Patents

Literature

165results about How to "Won't vibrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

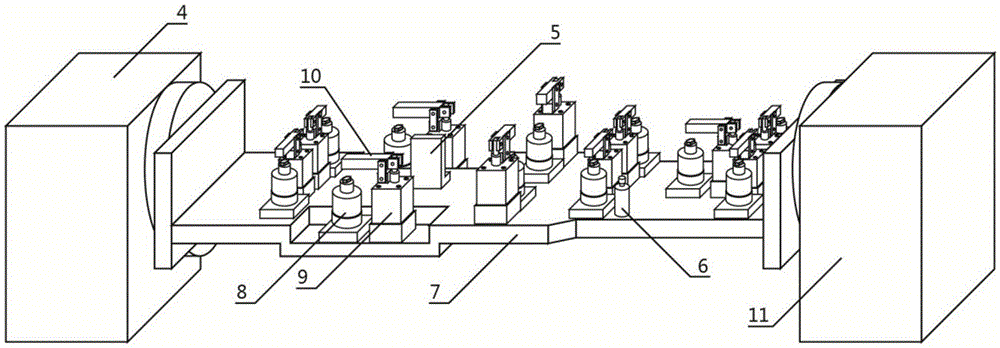

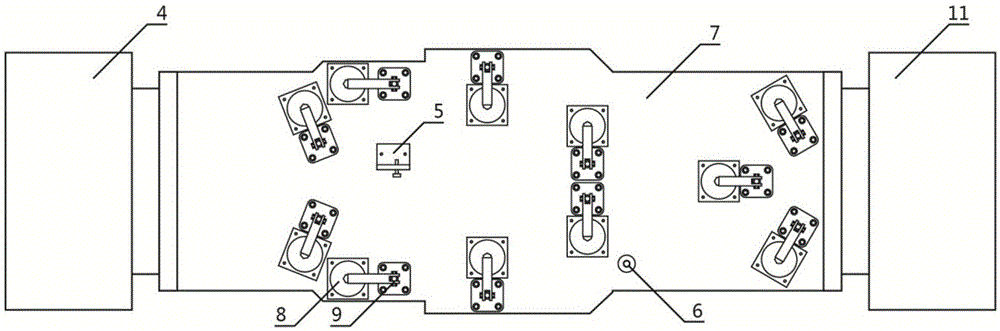

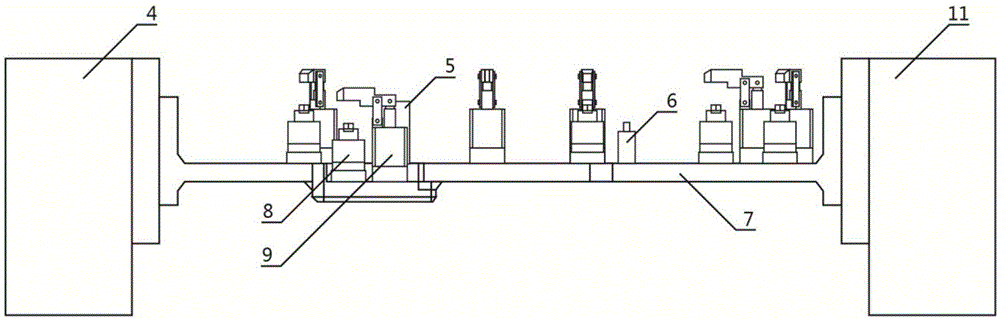

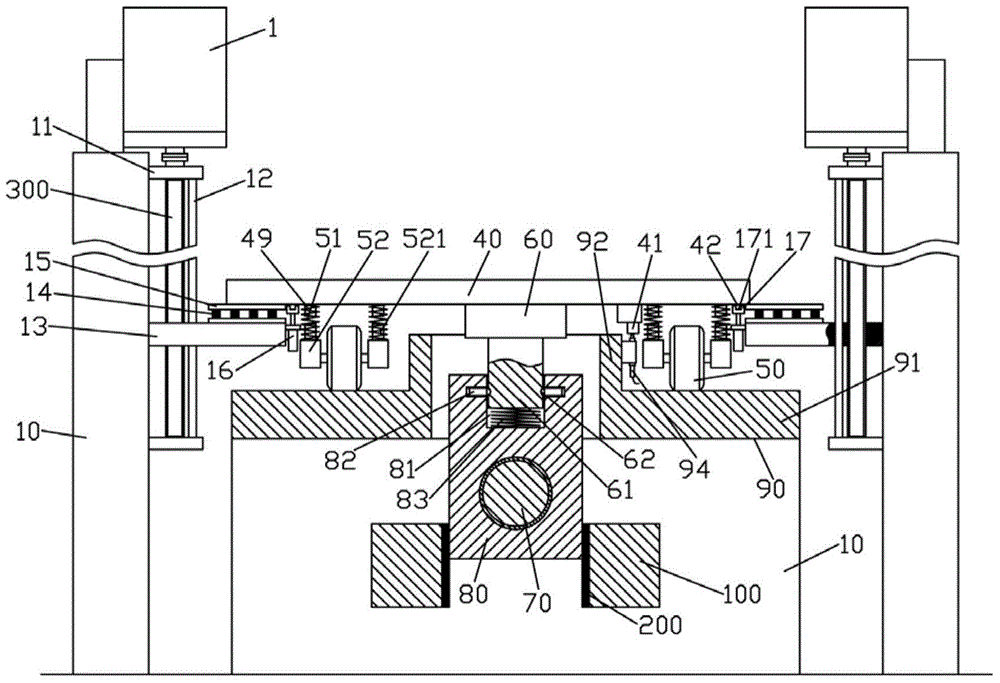

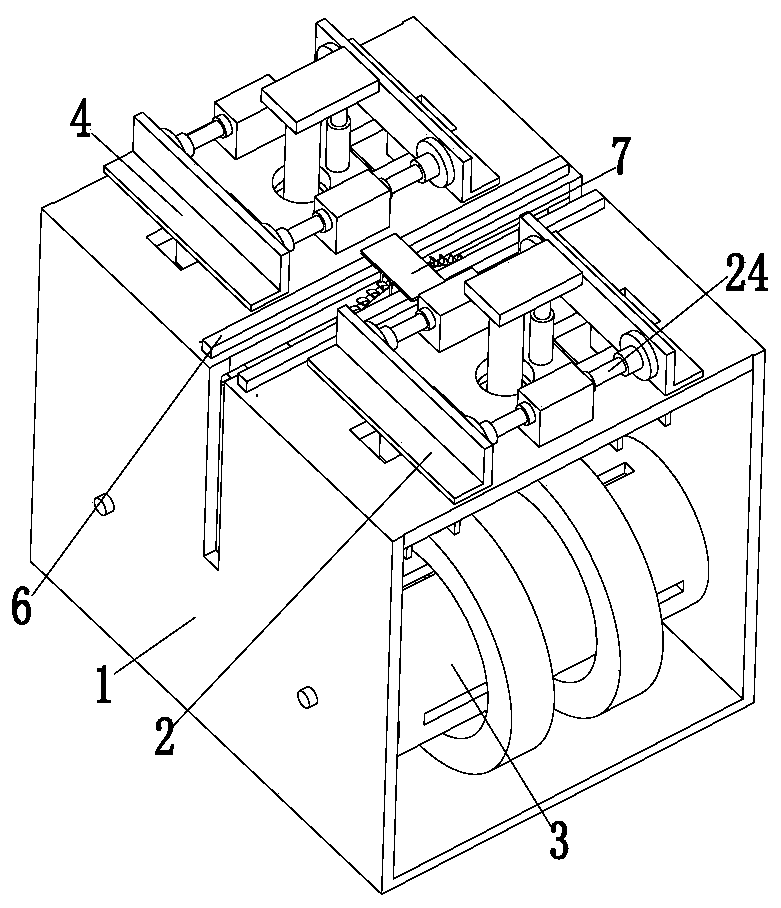

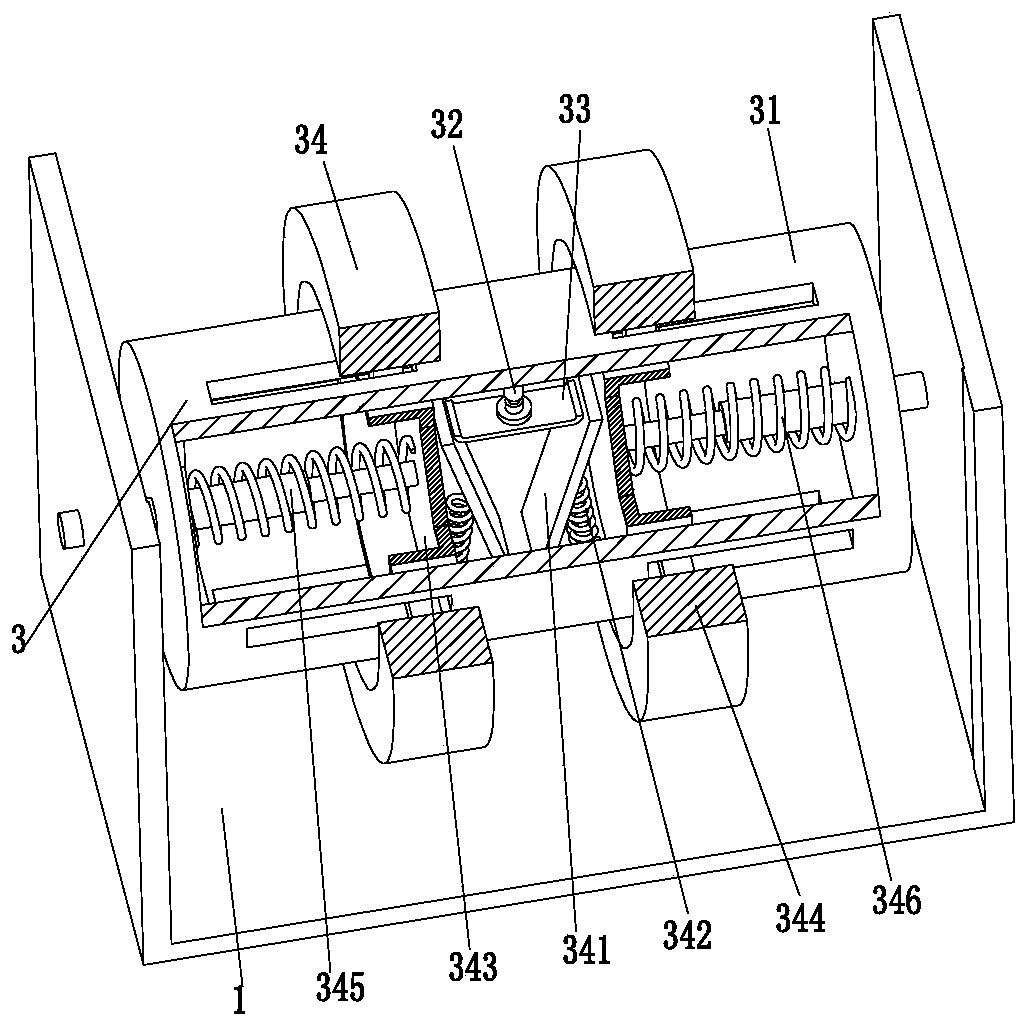

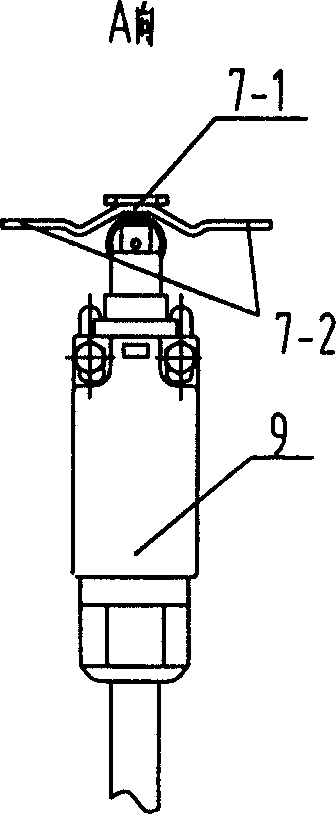

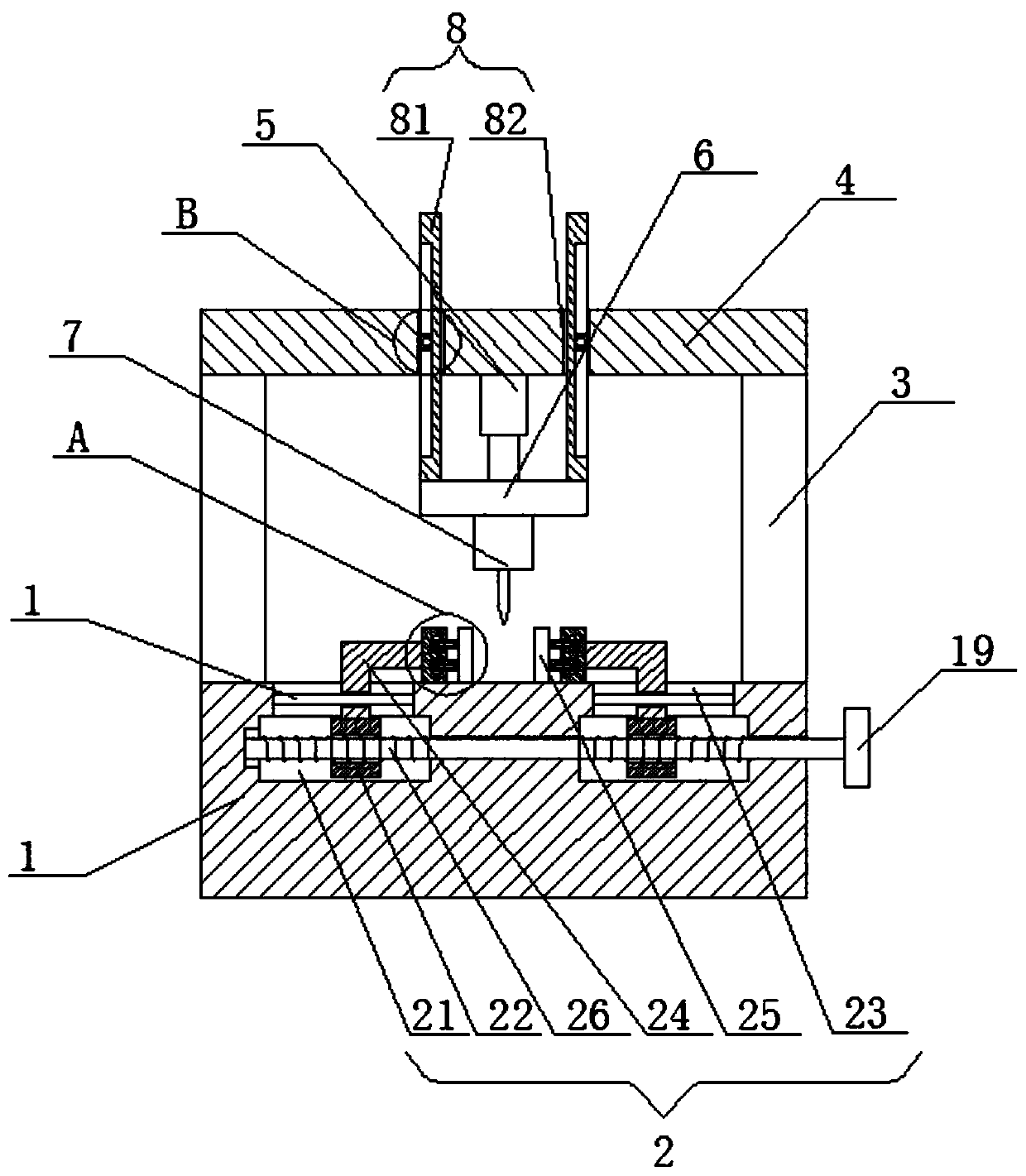

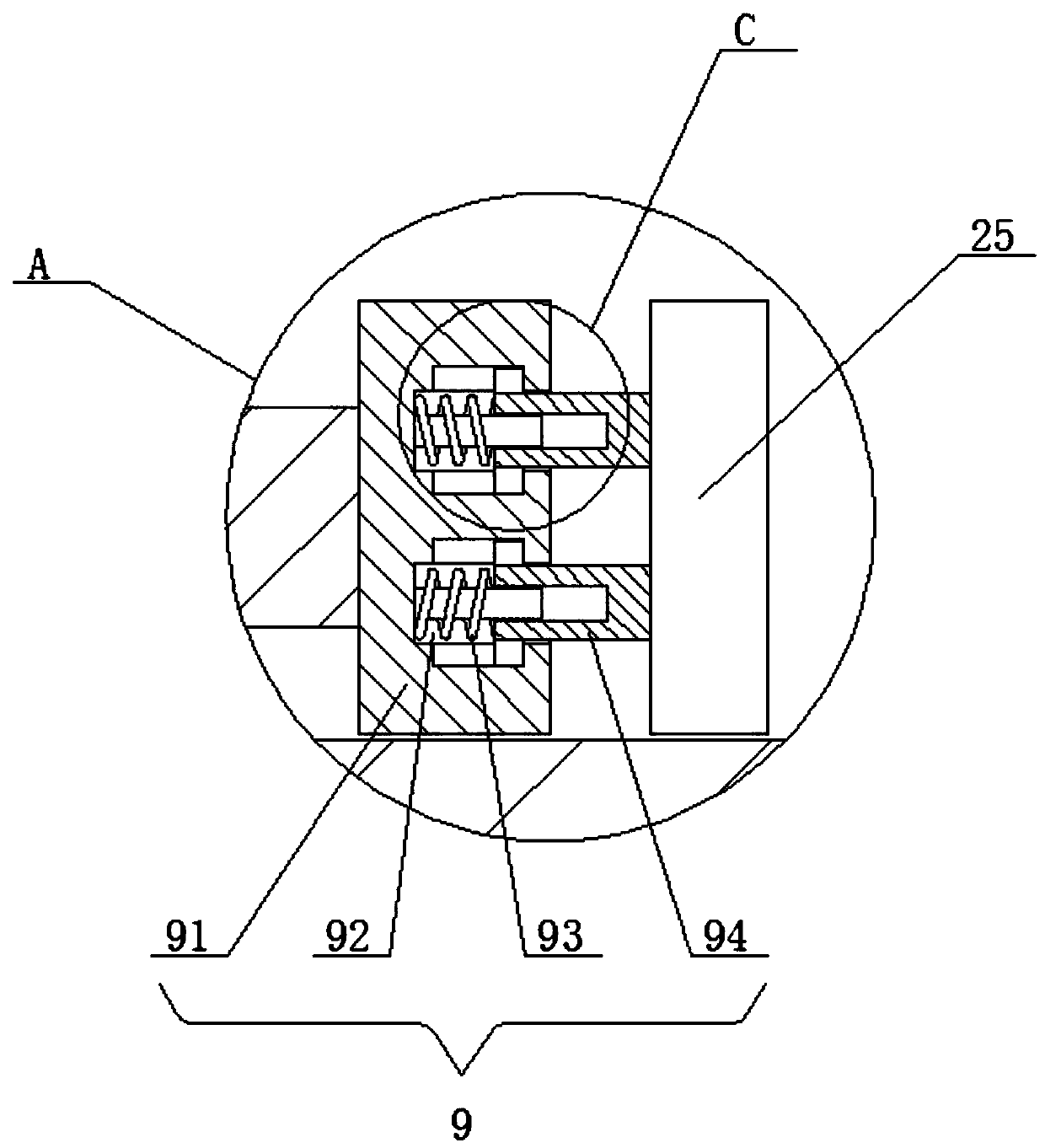

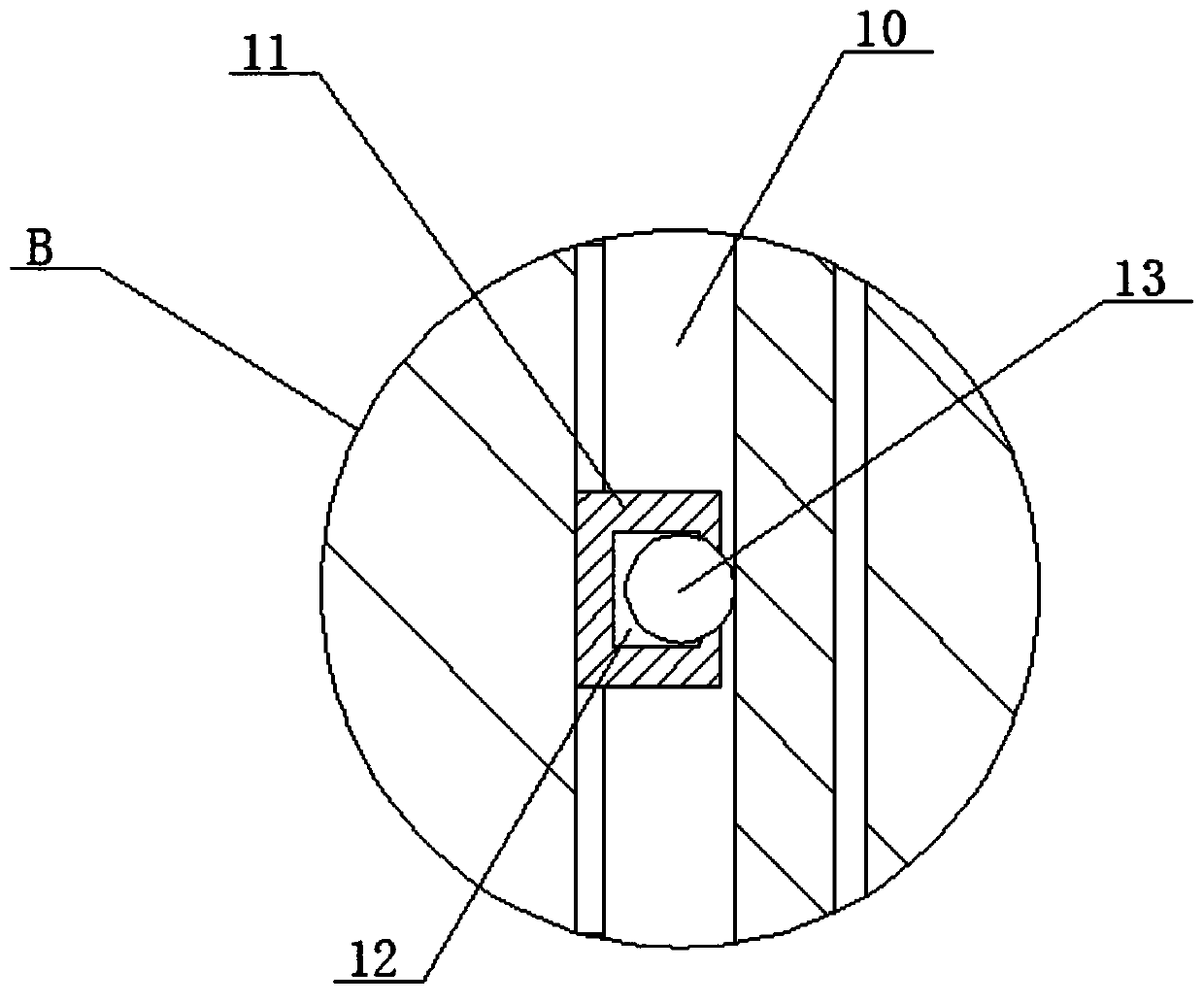

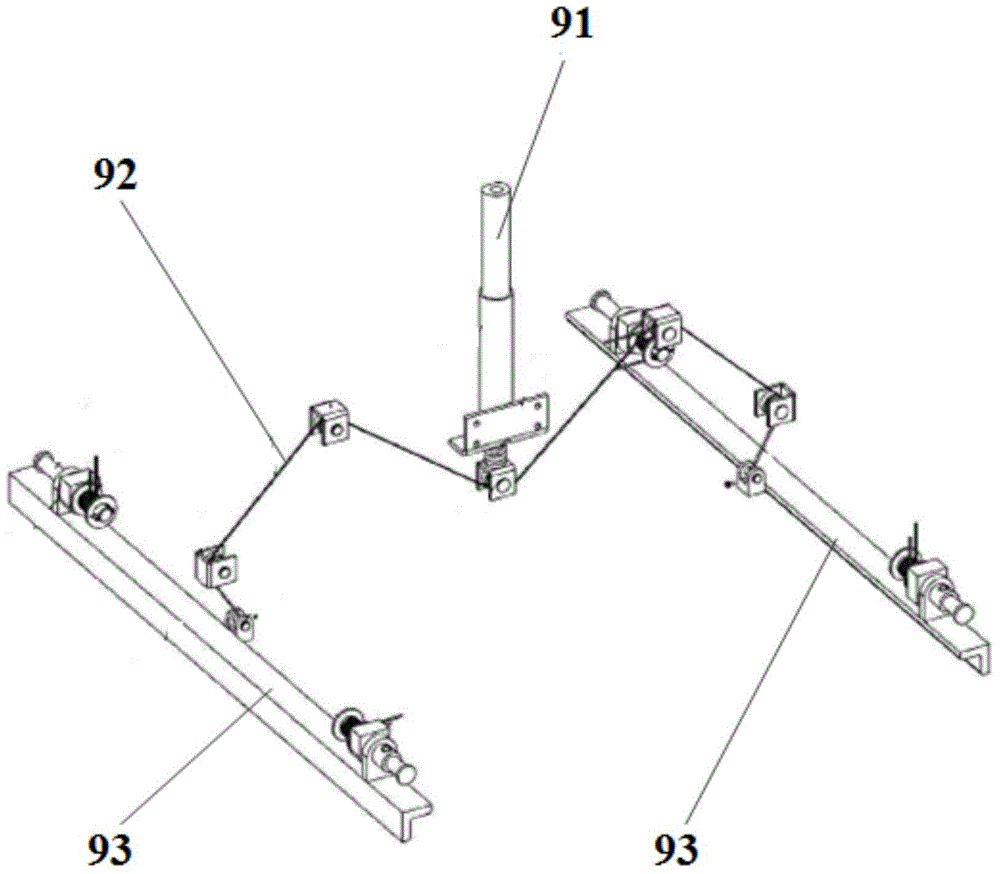

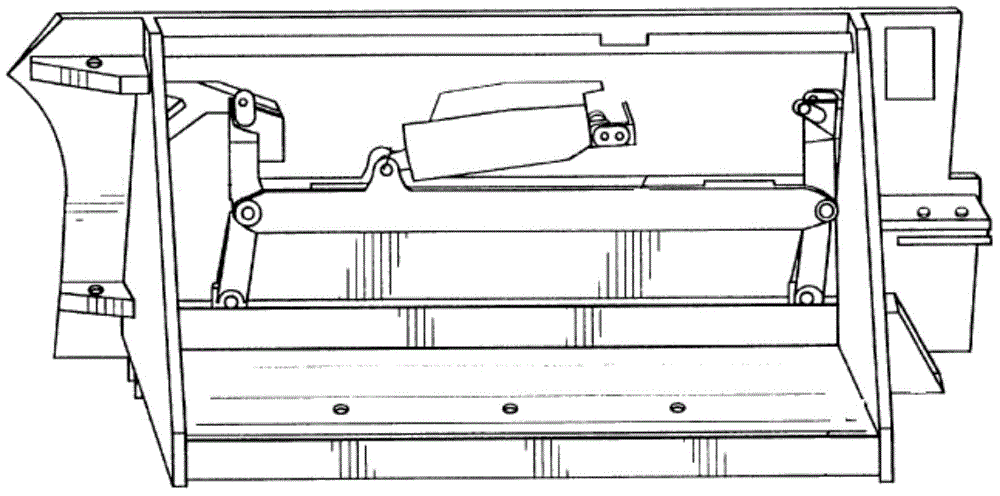

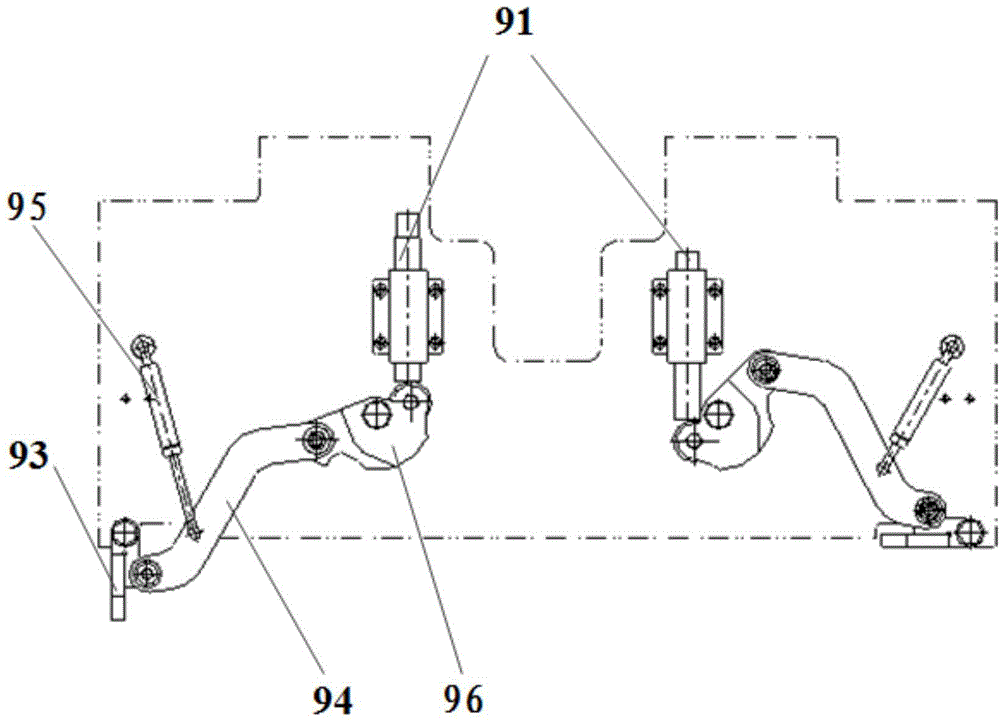

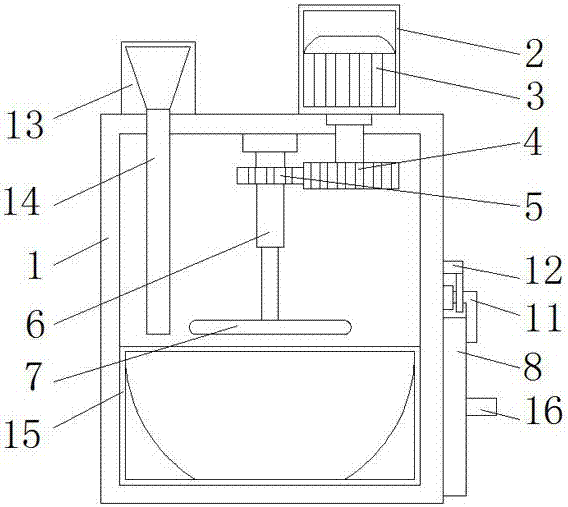

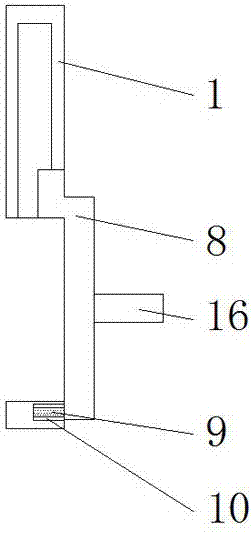

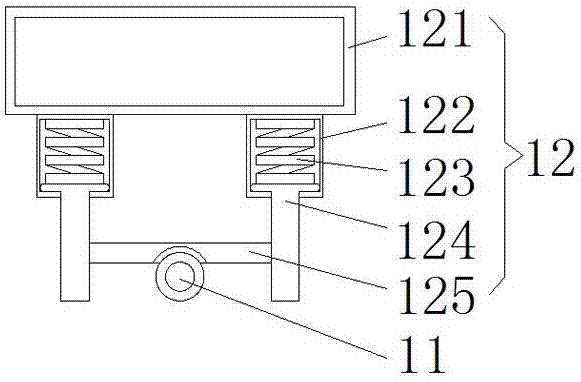

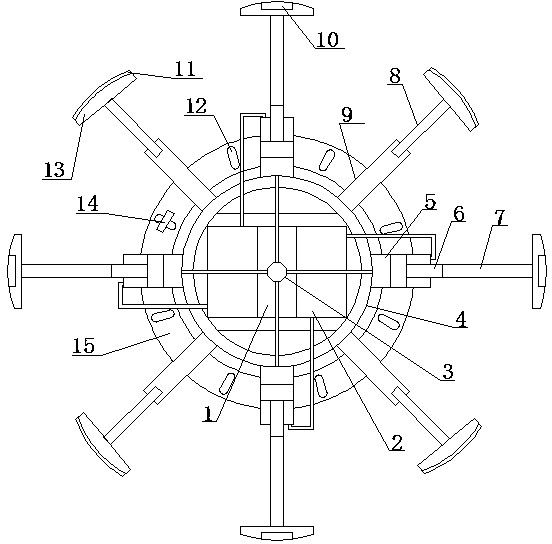

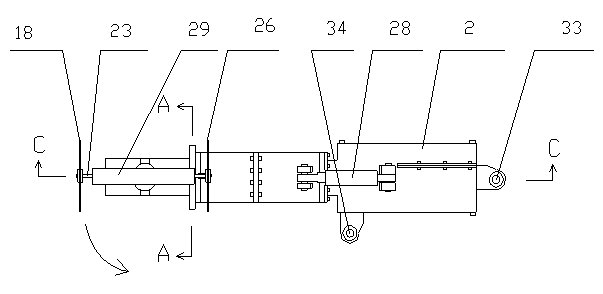

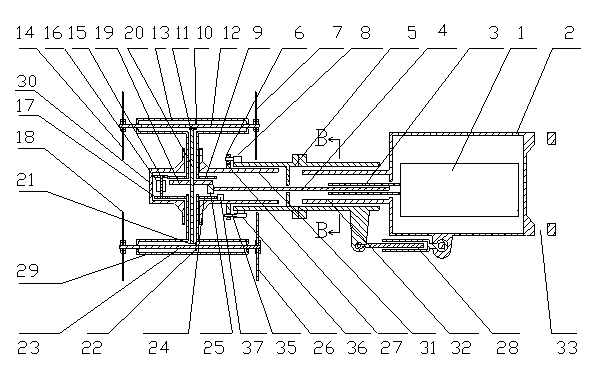

Four-axis linkage machining mechanism of numerical-control machining center and operating method of four-axis linkage machining mechanism

