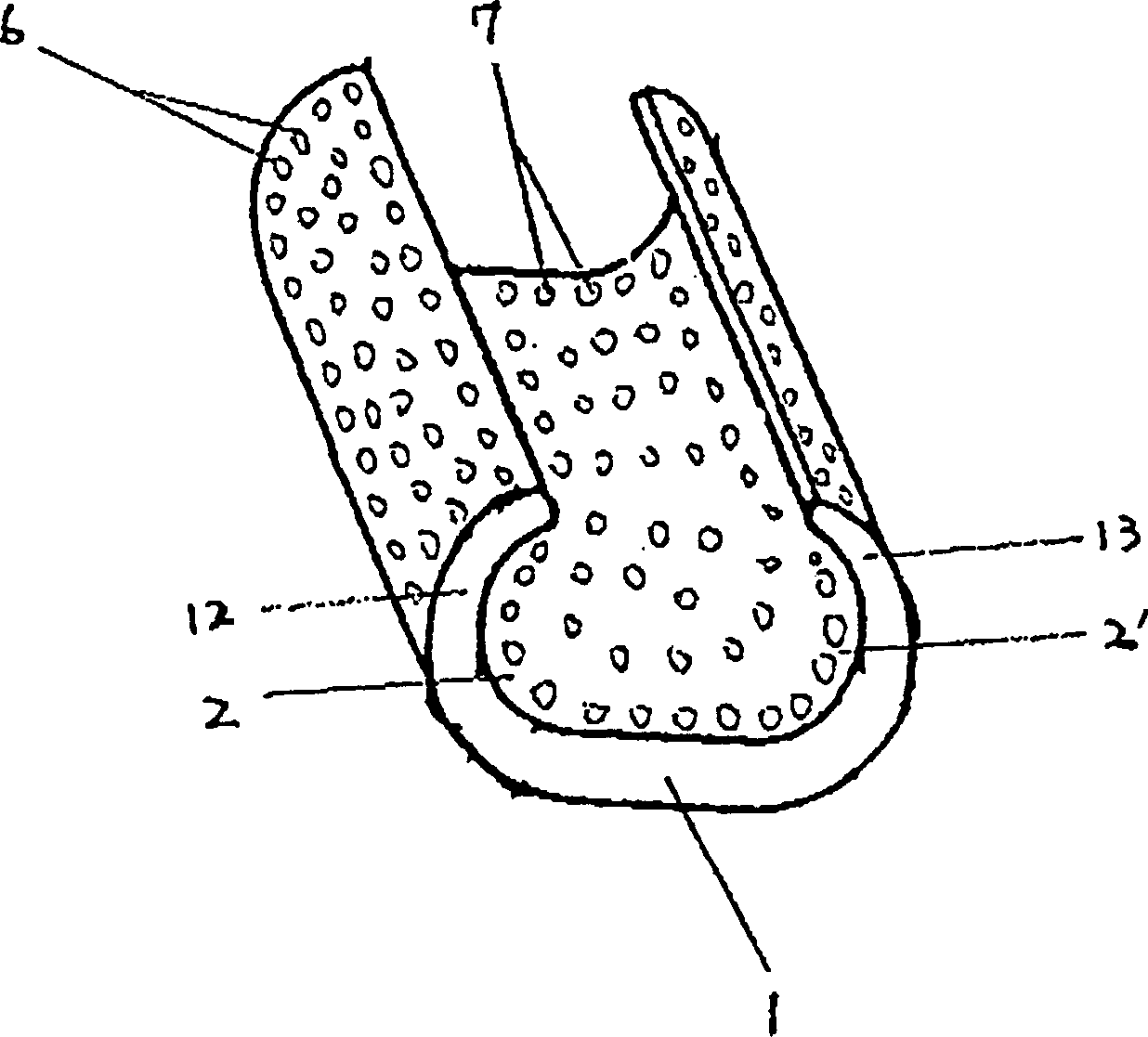

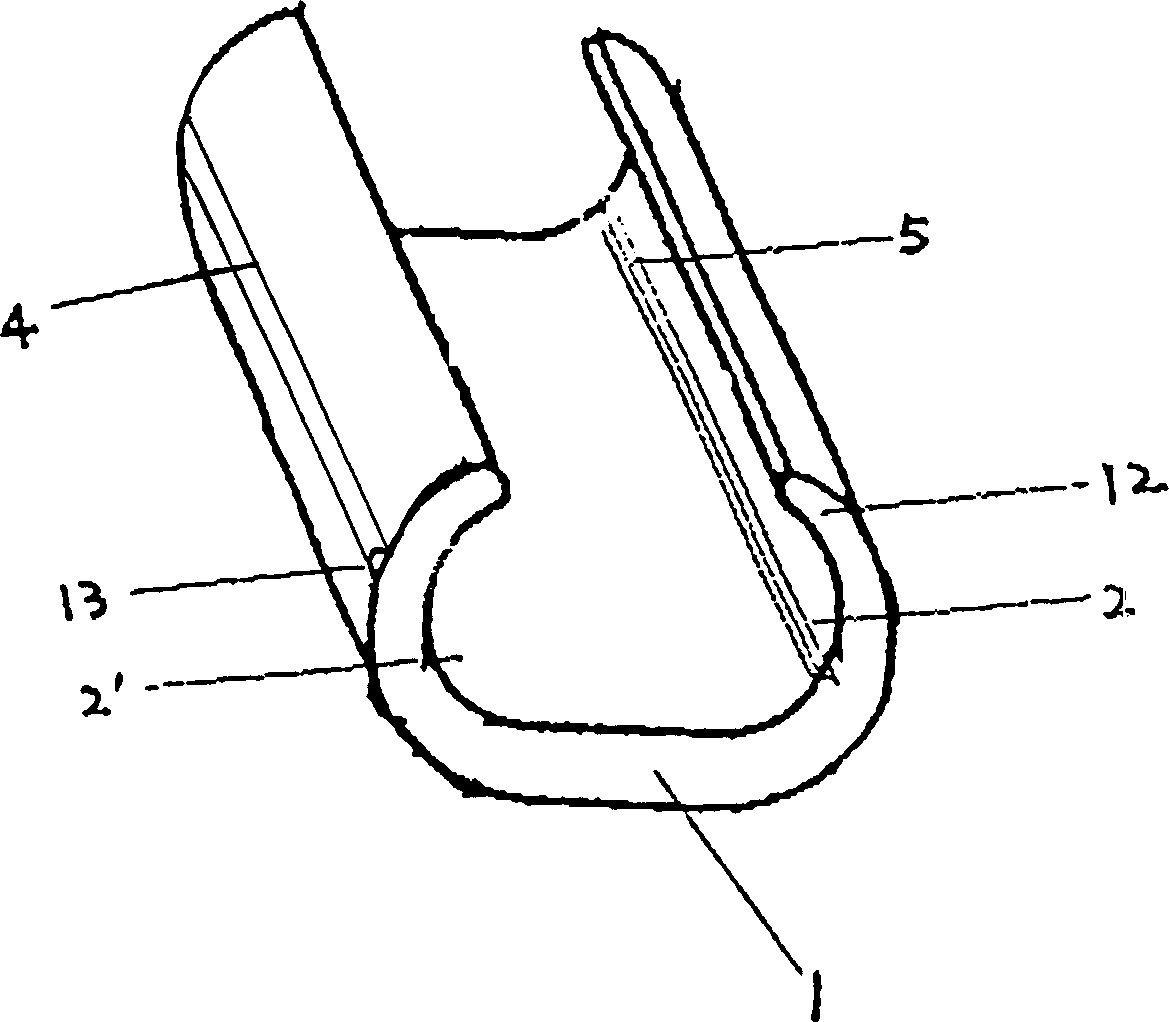

Method and system for heating and melting snow and ice on road surface under current surface effect

ActiveCN101718070AHigh mechanical strengthWill not disconnectPaving detailsRoad surfaceAlternating current

The invention relates to a method and a system for heating and melting snow and ice on the road surface under the current surface effect. The system comprises an alternating-current power supply, an input cable, a three-phase transformer, a three-phase balancer, an electrical switch, a temperature control device, a snow and ice melting sensor, a power supply terminal box, highly-ferromagnetic iron pipes, a transitional connecting tube, a high temperature wire, an electrical switch (3), a U-shaped bent-pipe wire penetrating part, an end terminal box, a grounding protector and a cathode protector. A U-shaped surface action heating element which is formed by connecting a plurality U-shaped highly-ferromagnetic iron pipes is energized under the surface effect and the proximity effect to efficiently emit heat to rapidly melt the snow and the ice on the road surface. The U-shaped highly-ferromagnetic iron pipes are buried in the teinforced concrete or asphalt road surface. The U-shaped surface action heating element has high mechanical strength and quite long service life, can be used permanently, is not easy to be subjected to the wire disconnection, is very easy to repair when being damaged, needs only one power supply point, can not affect the three-phase power supply balance, can be heated uniformly, adjusted randomly in temperature and constructed and installed conveniently with least labor, has high degree of automation, does not need electric insulation, is safe, reliable and economical and can not pollute the environment.

Owner:WUXI HENGYE ELECTRICAL HEATER EQUIP

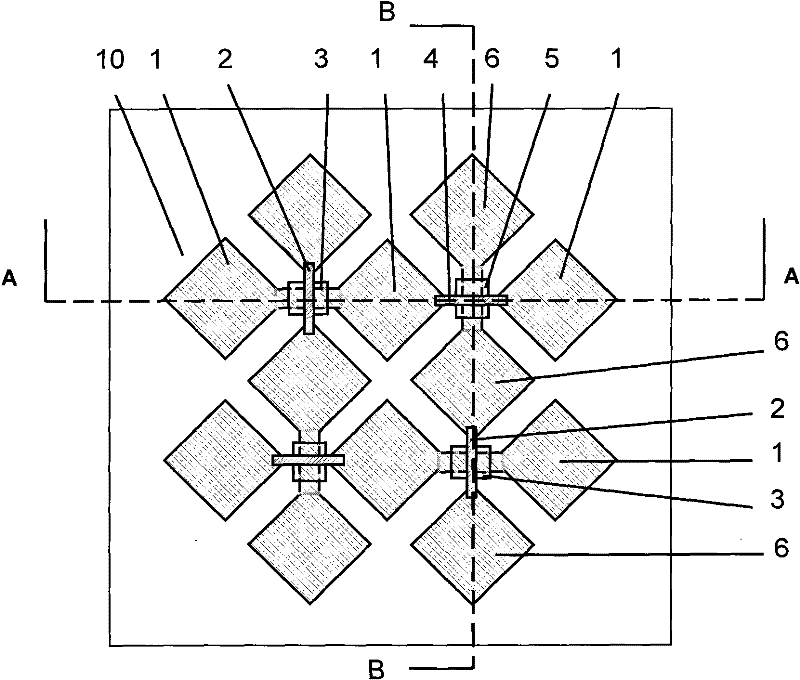

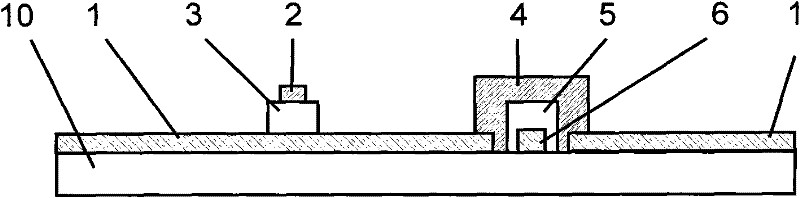

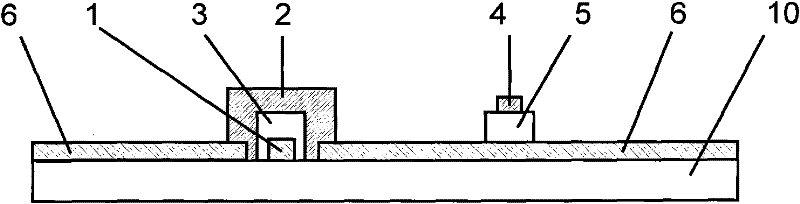

Capacitance touch screen and method for preparing the same

ActiveCN101587408AImprove continuityLess prone to disconnectionInput/output processes for data processingElectrical resistance and conductanceCapacitance

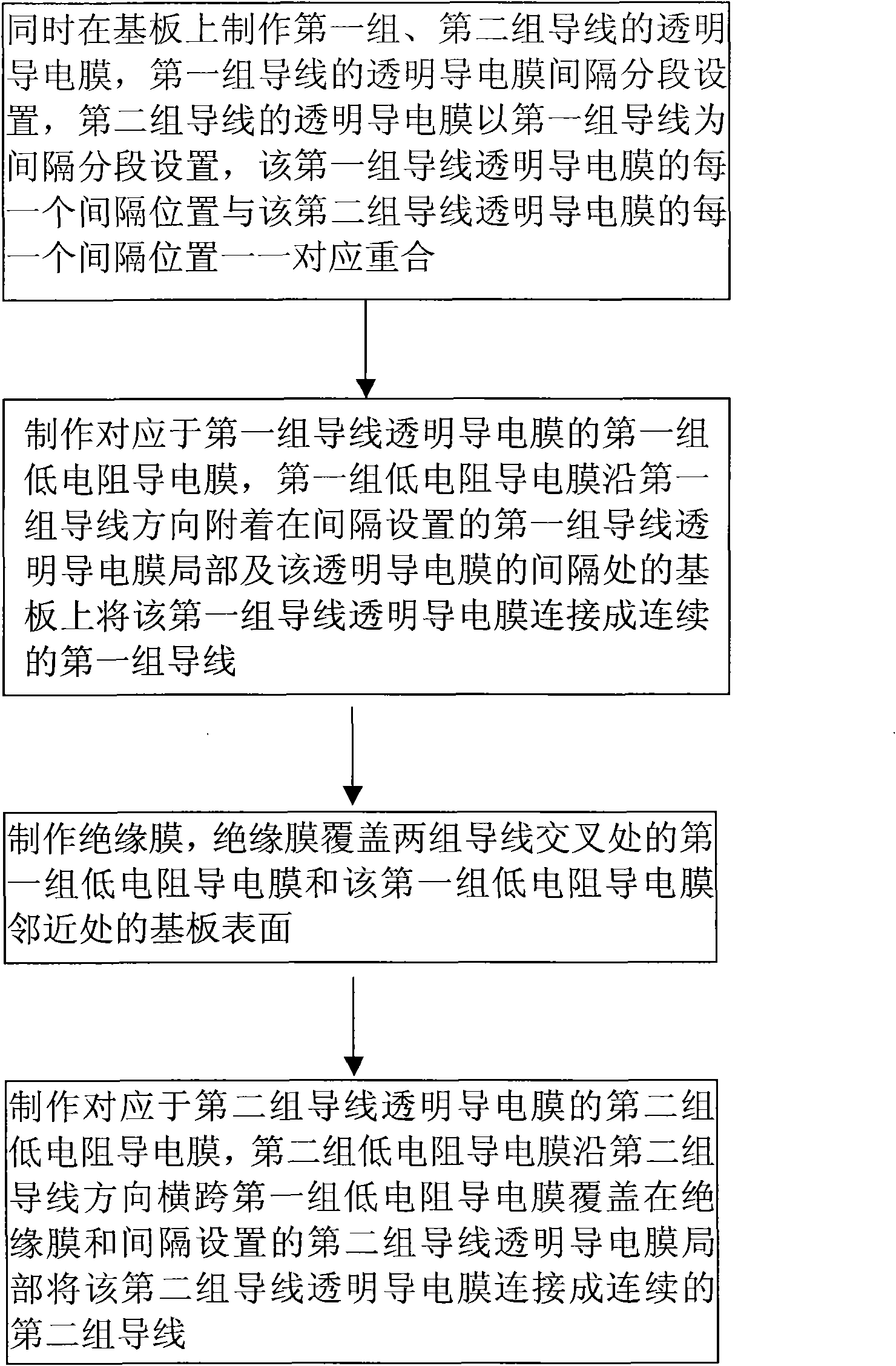

Capacitance touch screen and method for preparing the same, the touch screen includes a substrate, two sets of wire transparent conductive films, an insulation film, and two sets of low-resistance conductive film, two sets of transparent conductive films are disposed sectionally in interval and two sets of transparent conductive films are coincided corresponding to each other at every interval position; a first low-resistance conductive film connects with its transparent conductive film along direction of the first set of wires to form a continous set of wires, a second low-resistance conductive film crosses the first low-resistance conductive film along direction of the second set of wires to connect its transparent conductive film to form a second continous set of wires. An insulation film is disposed between two sets of low-resistance conductive films and covers surface of substrate adjacent to the first set of low-resistance conductive film, the second low-resistance conductive film covers the insulation film. The method produces the first, second set of transparent conductive films, an insulation film and low-resistance conductive film on the substrate step by step to implement the touch screen structure. The wires according to the invention are not easy to break which reduces resistance of wires, reduces chromatic aberration and electrical interference, and improves performance and quality of products.

