Patents

Literature

195results about How to "Increase rotational torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

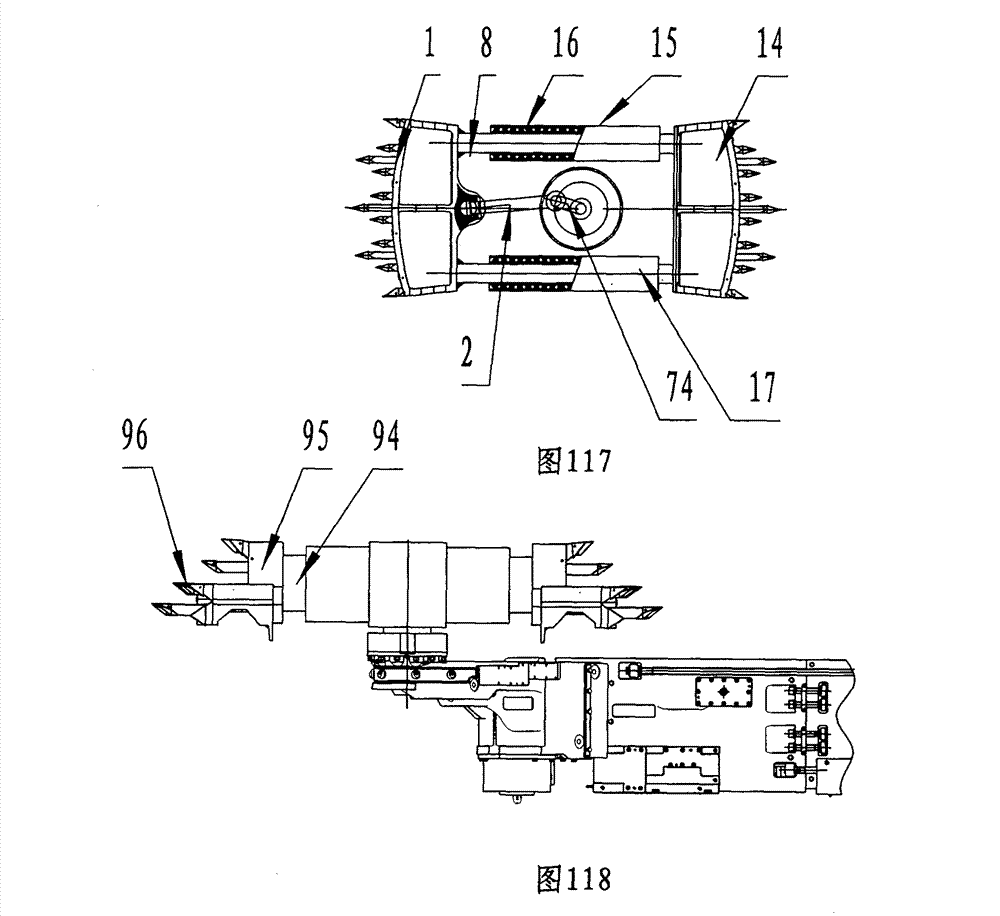

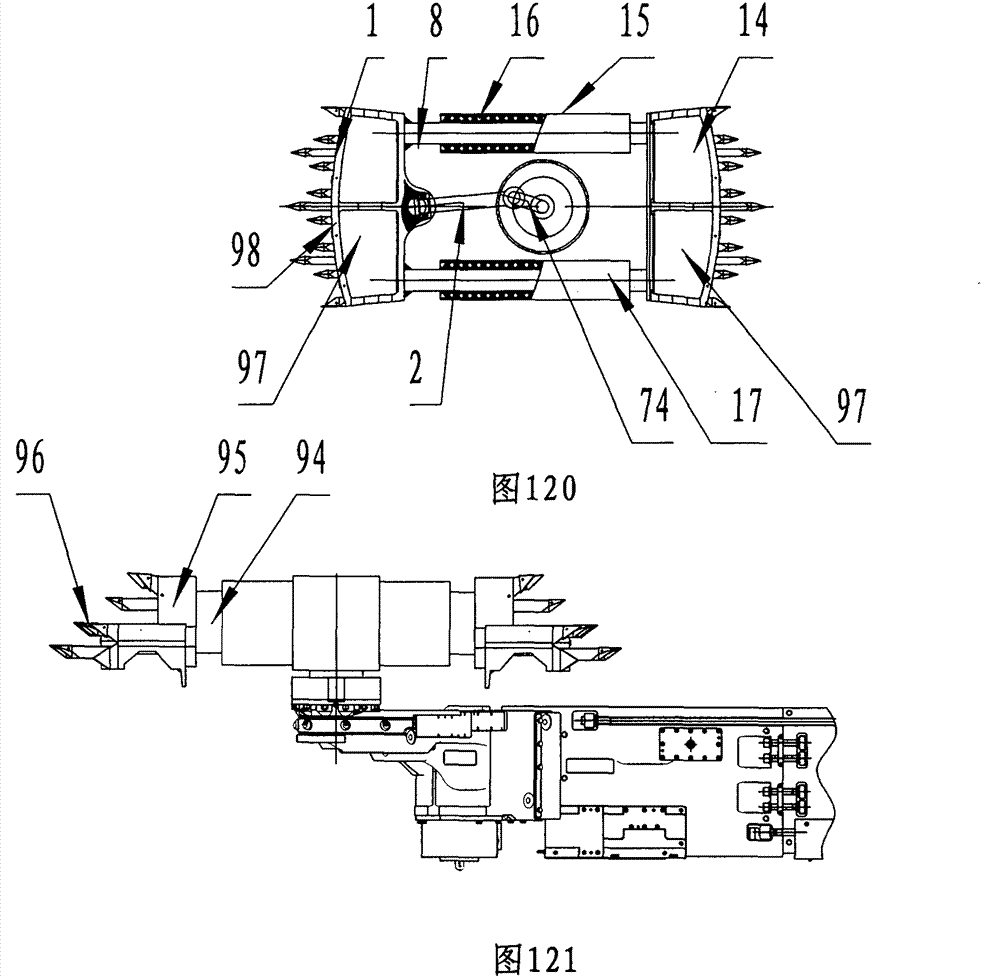

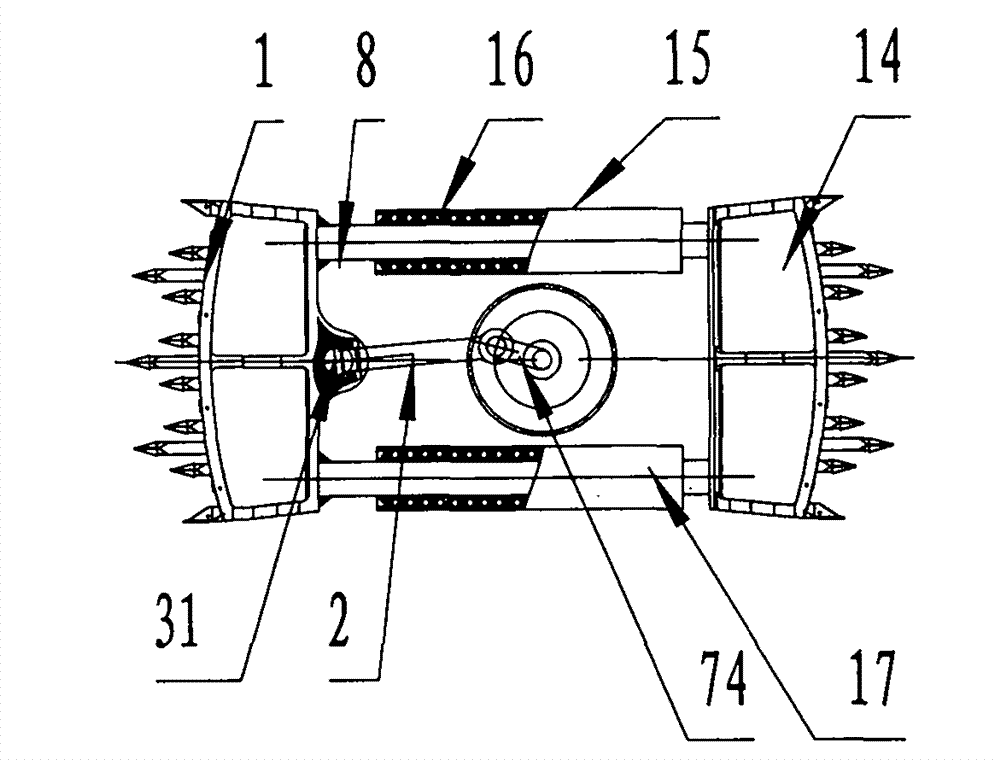

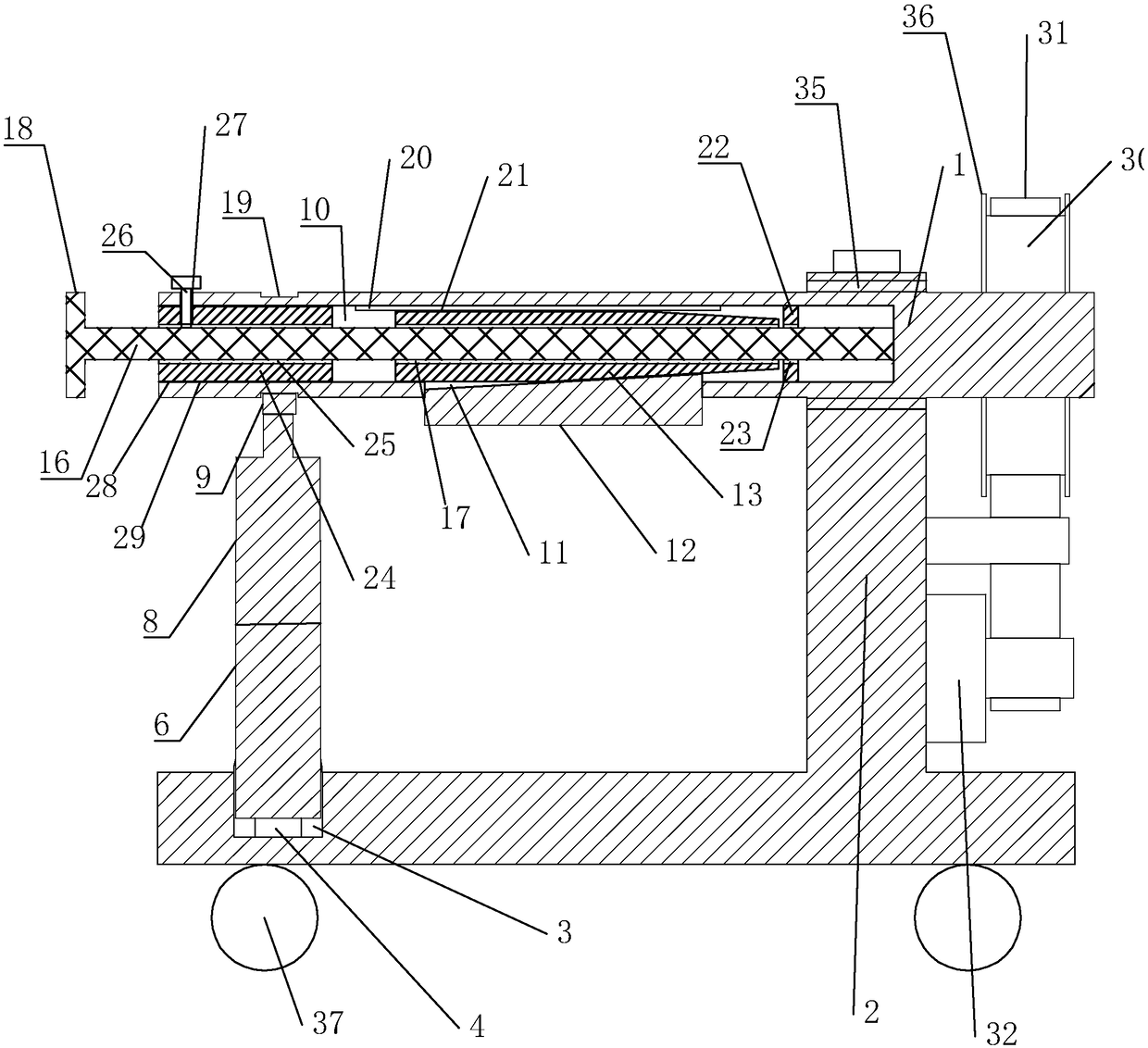

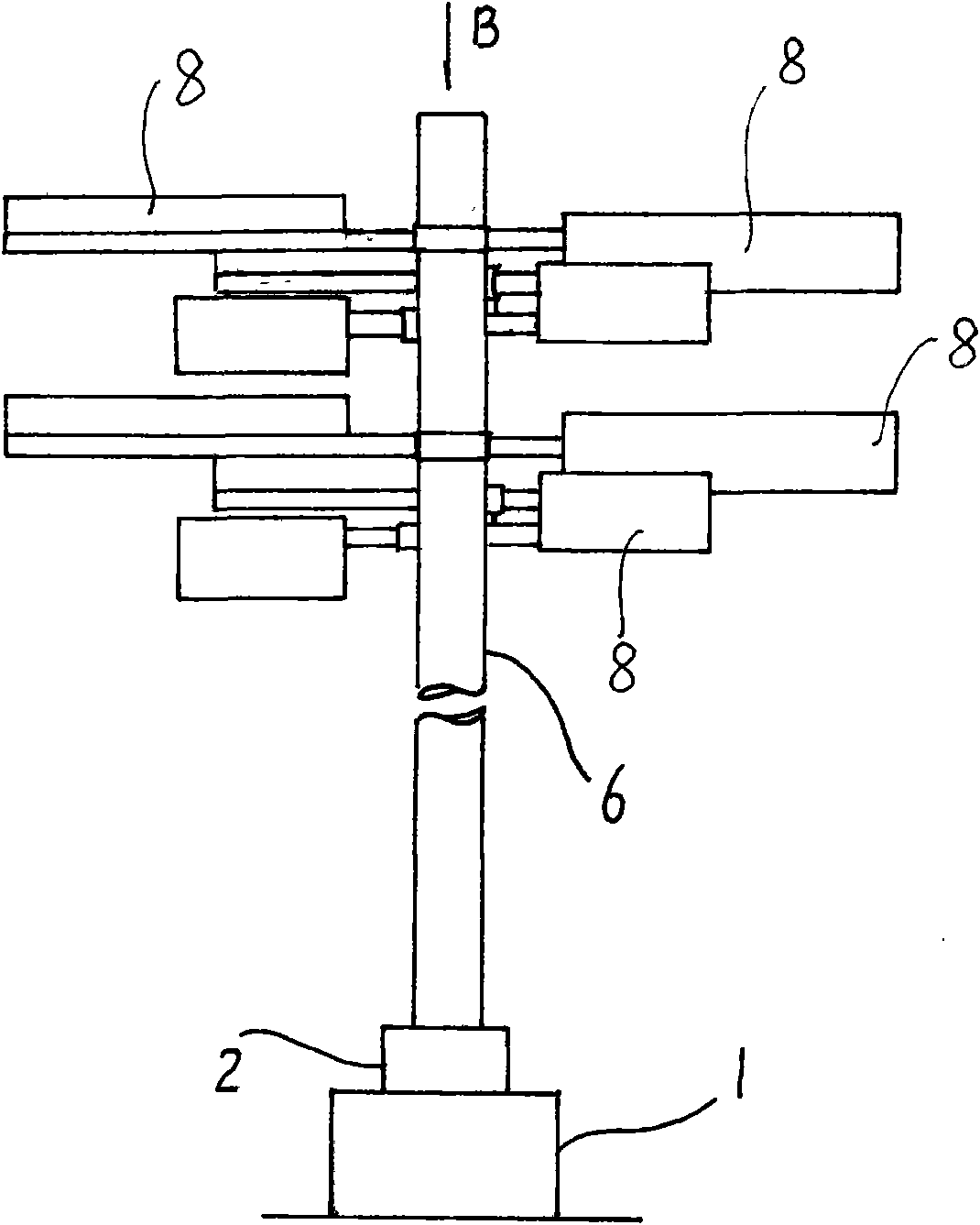

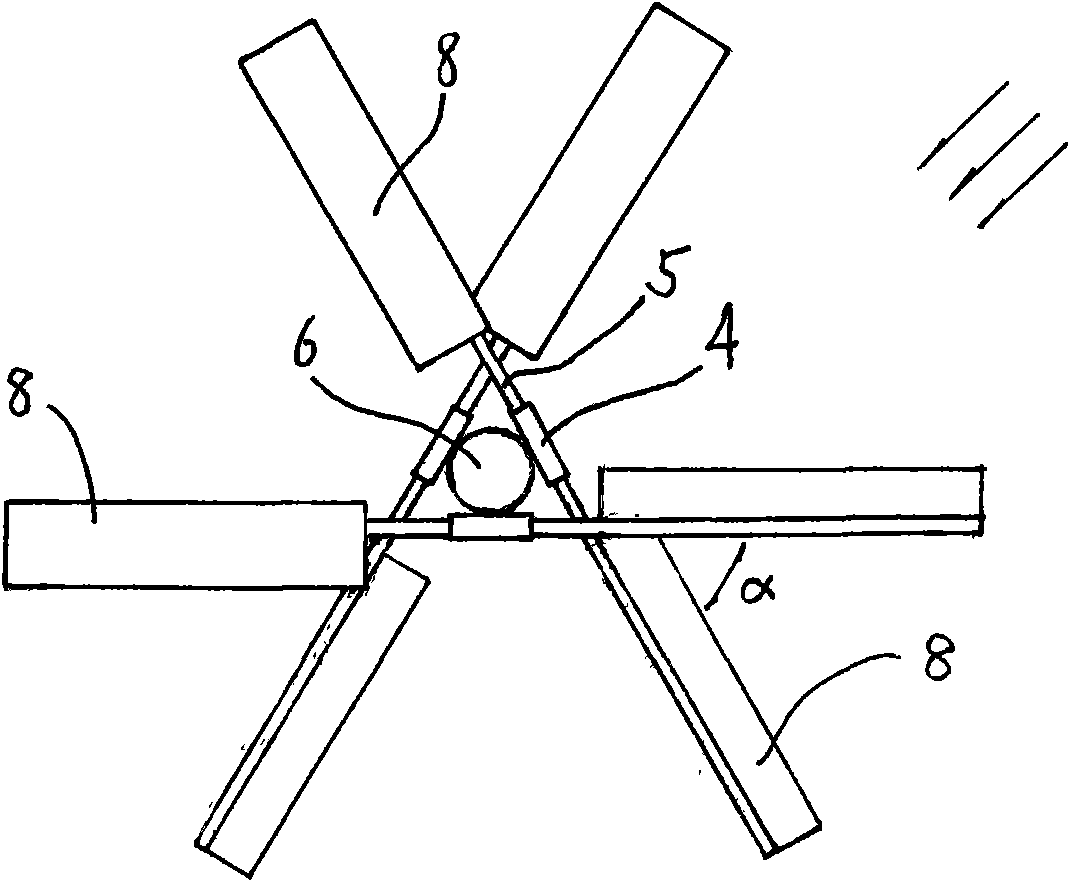

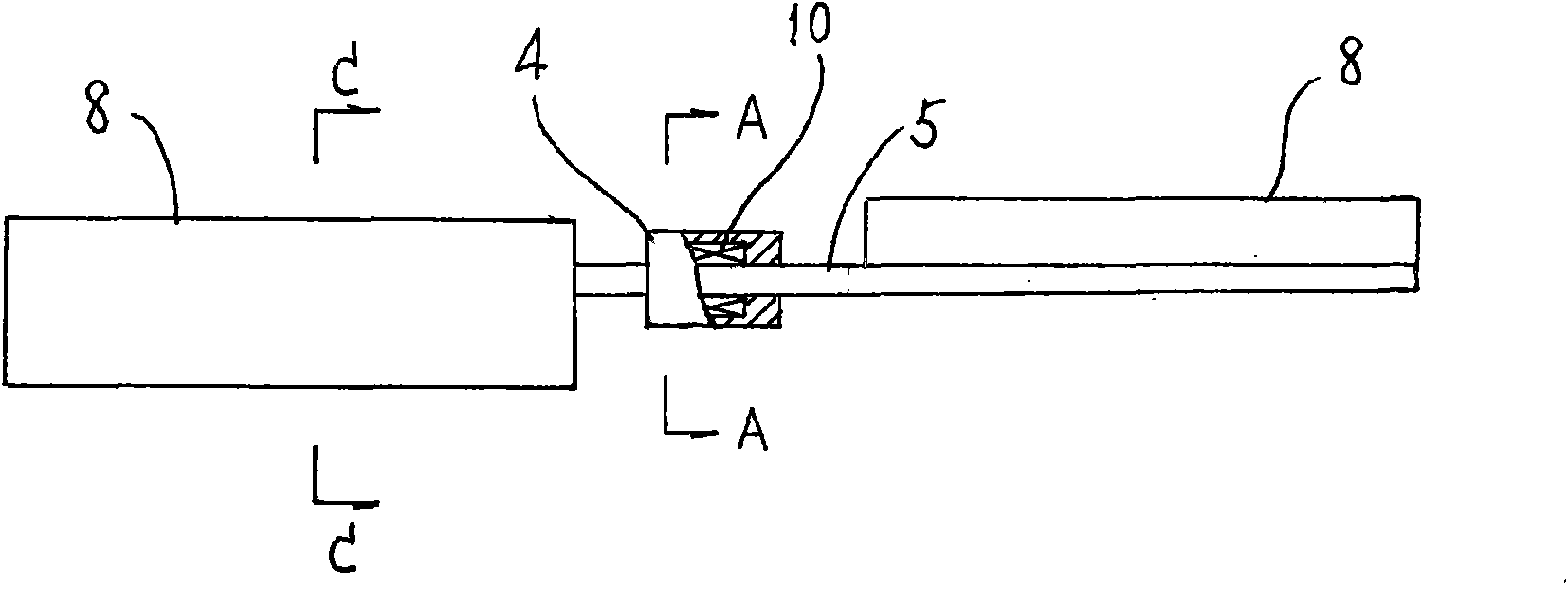

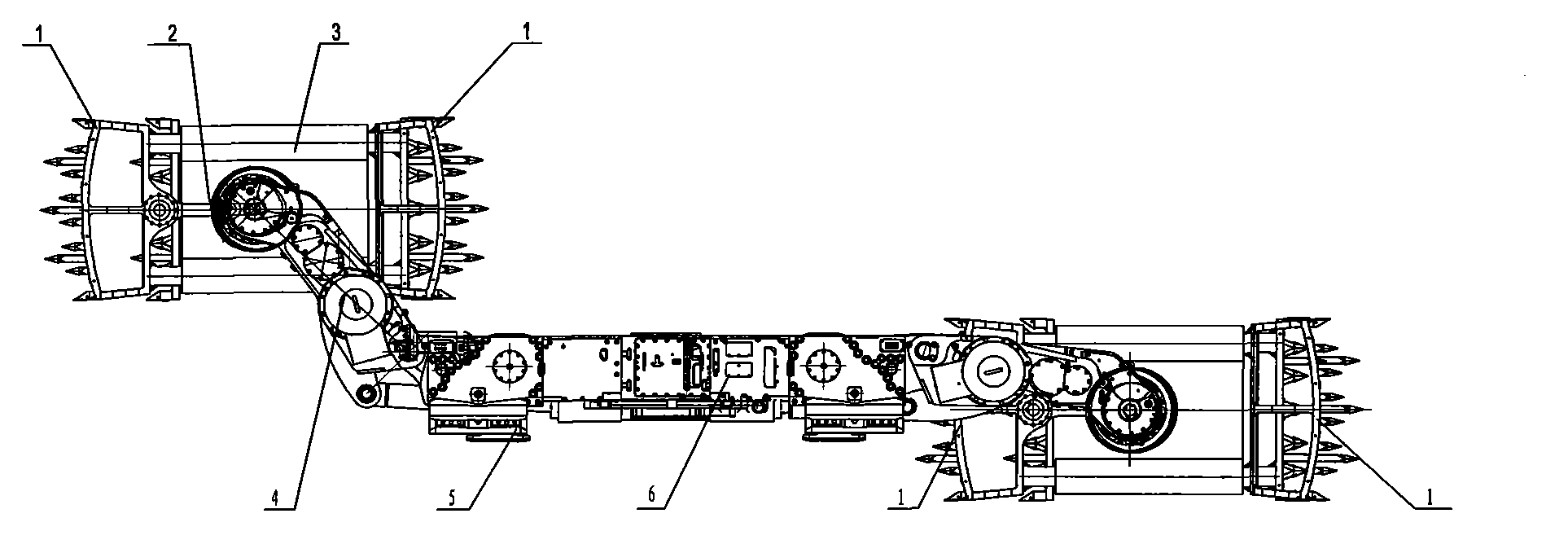

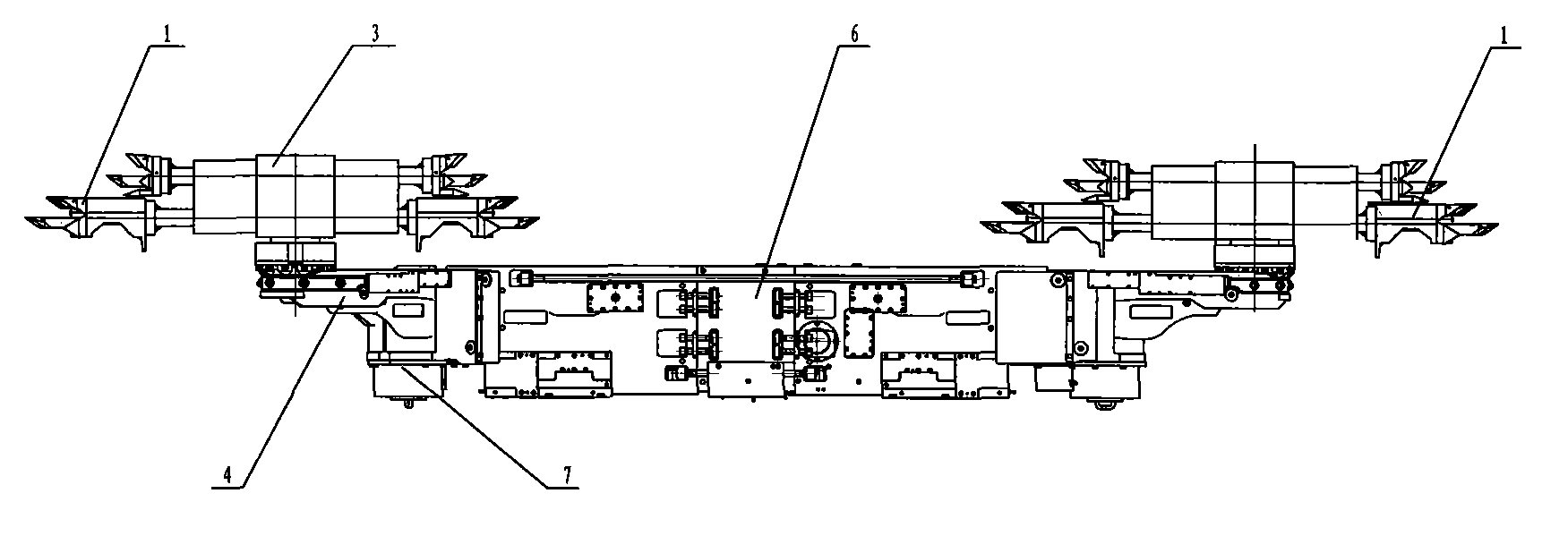

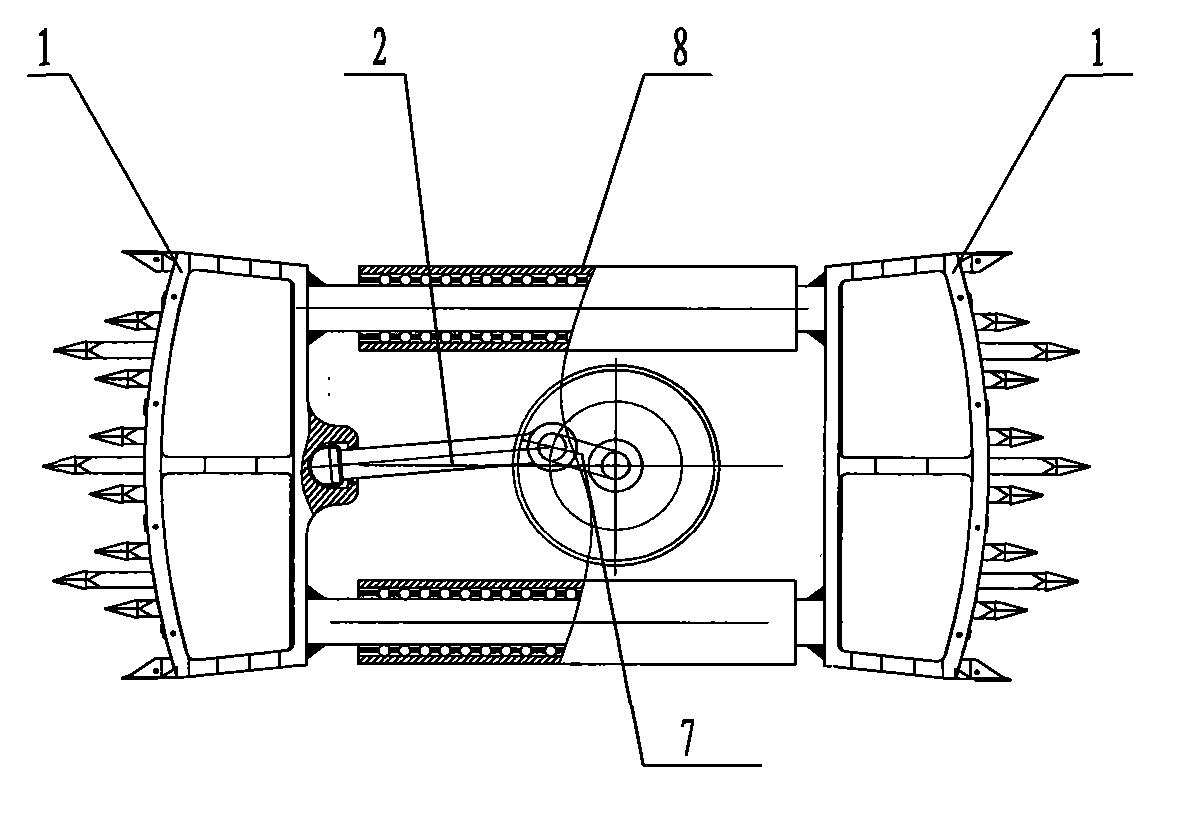

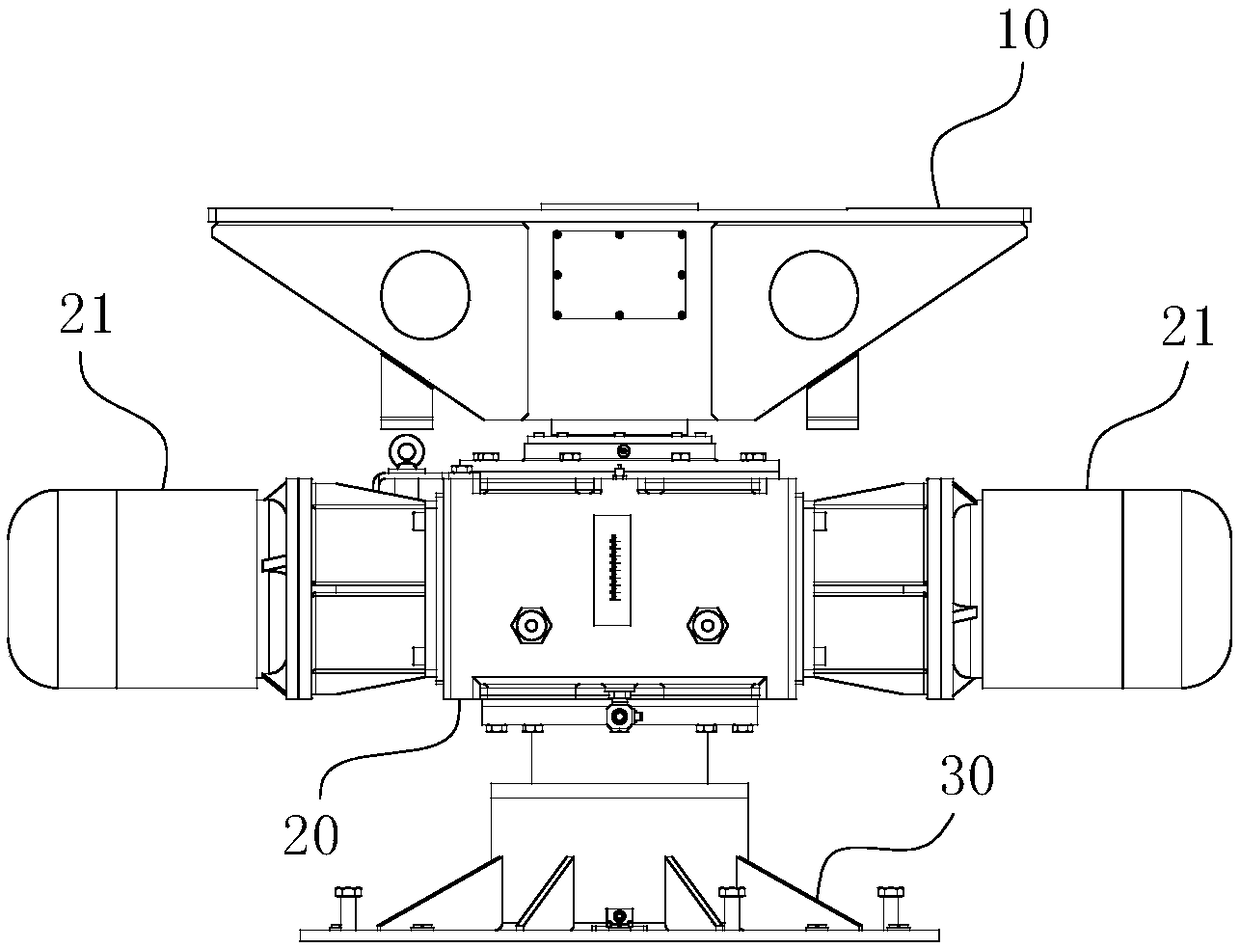

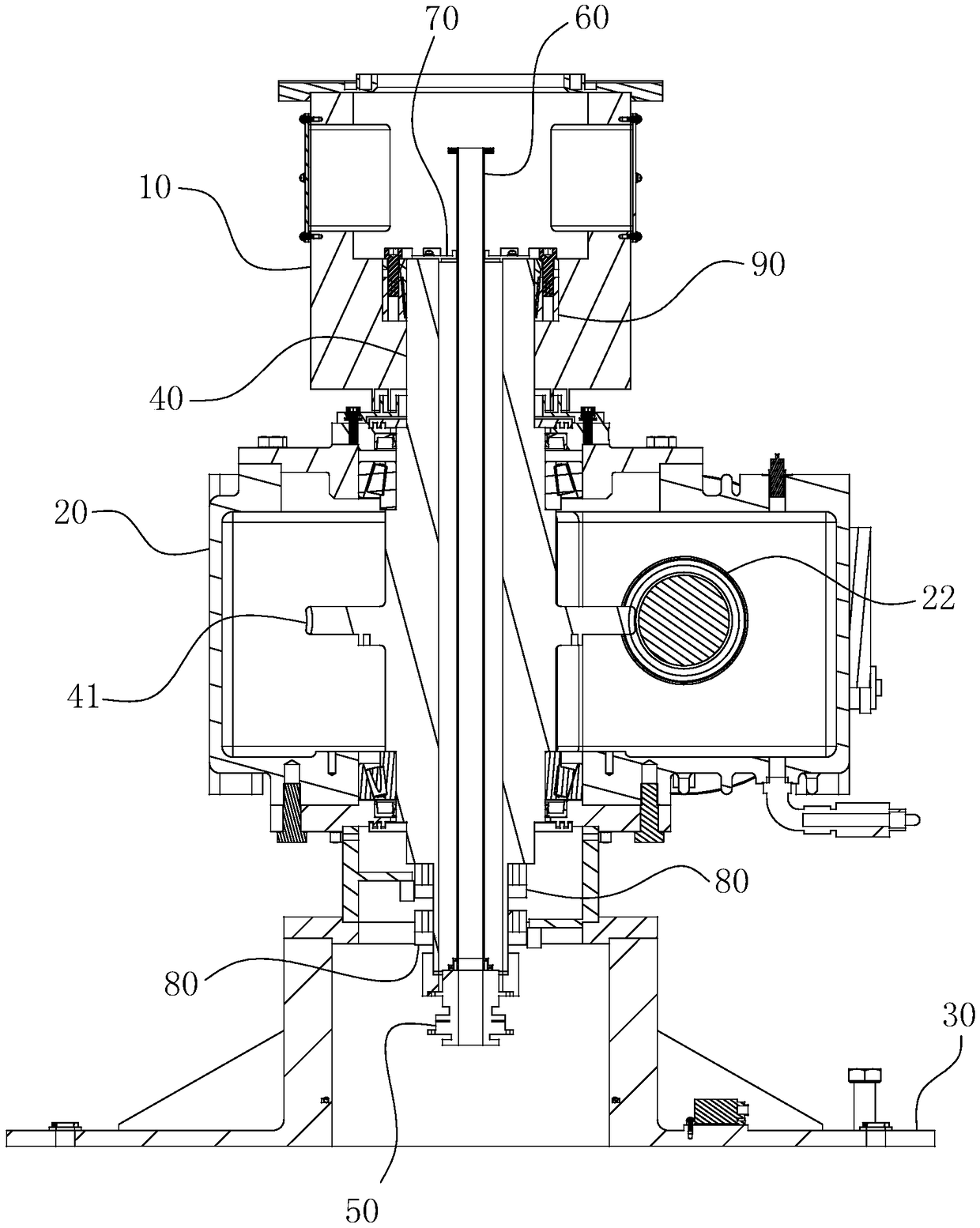

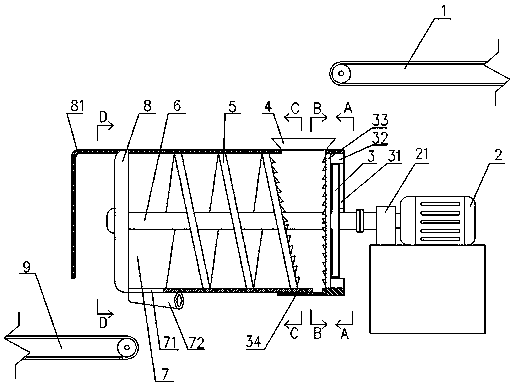

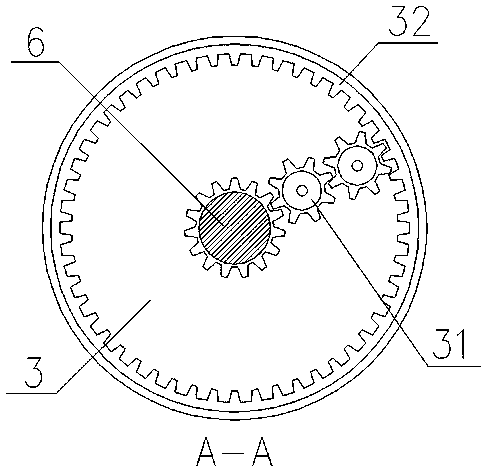

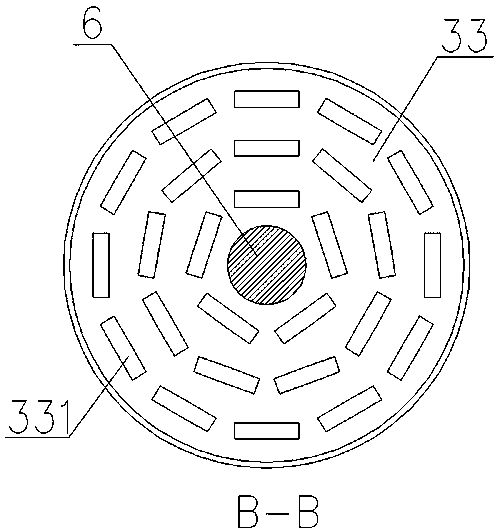

Bidirectional pounding and cutting excavating method and bidirectional pounding and cutting excavator for implementing same

ActiveCN103089259AReduce the number of adjustmentsExtend your lifeDriving meansReciprocating motionEngineering

The method provided by the invention comprises the following steps: a machine body, a walking part, a lifting part, a reciprocating pounding part and the like are arranged; a pounding guide element and the like are arranged on a pounding guide device; pounding heads are arranged at two ends of the pounding guide element, so that a power pounding element drives the pounding guide element; the reciprocating pounding part is arranged on the lifting part; the lifting part is arranged on the machine body; and the walking part drives the machine body to move ahead and retreats so as not to turn the machine body to excavate and drop materials forward and backward. Equipment provided by the invention comprises the machine body, the walking part, the lifting part, the reciprocating pounding part and the like; the reciprocating pounding part comprises the pounding guide device, the pounding driving device and the like; the pounding heads are both arranged at two ends of the pounding guide element; the pounding driving device comprises the power pounding element and the like; the power pounding element drives the pounding guide element to move in a reciprocating mode; the pounding guide element drives the pounding heads to pound; the reciprocating pounding part is arranged on the lifting part; the lifting part is arranged on the machine body; the walking part drives the machine body to move ahead and retreat so as not to turn the machine body to excavate and drop materials forward and backward.