InactiveCN105643294ASolve the problem of difficult clampingEasy to processLarge fixed membersPositioning apparatusNumerical controlMachine parts

The invention provides a four-axis linkage machining mechanism of a numerical-control machining center and an operating method of the four-axis linkage machining mechanism. According to the technical scheme, the four-axis linkage machining mechanism of the numerical-control machining center comprises an operation chamber, a machining spindle and a machining table; the machining table is composed of a rotary table tailstock, a main part positioning device, an auxiliary part positioning device, a clamp body and a rotary table body; and a plurality of hydraulic supporting cylinders and a plurality of hydraulic pressing cylinders are further arranged on the clamp body. By the adoption of the four-axis linkage machining mechanism, the problems that a workpiece cannot be clamped easily, multiple procedures are needed for machining, and the precision is difficult to control are mainly solved, and a machining mode requiring multiple machine tools is changed, so that the numerical-control machining mechanism which can achieve rapid machining and high-precision machining and simplify machining procedures is obtained. The four-axis linkage machining mechanism is suitable for machining parts which are huge in boundary dimension, light and thin in structure and prone to deformation, and thus the phenomenon that clamping is difficult is avoided. The mechanism has a strict form and location tolerance requirement, the requirements for assembly and detail treatment of a system are improved, and the effect that the stability of the product quality and high efficiency are still kept in long-time continuous production is guaranteed.

Owner:TIANJIN HUATIAN CENTURY MACHINERY

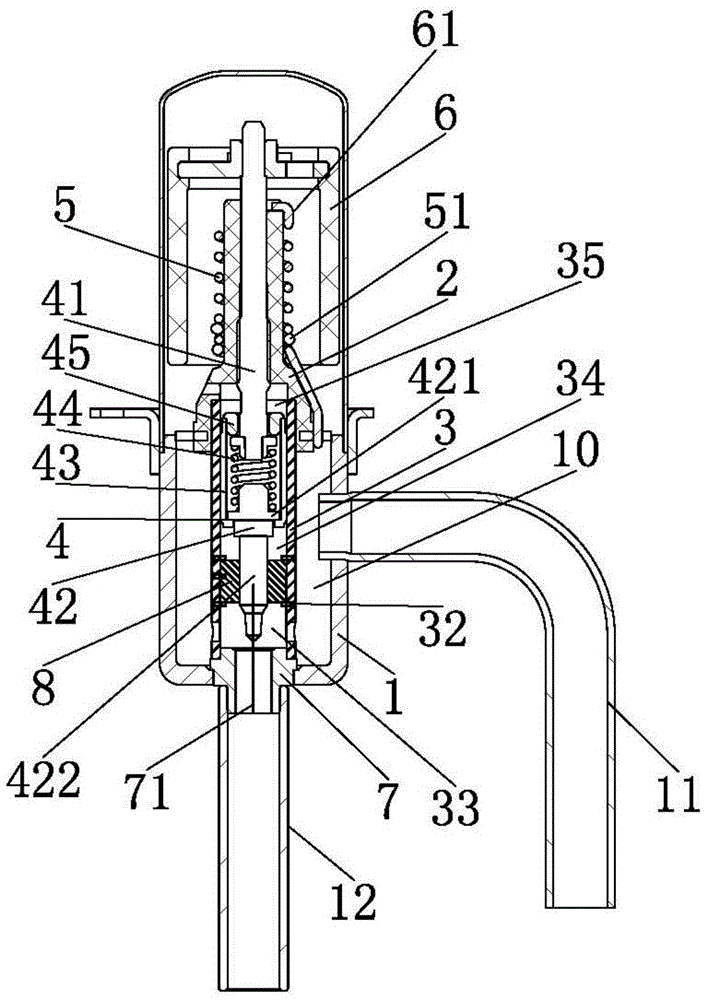

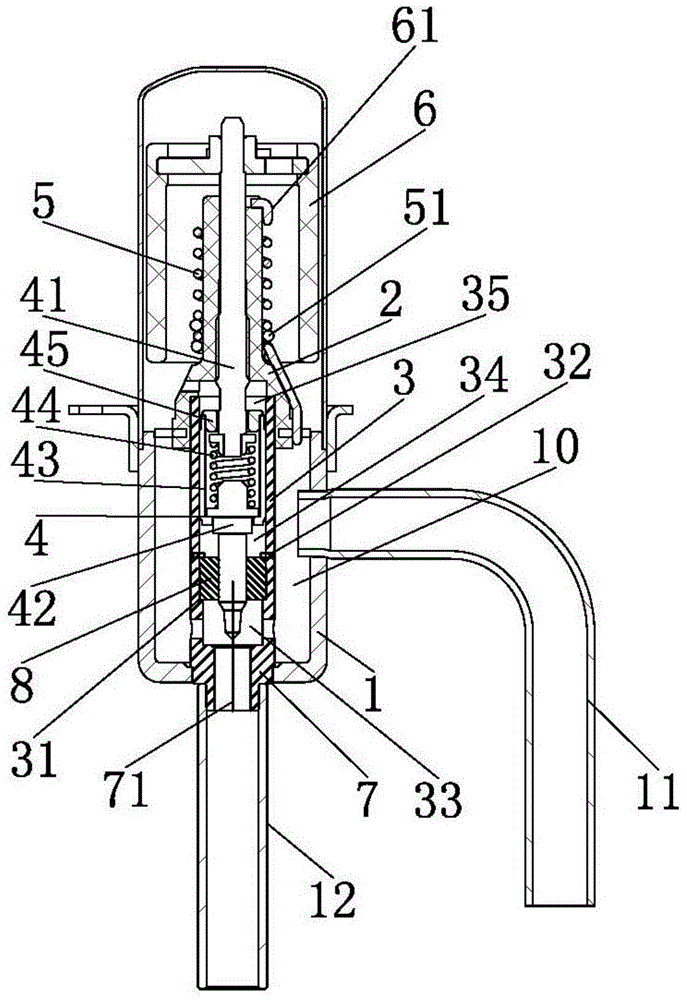

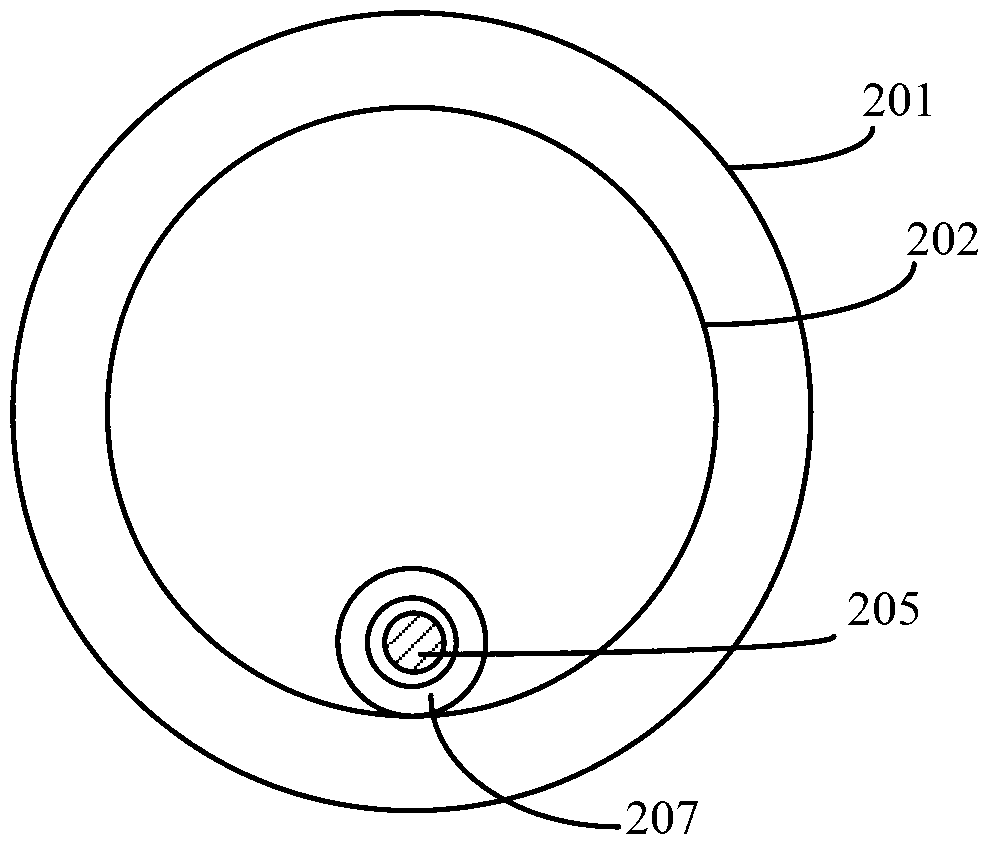

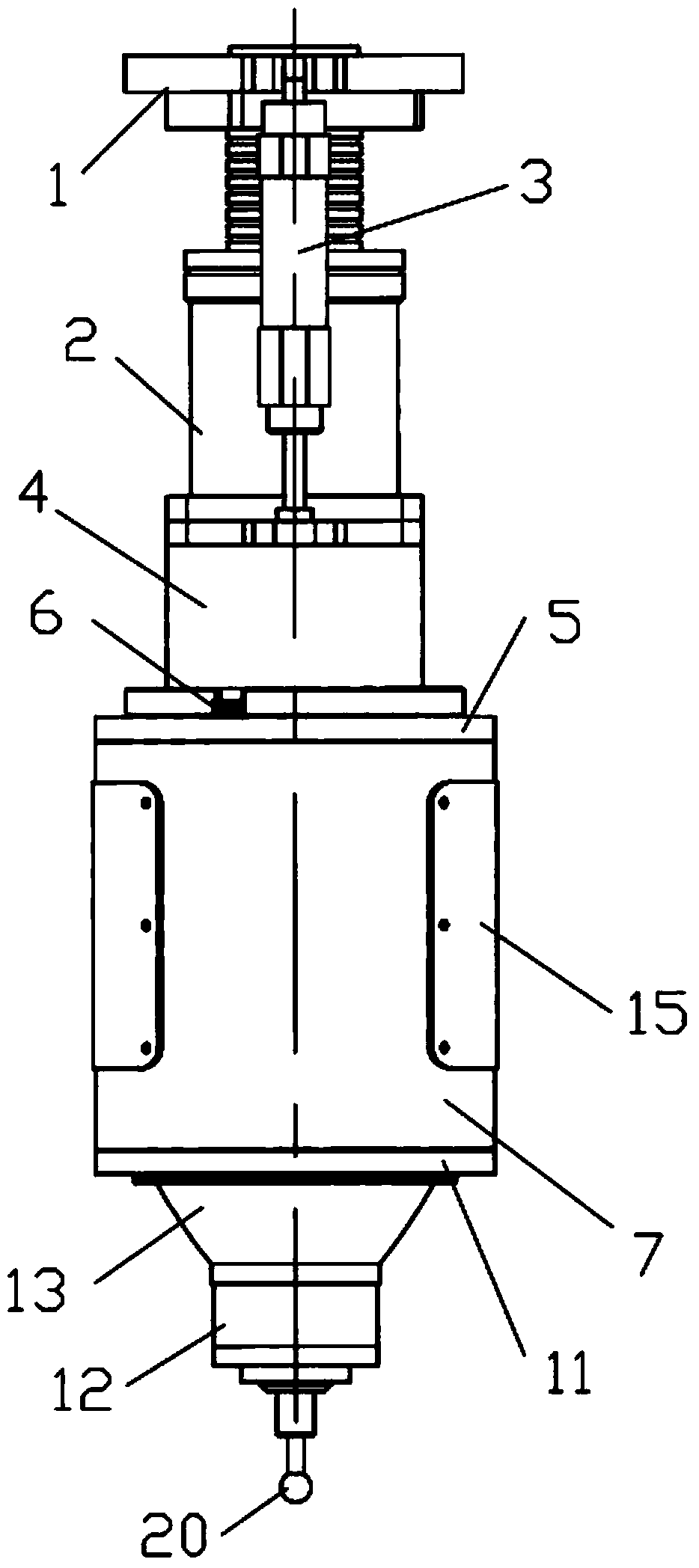

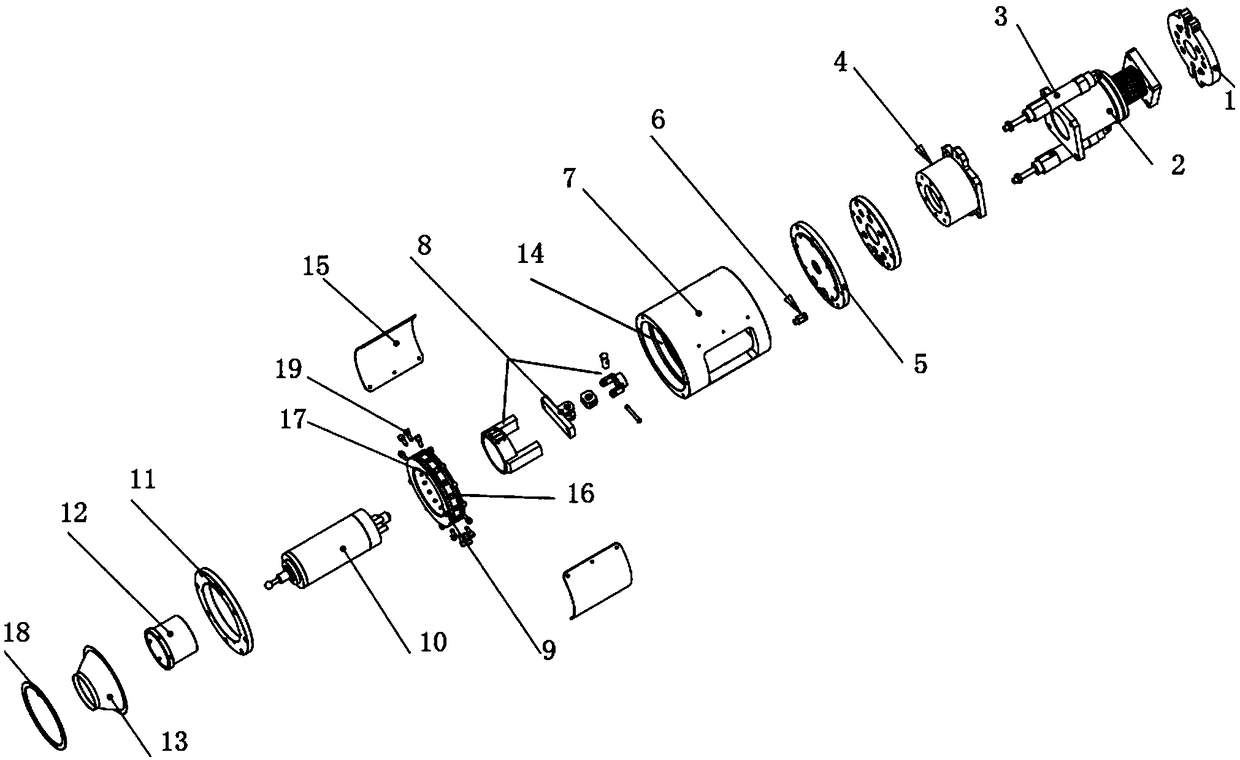

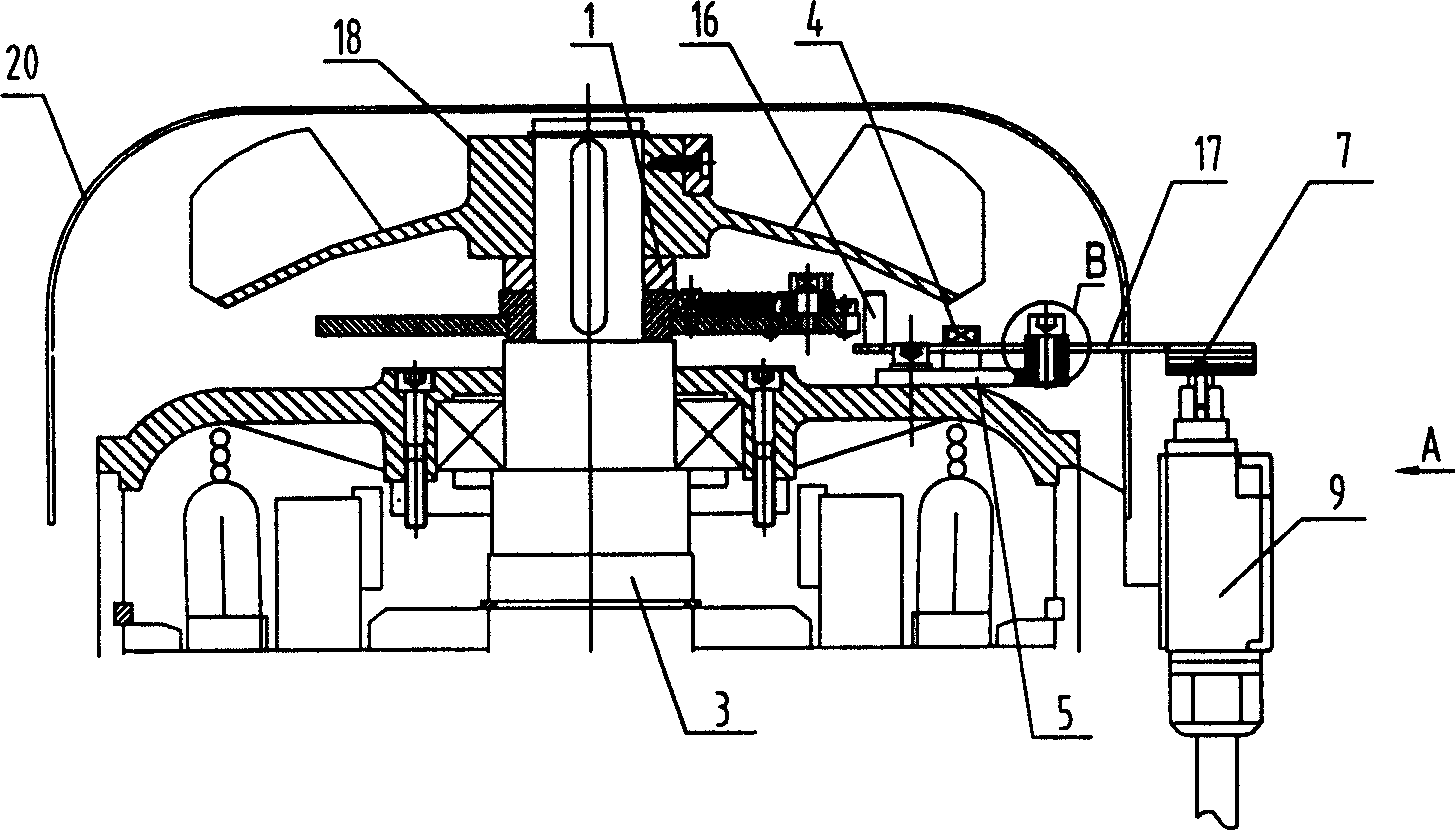

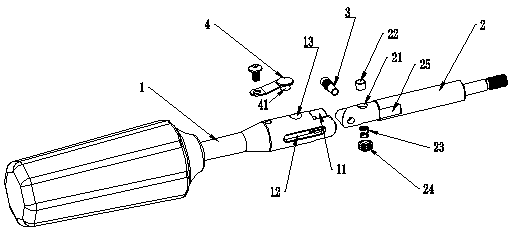

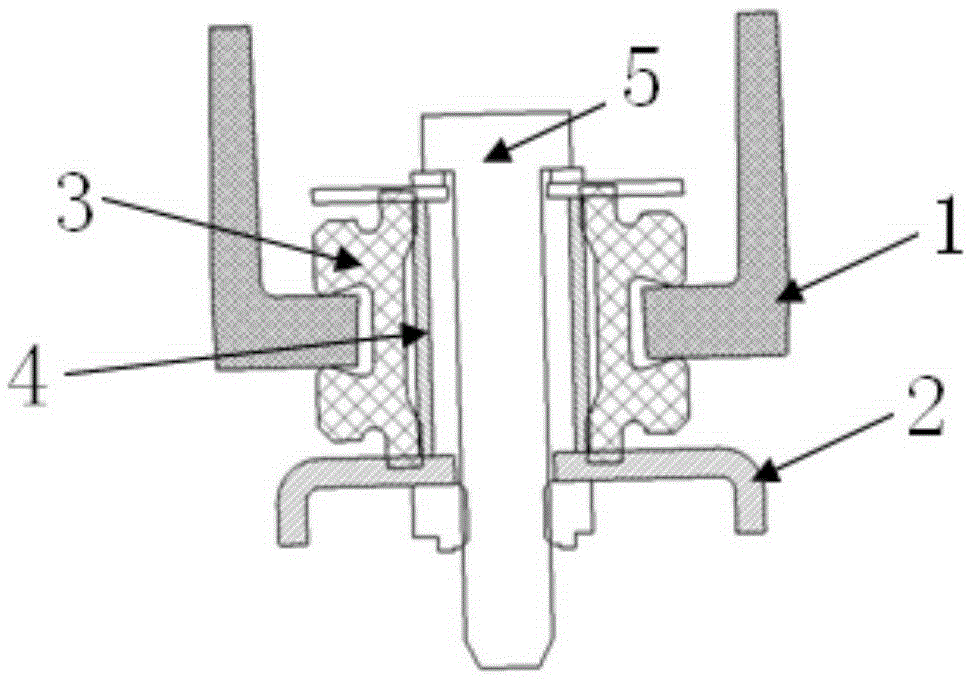

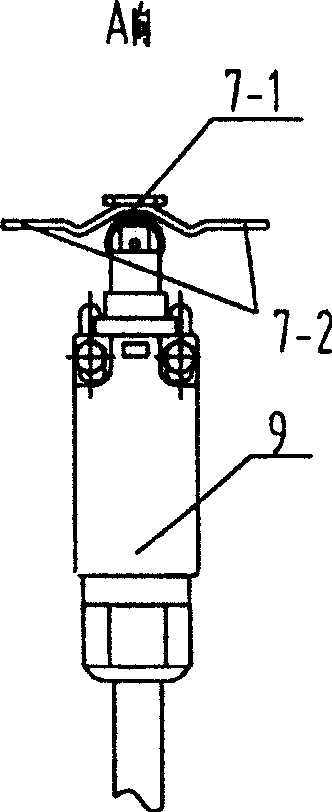

Electronic expansion valve

ActiveCN106322861AAvoid shockWon't vibrateEfficient regulation technologiesFluid circulation arrangementReciprocating motionEngineering

The invention discloses an electronic expansion valve. The electronic expansion valve comprises a valve opening base, a guiding sleeve and a valve needle. The lower end of the guiding sleeve is sleeved with the upper end of the valve opening base in a connected manner or the lower end of the guiding sleeve and the upper end of the valve opening base are integrally connected or the guiding sleeve and the valve opening base are an integrated piece. The upper portion of the valve needle is provided with a large-diameter part, and the lower portion of the valve needle is provided with a small-diameter part. The small-diameter part of the valve needle is located in the guiding sleeve and can do the reciprocating movement in the guiding sleeve in the axial direction. The small-diameter part is sleeved with a lantern ring in a sliding manner, and the lantern ring is used for stopping airflow. The outer side wall of the lantern ring and the inner side wall of the guiding sleeve are fixedly connected or the lantern ring and the guiding sleeve are an integrated piece. According to the electronic expansion valve, airflow can be effectively prevented from directly impacting on the valve needle, and when airflow impact force is very large, most of airflow is blocked by the lower end face of the lantern ring, only the head part of the valve needle can be subjected to an extremely small part of airflow impact, and the valve needle cannot be greatly vibrated; and thus, noise, formed through vibration, of the valve needle can be reduced, and even noise can be eliminated.