Owner:SHENZHEN LAIBAO HI TECH

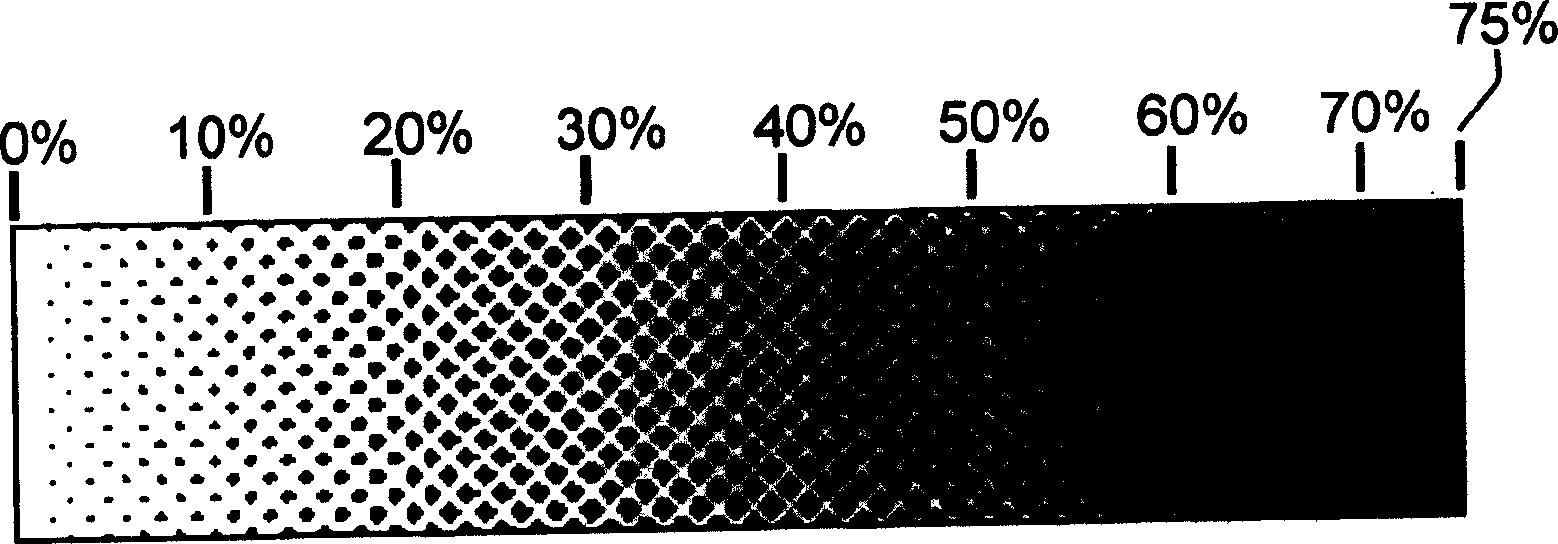

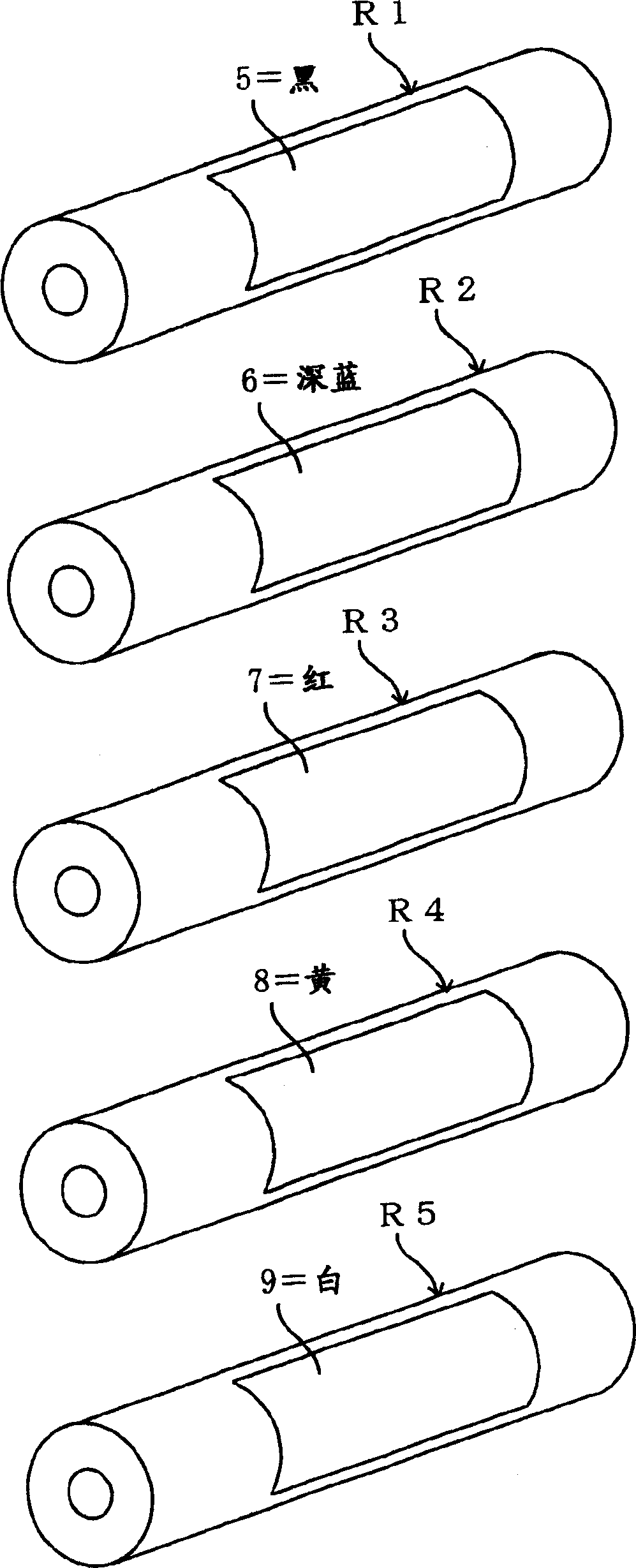

Gravure printing method and gravure printing article

InactiveCN1648769AGuaranteed concentrationAvoid rippleRotary intaglio printing pressScreening processesFine linePhotogravure

The photogravure printing is completed with photogravure comprising AM screen and FM screen. The text and reproduced image needing dense ink are formed with the meshes of corresponding AM screen, while the picture and fine lines with dark and light ink for representing are formed with the meshes of corresponding FM screen.

Owner:THINK LABORATORY CO LTD

Wiring and manufacturing method of capacitive touch screen

ActiveCN101639749AImprove product qualityAvoid chromatic aberrationInput/output processes for data processingElectrical resistance and conductanceTransparent conducting film

The invention relates to a wiring and a manufacturing method of a capacitive touch screen, wherein the wiring comprises two groups of transparent conducting films on X and Y directions on a substrate,an insulating film and a connecting film, wherein the surface resistance of the connecting film is lower than the surface resistance of the transparent conducting films, an intersection structure ofthe transparent conducting films on the two directions adopts continuous connection and tunnel connection, wherein the continuous connection structure is a continuation of transparent conducting filmmaterials at two sides of the intersection point, and the tunnel connection structure is achieved as follows: the transparent conducting film on X or Y direction is continuously connected at the intersection point, and the transparent conducting film on the other direction is disconnected; the connecting film is sectionally arranged corresponding to the disconnected transparent conducting films atthe intersection point; the insulating film is covered at the middle part of the connecting film, the disconnected transparent conducting films are covered at the end part of the connecting film andthe substrate to form a continuous wire, and the transparent conducting films which are continuously connected at the intersection point stretch over the connecting film to be covered on the insulating film and the substrate. The manufacturing method comprises the step of manufacturing the connecting film, the insulating film and two groups of wire conducting films. The invention can avoid colordifference and improve the sensitivity, the standard ratio and the quality of the touch screen.

Owner:SHENZHEN LAIBAO HI TECH

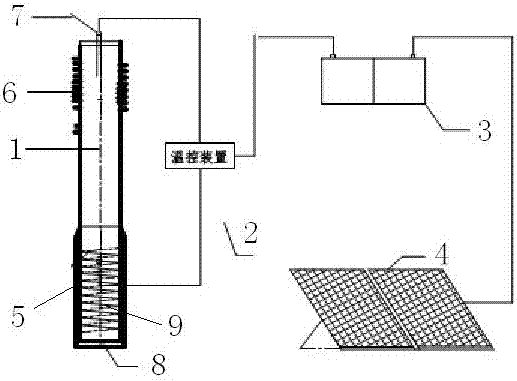

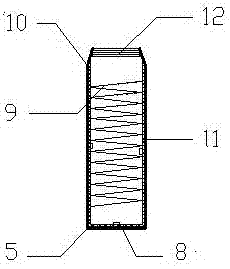

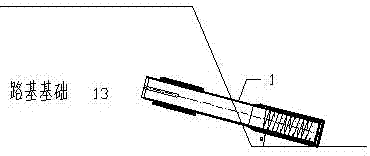

Efficient nano-infrared energy-saving low-temperature hot stick

PendingCN106894408AWill not disconnectUniform resistanceRoadwaysProtective foundationTemperature controlEngineering

An efficient nano-infrared energy-saving low-temperature hot stick is formed by sequentially connecting an evaporation section and a condensation section. The efficient nano-infrared energy-saving low-temperature hot stick is characterized in that a heating outer tube (5) is additionally arranged on the evaporation section, and a nano-alloy material molecular vibration dark infrared heating wire (9) is spirally arranged in the heating outer tube (5) in the longitudinal direction; multiple heat-sensitive sensors (8) are mounted in the heating outer tube (5); a center temperature measuring tube (7) is arranged at the center of the condensation section, the heat-sensitive sensors (8) and the center temperature measuring tube (7) are connected with a temperature control device (2), and the temperature control device automatically controls the heating outer tube (5) to heat the evaporation section; and the nano-alloy material molecular vibration dark infrared heating wire (9) is electrically connected with a storage battery (3), and the storage battery (3) is charged by a solar power generation panel (4). The efficient nano-infrared energy-saving low-temperature hot stick is simple in structure, safe and reliable to work, efficient and capable of saving energy, solving the problem of frost heave of roadbeds in frozen earth regions and improving the safety and stability of the roadbeds.