Owner:刘素华

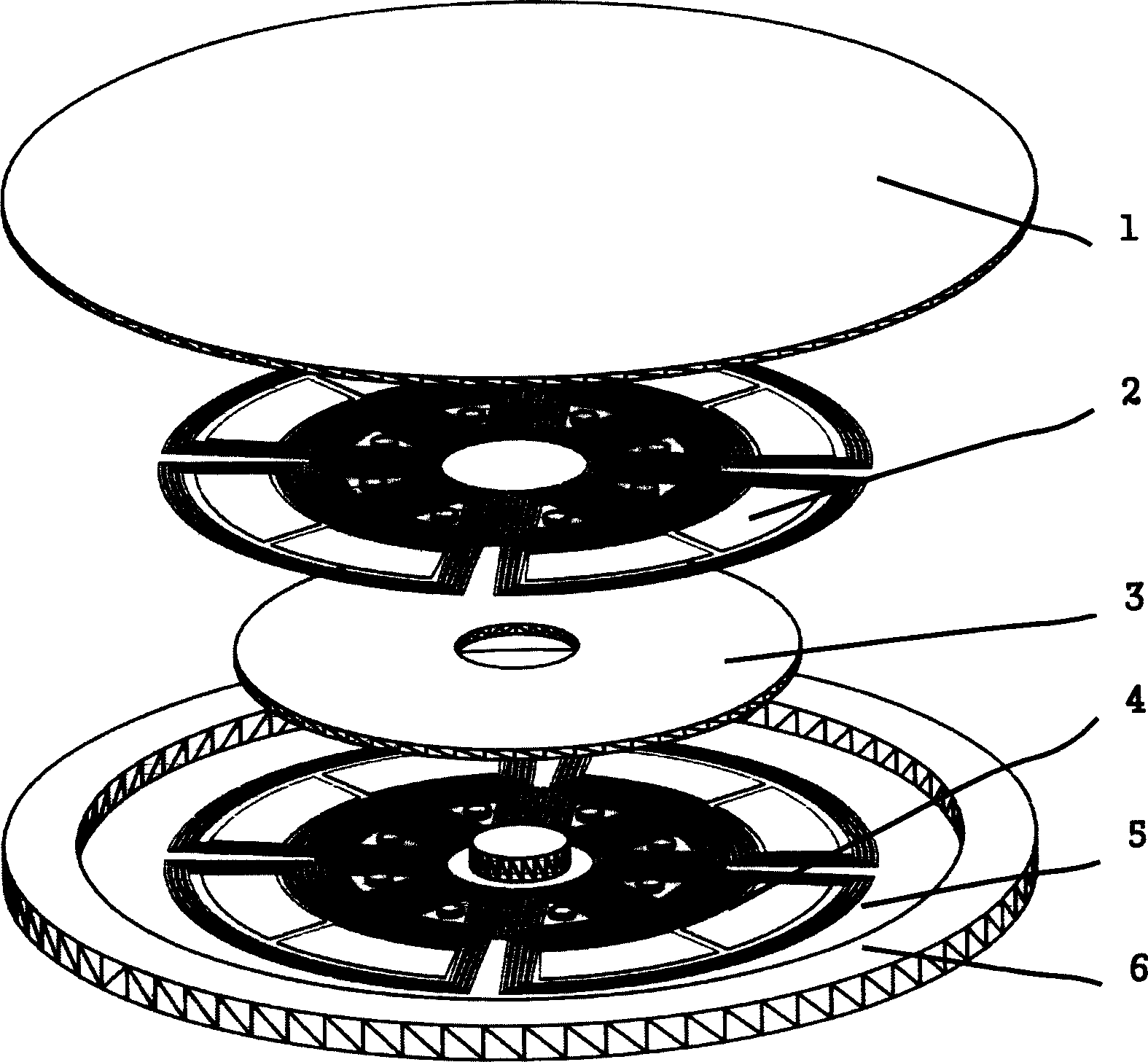

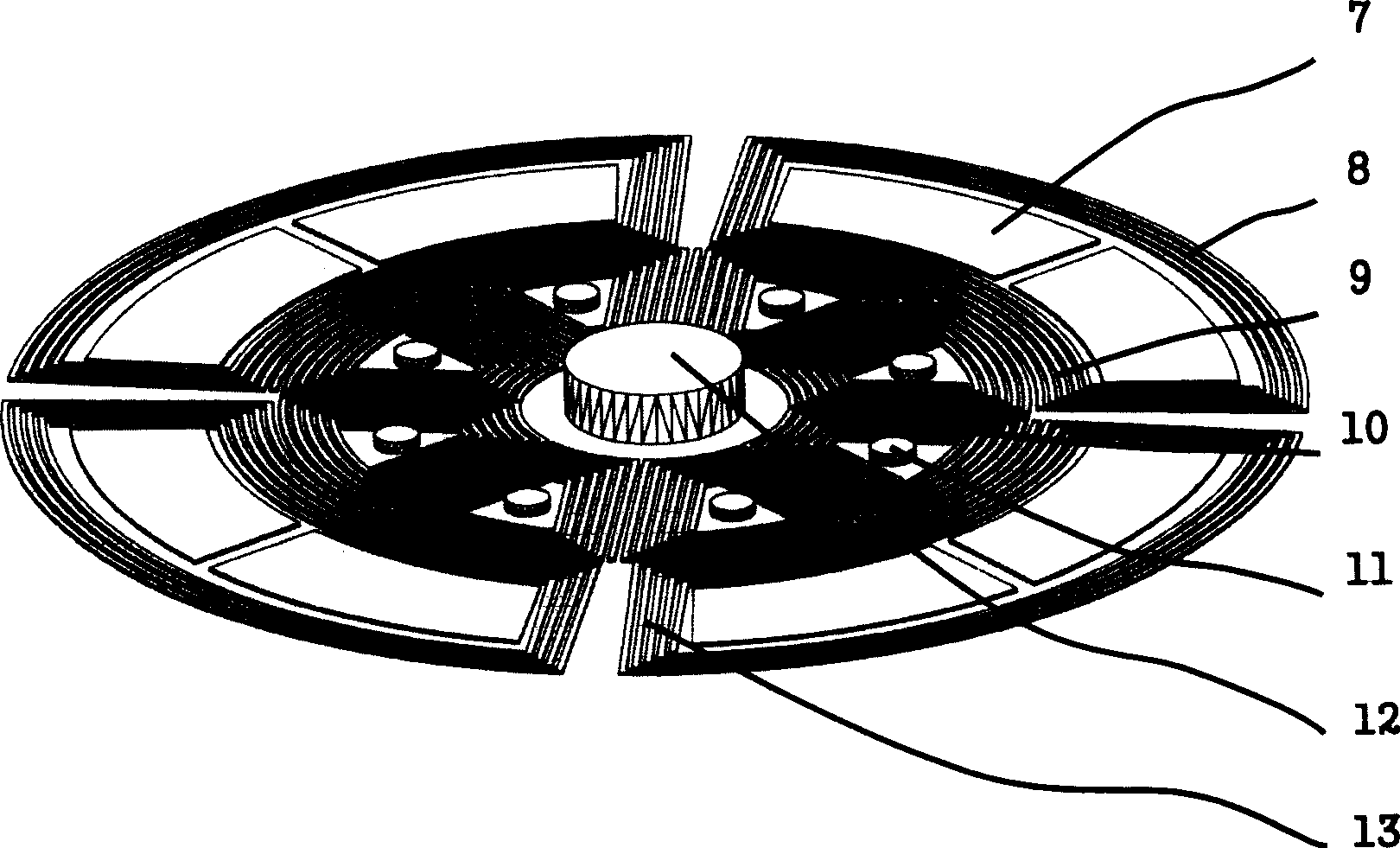

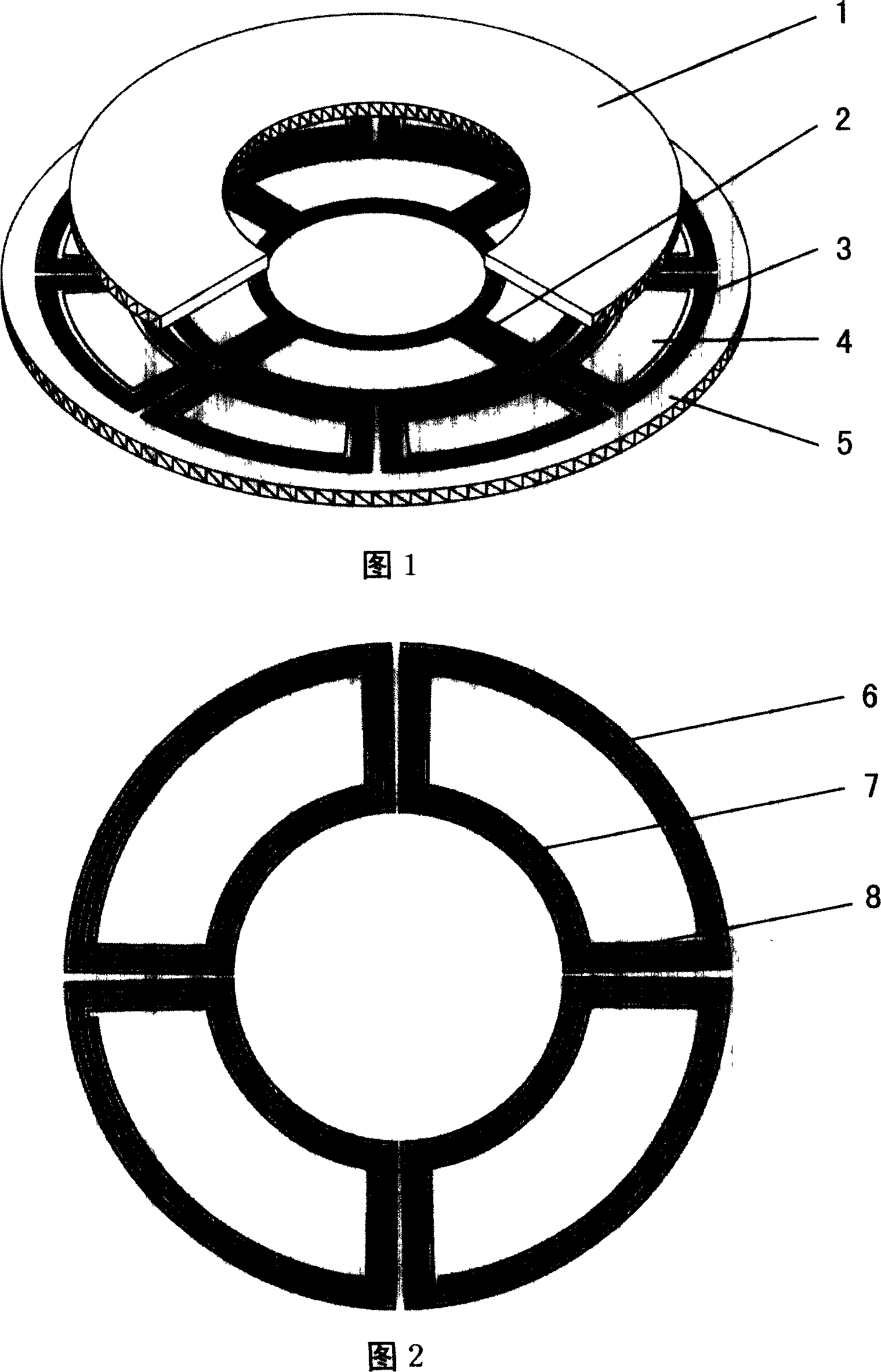

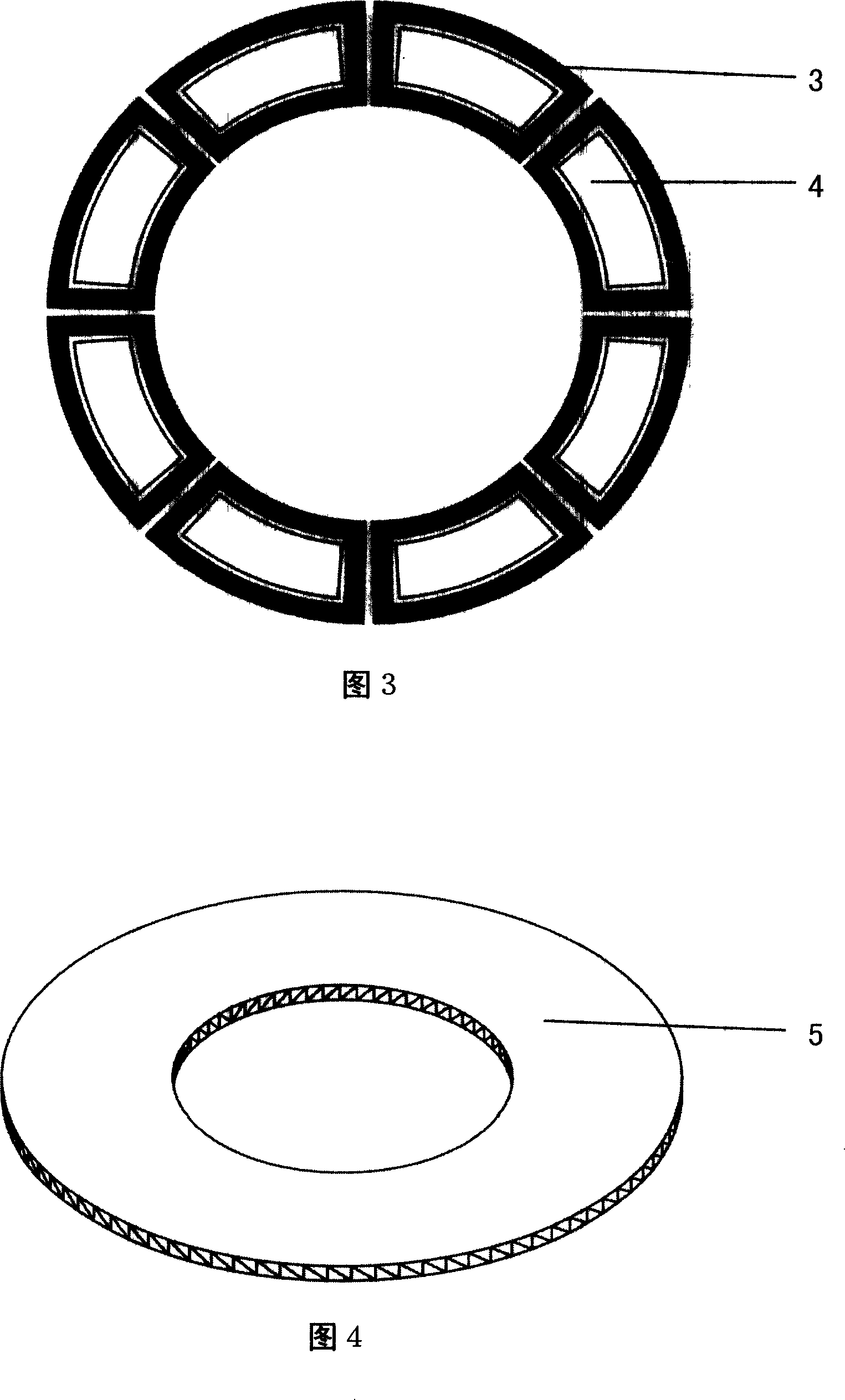

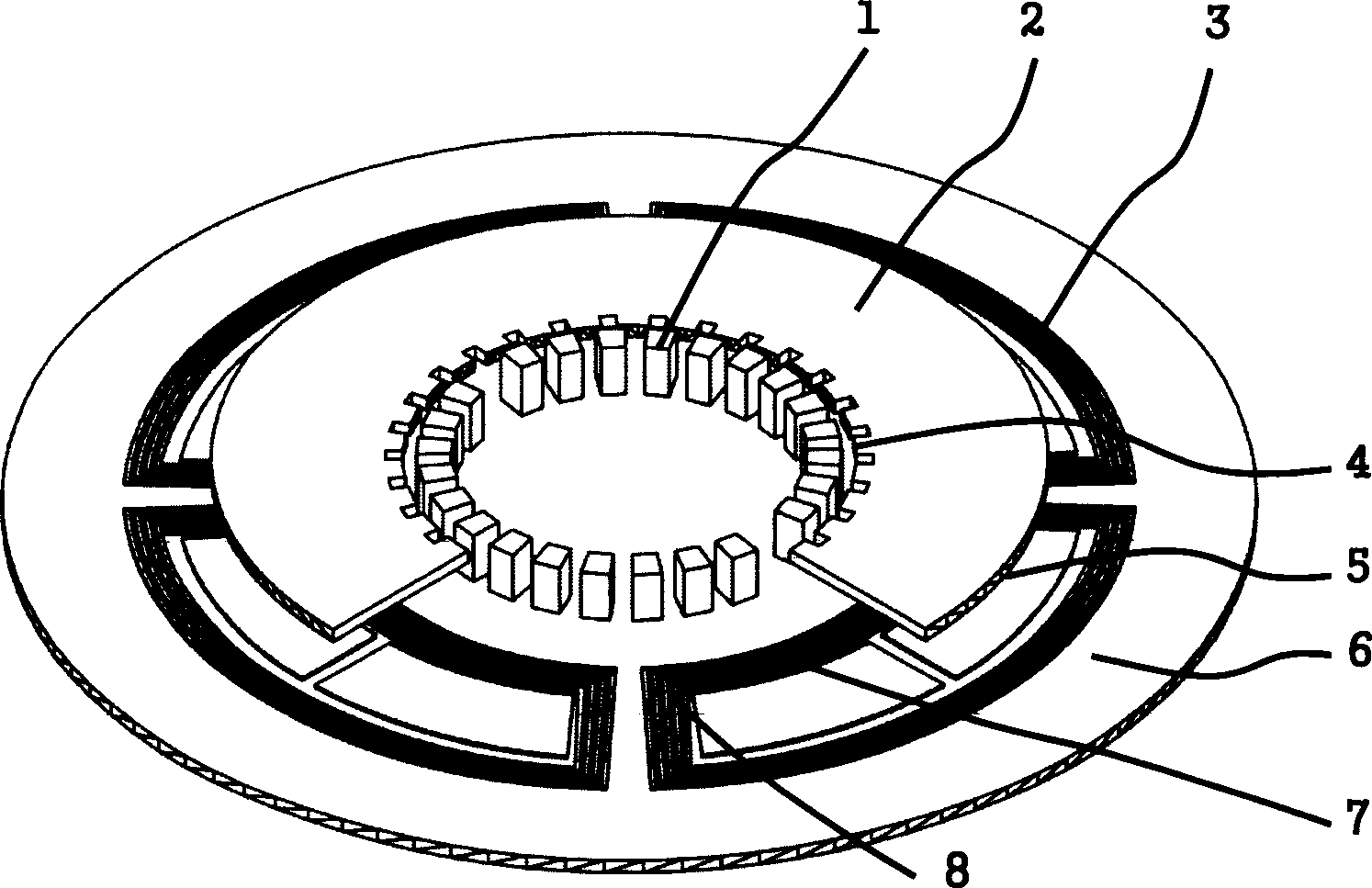

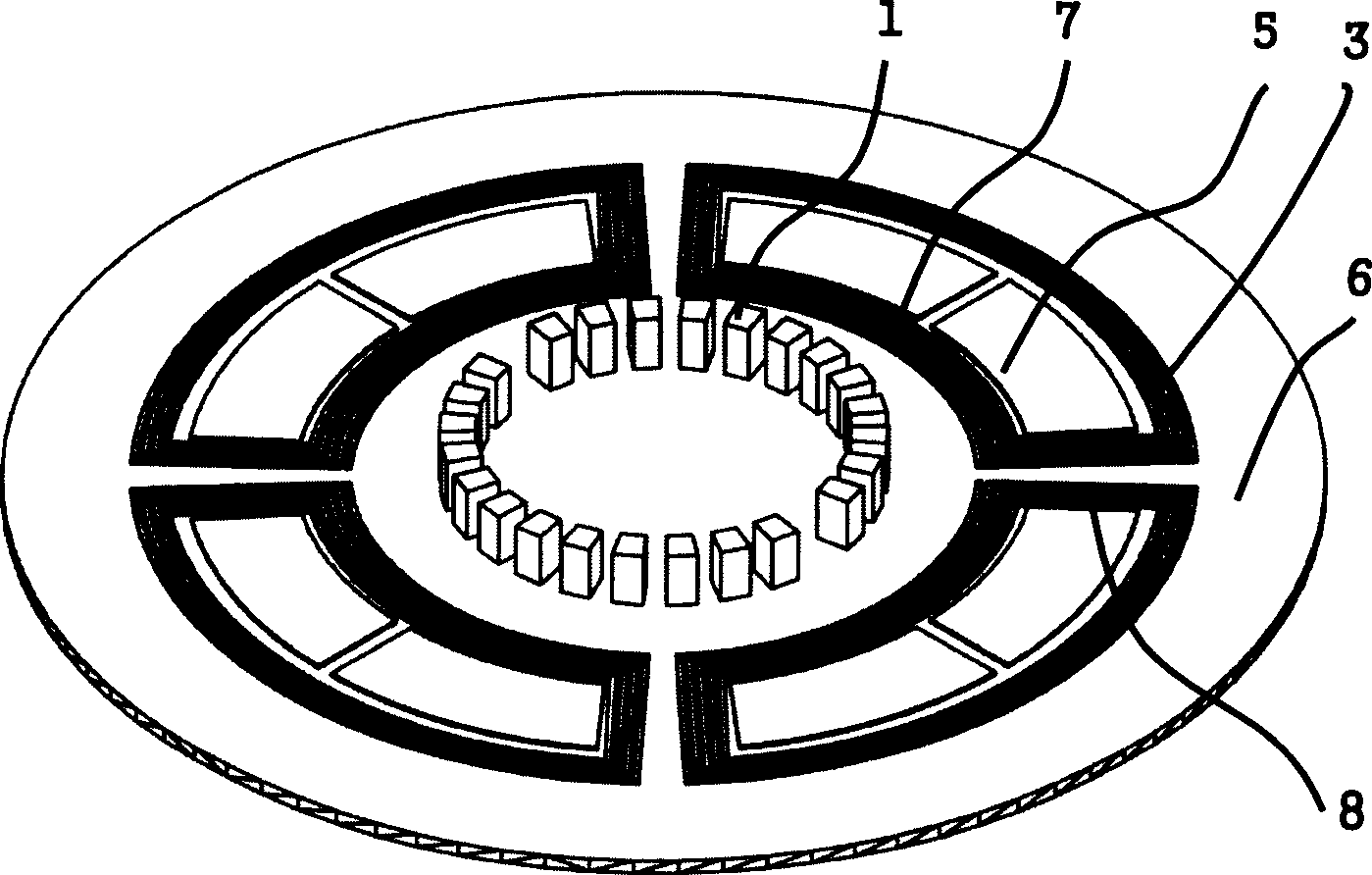

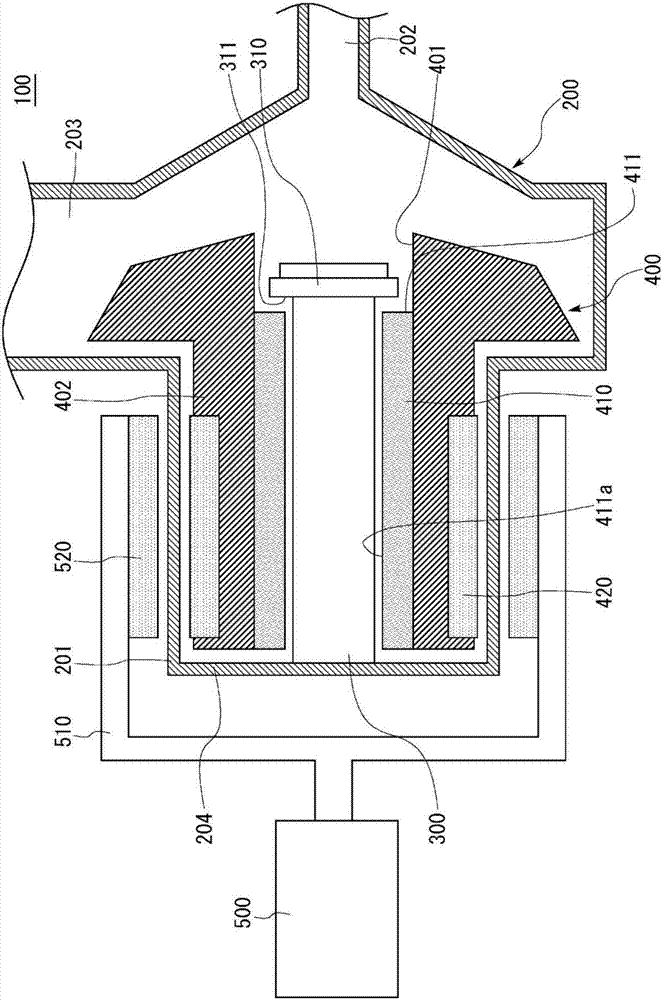

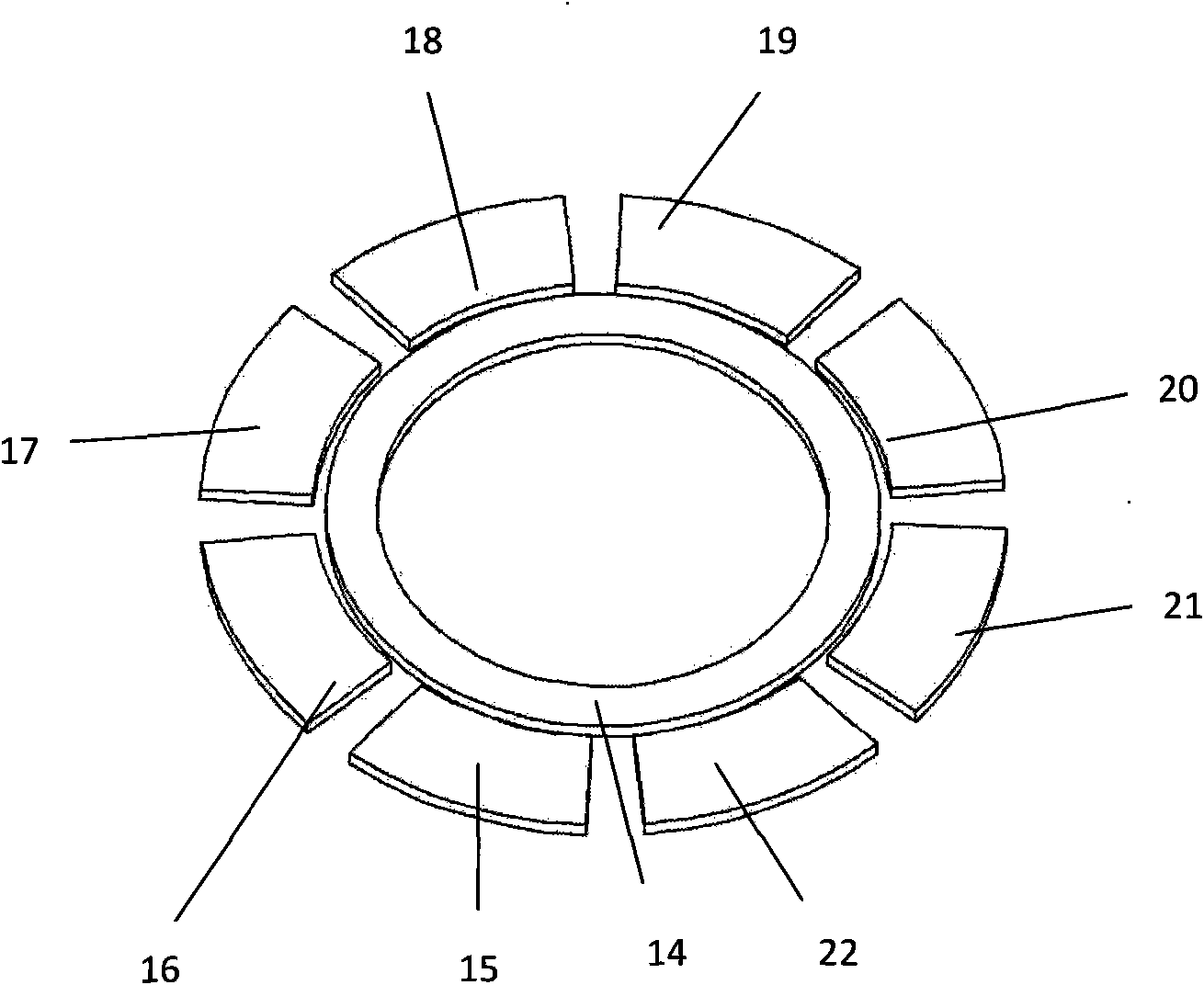

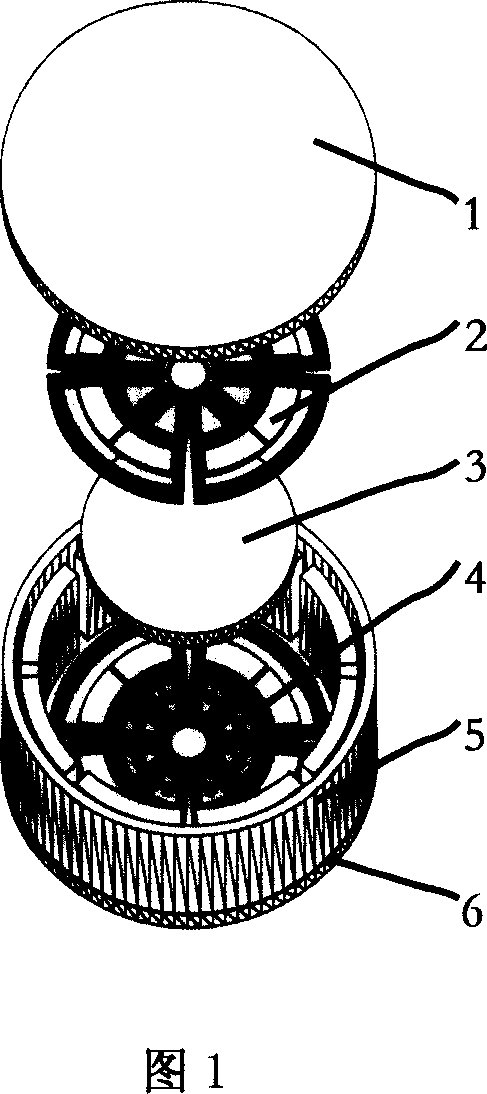

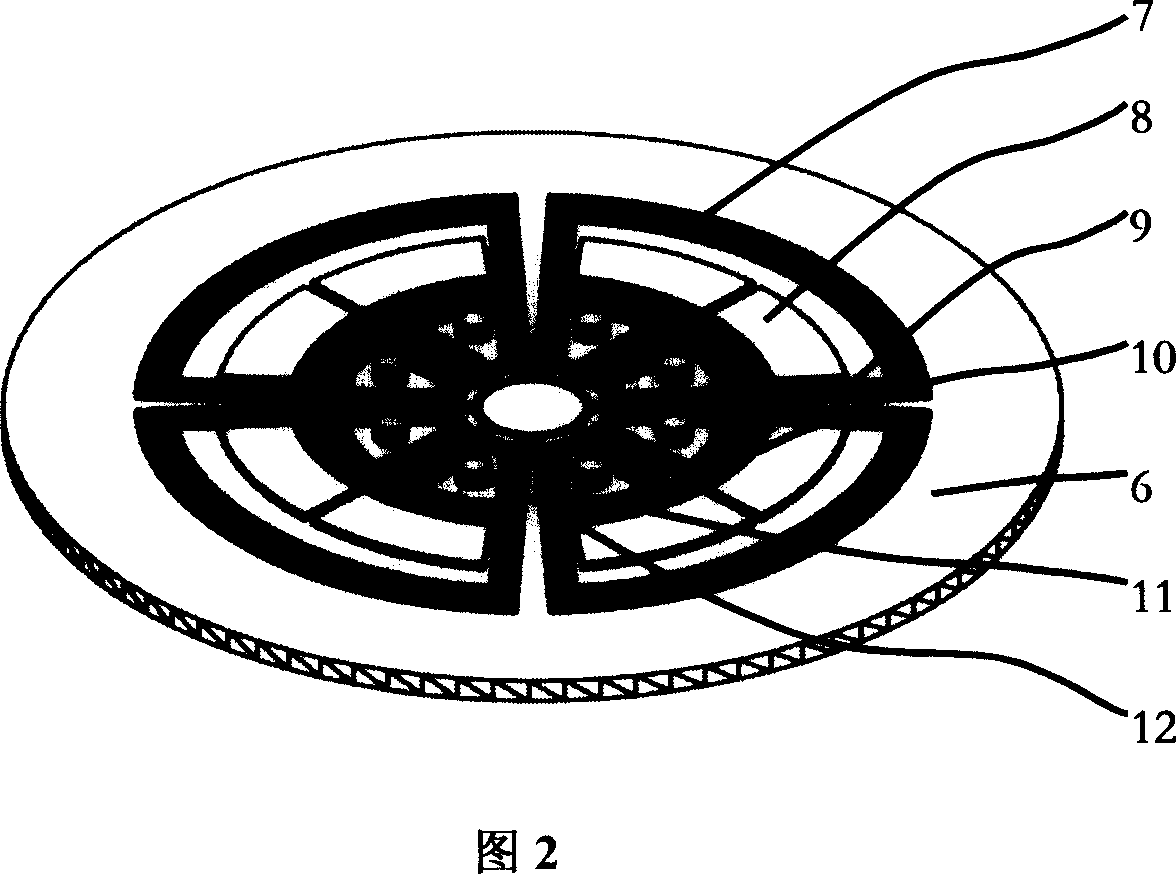

Micro-rotation top with double-stator electromagnetic suspension rotor

InactiveCN1818552AImprove impact resistanceRestricted degrees of freedomSpeed measurement using gyroscopic effectsRotary gyroscopesGyroscopeLaser

A micro rotation gyroscope with double stator and electromagnetic suspension rotator consists of top base body, top stator, micro rotator, bottom stator, bottom base body and seal ring .It features that micro rotator is a conductive ring; rotary coil sensing electrode and suspension-stabilizing coil prepared by photo etching-plating are applied on top and bottom base bodies; the structure of top stator is completely the same as the structure of bottom stator except spacing column of micro rotator is set on bottom stator.