Owner:ZHEJIANG DUNAN HETIAN METAL CO LTD

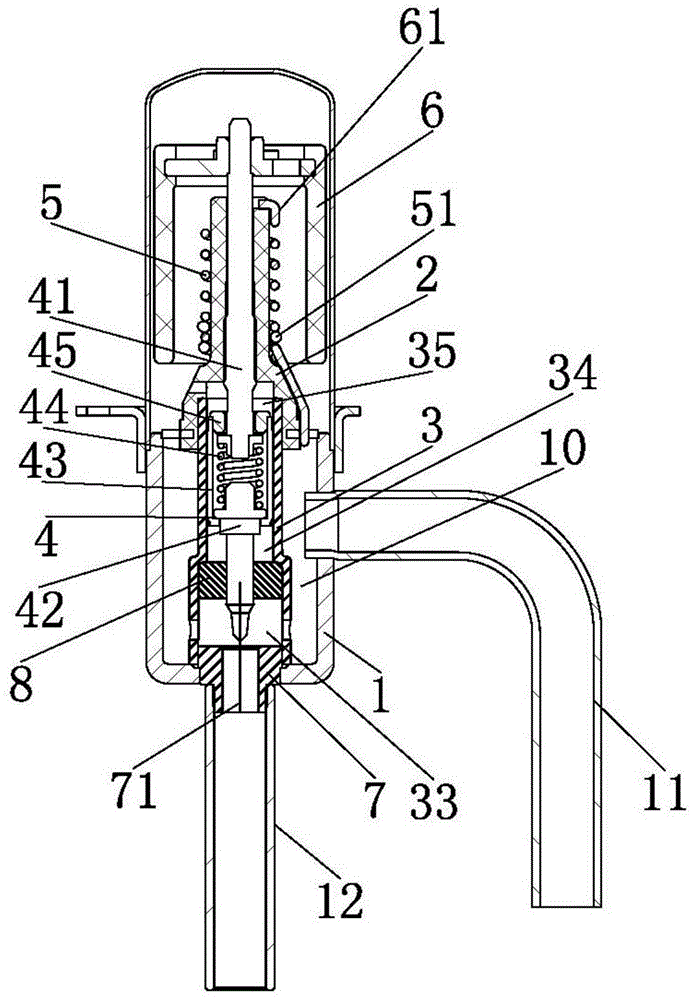

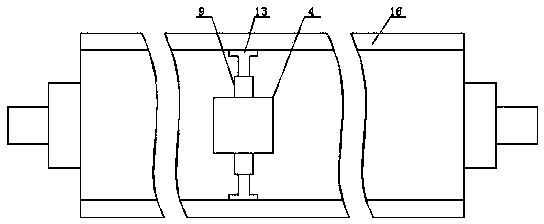

Depositing device

ActiveCN102938389AWon't vibrateAvoid it happening againSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringExhaust pipe

A depositing device comprises an outer furnace tube, an inner furnace tube located in the outer furnace tube, a base located at the bottom in the inner furnace tube, a plurality of overlapped boats fixed on the base surface, an air supply pipe extending into the inner furnace tube from the outside of the outer furnace tube, a fixing device fixedly arranged on the lateral wall of the inner furnace tube and an exhaust pipe located between the outer furnace tube and the inner furnace tube, wherein the bottom of the inner furnace tube is fixed at the bottom of the outer furnace tube, an opening is arranged at the top of the inner furnace tube, and the top of the inner furnace tube is not contacted with the top of the outer furnace tube; the air supply pipe extends from the bottom of the inner furnace tube to the top of the inner furnace tube; and the fixing device is used for fixing the air supply pipe extending from the bottom of the inner furnace tube to the top of the inner furnace tube. The depositing device can be prevented from toppling caused by too fast instantaneous velocity of air in the air supply pipe or cannot generate scraps caused by the fact that the air supply pipe collides with the lateral wall of the inner furnace tube or the boat, and accordingly formed films are good in quality.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

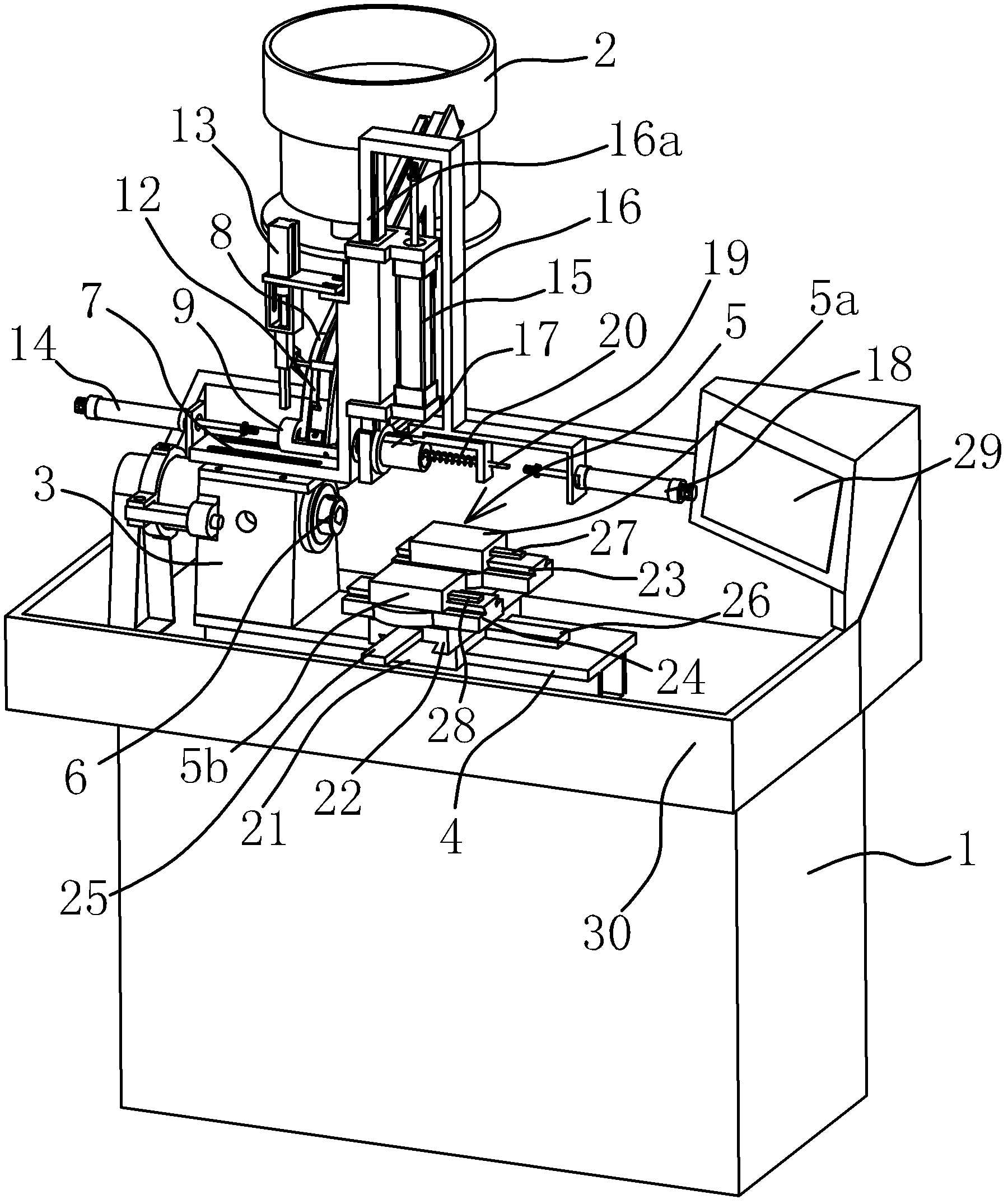

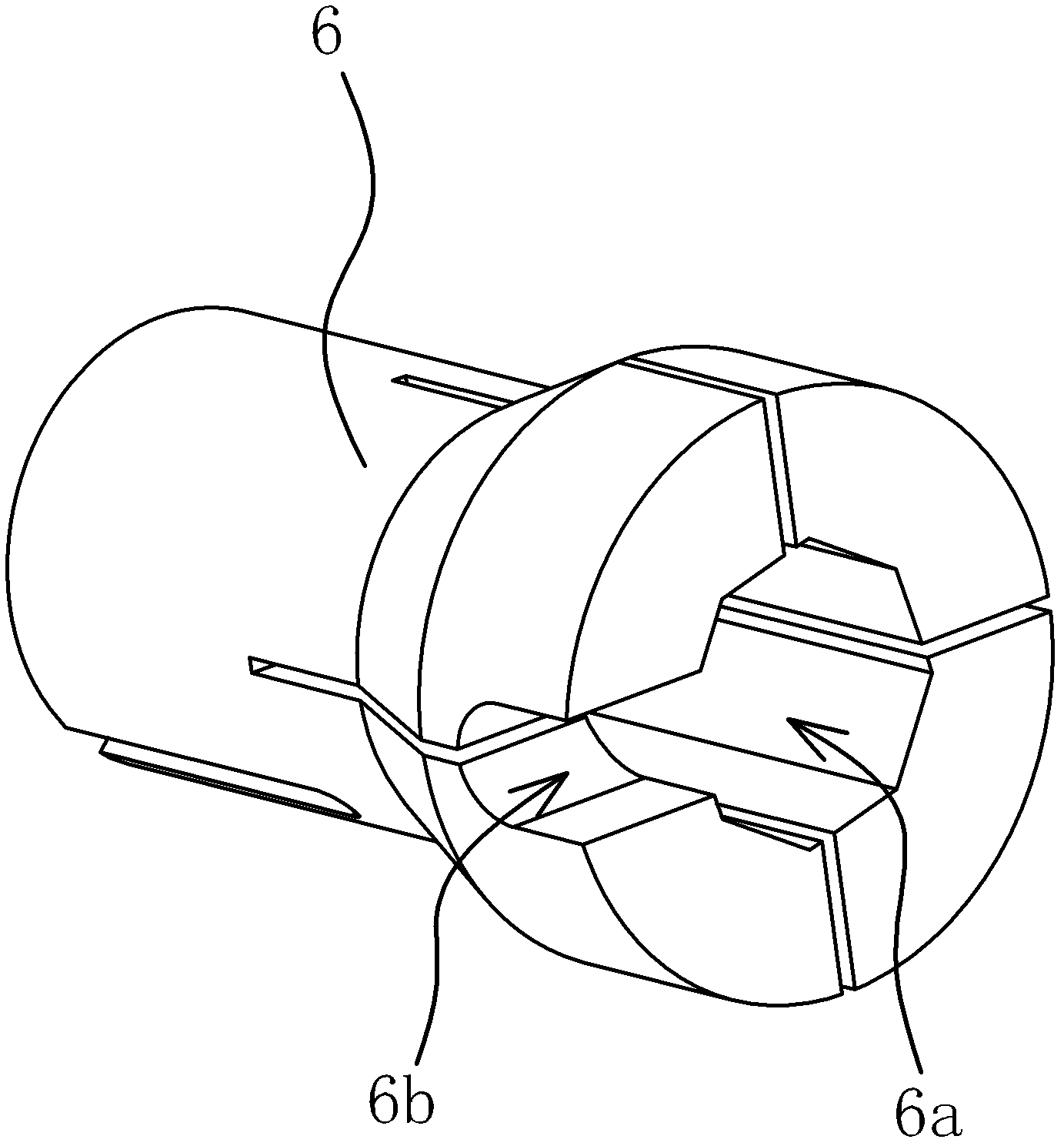

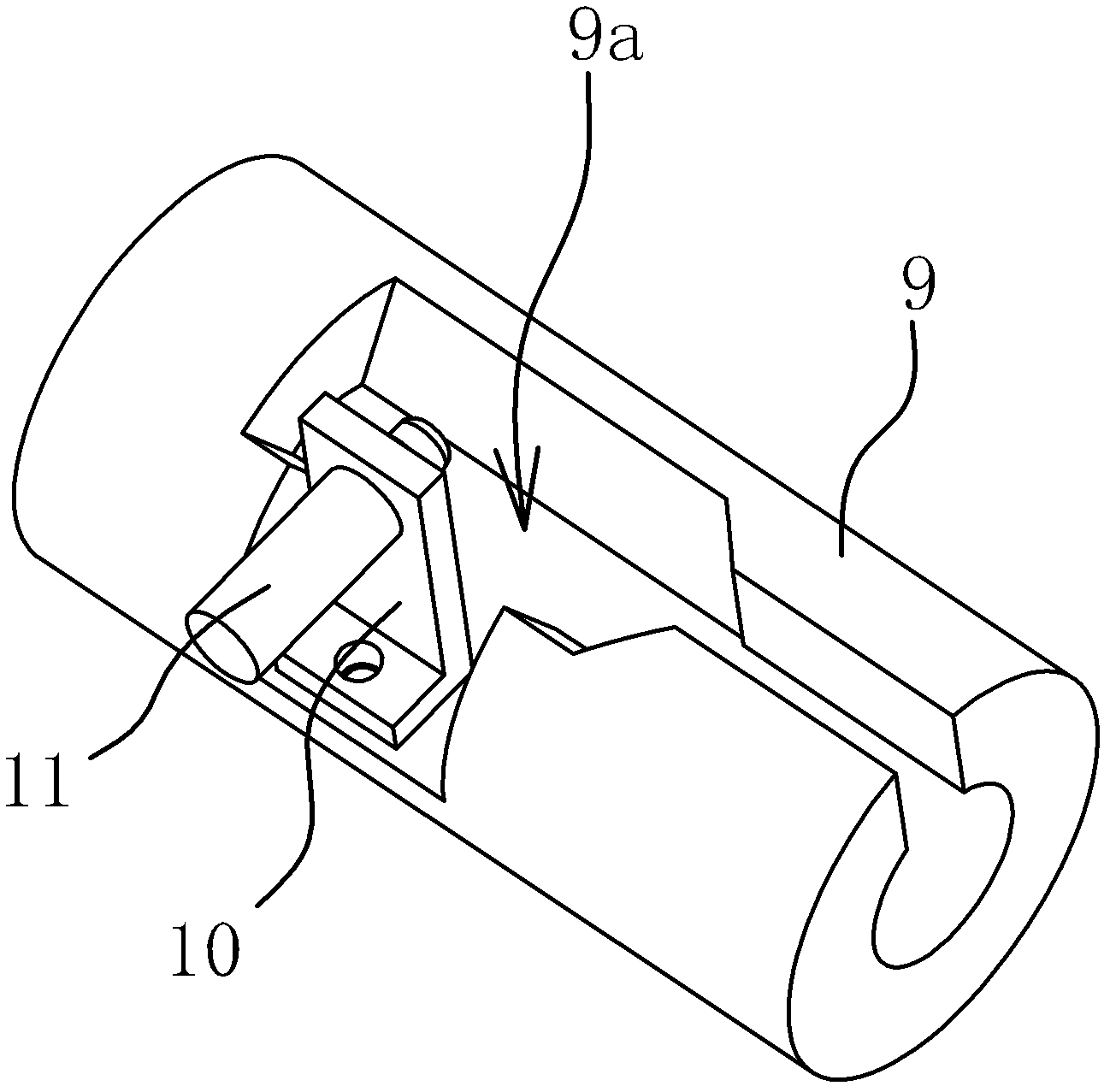

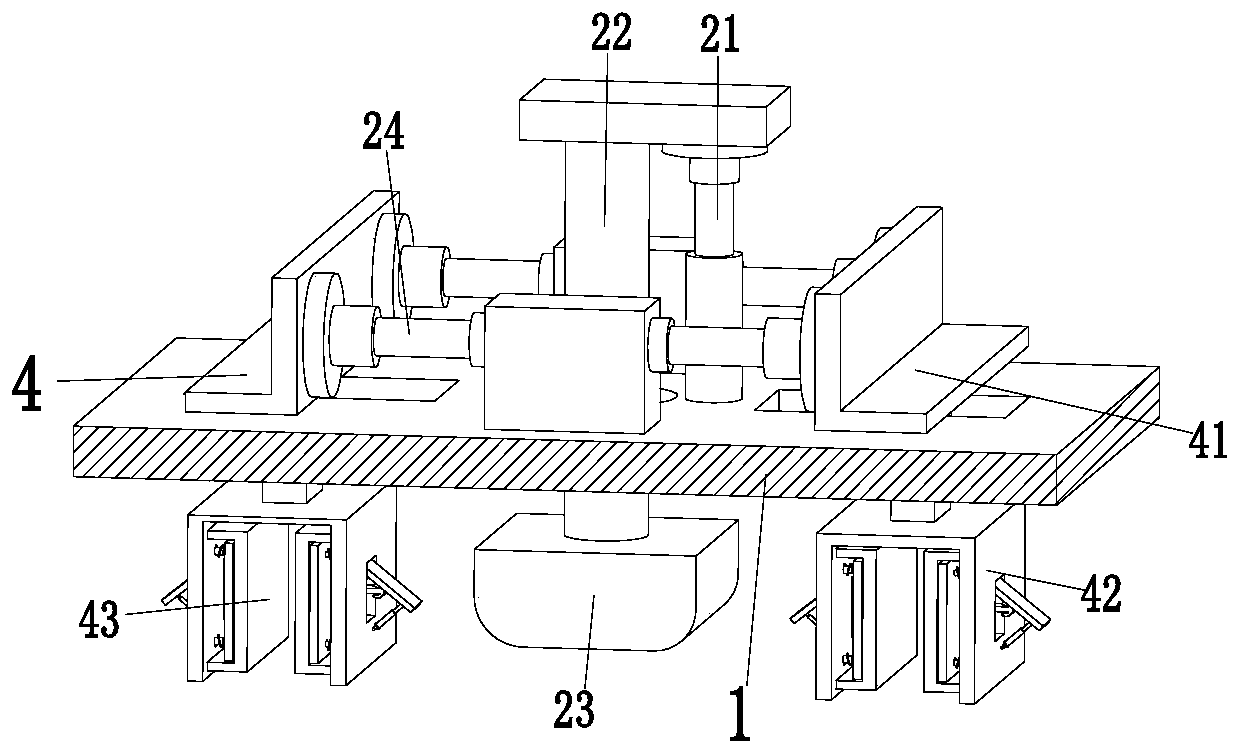

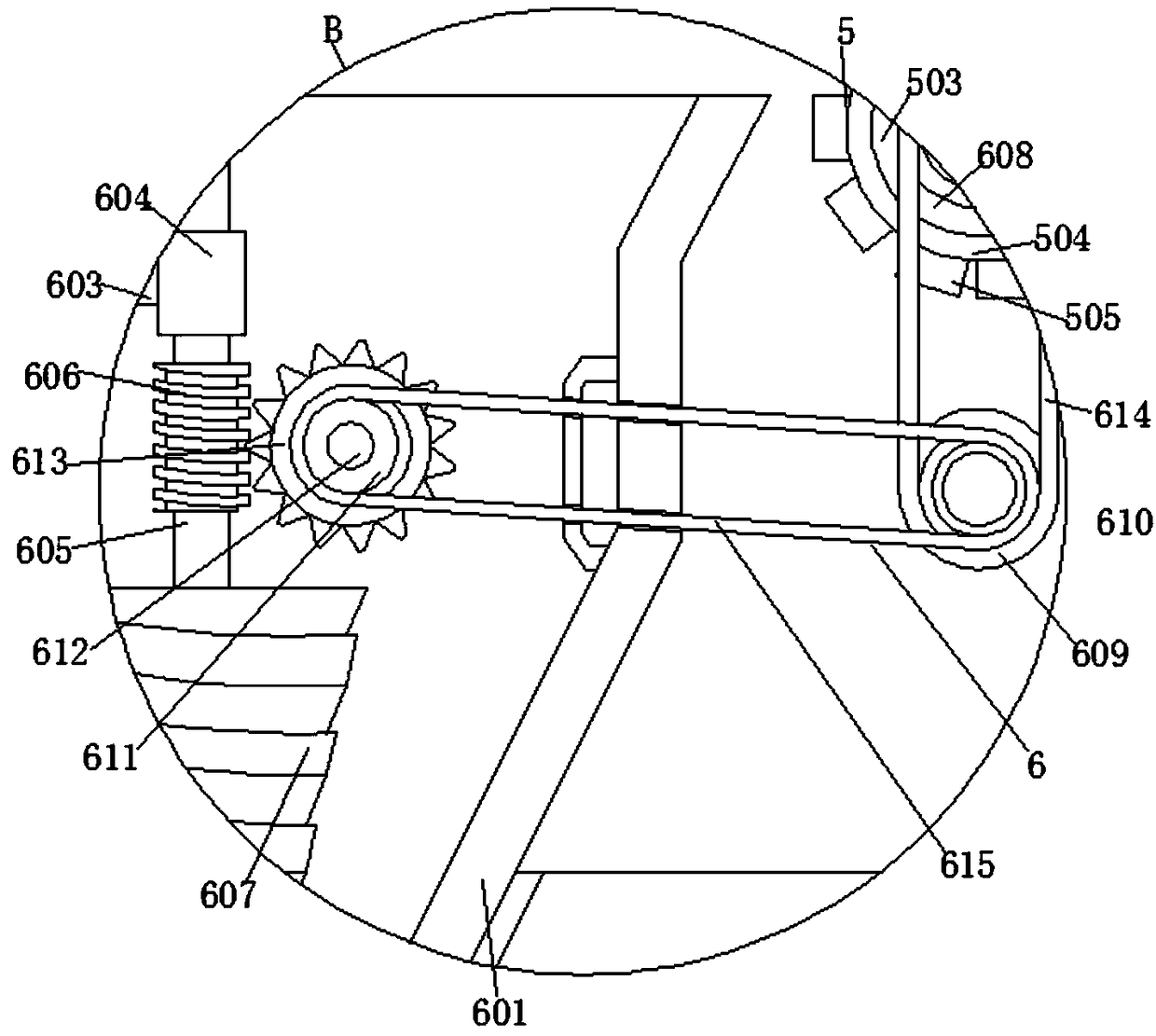

Processing machine tool for valve body connection hole

InactiveCN102357803ARealize automatic feedingRealize the processing effectOther manufacturing equipments/toolsPositioning apparatusMachine toolKnife holder

The invention provides a processing machine tool for a valve body connection hole, which belongs to the technical field of machinery and solves the problems that the existing valve body processing machine tool is small in processing range, cannot process the valve body connection hole and the like. The processing machine tool of the valve body connection hole comprises a machine tool body, a feeding hopper and a spindle box fixedly connected onto the machine tool body. A transverse guide rail is arranged on the machine tool body, a processing cutter rest used for processing the connection hole is arranged on the transverse guide rail, and a clamp used for clamping a valve body and enabling the end of the valve body to face the processing cutter rest is fixedly connected with the spindle end of the spindle box. A conveying mechanism used for conveying the valve body to be processed in the feeding hopper to the clamp of a spindle in positioning mode is arranged on the machine tool body,and a driving mechanism used for pushing the processing cutter rest to process the valve body when the valve body to be processed is located in the clamp is further arranged on the machine tool body.The processing machine tool for the valve body connection hole has the advantages of being convenient to operate, high in automation degree, good in product uniformity and the like.

Owner:杨建龙 +1

Chemical raw material transporting trolley walking lifting mechanism

The invention discloses a chemical raw material transporting trolley walking lifting mechanism comprising a pedestal plate. The bottom surface of the pedestal plate is provided with multiple walking wheels. A moving connecting block is fixed at the middle part of the bottom surface of the pedestal plate. The middle part of the bottom surface of the moving connecting block is provided with a plugging part. The plugging part is sleeved in a plugging hole arranged on a walking block screwed on a rotating screw rod below the pedestal plate in a plugging way. The two ends of the rotating screw rod are hinged on two fixing plates. The output shaft of a servo motor is connected with the end part of one end, which stretches out of the fixing plates, of the rotating screw rod via a shaft coupler. Stand columns are fixed on the ground of the external side of moving tracks. Driving servo motors are fixed at the top parts of the stand columns. The output shafts of the driving servo motors and one end of vertical screw rods are fixed via shaft couplers. The two ends of the vertical screw rods are hinged on connecting supporting plates. The chemical raw material transporting trolley walking lifting mechanism is fixed on the walking block via a detachable type structure and can automatically move to realize transporting of raw materials. Besides, the pedestal plate can be lifted to a high position so that high position lifting transporting can be met.

Owner:HAIMEN BIWEI INTPROP SERVICE CO LTD

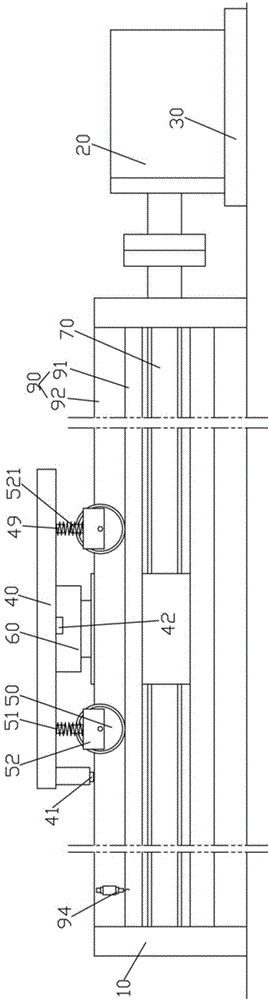

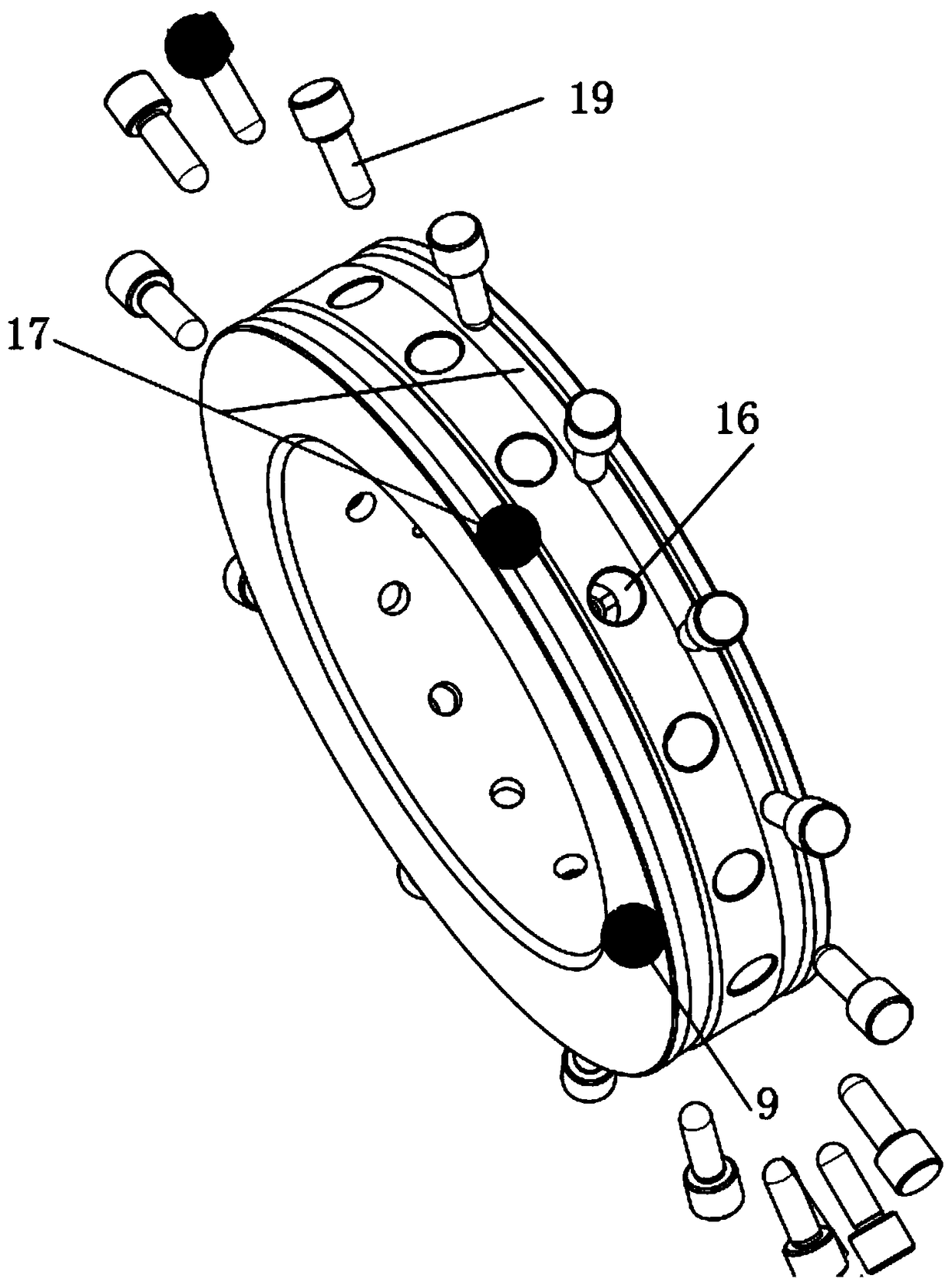

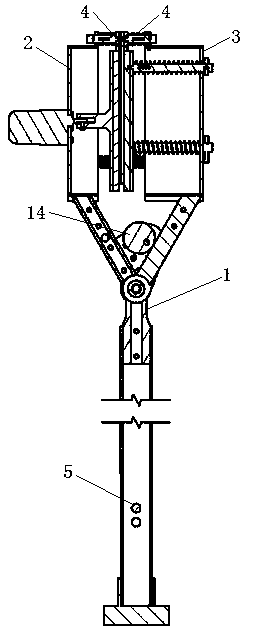

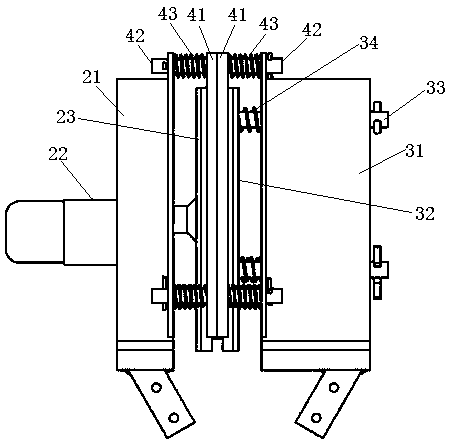

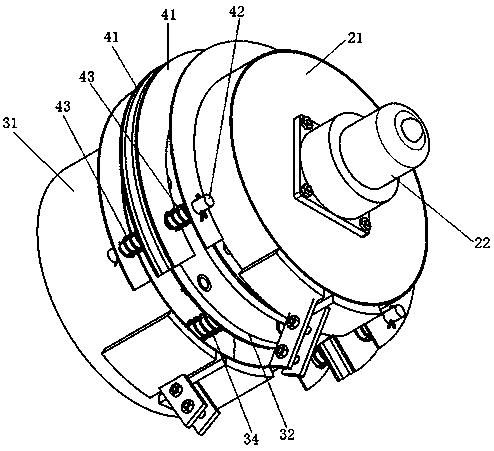

Constant force grinding and polishing head mechanism

ActiveCN109318120AAutomatic route optimizationReduce idle timeGrinding machine componentsGrinding machinesConstant forceEngineering

The invention provides a constant force grinding and polishing head mechanism. The constant force grinding and polishing head mechanism comprises a robot connecting flange, a linear motor, balance low-friction air cylinders, a motor flange base, a top connecting flange, an air source connecting head, an outer shell, a floating universal connecting base, a radial constant force floating air ring, aspindle motor and a front fixed flange. The bottom of the robot connecting flange is perpendicularly connected with the linear motor, the two sides of the linear motor are vertically connected with the balance low-friction air cylinders, the bottom ends of the balance low-friction air cylinders are connected with the motor flange base, the upper top surface of the motor flange base is connected with the bottom of the linear motor, and the bottom of the top connecting flange is connected with the outer shell. An annular mounting groove is arranged in the inner wall of an inner cavity of a shell body, the radial constant force floating air ring is arranged in the annular mounting groove, and a plurality of constant force pistons are uniformly distributed on the radial constant force floating air ring. The spindle motor penetrates through the radial constant force floating air ring, one end of each constant force piston abuts against the outer wall of the spindle motor, and the bottom ofthe spindle motor is connected with a grinding head.

Owner:HUNAN JINGYI AUTOMATION

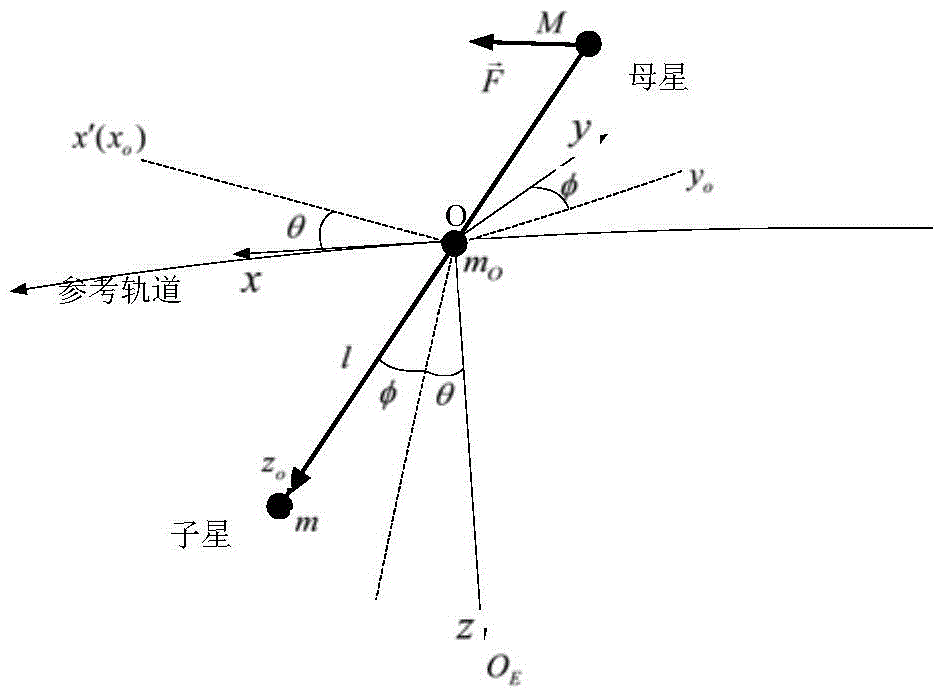

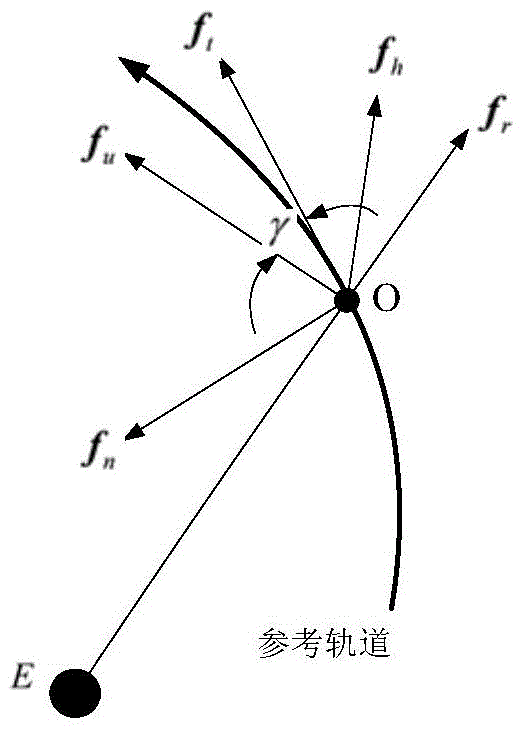

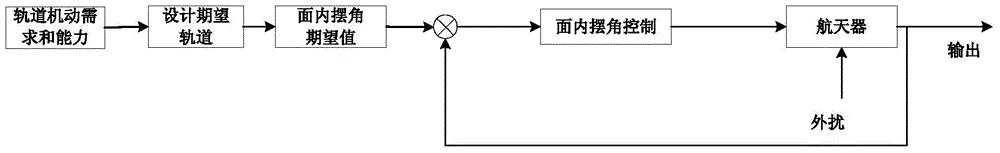

Active-passive-combined rope net dragging safety orbit leaving control method

ActiveCN104407620AEnsure safetyTo achieve the purpose of anti-collision controlPosition/course control in three dimensionsIn planeActive tension

An active-passive-combined rope net dragging safety orbit leaving control method includes: tethered system mass center acceleration is designed according to tethered satellite orbit leaving task, and a propelling system applies corresponding push force on a primary satellite so as to track the designed orbital maneuver path in real time; tension control quality is designed, a tethered winch mechanism generates corresponding tension to be applied to the primary satellite so as to actively control the in-plane swing angle of a tether, and orbital maneuver of the tethered system is achieved by dragging secondary satellites through the orbital maneuver of the primary satellite and tether tension control. The method has the advantages that the large vibration of the in-plane swing angle of the tether is avoided during dragging, the in-plane swing angle of the tether is stabilized in a constraint range, and collision is prevented; meanwhile, the in-plane swing angle is restrained by the appropriate orbital maneuver path design and the active tension control applied to a combined body, and safety orbit leaving control of a target is achieved.