Owner:中圣科技(江苏)股份有限公司

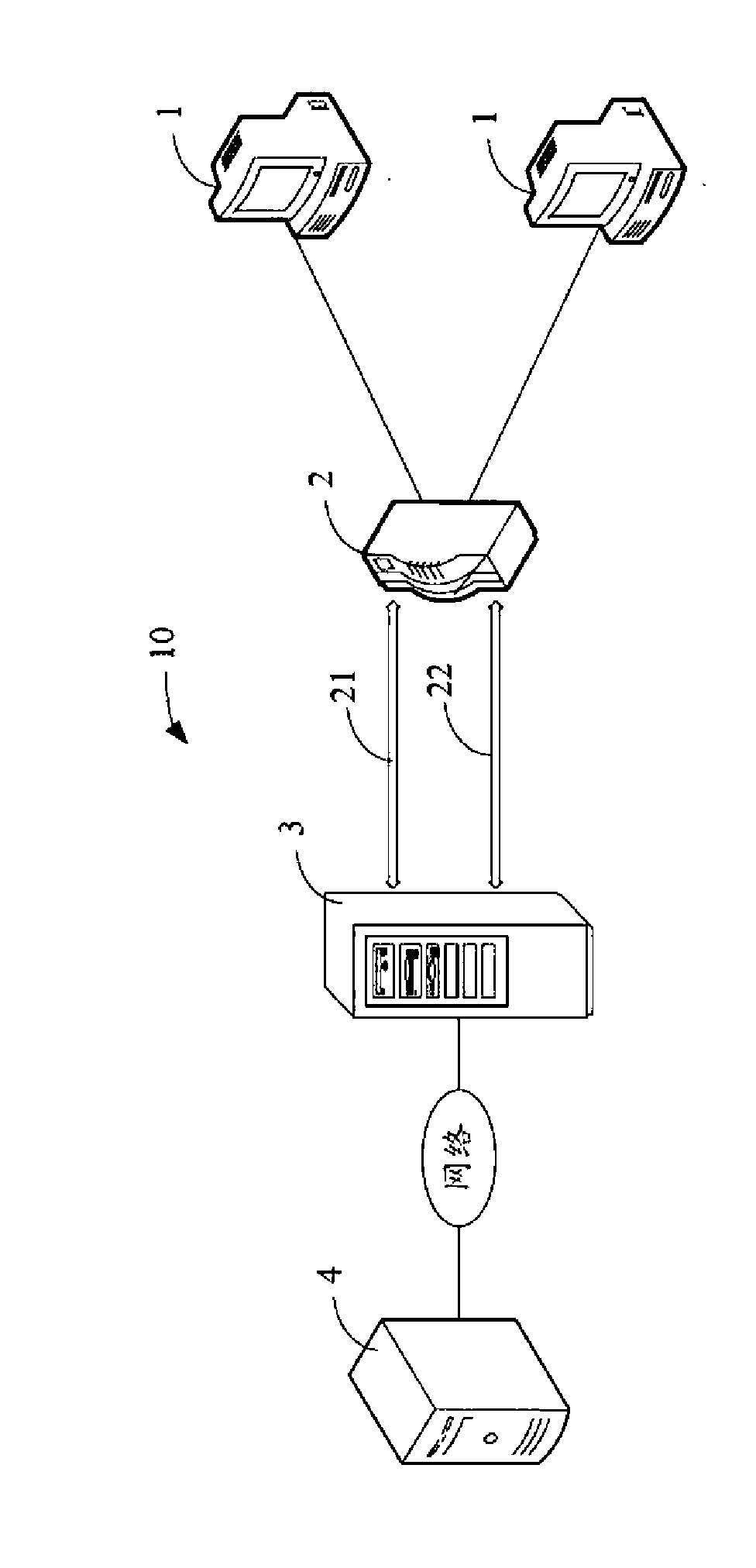

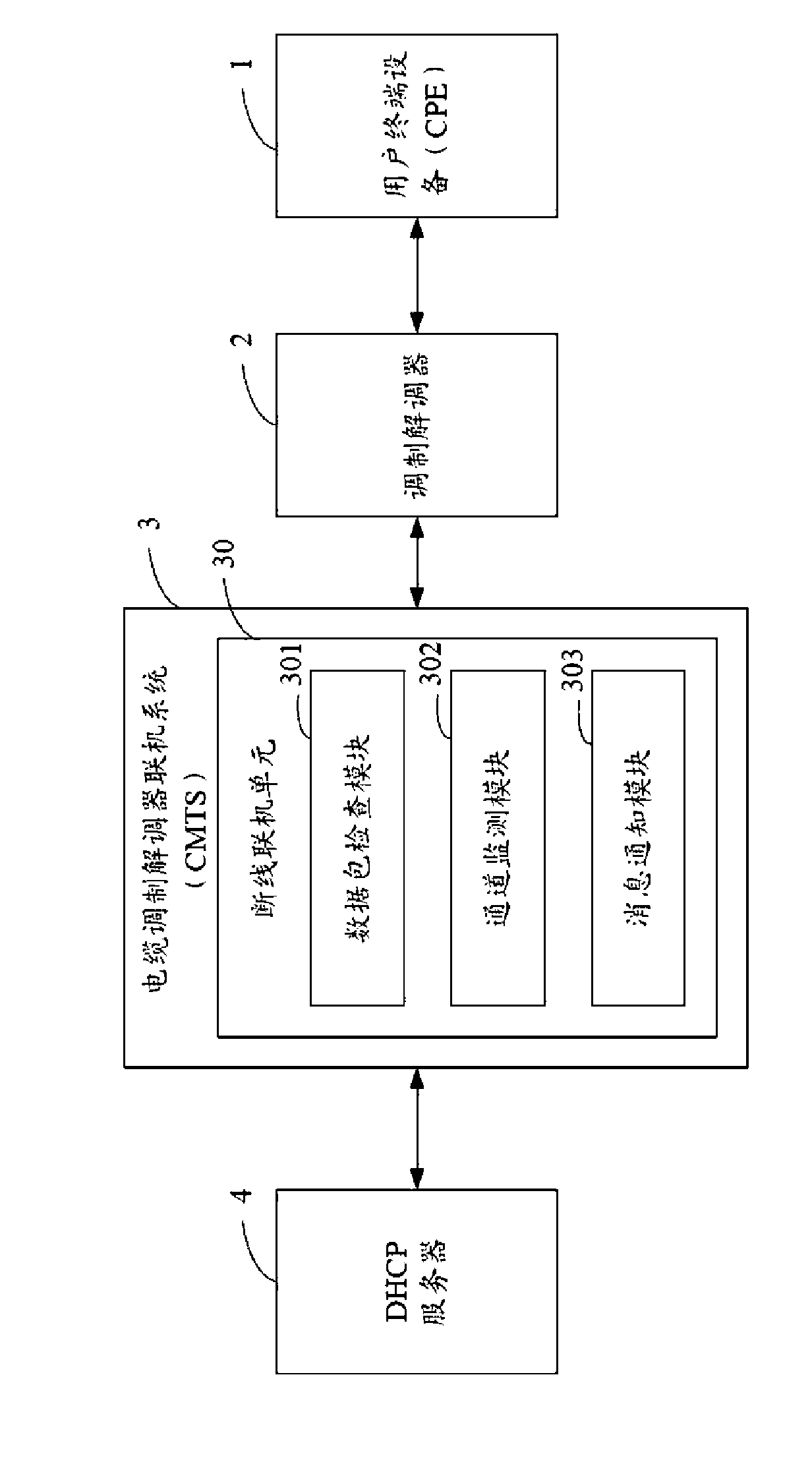

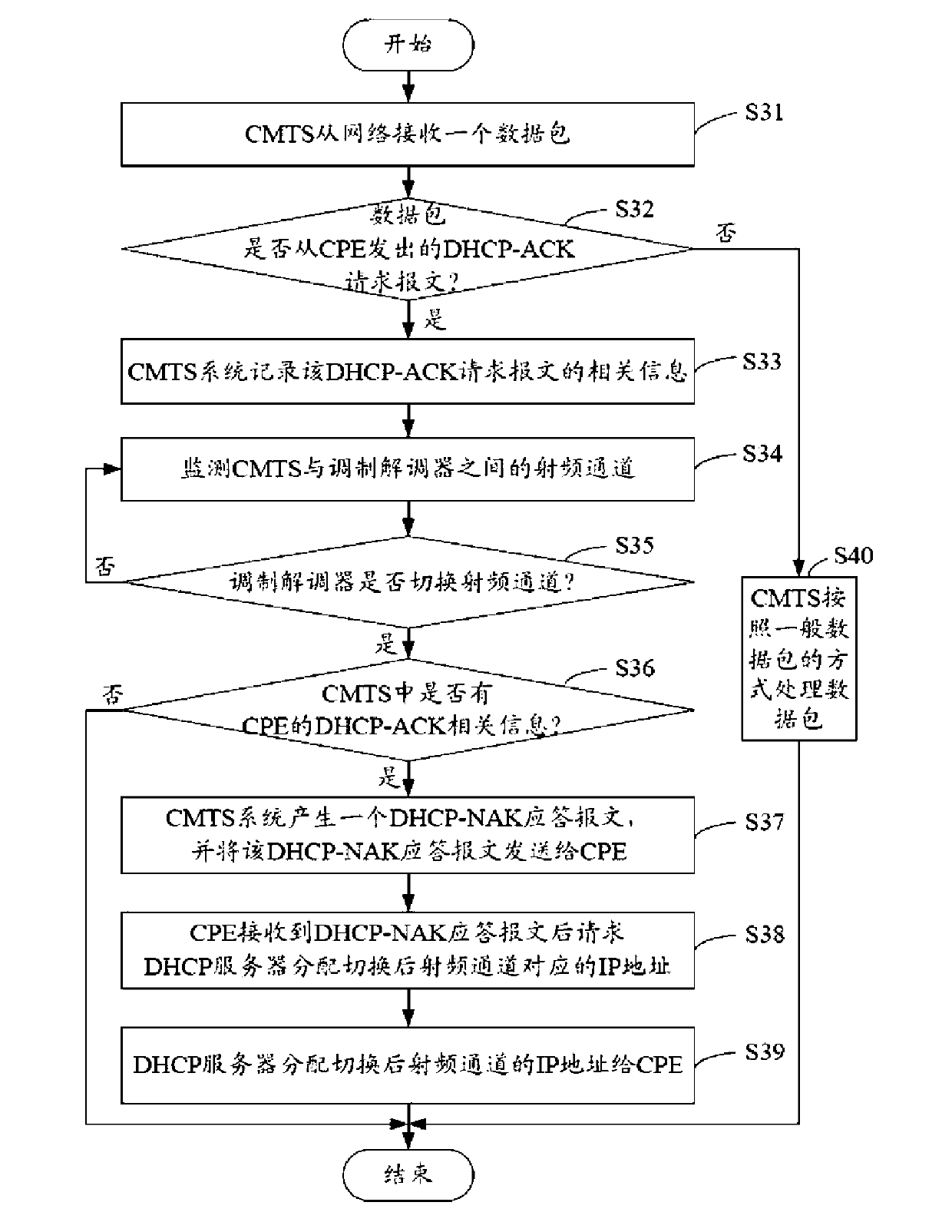

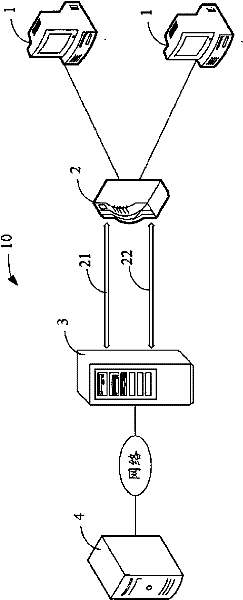

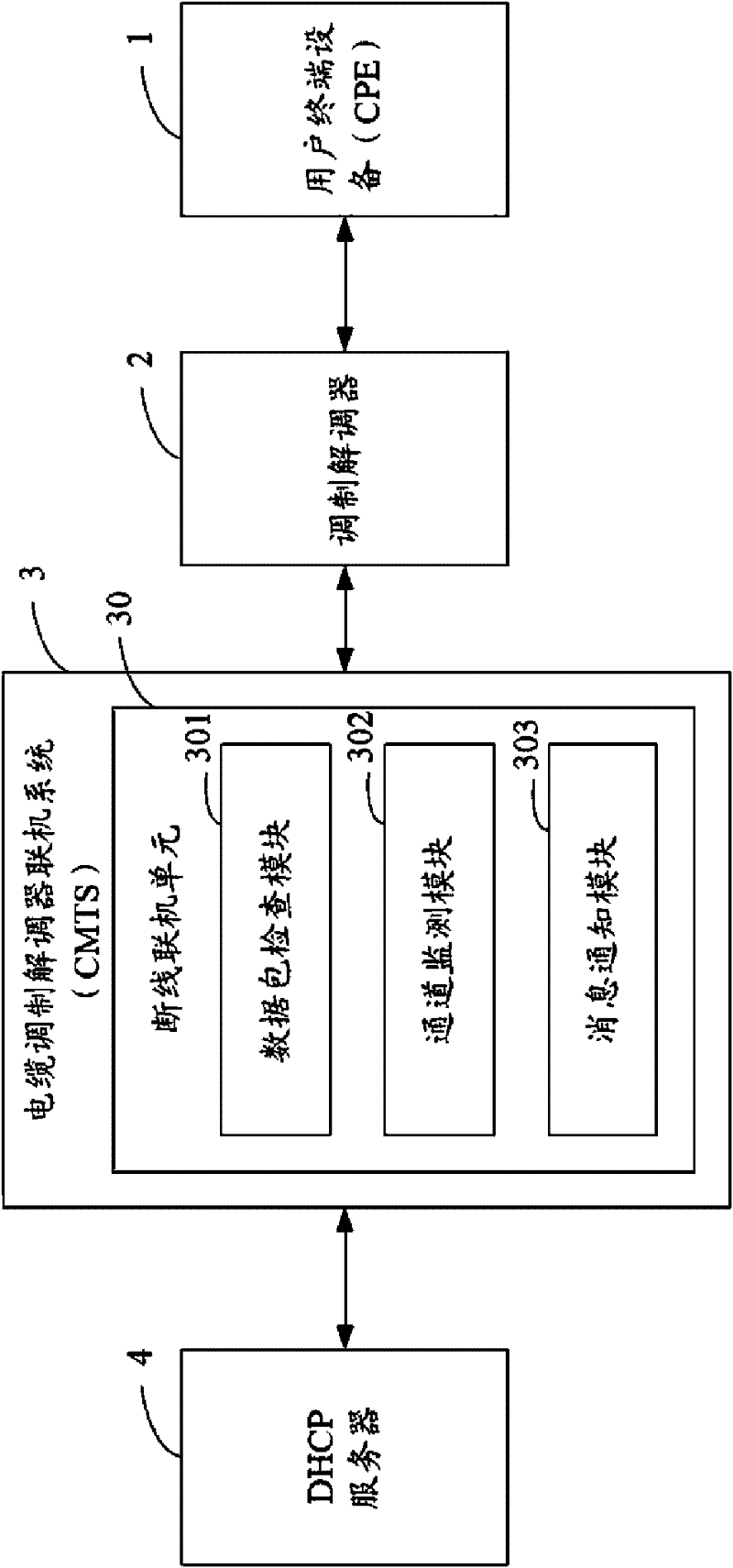

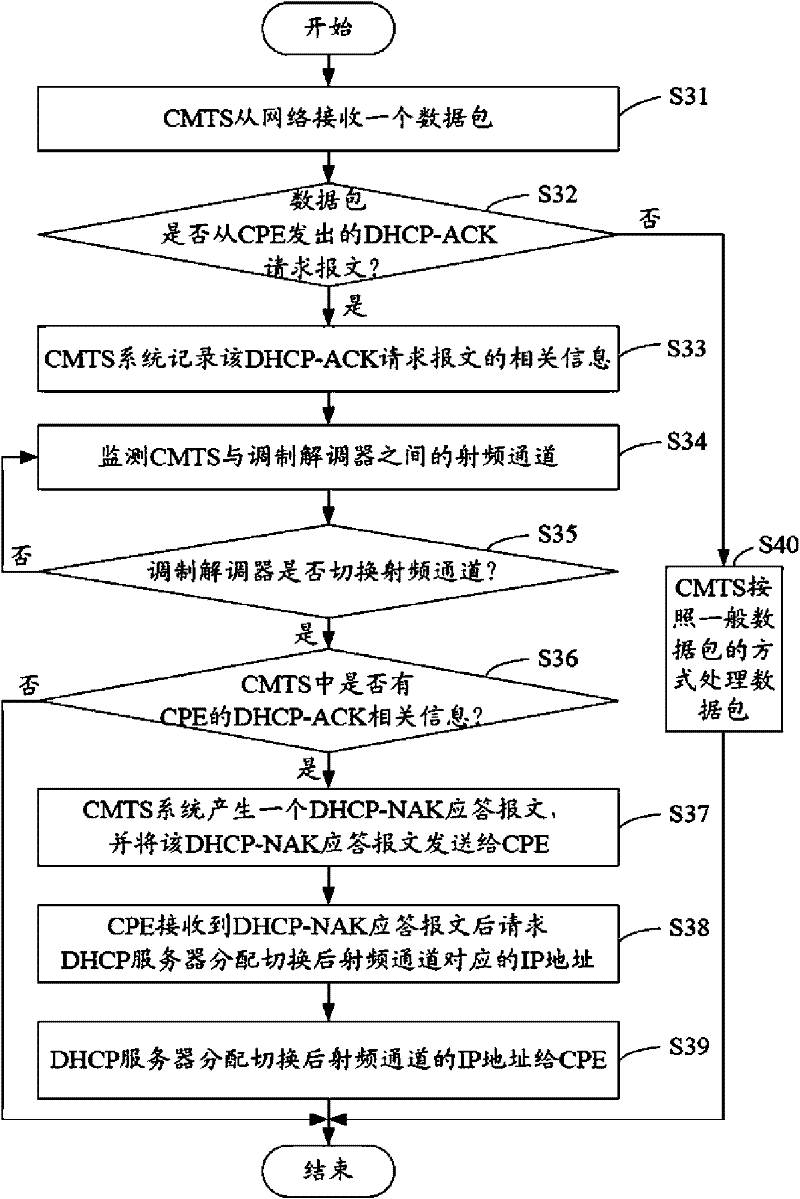

Cable modem termination system and method

InactiveCN102025574AWill not disconnectError prevention/detection by using return channelBroadband local area networksRadio frequencyIp address

The invention relates to cable modem termination system and method. The cable modem termination system is connected with a dynamic host configuration protocol (DHCP) server through a network and is connected with customer premise equipment through a cable modem; the cable modem termination system comprises a disconnection termination unit; and when the cable modem changes a radio-frequency channel to carry out network communications, the disconnection termination unit informs the customer premise equipment of requesting for the IP address reallocation from the DHCP server, and the customer premise equipment is connected to the network to carry out network communication according to the IP address. According to the invention, the disconnection of the customer premise equipment to the network can be prevented when the cable modem changes the radio-frequency channel, thus the customer premise equipment can request for the IP address reallocation from the DHCP server so as to be connected to the network to carry out network communications without being restarted.

Owner:AMBIT MICROSYSTEMS (SHANGHAI) LTD +1

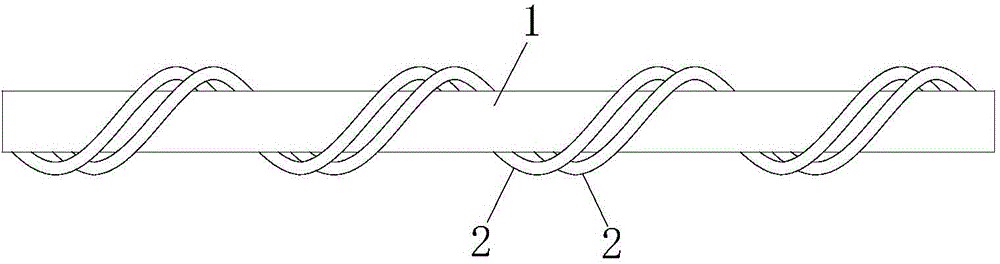

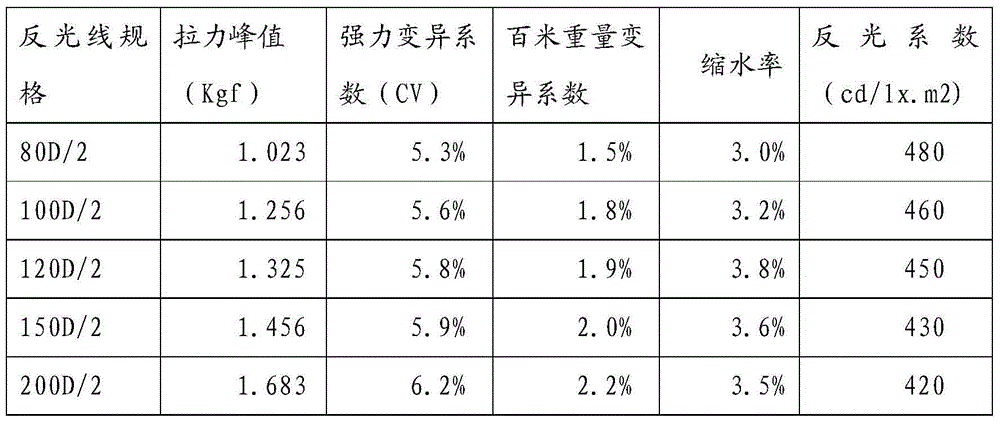

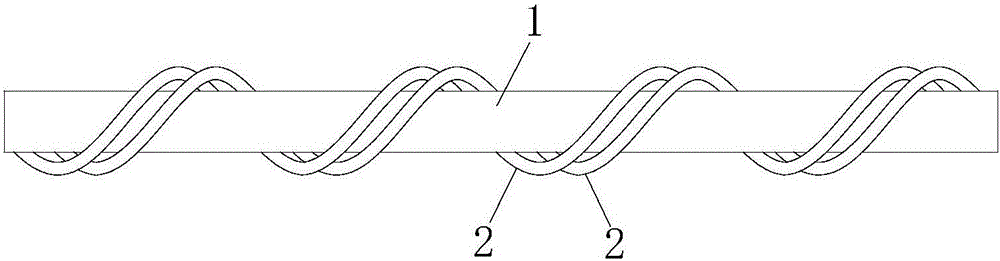

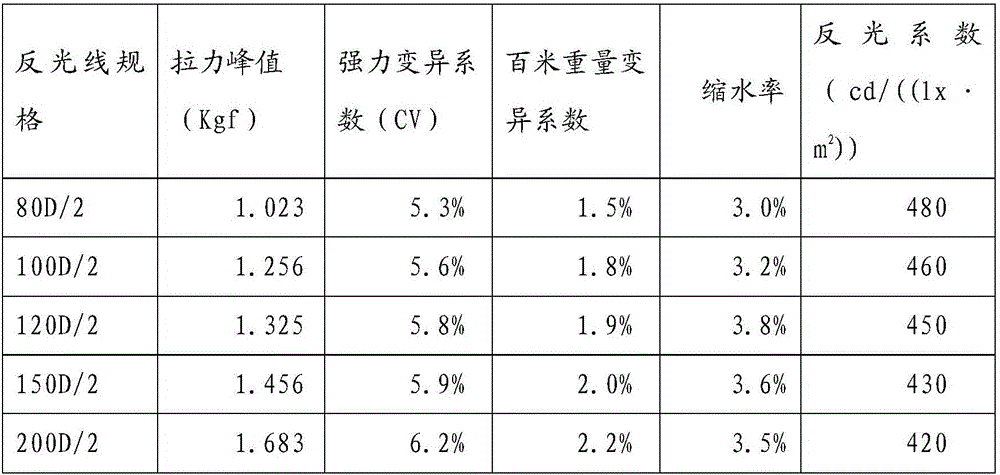

Water-soluble reflective thread and production process thereof

The invention discloses water-soluble reflective thread. The water-soluble reflective thread is formed by compositing a yarn core and at least one wrapped yarn. The wrapped yarn is wound on the outer surface of the yarn core in a spiral mode. The yarn core is a reflective silk, and the wrapped yarn is water-soluble yarn. A water-soluble reflective thread production process includes the following steps that (1) the water-soluble yarn is twisted; (2) the reflective silk is selected, wherein the surface of a PET film is coated with glass beads and are cut into different specifications, and reflective silks are obtained; (3) at least one water-solute yarn treated through the step 1 is wound on the reflective silk obtained through the step 2 in a spiral mode, and reflective yarn is obtained; (4) the reflective yarn is branched and coiled to be of the fixed length, and the water-soluble reflective thread is obtained. According to the water-soluble reflective thread and the production process, the water-soluble yarn is matched with the reflective silk, the sewability of the water-soluble reflective thread is enhanced, no twisting happens, no thread breakage occurs in the using process, and sewing is facilitated; meanwhile, after the thread is used, textile is washed, the water-soluble yarn part can dissolve and disappear, and the reflective effect is improved.