Owner:SHANGHAI JIAO TONG UNIV

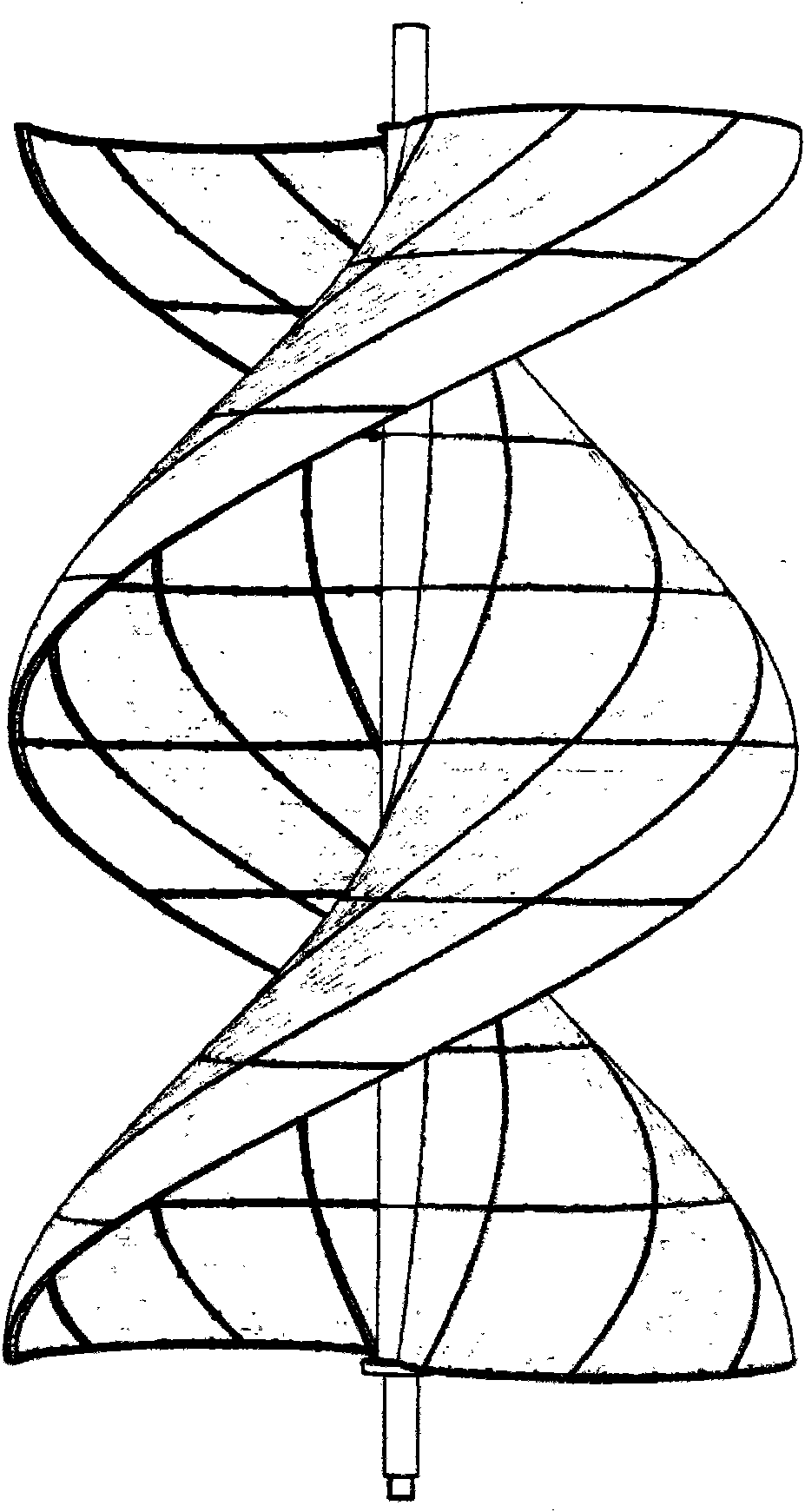

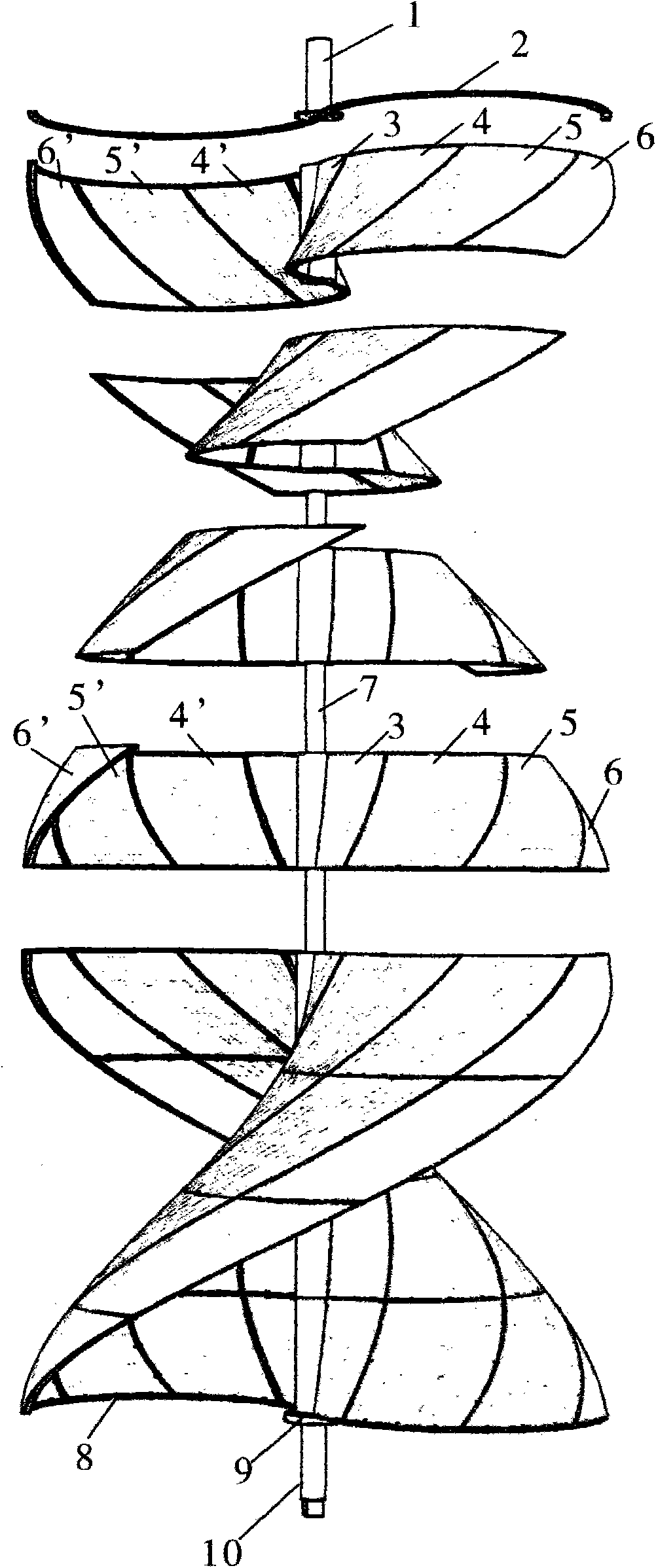

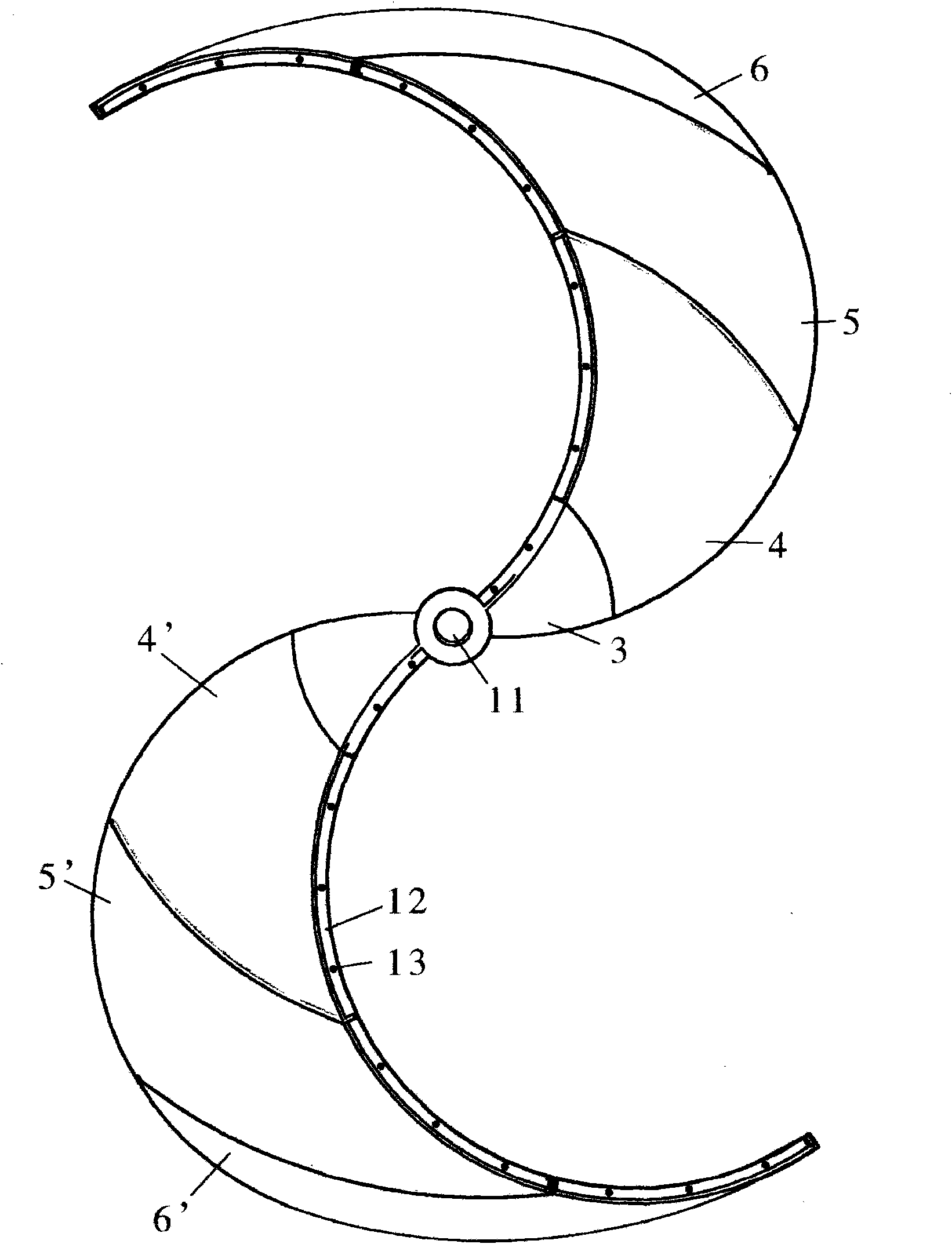

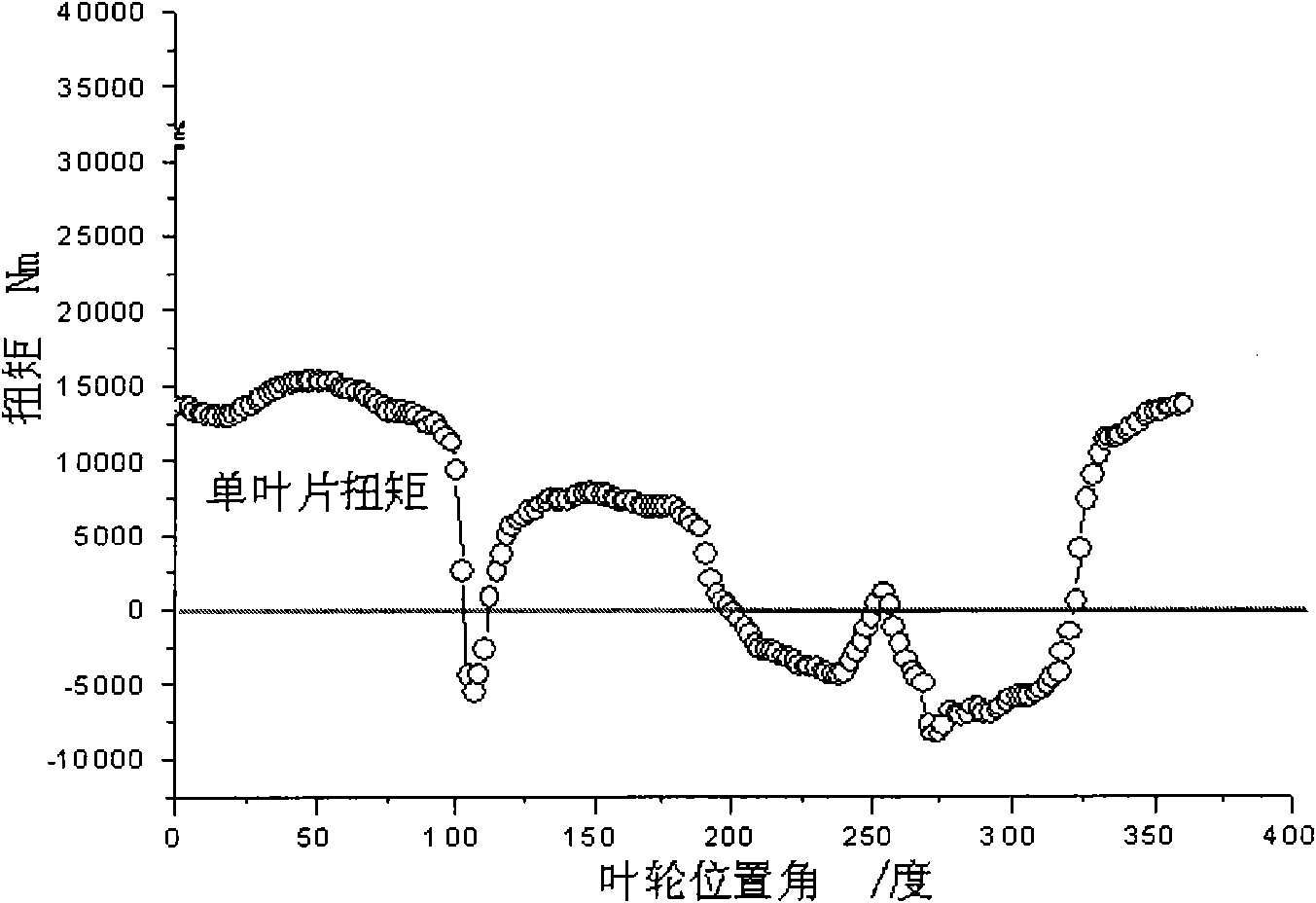

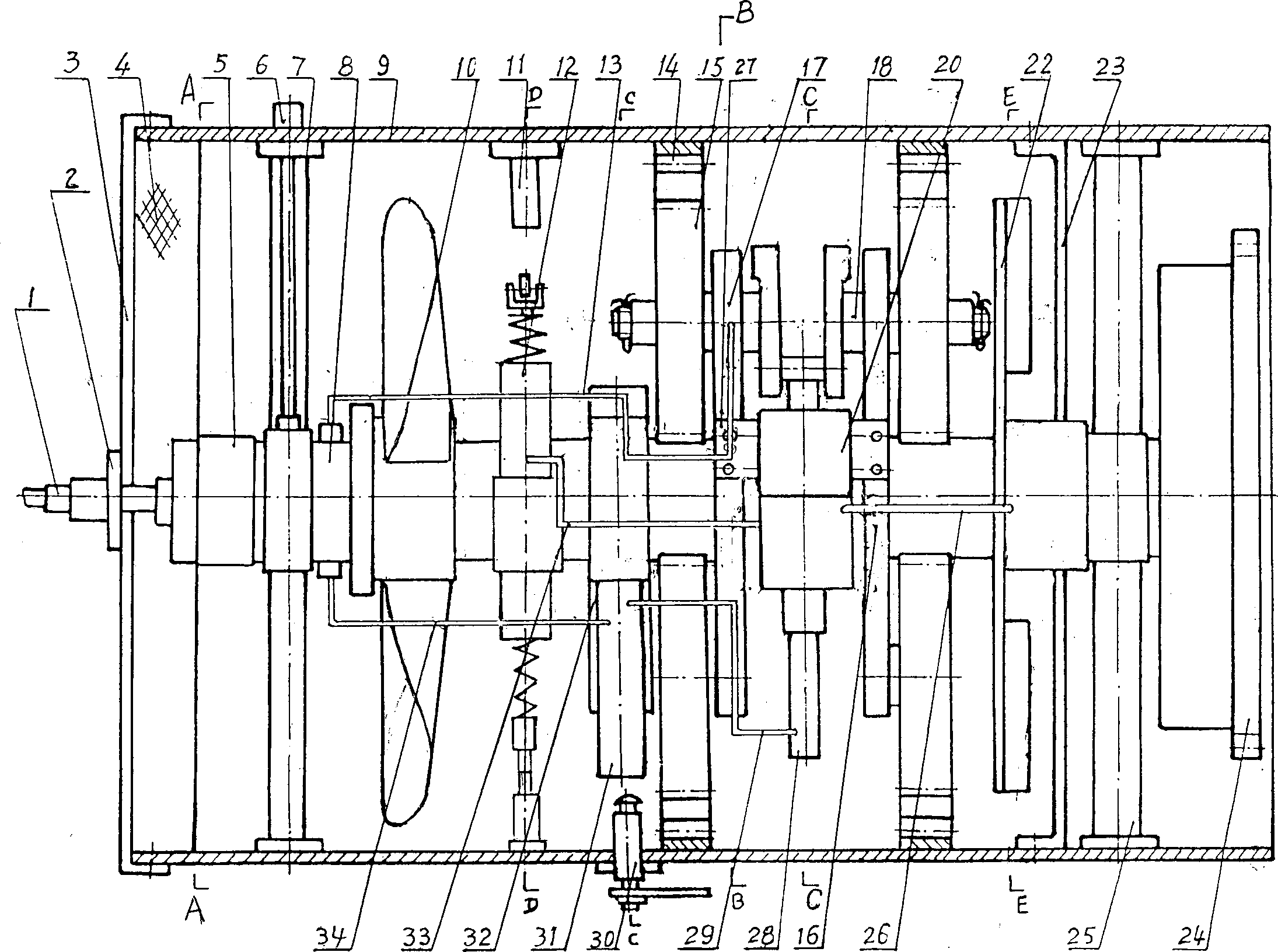

Combined screw impeller wind power generation system

ActiveCN101526068AIncrease rotational torqueReduce manufacturing difficultyWind motor controlFinal product manufactureWind power generationImpeller

The invention relates to a screw impeller wind power generation system, which is mainly characterized in that a screw impeller is formed by assembling a plurality of vertical impeller members along the axial direction, each vertical impeller member is formed by splicing and assembling a plurality of horizontal impeller members along the radial direction of the screw impeller at the same time, the screw impeller is linked with a plurality of generating units through a transmission mechanism, and the generating units output electric energy in a parallel connection mode, thereby being favorable for the after-treatment of the output electric energy, and improving the quality of the supplied electric energy. A clutch device is arranged between the generating units and the transmission mechanism, and a control device receives a wind velocity and wind direction treatment electric signal and performs real-time control of the disengagement or engagement between the single generating unit and the transmission mechanism according to a preset program further to change starting and operation loads of the screw impeller. In addition, the adoption of magnetic suspension bearings can overcome the partial gravitational force born by the impeller, and can also reduce the friction resistance between the impeller and other components further to reduce the lowest starting wind velocity of the impeller and improve the wind-electricity conversion efficiency. The wind power generation system greatly reduces manufacturing, transportation, installation, maintenance, and series costs.

Owner:江苏易佳节能科技有限公司

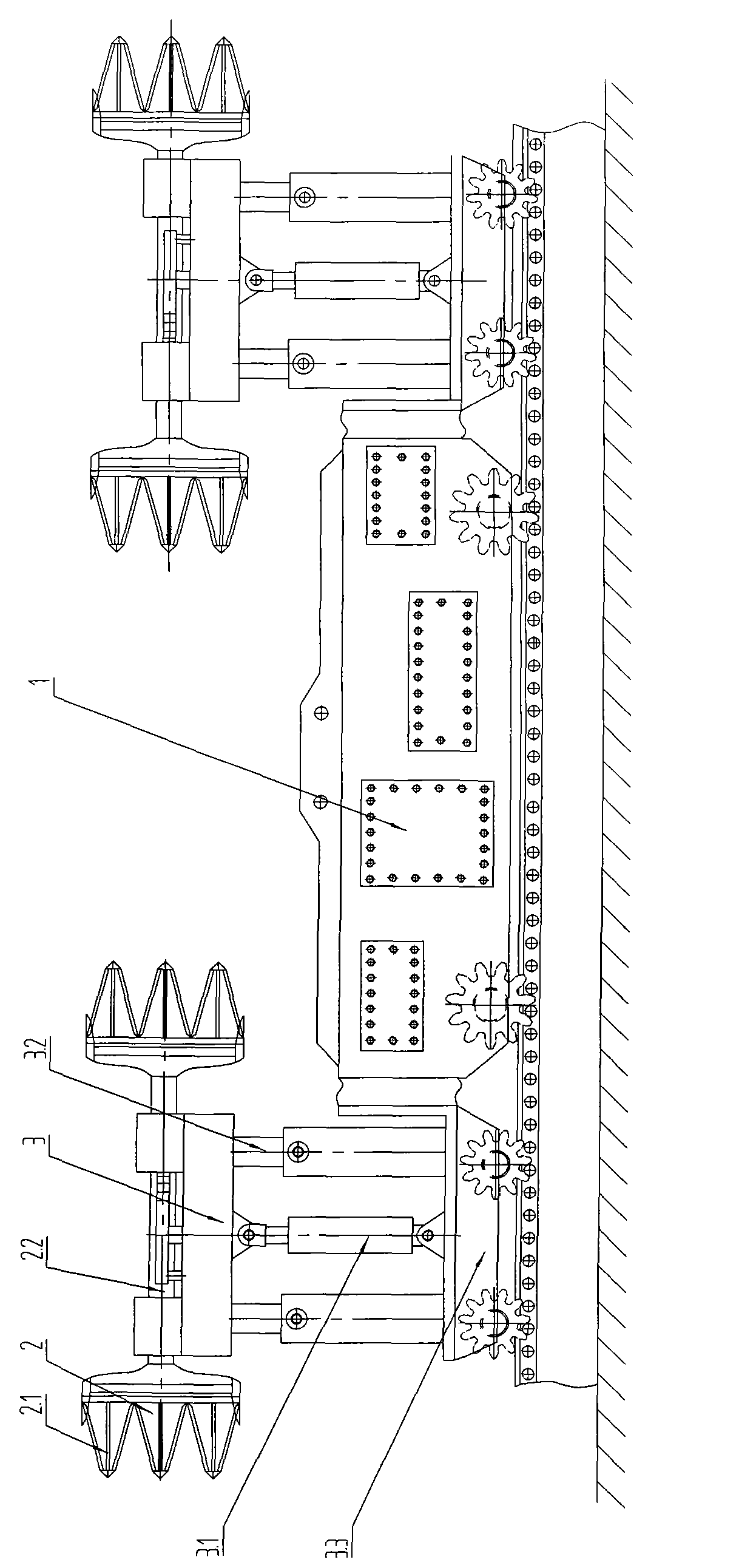

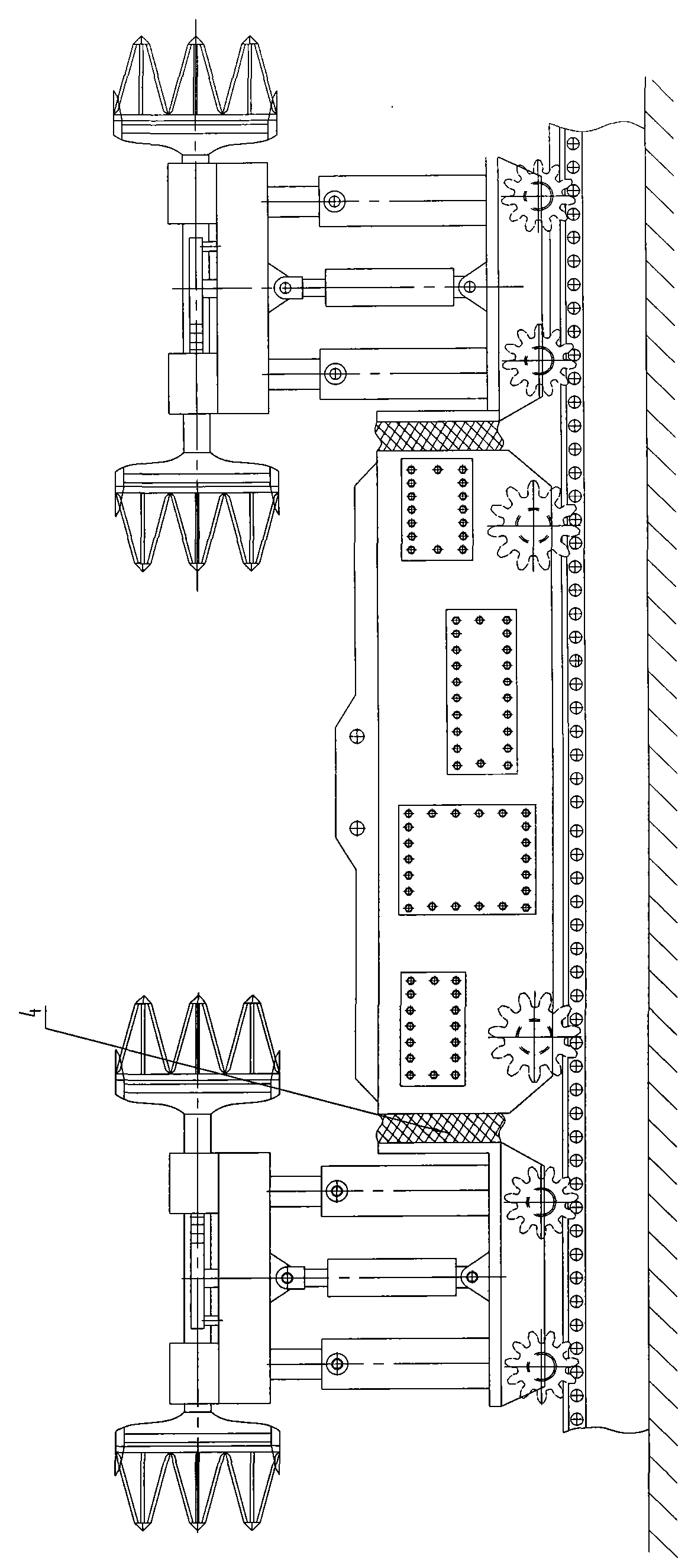

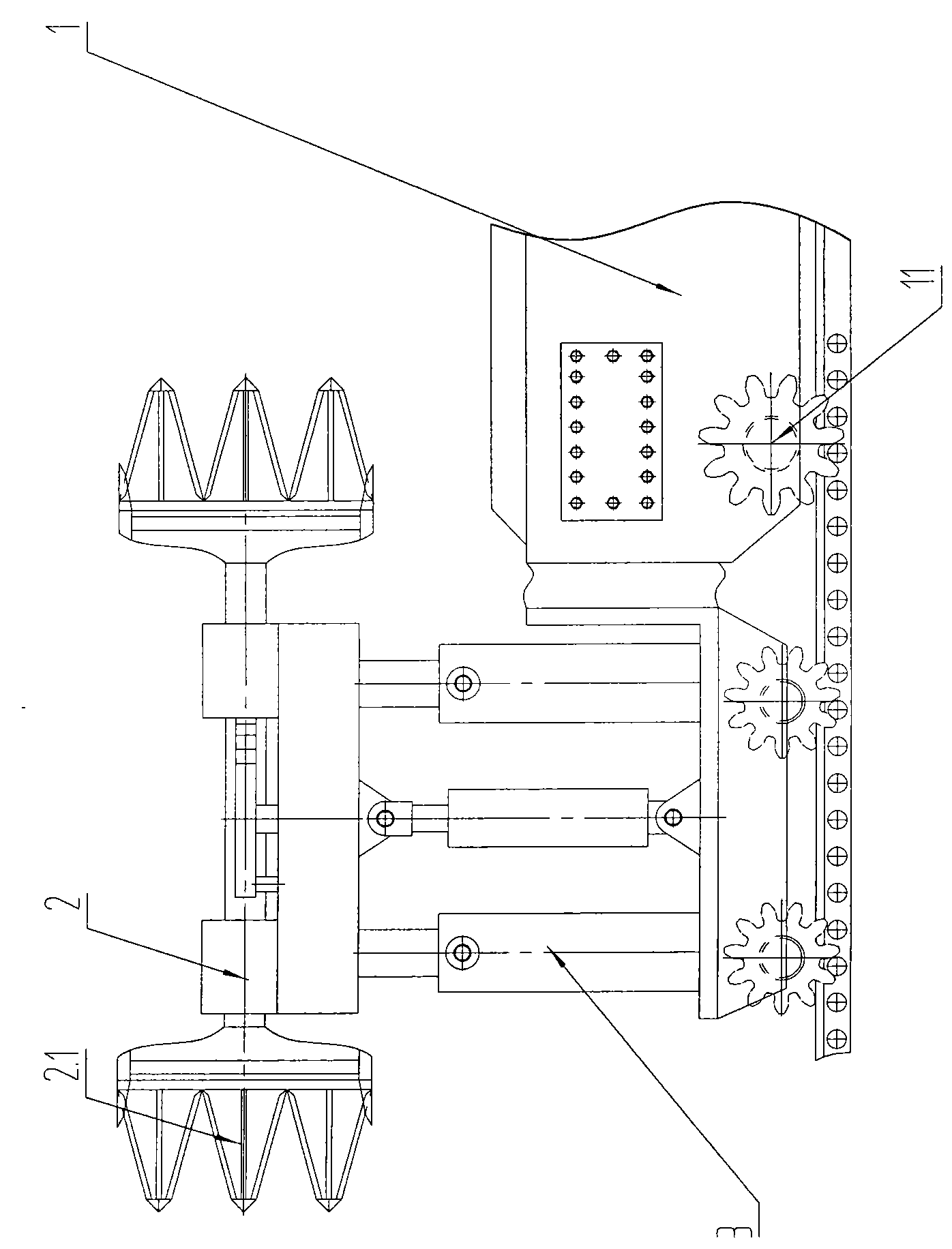

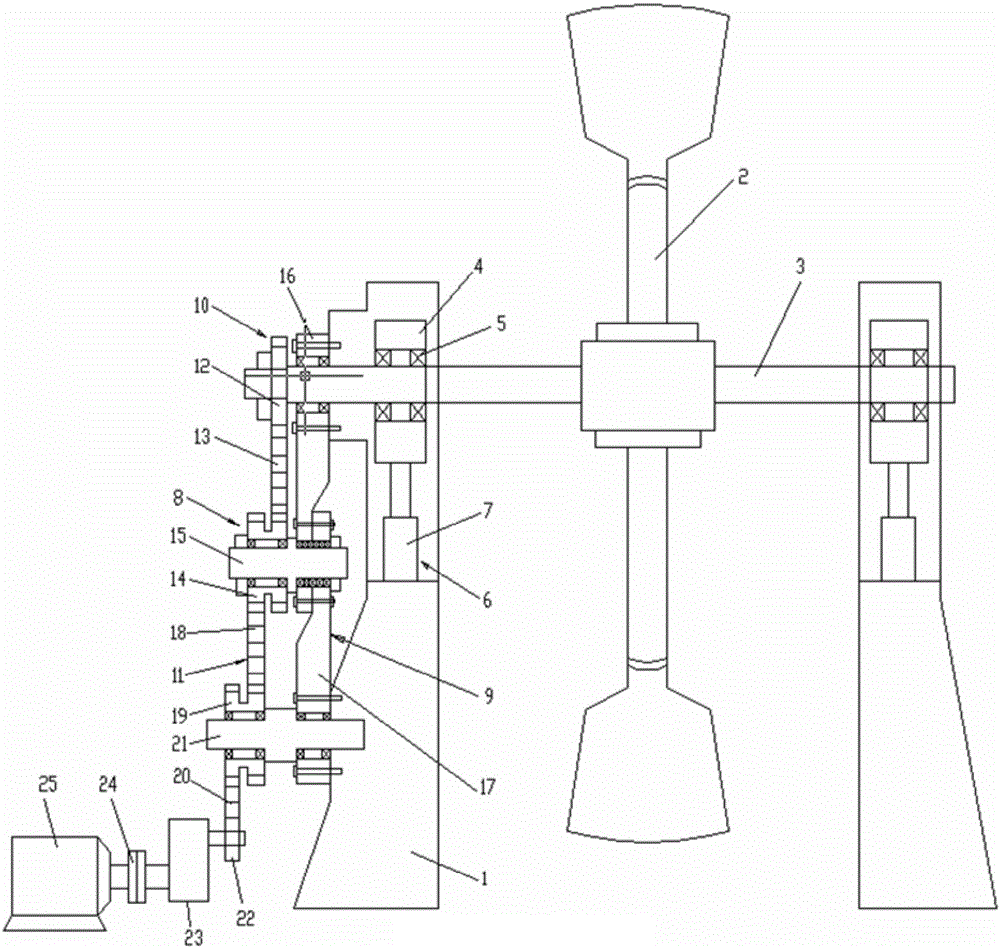

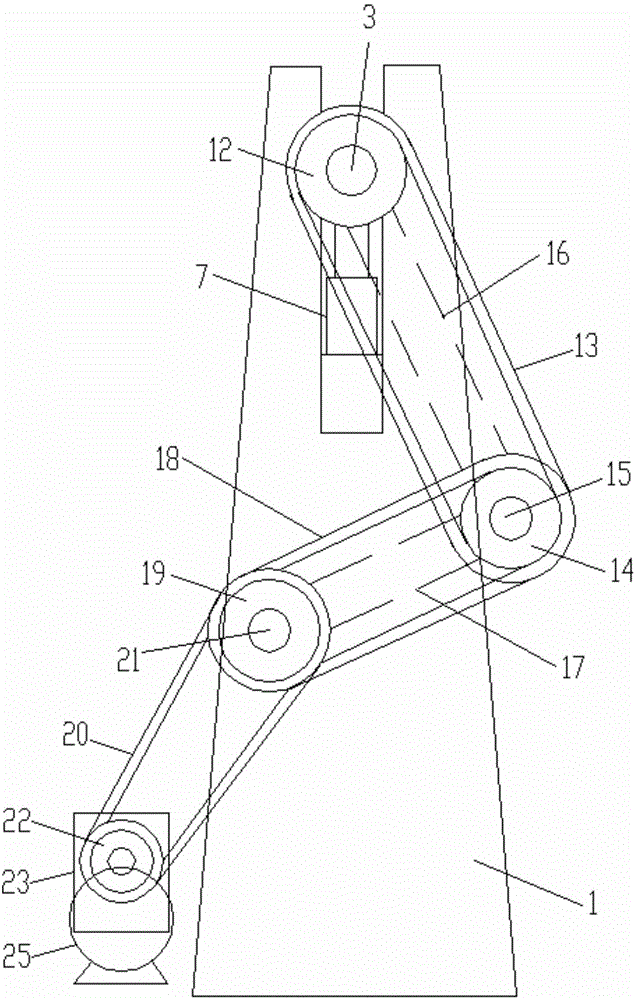

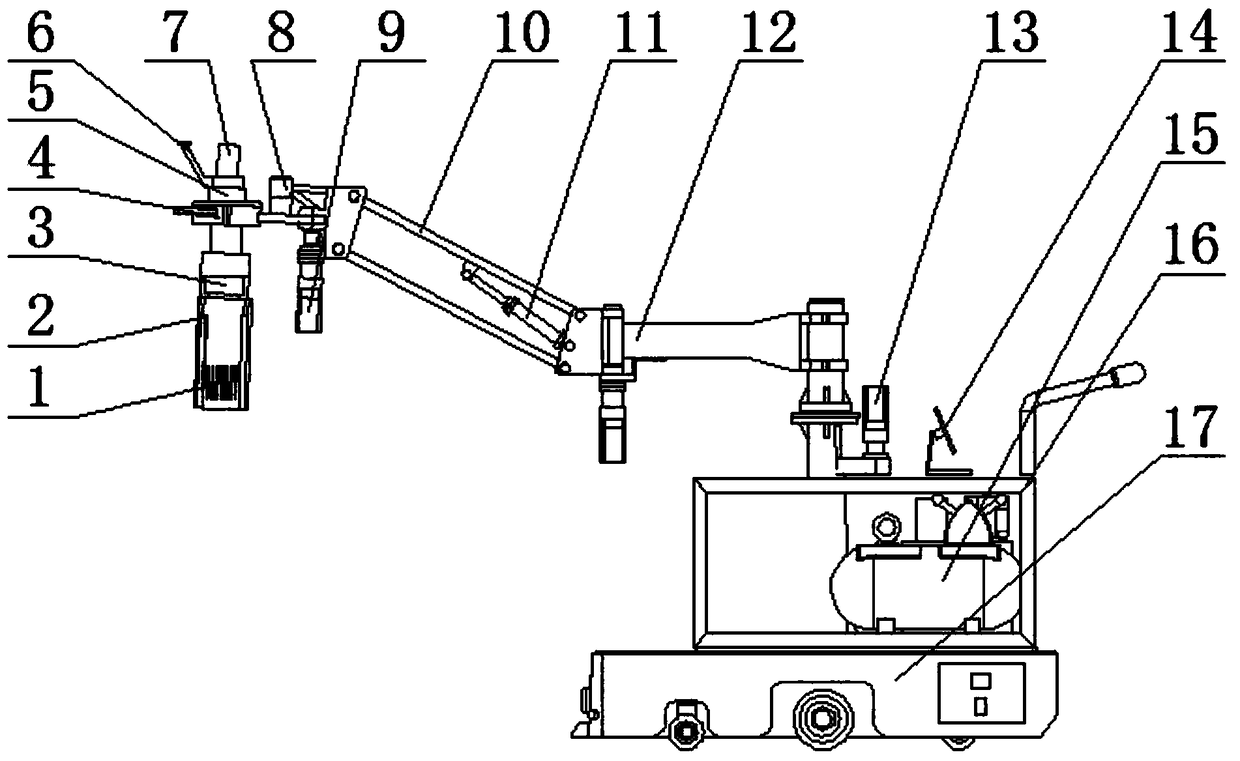

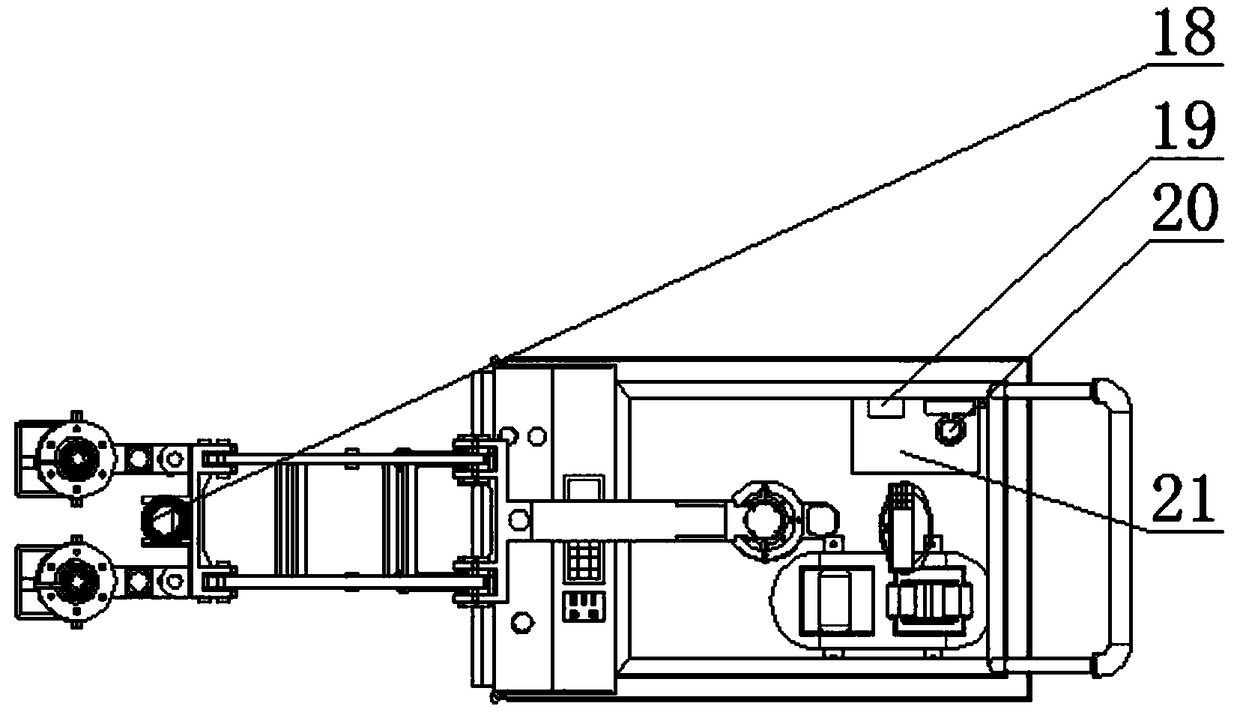

Method for retaining vertical impact of impacting mechanism and vertical-lift impact-cutting digger implementing same