Owner:BEIJING INST OF CONTROL ENG

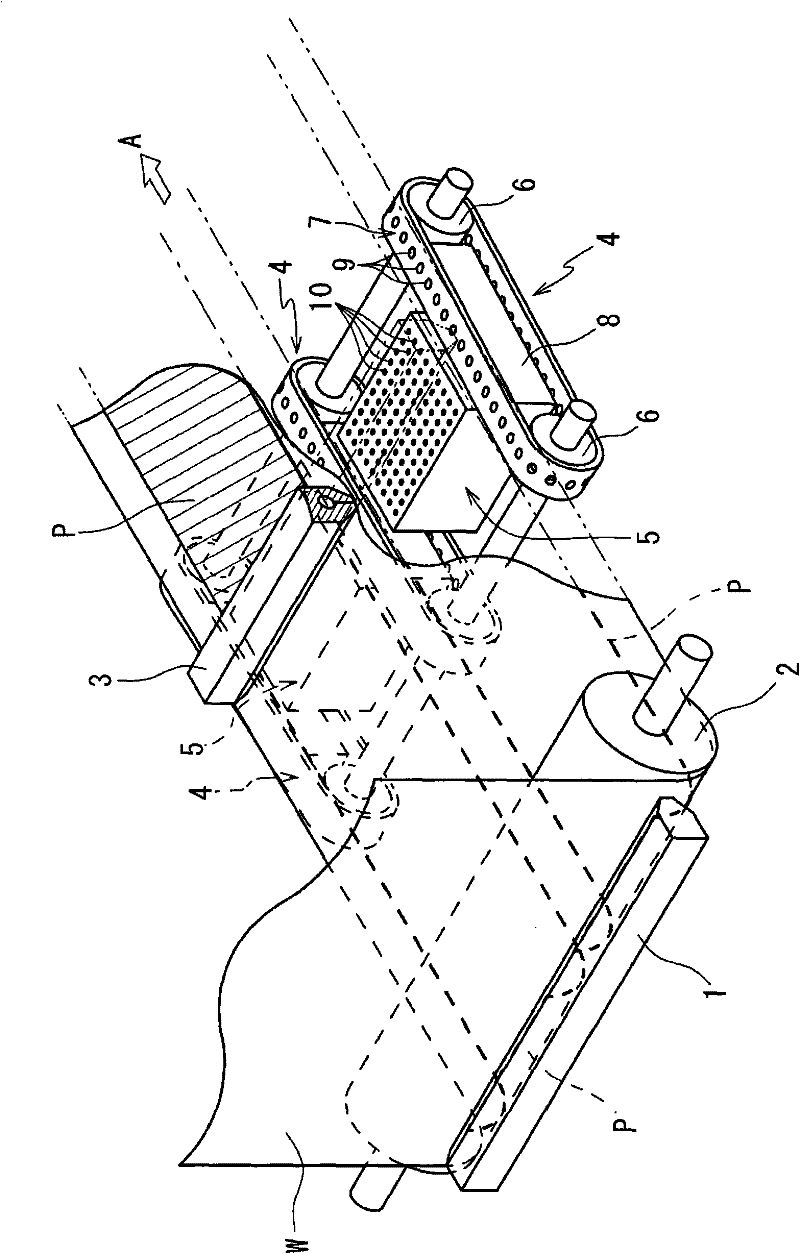

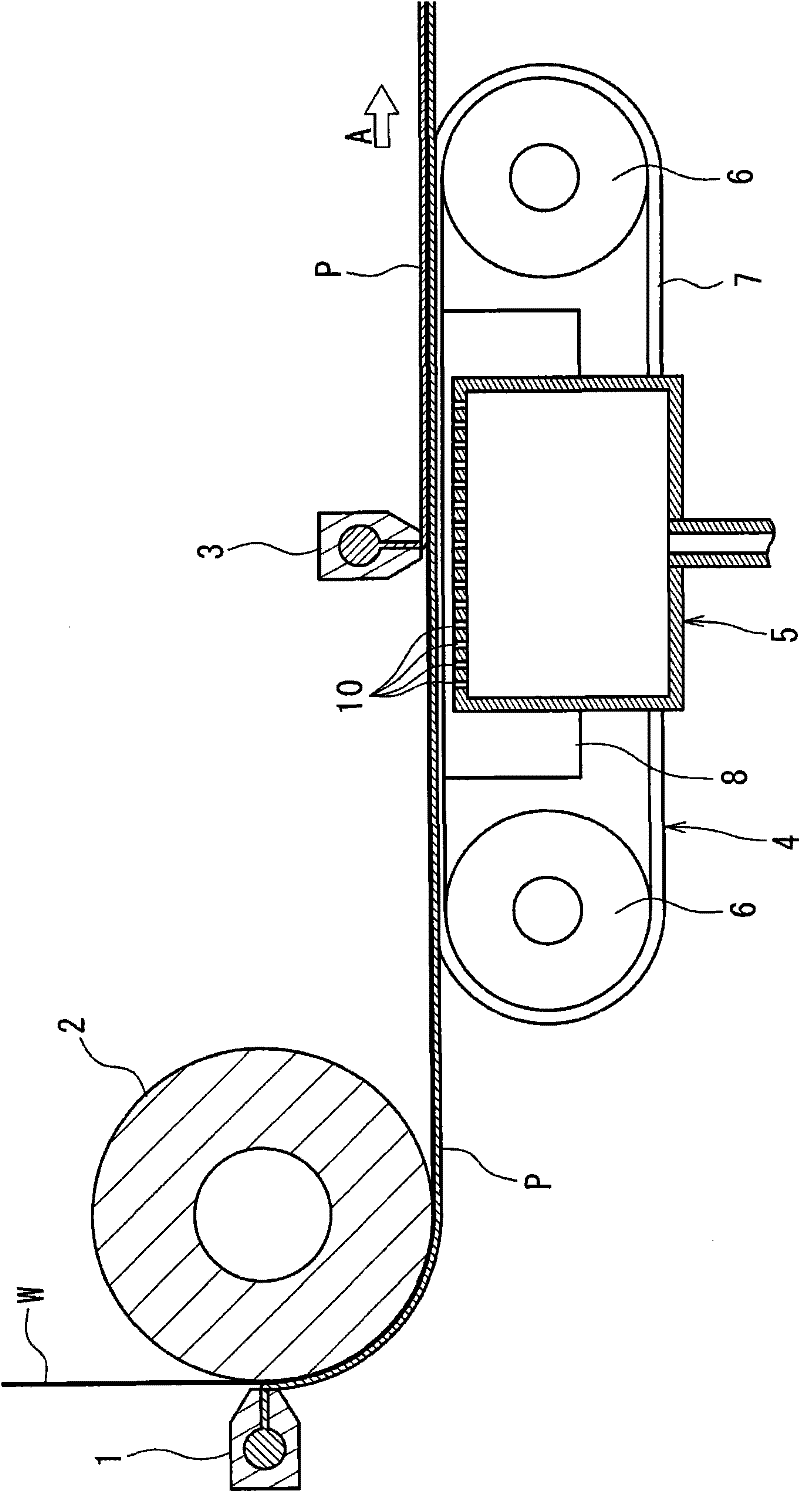

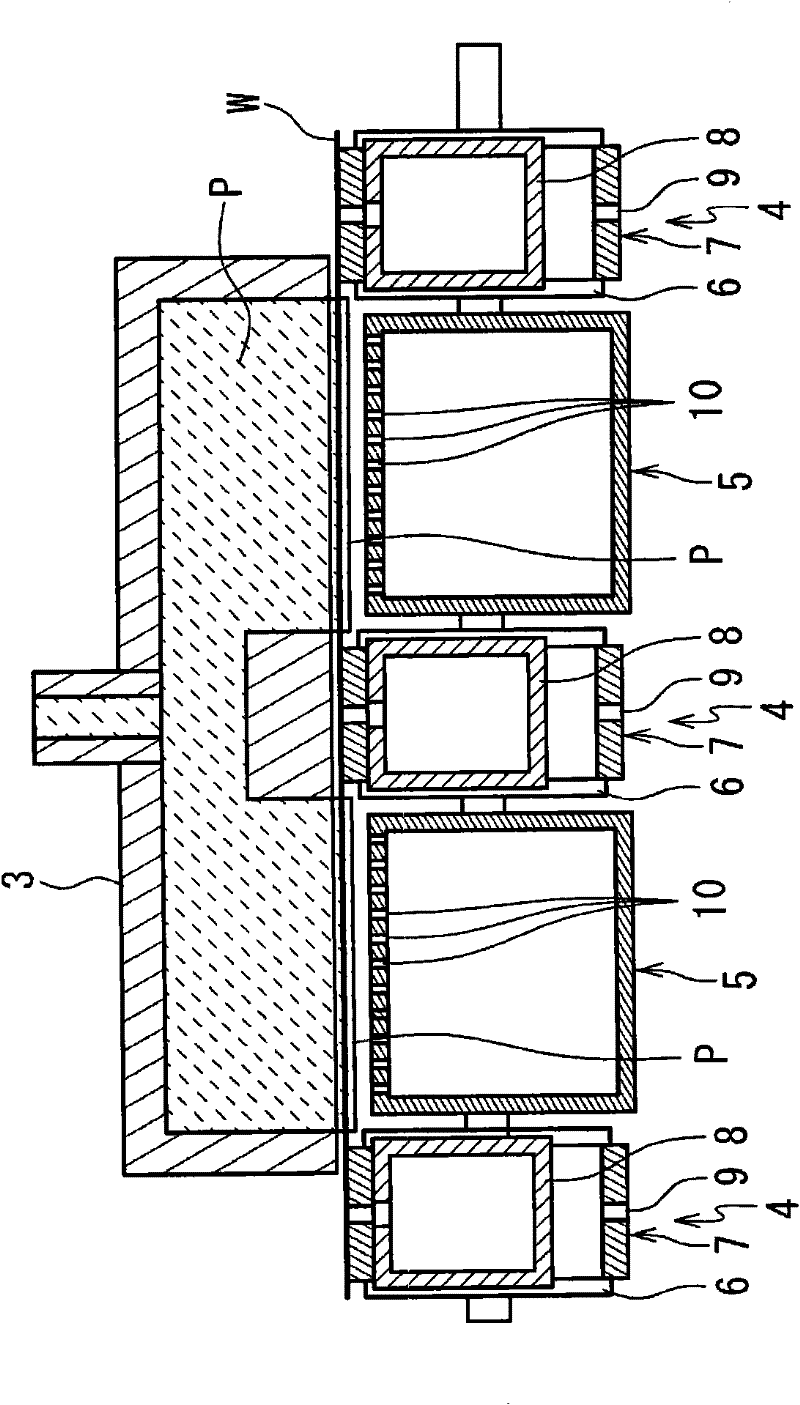

Double side coating device

InactiveCN102371228AWon't vibrateUniform thicknessLiquid surface applicatorsFinal product manufactureEngineeringVacuum chamber

A double side coating device which can maintain a thickness of a coated film in constant has a first coating head (1) that coats a first surface of a web material (W) with a coating material (P), two or more vacuum conveyors (4) that are placed downstream of the first coating head (1) in a conveying direction for the web material (W) and have a endless belt (7) formed with a number of through holes (9) and a vacuum chamber (8) sucking the web material (W) through the through holes (9) so as to suck uncoated portions of the first surface of the web material (W), and a second coating head (3) that is placed opposite to the vacuum conveyors (4) and coats a second surface of the web material (W) with a coating material (P).

Owner:CHUGAI RO CO LTD

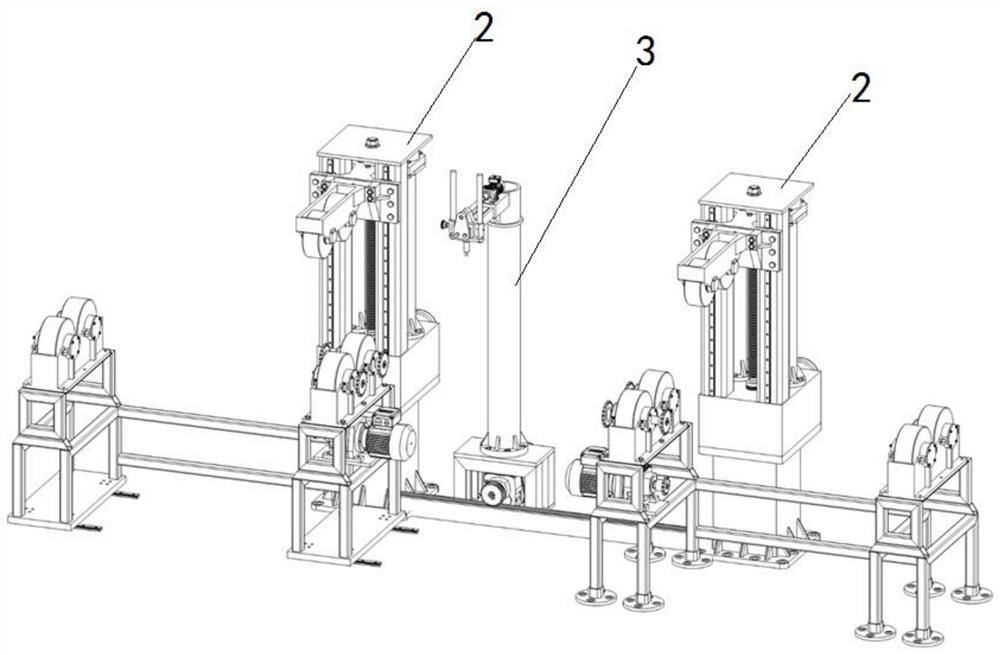

H-shaped steel intelligent machining system for steel structure building construction

ActiveCN109693001AIntelligent, stable and efficient cutting processingGood stabilityMetal sawing devicesMachining systemArchitectural engineering

The invention relates to an H-shaped steel intelligent machining system for steel structure building construction. The H-shaped steel intelligent machining system for the steel structure building construction comprises a mounting frame, wherein clamping and positioning devices are symmetrically arranged on the front side and the back side of the mounting frame. The clamping and positioning devicescomprise rotation supporting mechanisms installed between the inner walls of the mounting frame, clamping adjusting grooves are symmetrically formed in the left side and the right side of the mounting frame, a driving bidirectional air cylinder is arranged on the mounting frame, and execution clamping mechanisms are symmetrically arranged at the two ends of the driving bidirectional air cylinder.According to the H-shaped steel intelligent machining system for the steel structure building construction, the difficulty problems that H-shaped steel is cut and machined manually in an existing steel structure building construction process, the H-shaped steel needs to be fixed manually through an existing clamp, the H-shaped steel with different specifications requires to manually adjust the clamp, the stability of manually controlling the clamp to clamp the H-shaped steel to be cut and machined is poor, during cutting, a cutting saw blade is prone to breaking due to the vibration of the H-shaped steel, the machining cost is increased, the operation is complex, the labor intensity is high, and the working efficiency is low are solved.