Owner:DONGGUAN COCOU TEXTILE MATERIALS

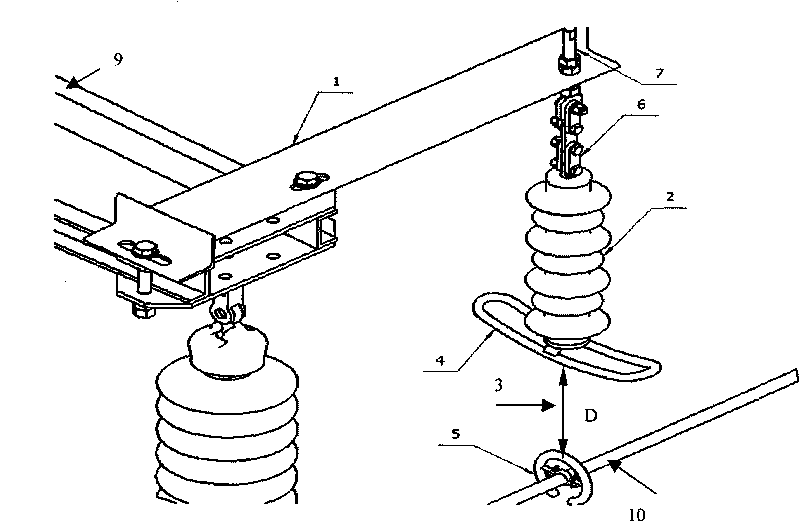

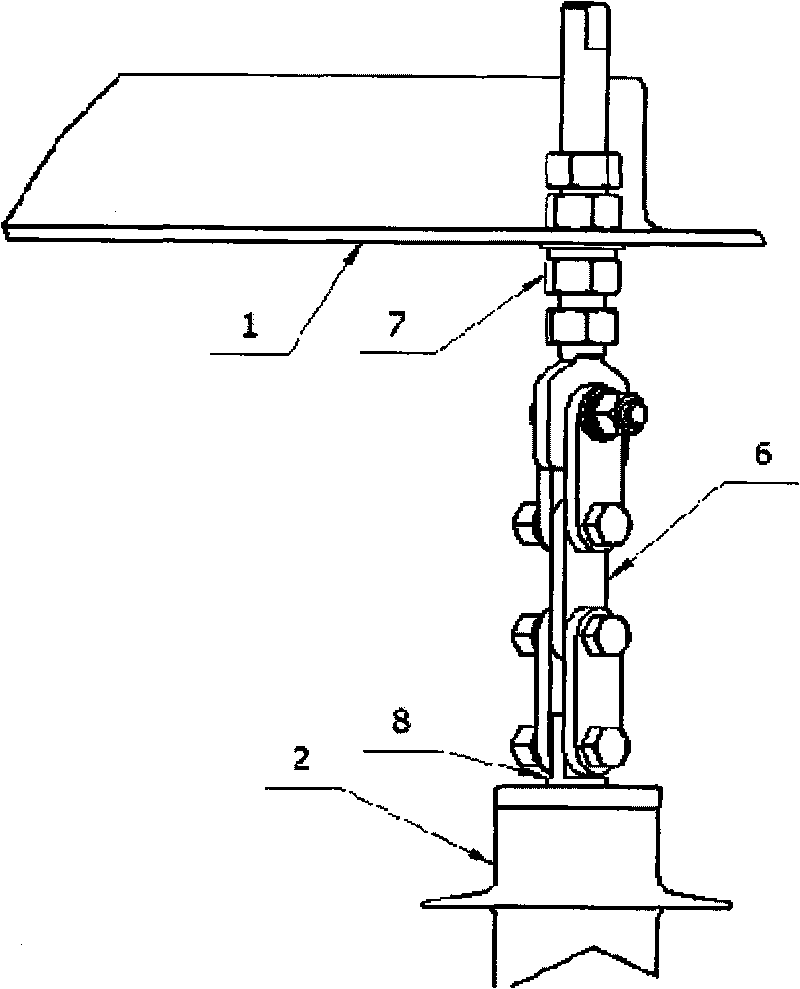

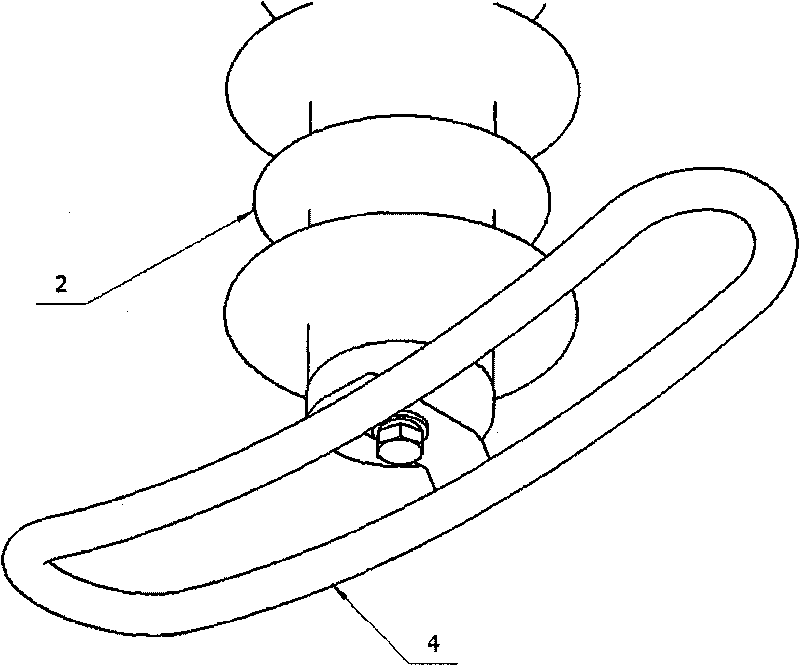

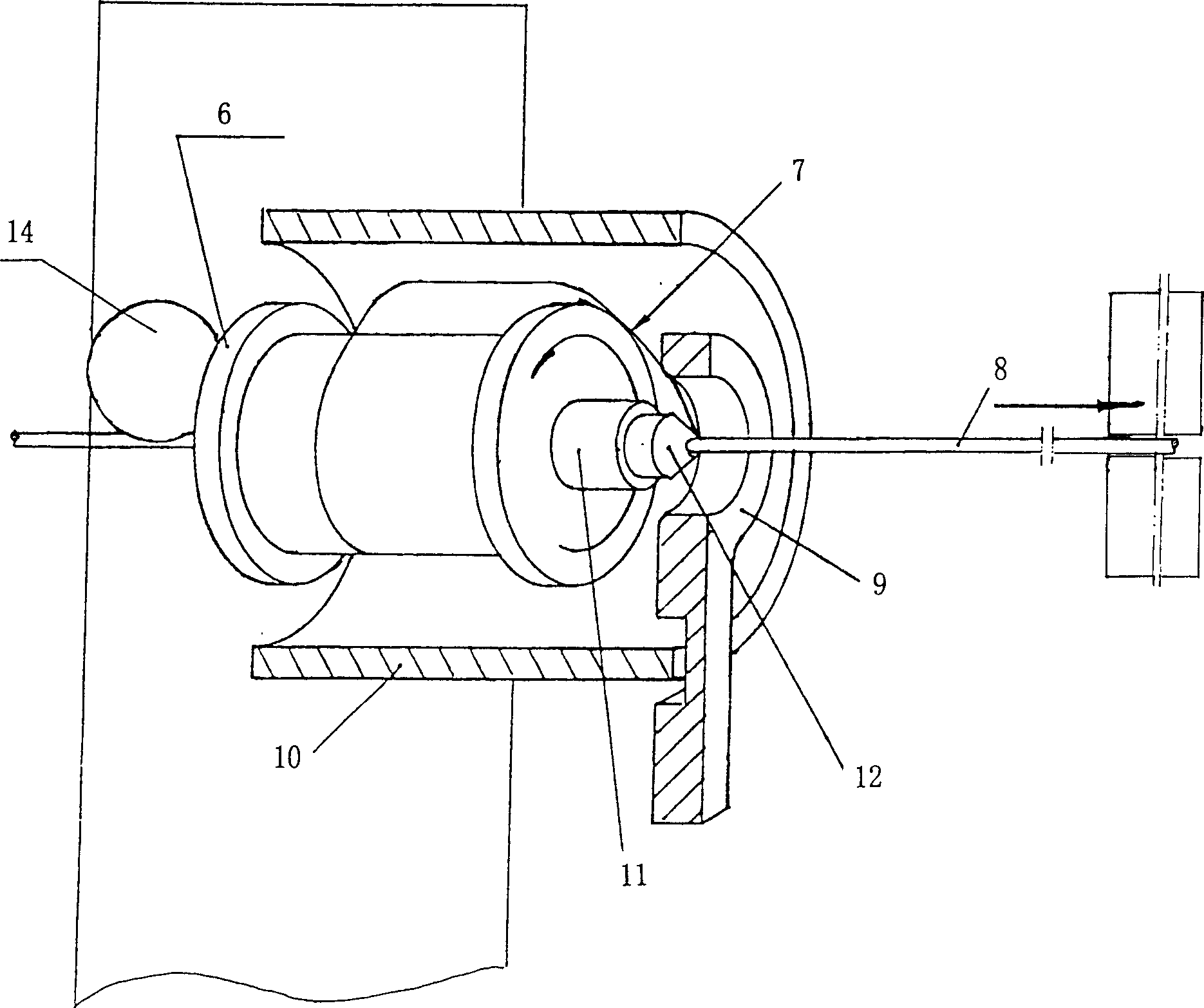

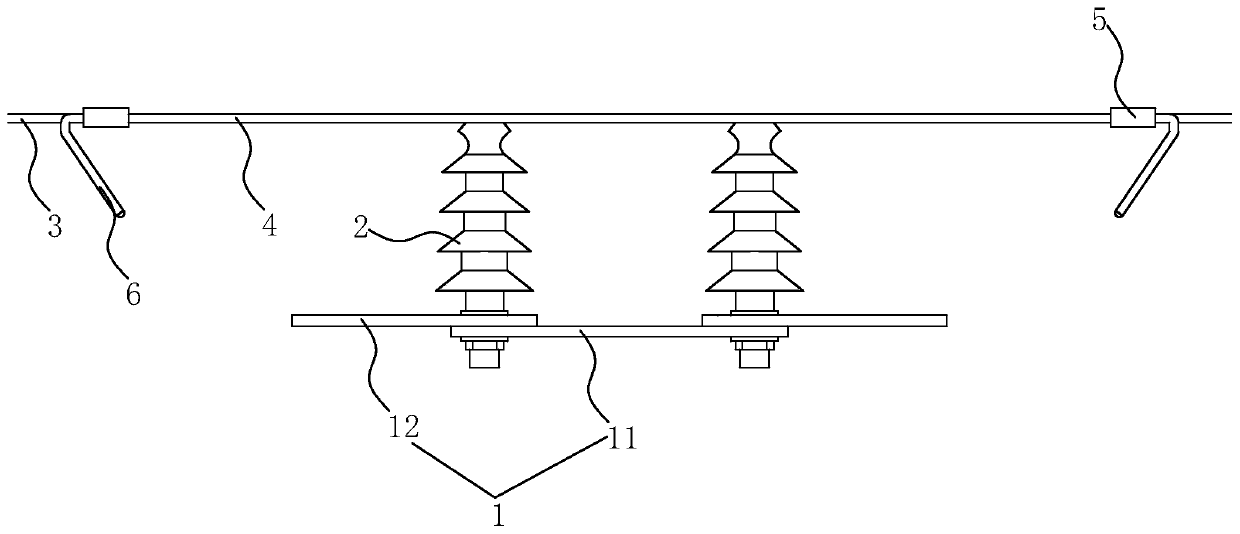

Arrester for electrified railway traction power supply system

InactiveCN101728808AReliable actionImprove stabilityInstallation of lighting conductorsSpatial arrangements/dispositions of cablesLightning strikeLow voltage

The invention discloses a metal oxide arrester which is used for protecting an alternating current electrified railway traction power supply system, is provided with an air gap, and comprises a cross arm and an arrester body, wherein the cross arm is fixed on a pole tower shoulder support, and the arrester body is suspended and fixed on the cross arm; in addition, the arrester also comprises a high voltage electrode and a low voltage electrode, wherein the low voltage electrode is assembled at the lower end of the arrester body and is firmly electrically connected with the arrester body, the high voltage electrode is assembled on a line lead and is firmly electrically connected with the line lead, and an air gap is formed between the high voltage electrode and the low voltage electrode. When overvoltage happens to lighting, the arrester can reliably act; after the lightning passes, the arrester easily restores insulation, has good stability, basically needs no maintenance and can be used on a 27.5kV electrified railway F line suspension insulator to effectively prevent the problem of line break of a traction power supply system due to lightning strike.

Owner:SHANDONG XUNSHI ELECTRIC

Crimped casing for electric transmission and distribution wire

InactiveCN1409439AReduce tensile stressHigh strengthConnections effected by permanent deformationElectric power transmissionPull force

This invention discloses a crimp connection for casing tube or crimped lock for wire used in power transmission and distribution line composed of a columnary matrix, the section of which exhibits C shape, two lineal furrows are set at both ends point distributed locking reentrants / humps or continuous or discontinuous locking furrows or locking ribs are set up on the surfaces of inner / output surfaces of the matrix and the furrows to stitch the crimped lock with wires due to the above-mentioned crimped lock structure, increasing its pulling force, reducing its connection adapted resistance and temperature rising.

Owner:陈国雄

Stabilizing treatment production method for prestress zinc-coated steel wire connector

The invention discloses a stabilizing treatment production method for a zinc-coated steel wire connector. The stabilizing treatment production method comprises the steps of connector welding, steel tube flattening, paying-off, first tensioning, straightening, intermediate frequency heating, water cooling, second tensioning, hauling, winding-up. The stabilizing treatment production method has the characteristics that waste wire in the production process is largely reduced, the percent of pass is increased by 2-4%, and production and operation efficiency is improved.

