Flat shape electronic component and its mfg. method

An electronic component and sheet-like technology, applied in electrical components, inductance/transformer/magnet manufacturing, coil manufacturing, etc., can solve problems such as broken wires, internal conductor vibration, metal fatigue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

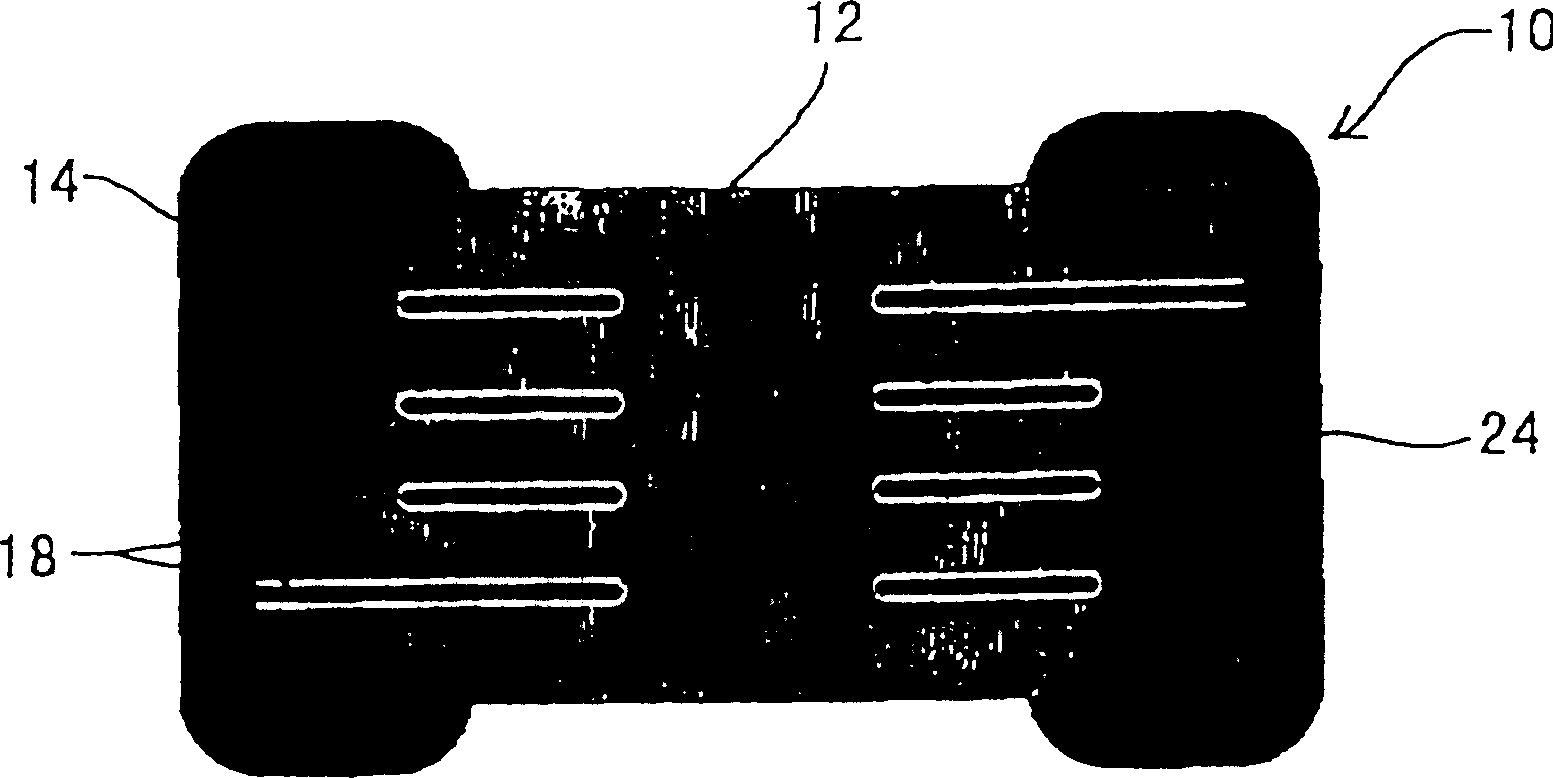

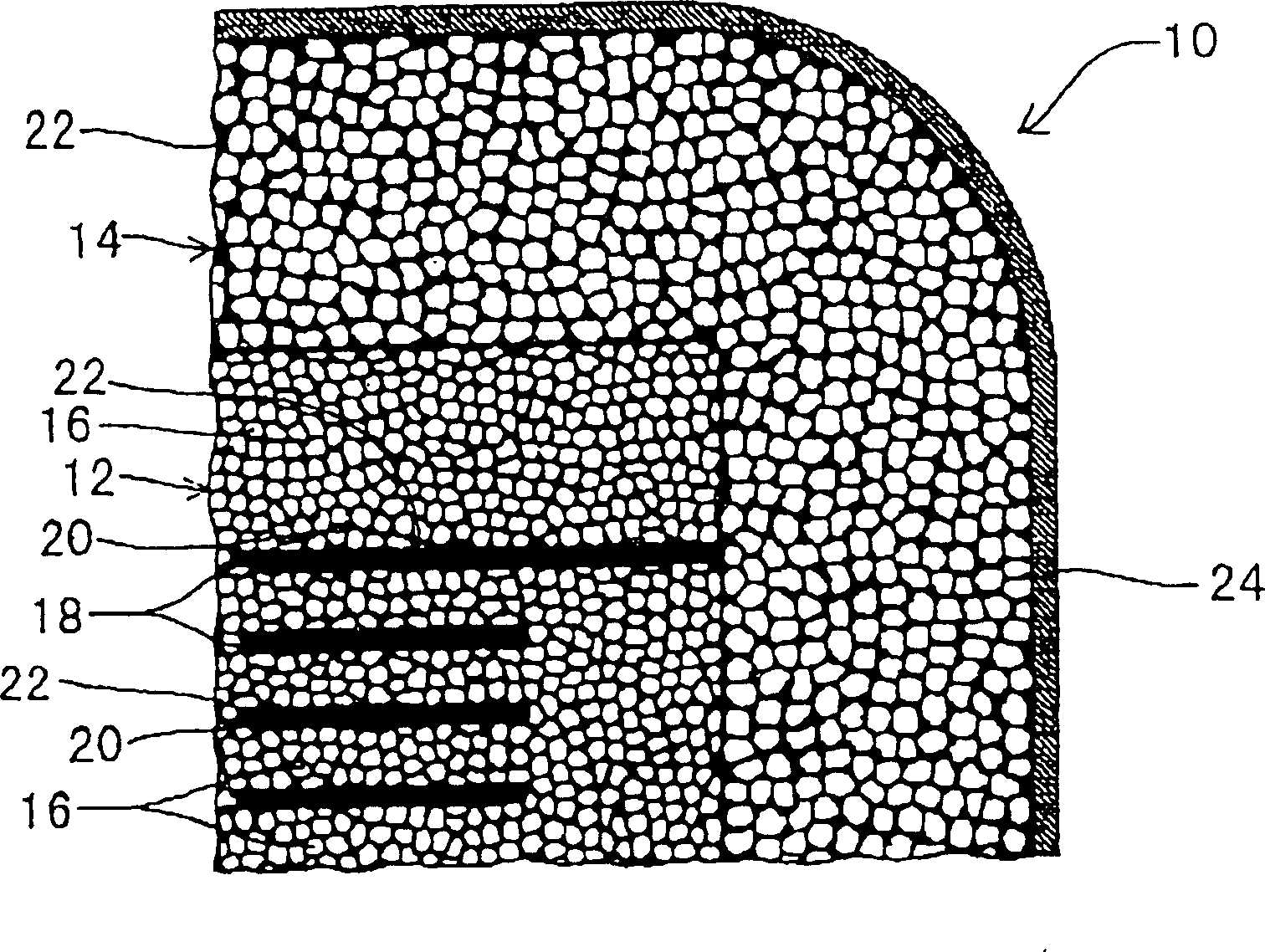

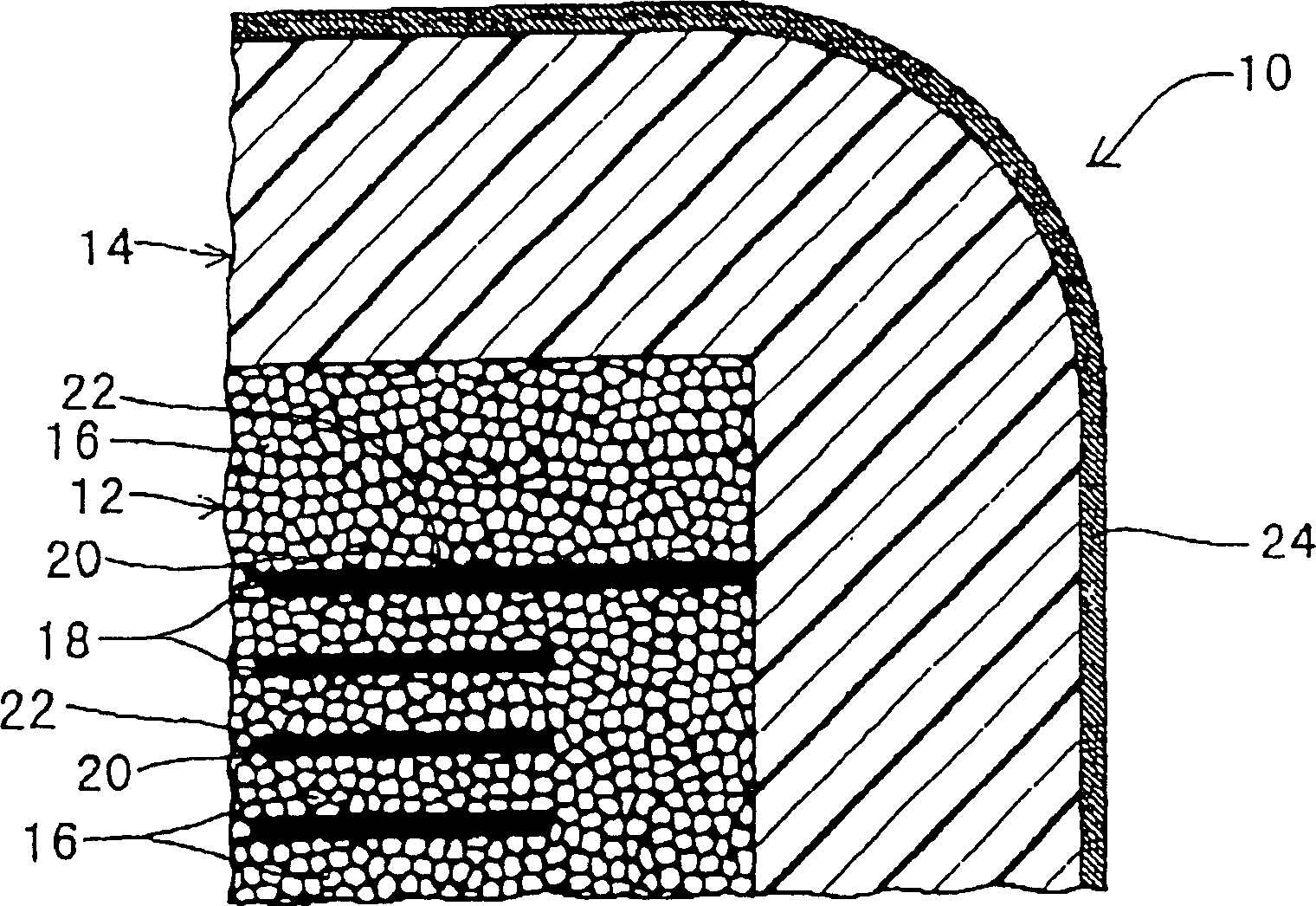

Embodiment 1

[0027] First, Fe was weighed at the following compounding ratio (mole %) (mol%) 2 o 3 , NiO, ZnO and CuO powders, adding water and stirring them with a ball mill for 15 hours, spraying and drying them with a spray dryer to obtain mixed powders.

[0028] Oxide type Mixing ratio

[0029] Fe 2 o 3 49mol%

[0030] NiO 35mol%

[0031] ZnO 10mol%