Owner:合肥巍华钢结构有限公司

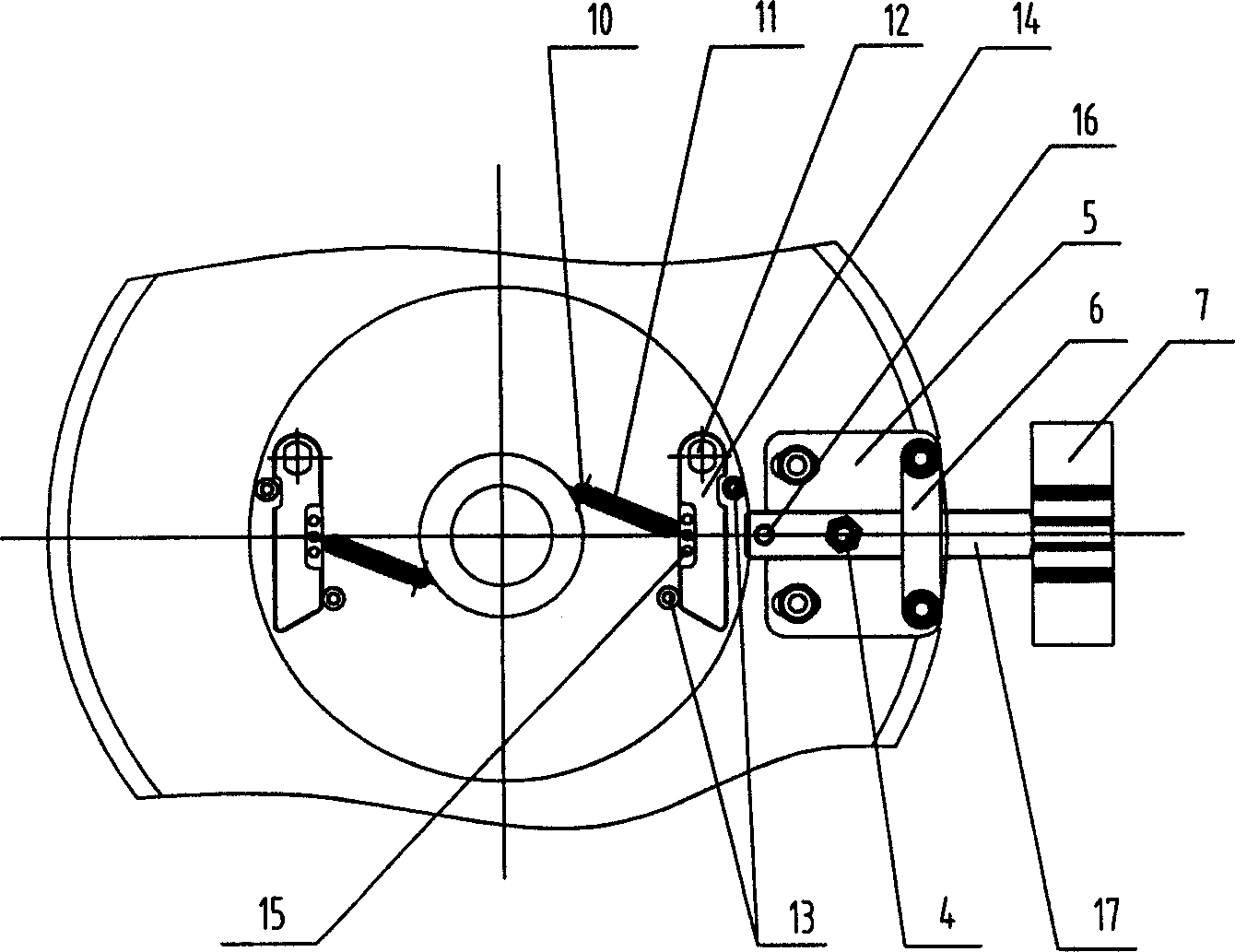

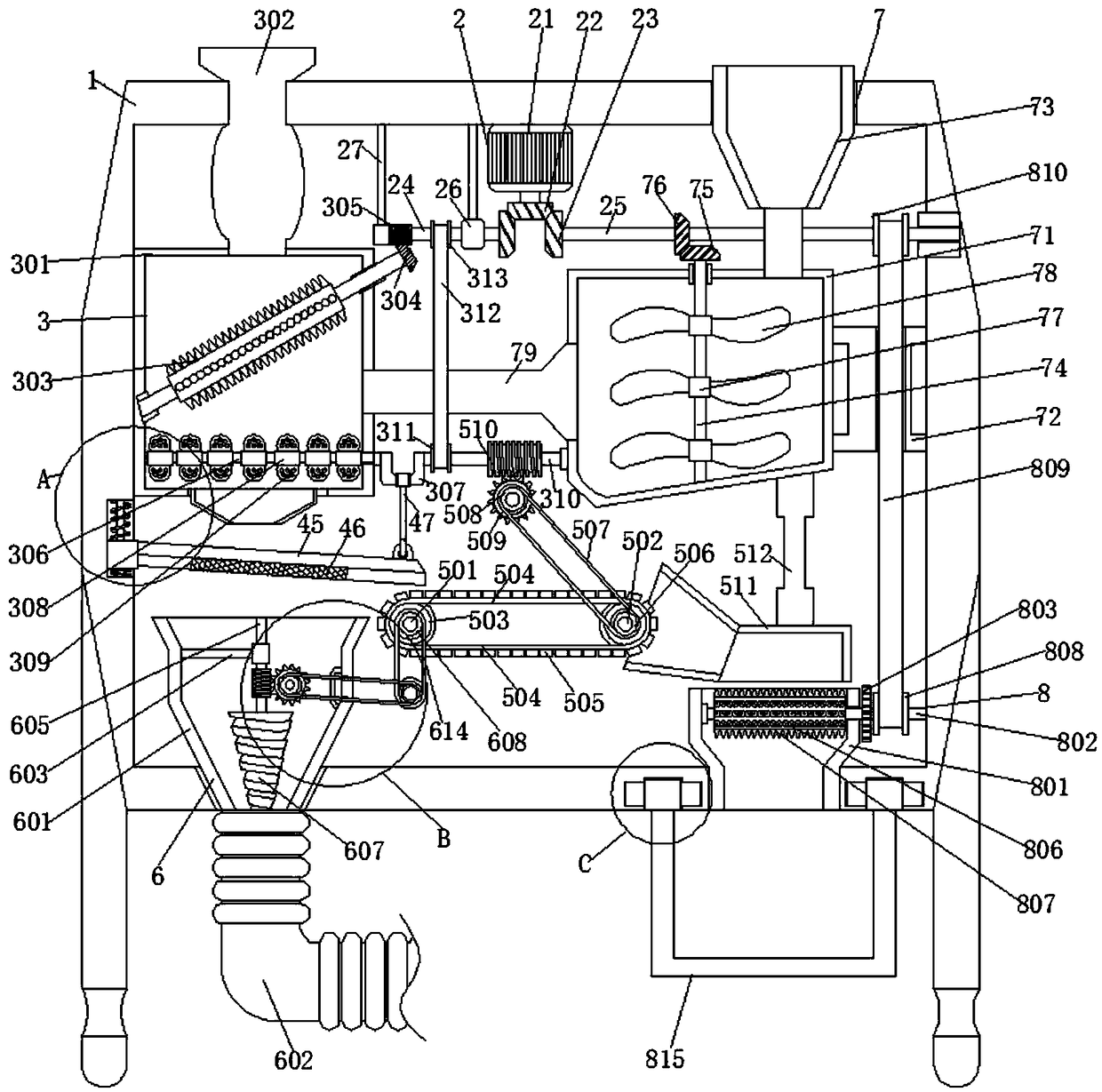

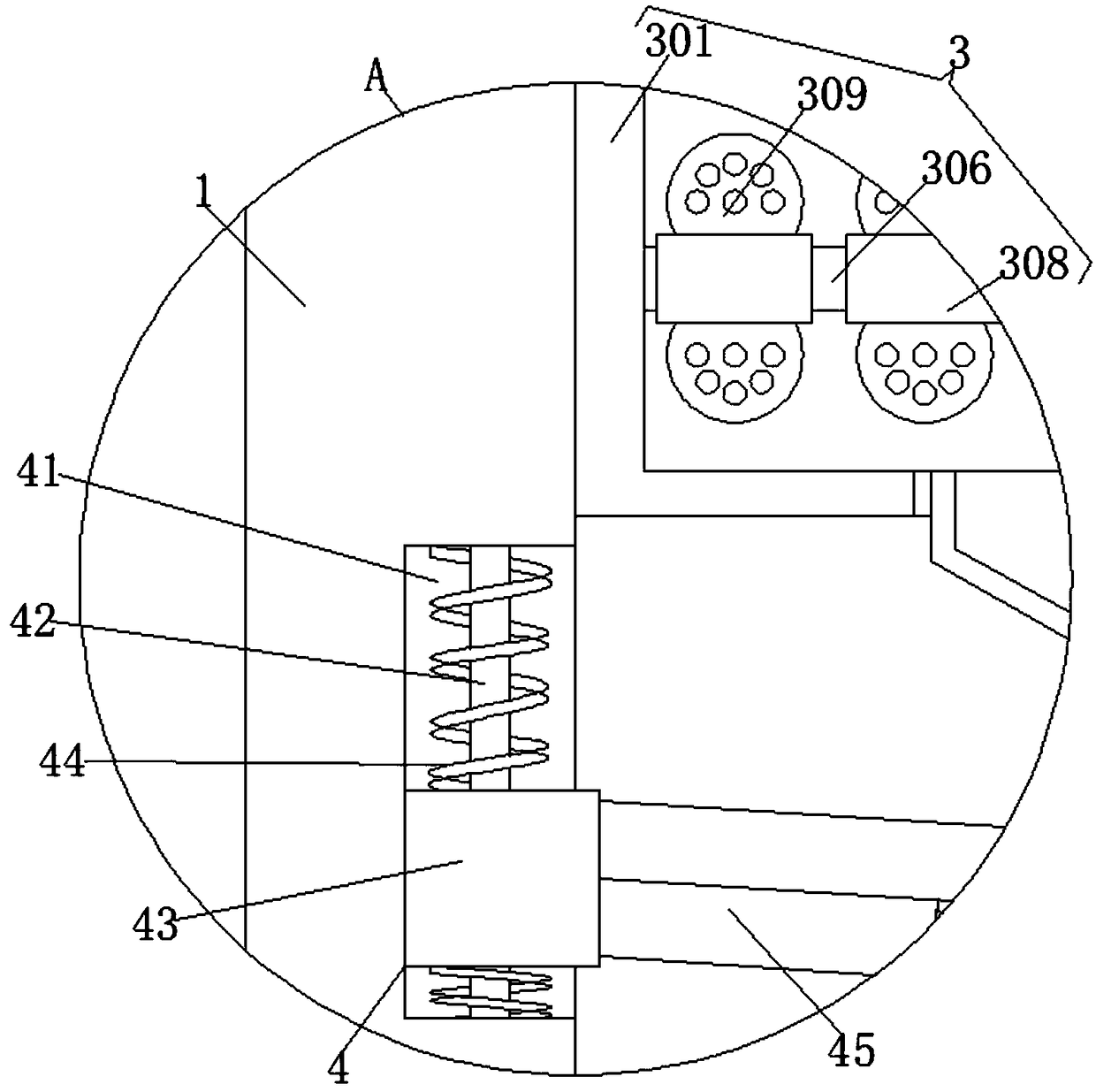

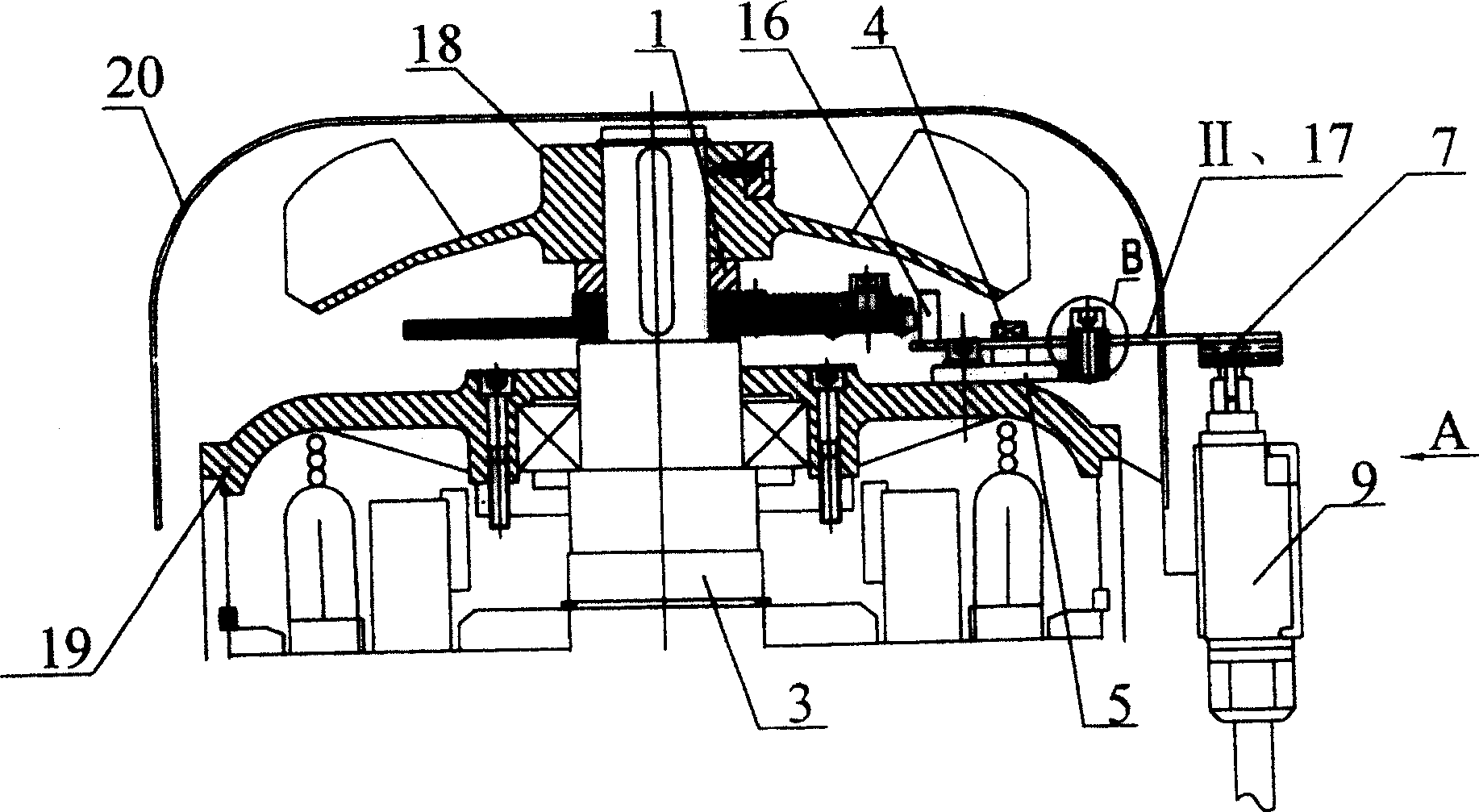

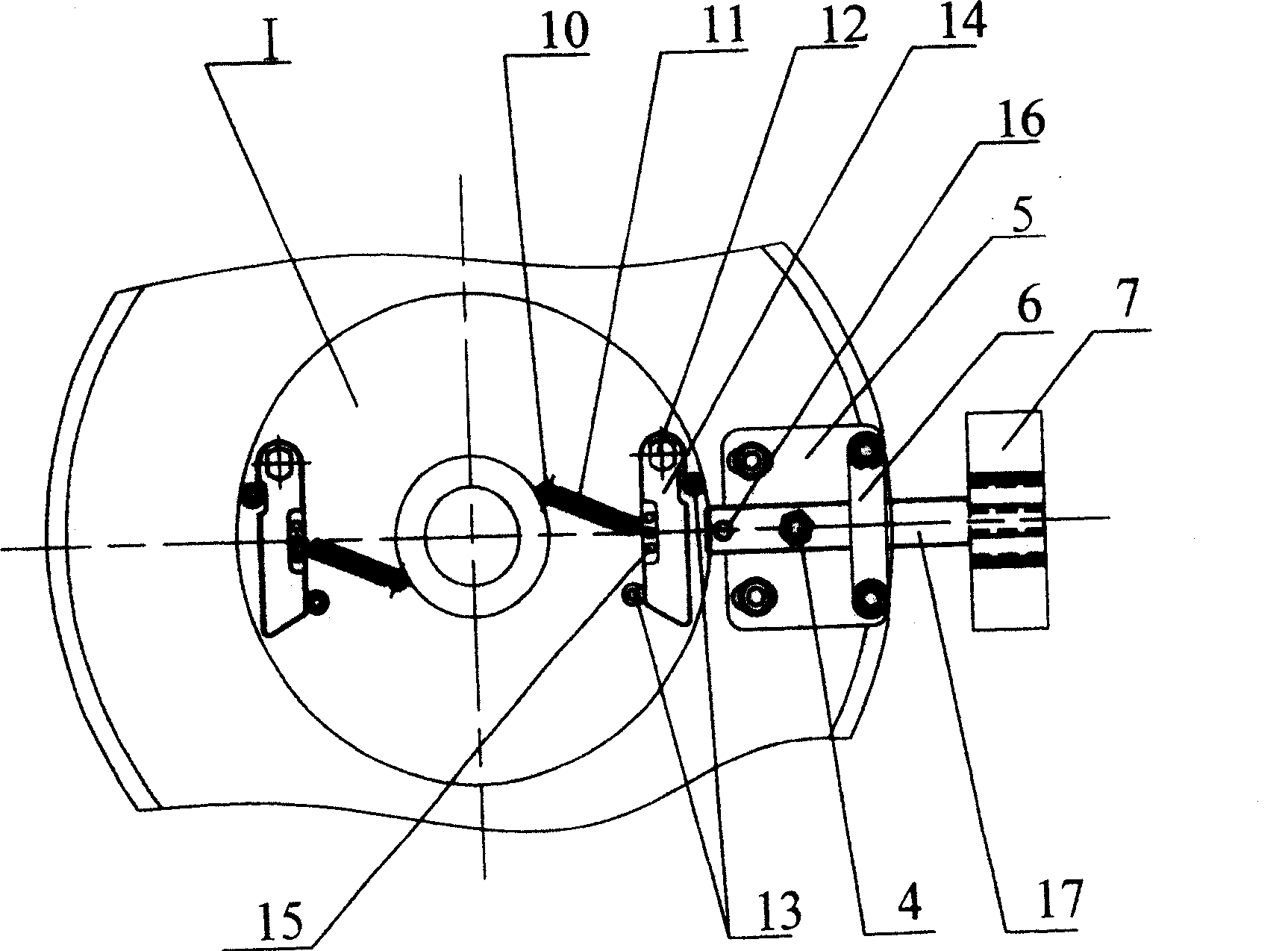

Mechanical overspeed protective device

A mechanical overspeed protector for escalator is composed of a rotation unit consisting of rotating bottom plate, spring, weight and limiting screw, and a control arm unit consisting of drive rod, slide rod and bent rod.

Owner:XIZI OTIS ELEVATOR

Cutting device for novel macromolecule jade slab

InactiveCN110900672AEasy to holdEasy to processMetal working apparatusClassical mechanicsEngineering

The invention relates to the technical field of jade cutting, and discloses a cutting device for a novel macromolecule jade slab. The cutting device comprises a base, wherein a clamping device is arranged at the upper end of the base, supporting plates are symmetrically and fixedly connected with the two sides of the upper end of the base, the upper ends of the two supporting plates are fixedly connected with a cross plate together, a cylinder is fixedly connected with the center of the lower end of the cross plate, the output end of the cylinder is fixedly connected with a moving plate, the lower end of the moving plate is fixedly connected with a cutting machine main body, and a stabilizing mechanism is arranged on the moving plate; the clamping device comprises two sliding slots, two sliding blocks, two channels, two connecting rods, two clamping plates, two threaded holes and screws, the two sliding slots are symmetrically arranged in the base, the two sliding blocks are respectively and slidingly connected with the two sliding slots, and the two channels are respectively formed on the upper end of the base and arranged through the two sliding slots. The cutting device for thenovel macromolecule jade slab can clamp the jade very conveniently, is stable and reliable, and does not generate large cutting errors.

Owner:江苏德丰新建材科技有限公司

Aerial operation car pit protection mechanism and aerial operation car

ActiveCN106315471AMove preciselyImproved ability to resist horizontal lateral forcesSafety devices for lifting equipmentsVehicle fittings for liftingProtection mechanismState switching

The invention discloses an aerial operation car pit protection mechanism and an aerial operation car, relates to the technical field of engineering machinery, and solves the technical problem that a protection plate is difficult to accurately move to a horizontal state and a vertical state in the prior art. The aerial operation car pit protection mechanism comprises a lifting device linkage part, a transmission mechanism and a protection plate; the lifting device linkage part can drive the transmission mechanism to move in the falling process, and the transmission mechanism drives the protection plate to move to the horizontal state for keeping; in the vertical state, the driving device is connected with the transmission mechanism; and when a lifting device of the aerial operation car is ascended, the vertical-state driving device can drive the transmission mechanism to drive the protection plate to move to the vertical state for locking at least in the horizontal direction. The aerial operation car includes the aerial operation car pit protection mechanism. The aerial operation car pit protection mechanism is used for improving the protection plate state switching accuracy and reliability.

Owner:XCMG CONSTR MACHINERY

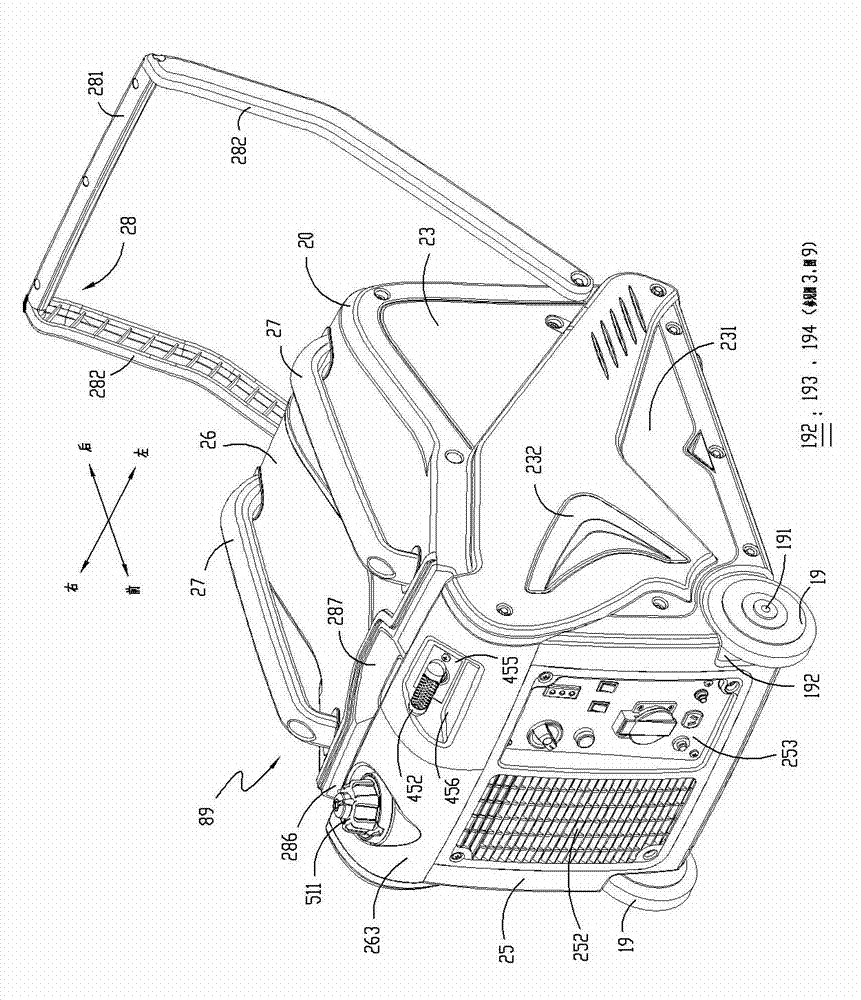

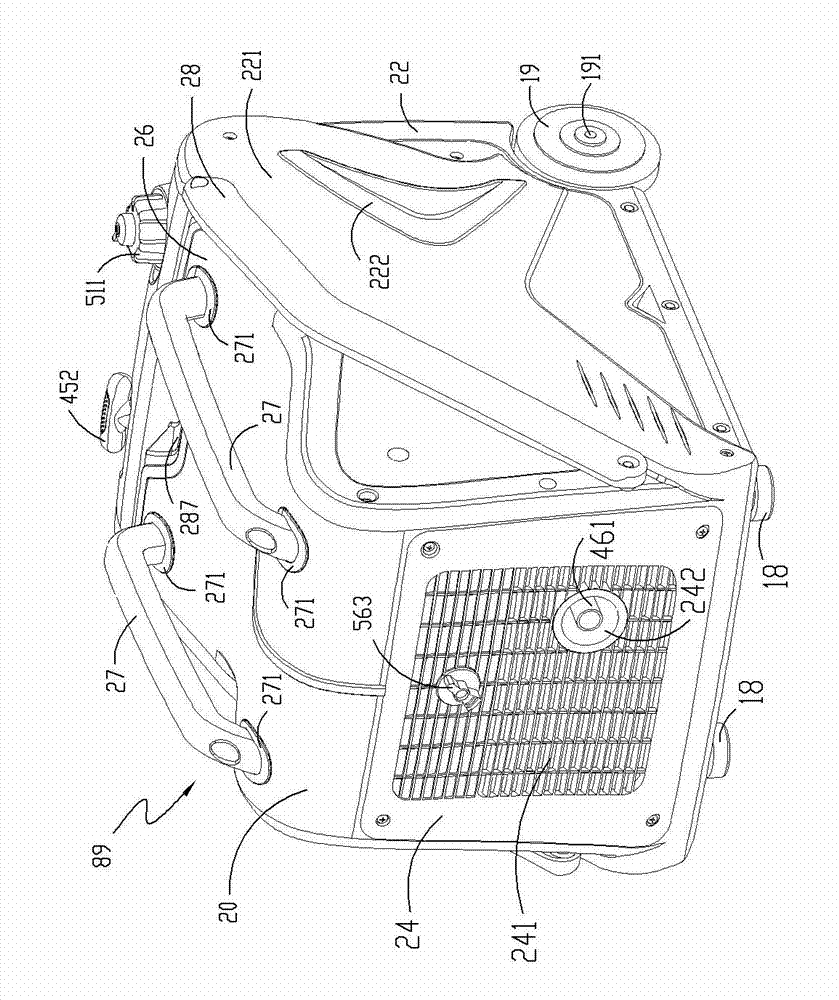

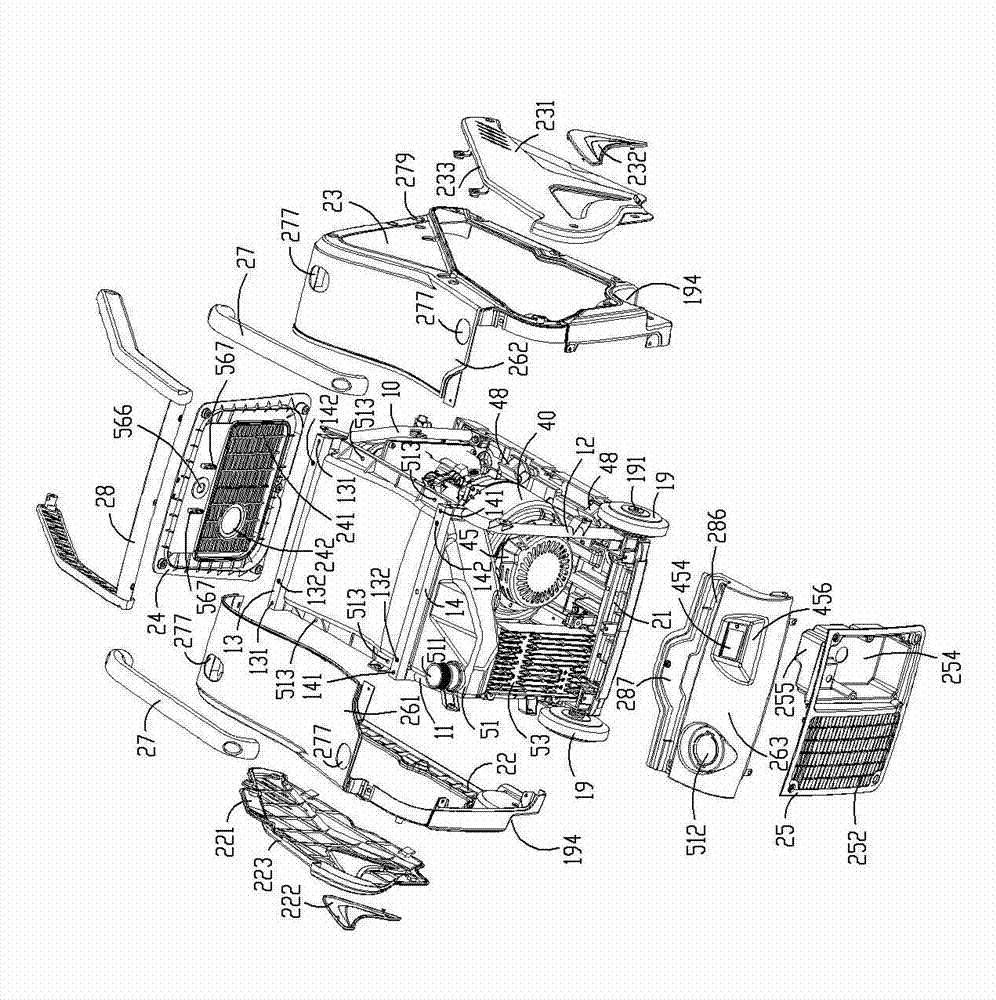

Engine type generator

InactiveCN102733941AGuaranteed StrengthSave height spaceExhaust apparatusMuscle operated startersElectric generatorChassis

The invention aims to provide an engine type generator, which is reliable and convenient for carrying and moving in a labor-saving way and is used for reinforcing an entire machine. The engine type generator comprises an engine, a chassis and a pull rod, wherein the generator is driven by using the engine; two wheels are set as movable pieces of the chassis; the pull rod is used for driving the generator to move in cooperation with the wheels; and a frame is arranged in the chassis.

Owner:CHONGQING RATO POWER

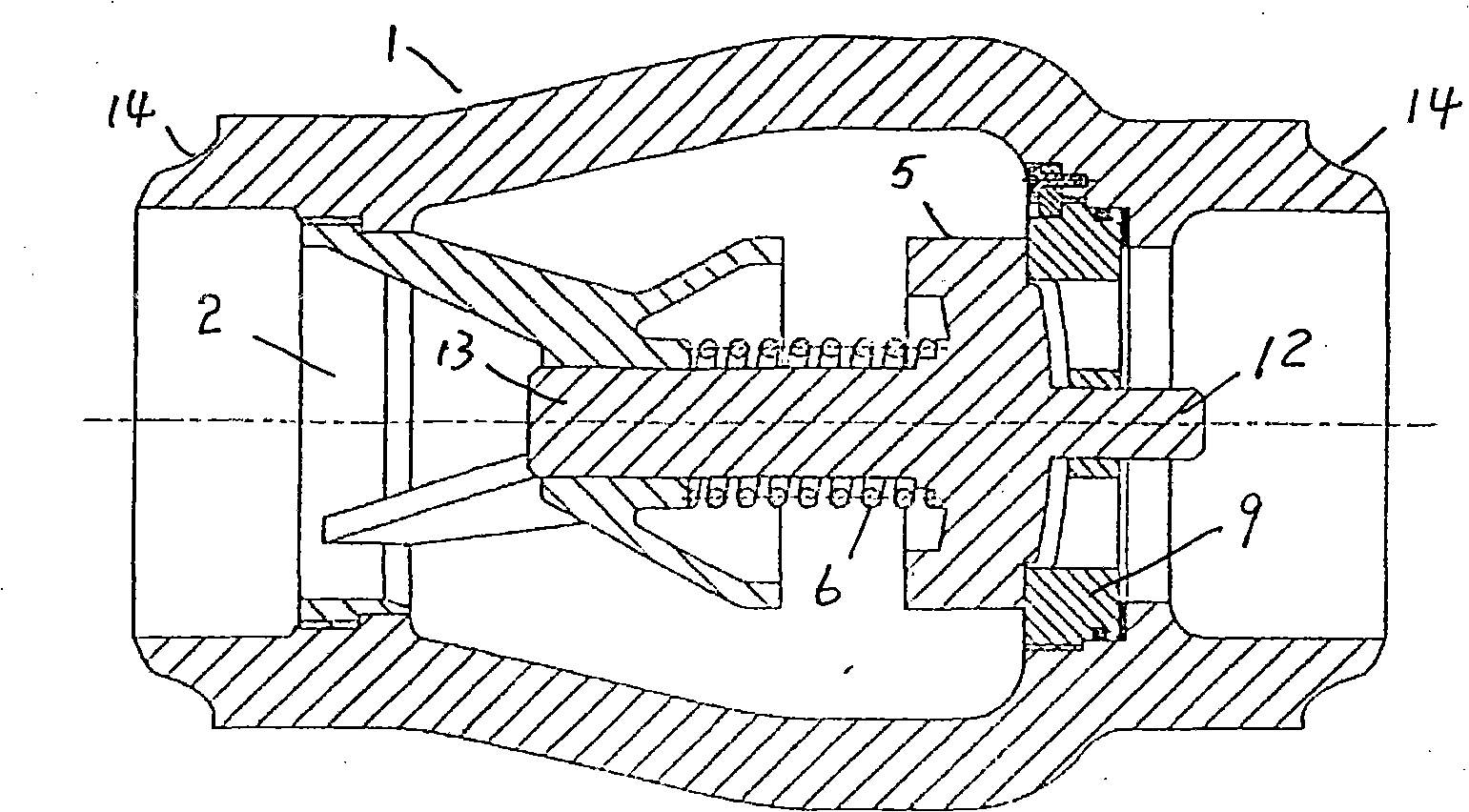

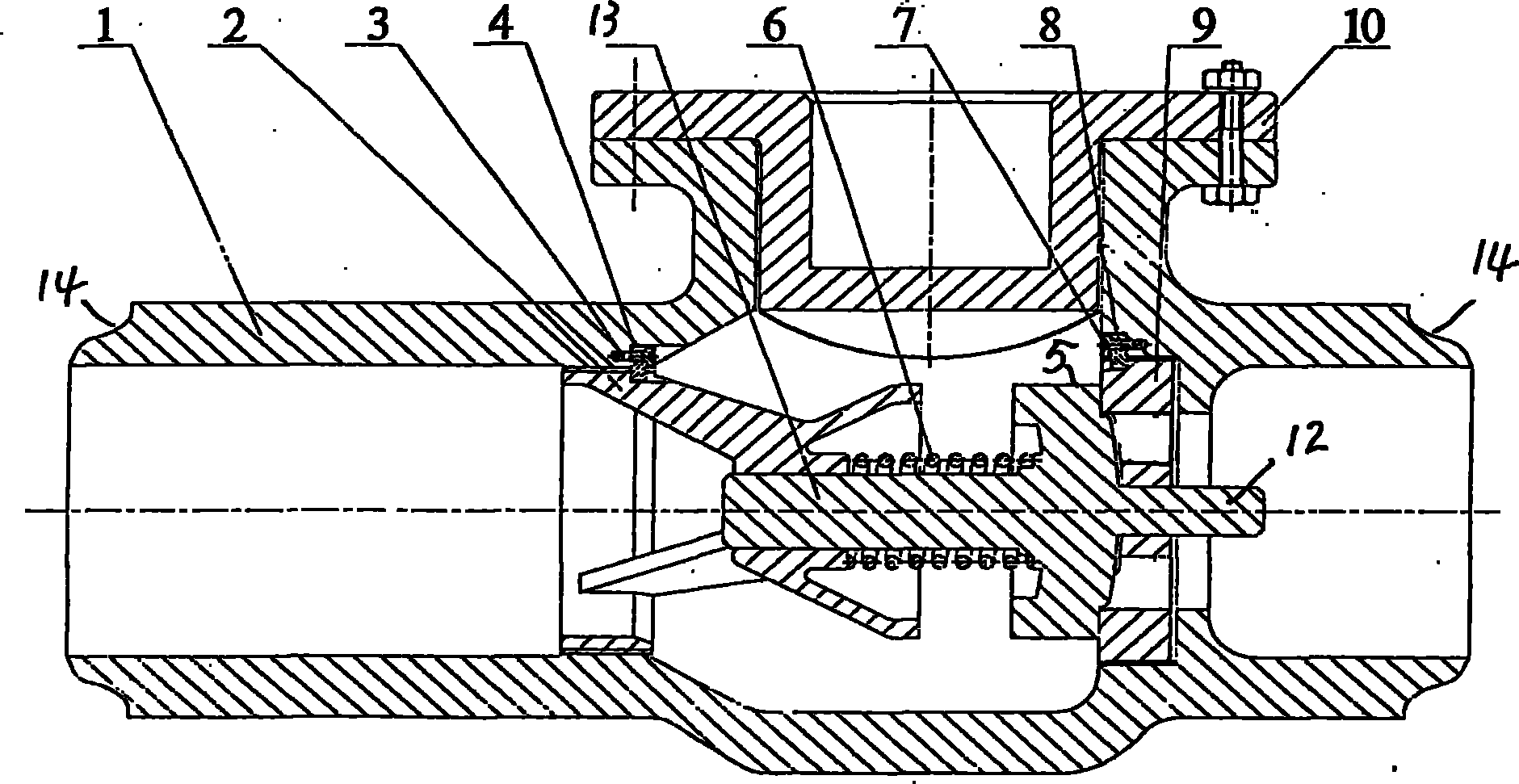

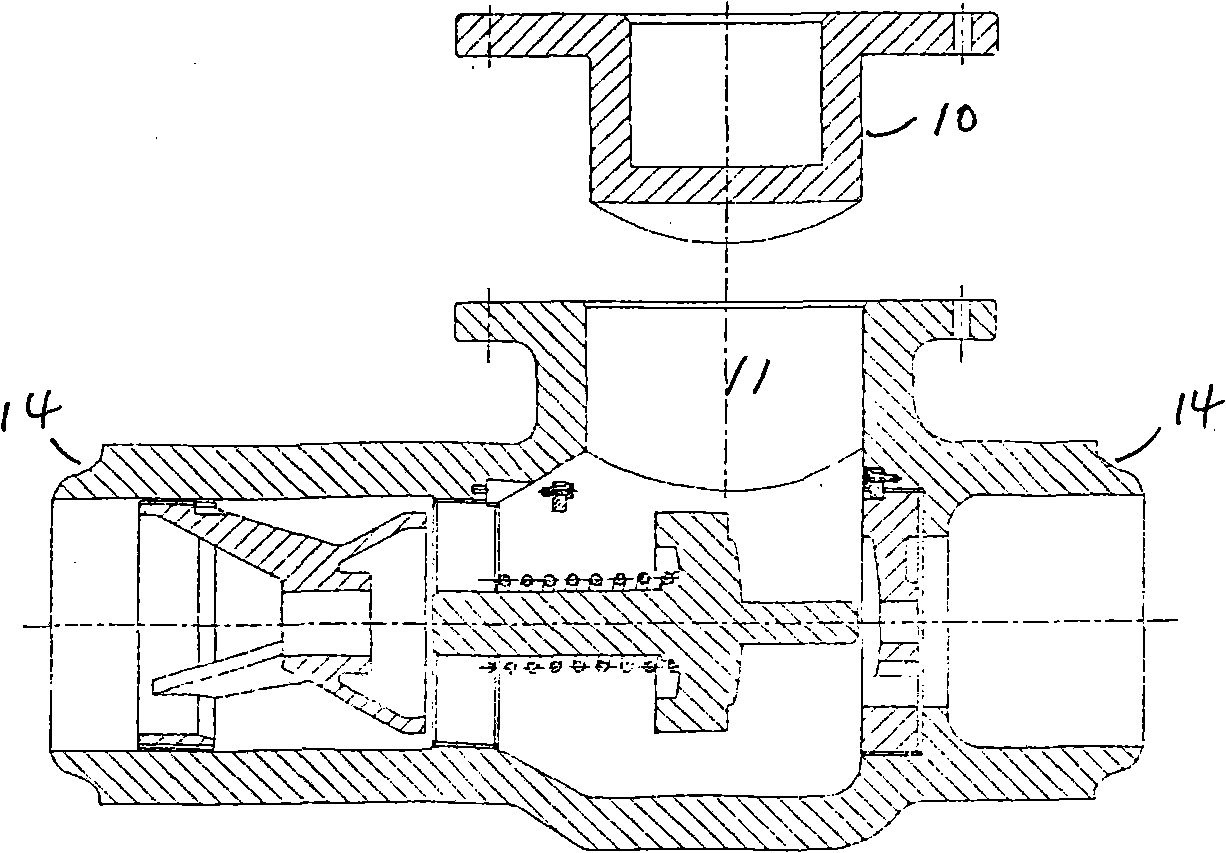

Shuttle-type high-temperature and high-pressure welding check valve

InactiveCN101776168ASimple structureSmall opening and closing resistanceCheck valvesValve housingsCouplingEngineering

The invention relates to a shuttle-type high-temperature and high-pressure welding check valve and solves the problems that the welded check valve cannot be installed at any angle and leakage happens easily. In the shuttle-type high-temperature and high-pressure welding check valve, a middle cavity of a valve body (1) is connected with a coupling at two axial ends, and an outer wall of a port of the coupling is provided with a welding groove (14); the two axial ends of the middle cavity and a connecting passage of the coupling are fixedly connected with a valve bush (2) and a front bearing (9) respectively; a valve flap (5) is in rigid connection with a front shaft (12) and a back shaft (13) which are coaxial; and the front shaft (12) is in movable fit with an axial central hole of the front bearing (9), the back shaft (13) is in movable fit with an axial central hole of the valve bush (2), and the back shaft (13) is sleeved with a spring (6).