InactiveCN103206213AIncrease arm lengthReduce farewellDriving meansCutting machinesEngineeringFuselage

The invention specifically relates to a method for retaining vertical impact of an impacting mechanism and a vertical-lift impact-cutting digger implementing the method, belonging to the field of machinery, especially to the field of mining. The digger comprises a body, the impacting mechanism and a vertical lift mechanism, wherein the impacting mechanism comprises a guiding member and an impacting head, the vertical lift mechanism comprises a vertical lift driving unit, a lifting and moving part, a supporting seat and the like, the lifting and moving part is movably connected with the supporting seat, the supporting seat is connected with the body, the impacting mechanism is arranged on the lifting and moving part, the vertical lift driving unit drives the lifting and moving part to vertically move up and down, and the lifting and moving part drives the impacting mechanism to vertically rise and fall. The digger provided by the invention has the advantages of a long service life, a small amount of maintenance, high work efficiency, shortened body length and applicability to a complex usage occasion.

Owner:刘素华

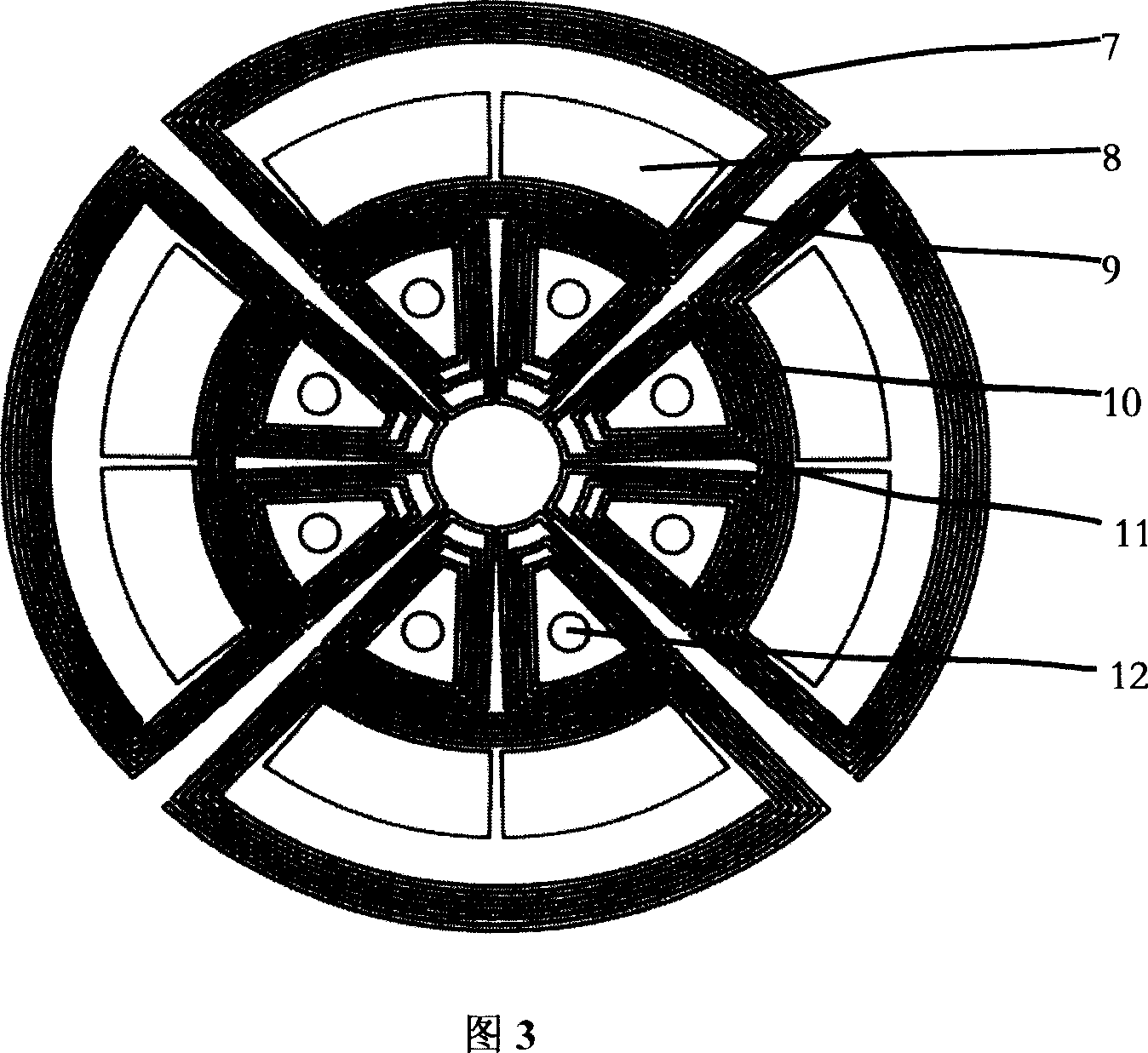

Internal stabilized electromagnetic suspension ring-shaped micro-rotating gyroscope

InactiveCN101017088AIncrease rotational torqueRotary gyroscopesMechanical energy handlingGyroscopeEngineering

This invention relates to one inner stable hanging ring rotor micro rotation top in micro machine system technique field, wherein, setting the stable float coil, rotation coil and sensor electrode onto base to form fix connection and base; micro rotor is floating one the base under electronic magnetic force and the ring rotor is under function of hanging coil force to get stable hanging outside rotation coil to generate rotation magnetic field; micro rotor is under rotation magnetic field to generate rotation torque for high speed rotation through sensor electrode.

Owner:SHANGHAI JIAO TONG UNIV

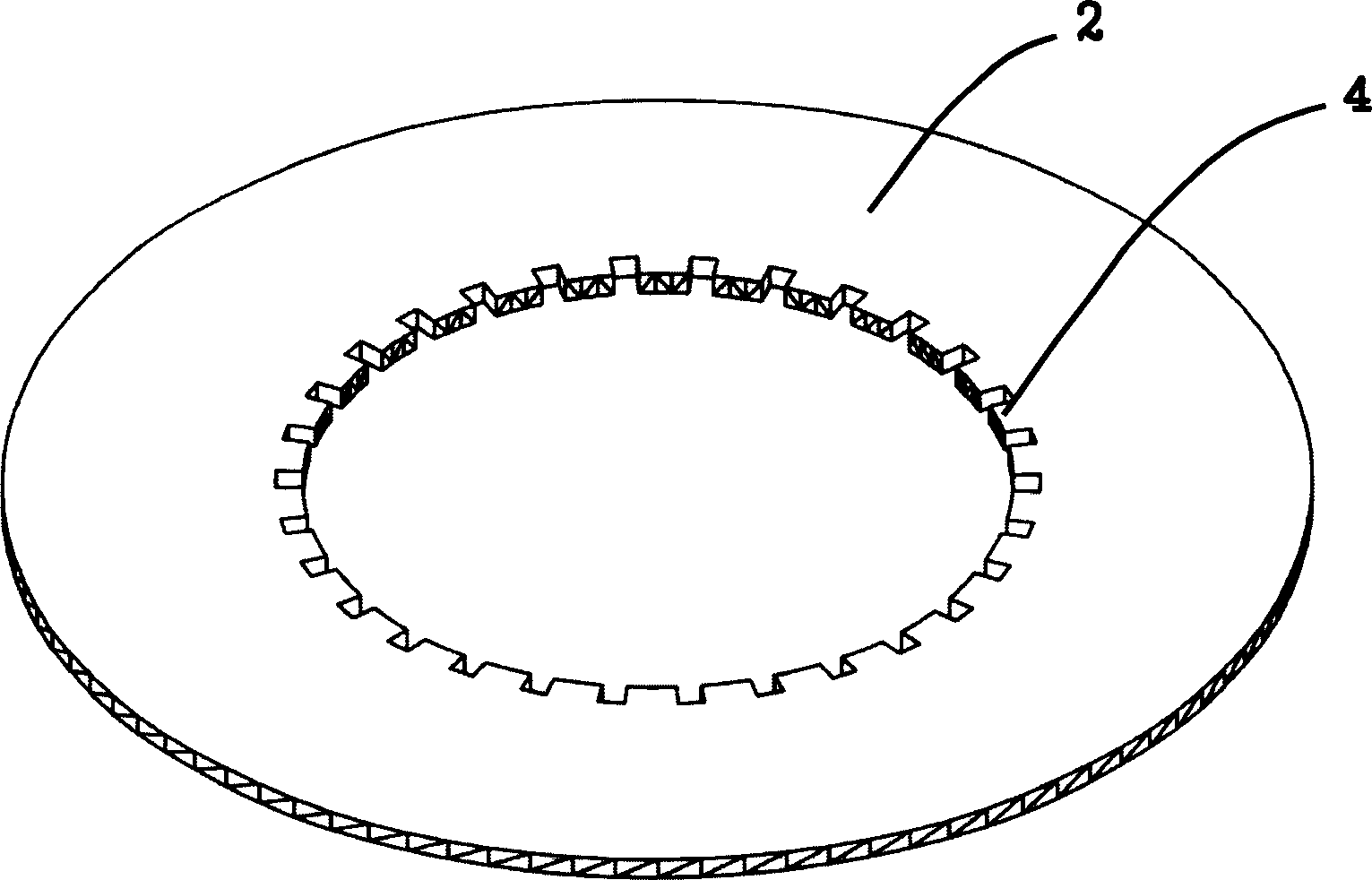

Electromagnetic levitation static driven micro-rotation gyro

The invention relates to an electromagnetic suspension static electricity driving micro-rotating gyrostat in the field of Micro Electro-Me-chanical Systems technique. It comprises: a rotation driving electrode, a micro-rotor, a stabilizing floating coil collar, a tooth outline electrode, a sensing electrode, a base body, a stabilizing floating coil inner ring and a connecting line, wherein the stabilizing floating coil collar, the stabilizing floating coil inner ring, the sensing electrode and the rotation driving electrode are fixed on the base body and forms to the fixed connection; the micro-rotor is positioned on the upper of the base body on the electromagnetic force effect; the micro-rotor is loop type with the tooth outline electrode, the rotation driving electrode and the tooth outline electrode distributed on the inner side of the loop to form the variable capacity; the stabilizing floating coil inner ring is connected with the stabilizing floating coil collar by connecting wire.

Owner:SHANGHAI JIAO TONG UNIV

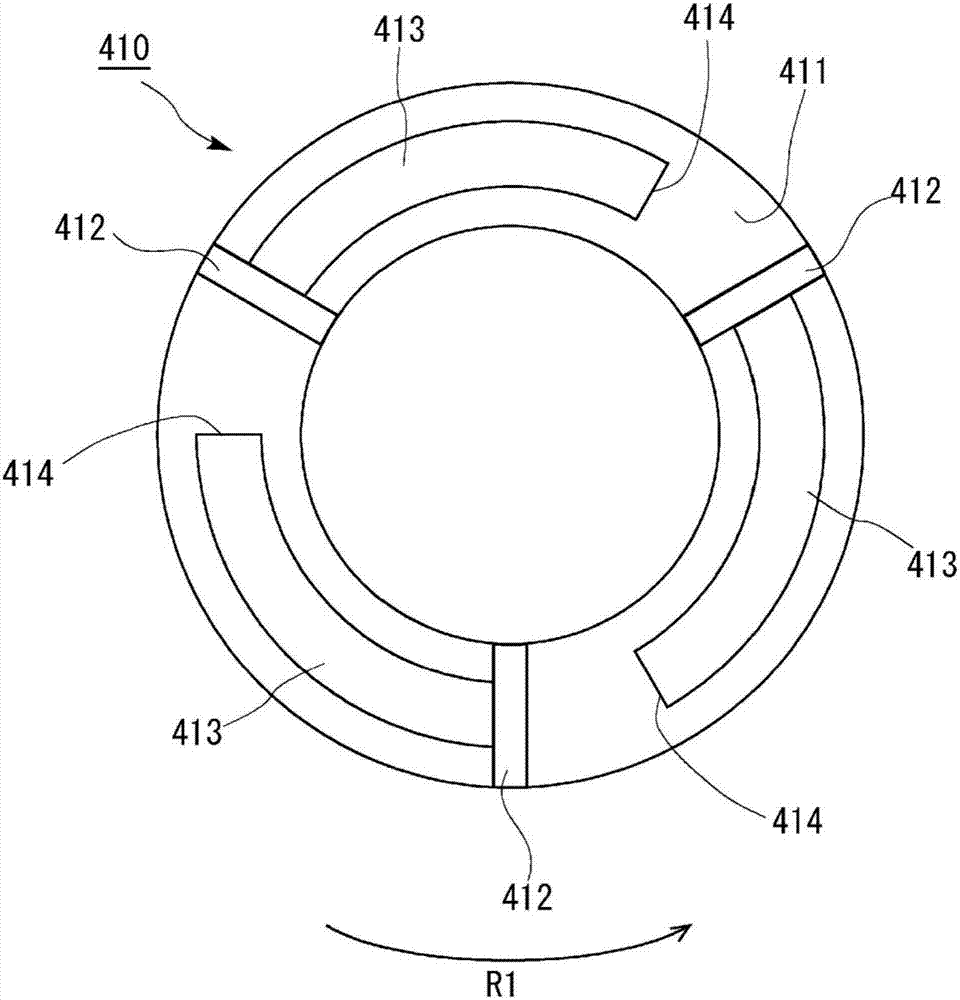

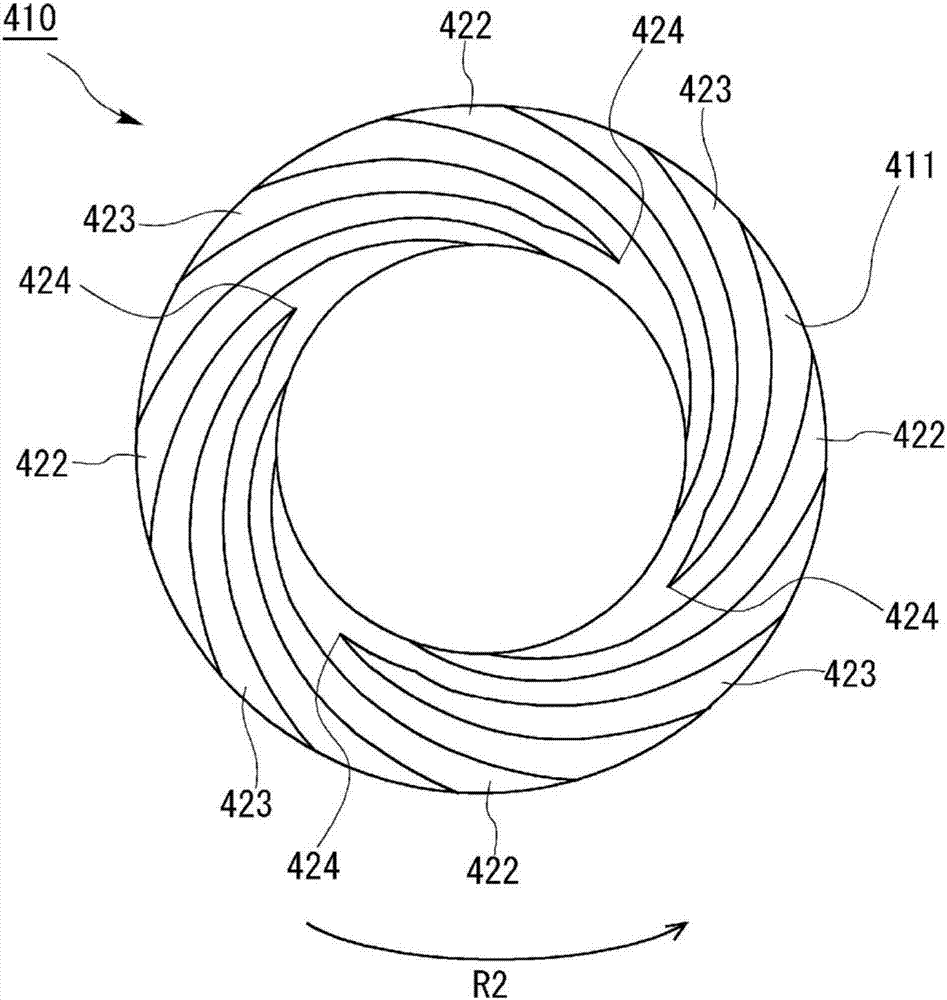

Energy storage device for storing energy as spring torsion

InactiveCN103573952AAvoid destructionIncrease rotational torqueSpring motorGearingEngineeringUp conversion

The invention discloses an energy storage device for storing energy as spring torsion, which is used for storing a motive force generated by an energy generation device in a spring type energy form. The energy storage device for storing the energy as the spring torsion comprises a torsion conversion gear used for connecting an energy source and converting the energy into torsion for outputting; the output end of the torsion conversion gear is connected to a torsion limiter and is used for preventing oversized torsion from being input to subsequent structures to result in damage; the output end of the torsion limiter is connected to a one-way input bearing so as to transmit the torsion to the subsequent structures in a single direction and prevent the output torsion from being output inversely to result in damage to the former structures; the output end of the one-way input bearing is connected to an energy storage group; the energy storage group is formed by coaxially connecting at least two turntables; a torsion spring is wound between two adjacent turntables; the terminal end of the torsion spring is bent in the direction opposite to the winding direction, so that when the turntables rotate, the torsion spring is bent and wound for twice to increase a rotary torsion; the turntable at the torsion output end of the energy storage group is connected to an speed-up conversion gear and is used for speeding up the rotary torsions so as to perform energy outputting; the energy storage group further can be arranged in a serial / parallel mode to increase energy storage and use efficiency.

Owner:邱垂南

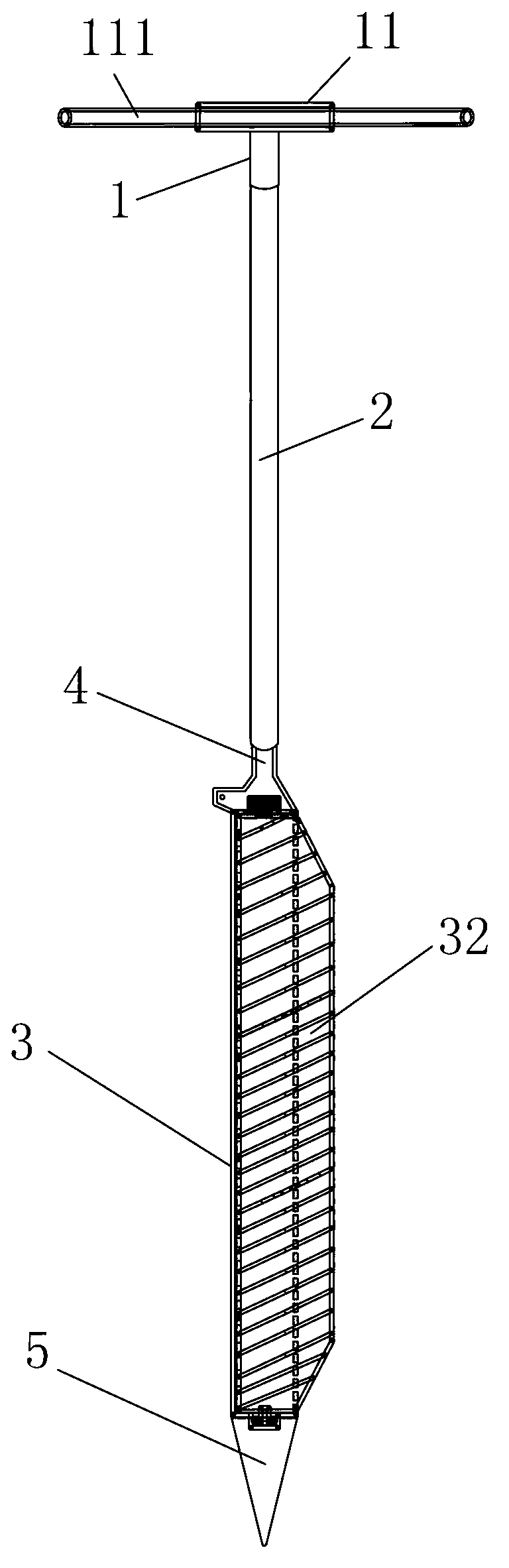

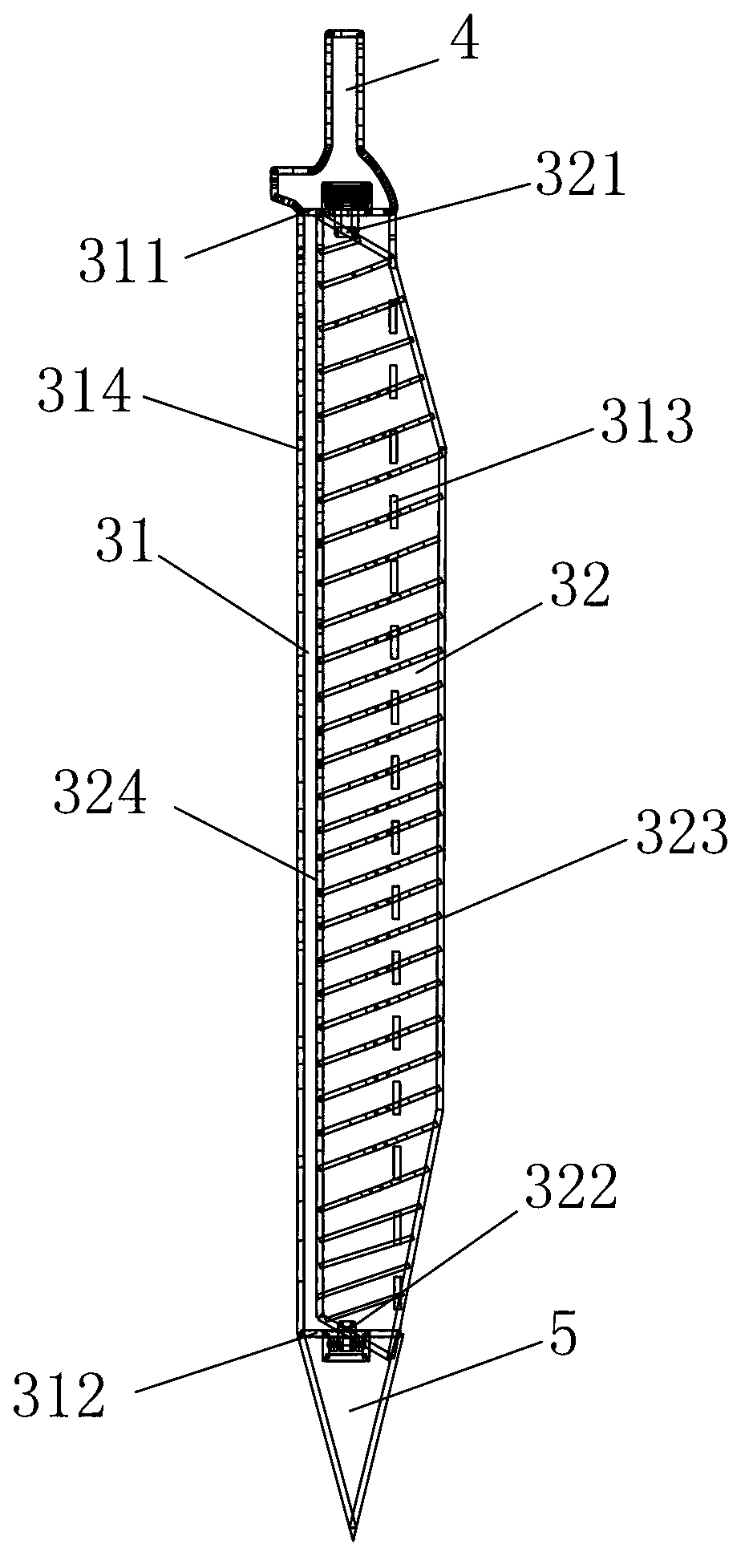

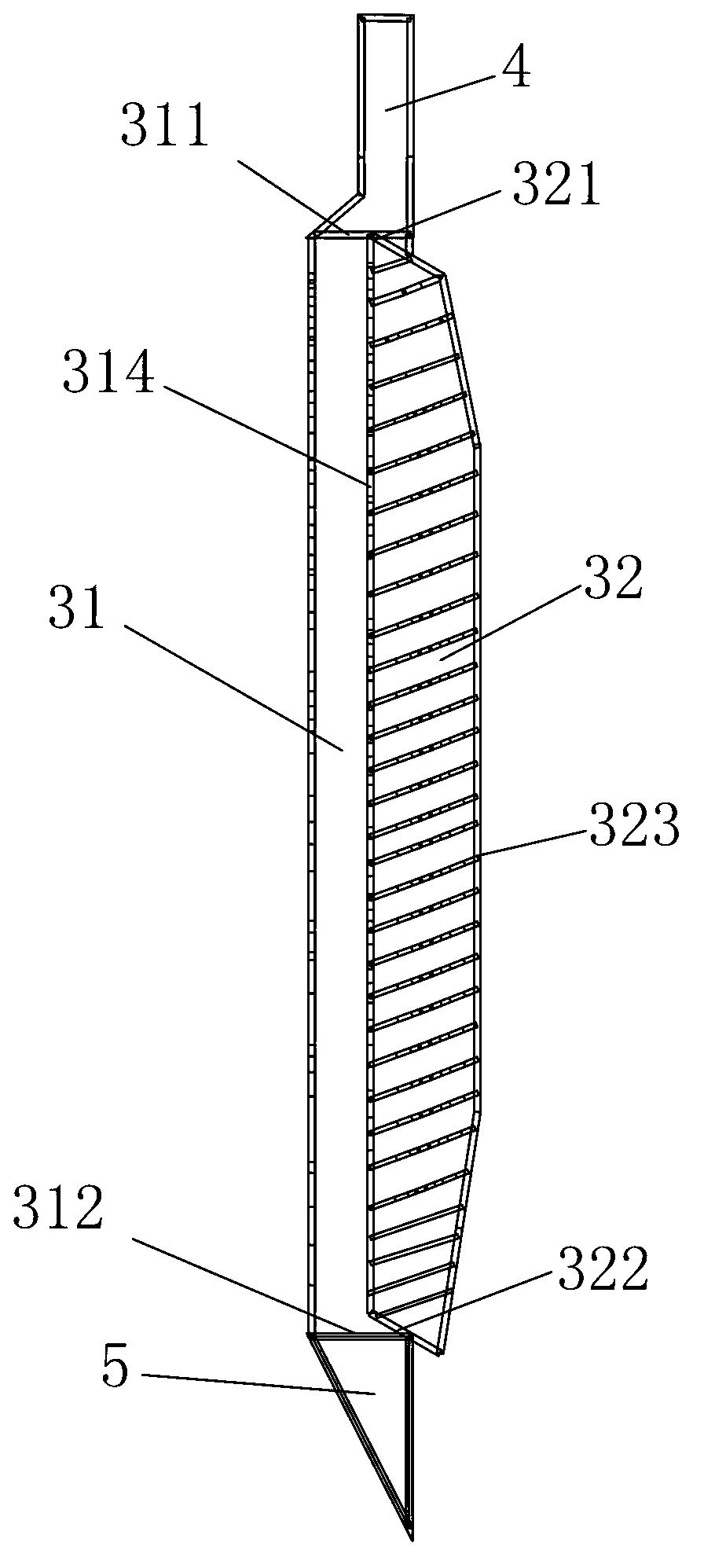

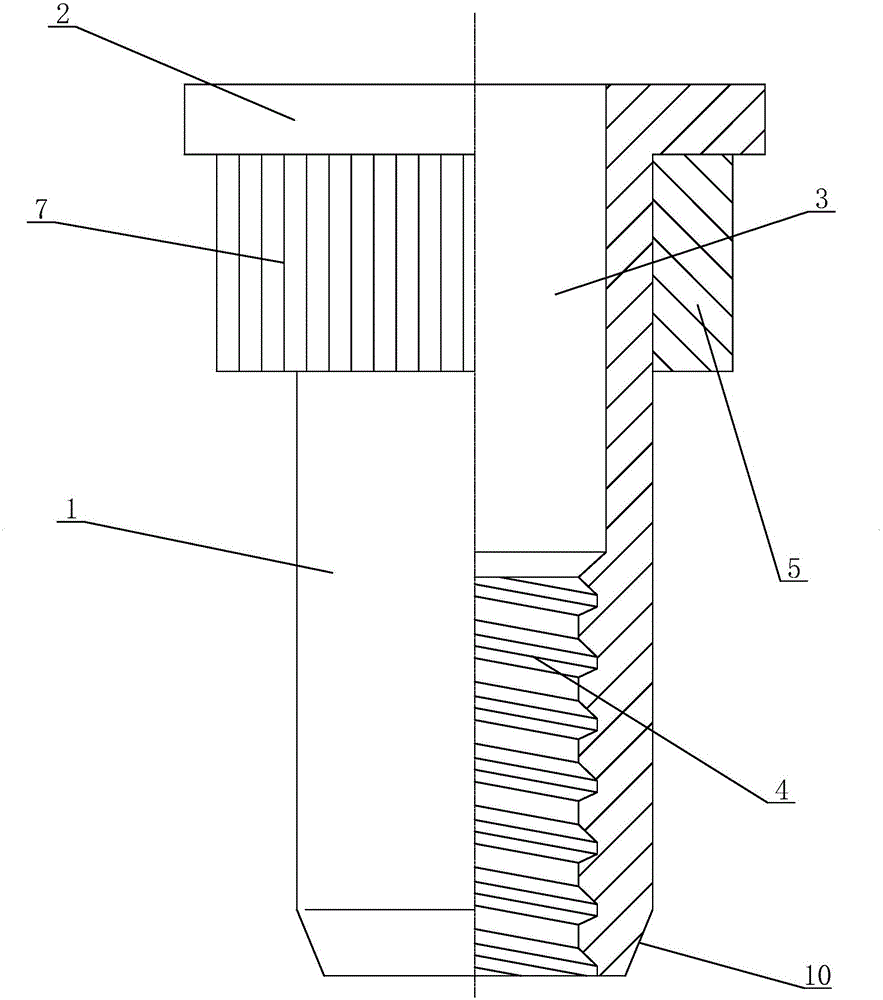

Lacustrine core sampling device for sediments in lakes with different depths

InactiveCN103308344AAvoid disadvantagesImprove integrityWithdrawing sample devicesMarshSample integrity

The invention discloses a lacustrine core sampling device for sediments in lakes with different depths. The lacustrine core sampling device comprises a handle rod, a drilling rod and a rotary core capturing device which are sequentially fixedly connected from top to bottom, wherein the rotary core capturing device comprises a sample pipe and a rotary blade, a sample pipe body is a semicircular groove body, a connecting rod connected with the drilling rod is arranged at the top end of the semicircular groove body, a drill bit is fixedly arranged on the outer side surface of the bottom end of the semicircular groove body, and two ends of the rotary blade are respectively rotatably connected to the top end and the bottom end of the semicircular groove body. According to the lacustrine core sampling device, the defect of an existing mechanical sediment sampler is overcome, the sampling success rate and the sample integrity are increased, lacustrine cores of water bodies and marshes in different depths are sampled through the arrangement of prolongable drilling rod and a hammer, the dismantling link is greatly simplified, the time is effectively saved, and the demand on research is also met.

Owner:BEIJING NORMAL UNIVERSITY

Environment-friendly water surface hydroelectric power plant

ActiveCN106438172AIncrease rotational torqueImprove power generation efficiencyHydro energy generationReaction enginesPotential energyHydroelectricity

The invention provides an environment-friendly water surface hydroelectric power plant which comprises iron tower supports, a water wheel supported to the tops of the iron tower supports through a water wheel centre shaft, a reduction box and an electric generator. The water wheel is evenly provided with a plurality of groove-type blades, the two ends of the water wheel centre shaft are supported to the tops of the corresponding iron tower supports through lifting mechanisms and move up and down to adjust the height of the water wheel, one end of the water wheel center shaft is connected with the input end of the reduction box through a crank type transmission device. According to the environment-friendly water surface hydroelectric power plant, the groove-type blades are adopted and are in holding type contact with water flow, stress is concentrated, the fluid potential energy can be received to the maximum degree, the rotation twisting force of the water wheel and the water wheel center shaft is increased, and the aims of energy conservation and efficiency improvement are achieved; in addition, the water wheel center shaft and the water wheel of the environment-friendly water surface hydroelectric power plant move up and down through the lifting mechanisms, the end of the water wheel center shaft outputs power through the crank type transmission device, normal transmission of power at different heights of the water wheel center shaft is guaranteed, impact damage of floating objects in a river on the blades during large waves and fast flow is avoided, and the electric generation capacity and the viability of the power plant under the extreme hydrologic condition are guaranteed.