Owner:奥盛(九江)新材料有限公司 +1

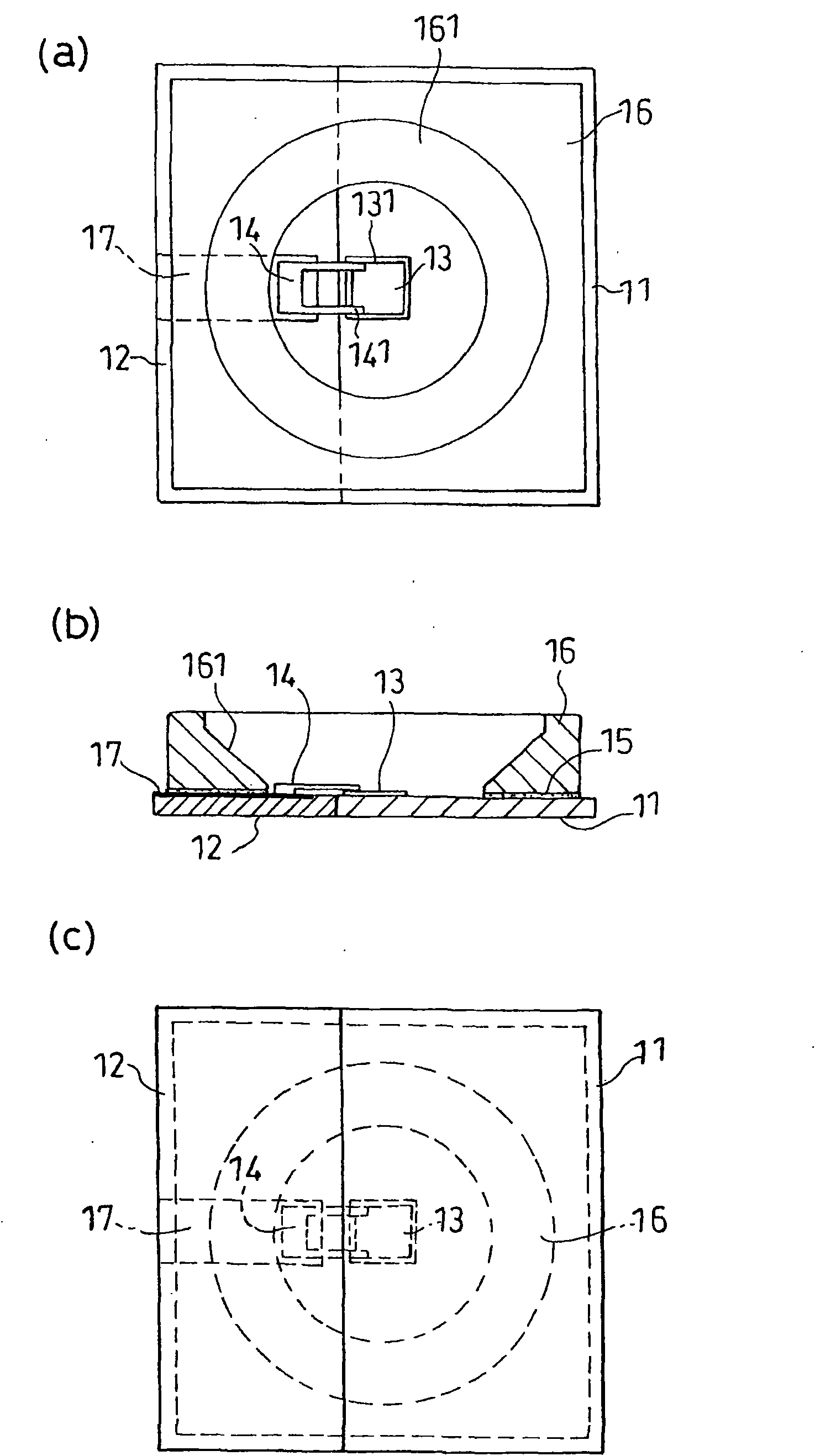

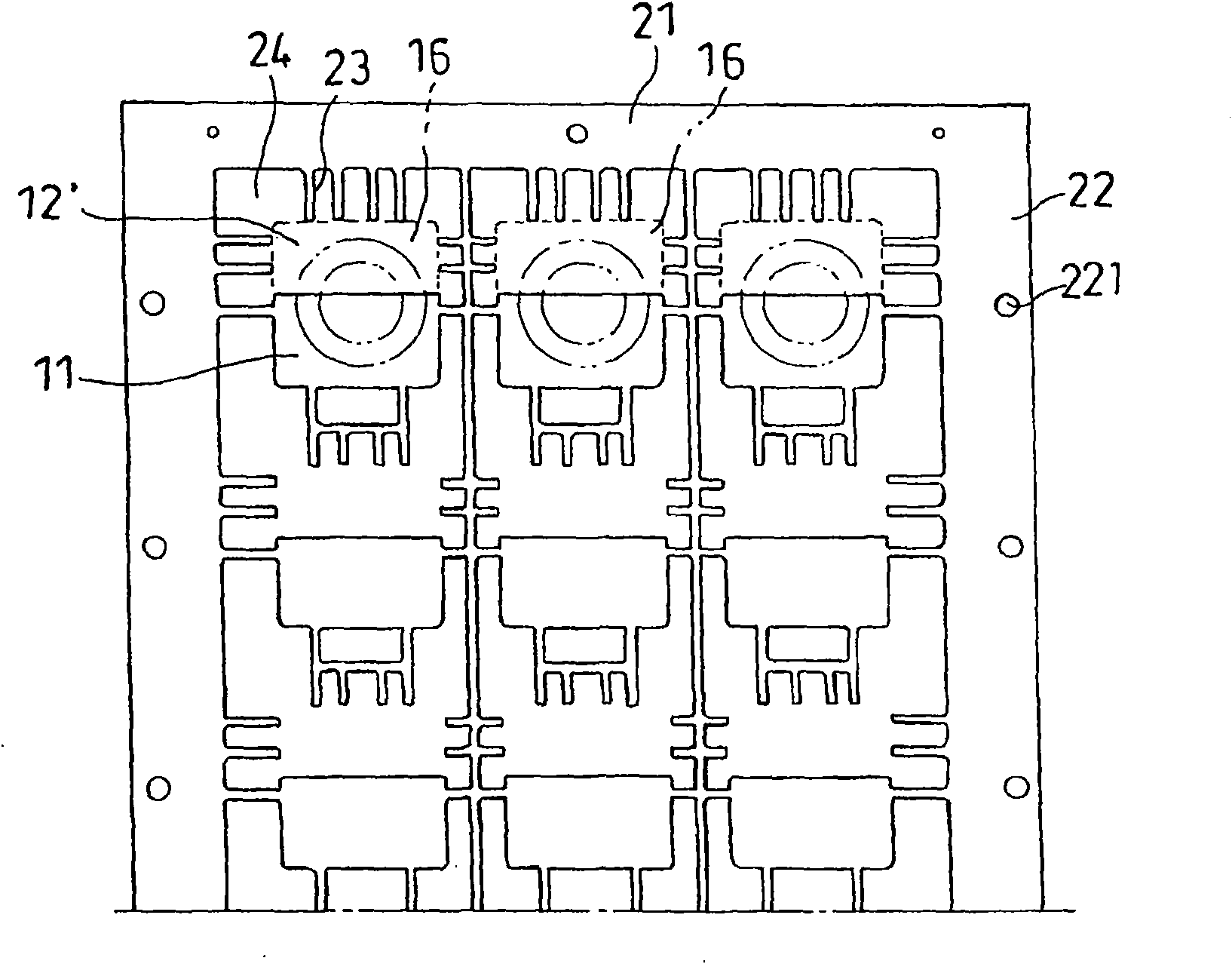

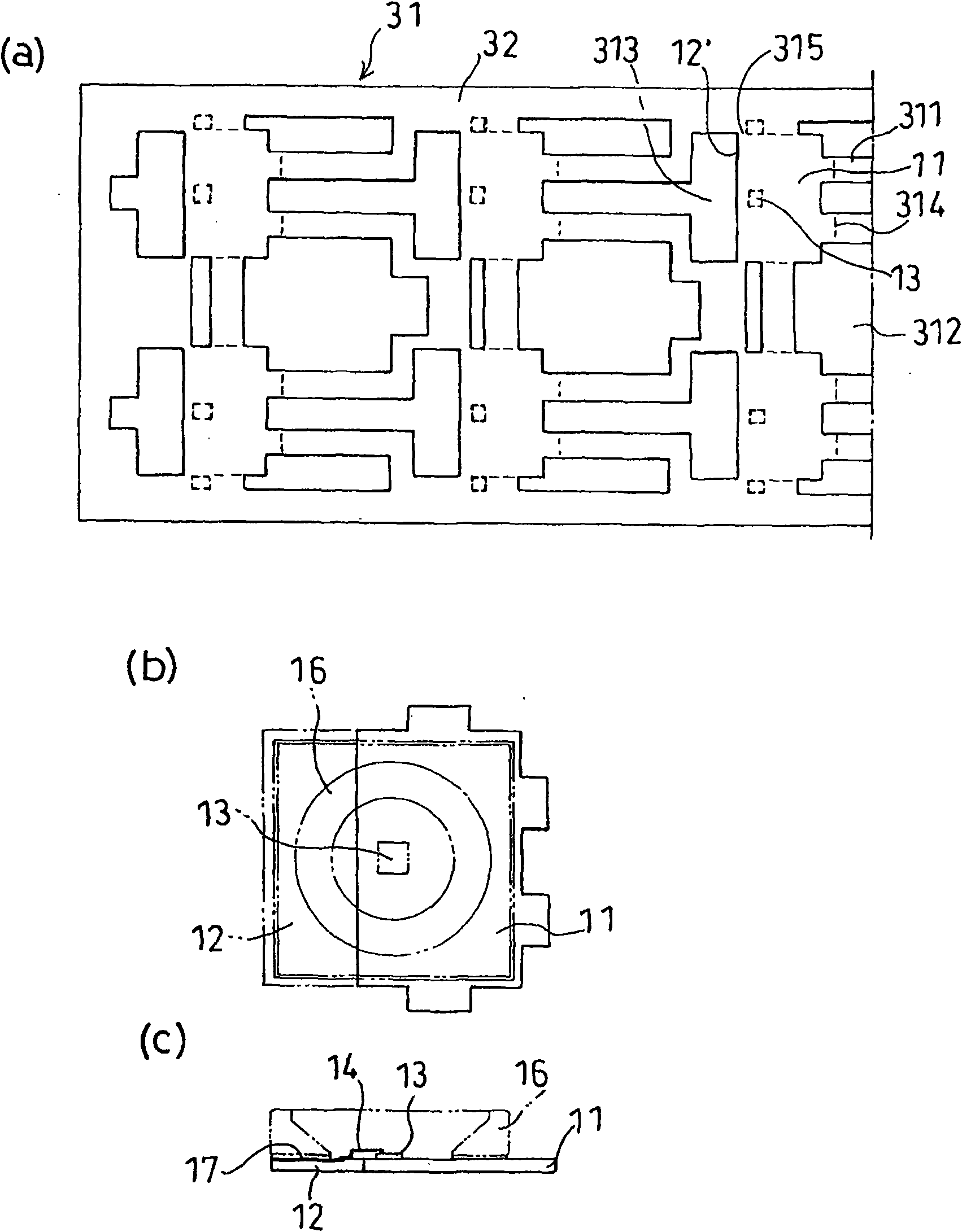

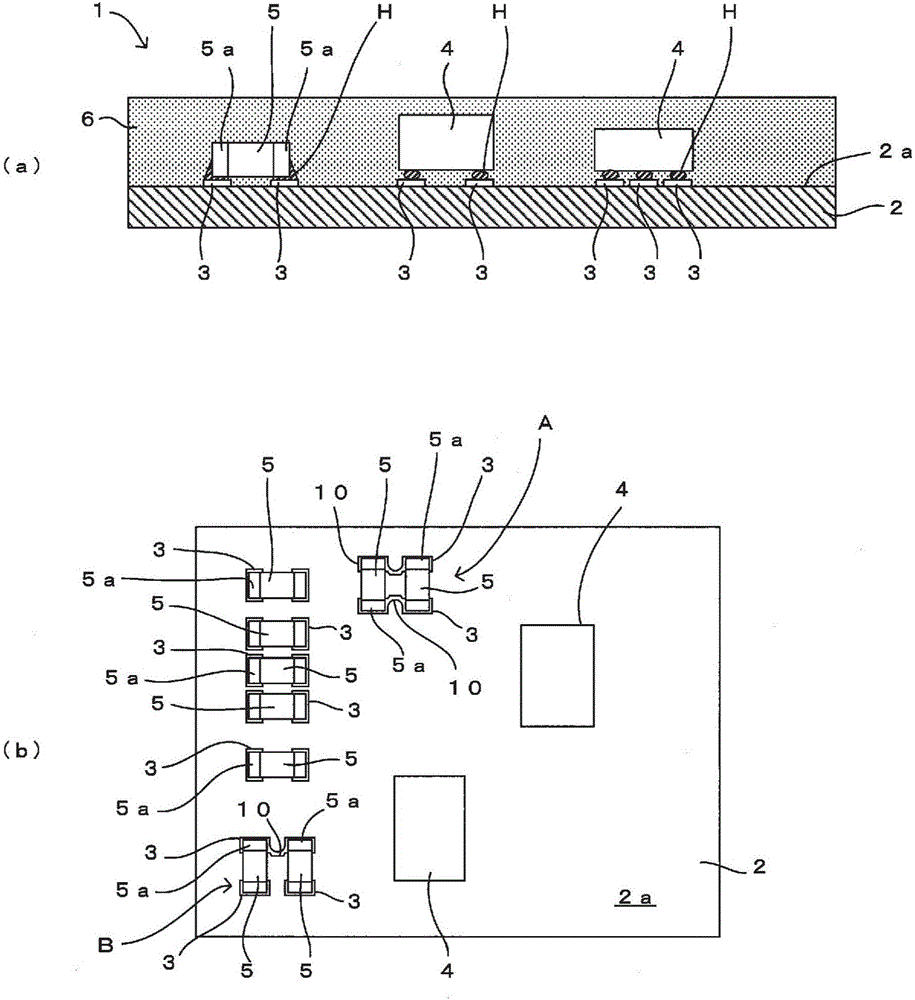

Light emitting device and package assembly for light emitting device

InactiveCN101681960AImprove efficiencyNo light leakageSolid-state devicesSemiconductor devicesAdhesiveLead frame

Provided is a light emitting device having an upper / lower electrode type light emitting diode on a substrate composed of a ceramic board composed of a metal substrate and a ceramic substrate abuttingto the metal substrate. A substrate lead frame for manufacturing the light emitting device is also provided. In the light emitting device, a light emitting section or the like is arranged on a substrate wherein a metal substrate (11) and a ceramic board (12) abut to each other on one side. The ceramic board (12) has a conductive film (17) formed on an upper section. The metal substrate (11) and the ceramic board (12) are bonded with an adhesive such as a thermosetting resin so that a reflection frame (16) composed of an insulating member having an opening section is over the metal substrate and the ceramic board. At least one upper / lower electrode type light emitting diode (13) has a lower electrode on the metal substrate (11). At least one conductive connecting member (14) connects an upper electrode (131) of the upper electrode type light emitting diode (13) and the conductive film (17).

Owner:CI KASEI COMPANY

Copper and aluminum connection structure with flame retardant insulation bush

InactiveCN102025031AIncrease contactHigh strengthConnections effected by permanent deformationConnection contact member materialCopper conductorUltimate tensile strength

The invention relates to a copper and aluminum connection structure with a flame retardant insulation bush. In the connection structure, cold welding and pressure welding manners are simultaneously adopted for fixedly connecting a copper conductor joint section of a copper conductor and an aluminum conductor joint section of an aluminum conductor into a copper and aluminum conductor joint section; the copper and aluminum conductor joint section and the peripheries of the copper conductor joint section and the aluminum conductor joint section which are adjacent to the copper and aluminum conductor joint section are coated by heat-shrinkable insulation bushes with a good flame retardant property; and the tension resistance strength of the copper and aluminum conductor joint section is not less that 200 N. The copper and aluminum connection structure with the flame retardant insulation bush can ensure that the two different metal conductors can well contact, have the characteristics of good strength and good insulation property, and can not be broken, carbonized and burnt easily in operation for a long time.

Owner:JIANGSUSNGSHANG CABLE GROUP

Wiring and manufacturing method of capacitive touch screen

ActiveCN101639749BImprove product qualityAvoid chromatic aberrationInput/output processes for data processingContinuationEngineering