Owner:WINJET HIGH TECH INVESTMENT BEIJING

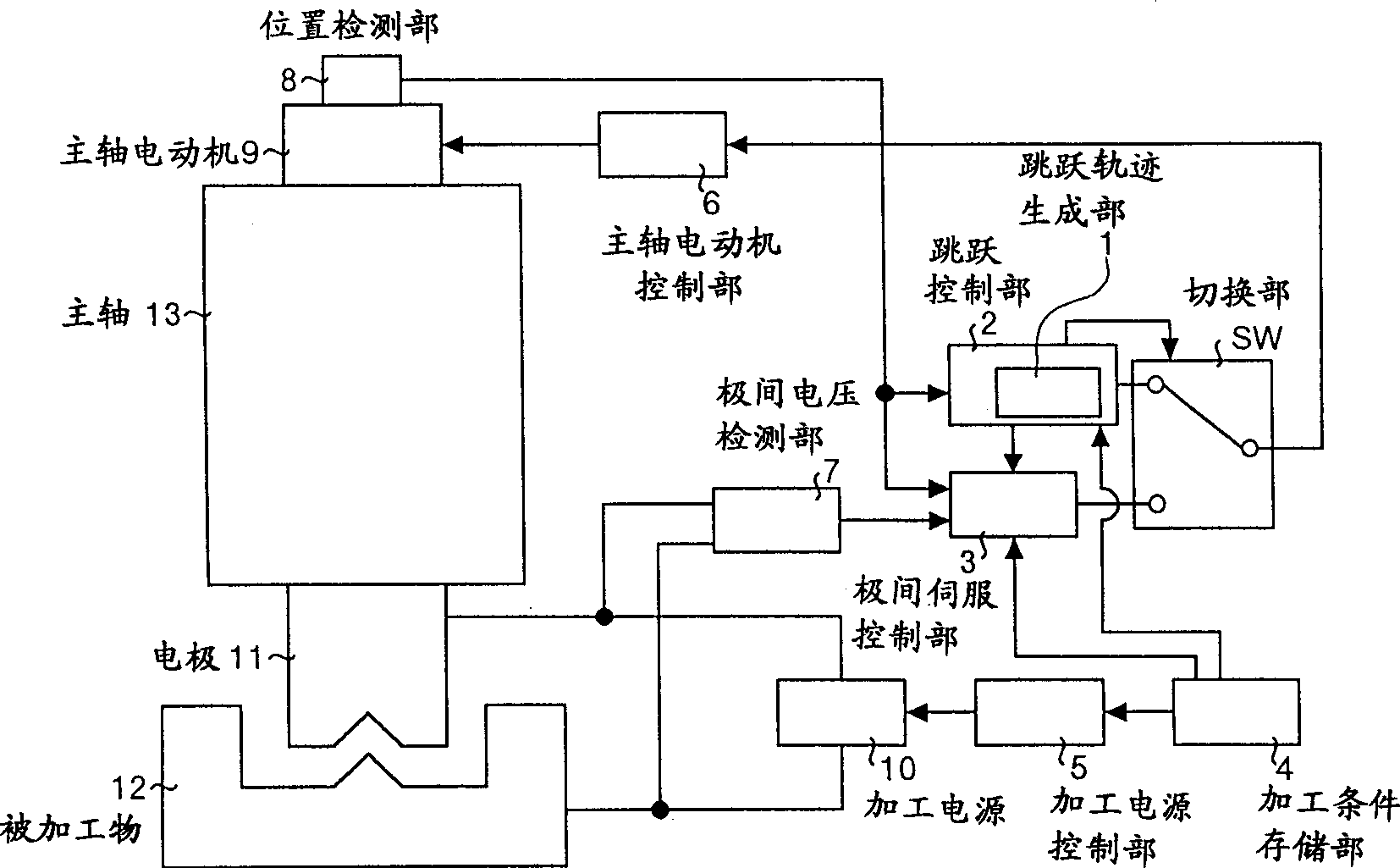

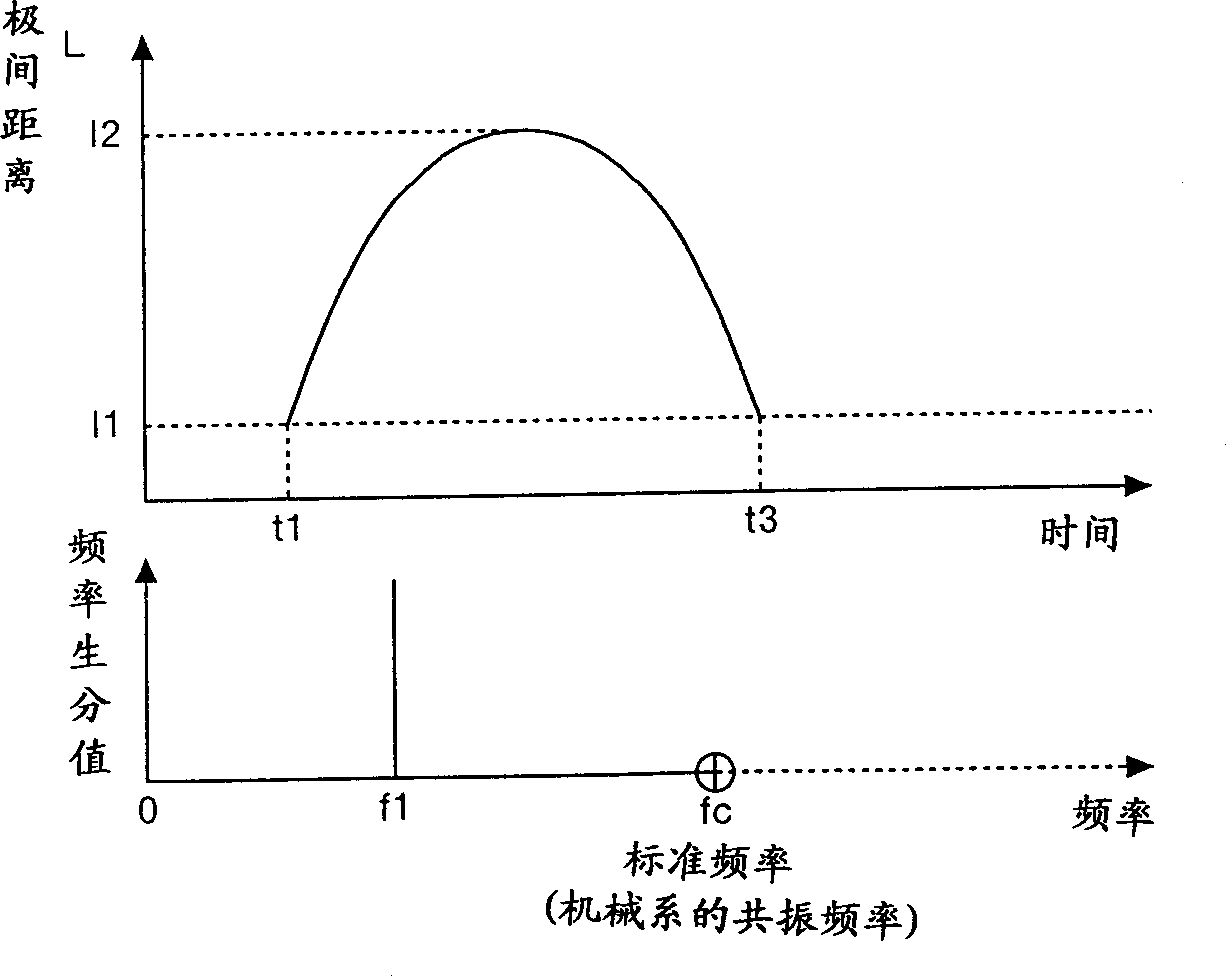

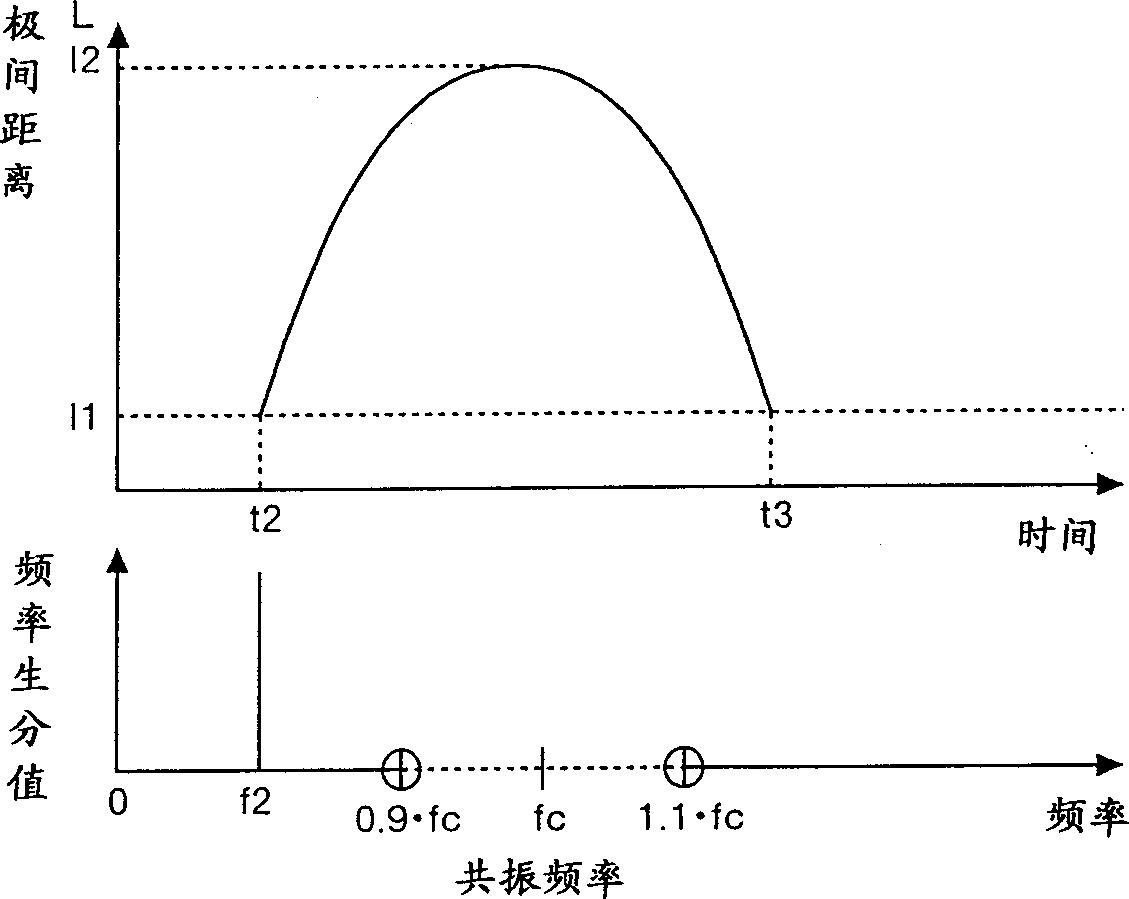

Electric discharge machine and method of electric discharge machining

InactiveCN1355735AWon't vibrateReduce deceleration distanceSpecial service for subscribersElectric circuitsElectric dischargeElectrical discharge machining

An electric discharge machine is provided with a gap servo control unit for controlling the gap distance between an electrode and a workpiece while applying a prescribed voltage between the electrode and the workpiece, and a jump control unit for controlling a jump that allows the gap distance to be large temporally for a prescribed time or correspondingly to the machined state. The jump control unit is provided with a jump locus generating section for generating a smooth command locus having a frequency component within a prescribed frequency region not greater than the prescribed frequency or less than the prescribed frequency. The jump control unit controls a jump by using the smooth command locus generated by the jump locus generating section.

Owner:MITSUBISHI ELECTRIC CORP

Grinding machine facilitating discharging

PendingCN107497568ASimple unloading operationReduce the use of manpowerGrain treatmentsEngineeringMechanical engineering

The invention provides a grinding machine facilitating discharging. The grinding machine comprises an outer shell; a motor box is welded to one side of the top of the outer shell; a servo motor is fixedly mounted in the motor box; one end of a rotary shaft of the servo motor sequentially penetrates through the motor box and the outer shell, extends into the outer shell and is in transmission connection with a driving gear; a driven gear engaged with the driving gear is arranged on one side of the driving gear; an electric pushing rod is fixedly mounted at the bottom of the driven gear; a grinding disc is fixedly mounted at the bottom end of the electric pushing rod; a side seal plate is arranged at a notch of one side of the outer shell; a clamping block is welded to the left side of the side seal plate; and one side of the bottom plate of the outer shell is clamped and connected with a clamping block through a formed clamping groove. According to the grinding machine facilitating discharging, by arranging the side seal plate to be clamped and connected with the outer shell, dismounting of the side seal plate is facilitated, a grinding box can be taken out of the outer shell conveniently, thus, discharging operation is simpler, labor force is saved, and time consumed by discharging is reduced.

Owner:FORTURE TOOLS CO LTD

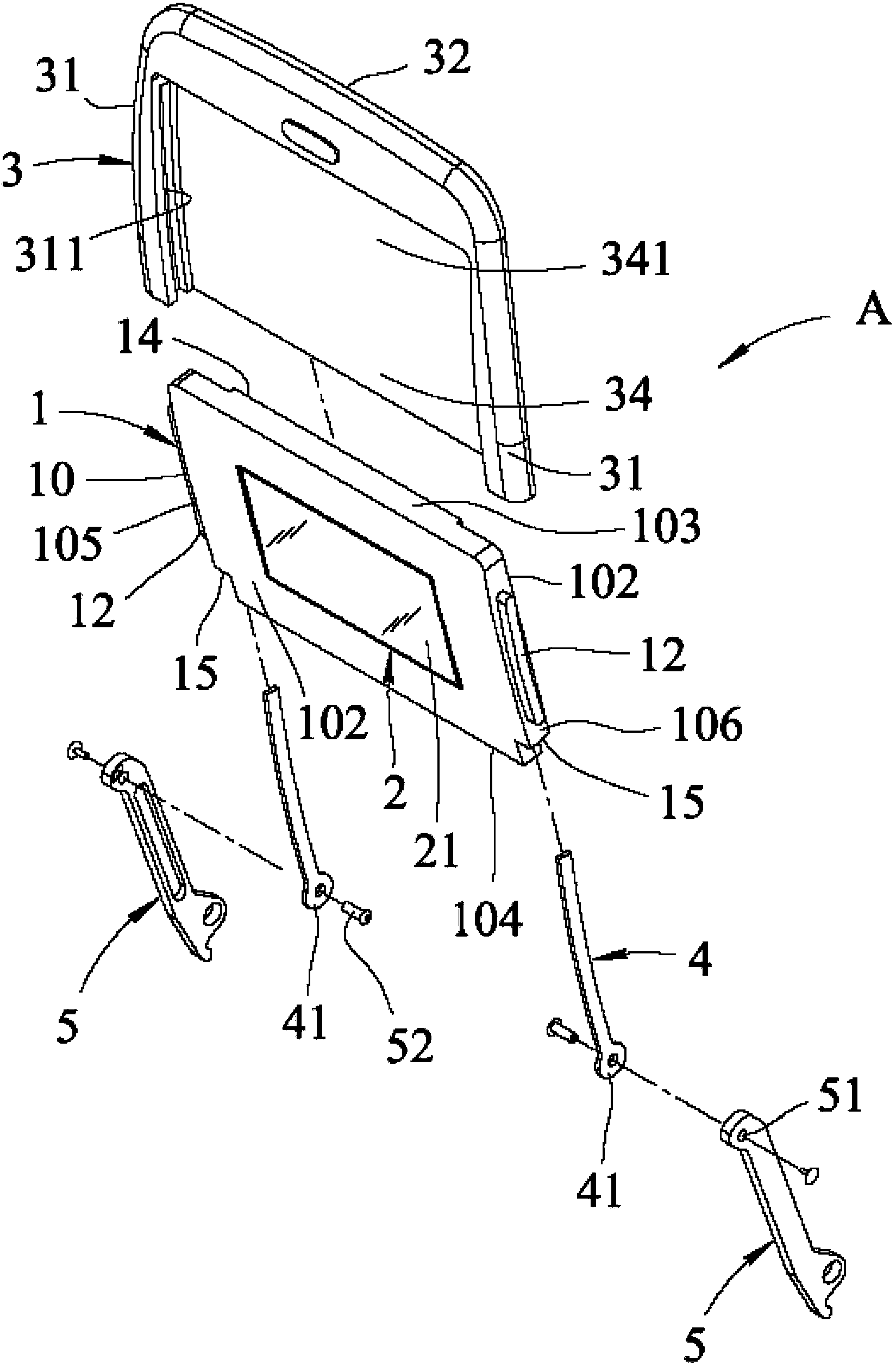

Foldable handle

ActiveCN102998882AFirmly connectedIncrease rotational torqueCamera body detailsEngineeringMechanical engineering

The invention discloses a foldable handle. The handle comprises a handle rod, a locking rod which is connected to the handle rod through a rotary shaft in a rotary mode, a locking structure which is used for locking the handle rod and the locking rod which are in the linear connection state and an axial telescopic structure, wherein the axial telescopic structure comprises an axial containing cavity which is formed at the connection end of the handle rod, a chute which extends axially and in which a rotary shaft end is inserted is formed on the side wall of the containing cavity, the connection end of the locking rod extends into the containing cavity to slide back and forth, the shape of the end of the containing cavity is matched to the locking rod which rotates and is folded round the rotary shaft, the locking structure comprises a stopping through hole which is formed on the side wall of the handle rod, a stopping shaft pin hole formed on the locking rod, a stopping pin shaft and a bias part, and the stopping pin shaft and the bias part are arranged in the stopping pin shaft hole. The handle can be folded and can be fixed to the linear shape, the operation is facilitated and the touch is comfortable.

Owner:GUANGDONG SIRUI OPTICAL CO LTD

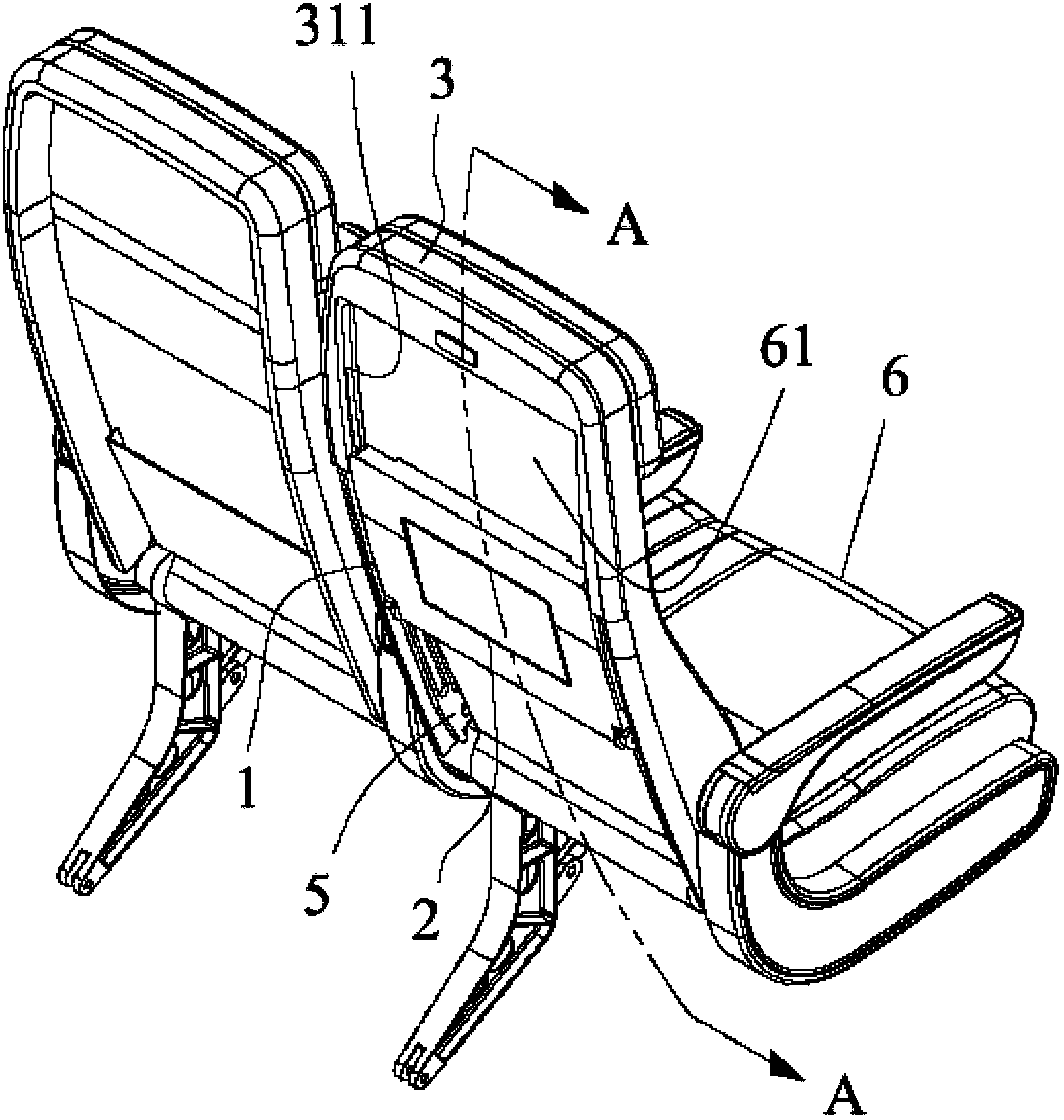

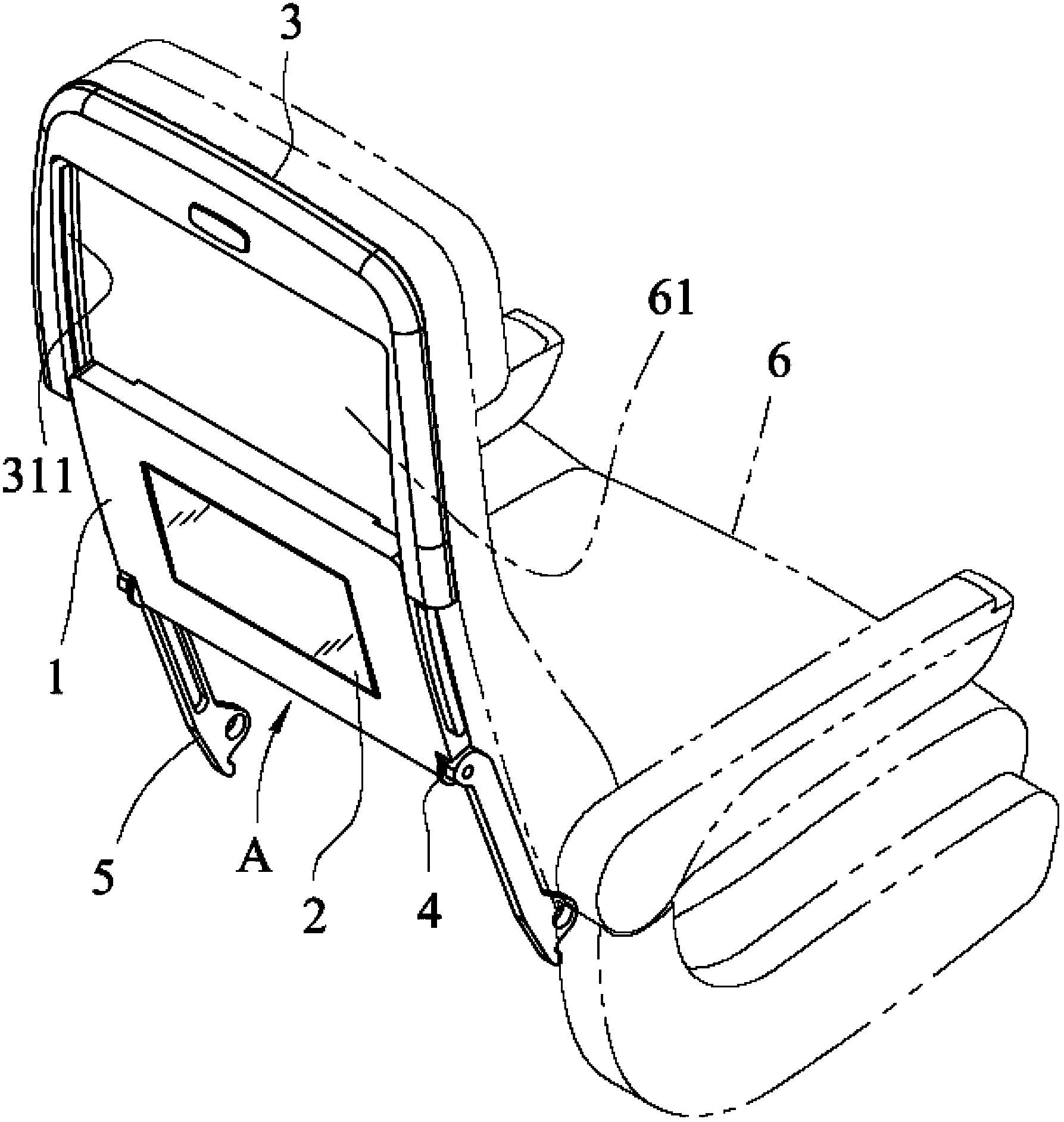

Dining table device with chair back

InactiveCN103661951ASimplify assembly procedures and partsSimplify the manufacturing processSeating arrangementsTablet computerDisplay device

The invention provides a dining table device with a chair back. The dining table device with the chair back is arranged in a table plate of a chair back of a vehicle, and a display device is arranged on the bottom end face in the table plate, and the display device can be a tablet computer or an air amusement device or other plane electronic display devices. The back side edge of the table plate is arranged on two first guide devices in an inserting mode, the bottom end of each first guide device is arranged on a supporting rod arranged on the back face of a chair in a pivoted mode so that a passenger in the back can turn the table plate to a horizontal position and place meals or books, newspapers and magazines or other objects. The left side edge and the right side edge of the table plate are respectively provided with a second guide device, the second guide devices can slide, be folded in storage seat bodies and enable the table plate to be fixed and folded on the chair back, and therefore the passenger in the back can watch amusement programs in the display device to pass long-distance traveling time.

Owner:SUPERALLOY IND

Device for correcting flexibly-deformed rotary roller and provided with balancing device

The invention discloses a device for correcting a flexibly-deformed rotary roller and provided with a balancing device. The device comprises a barrel, wherein the outer wall of the barrel is provided with a hollow ejection rod in the peripheral direction, the ejection rod is connected with a supporting rod through threads, and the end of the supporting rod is connected with an arc-shaped supporting plate. An oil pump and an oil tank are fixedly installed in the barrel, an inlet of the oil pump is communicated with the oil tank, an outlet of the oil pump is connected with an inlet of a flow divider valve, piston cylinder bodies identical to outlets of the flow divider valve in number are evenly installed on the outer wall of the barrel in the peripheral direction, liquid inlets of the piston cylinder bodies are communicated with the outlets of the flow divider valve, liquid outlets of the piston cylinder bodies are communicated with the oil tank, piston rods of the piston cylinder bodies are connected with supporting rings, pressure sensors are installed on the faces of the supporting rings, in contact with the roller, and installing grooves for balancing rods to be installed are further formed in the supporting rings. The device can ensure fitting stability between the balancing rods and the inner wall of the roller, and the problem that the correction accuracy is influenced by centrifugal force is eliminated.