Owner:杨长易

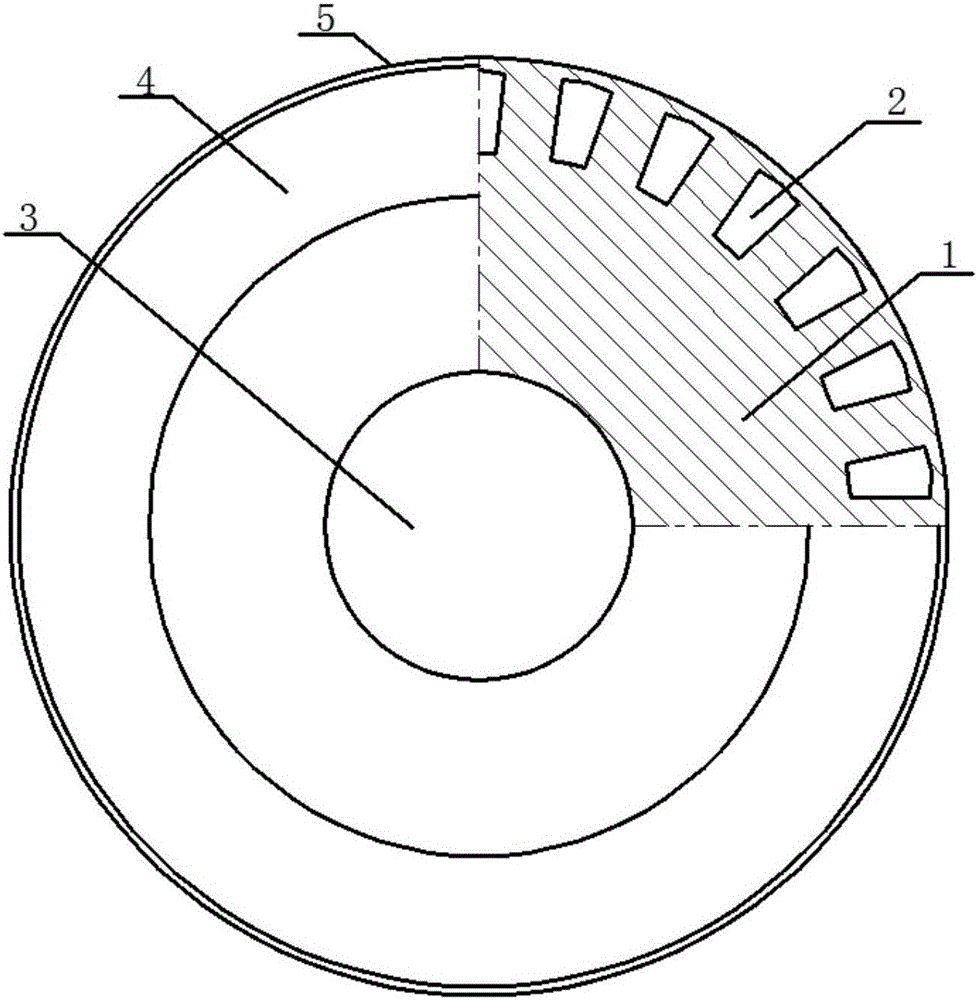

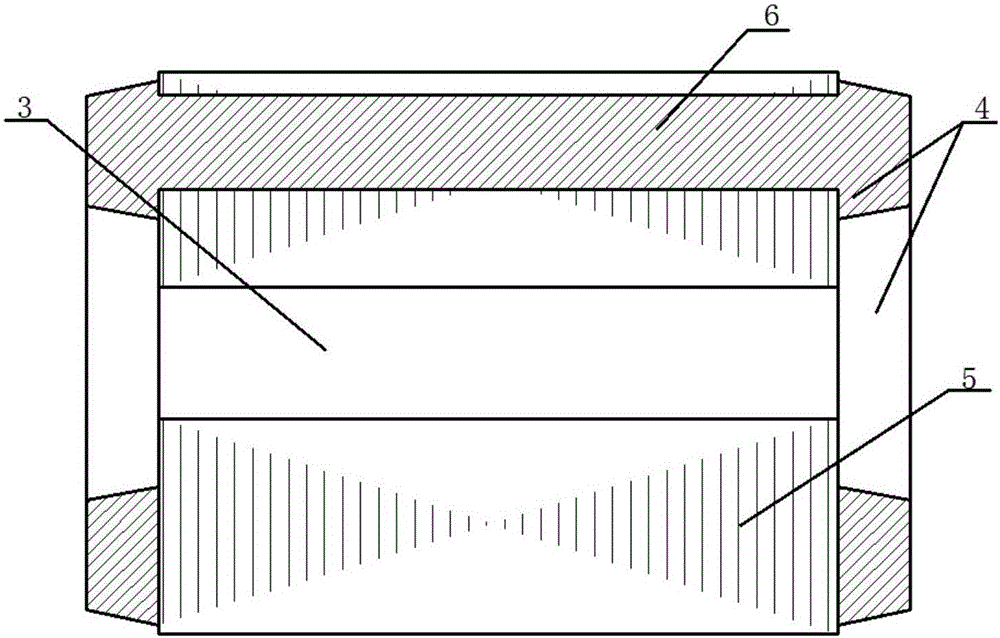

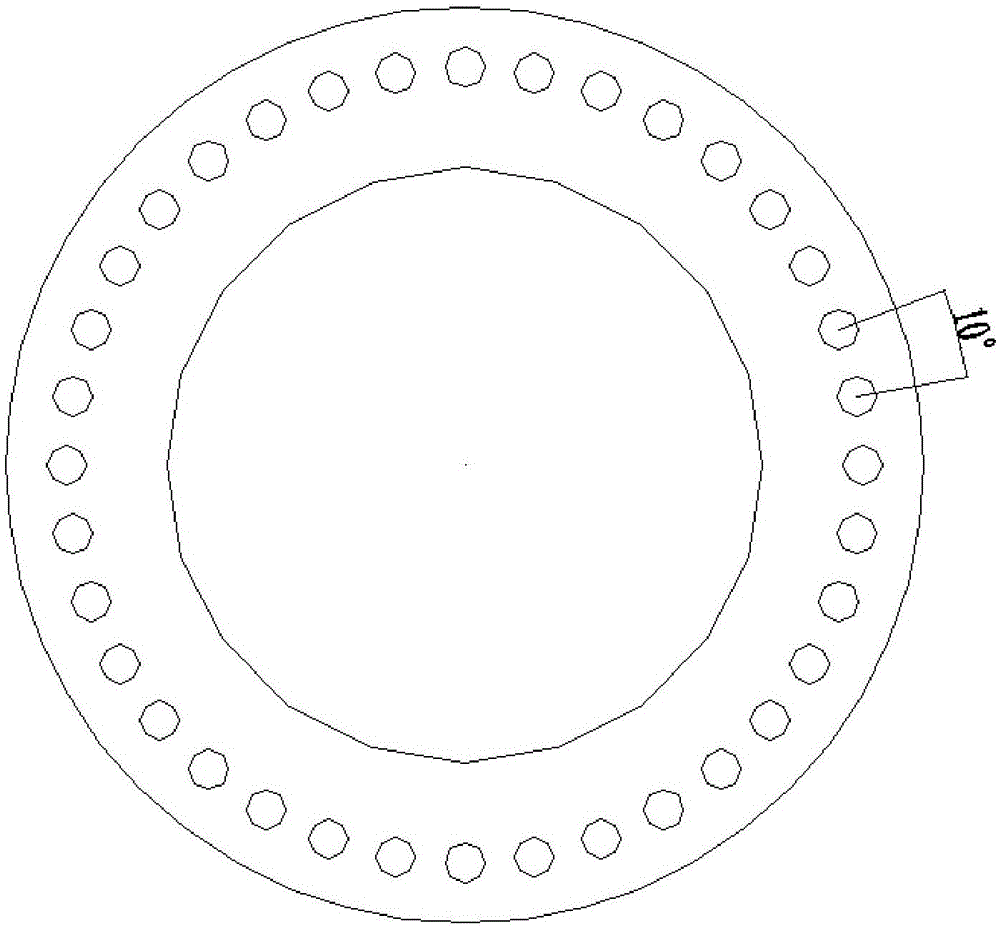

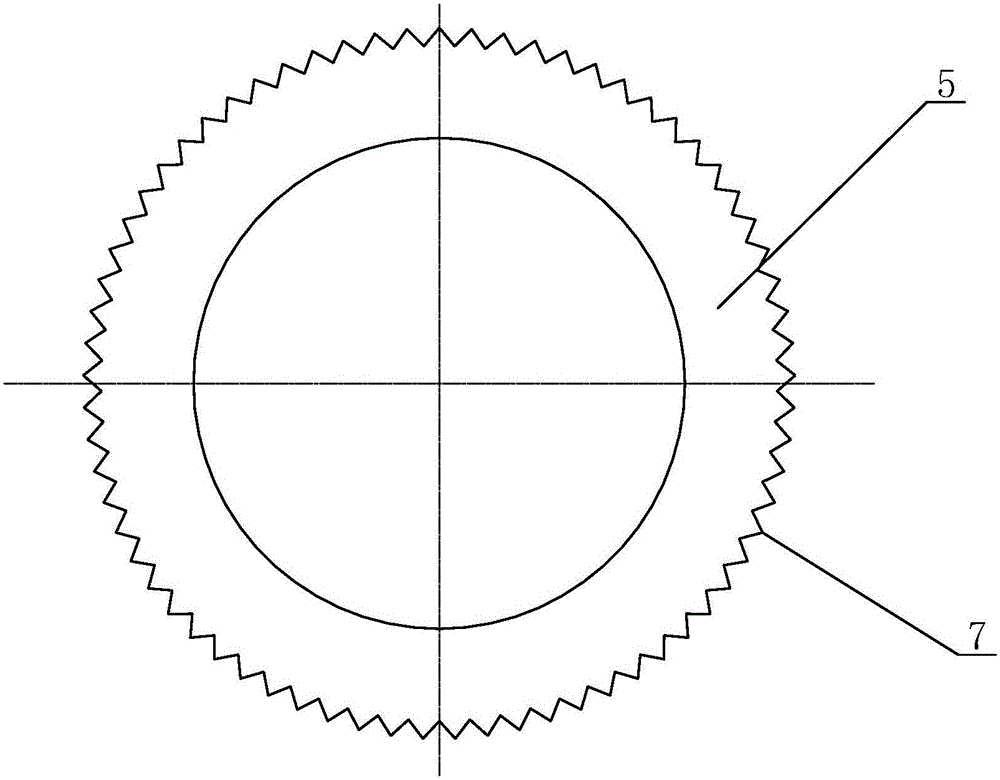

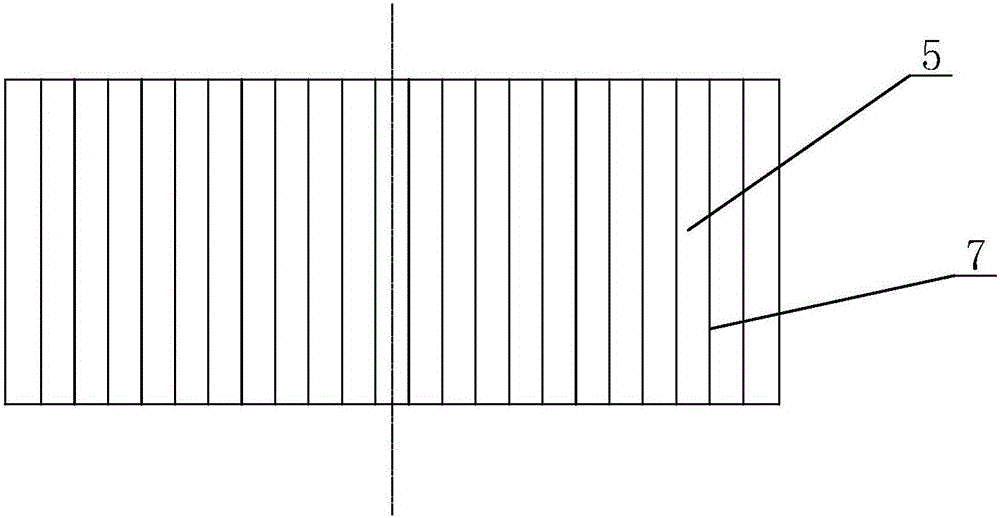

Cast copper rotor for variable frequency motor

InactiveCN105048744AIncrease rotational torqueImprovement exhibits a linear increase in rotational torqueMagnetic circuit rotating partsAsynchronous induction motorsEngineeringCopper

The invention discloses a cast copper rotor for a variable frequency motor. A rotor core (5) of the rotor is formed by overlapping of a certain quantity of rotor sheets (1) of the same sizes and shapes; the rotor sheets (1) are of circular hollow structures, and the central parts are shaft holes (3) for mounting a motor revolving shaft; a certain quantity of closed conducting bar holes (2) are uniformly distributed in the circumferences of the rotor sheets (1); the conducting bar holes (2) are of reverse trapezoidal structures being wider on upper parts and narrower on lower parts; the conducting bar holes (3) in the rotor sheets (1) form conducting bar grooves in the rotor core (5) after overlapping; and melted copper is filled into the conducting bar grooves in a one-to-one correspondence manner, and integrated with cast copper end rings (4) which are firmly bonded at the two ends of the rotor core (5), thereby constructing a cast copper mouse cage structure of the rotor.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

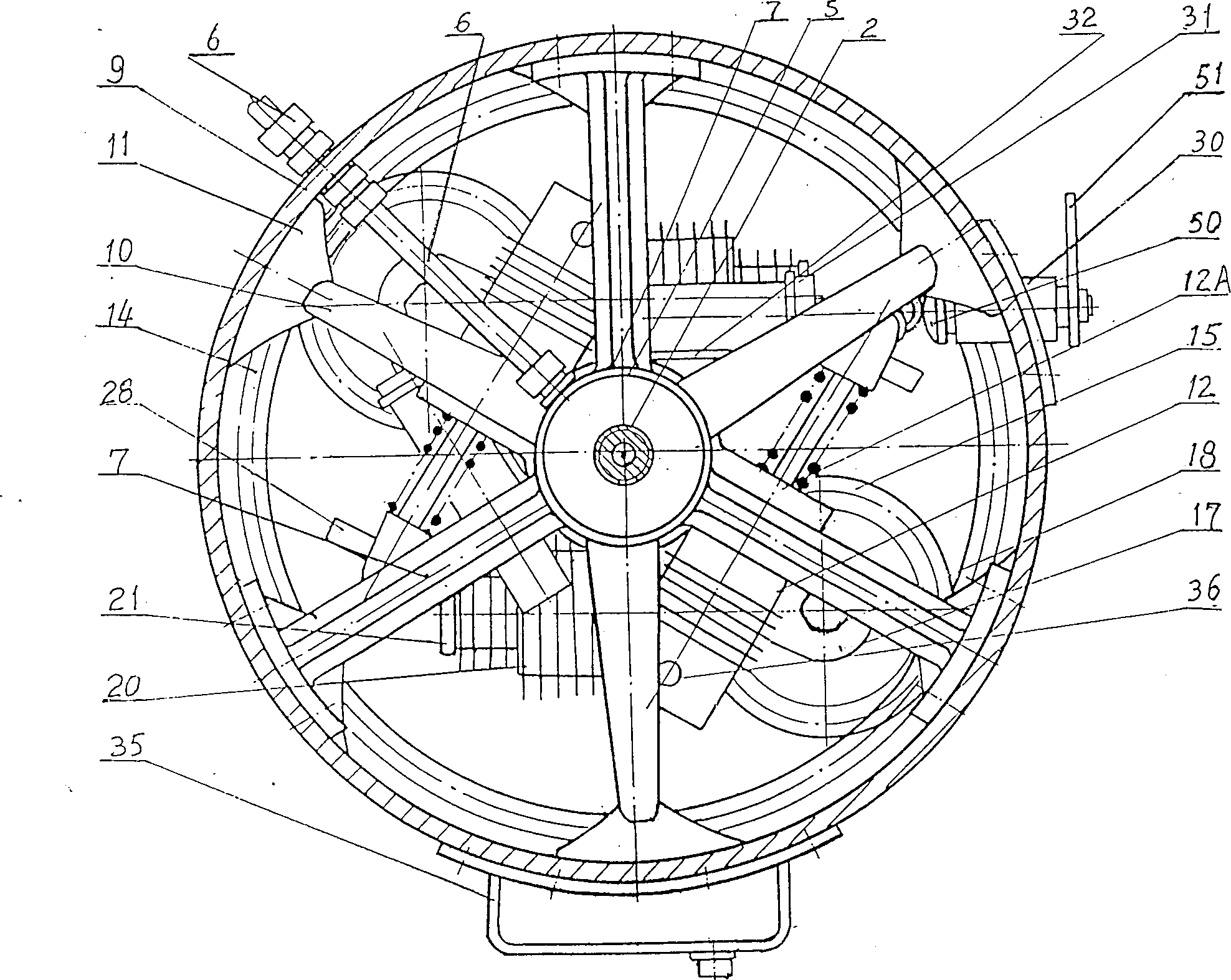

High-efficiency and large-power vertical axis wind power generator

InactiveCN102146887AImprove efficiencyIncrease rotational torqueWind motor controlRenewable energy generationFixed frameVertical axis

The invention provides a high-efficiency and large-power vertical axis wind power generator, which comprises a vertical blade wind wheel and further comprises an energy increasing wing; the energy increasing wing is a wind shielding object; the wind shielding object is arranged on a support frame in a manner of not shielding the rotation of a blade and is positioned in front of the windward side of the wind wheel; the wind shielding side of the energy increasing wing corresponds to a blade at the windward side of one side of the wind wheel used for receiving the windward airflow to cause hindered rotation, so that the side surface of the wind wheel is shielded by the hindered rotation caused by the windward airflow; and the support frame is arranged on a fixed frame. Through arranging theenergy increasing wing in front of the windward side of the wind wheel, the resistance moment is blocked from being generated by the airflow on the wind wheel of the power generator, so that the rotating moment is increased, and the efficiency of the wind power generator is improved. The efficiency of the wind power generator can be increased by more than 25 percent.

Owner:NAT WIND ENERGY

Plain bearing and method for producing same

ActiveCN107110202ALow sliding resistanceIncrease rotational torqueEngine sealsPositive displacement pump componentsPlain bearingFlange

A bearing 10 comprises: a half bearing member having an inner peripheral surface against which slides a corresponding shaft, and a plurality of recesses provided to a first end surface in the axial direction of said opposing shaft; a first flange member having a plurality of protrusions provided at positions corresponding to the plurality of recesses provided to the first end surface; and a plurality of crimping marks respectively formed in the periphery of each recess when crimping the recess with the plurality of protrusions on the first end surface engaged with the plurality of recesses in order to fix the first flange member to the half bearing member. With regard to the crimping marks that are formed on both sides of at least one of the plurality of recesses, the volume of the deformed part of the crimping mark positioned to the outside in the circumferential direction when viewed from the radial direction of the opposing shaft, is smaller than the volume of the deformed part of the crimping mark positioned to the inside.

Owner:EAGLE INDS

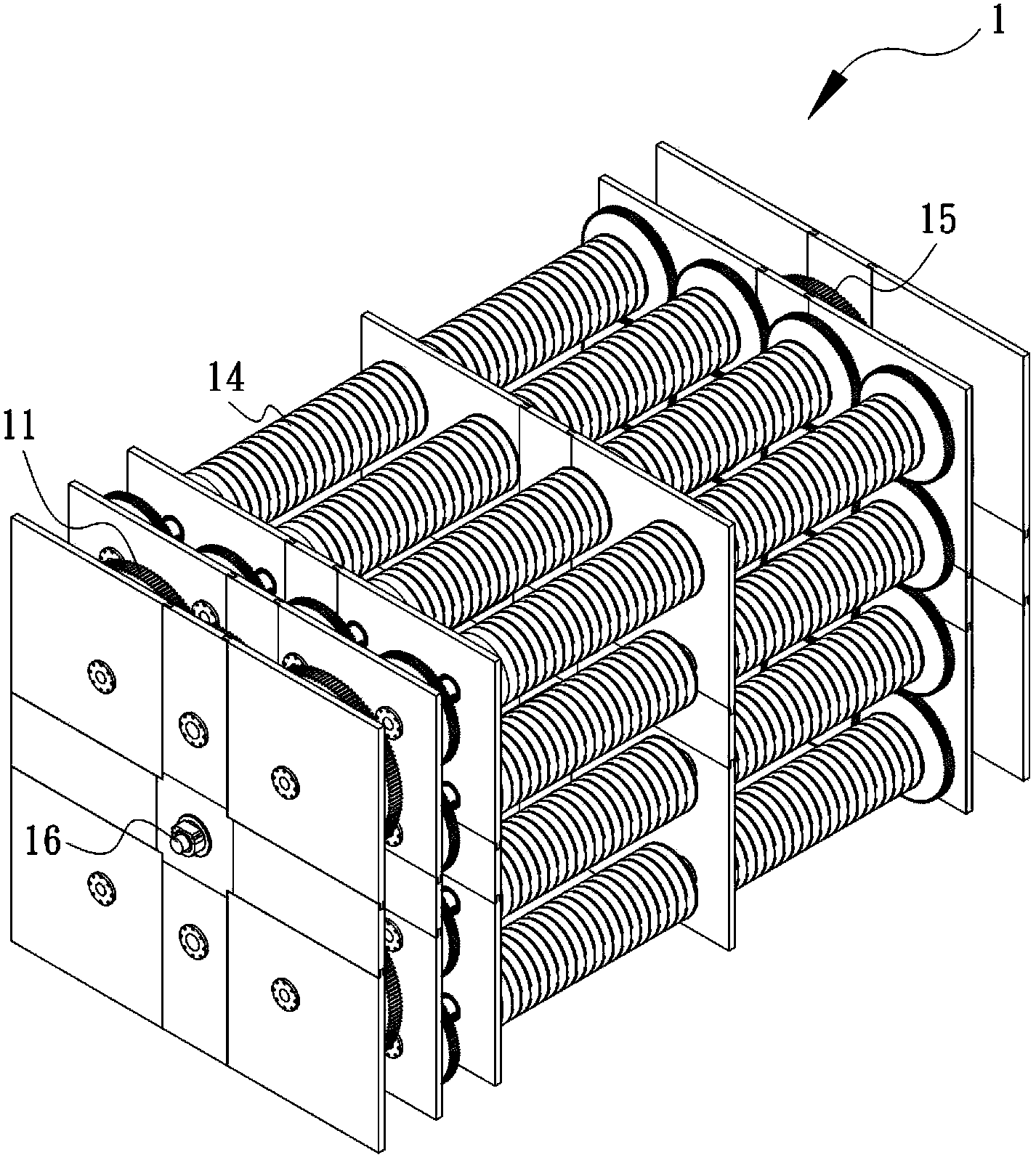

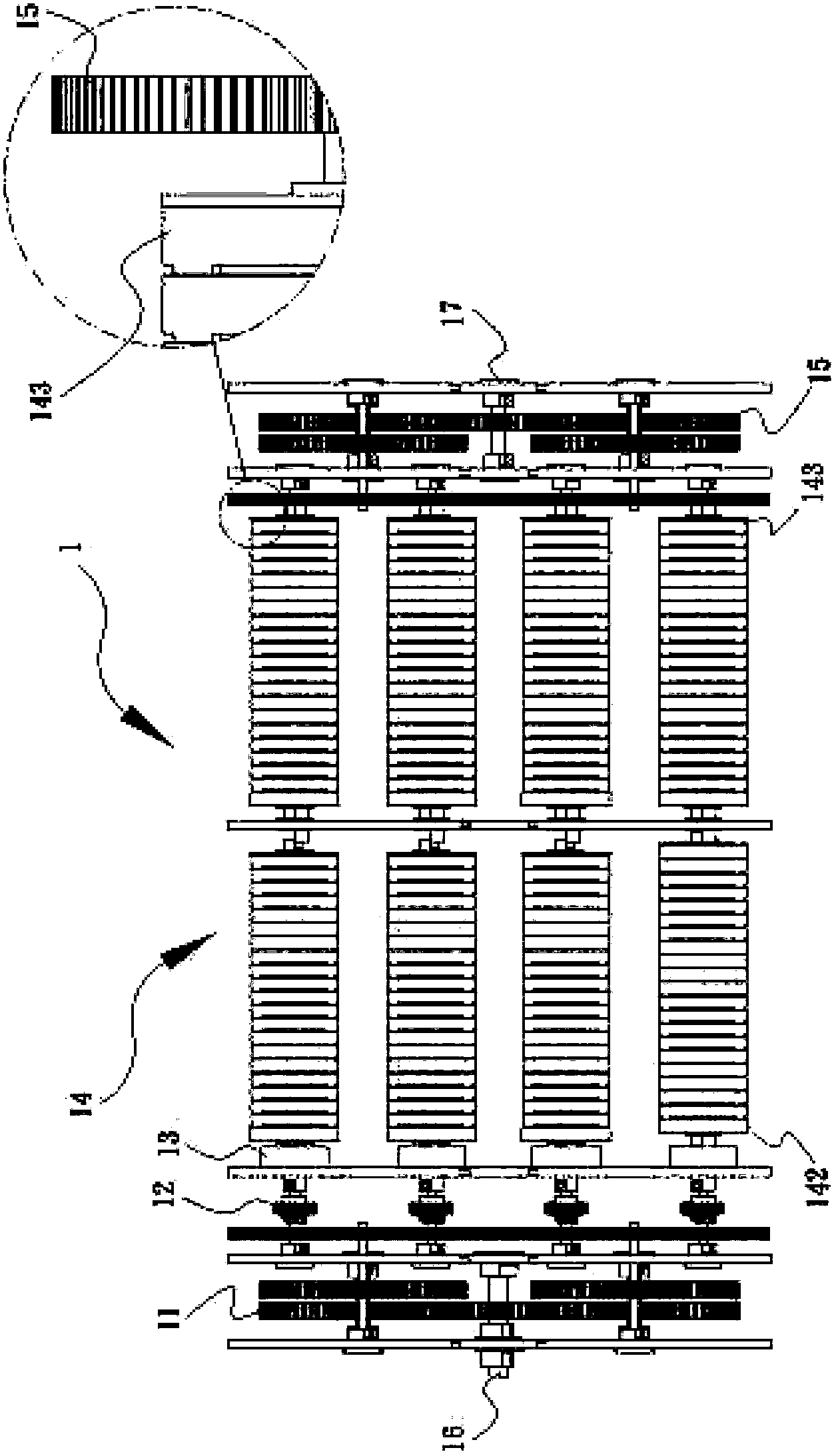

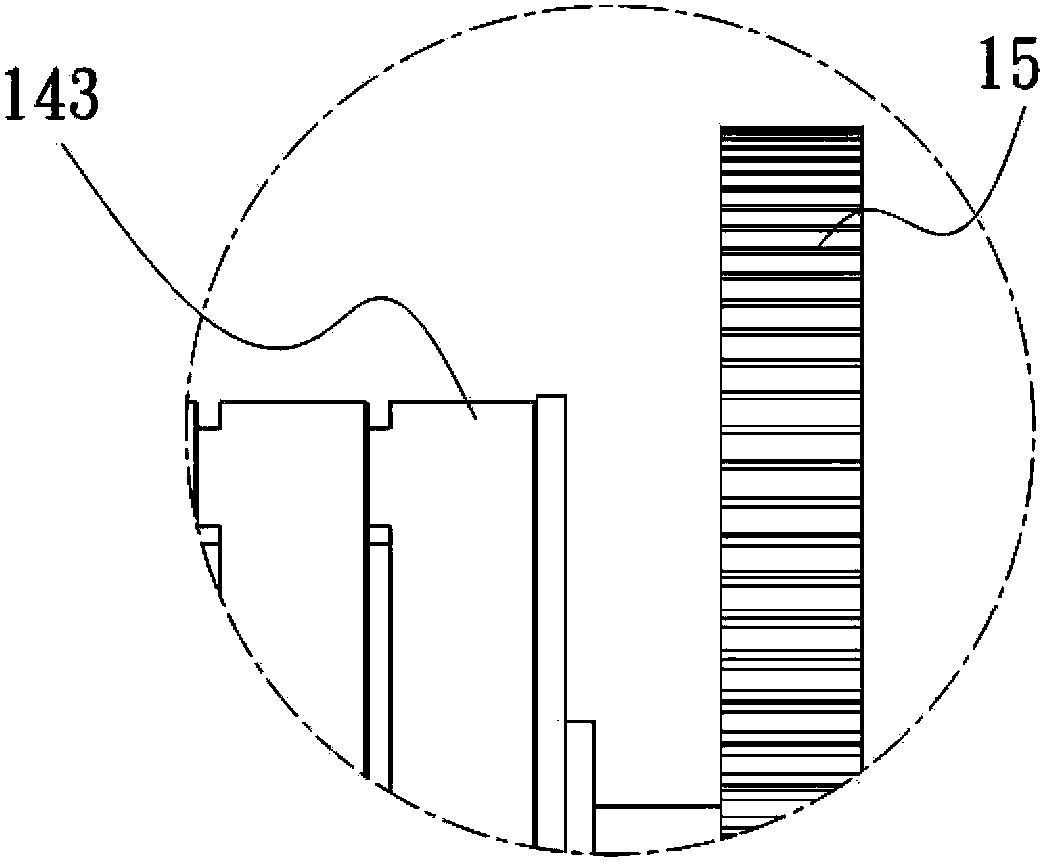

Transformer wire placement rack and method of using the same

PendingCN108666129ASmooth rotationAvoid shaking and falling offInductances/transformers/magnets manufactureHydraulic cylinderTransformer

The invention discloses a transformer wire placement rack and a method of using the same, the technical scheme is characterized by comprising a rack, a rotating shaft, a friction disc, a friction strip, a servo motor, a sensor and a controller, wherein a square groove is arranged at one end of the rack directly facing the rotating shaft protruding from the shaft barrel; a square rod is arranged inthe square groove in a sliding manner; a hydraulic cylinder is arranged at one end of the square rod away from the square groove; a semicircular bearing matched with the rotating shaft is arranged atthe top end of a piston rod of the hydraulic cylinder; a sliding block is mounted in a through groove in a sliding mode, a push block is installed in a circular cavity in a sliding mode, and a screwis mounted in the circular cavity in a rotating mode. According to the transformer wire placement rack, the rotating shaft can be dynamically loaded and output, the situation that the output load andthe preset parameters are the same in the wire drawing process are improved, the product quality rate and the production efficiency are improved, the stability of the shaft barrel on the rotating shaft can be improved, and the shaking situation of the rotating shaft on the rack can be avoided.

Owner:浙江派尔电气有限公司

Direct drive type reciprocating piston IC engine

A direct drive type engine with reciprocating piston is composed of main body, front and back bearings of mainshaft, the mainshaft with cooling fan, hollow front end for flowing fuel oil through it and eccentrical hole for lubricating oil, scavening pump system, high-pressure fuel oil pump system, lubricating oil system, cylinder, piston and crank-linking rod mechanism. It is characterized by no need of air distributing system.