[0032] CuO 6mol%

[0033] Next, the mixed powder was calcined at 800° C. for 1 hour, and the obtained calcined product was put into a ball mill, and water was added to pulverize it for 15 hours. Then, the obtained slurry was spray-dried with a spray dryer to obtain a calcined product powder.

[0034] Next, the powder was stirred with an organic binder and an organic solvent, and a ferrite printed circuit board with a thickness of 50 μm was produced by using the obtained slurry by a doctor blade method.

[0035] Next, a plurality of through holes are formed at predetermined positions on the ferrite printed cir...

Embodiment 2

[0053] A unit body was formed in the same manner as in Example 1.

[0054] Next, put silicone resin diluted with toluene into the container, put the above-mentioned unit body in the silicone resin liquid, put the container into a decompression container, and depressurize it to 3.99966×10 with a vacuum pump. 3 Pa, keep in this state for about 10 minutes. Through this process, the gap between the magnetic body and the internal conductor is impregnated with the resin solution.

[0055] Next, this unit body was taken out of the container, and heated at 200° C. for 1 hour to harden the silicone resin impregnated in the cavity.

[0056] Next, put it in the rotating cylinder, and remove the synthetic resin adhering to the lead-out part of the inner conductor.

[0057] Next, a thermosetting epoxy resin-based conductive paste was applied to both ends of the unit body, and heated at 150°C for 60 minutes and 200°C for 30 minutes to harden. Furthermore, electroplating is applied to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com