Owner:JIANGSU JINHANG MACHINERY MFG CO LTD

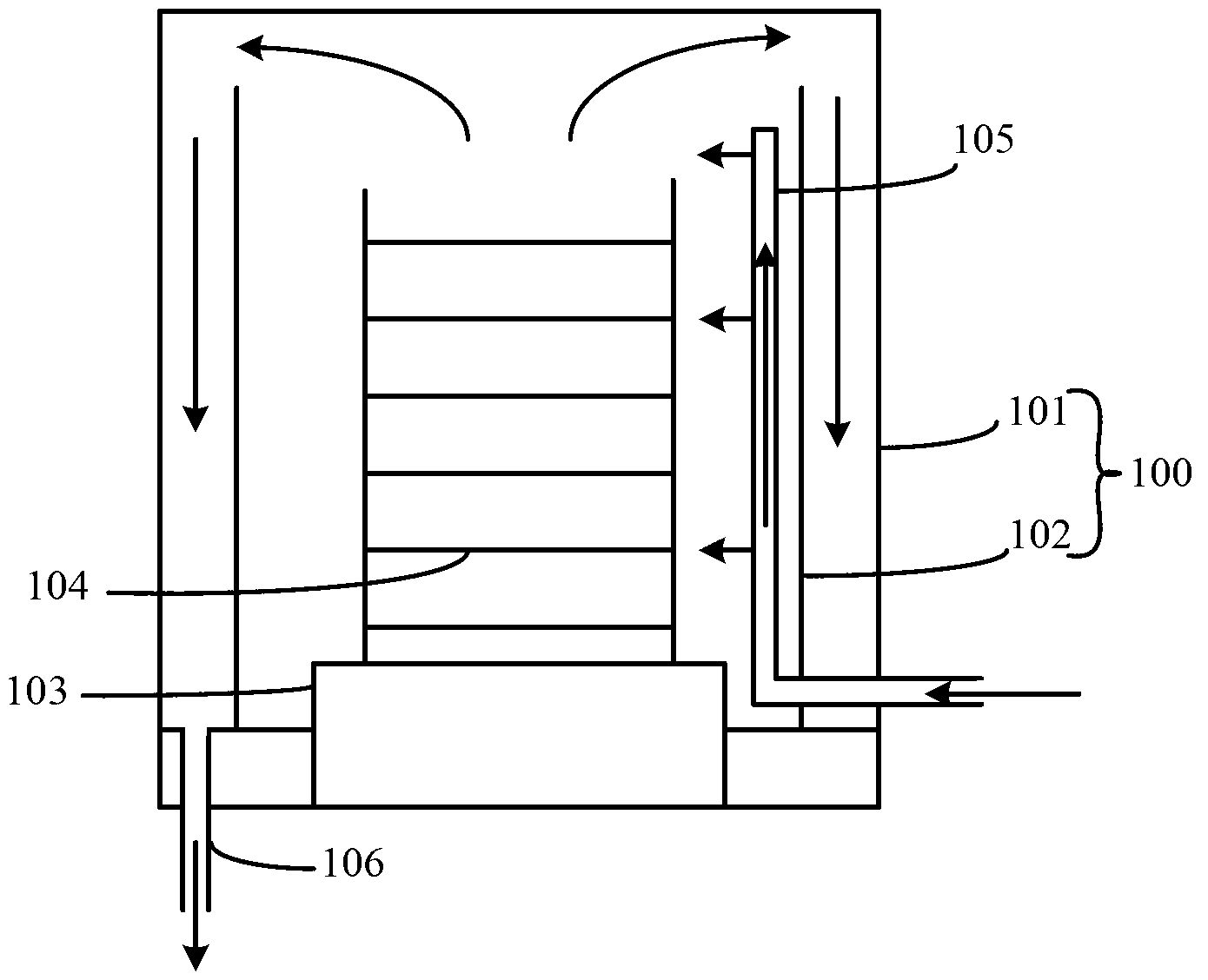

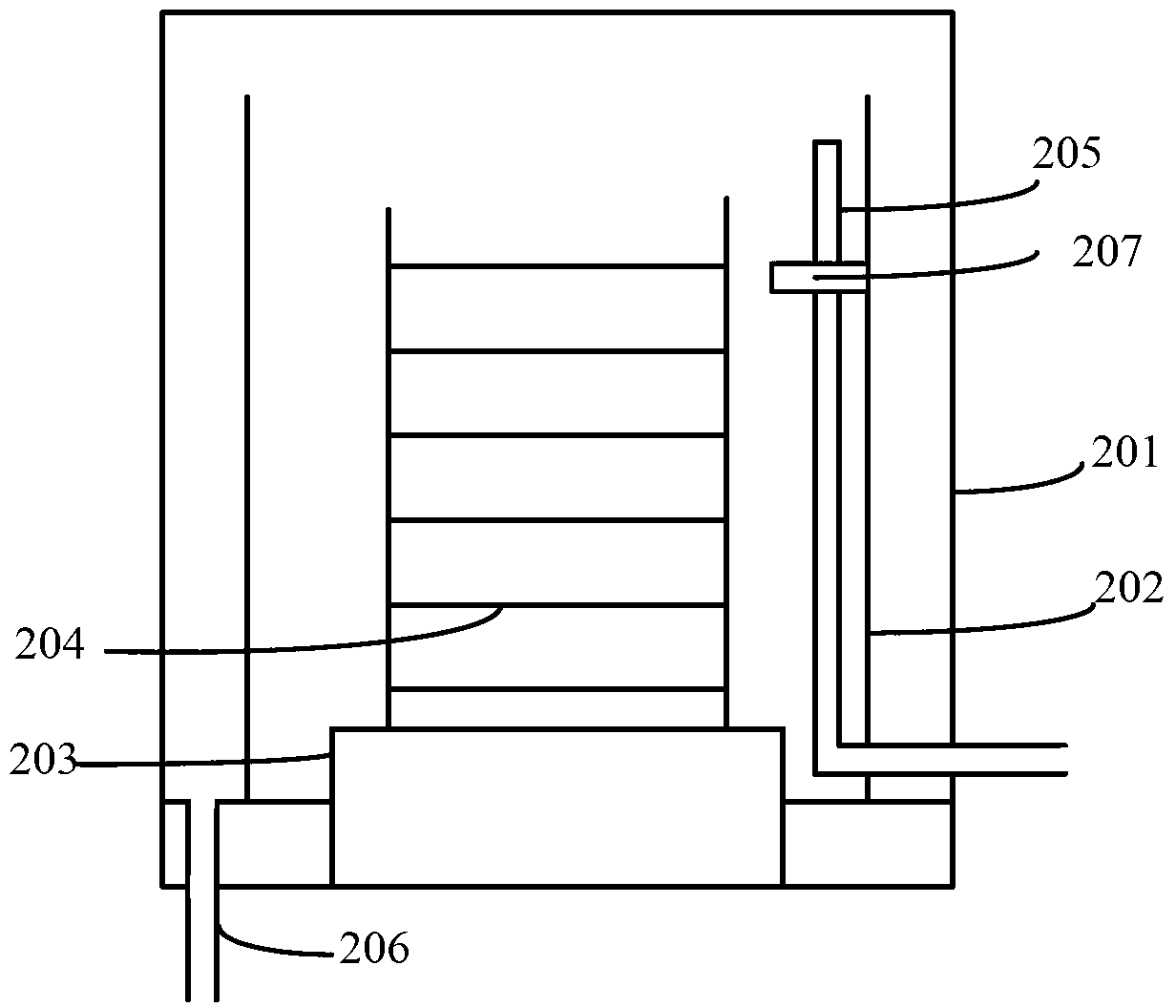

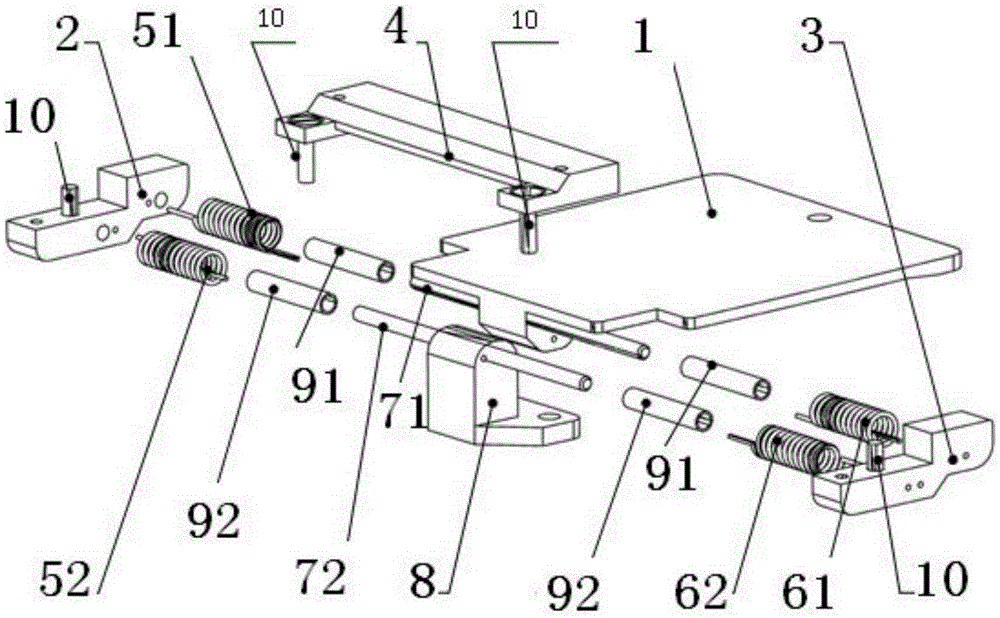

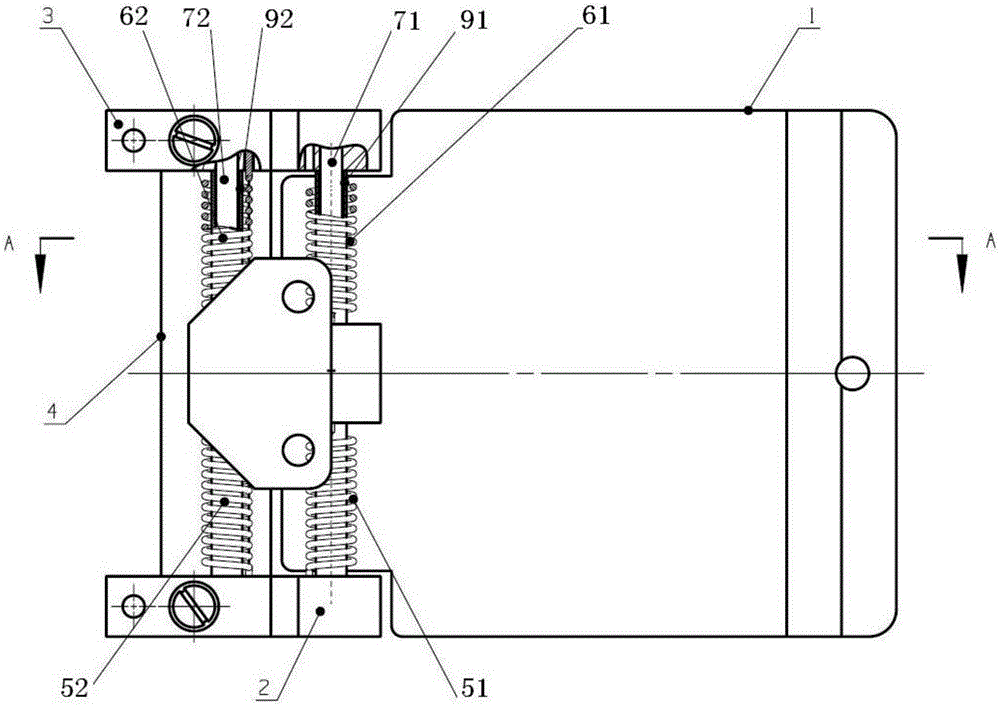

Protective cover mechanism of separation socket

ActiveCN105244670AAvoid excessive frictionOpen smoothlyCoupling device detailsSystem structureCruise missile

The invention, which belongs to the field of the cruise missile system structure, relates to a protective cover mechanism of a separation socket, wherein the protective cover mechanism is suitable for protecting a separation socket on a cruise missile with a small size and a planar upper surface of the cruise missile body. After emission and separation of a missile, a separation plug arranged on an emission carrier is separated from a separation socket of a missile body; and automatic springback of the protective cover mechanism is carried out and thus the separation socket is protected. The protective cover mechanism is fixed on the missile body by mounting holes of a support (8). Besides, the protective cover mechanism includes a first-level torsional spring set (100) and a second-level torsional spring set (200). According to the technical scheme, the single-fan-shaped protective cover mechanism with the largest starting angle of 170 degrees is provided and is applied to a cruise missile with a small size and a planar upper surface of the cruise missile body to protec the separation socket.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

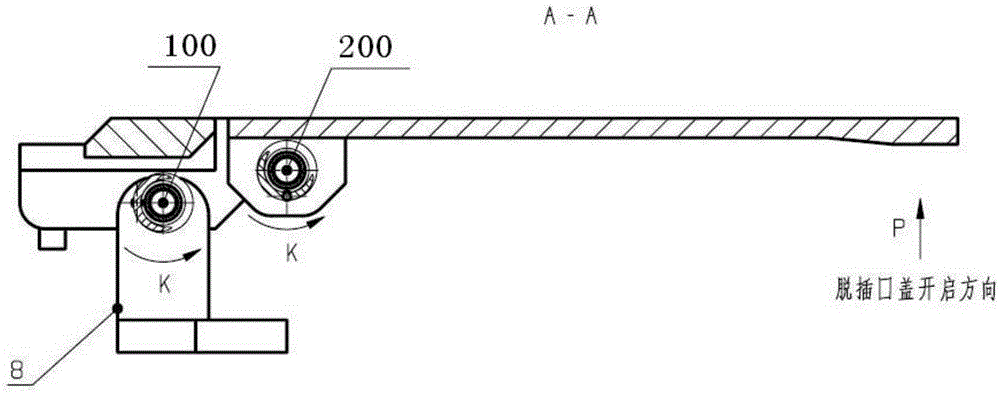

Waste sterile and crushing mechanism for disposable syringes

ActiveCN108816388AEasily brokenAvoid cloggingMedical waste disposalGrain treatmentsDisinfectantEngineering

The invention relates to the technical field of environmental protection equipment, in particular to a waste sterile and crushing mechanism for disposable syringes. The technical problems that the efficiency of a disposable syringe crushing device is low, the solid-liquid separation is inconvenient, and the continuous delivery of the disinfectant is inconvenient are solved. The waste sterile and crushing mechanism for the disposable syringes includes a box body; supporting legs are fixedly connected with four right angles at the bottom of the box body, the top of the inner wall of the box bodyis fixedly connected with a driving mechanism, and a pretreatment device is welded to one side of the inner wall of the box body, the output end of the driving mechanism is movably connected with theoutput end of the pretreatment device. In the operating process of the crushing mechanism, the syringes can be crushed through crushing teeth arranged on a crushing roller, a collection box arrangedat the bottom of the crushing roller conveniently collects the crushed syringe debris, and the collection box can be conveniently removed from the box body.

Owner:喀什地区第一人民医院 +2

Intercooler pipeline fixing structure

ActiveCN105298627AEven by forceWon't vibrateInternal combustion piston enginesNon-rotating vibration suppressionIntercoolerCushion

An intercooler pipeline fixing structure comprises an intercooler pipeline support, an engine fixing support, a bolt, a steel sleeve and a soft cushion. The steel sleeve is provided with a flange. The soft cushion is provided with an upper flange, a lower flange and a first annular groove located between the upper flange and the lower flange. The lower flange is provided with a plurality of concentric second annular grooves with openings located in the bottom face. The height of the soft cushion is larger than the height between the lower surface of the flange of the steel sleeve and the bottom end of the soft cushion. The first annular groove of the soft cushion is clamped in the intercooler pipeline support. The steel sleeve penetrates the soft cushion, and the flange is pressed on the top face of the soft cushion. The bolt penetrates the steel sleeve and the engine fixing support, then the bolt is fastened through a nut till the bottom end of the steel sleeve is supported on the engine fixing support, the lower flange elastically deforms at the second annular grooves, and the bottoms of the second annular grooves are located above the bottom end of the steel sleeve. The vibration damping and stability of fixing of an intercooler pipeline are combined.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

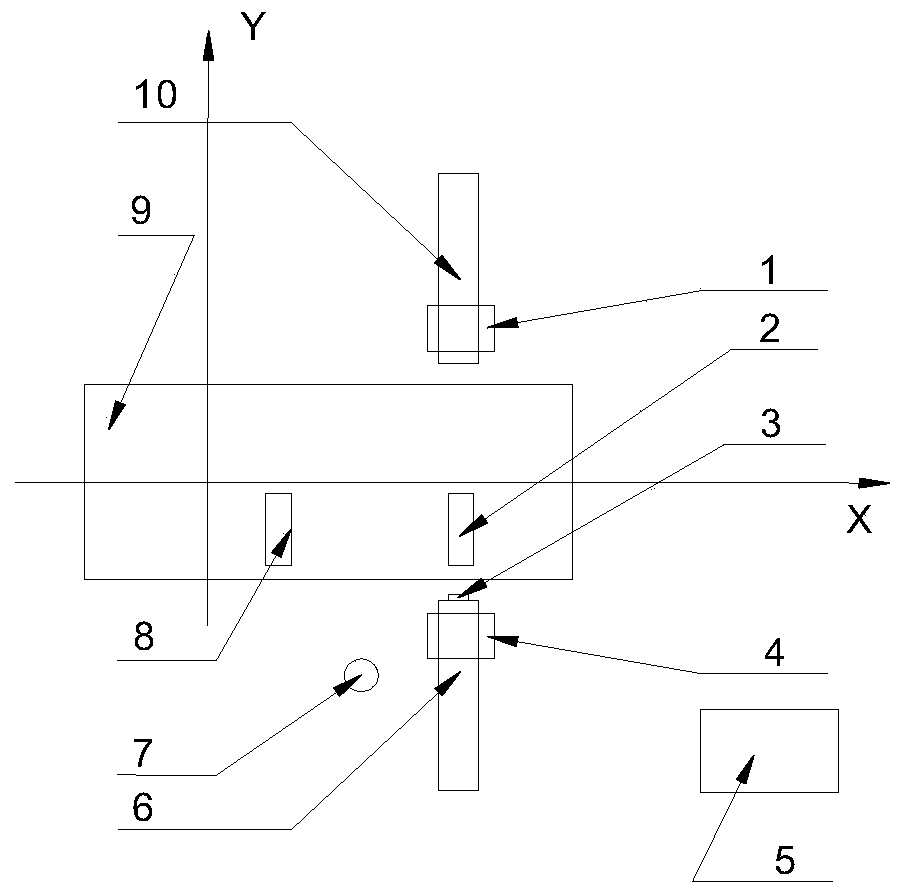

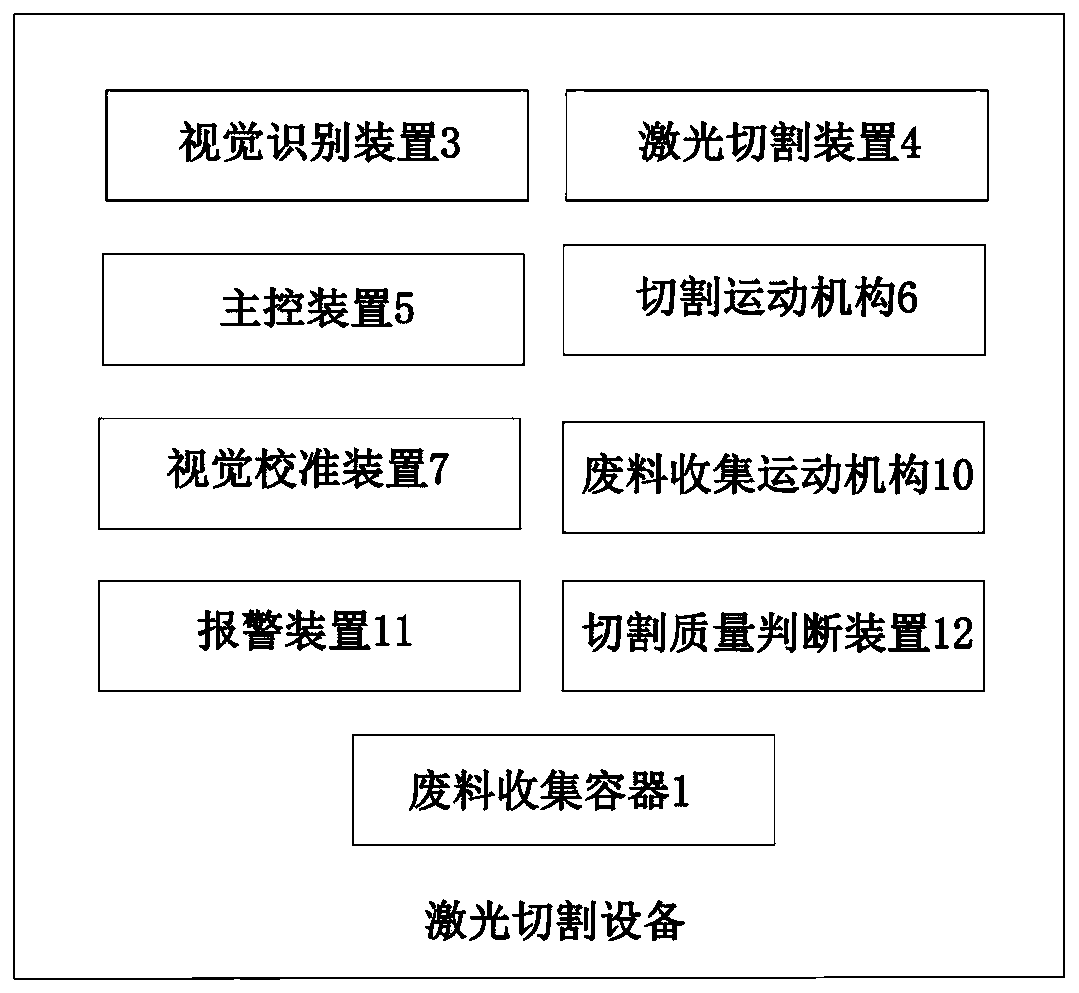

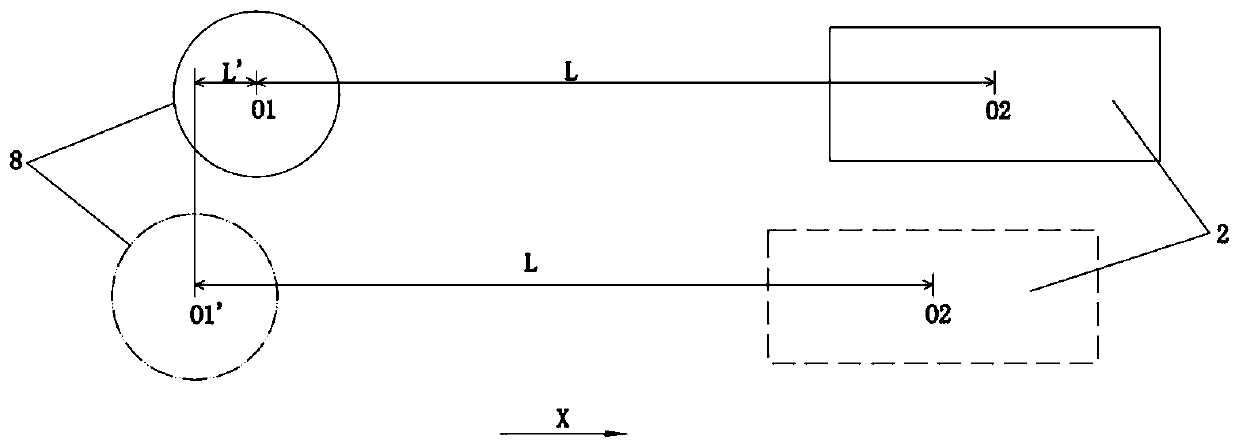

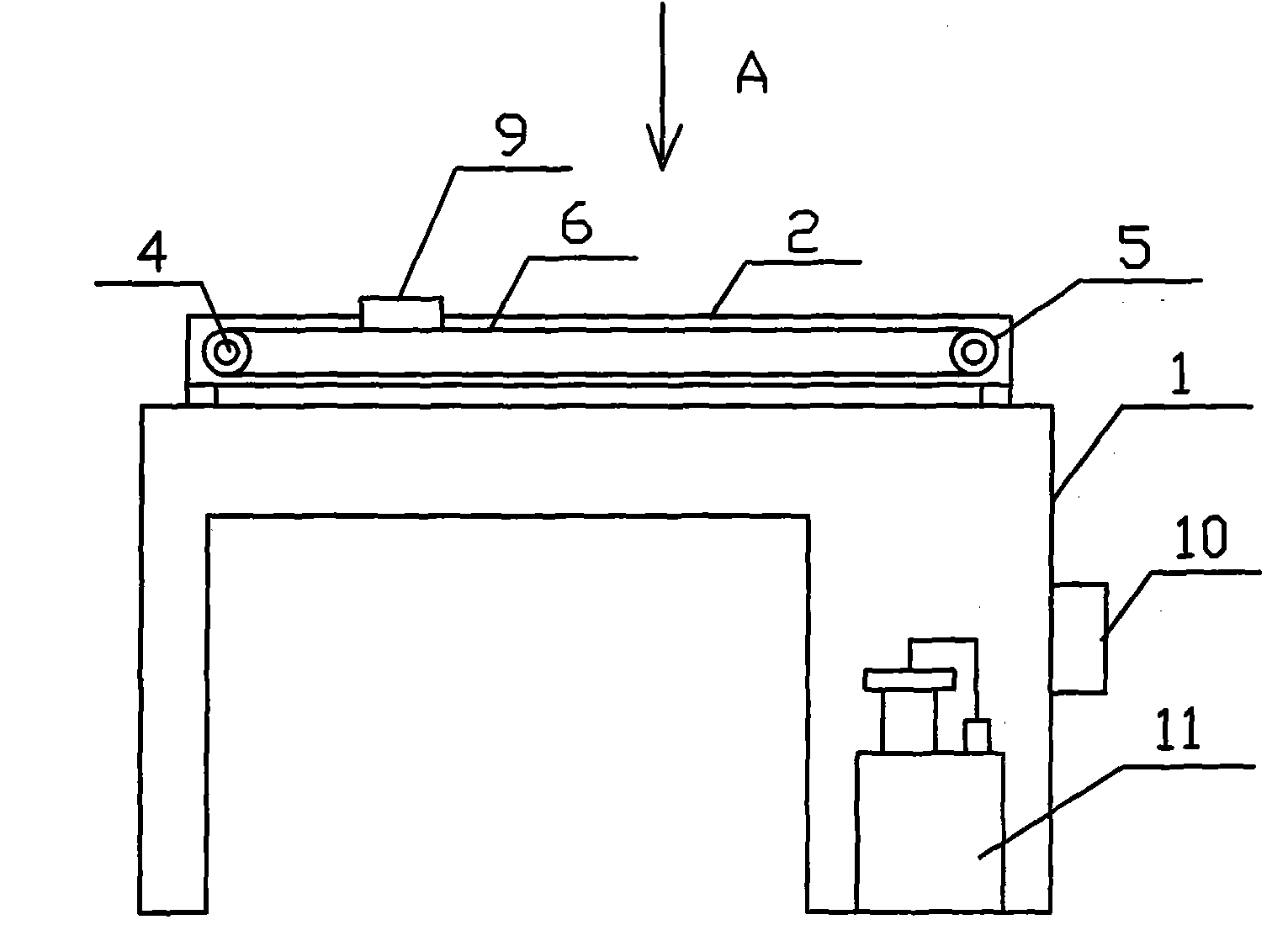

Laser cutting device and laser cutting work method

ActiveCN110711953AMeet cutting needsWon't vibrateLaser beam welding apparatusLaser cuttingVisual recognition

The invention relates to a laser cutting device and a laser cutting work method. The laser cutting device comprises a cutting movement mechanism, a laser cutting device, a visual recognition device and a master control device. The laser cutting device is connected with the cutting movement mechanism and generates lasers used for cutting. The visual recognition device is connected with the cuttingmovement mechanism and is used for obtaining image information of a specific structure on a vehicle body. The master control device is connected with the cutting movement device, the laser cutting device and the visual recognition device and is used for obtaining vehicle model information and controlling the laser cutting device to generate lasers used for cutting. The laser cutting device and thelaser cutting method are suitable for production of various vehicle models, the flexible degree is high, in addition, a cutting area can be accurately positioned, the machining precision is improved,the completion quality cutting work is detected online, and it is ensured that subsequent processes are implemented smoothly.

Owner:WUHAN FARLEYLASERLAB CUTTING SYST ENG

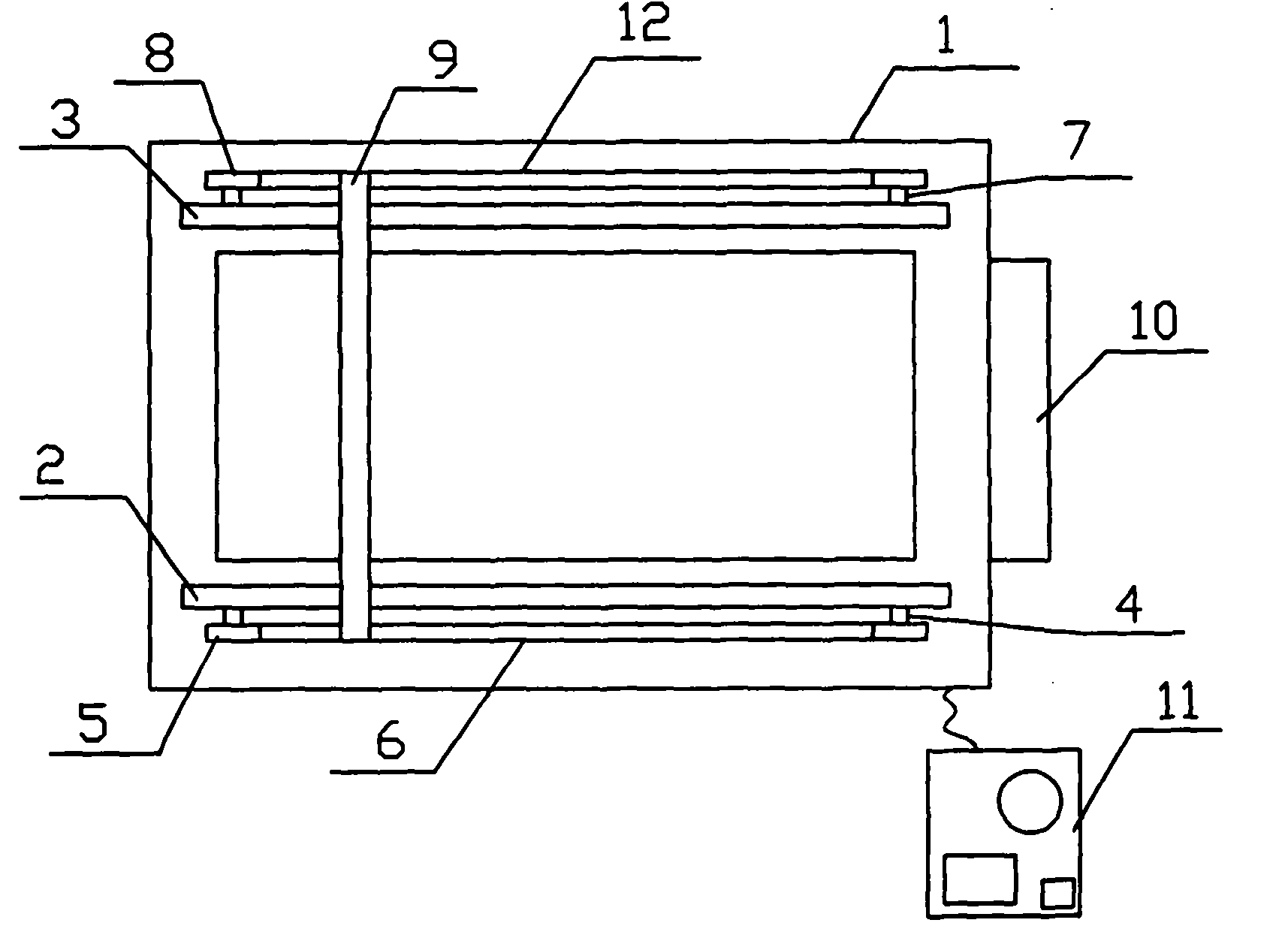

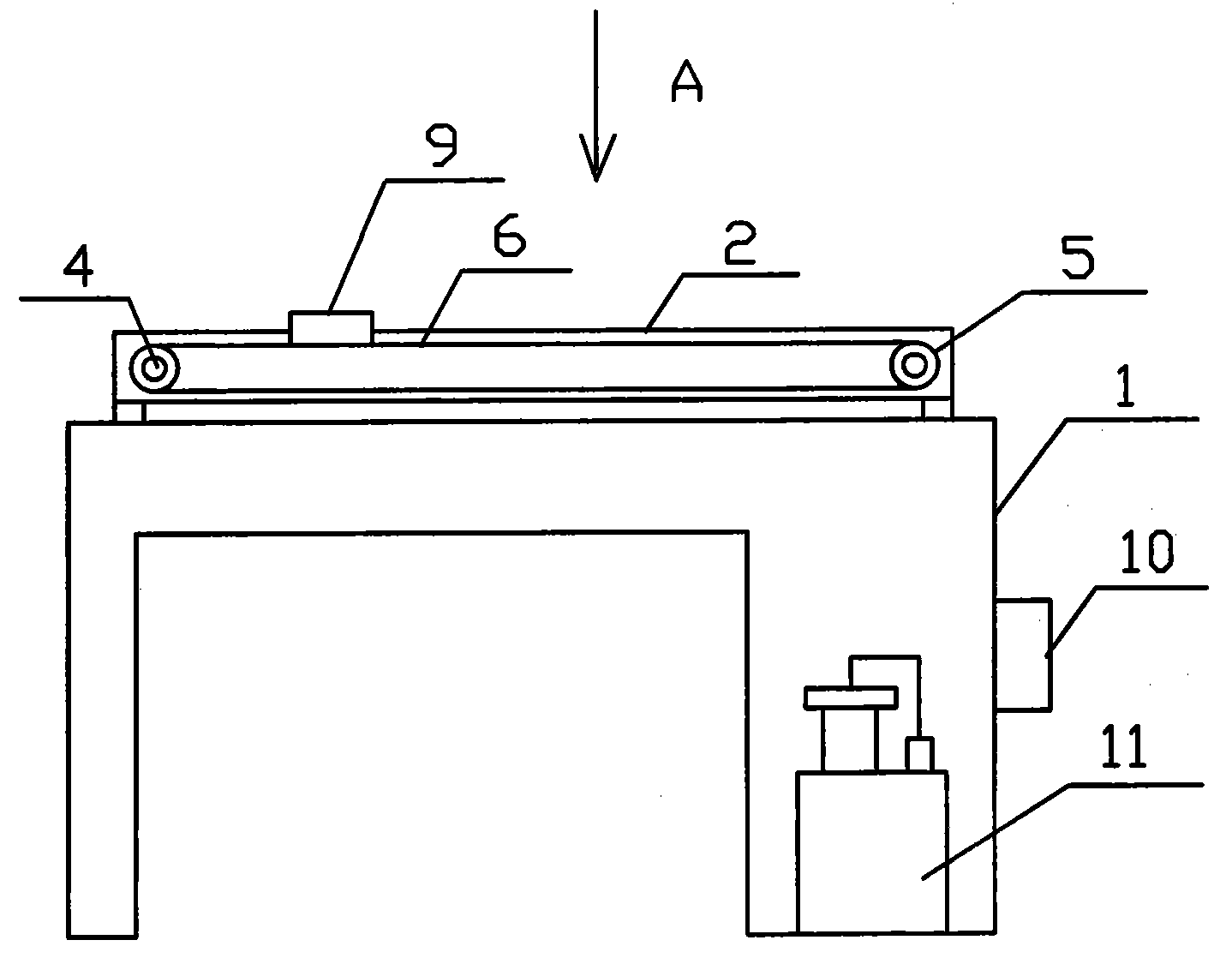

Paint spraying system

The invention discloses a paint spraying system which comprises a working chamber, wherein the top of the working chamber is transversely provided with a through groove; the front part of the through groove on the working chamber is transversely provided with a first track, and the rear part of the through groove on the working chamber is transversely provided with a second track; both ends of the first track and the second track are connected with each other through connecting pieces; the left and right ends of the front part of the first track are respectively connected with a first gear through a first shaft, and the two first gears are connected by a first chain; the left and right ends of the rear part of the second track are respectively connected with a second gear through a second shaft, and the two second gears are connected by a second chain; a movable plate is arranged between the upper surfaces of the first track and the second track; both ends of the movable plate are respectively connected with the first chain and the second chain; the lower part of the movable plate is connected with a spray head; one side wall of the working chamber is connected with a control box; and the control box is connected with a hydraulic system. The invention has the advantages of even spraying, ensured spraying quality and enhanced spraying efficiency.