Owner:孔维忠

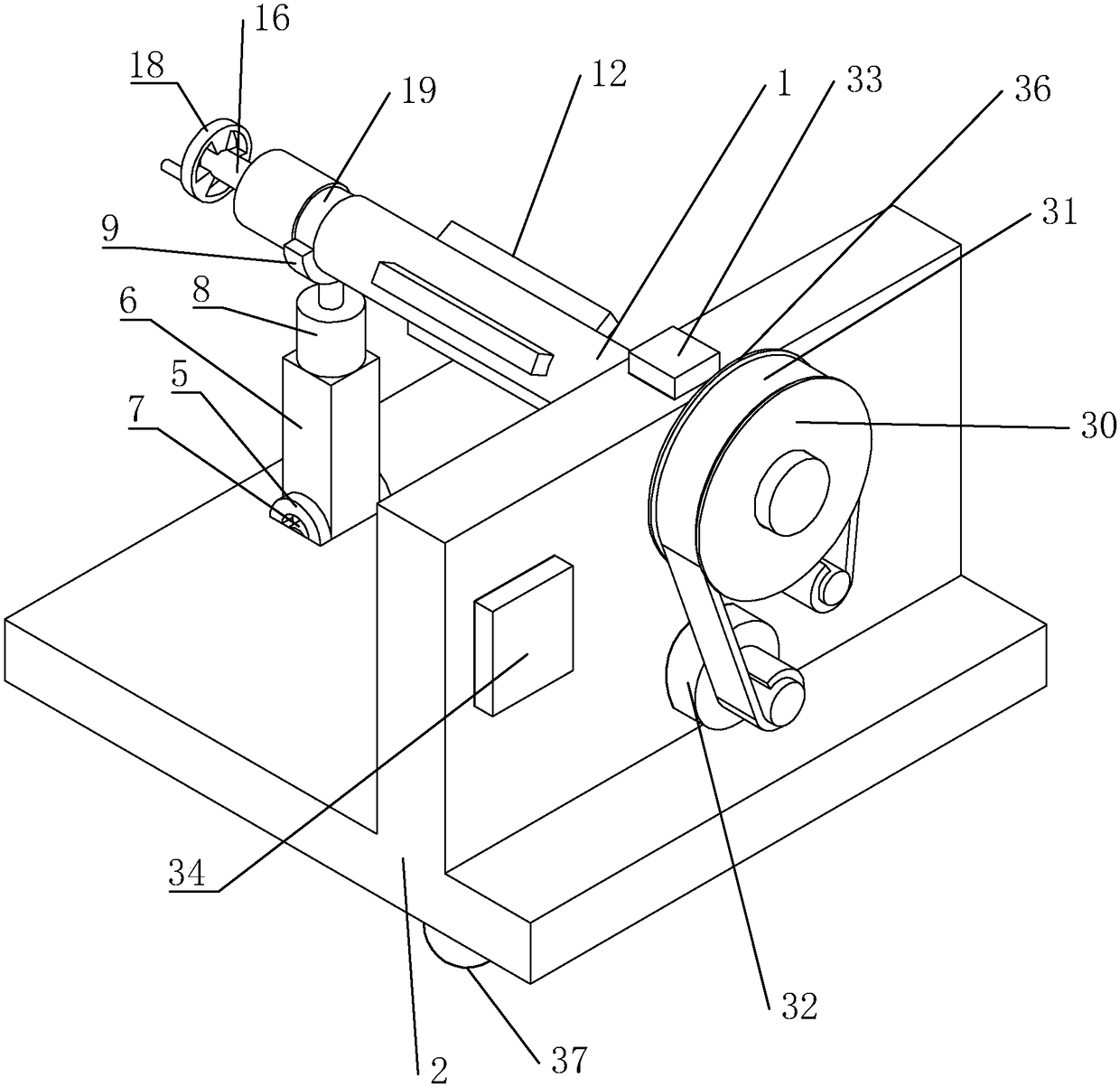

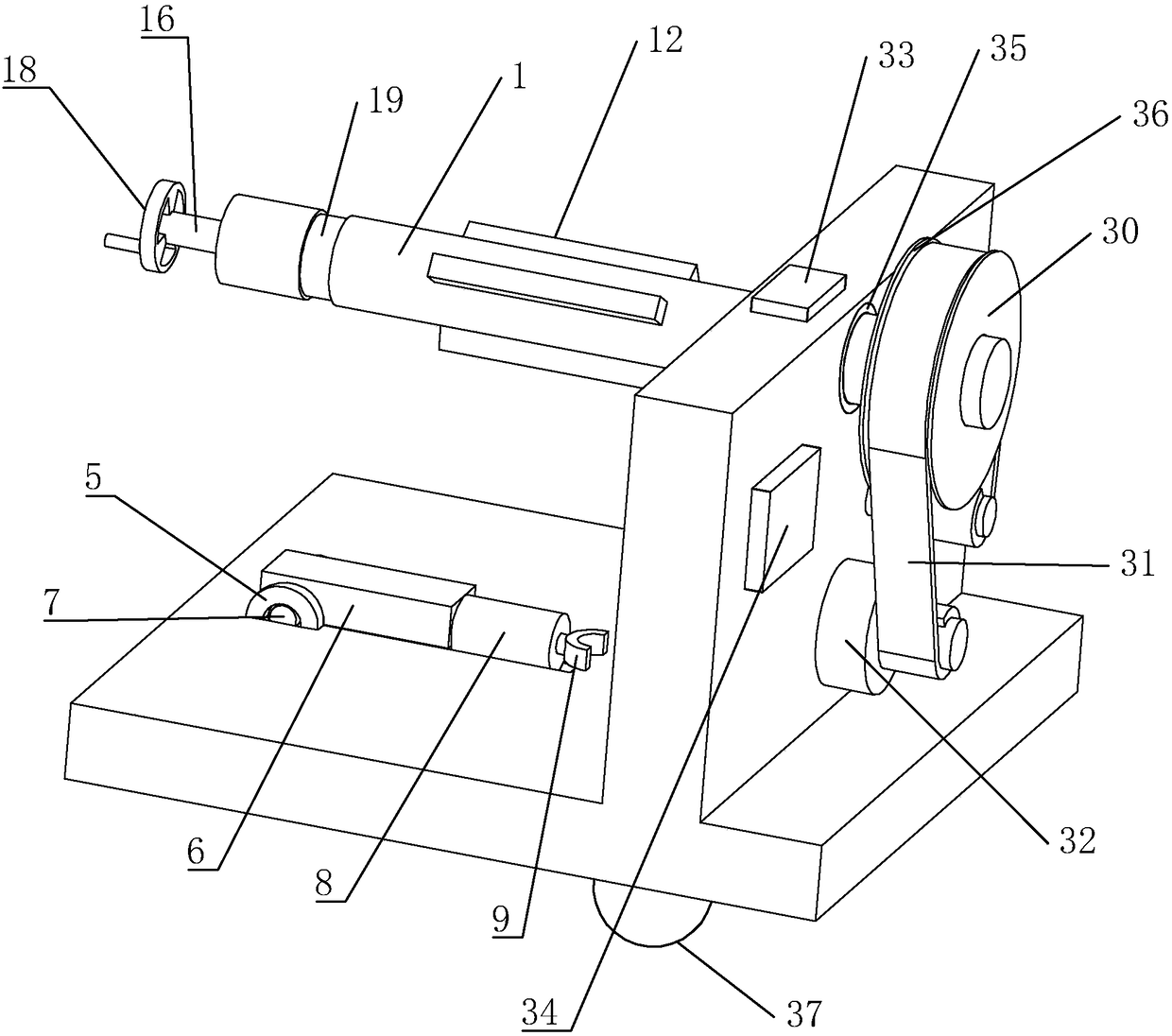

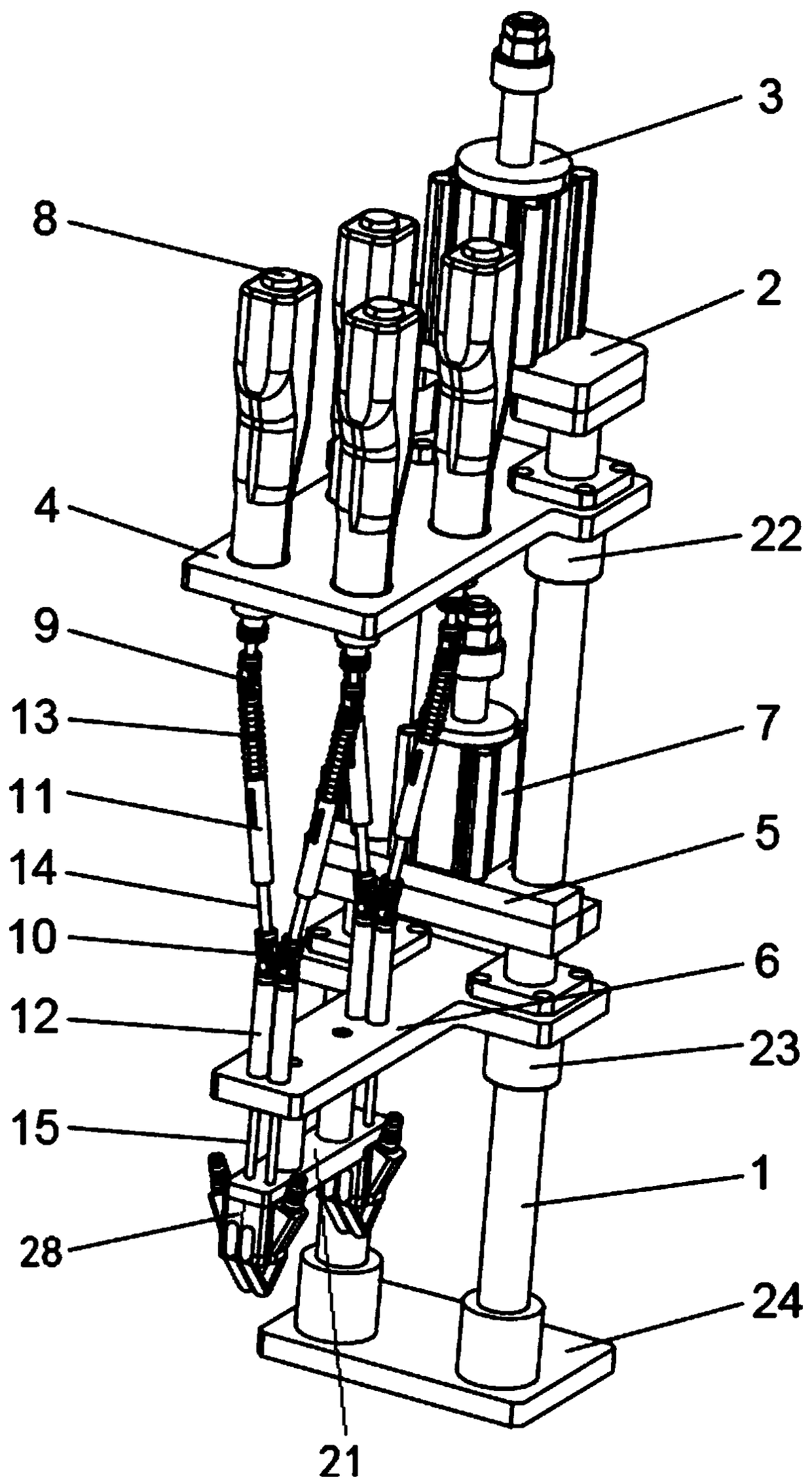

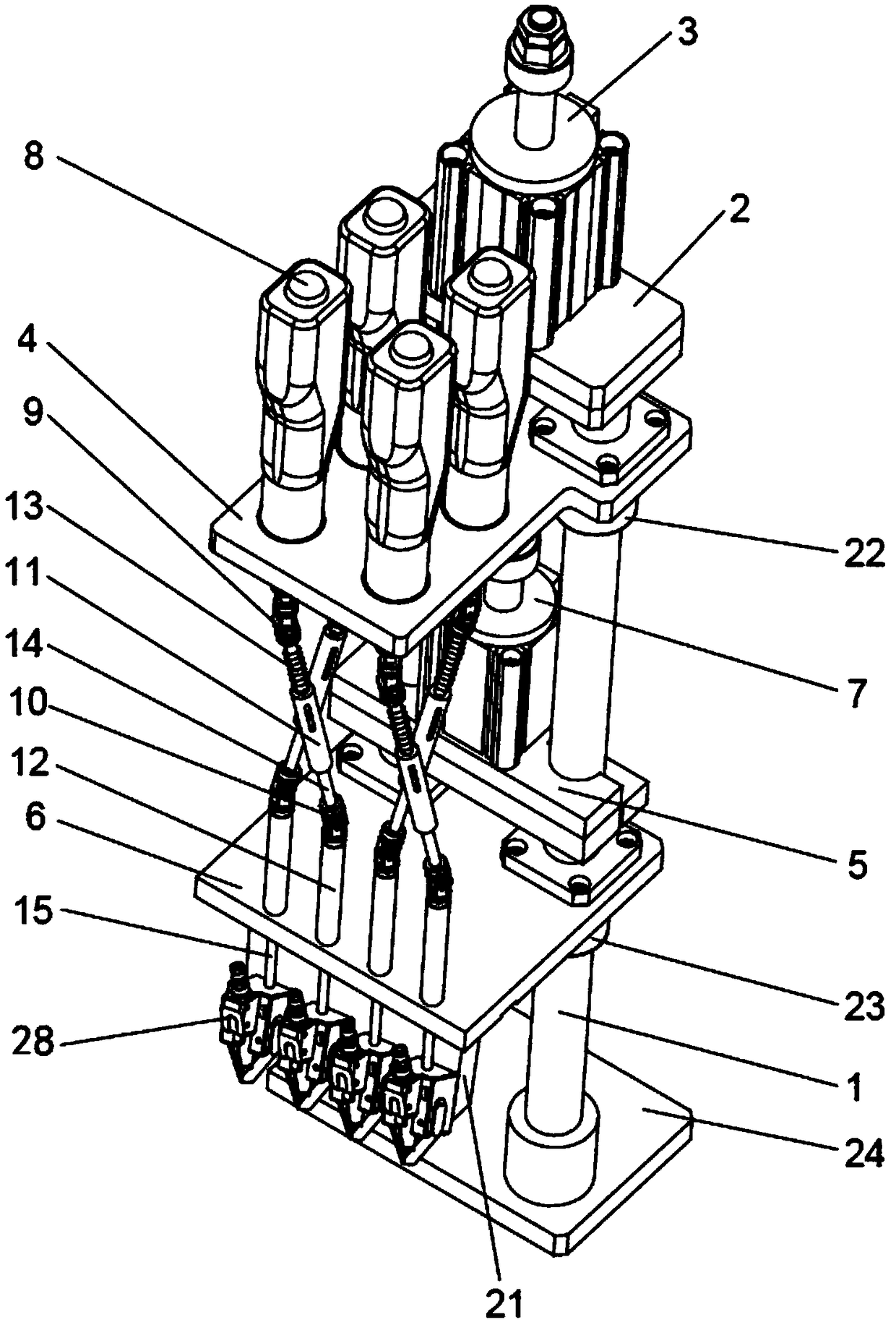

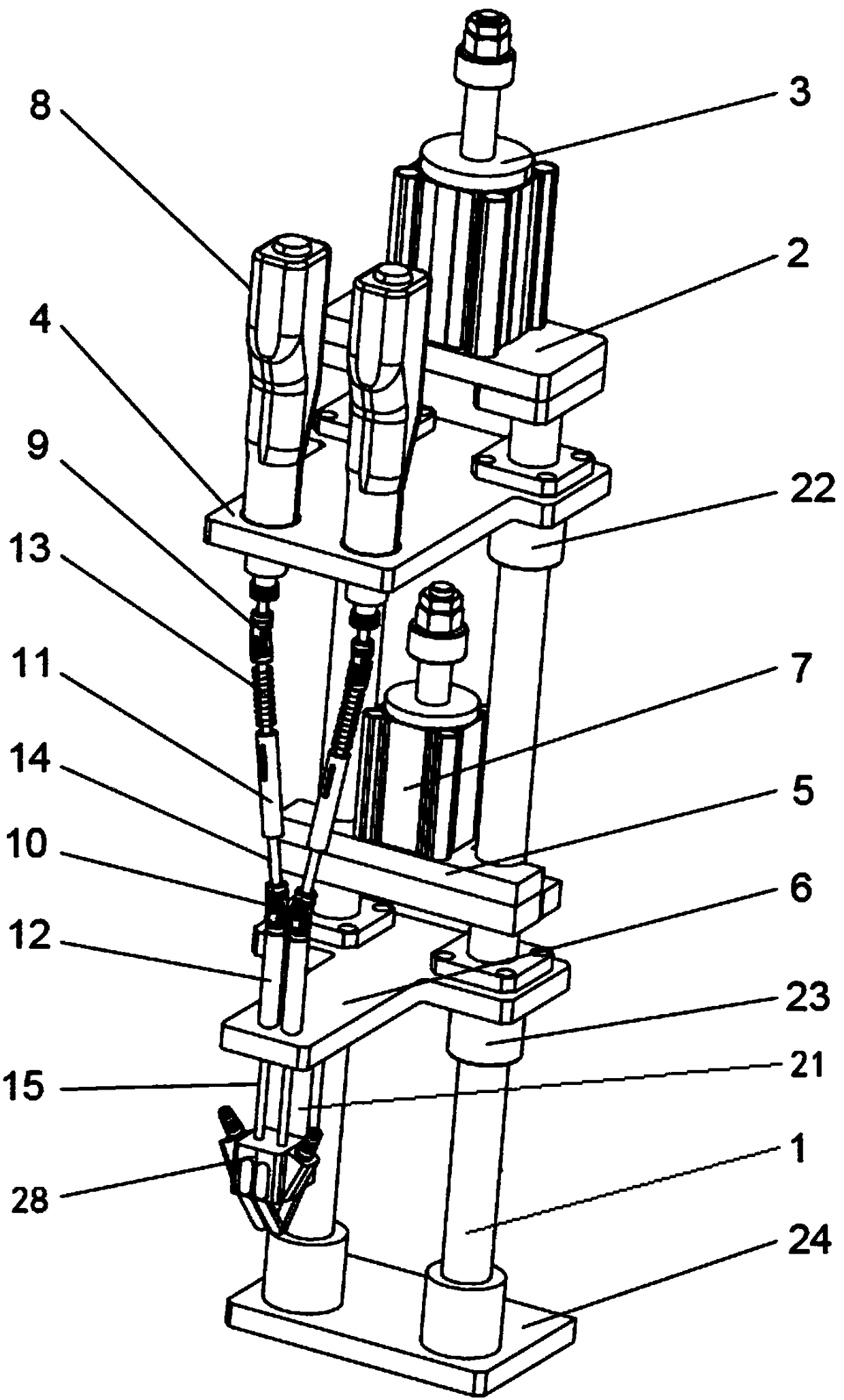

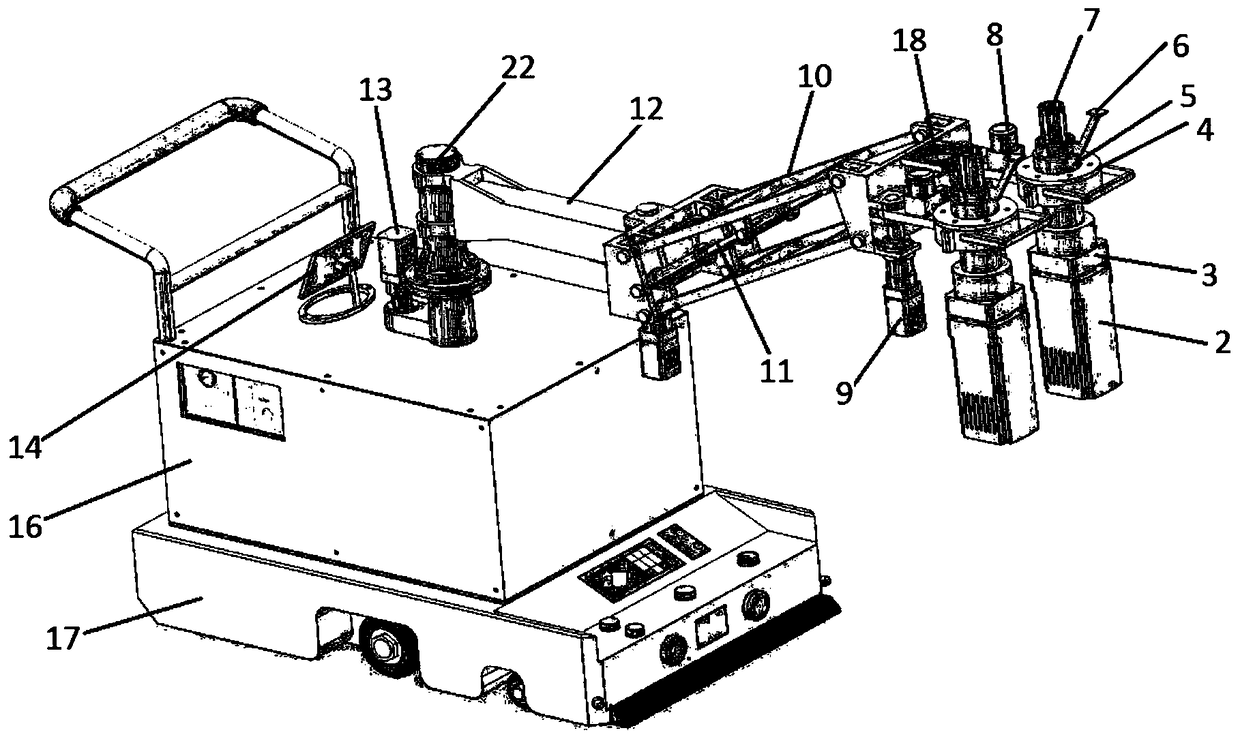

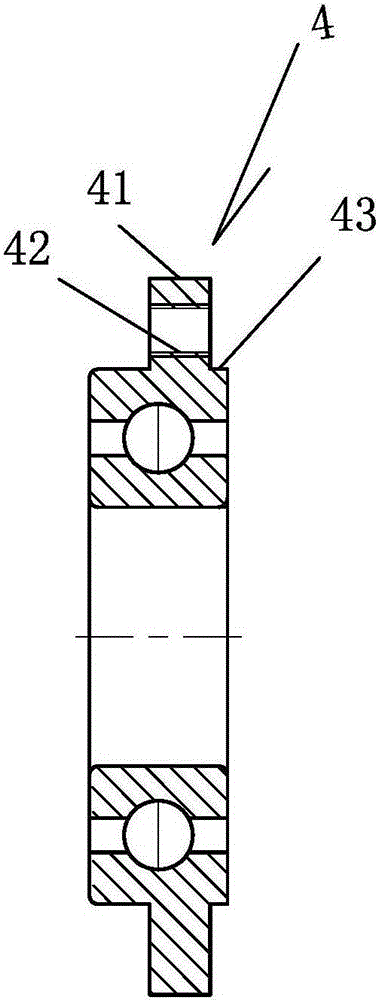

Automatic screw locking mechanism for molded case circuit breaker base and locking and attaching method

ActiveCN108127387AHigh degree of automationIncrease productivityMetal working apparatusBall bearingUniversal joint

The invention provides an automatic screw locking mechanism for a molded case circuit breaker base. The automatic screw locking mechanism comprises a first air cylinder, a second air cylinder, a locking and attaching mechanism, a screw clamping head and a supporting frame, wherein the supporting frame comprises a slide rod, an upper supporting plate and a lower supporting plate; an upper double-rolling-ball bearing, a lower double-rolling-ball bearing, an ejector plate and a transverse frame arranged on the slide rod; the first air cylinder is arranged on the ejector plate; the upper double-rolling-ball bearing is connected with the upper supporting plate; the piston rod of the first air cylinder is connected with the upper supporting plate; the second air cylinder is arranged on the transverse frame; the lower double-rolling-ball bearing is connected with the lower supporting plate; and the piston rod of the second air cylinder is connected with the lower supporting plate. The screw clamping head comprises a base body, a feeding body, a bolt feeding part and two bolt clamping parts; the bolt feeding part is composed of a first connecting head and a tube body; and each bolt clamping part consists of a second connecting head, a transition part and a clamping head. By adopting a transmission mechanism with two stages of universal joints and the screw clamping head capable of enabling bolts to automatically align, the purposes of enabling the bolts to automatically align to locking and attaching holes, automatically increasing stator rotation twisting force and automatically locking and attaching bolts are realized.

Owner:YUEQING YEDAO ELECTROMECHANICAL CO LTD

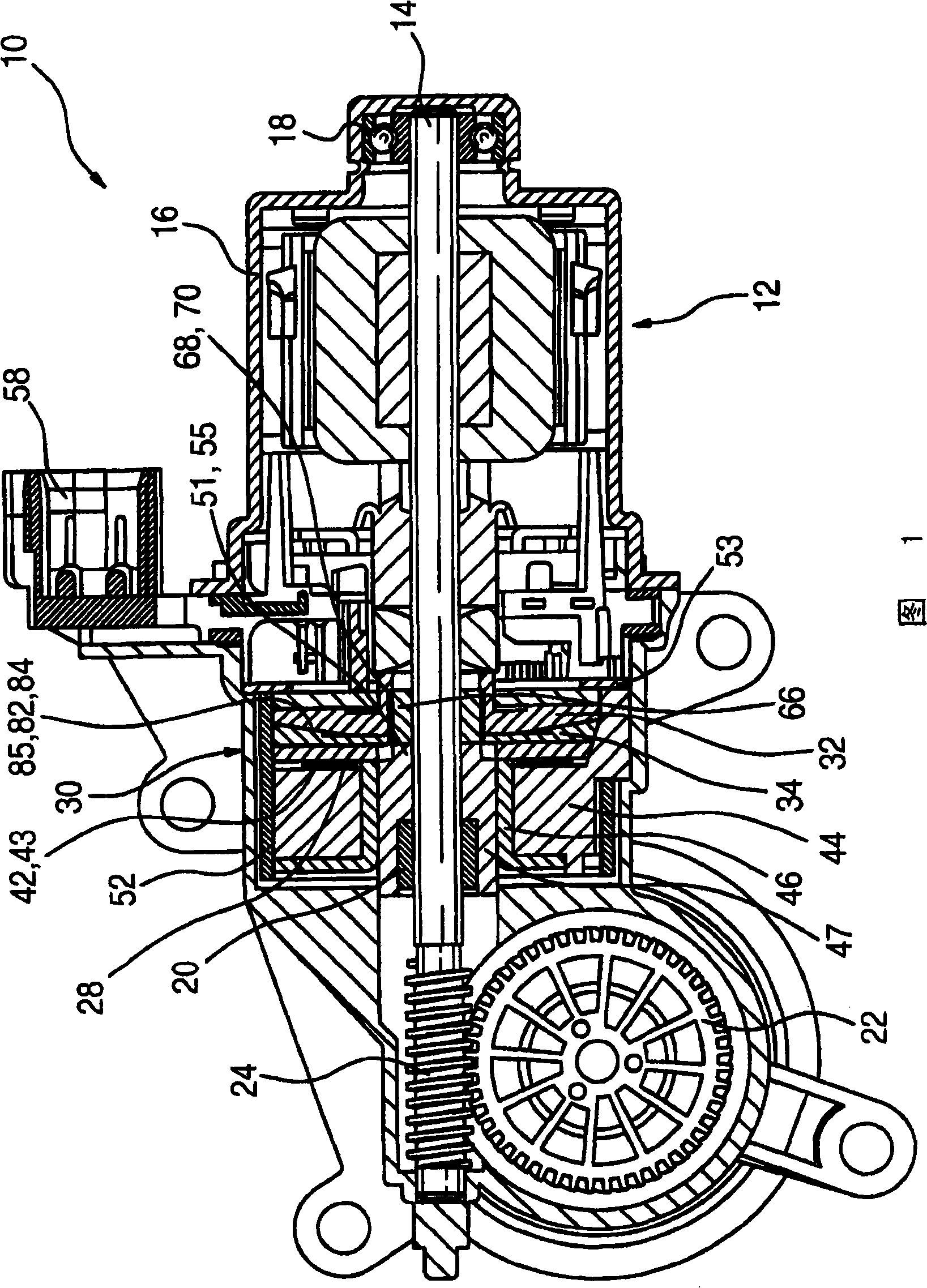

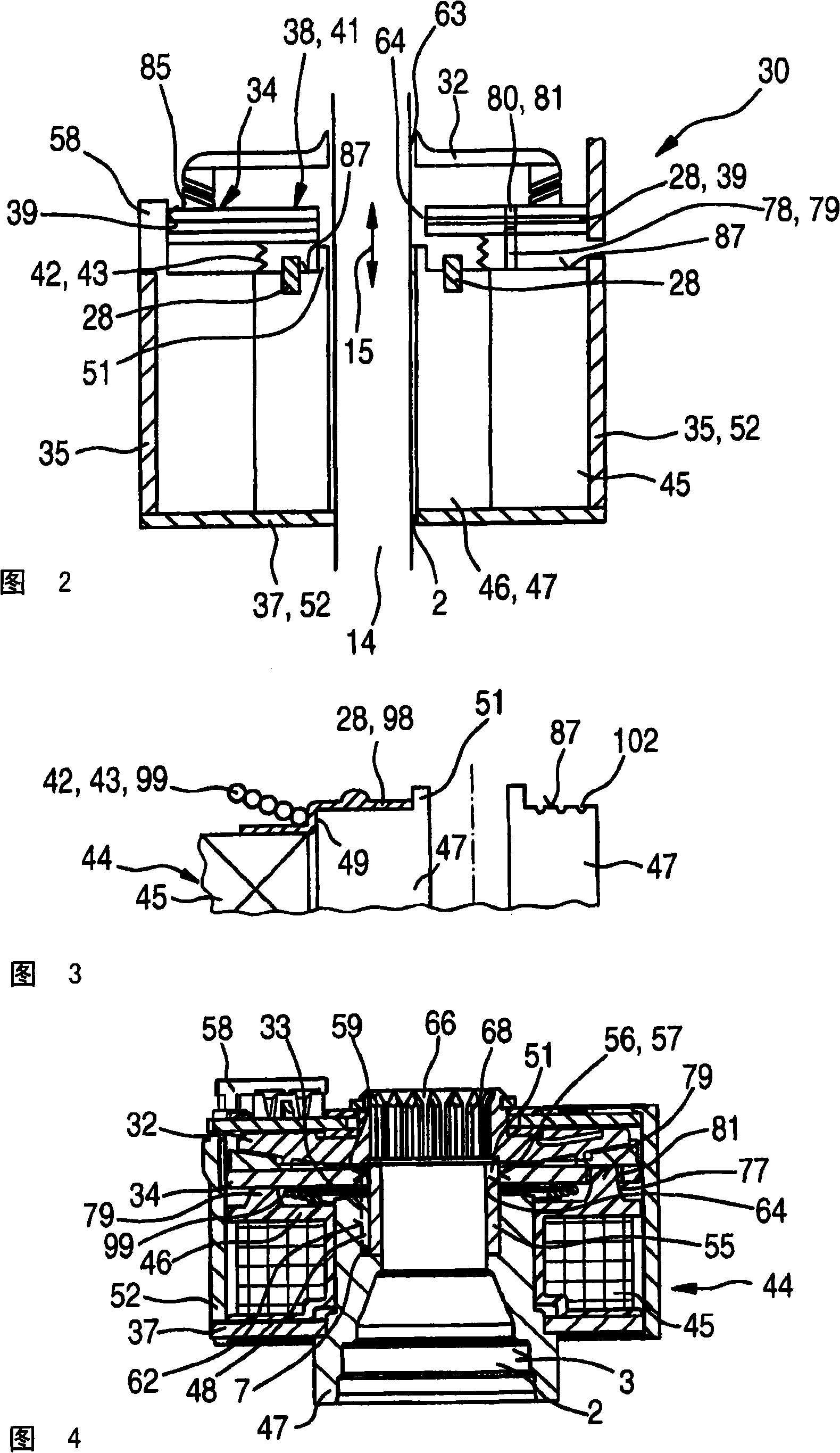

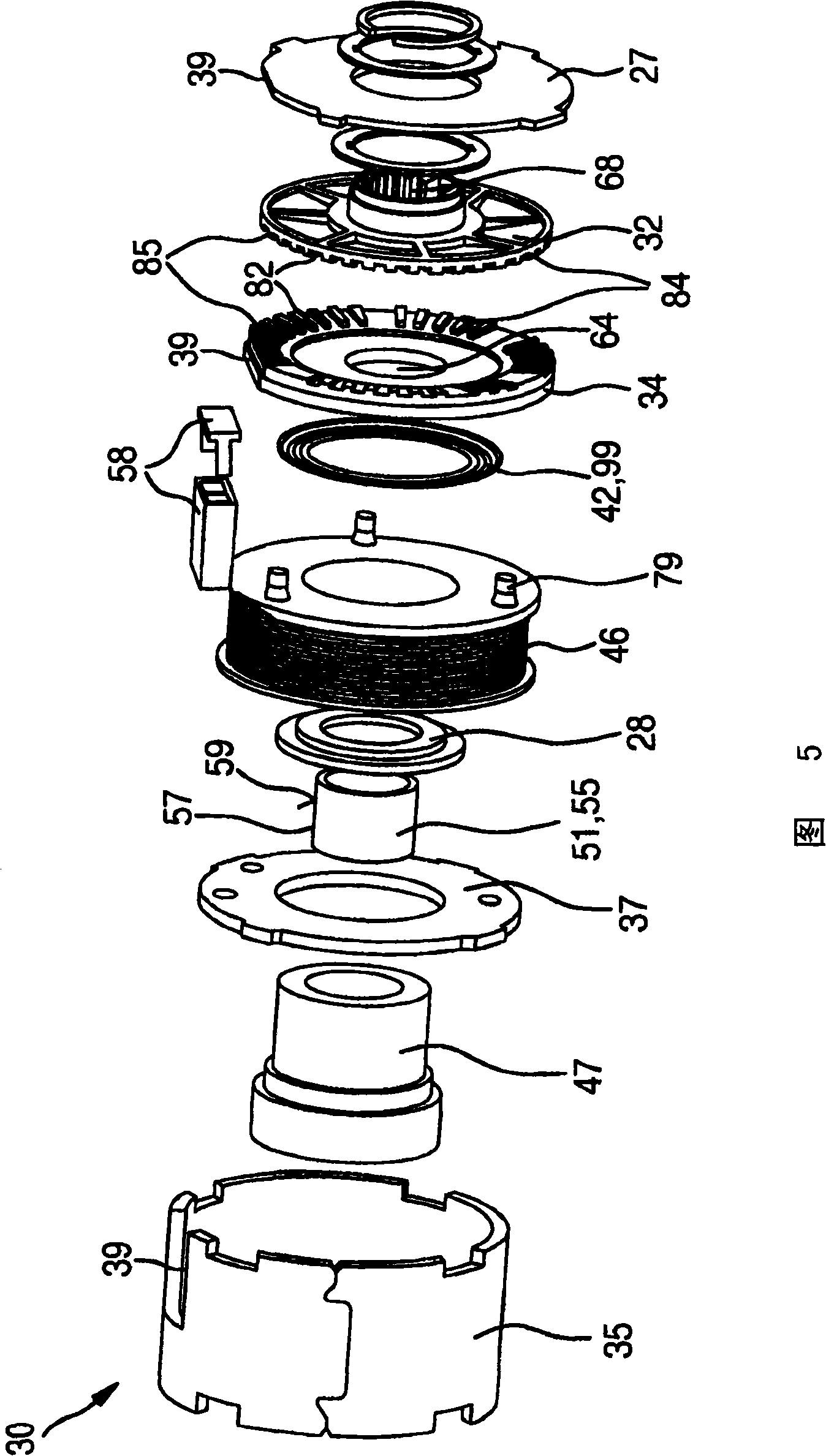

Blocking apparatus, gearbox drive unit containing a blocking apparatus such as this, as well as a method for production of a gearbox drive unit such as this

InactiveCN101317317ALower assembly costsExtended service lifeElectric machinesBrake actuating mechanismsEngineeringCentring

Blocking apparatus, as well as a gearbox drive unit containing such a blocking apparatus, as well as a method for production of a gearbox drive unit such as this for blocking any rotary movement of a shaft (14) with respect to a housing (16) of a gearbox drive unit (10), having a first blocking element (32) and having a second blocking element (34) which can be moved axially with respect to the first blocking element (32) by means of an electromagnet (44) and at least one return element (42), in order to produce a connection between the first blocking element (32) and the second blocking element (34) such that they cannot rotate with respect to one another, with the electromagnet (44) having an inner pole (47) which is surrounded by an electrical coil (45), and with the inner pole (47) having an axial projection (51) which engages in a corresponding opening (64); in the second blocking element (34), for axial guidance and centring.

Owner:ROBERT BOSCH GMBH

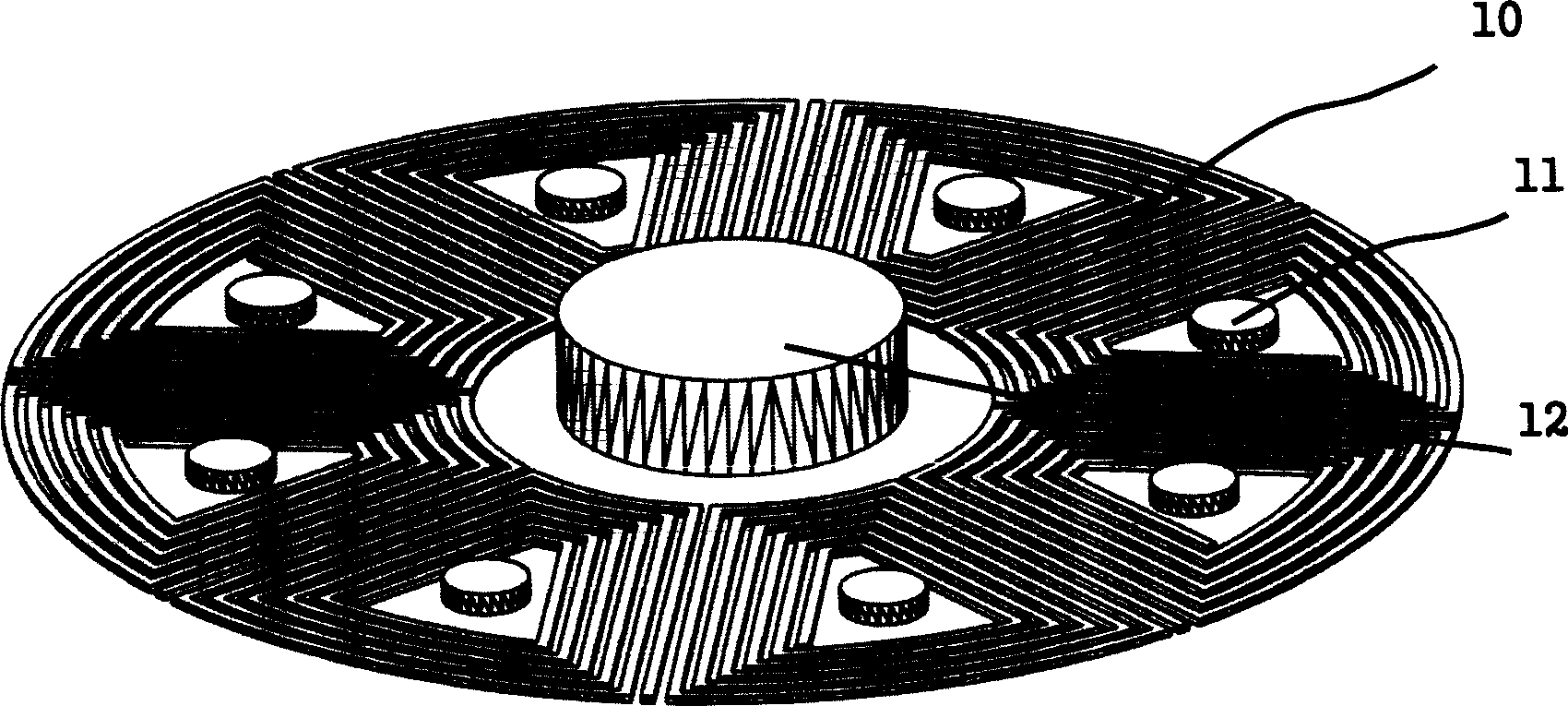

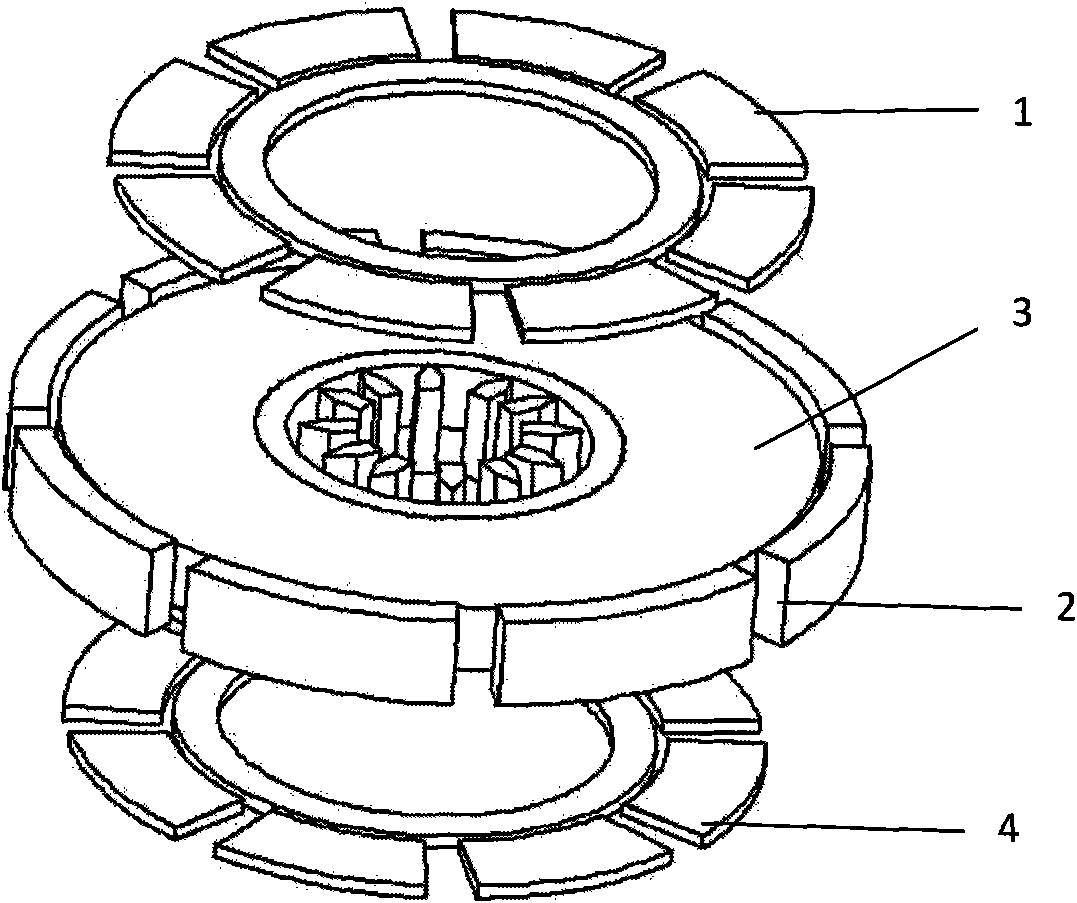

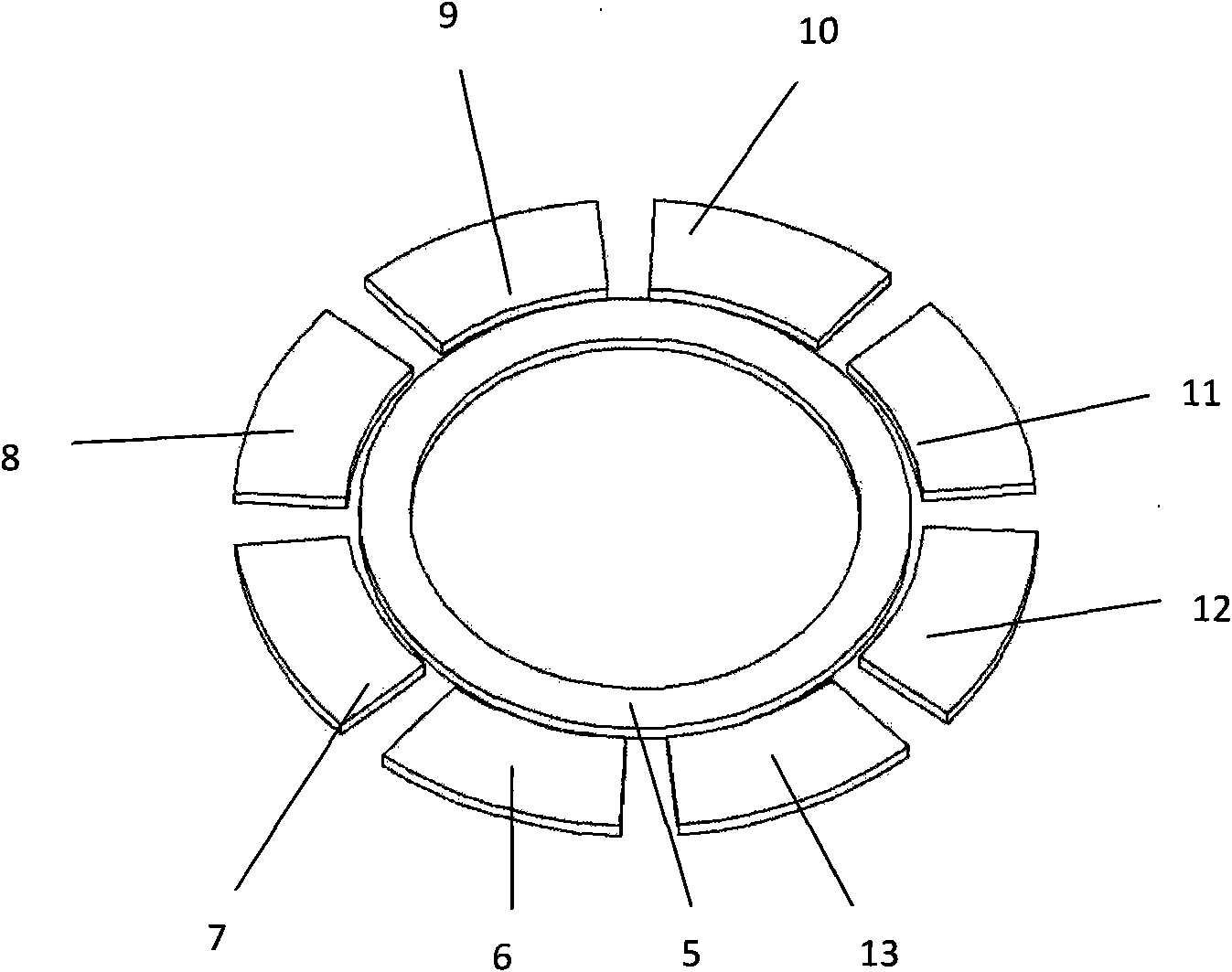

Micro gyro driven by static suspension corona to rotate

InactiveCN101561274ASimple structureHigh measurement accuracyTelevision system detailsAcceleration measurement using interia forcesEngineeringElectrostatic levitation

The invention relates to a micro gyro driven by static suspension corona to rotate. The micro gyro comprises upper and lower stators, a micro rotor and a peripheral structure which form a cage structure, and the rotor is arranged in the middle of the cage structure. The stators comprise rotary axial suspension and detection electrodes and public electrodes and are fixedly connected to a substrate; and because of the action of electrostatic force, the micro rotor suspends between the upper and lower stators and has an annular shape, the inside of the micro rotor has tooth-shaped electrodes, while the outside is distributed with a surrounding structure which is radial suspension detection electrodes. The micro gyro has simple structure, provides a corona driving rotary structure, does not need to arrange rotary electrodes on the stators, and can realize the rotation of the rotor at constant high speed without detecting rotating speed. Suspension control of the rotor and position detection can be realized through axial and radial suspension detection electrodes. The micro gyro is made by adopting MEMS micromachining, is easy to implement, and has the characteristics of small size, light weight, low cost, high precision and low power consumption.