Owner:SHENZHEN LAIBAO HI TECH

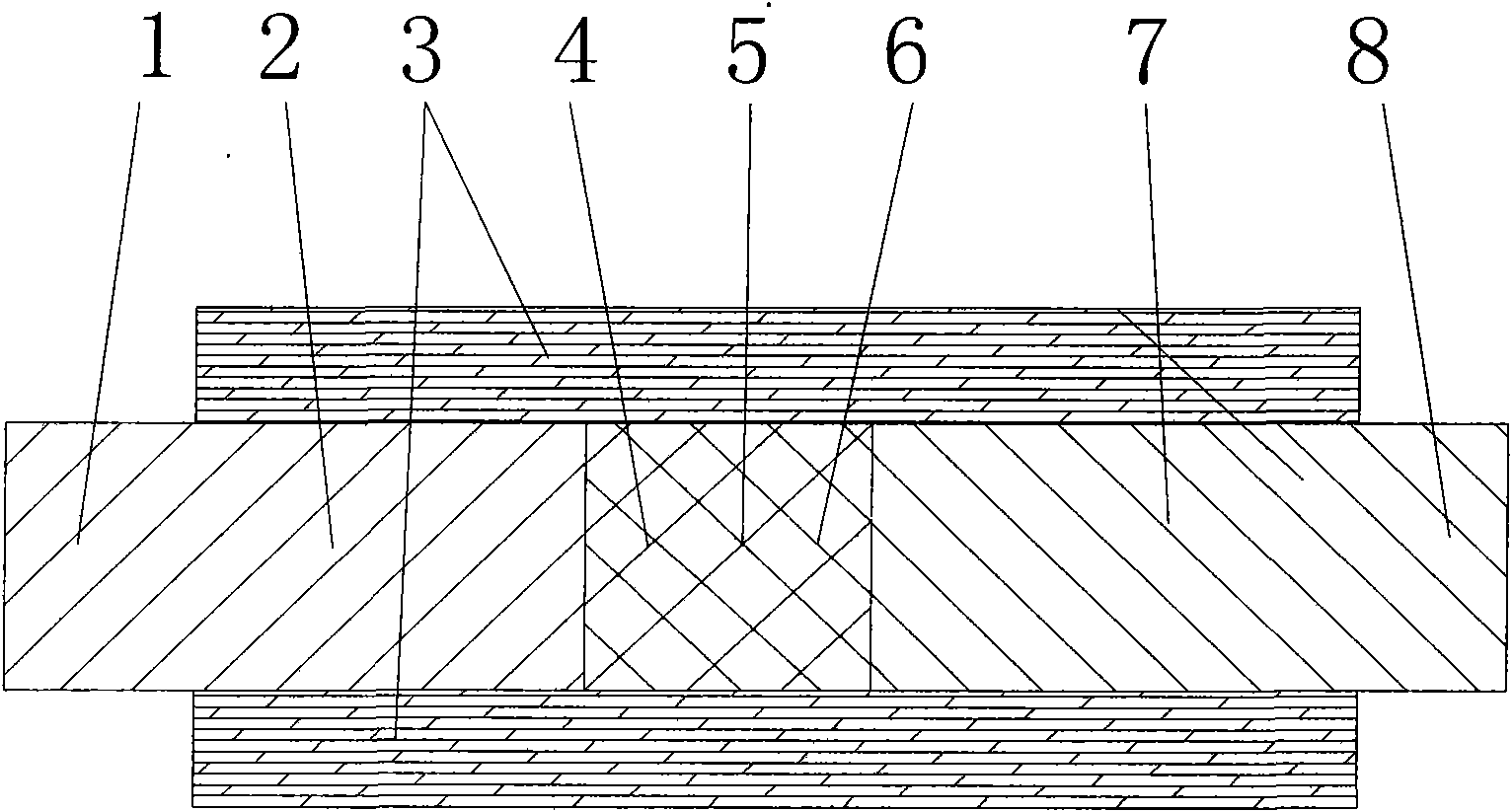

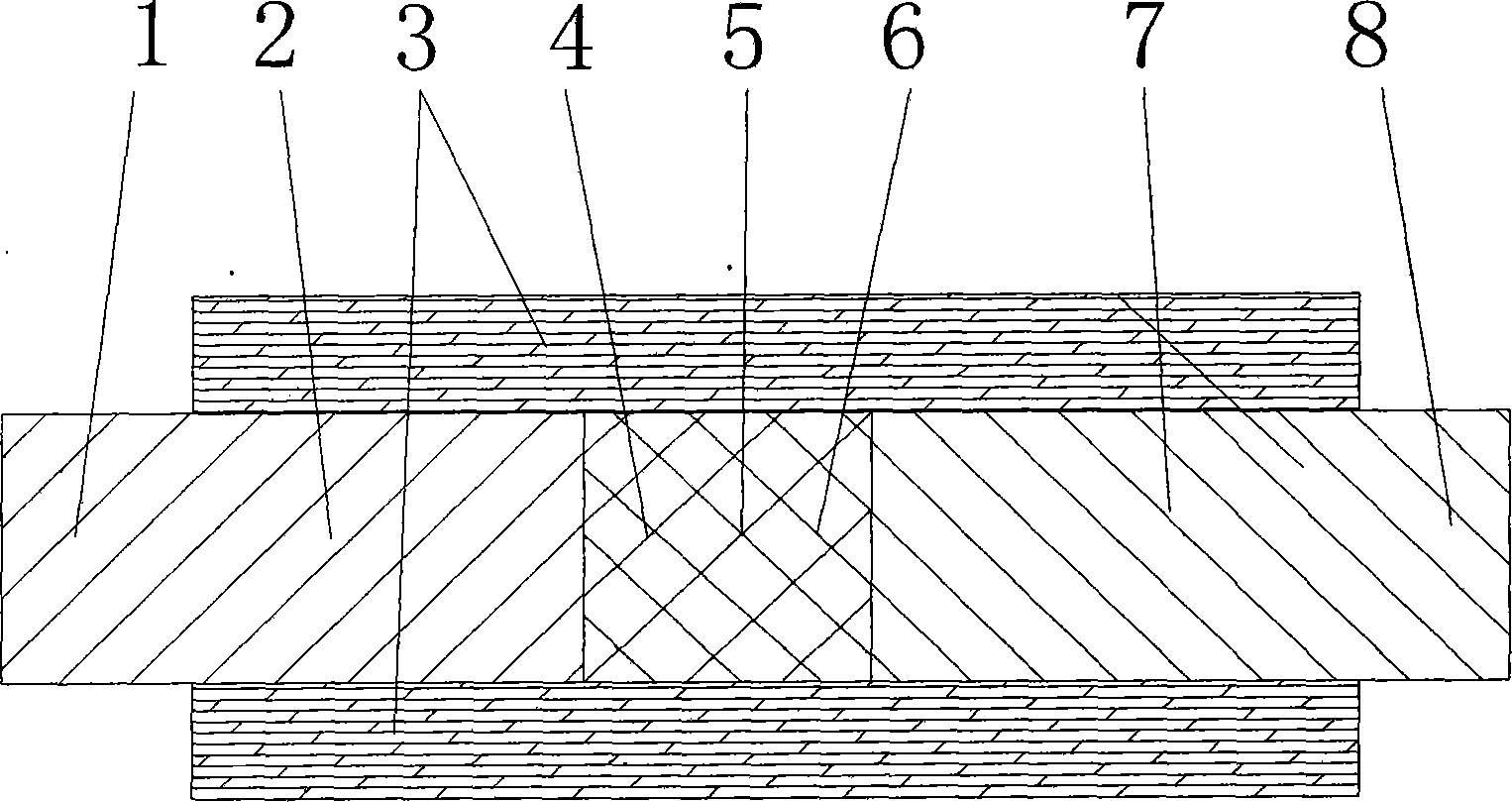

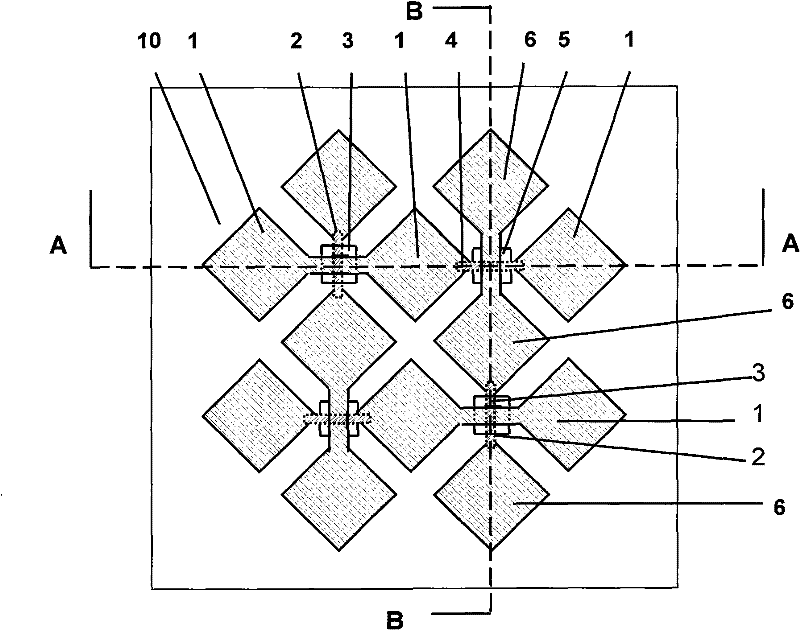

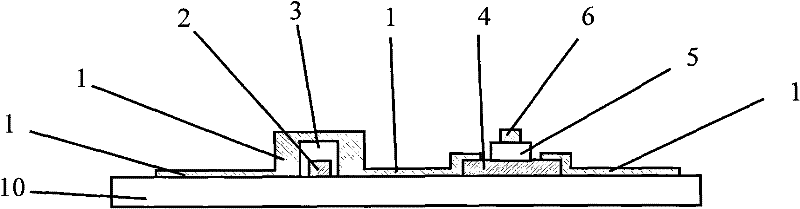

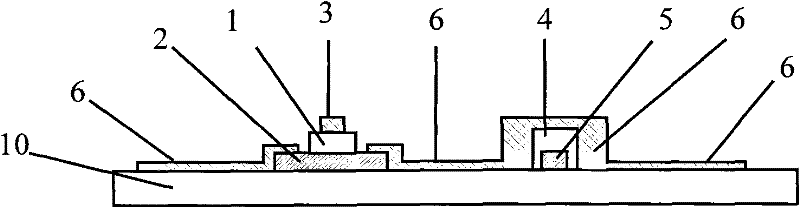

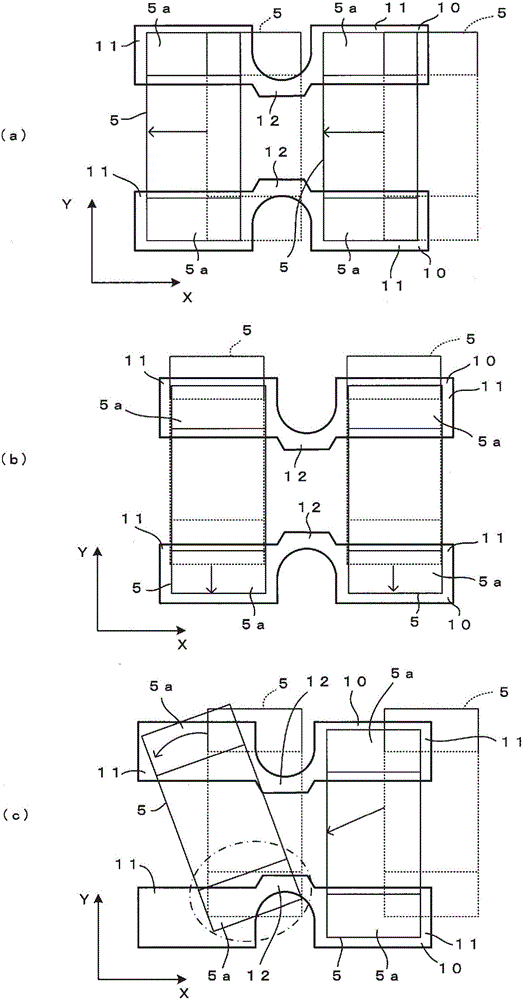

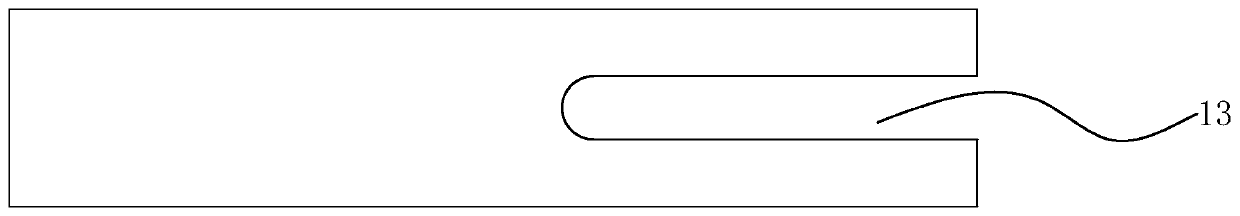

Resin sealed module

ActiveCN106465548AWill not disconnectReduce overlapPrinted circuit assemblingFinal product manufactureLine widthMiniaturization

Provided is a resin sealed module having a good resin filling property and provided with a circuit board, wherein a bridge part is not broken even if the size of a common land electrode is reduced with a reduction in the size of a circuit component, and when a plurality of circuit components are mounted, a gap between the components can be ensured. The present invention can provide a resin sealed module having a good resin filling property and provided with a circuit board, wherein a bridge part (12) is disposed while being displaced in a predetermined displacement direction in a region in which mounting parts (11) face each other, and therefore even if the line width of the bridge part (12) is made larger than in the prior art, a self-alignment phenomenon can be appropriately generated in a reflow step, the bridge part (12) is not broken even if the size of a common land electrode (10) is reduced with a reduction in the size of a circuit component (5), and when a plurality of circuit components (5) are mounted, a gap between the components can be ensured.

Owner:MURATA MFG CO LTD

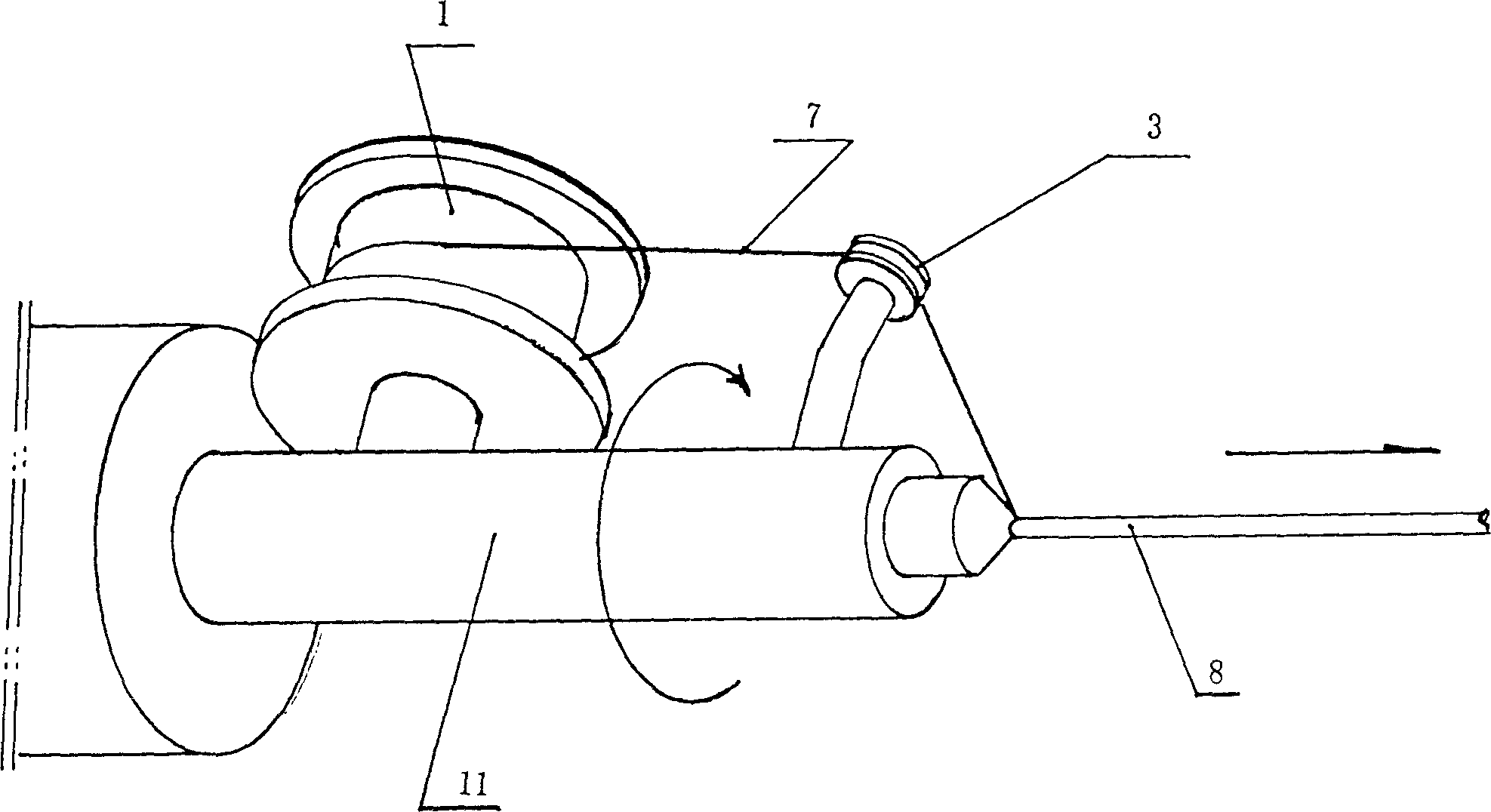

Method and its device for high speed winding metal wire on core wire

InactiveCN1901111AEven winding pitchWill not disconnectFilament handlingInsulatorsEngineeringCentrifugal force

This invention provides a method and a device for utilizing centrifugal force to pay off metal wires for winding metal wires quickly including a shaft, a core wire passing through the shaft, a wire leading nozzle mounted on a same end of the shaft to the outlet end, an outer winding disk fixed on the shaft and rotating synchronously with it, a wire-thrower cover mounted at the outside of the outer-winding disk, a blocking coil mounted on an end of the thrower near the leading nozzle, in which, the core wire passes through the blocking coil, the pay-out end of the wire is led out from the tangent direction on the outer winding disk opposite to the rotation direction of the shaft and fixed on the core wire in the blocking coil.

Owner:钱潜

Manufacturing method for 3D printing garment fabric and garment manufactured from 3D printing garment fabric

InactiveCN111216356ASave materialIncrease profitAdditive manufacturing apparatus3D object support structures3d printComputer printing

The invention discloses a manufacturing method for a 3D printing garment fabric. The manufacturing method comprises the following steps: utilizing computer 3D design software to perform shoe upper digital modeling; planning a printing layer number, a printing line size and a spacing distance according to motion needs, and tightly regulating special lines of a local material to be more fit to a body of a user; using software of a 3D printer to plan a printing path, manually setting the size of a printing spray head, a printing temperature and printing speed, guiding a digital model into the 3Dprinter to start printing; and sewing after standing and hardening. The garment fabric disclosed by the invention is strong in functionality, is easy to manufacture, is energy-saving and environmentally friendly, and is manufactured by a 3D printing technology; special lines of the local material are tightly regulated to be more fit to a body of a sport fan according to body shape needs, so that press on neck and arm arteries is avoided. Meanwhile, gas permeability of the 3D printing garment fabric exceeds that of a conventional woven fabric, so that the inner part of the garment is preventedfrom being moisturized and gaining weight as a result of sweat absorbing.

