Door for a thrust reverser with doors

A thrust reverser and door-type technology, applied in high-efficiency propulsion technology, jet propulsion devices, machines/engines, etc., can solve the problems of thrust reverser performance degradation, spoiler geometric structure, vibration, etc., to achieve Effects of weight reduction and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

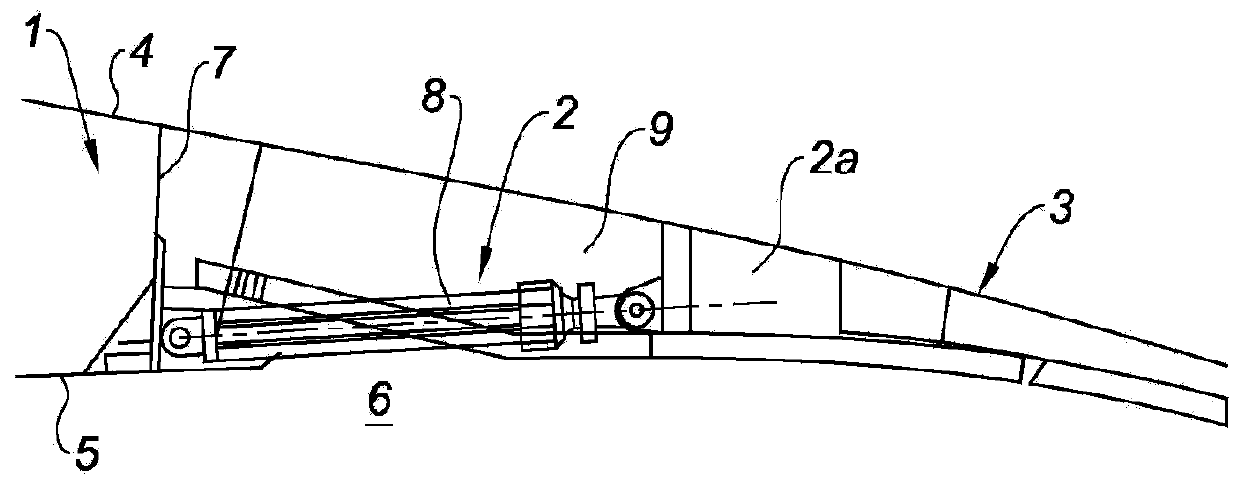

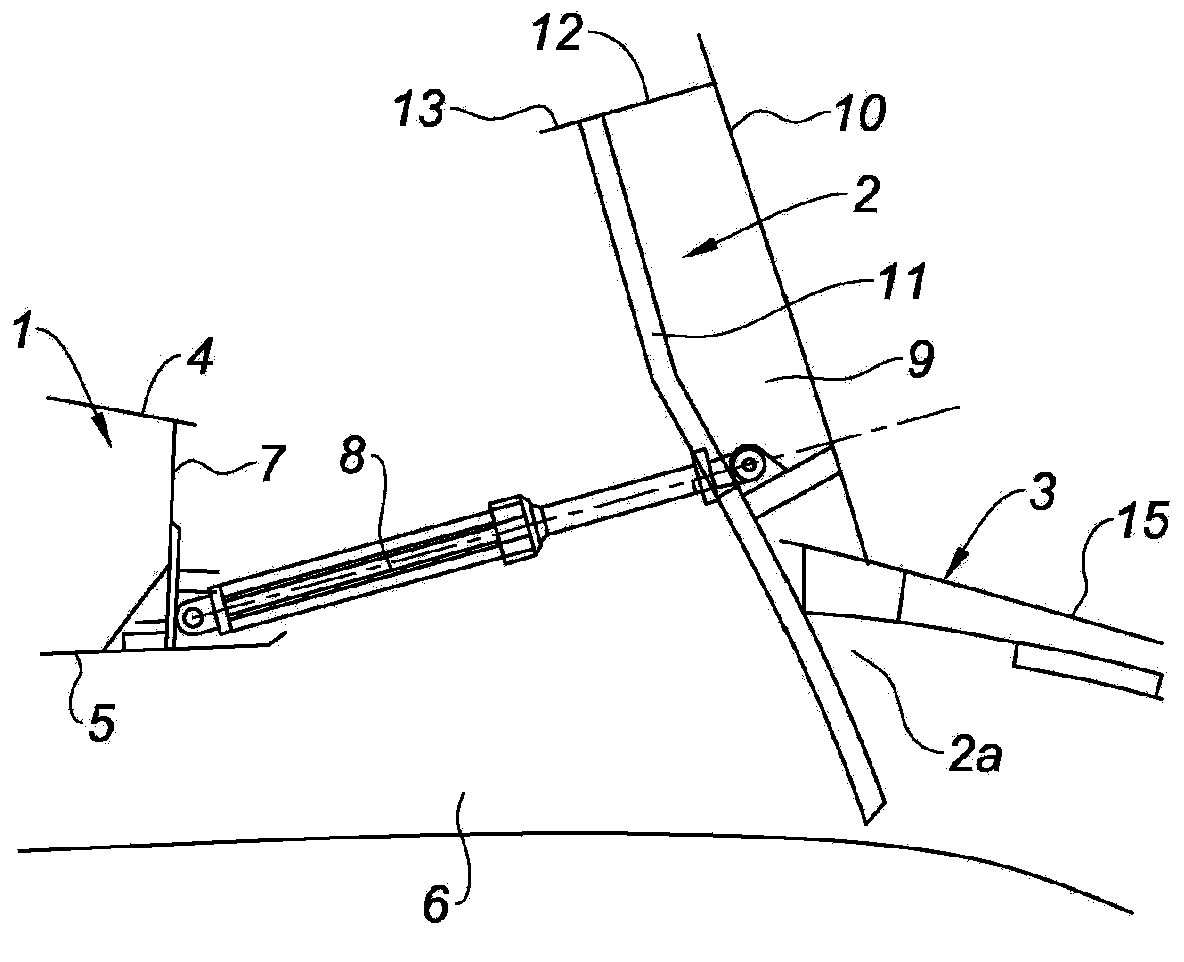

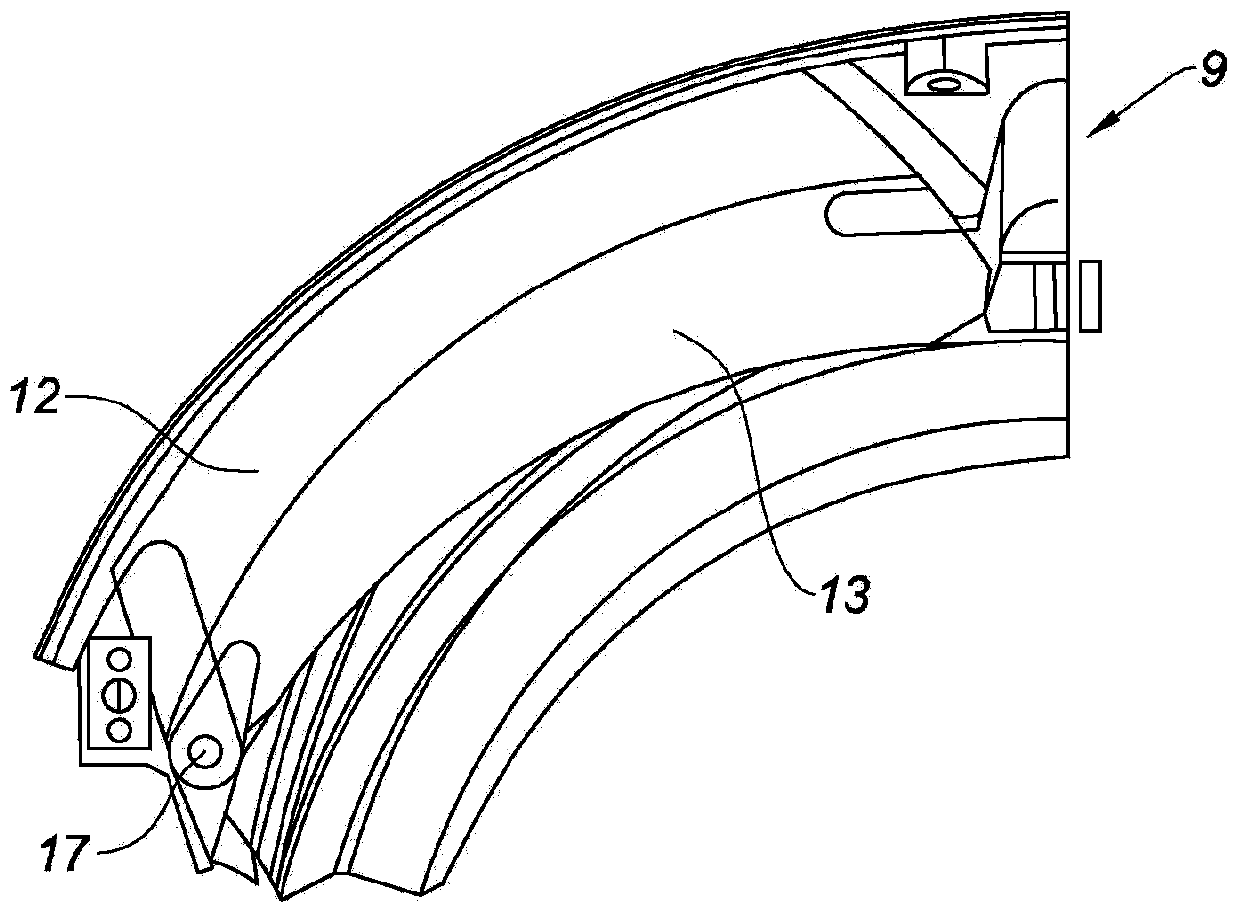

[0052] figure 1 A known example of a portal thrust reverser equipped with a deflecting spoiler is shown.

[0053] This type of thrust reverser comprises three main parts, namely a fixed part 1 upstream of the extension of the outer wall of the turbojet air flow passage, a movable part 2 and a rear fixed collar 3 .

[0054] The fixed part 1 comprises an outer panel 4 and an inner panel 5 of the nacelle, the inner panel 5 constituting the outer panel of an airflow flow path 6 .

[0055] The outer 4 and inner 5 panels of the fixed part 1 are connected by a front frame 7 which also ensures the support of the means for controlling the movable part 2 , constituted in this example by jacks 8 . The movable part 2 is broken down into one or several generally movable members called doors 9 .

[0056] Each door 9 is pivotally mounted in such a way as to be able to move under the action of the control device 8 between the open position and the position ensuring structural continuity bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com