Owner:SHANGHAI JIAO TONG UNIV

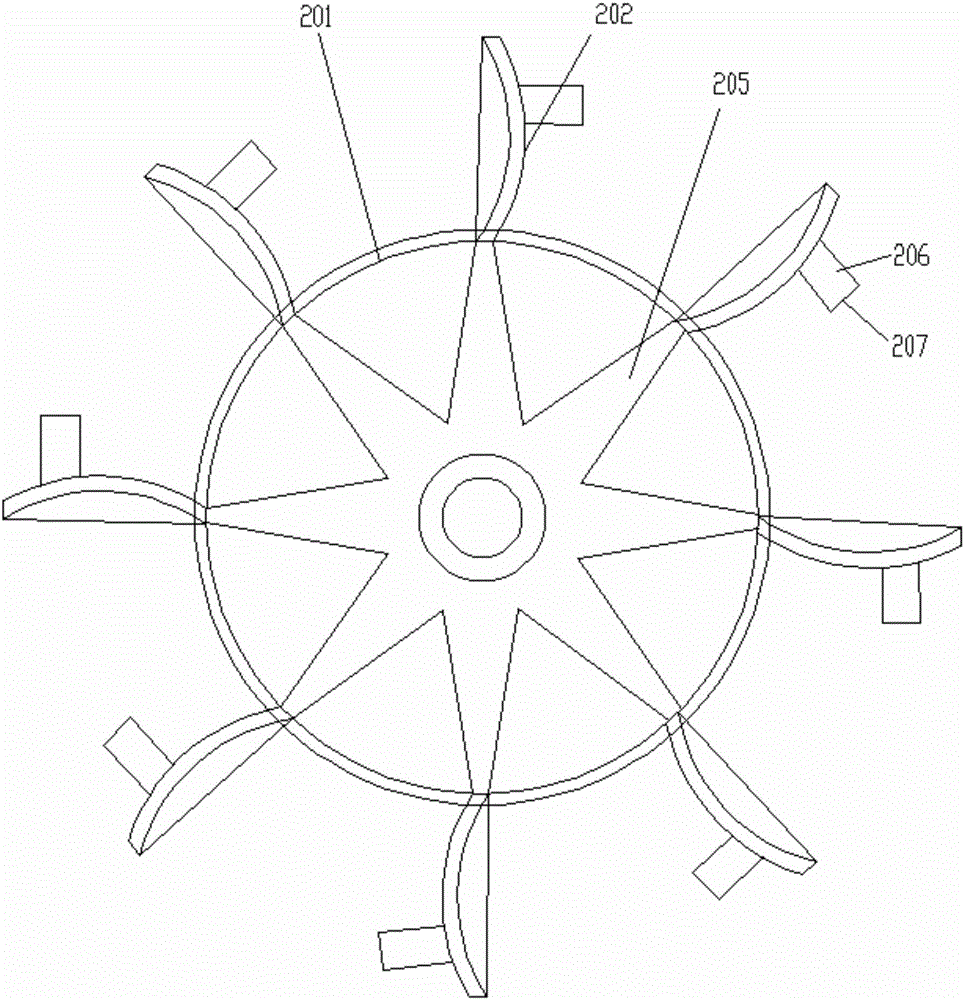

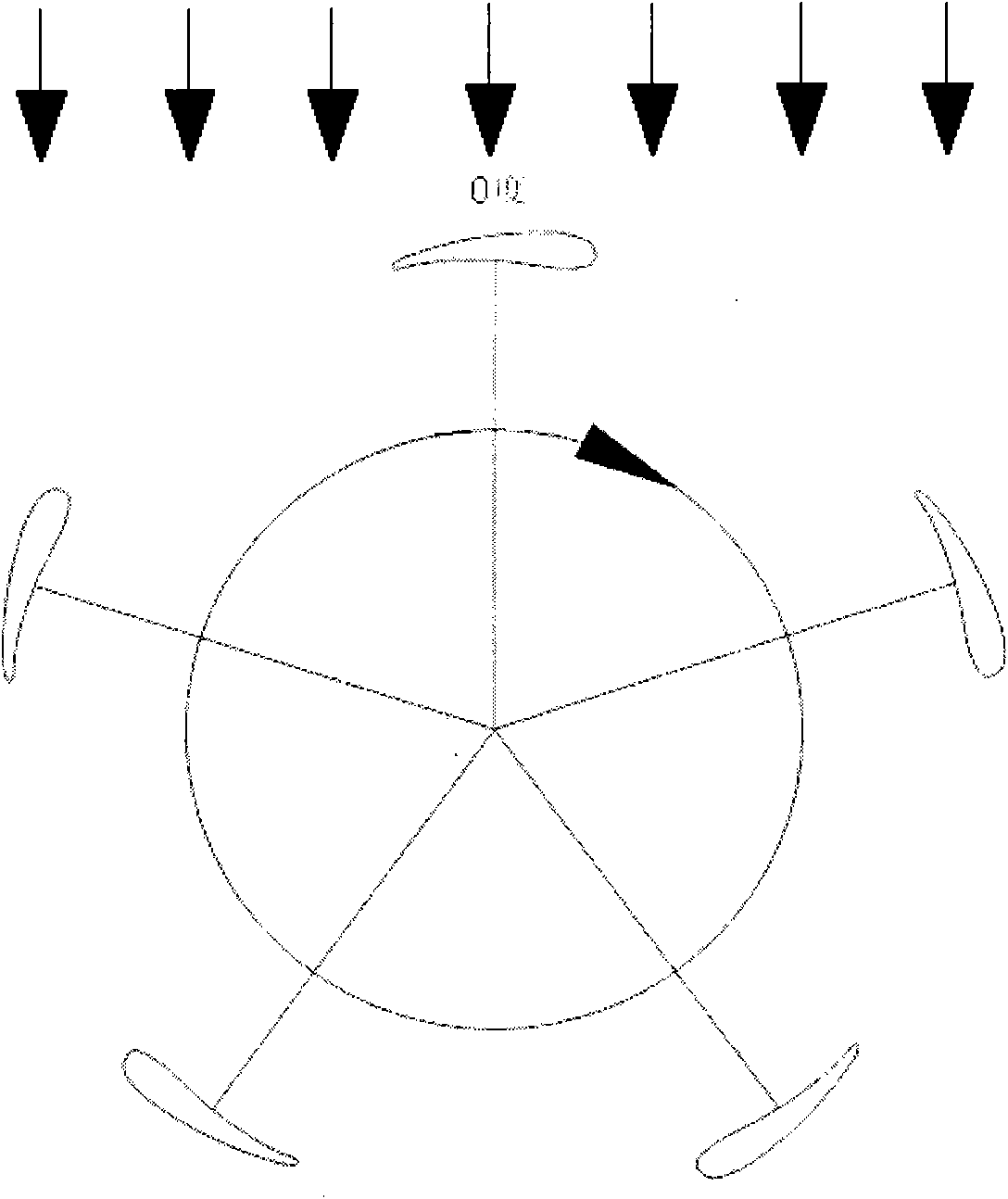

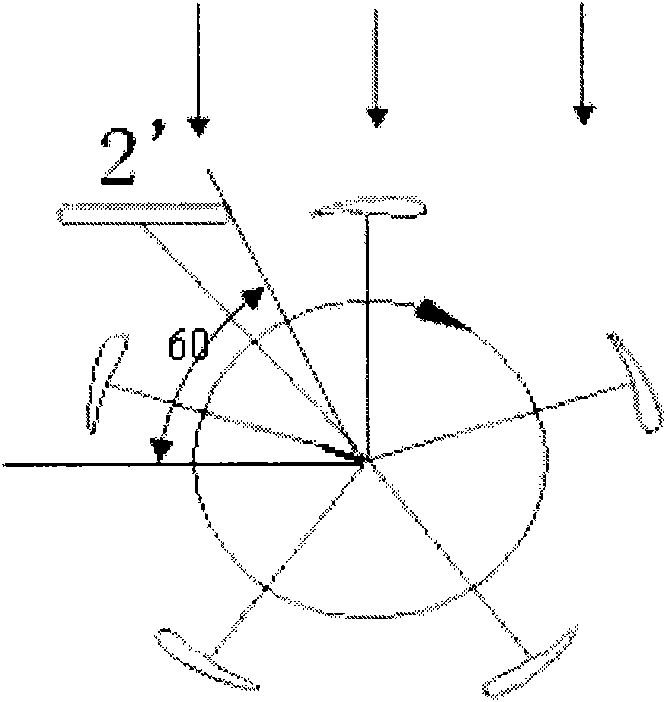

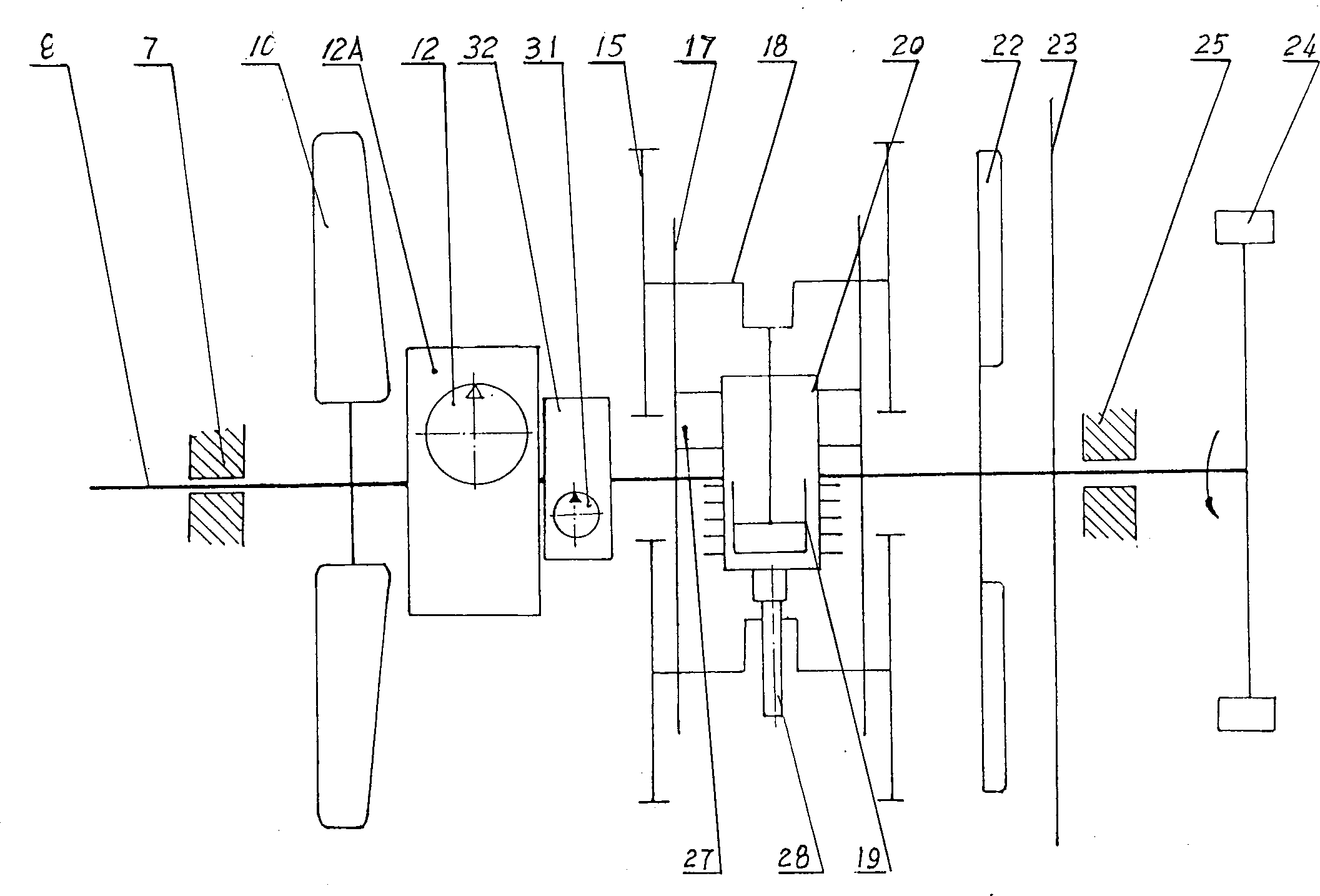

Vertical shaft integrated horizontal self-varied propeller-type wind power generation device

InactiveCN101649812AIncrease powerIncrease rotational torqueWind motor combinationsMachines/enginesPropellerEngineering

The invention discloses a vertical shaft integrated horizontal self-varied propeller-type wind power generation device. The device comprises a generator; the generator is connected with a main shaft arranged vertically through a speed changer. A plurality of paddle components are horizontally arranged on the excircle of the main shaft along axial direction; each paddle component comprises a shaftsleeve horizontally arranged on the excircle of the main shaft; a rotating shaft of the paddle is arranged in the shaft sleeve; the two ends of the rotating shaft of the paddle are respectively provided with paddles the paddle surfaces of which are vertical with each other; a clamping pin is mounted on the excircle of the rotating shaft of the paddle in a radial direction; a limited groove the width of which is one fourth of circumference of the shaft sleeve is arranged on the inner wall of the shaft sleeve; the clamping pin is arranged in the limited groove along the width direction of the limited groove in a swinging manner. The device of the invention has reasonable design, novel structure, high rotating speed, and great moment of rotation, and can drive generators with high power to work. As the paddle rotates horizontally, and the windage generated by the rotation of the paddle is small, so that high-speed rotation of the paddle can be realized in big wind.

Owner:陈效刚

Two-rotor statically stable electromagnetic suspension micro-rotary gyro

InactiveCN1920480AIncrease lateral stiffnessIncrease lateral anti-interference abilityNavigation by speed/acceleration measurementsAsynchronous induction motorsGyroscopeMechanical engineering

The invention relates to a dual-stator static stabilize electromagnetic suspension micro-rotation gyroscope, wherein it comprises: upper base, upper stator, micro rotator, lower stator, lower base, and sealing ring; said micro rotor is a conductive ring; the upper stator is above the upper base to be fixed with the upper base; the lower stator is above the lower base to be fixed with lower base; the edge of lower base is arranged with sealing ring, to be fixed with lower base; the sealing ring and upper base via bonding technique are fixed; the upper and lower stators, from outer to inner, are arranged with stabilize suspension outer coil, sensing electrode, connecting wire stabilize suspension inner coil, and rotation coil; the center of lower stator is arranged with anti-adhesive post. The invention leads in the static electrode, to improve the side rigidity of suspended micro rotator, and the anti-impact ability of micro gyroscope system.

Owner:SHANGHAI JIAO TONG UNIV

Punch-cutting mining method and punch-cutting mining machine implementing method

The invention belongs to the machinery field and especially relates to a punch-cutting mining method suitable for the mining field and a punch-cutting mining machine implementing the method. According to the method, a machine body, a walking part, a reciprocating impact part and the like are arranged; a lifting device is arranged or not arranged on the machine body; a dynamic impacting member is disposed on an impact driving device; a guiding device is provided with an impact guiding element; two ends of the impact guiding element are both equipped with an impactor or one end is provided with an impactor and the other end is provided with a counterweight; and the machine body supports the impactor to shock dropping materials back and forth. The equipment comprises the machine body, the walking part, the reciprocating impact part and the like. The reciprocating impact part comprises the dynamic impacting member, the impact driving device, the impactor and the like. The impact driving device comprises the dynamic impacting member. The guiding device comprises the impact guiding element; the dynamic impacting member drives the impactor to shock the coal wall or rock faces for blanking materials; the lifting device is arranged or not arranged on the machine body; the walking part is disposed on the lower part of the machine body and drives the machine body to walk so as to blank materials during walking and walk back to blank materials without turning the machine body.

Owner:刘素华

Equipment capable of intelligently disassembling and assembling truck tail hook frame layer board bolts

InactiveCN109227106AImprove disassembly efficiencyImprove working environmentMetal working apparatusVehicle frameControl system

The invention discloses equipment capable of intelligently disassembling and assembling truck tail hook frame layer board bolts. The equipment includes an AGV, a vehicle frame is arranged on the AGV and connected with an assisting arm through a rotary column, the free end of the assisting arm is connected with a motor through a connector, an output shaft of the motor is connected with a nut sleeveused for disassembling and assembling the bolts, and a column power system is connected to the rotary column; the free end of the assisting arm and the connector are also provided with a vision sensing system used for observing the positions of the bolts to be disassembled or assembled; a control system is arranged in the vehicle frame, a control panel is also arranged on the vehicle frame, the input end of the control panel is connected with the vision sensing system, the output end of the control panel is connected with the control system, and the output end of the control system is connected to the column power system. The equipment can achieve precise torque of the bolts and greatly improve the operation environment and the operation efficiency.

Owner:府谷县旭丽机电技术有限公司

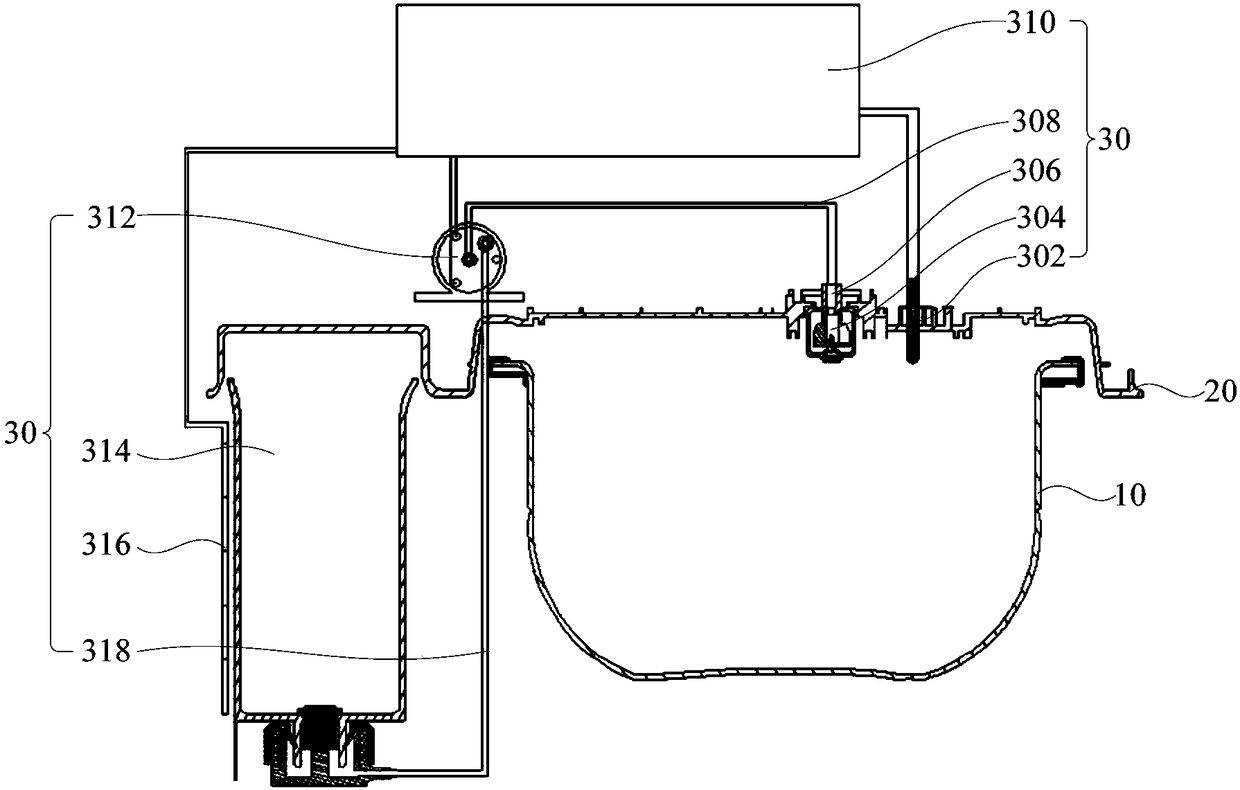

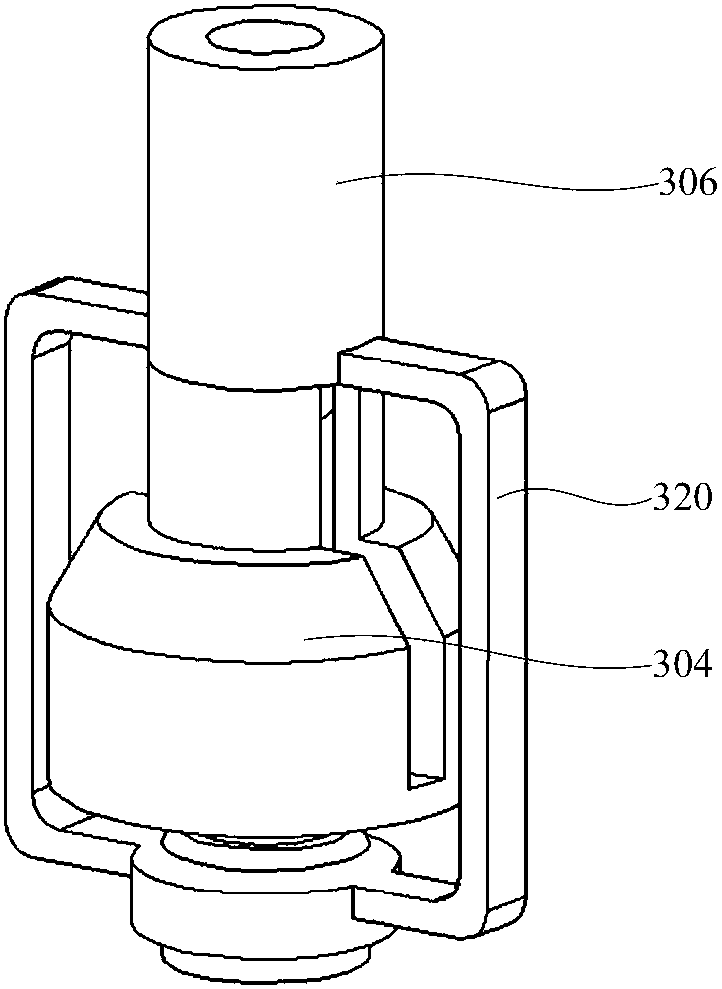

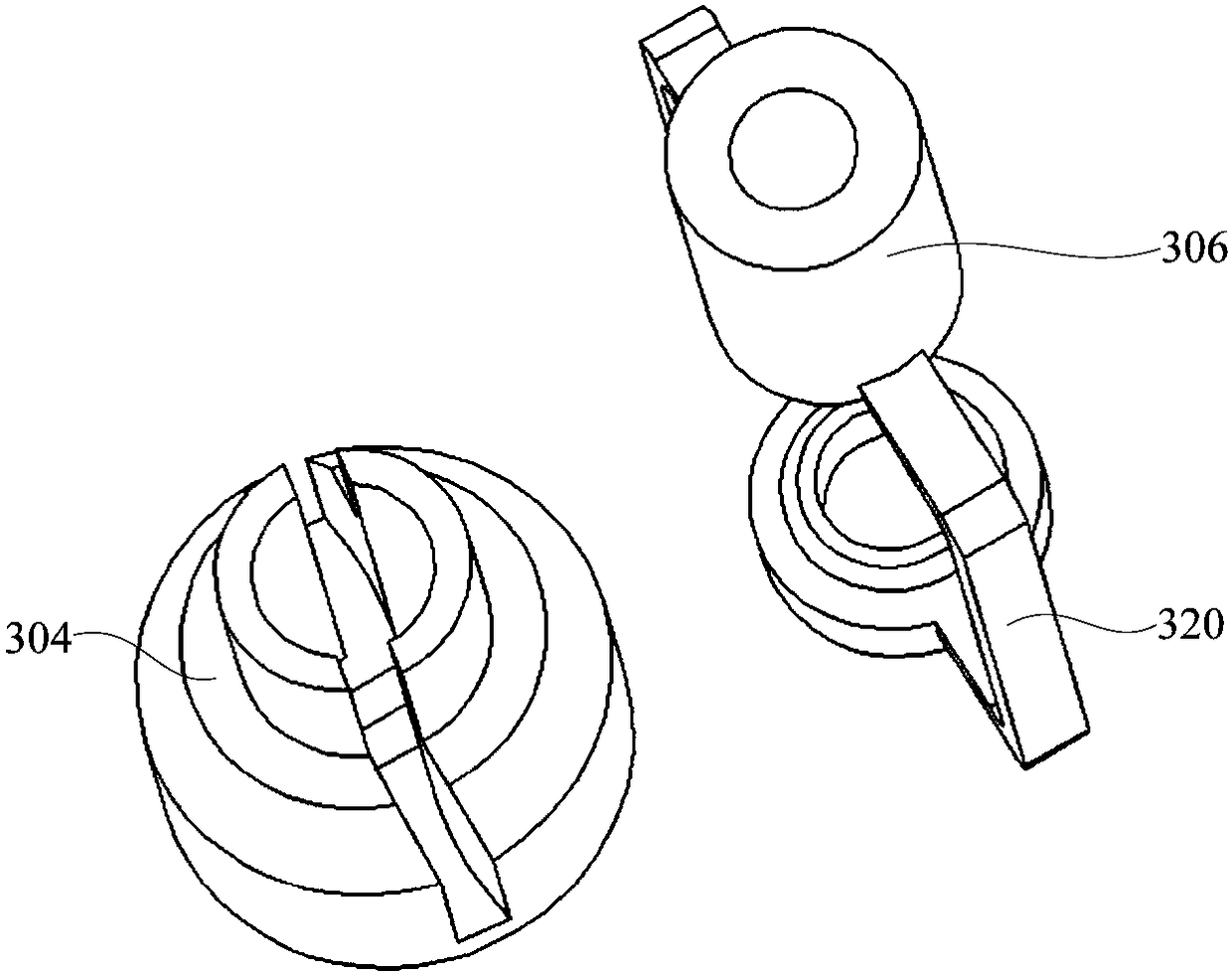

Anti-spilling assembly, method and system and cooking utensil

ActiveCN108201343AIncrease rotational torqueSimple structureBoiling over preventionHome appliance efficiency improvementAdditive ingredientSpray nozzle

The invention provides an anti-spilling assembly, method and system and a cooking utensil. The anti-spilling assembly comprises a water inlet pipe, a spraying nozzle and an anti-spilling detection device, the water inlet pipe is located above an inner pot, and a water outlet end of the water inlet pipe faces the inner pot; the spraying nozzle is provided with a cavity, a water inlet end of the spraying nozzle is connected with the water outlet end of the water inlet pipe, and the side wall of the spraying nozzle is provided with at least one water spraying port extending in the height direction of the spraying nozzle; the anti-spilling detection device is arranged on a cover body, connected with the cover body and used for controlling the spraying nozzle to start spraying water or stop spraying water. Through the arrangement of the anti-spilling detection device and the spraying nozzle, when the anti-spilling detection device detects that ingredients cooked in the inner pot are about to spill, the spraying nozzle is controlled to be opened to spray water into the inner pot, bubbles generated by boiling can be effectively reduced, and it is ensured that the ingredients in the innerpot can continuously be heated by the cooking utensil without spilling.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

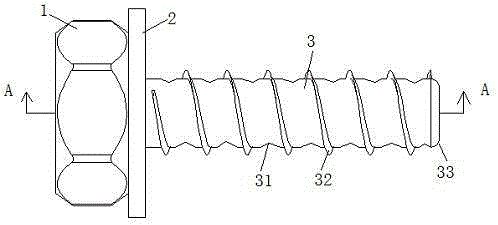

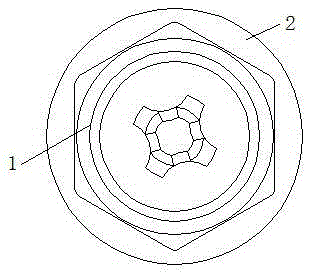

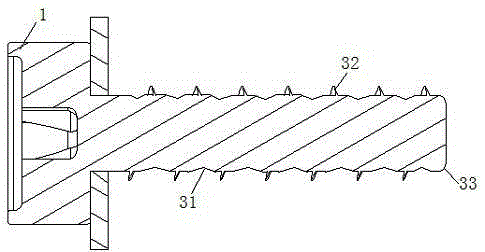

Self-tapping screw for plastic part

The invention discloses a self-tapping screw for a plastic part and belongs to the field of self-tapping screws. The self-tapping screw comprises a nut and a screw rod and further comprises a washer. The nut is arranged at one end of the screw rod, and the other end of the screw rod is a flat-head end face; a transition arc is disposed in the combining position of the flat-head end face and the side surface of the screw rod; the screw rod is provided with a screw thread which is arranged in the whole length direction of the screw rod; the washer is fixedly connected with the screw rod; one end face of the washer abuts against the nut; the nut is a hexagonal pan head nut; a cross-shaped countersunk head groove is formed in the center of the upper end face of the nut. By means of the technical scheme, the mounting performance is high when the self-tapping screw fastens the plastic part, damage to the plastic part is avoided at the same time, and the self-tapping screw is reasonable in structural design, simple in principle and low in cost.

Owner:WUHU HENGXIN AUTO INTERIOR TRIM COMPANY

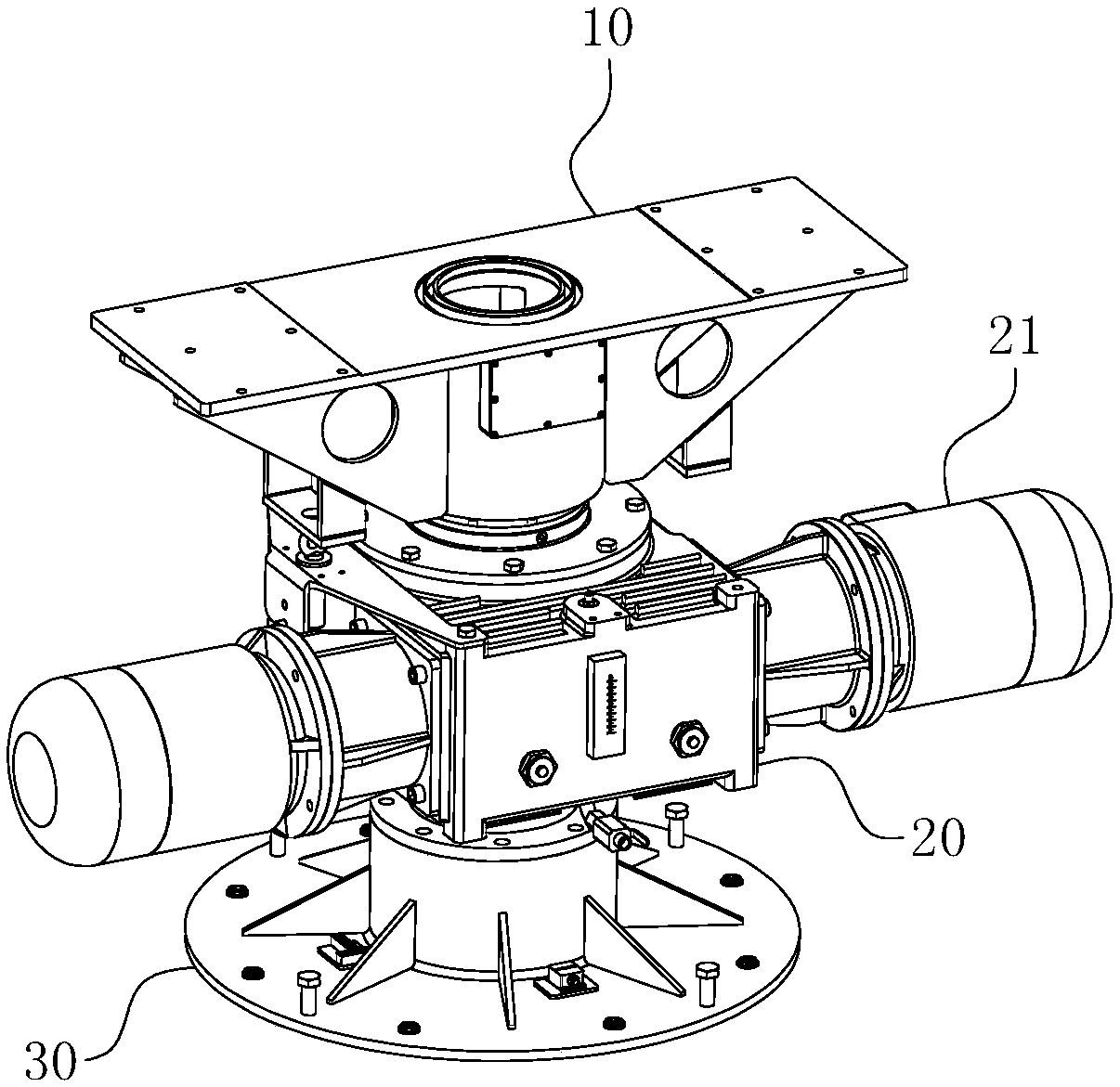

Antenna pedestal for airport surface detection radar

ActiveCN108919196AAchieve radial expansion functionAvoid eccentricityWave based measurement systemsInterference fitRadar antennas

The invention belongs to the technical field of airport surface detection radars, and particularly relates to an antenna pedestal for the airport surface detection radar. The antenna pedestal comprises an antenna support, a power box, a base and a rotating shaft, wherein a rotating support is arranged on the base; the antenna pedestal further comprises an encoder; the top end of the rotating shaftcoaxially penetrates into a small-aperture section of a mounting hole of the antenna support from bottom to top, and a hole-shaft inserting fit is formed between the rotating shaft and the mounting hole; the antenna pedestal further comprises an expansion ring; when a rotary screw of the expansion ring generates a rotary action, an inner expansion ring and an outer expansion ring generate radialexpansion due to conical fit, and interference fit is formed between the inner expansion ring and the rotating shaft and between the outer expansion ring and the mounting hole. The antenna pedestal issmall and exquisite in size, simple in structure and capable of ensuring normal operation of a radar antenna at the rotation speed of 60 revolutions per minute and even higher, and the high transmission efficiency, the operation stability and the high service life can be guaranteed synchronously.