Owner:QUANZHOU PEAK SHOES

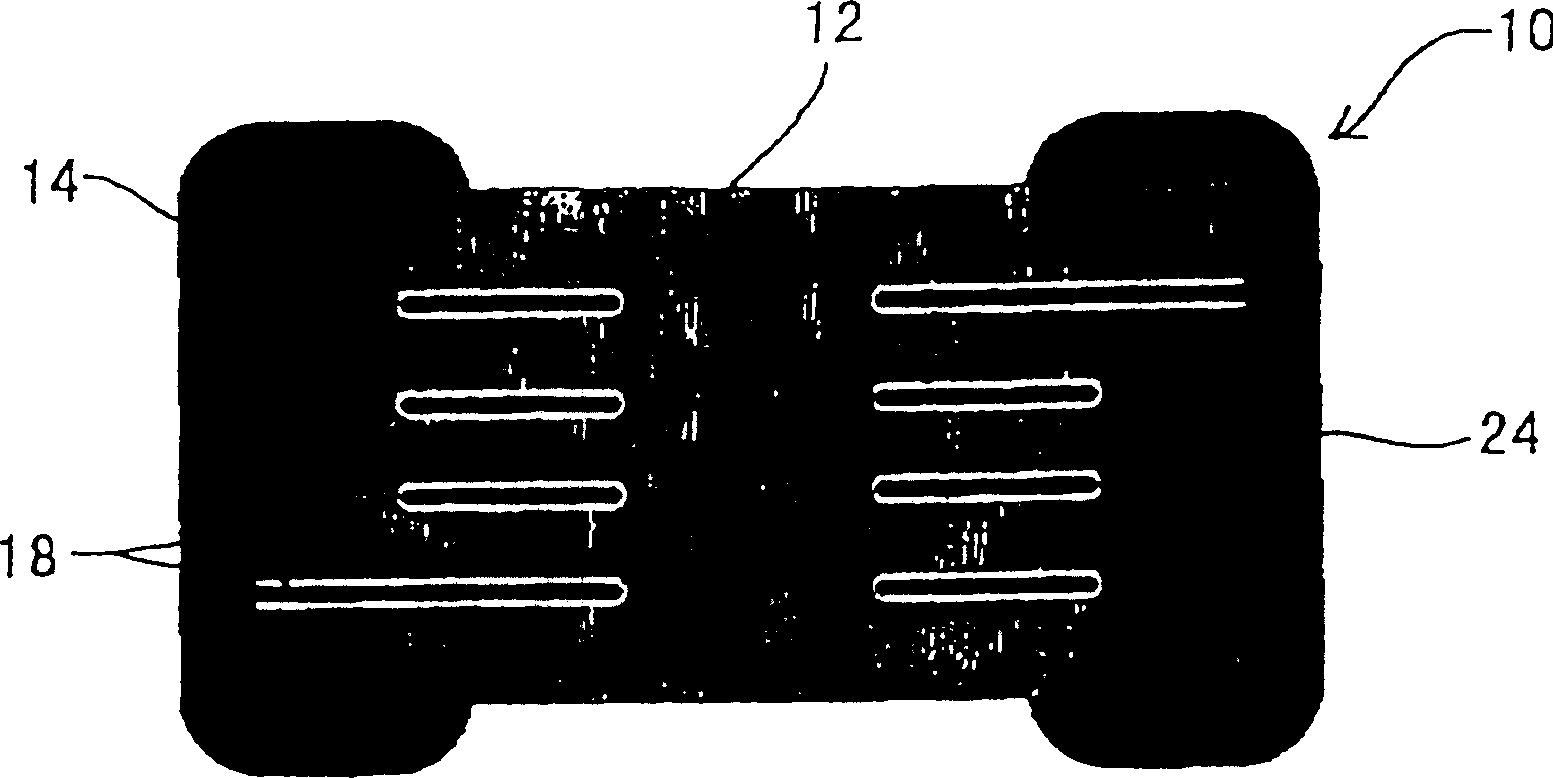

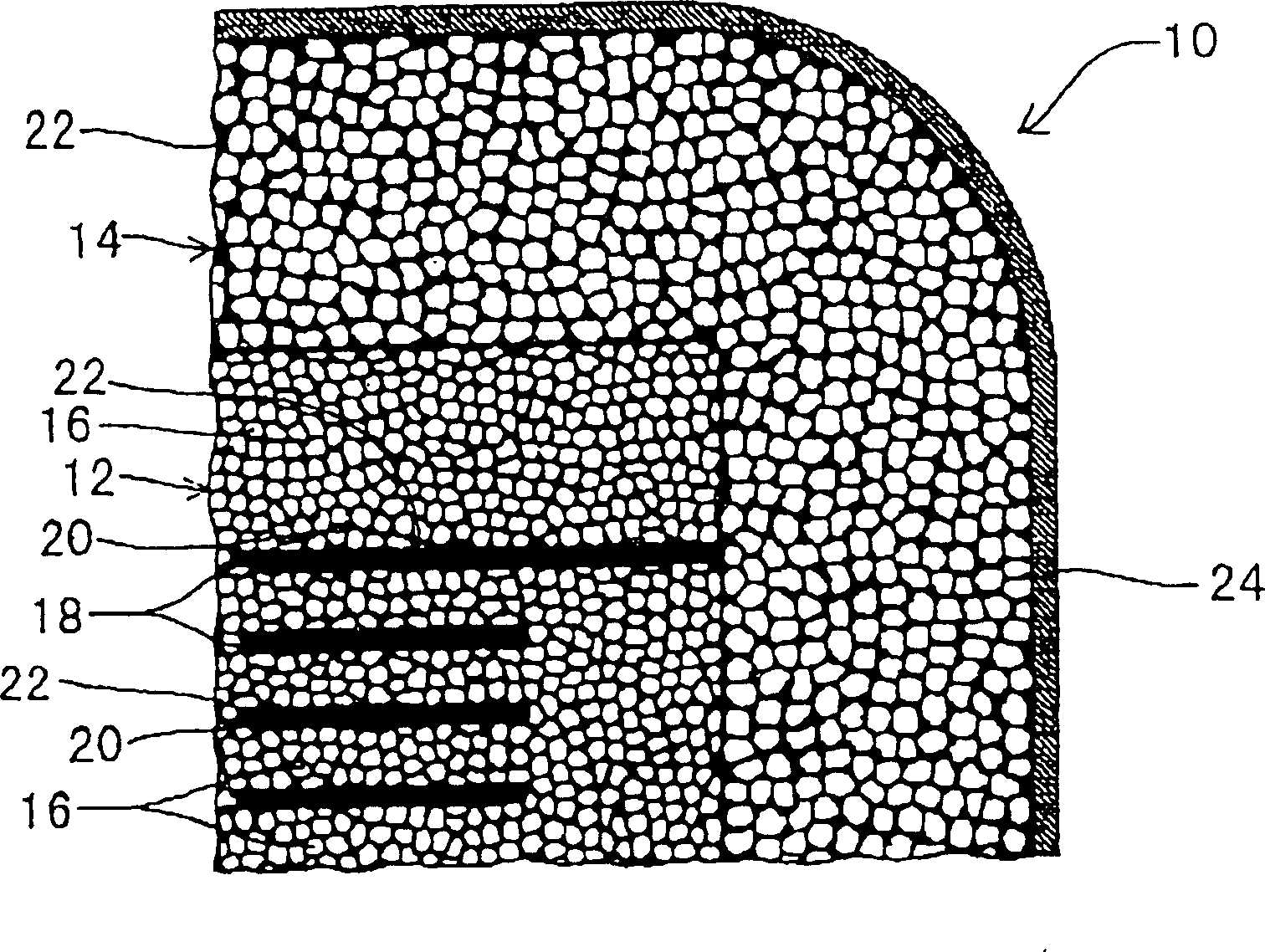

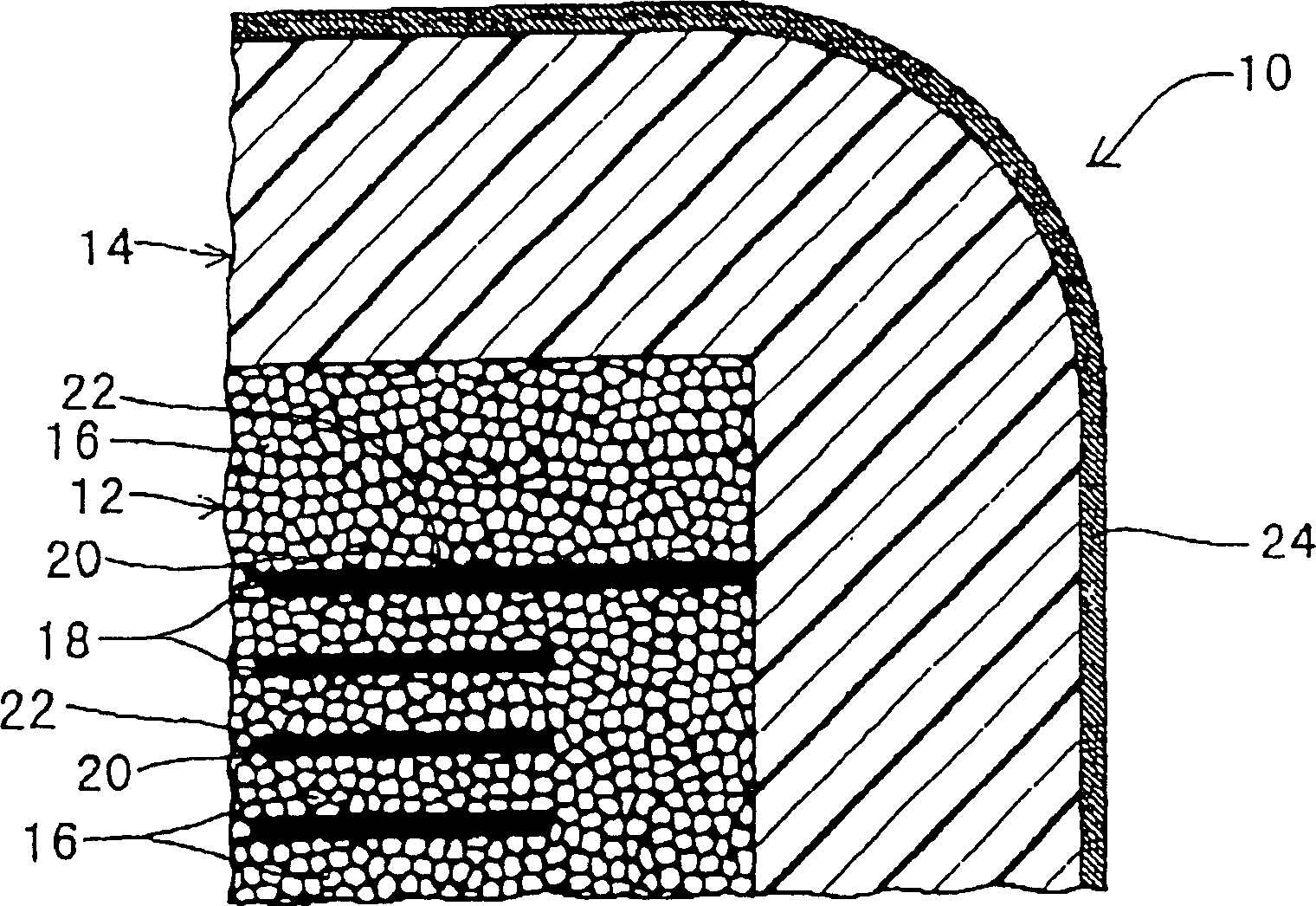

Flat shape electronic component and its mfg. method

InactiveCN1155025CWon't vibrateWill not disconnectFixed capacitor dielectricTransformers/inductances coils/windings/connectionsConductive pasteConductive materials

Delamination in the conventional chip-type electronic part may create voids thereinside, allowing an internal electrode therein to vibrate in presence of external impacts or large electromagnetic forces caused by a high frequency current flowing inside the electrode, in such a way that fatigue may accumulate in the internal electrode, which eventually will results in the internal electrode being electrically disconnected. To solve this problem, a chip-type electronic part of the present invention includes synthetic resins impregnated into the voids to secure the internal electrode, wherein external electrodes of the chip-type electronic part are made of a conductive synthetic resin or a porous conductive material formed by sintering a conductive paste. The former is achieved by impregnating the synthetic resins before the formation of the external electrodes and the later, by extending the pores from surfaces of the external electrodes to surfaces of a main body and then by impregnating the synthetic resins thereinto.

Owner:TAIYO YUDEN KK

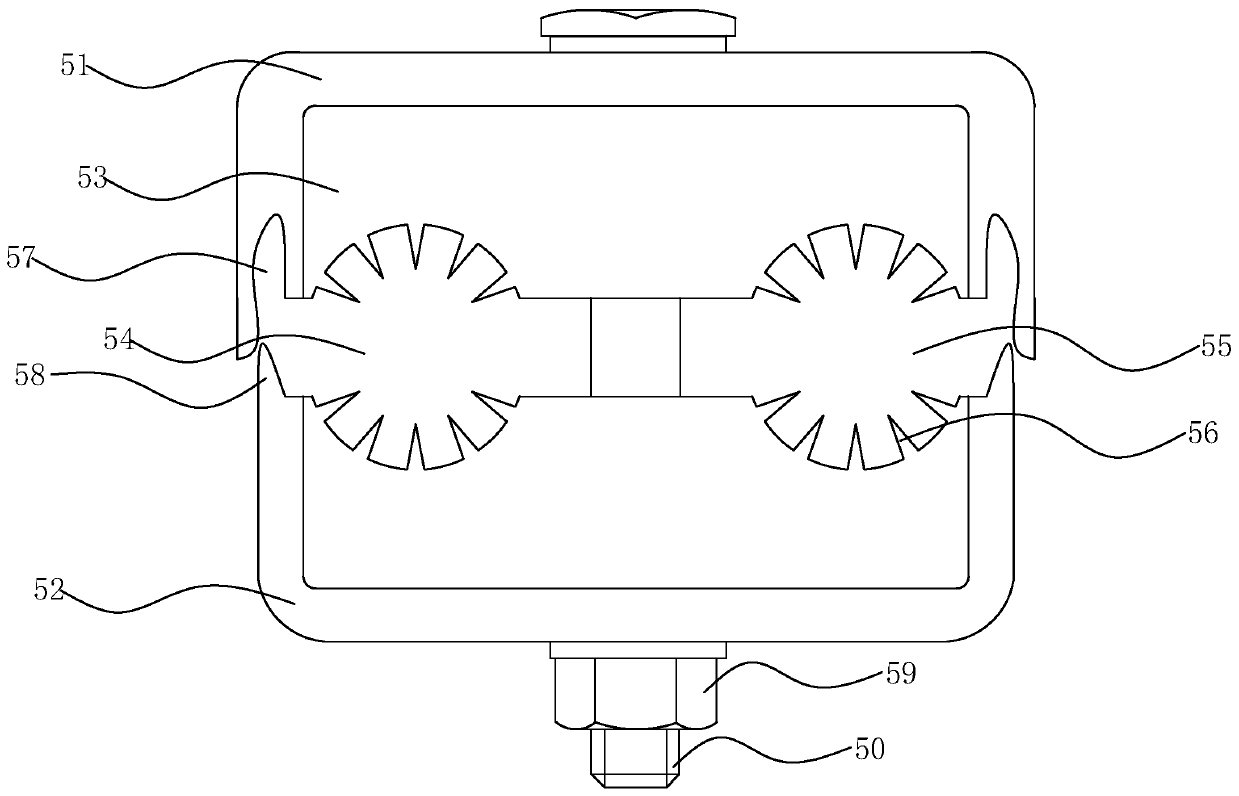

Bidirectional lightning-proof wire breakage protection method and device for insulated wire

ActiveCN111293661AWill not disconnectImprove flow capacityConnection to earthDischarge by conduction/dissipationLightning strokesControl theory

The invention discloses a bidirectional lightning-proof wire breakage protection method and device for an insulated wire. A grounding electrode is arranged at the low-voltage end of an insulator; an insulated wire and a current guide line are arranged at the high-voltage end of the insulator; the current guide line is connected with the insulated wire in parallel through puncture wire clamps; arcstriking electrodes are arranged on the two sides of the current guide line; protection gaps are formed between the arc striking electrodes and the grounding electrode. According to the bidirectionallightning-proof wire breakage protection method and device for the insulated wire of the invention, two sides of the insulator are each provided with one discharge protection gap; when any side is subjected to lightning overvoltage, both of the discharge protection gaps act and discharge; during discharging, the two wire clamps jointly provide fault current; the insulated wire, the current guide line and the arc striking electrodes are integrated; the structures of the protection gaps are stable; and therefore, the device of the invention has the advantages of stable performance, reliable action, strong through-current capability and the like, can effectively prevent the occurrence of lightning stroke disconnection faults of the insulated wire, ensures the safety of the insulated wire, andsolves the technical problems of poor power frequency follow current capability, unstable gap distances and low reliability of a single discharge protection gap.

Owner:国网浙江武义县供电有限公司 +4

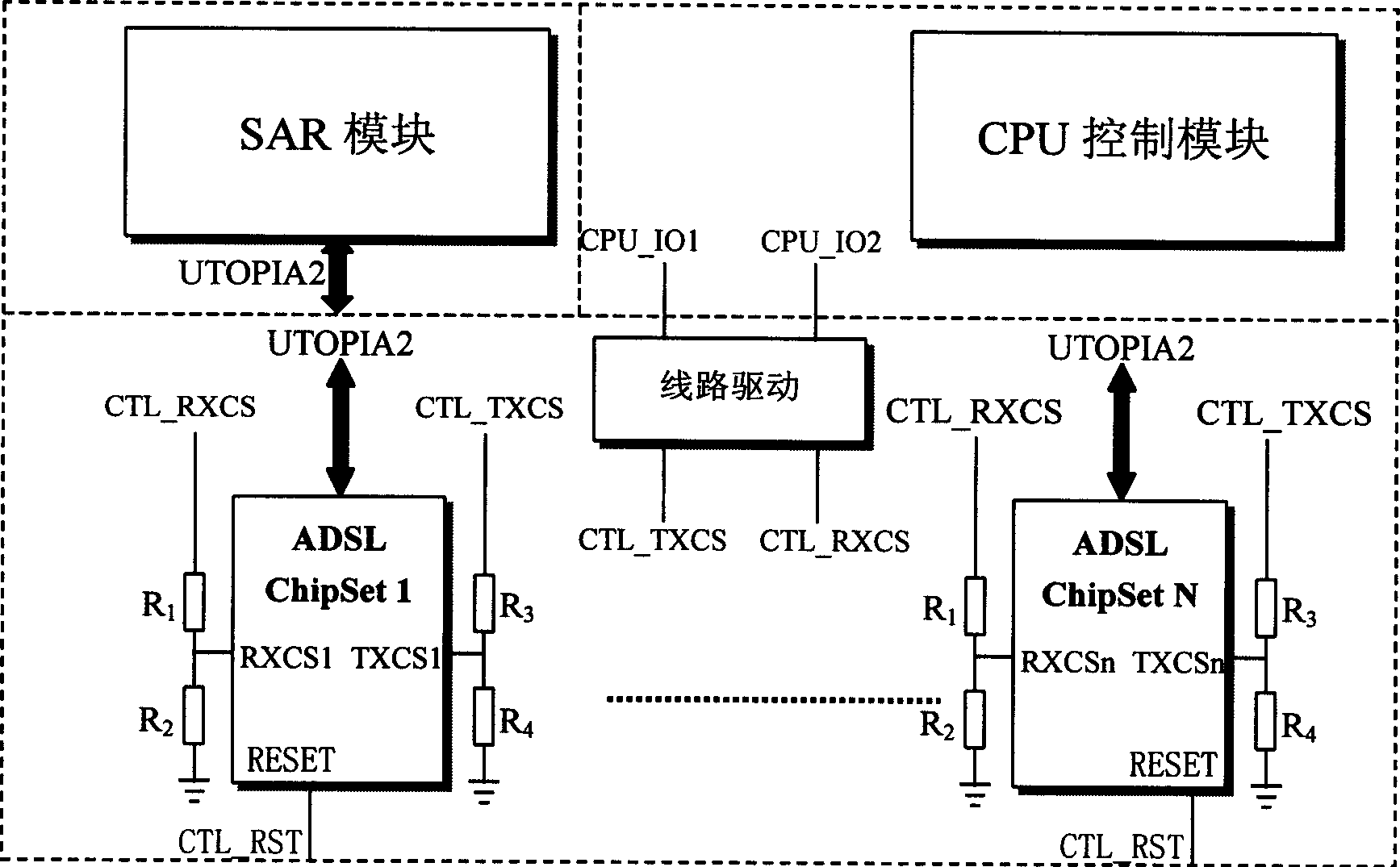

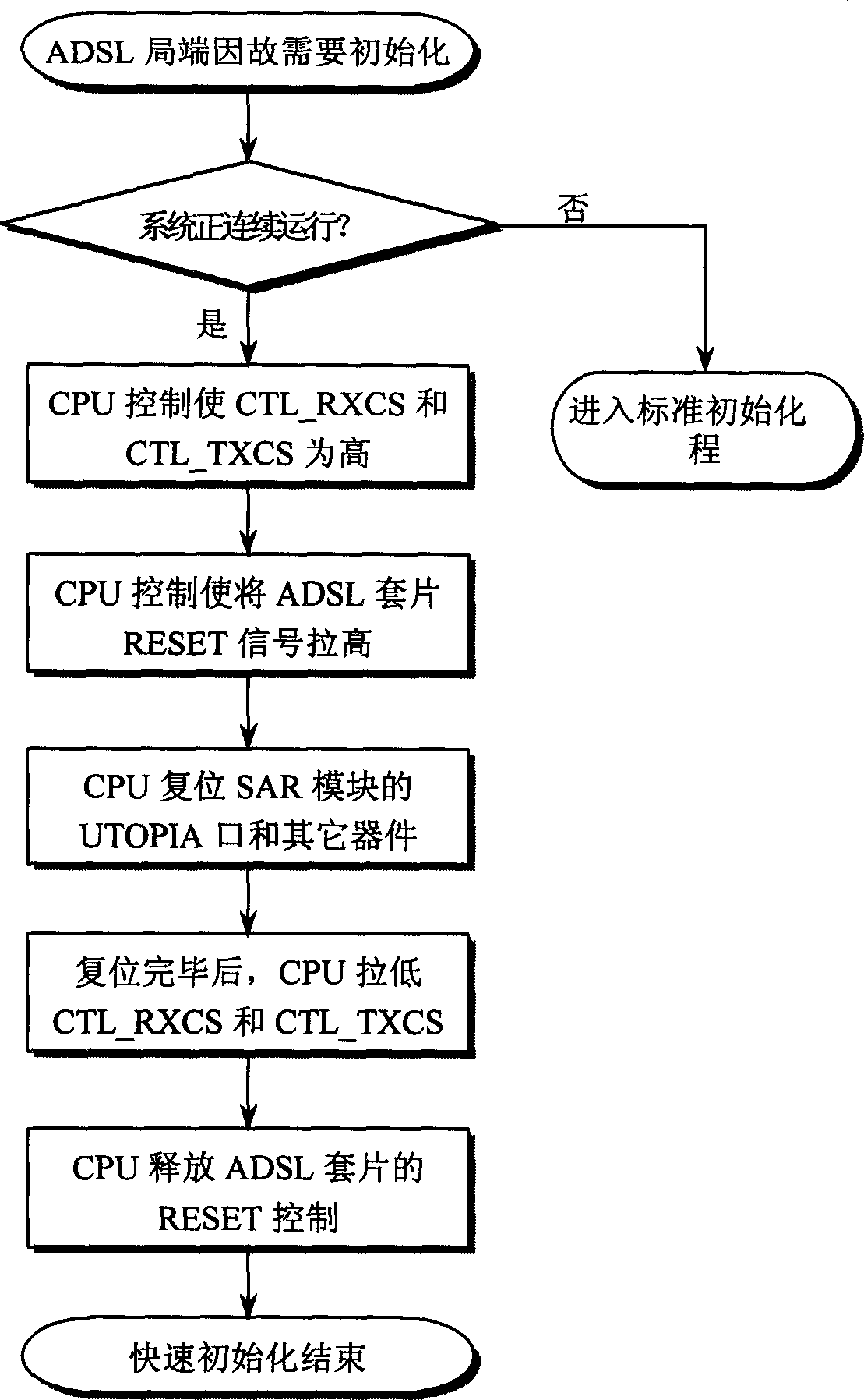

Fast initializing method for asymmetric digital user loop local side apparatus

InactiveCN1449179AShorten initialization timeWill not disconnectSpecial service provision for substationTelephonic communicationComputer hardwareQuality of service

The invention provides a method of initializing quickly an asymmetrical Digital Subscriber Loop device. The method includes, when initializing ADSL circuit, the system determines whether the device is operating continuously, if yes, enters the initialization flow; the ADSL control sends out CTL_RXCS and CTL_TXCS signals with high levels, and the data receiving / sending chip select of the UTOPIA port in the slave mode is in the prohibition state; CPU increases the RESET signal of ADSL; CPU resets the UTOPIA port and other members or ports of the SAR module in the master mode which are required to be reset; after resetting, CPU decreases CTL_RXCS and CTL_TXCS. By the invention, initialization will be very fast. The use end of ADSL can't detect initialization of the area end. Data access won't disconnect, which improves greatly the service quality of ADSL devices.

