Self-tapping screw for plastic part

A technology of self-tapping screws and plastic parts, which is applied in the direction of screws, connecting components, threaded fasteners, etc., can solve the problems of poor fastening and affecting the local integrity of plastic parts, etc., to increase pull-off force, increase rotation torque, The effect of increasing pull-off force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

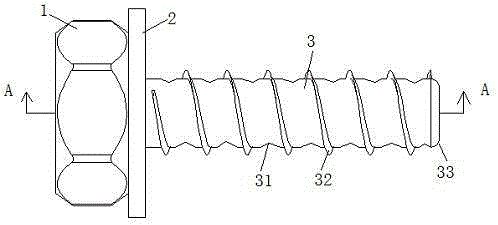

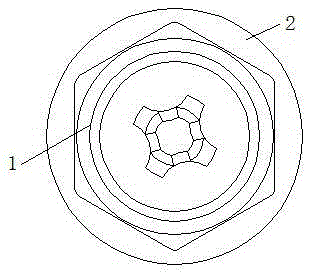

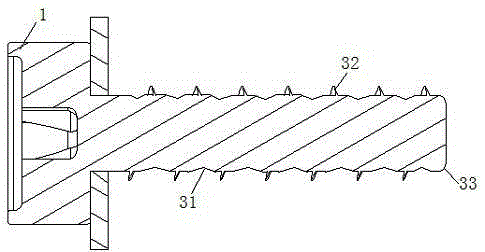

[0030] combine figure 1 , figure 2 , image 3 and Figure 4 , a self-tapping screw for plastic parts in this embodiment includes a nut 1, a screw 3, and a washer 2. One end of the screw 3 is provided with a nut 1, and the other end is a flat end surface, and the flat end surface is connected to the screw 3. The junction of the side is provided with a transition arc 33, and the screw 3 is provided with a thread 32, and the thread 32 is arranged along the entire length direction of the screw 3; The nut 1 is a hexagonal pan-head nut, and the center of its upper end surface is provided with a cross-shaped countersunk groove. In this embodiment, the other end of the screw rod 3 is a flat end face, so that when using pneumatic or electric tools to install self-tapping screws in industrial assembly, it is not easy to damage the plastic mounting part due to the fast installation speed, that is, the flat end face can reduce the impact on the plastic part. The impact force ensures...

Embodiment 2

[0035] A kind of self-tapping screw that is used for plastic parts of this embodiment, its basic structure is the same as embodiment 1, difference is: the thread pitch of thread 32 in this embodiment is 2.4mm, and the thread depth of thread 32 is 0.5mm .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com