Owner:ANHUI SUN CREATE ELECTRONICS

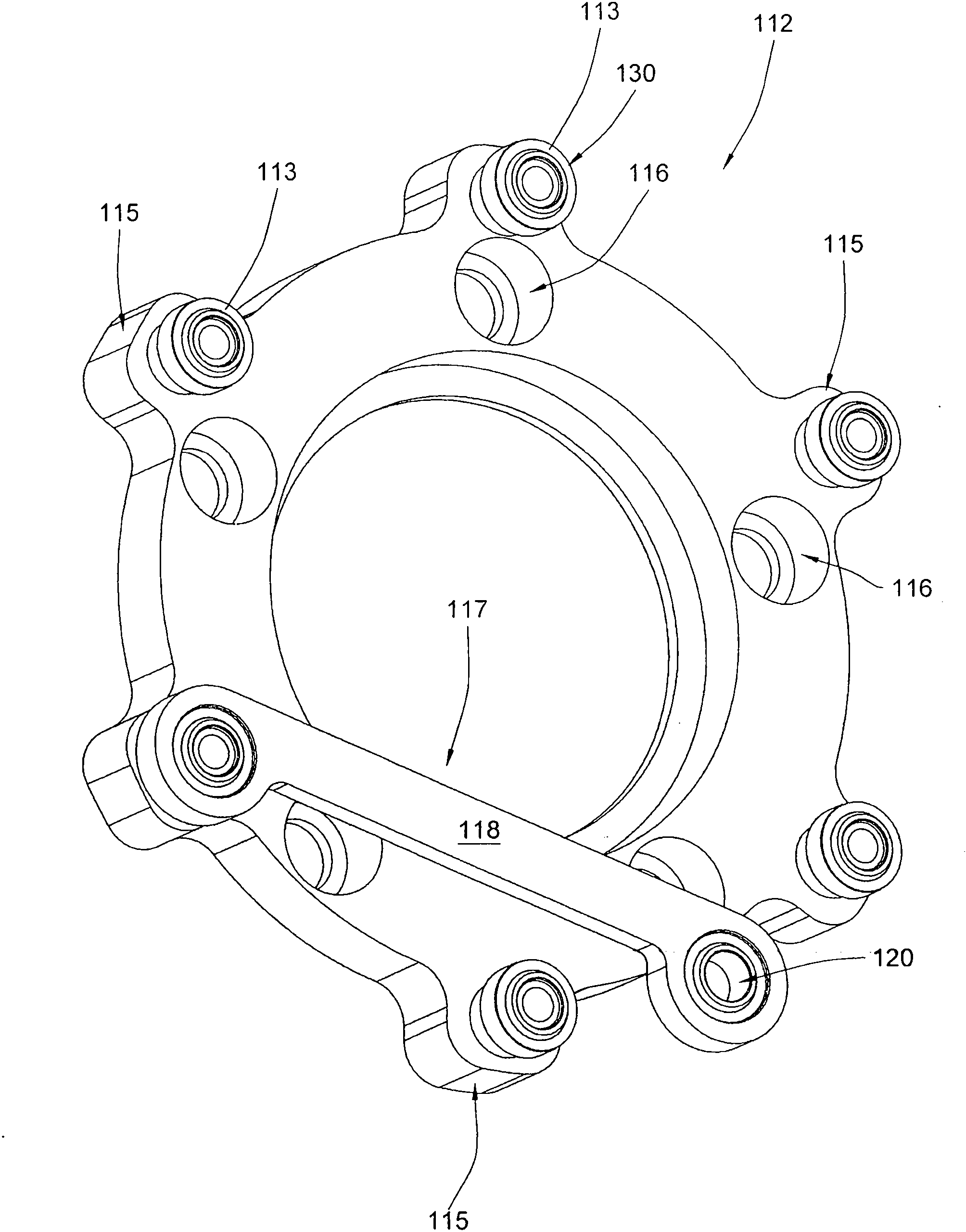

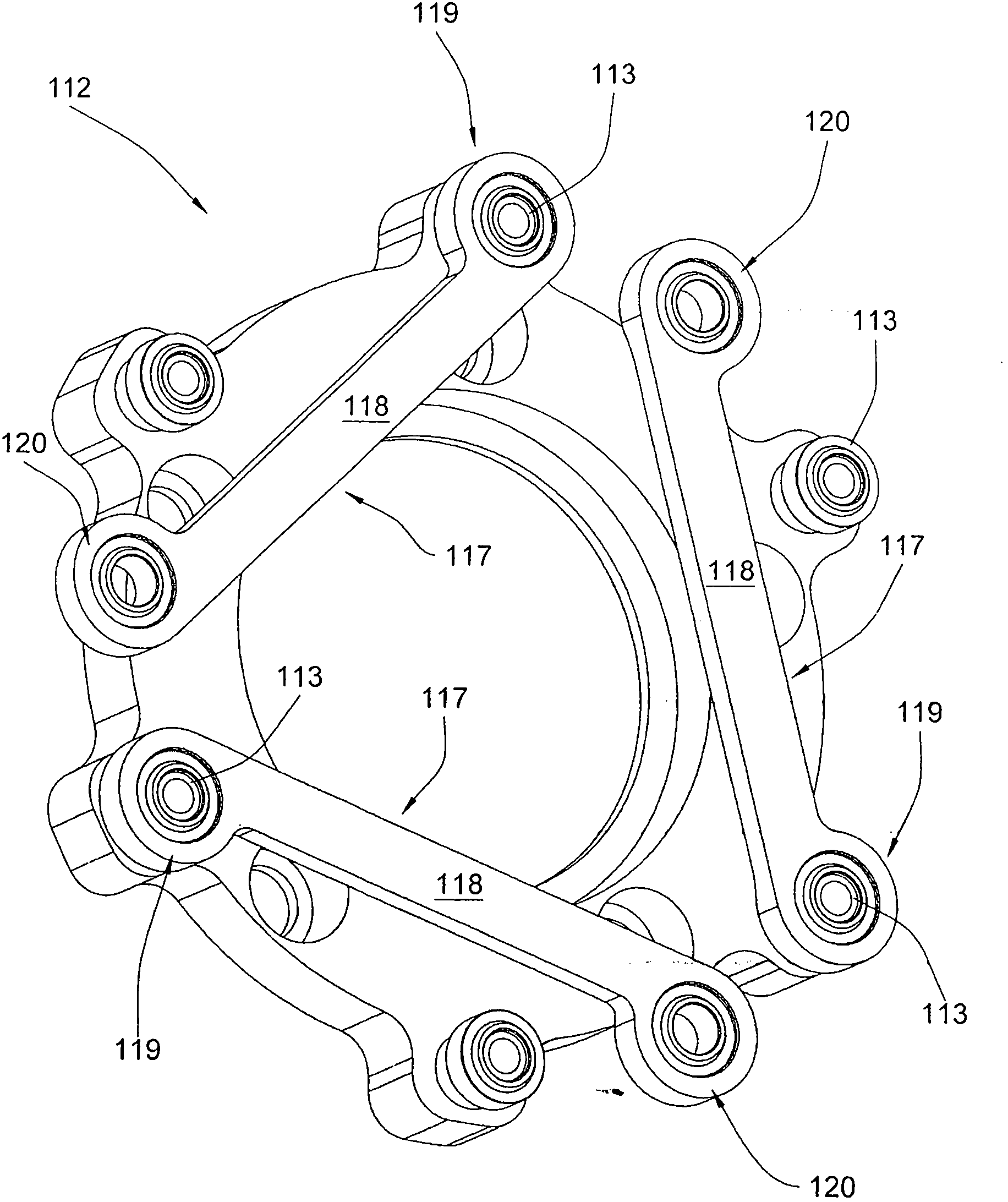

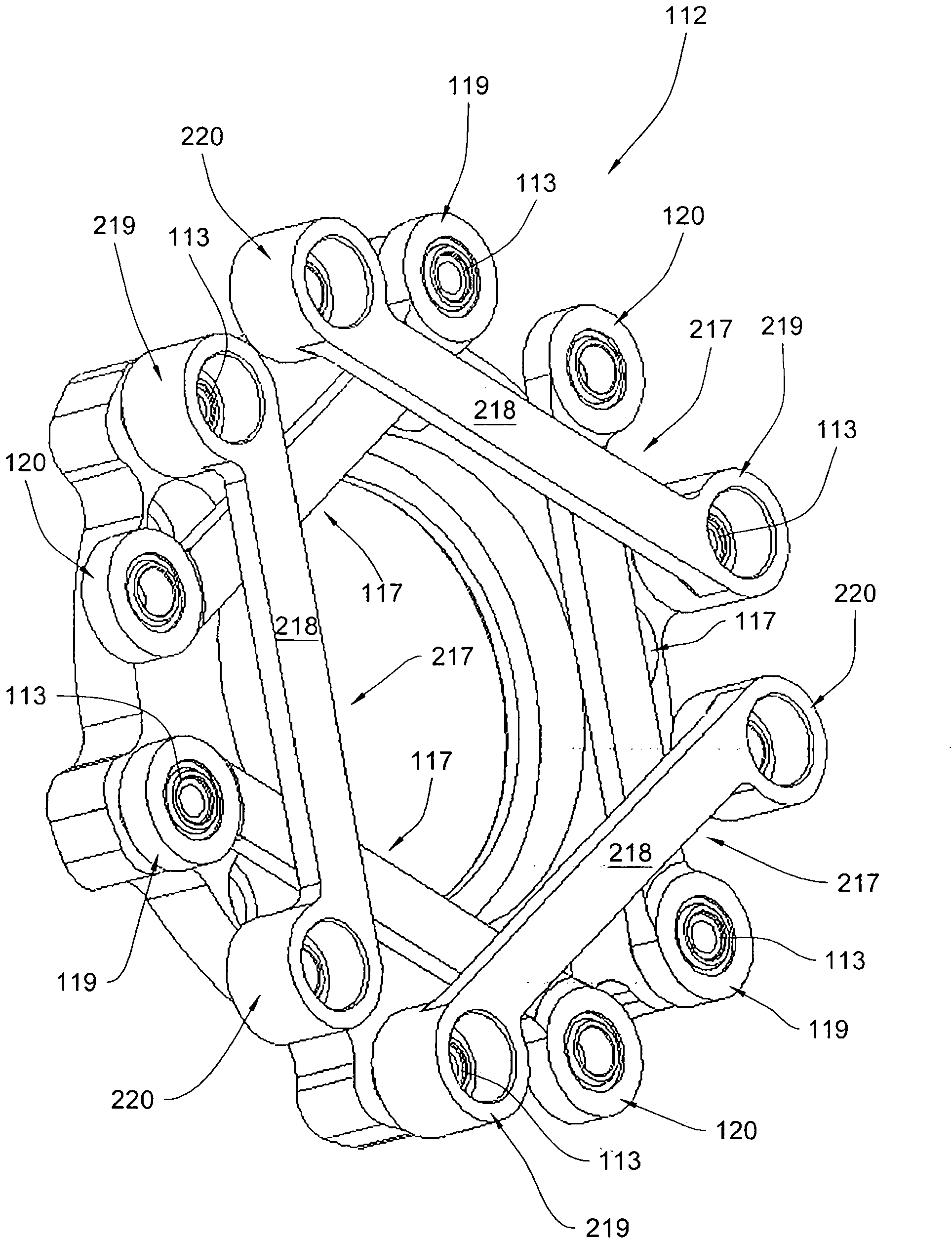

Coupling unit for connecting a drive with an output

InactiveCN102927147AImprove carrying capacityIncrease rotational torqueYielding couplingRotational axisRadial plane

A coupling for connecting a drive to a load has an input connector that defines with a plurality of radially spaced input attachment points all lying on a common radial plane of a rotation axis and a similar output connector with a plurality of output attachment points. Connecting elements each have one end connected to a respective input attachment point and an opposite end connected to a respective output attachment point by a link joint. The radial spacing of the input attachment points from the input rotation axis and the radial spacing of the output attachment points from the output rotation axis are the same. The input attachment points and the output attachment points coupled to these input attachment points by a connecting element are angularly spaced relative to each other about the input rotation axis by 80 DEG to 100 DEG .

Owner:CENTA ANTRIEBE KIRSCHEY GMBH

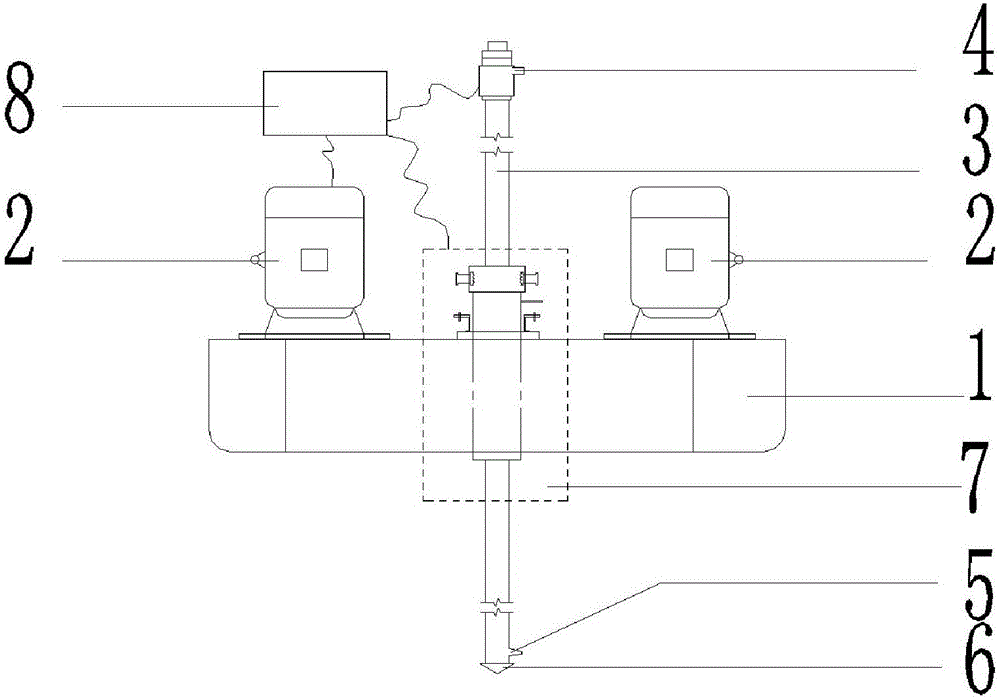

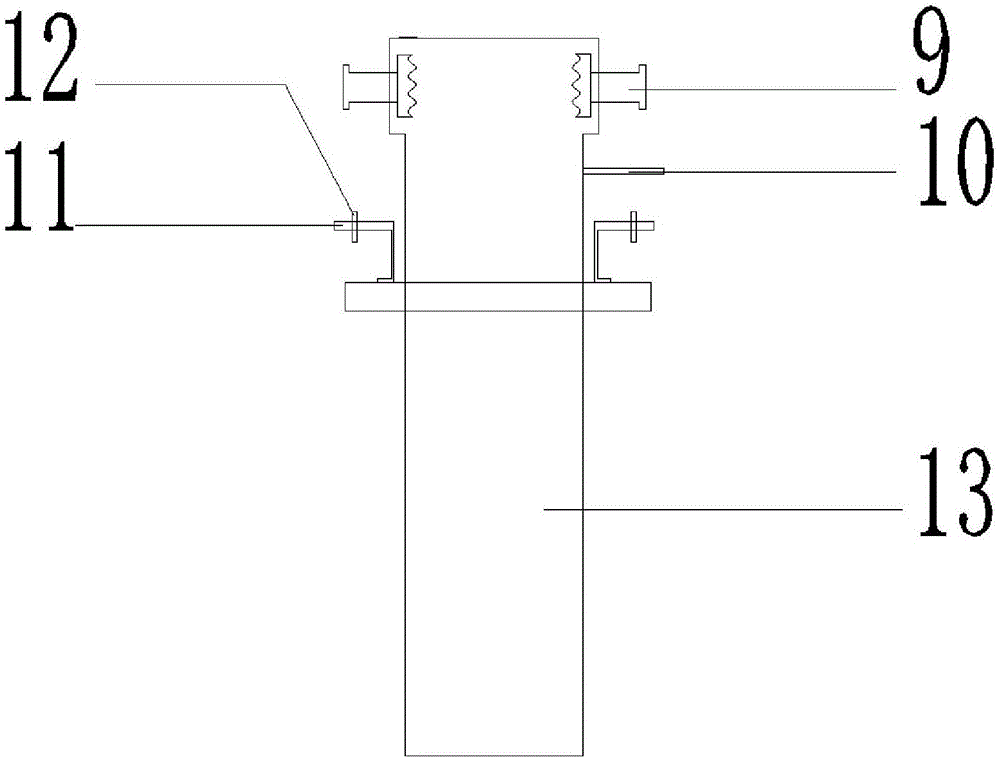

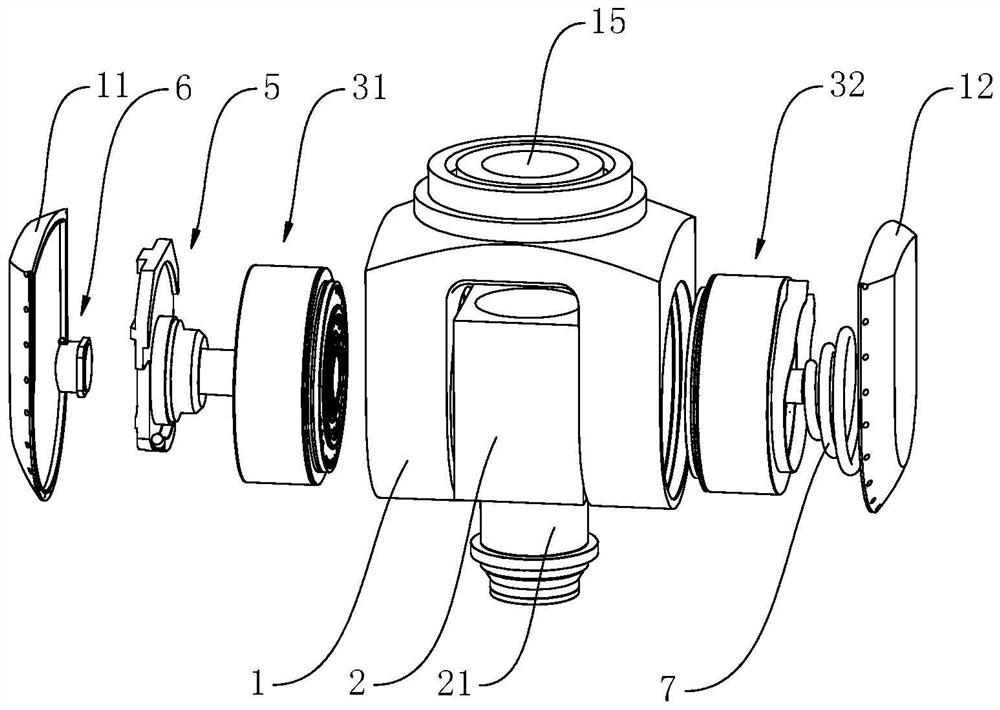

Power head device for high-pressure spraying and grouting and working method of power head device

The invention provides a power head device for high-pressure spraying and grouting and a working method of the power head device. The device comprises a speed changing box, two motors, a multi-pipe drilling spraying rod, a flow divider, a multifunctional nozzle, a drill bit, a rotary spraying and swinging spraying device and a control system, wherein the rotary spraying and swinging spraying device comprises a chuck, an induction sheet, a probe bearing disc, an induction probe and a rotary spraying and swinging spraying main body part; the speed changing box and the motors have combined action through bolt connection and inner gear or belt connection. The working method comprises the following steps: putting equipment in position and setting parameters, starting rotary spraying or swinging spraying, pulling out the multi-pipe drilling spraying rod and the like. According the device and the working method, provided by the invention, all technical parameters can be accurately controlled, the rotary spraying and the swinging spraying can be simply and conveniently switched and the swinging spraying at any angle can be realized.

Owner:BEIJING ZHONGYAN DADI TECH CO LTD

Shield type urban garbage bag breaking machine

PendingCN109987298AReduce loadImprove bag breaking efficiencyBags openingEngineeringCounter rotation

The invention discloses a shield type urban garbage bag breaking machine. A bag breaking shield and rotating mechanism backward rotating cutting manner is adopted for bag breaking and segmenting, a screw device is used for conducting garbage extruding and draining, and then water is output in several streams. The processes of bag breaking, segmenting and water removing can be conducted at a time,bar-shaped garbage is not likely to being wound around a rotating shaft, cleaning is convenient and fast, the garbage treatment efficiency is greatly improved, and the outage rate is low.

Owner:广西大自然再生资源有限公司

Composite detachable step riveting nut

The invention discloses a composite detachable step riveting nut which comprises a riveting tube body. A nut rim body extending outwards is arranged at the head end of the riveting tube body. A large step hole is formed in the riveting tube body, and a threaded hole is formed in the bottom of the large step hole. The riveting tube body is sleeved with a liner lantern ring which is freely detached selectively according to the sizes of pre-drilled holes of riveted workpieces. An excellent riveting effect between the composite detachable step riveting nut and the riveted workpieces with different thicknesses and pre-drilled holes is achieved; the composite detachable step riveting nut has more superior mechanical strength compared with common riveting nuts; and the composite detachable step riveting nut can be used as a general riveting nut only by detaching the detachable liner lantern ring. The riveting nut can be applicable to a wider thickness range of the riveted workpieces, and cost is reduced for customers.

Owner:WUXI ANXINDA SCI & TECH

Low-carbon economical electromagnetic fan clutch

ActiveCN105221600ASimple processPlay a protective effectCoolant flow controlMagnetically actuated clutchesEddy currentNon magnetic

A low-carbon economical electromagnetic fan clutch comprises a main shaft and a fan fixing disc. The low-carbon economical electromagnetic fan clutch is characterized by further comprising an electric eddy current disc; the fan fixing disc and the electric eddy current disc are sequentially arranged from left to right in the axial direction from the left end of the main shaft; one or more permanent magnets surrounding the main shaft are arranged on the fan fixing disc; a conductive non-magnetic material is fixed to the position corresponding to the electric eddy current disc; the fan fixing disc is rotatably connected with the main shaft through a first bearing, and the electric eddy current disc is rotatably connected with the main shaft through a second bearing. According to the low-carbon economical electromagnetic fan clutch, an electromagnetic eddy current high heat accumulation area is effectively separated from the fan fixing disc which rotates at a high speed, energy consumption and materials used for manufacturing the low-carbon economical electromagnetic fan clutch have great advantages compared with a traditional model, and the effects of being economical and environmentally friendly are achieved.

Owner:LONGKOU ZHONGYU THERMAL MANAGEMENT SYST SCIAND TECH

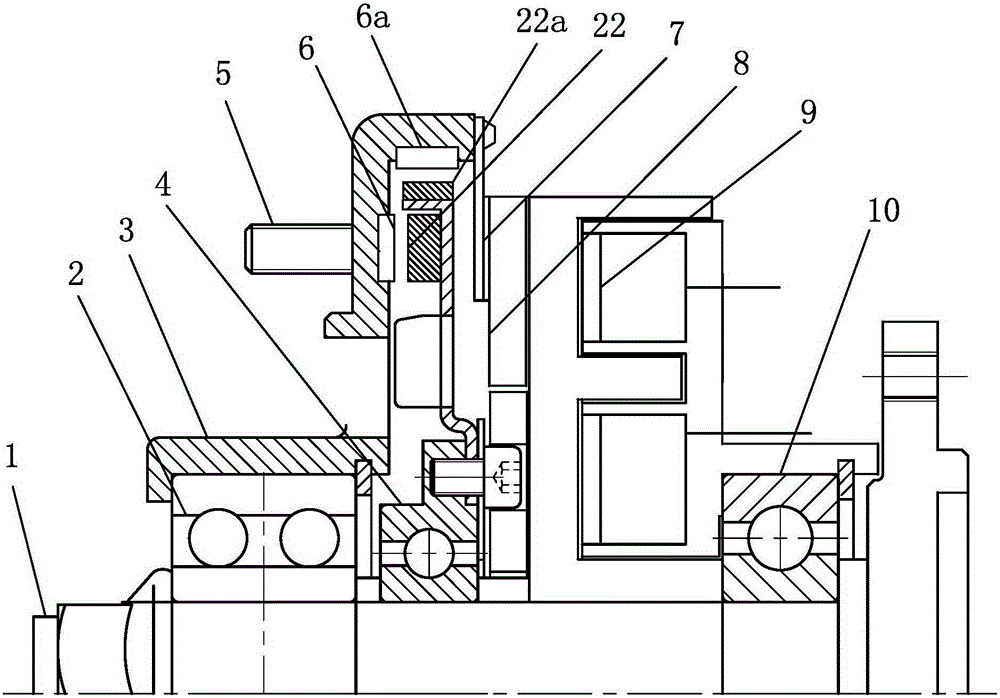

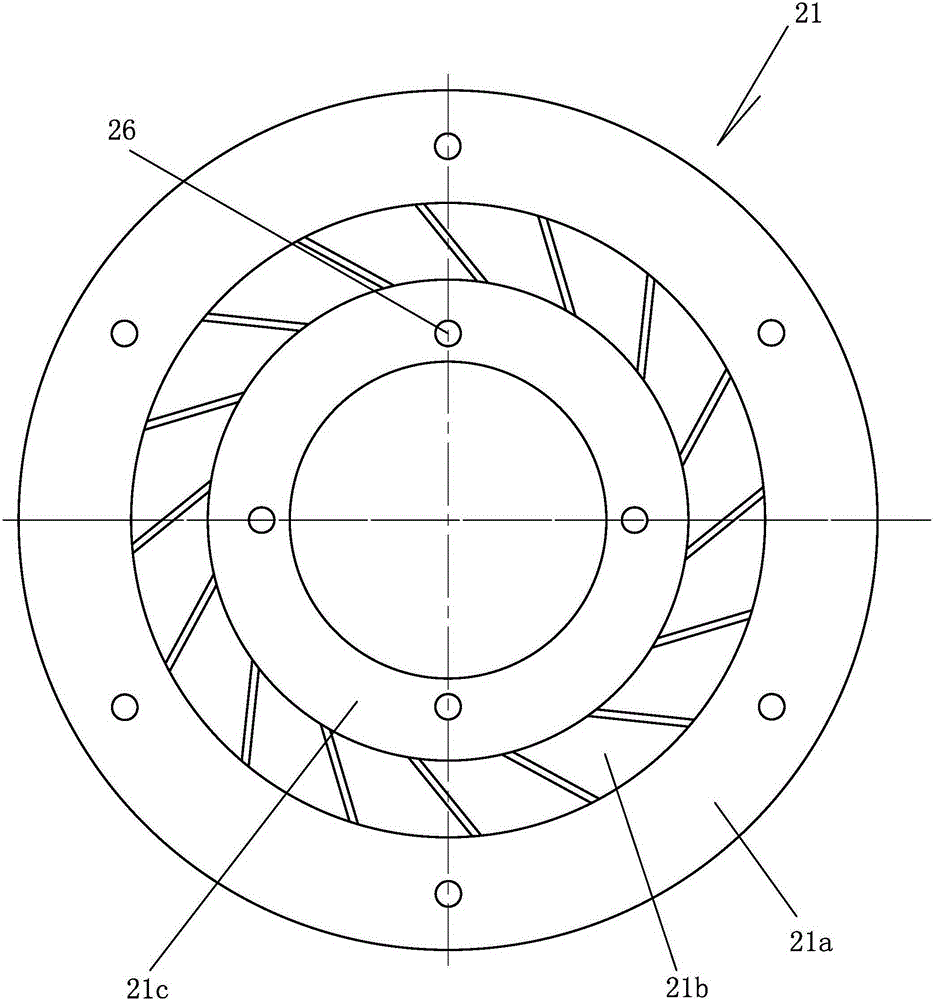

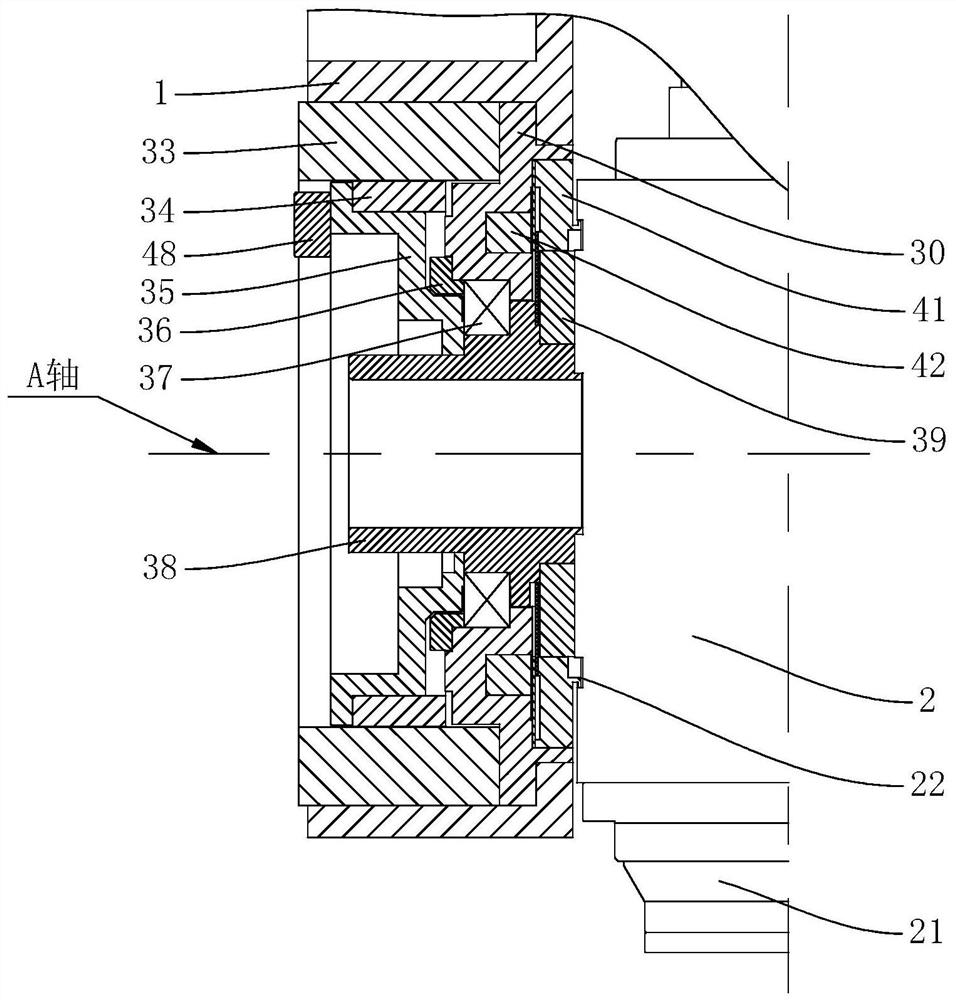

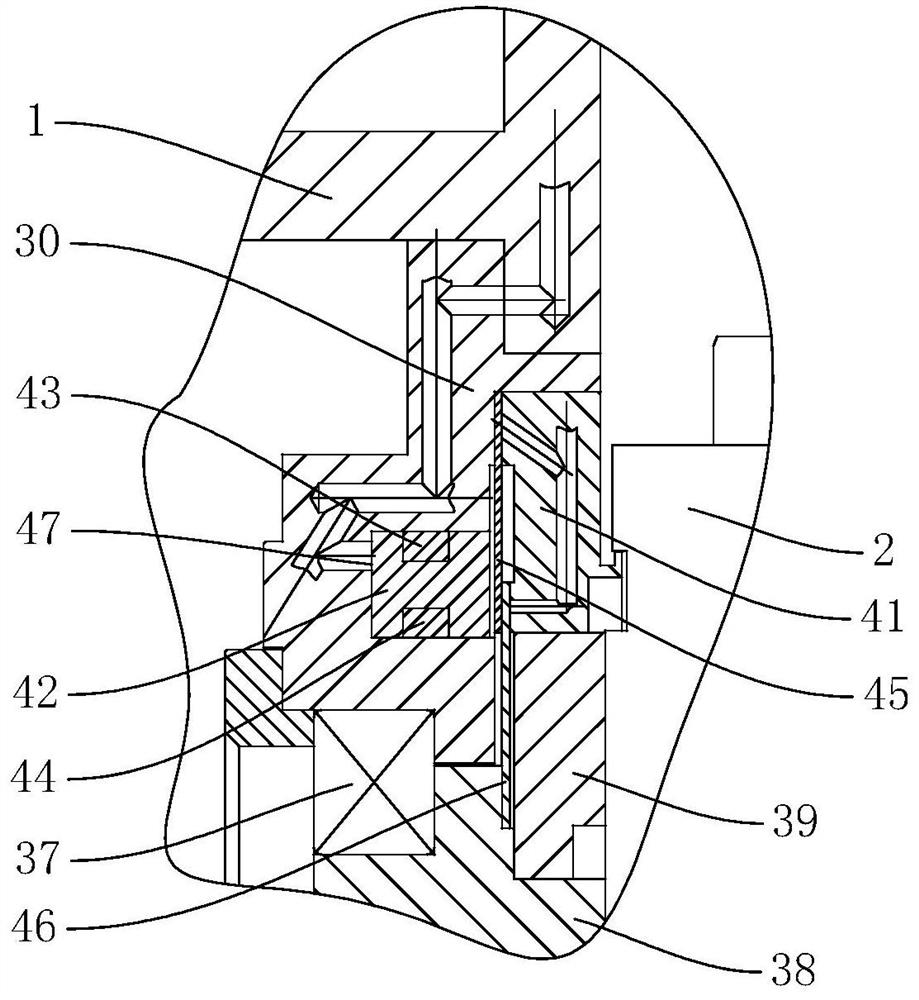

Double-drive single-swing head for vertical machining center

PendingCN112171351AGuaranteed stiffnessIncrease rotational torqueDriving apparatusLine tubingControl engineering

The invention discloses a double-drive single-swing head for a vertical machining center. The double-drive single-swing head for the vertical machining center comprises a swing head box body, a main shaft box, a main shaft, an A-axis left driving assembly, an A-axis right driving assembly, an A-axis oil distributor assembly, an A-axis encoder assembly and a main shaft pipeline outlet unit. The A-axis left driving assembly comprises a left torque motor assembly and a left hydraulic clamping mechanism. The A-axis right driving assembly comprises a right torque motor assembly and a right hydraulic clamping mechanism. A main shaft pipeline spirally surrounds the main shaft pipeline outlet unit, and a left protective cover and a right protective cover are fixed to the left side and the right side of the swing head box body respectively. According to the double-drive single-swing head, the main shaft box is driven by the double-torque motors which are symmetrically designed, larger rotatingtorque can be provided, high dynamic characteristics and stability required by machining are guaranteed, and the problem that a rotating shaft is distorted and deformed in a traditional single-side driving mode is solved. Meanwhile, the double hydraulic clamping mechanisms are adopted, larger locking torque can be provided, the braking effect can be ensured, and the rigidity of the single swing head in the machining process is ensured.

Owner:NINGBO HAITIAN PRECISION MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com