Owner:ZTE CORP

A water-soluble reflective thread and its production process

The invention discloses water-soluble reflective thread. The water-soluble reflective thread is formed by compositing a yarn core and at least one wrapped yarn. The wrapped yarn is wound on the outer surface of the yarn core in a spiral mode. The yarn core is a reflective silk, and the wrapped yarn is water-soluble yarn. A water-soluble reflective thread production process includes the following steps that (1) the water-soluble yarn is twisted; (2) the reflective silk is selected, wherein the surface of a PET film is coated with glass beads and are cut into different specifications, and reflective silks are obtained; (3) at least one water-solute yarn treated through the step 1 is wound on the reflective silk obtained through the step 2 in a spiral mode, and reflective yarn is obtained; (4) the reflective yarn is branched and coiled to be of the fixed length, and the water-soluble reflective thread is obtained. According to the water-soluble reflective thread and the production process, the water-soluble yarn is matched with the reflective silk, the sewability of the water-soluble reflective thread is enhanced, no twisting happens, no thread breakage occurs in the using process, and sewing is facilitated; meanwhile, after the thread is used, textile is washed, the water-soluble yarn part can dissolve and disappear, and the reflective effect is improved.

Owner:DONGGUAN COCOU TEXTILE MATERIALS

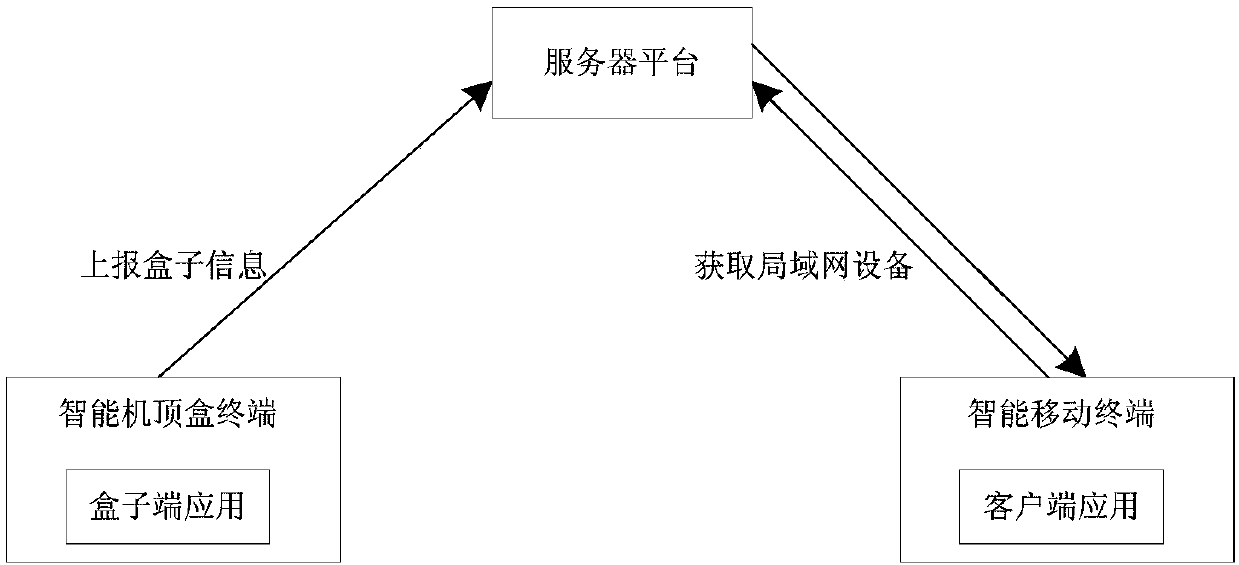

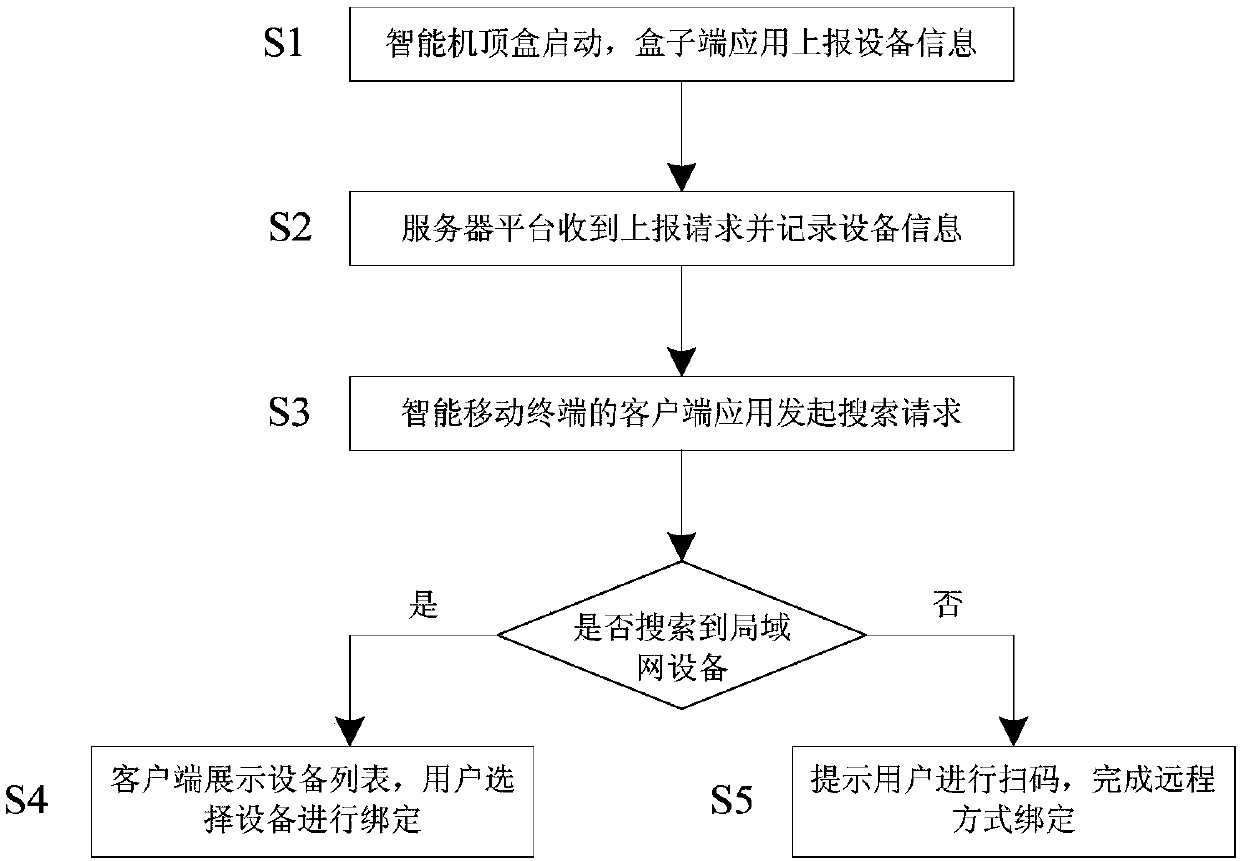

Intelligent binding method of intelligent mobile terminal and intelligent set top box terminal

InactiveCN107613343ANot easy to searchEasy to disconnectSelective content distributionService developmentArea network

The invention provides an intelligent binding method for an intelligent mobile terminal and an intelligent set top box terminal. An intelligent set top box terminal in a local area network is searchedpreferentially by matching an external network export IP of the intelligent set top box terminal and the intelligent mobile terminal, if the local area network has the intelligent set top box terminal, a terminal list is displayed on the intelligent mobile terminal, the user can select the demanded intelligent set top box terminal, if the local area network does not have the intelligent set top box terminal, the user can bind the intelligent set top box terminal in a long distance. Through adoption of the method, devices of the local area network and devices of non-local area network can be searched and bound intelligently, the multi-screen interaction experience of the user is improved, and the service development demand is met.

Owner:天翼智慧家庭科技有限公司

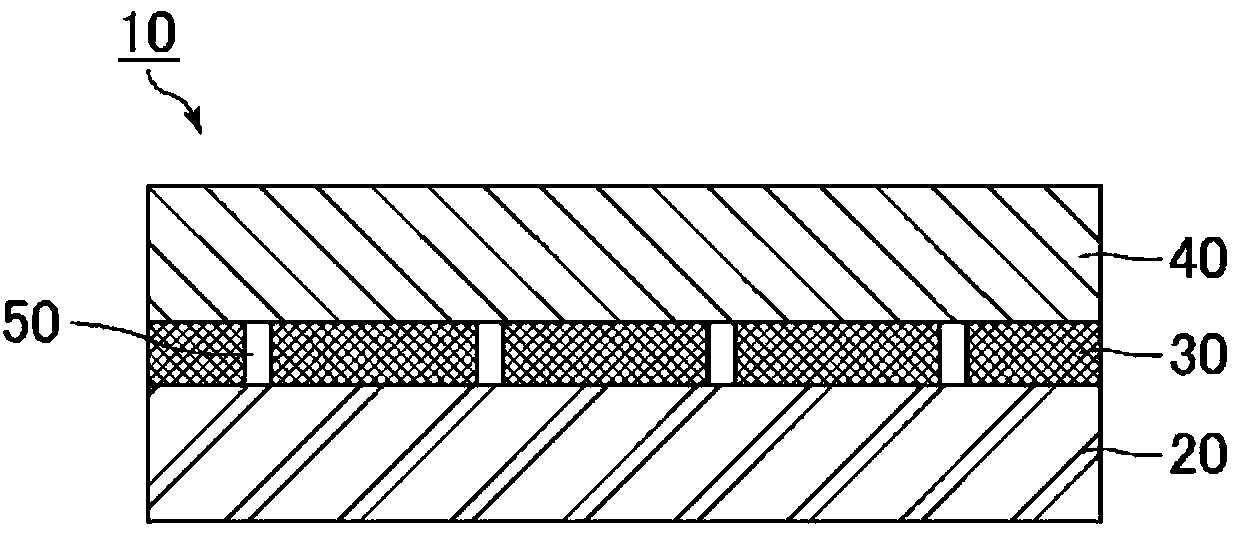

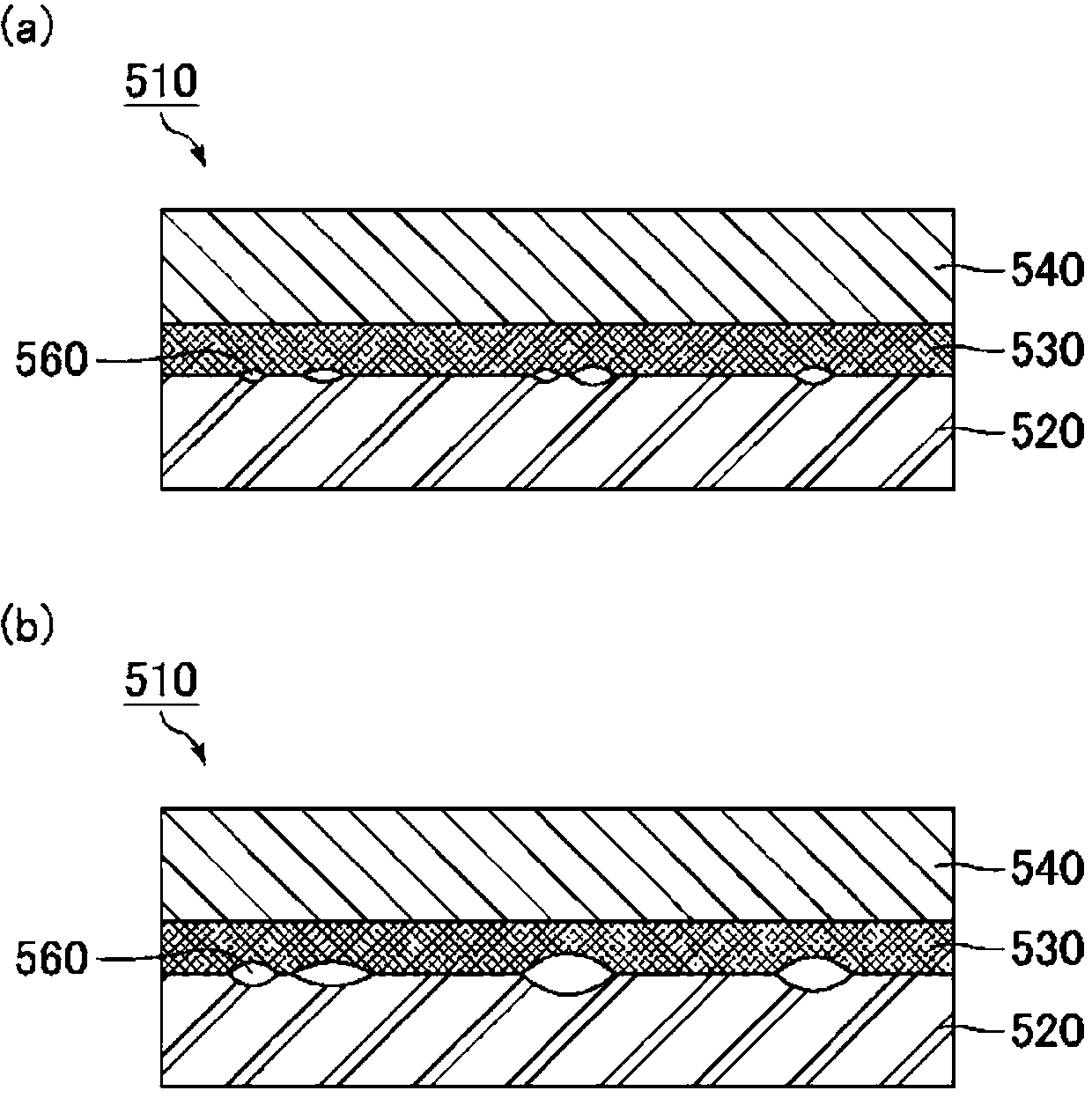

Electromagnetic wave shielding film, shielded printed wiring board, and electronic device

ActiveCN110199583ALess prone to disconnectionImprove shielding propertiesMagnetic/electric field screeningCross-talk/noise/interference reductionFolding enduranceAdhesive

The purpose of the present invention is to provide an electromagnetic wave shielding film that has sufficient folding endurance and a sufficiently high electromagnetic wave shielding property. An electromagnetic wave shielding film according to the present invention comprises a conductive adhesive layer, a shielding layer that is laminated upon the conductive adhesive layer, and an insulating layer that is laminated upon the shielding layer. The electromagnetic wave shielding film is characterized in that a plurality of openings are formed in the shielding layer, no breaks occur when folded 600 times according to the MIT folding endurance test delimited in JIS P8115:2001, and the electromagnetic wave shielding property of the electromagnetic wave shielding film at 200 MHz as measured usingthe KEC technique is 85 dB or greater.

Owner:TATSUTA ELECTRICWIRE & CABLE +1

Wiring structure and manufacturing method of capacitive touch screen

ActiveCN101634922BImprove product qualityAvoid chromatic aberrationInput/output processes for data processingElectrical resistance and conductanceEngineering

The invention relates to a wiring structure of a capacitive touch screen and a manufacturing method thereof, wherein the wiring structure comprises the step of arranging two groups of wire transparent conducting films in X and Y directions, an insulating film and a bridging film on a basal plate, wherein the surface resistance of the bridging film is lower than the surface resistance of the transparent conducting films, an intersection structure of the transparent conducting films in the two directions comprises continuous connection or bridging connection, wherein the continuous connection structure is a continuation of transparent conducting film material at two sides of the intersection point, and the bridging connection structure has the structures that the transparent conducting film in X or Y direction is continuously connected and positioned on the basal plate at the intersection point, the transparent conducting film in the other direction is disconnected at the intersection point, the insulating film is covered on the transparent conducting films that are continuously connected at the intersection part, and the bridging film stretches over the transparent conducting films that are continuously connected at the intersection point and is covered on the insulating film and connected with the transparent conducting film disconnected at the intersection point; and the method comprises the step of manufacturing two groups of wire conducing film, the insulating film and the bridging film. The invention can avoid color difference and improve the sensitivity, the standard ratio and the quality of the touch screen.

Owner:SHENZHEN LAIBAO HI TECH

Cable modem termination system and method

InactiveCN102025574BWill not disconnectError prevention/detection by using return channelBroadband local area networksModem deviceIp address

Owner:AMBIT MICROSYSTEMS (SHANGHAI) LTD +1

A production method for stabilizing prestressed galvanized steel wire joints

The invention discloses a stabilizing treatment production method for a zinc-coated steel wire connector. The stabilizing treatment production method comprises the steps of connector welding, steel tube flattening, paying-off, first tensioning, straightening, intermediate frequency heating, water cooling, second tensioning, hauling, winding-up. The stabilizing treatment production method has the characteristics that waste wire in the production process is largely reduced, the percent of pass is increased by 2-4%, and production and operation efficiency is improved.

Owner:奥盛(九江)新材料有限公司 +1

Preparation method of copper covered steel woven wire special for communication cable shielding layer

InactiveCN100411064CWill not disconnectGood flexibilitySingle bars/rods/wires/strips conductorsExtrusion cleaning devicesCopper wireThin wire

This invention relates to a preparation method for special steel woven filaments for communication cable shield layers including rough drawing, plating, mid-drawing, fine-drawing and annealing of copper-wrapped steel filaments with the mechanical performance approaching to copper wires, the extension rate of which reaches to 20% and the tensile strength reaches to that of copper wires, so it will not be broken when used in weaving cable shield layers and the product will not be hard and keep fine flexibility.

Owner:仲庆

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com