Owner:NANTONG ZHONGLIAN S&T SERVICE

Mechanical overspeed protective device

Owner:XIZI OTIS ELEVATOR

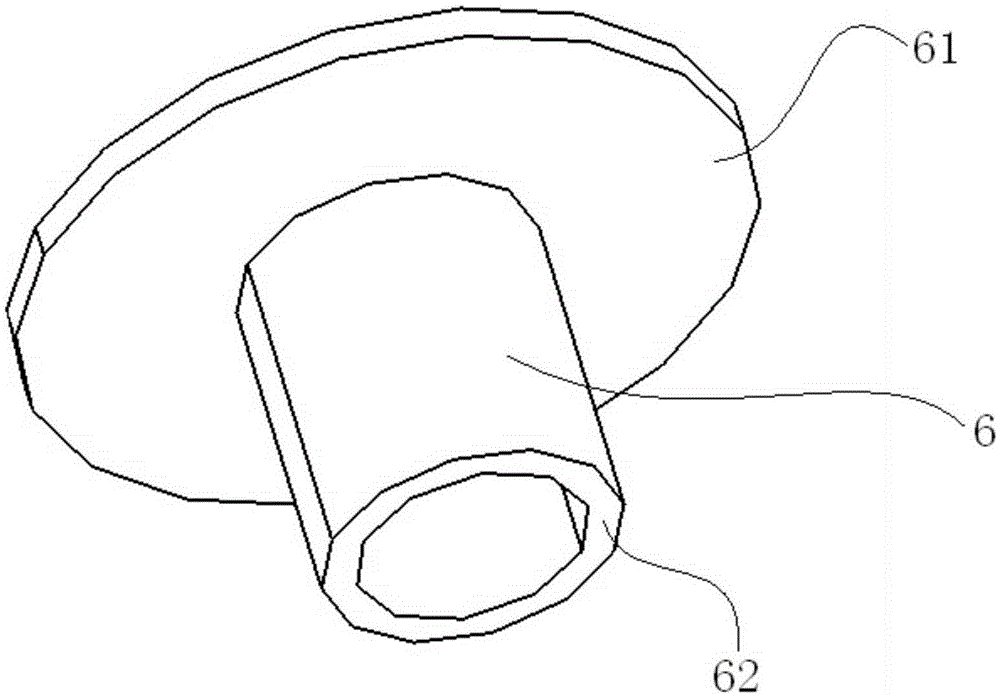

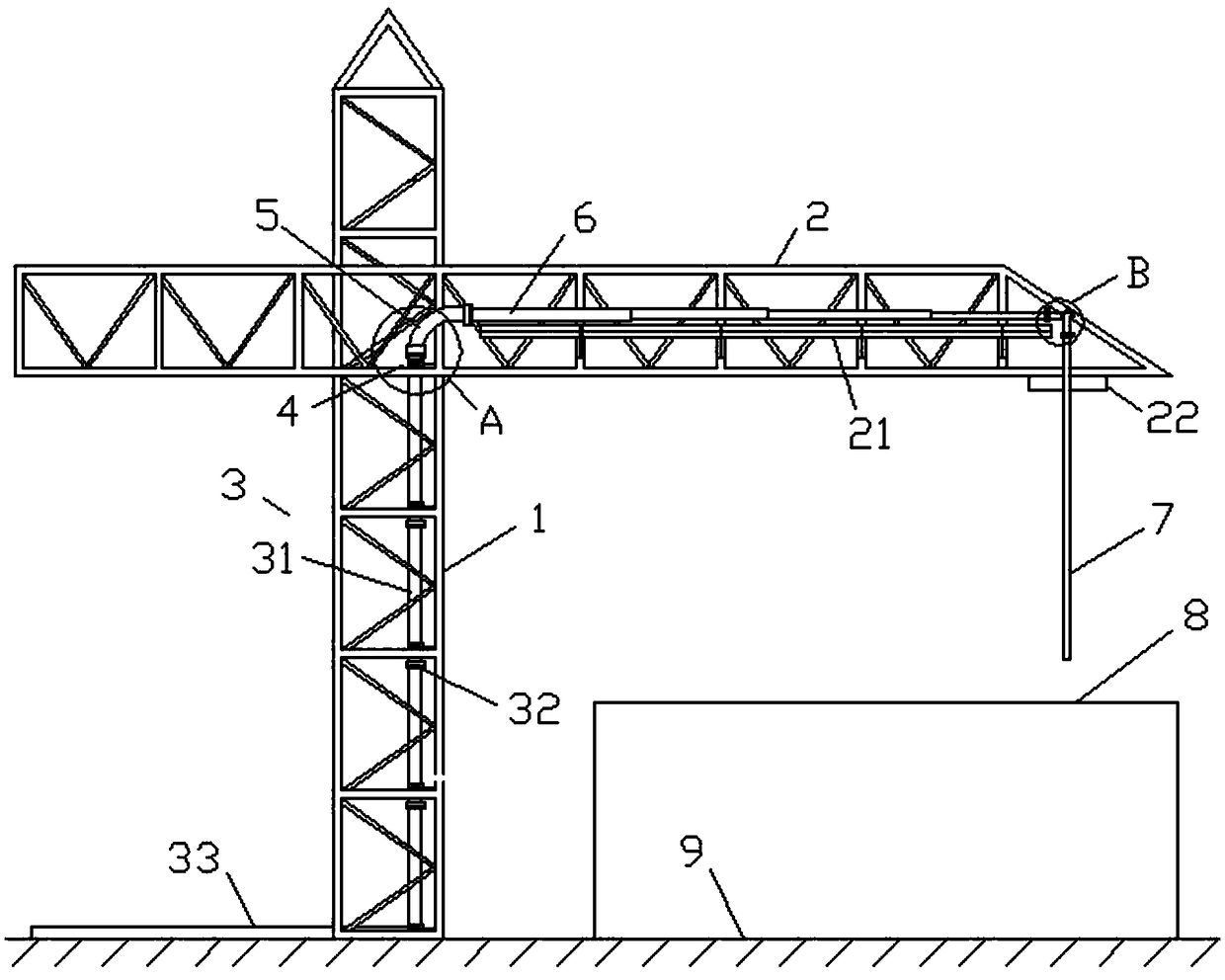

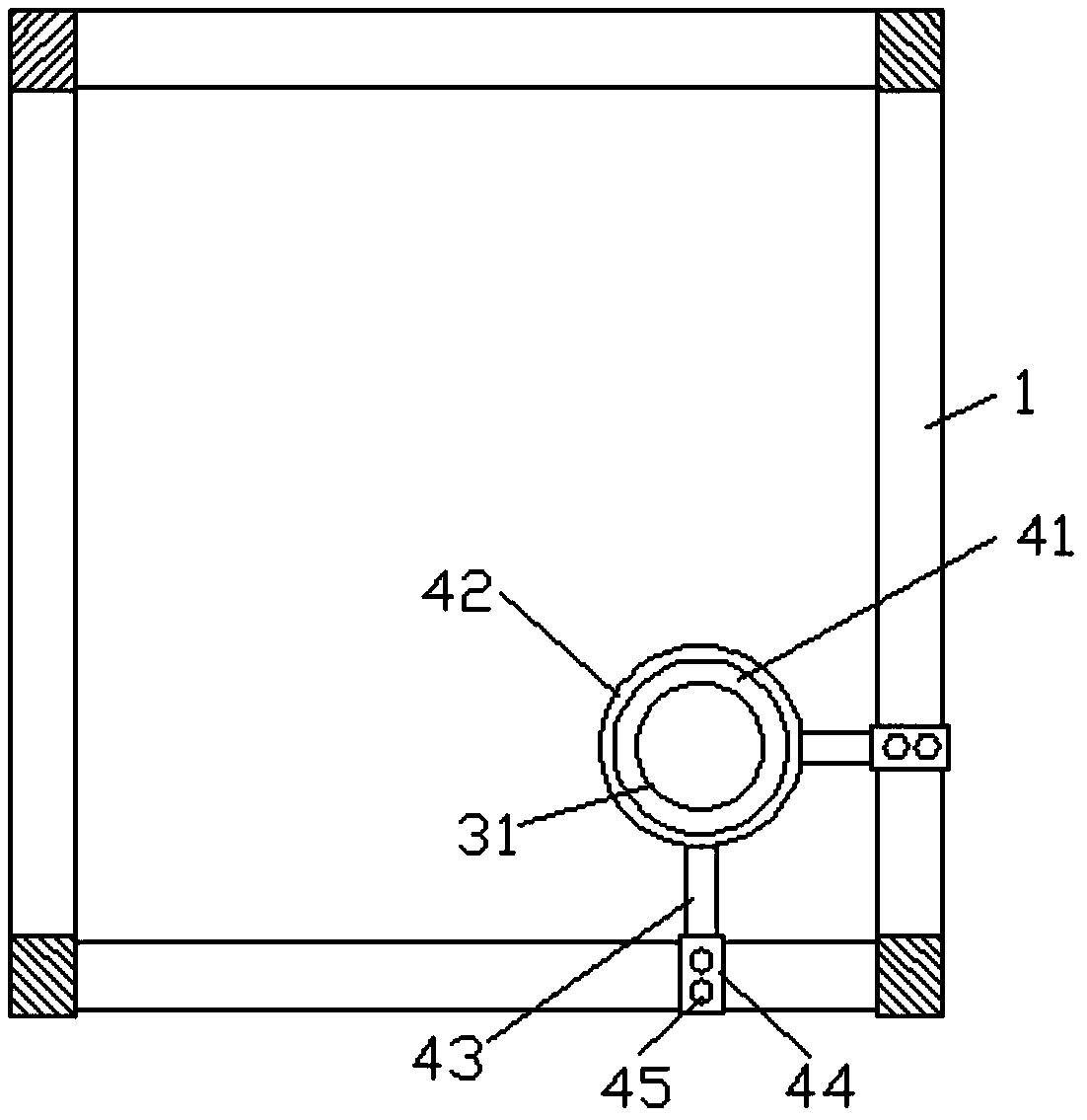

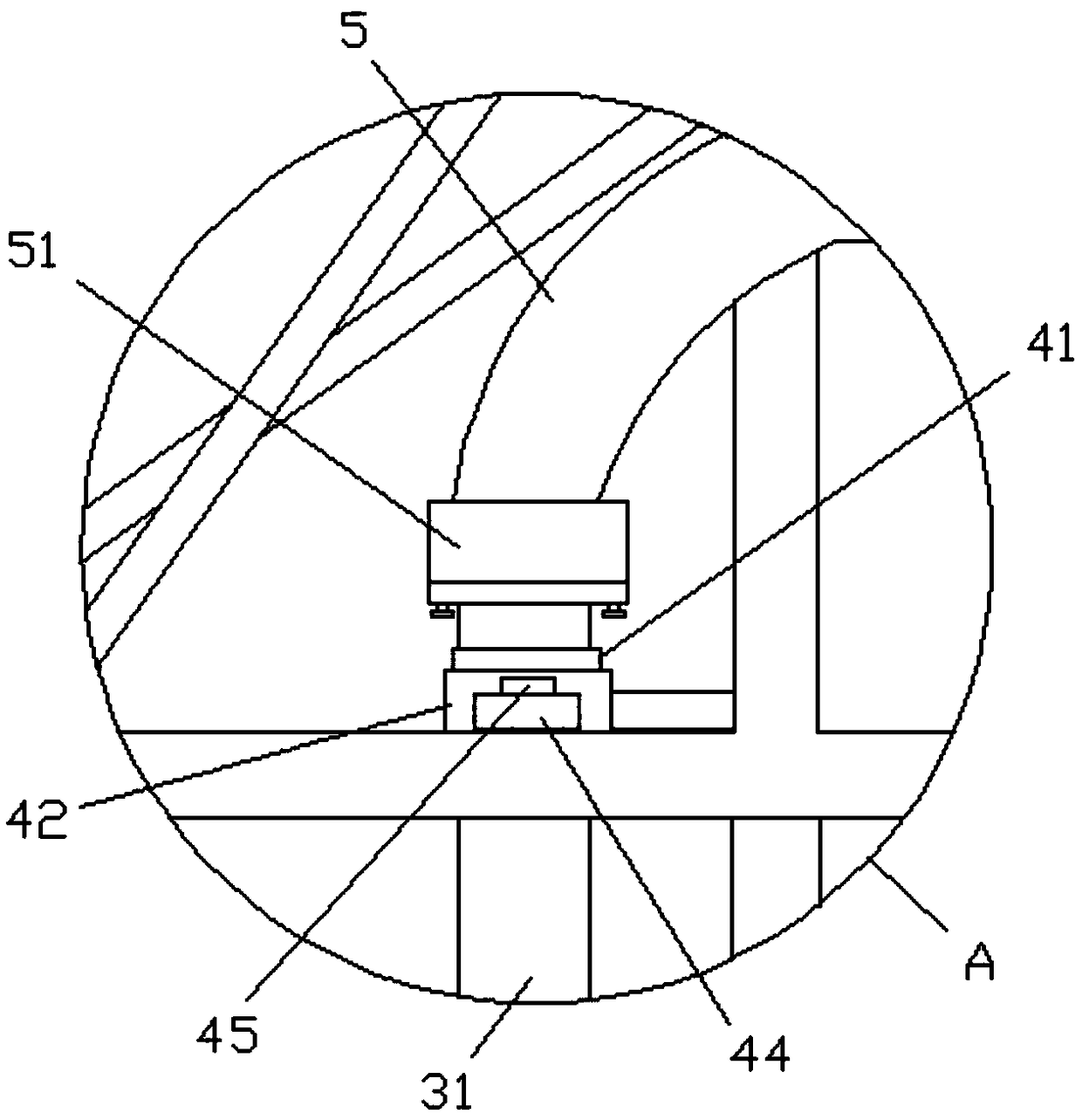

Conveying and pouring device based on concrete construction of high-rise building

PendingCN109403636AExtended pumping rangeSolve the pouring dead angleBuilding material handlingBuilding constructionTower crane

The invention relates to the field of concrete pouring equipment, and discloses a conveying and pouring device based on the concrete construction of a high-rise building. According to the conveying and pouring device based on the concrete construction of the high-rise building, high-rise concrete conveying pipelines are arranged on a tower crane standard section and a tower crane boom, and the length of each section of vertical pump pipes is consistent with the length of the tower crane standard section and increases at the same time. The conveying and pouring device has the characteristics ofsimple operation, flexible rotation and the like. The conveying and pouring device based on the concrete construction of the high-rise building structurally comprises a vertical conveying pipeline arranged in the tower crane standard section and a transverse conveying pipeline arranged on the side surface of the tower crane boom. The upper end part of the vertical conveying pipeline is connectedto the left end part of the transverse conveying pipeline through a first elbow, and rotating joints matched with the vertical conveying pipeline and the transverse conveying pipeline are arranged atthe two end part of the first elbow correspondingly. A shock absorption fixed assembly device matched with the tower crane standard section is arranged on the vertical conveying pipeline, and a supporting assembly matched with the transverse conveying pipeline is fixedly arranged on the side surface of the boom. The conveying and pouring device based on the concrete construction of the high-rise building is simple in operation and convenient to use, and is suitable for all kinds of building construction sites, especially for the construction of the high-rise building.

Owner:陈兴龙

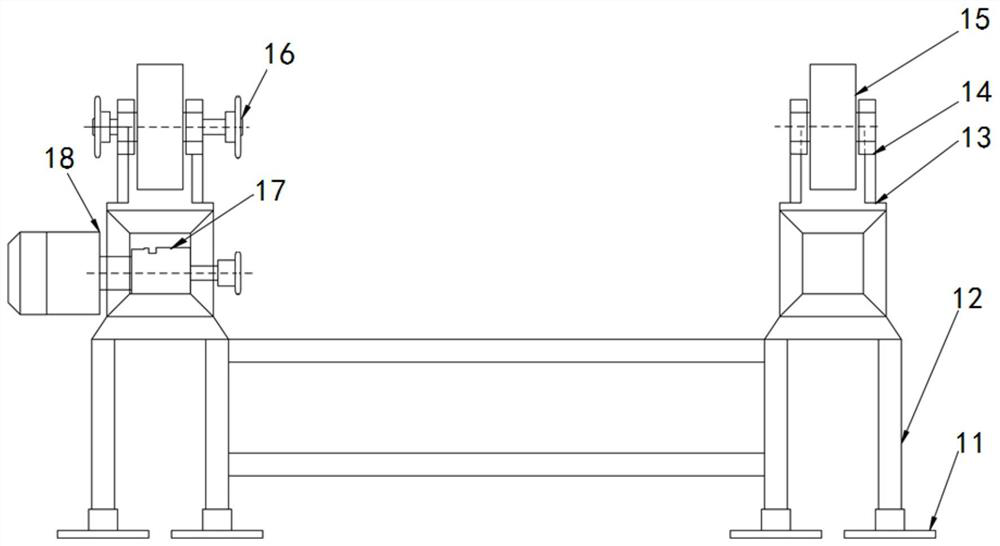

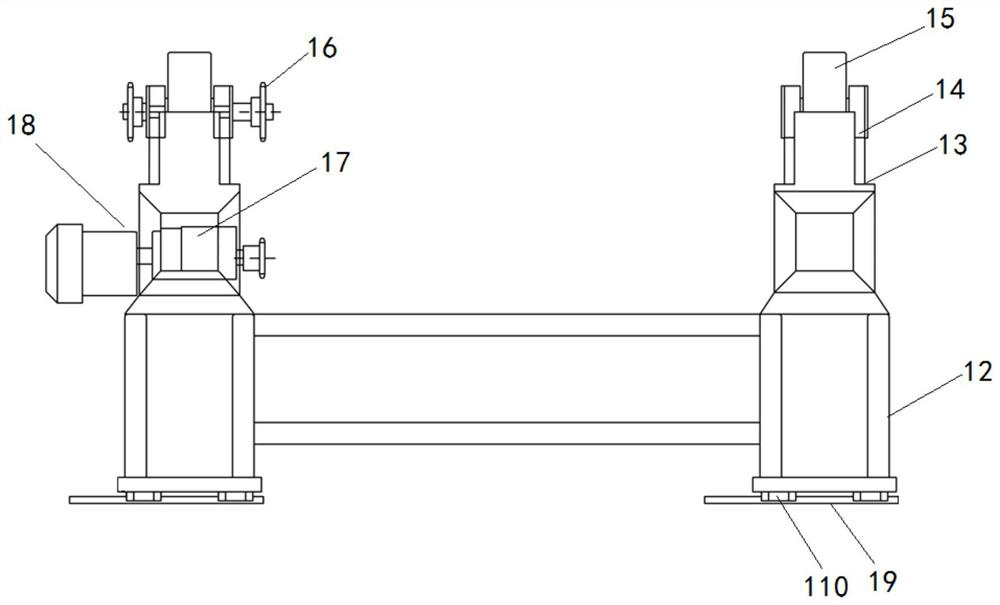

Automatic circular-pipe welding device

InactiveCN112222740AImprove straightnessWon't vibrateWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringPipe

The invention belongs to the technical field of pipeline mechanical welding, and discloses an automatic circular-pipe welding device. The device comprises two rotating device fixed ends, two rotatingdevice movable ends, a clamping device and a welding device body, wherein one circular pipe is arranged at the two rotating device fixed ends, and one circular pipe is arranged at the two rotating device movable ends, the two rotating device fixed ends and the two rotating device movable ends are located on the same straight line, the clamping device is located between the two rotating device fixed ends, and the welding device is located at the welding position of the two circular pipes. According to the device, the circular pipes are adjusted from three directions, so that the two circular pipes can be accurately butted, and the welding work is automatically carried out.

Owner:YANCHENG INST OF TECH

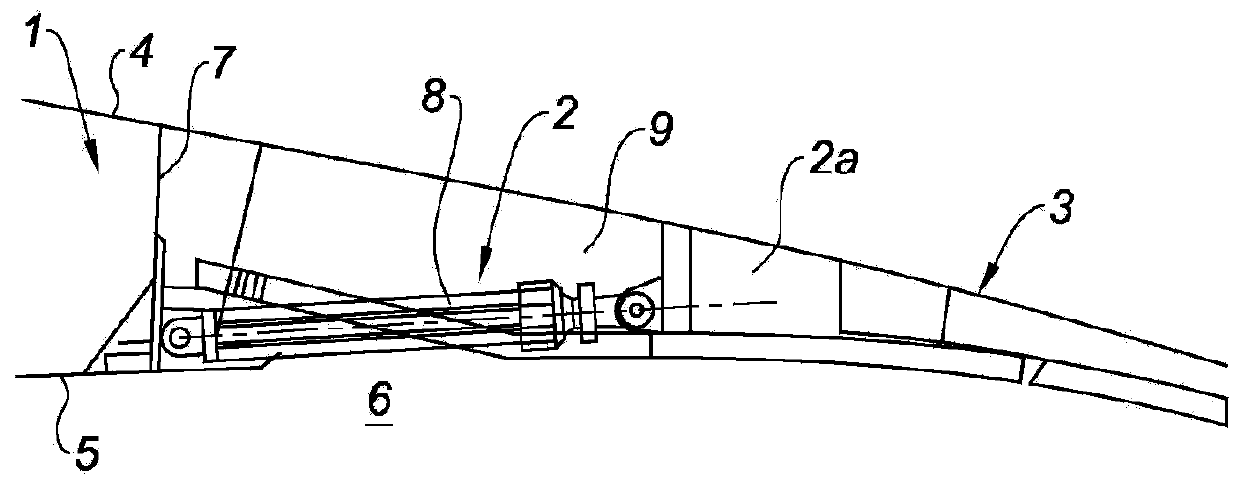

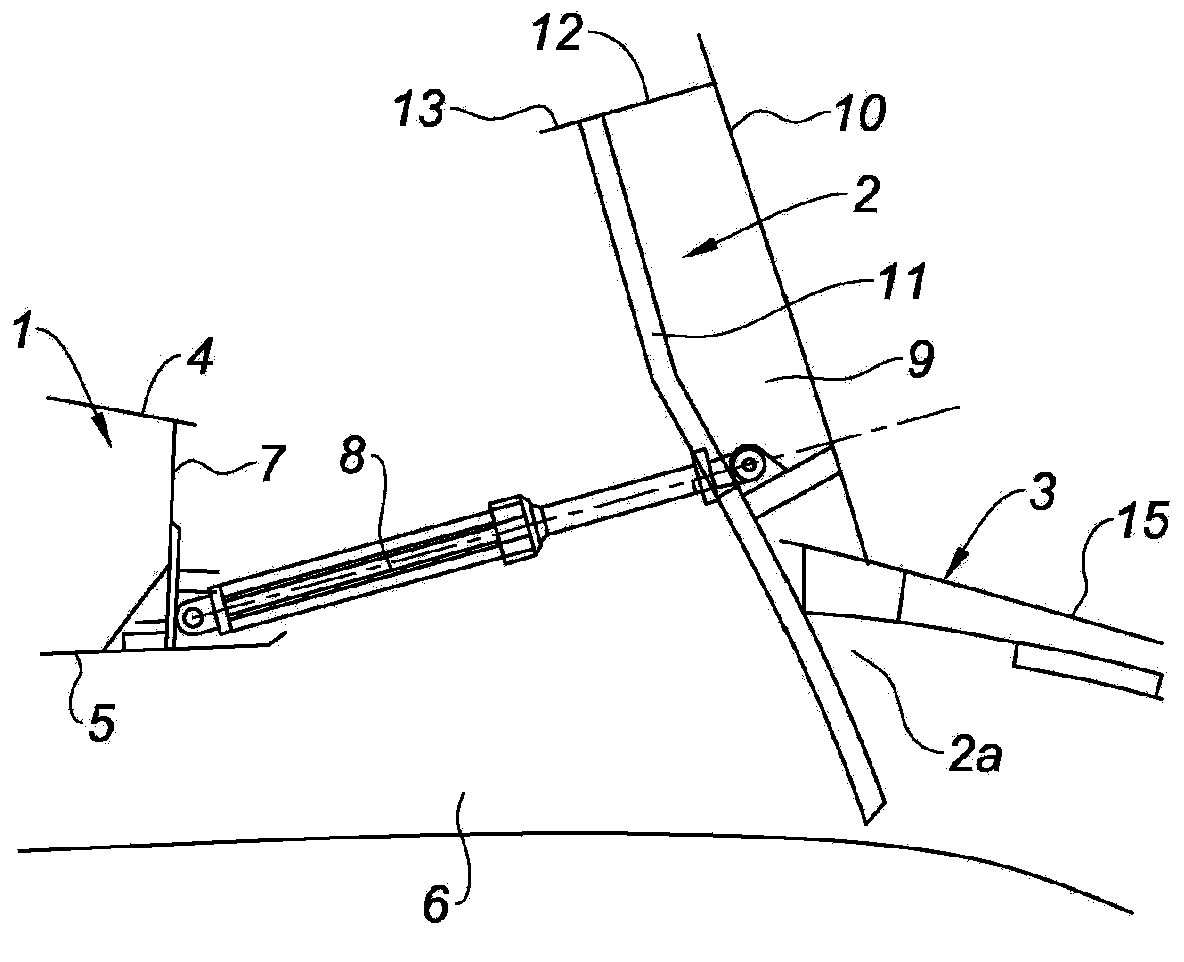

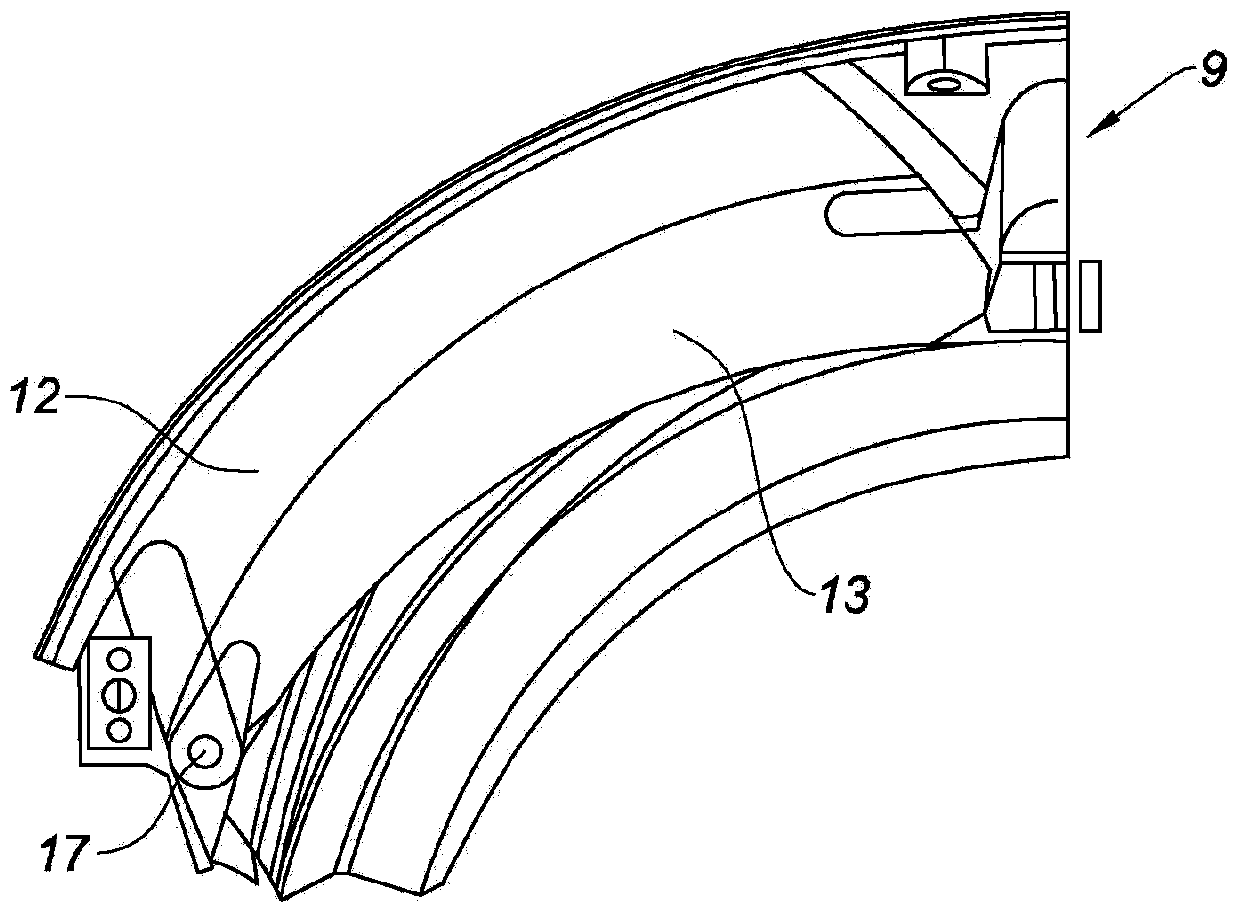

Door for a thrust reverser with doors

InactiveCN104011360AIdeal redirectionReduce weightEngine fuctionsEfficient propulsion technologiesNacelleActuator

A door for a door-type thrust reverser is pivotally mounted on a stationary structure of a thrust reverser. The door includes an inner surface integrated to a flow path of an air flow generated by a turbojet engine, an outer surface providing an outer aerodynamic continuity of a nacelle equipped with the thrust reverser, a spoiler to deflect the air flow disposed at an upstream end of the door, and an actuator actuating the spoiler. The spoiler is movably mounted, in rotation around a rotation axis substantially perpendicular to a front frame of the door, between a retracted and a deployed position. In particular, the actuator includes a first rod connected to the spoiler, a second rod connected to the first rod and the front frame, and a third rod connected to the first and second rods as well as to the spoiler.

Owner:AIRCELLE

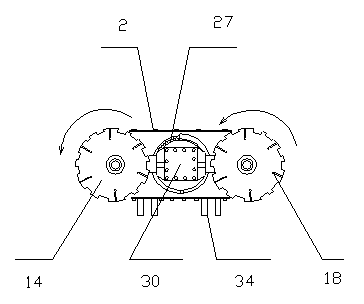

Cutting disc type rotating arm heading machine cutting device

The invention relates to treatment of gas under a coalmine well and laneway roofs, in particular to a heading machine cutting device capable of preventing coal and gas outburst and effectively reducing breaking of laneway roofs. The cutting disc type rotating arm heading machine cutting device comprises the following components: a cutting head, a cutting arm, a power transmission system and a power unit, wherein rotating arms on the cutting head are driven by a rotary arm motor to rotate at low speed; cutting discs mounted on the rotating arms are driven by a main power system to rotate at high speed and rotate together to cut coal; vibration is not generated when the cutting discs rotate at high speed to cut coal-rock mass, so that a vibration source for generating mechanical waves is eliminated, the roof completeness of a working face is effectively protected, the occurrence of a roof accident is prevented, the energy is prevented from being delivered to the deep coal-rock mass, the formation condition of coal and gas outburst is prevented, the occurrence of coal and gas outburst phenomenon is completely prevented, and the safety production in a coal mine is guaranteed.

Owner:王庆军

Rotary nut-picking manipulator and nut picking method

A rotary nut-picking manipulator and a nut picking method are provided. The rotary nut-picking manipulator comprises a Y-shaped electric handle having an automatically openable upper end, and is characterized in that an electric fruit rotation component capable of generating rotational torque and a fruit clamping component coaxially facing the electric fruit rotation component with no contact; branch clamping components are mounted on the peripheries of the electric fruit rotation component and the fruit clamping component respectively; the two branch clamping components coaxially face each other and are in elastic contact; the electric fruit rotation component and the fruit clamping component separate or approach with opening or closing of the Y-shaped electric handle, the two branch clamping components are driven to separate or approach, branches connected with a fruit are clamped between the two branch clamping components, the fruit is clamped between the electric fruit torsion component and the fruit clamping component and is separated from the branches through the rotational torque of the electric fruit rotation component; actions of the Y-shaped electric handle and the fruitclamping component are centrally and coordinatively controlled through control keys.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com