Power head device for high-pressure spraying and grouting and working method of power head device

A high-pressure jet and power head technology, which is applied in infrastructure engineering, construction, sheet pile walls, etc., can solve the problems of complicated rotary jet and swing jet conversion operations, inability to precisely control technical parameters, complex underground structures, etc., and achieve a simple structure. , the effect of increasing the rotational torque and easy switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be exemplarily described below in conjunction with the accompanying drawings in the embodiments, but the present invention is not limited by the following embodiments, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

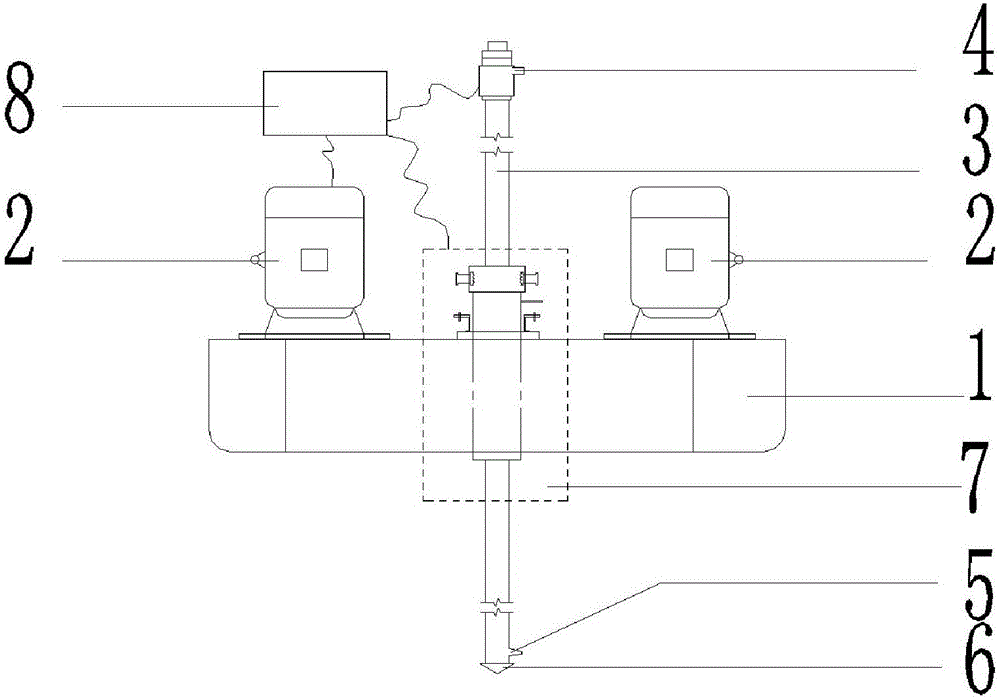

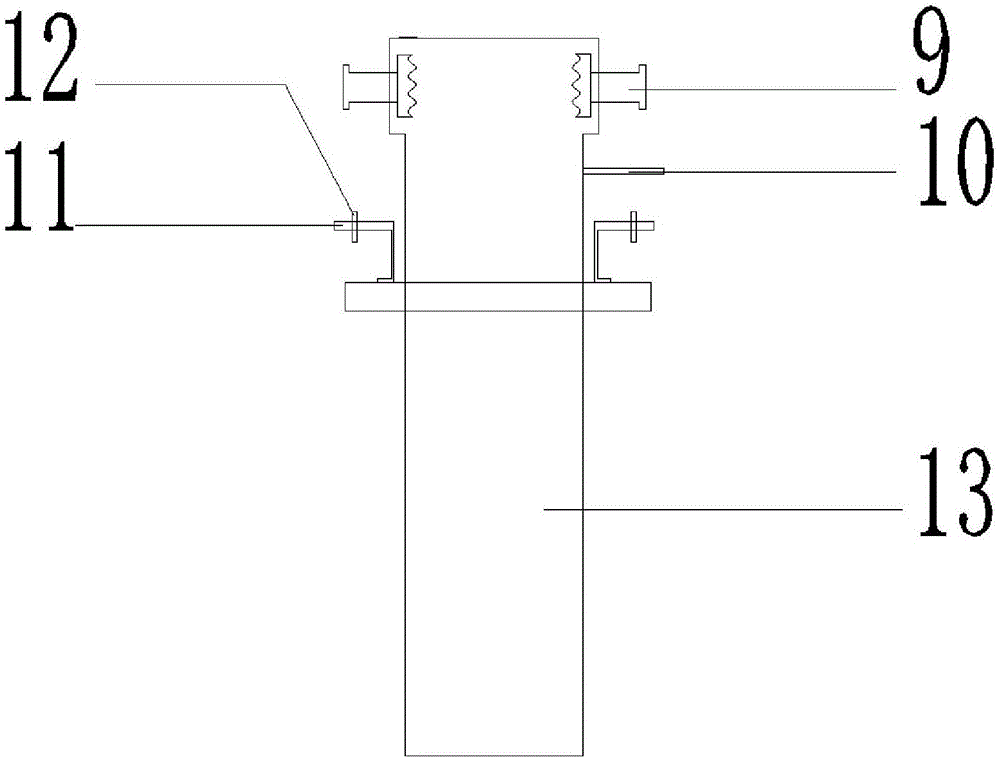

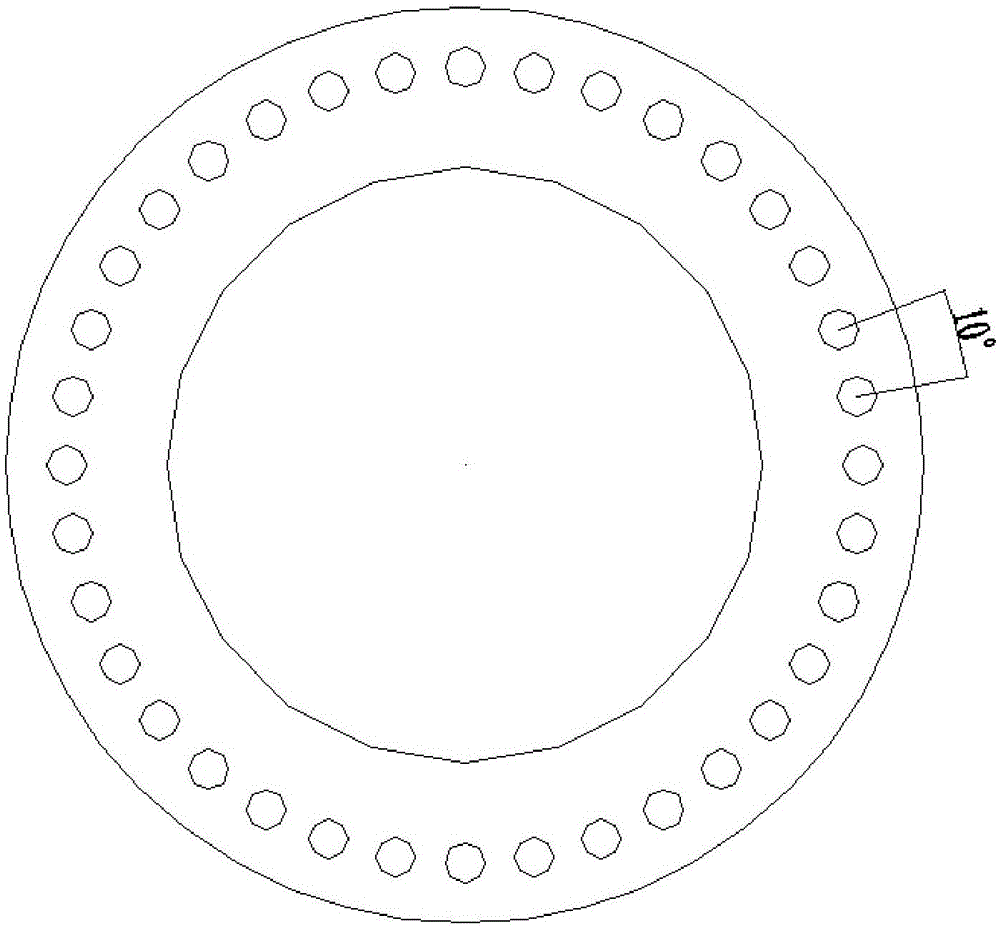

[0030] A power head device for high-pressure jet grouting, including a gearbox 1, two motors 2, a multi-pipe drill spray rod 3, a flow divider 4, a multifunctional spray head 5, a drill bit 6, a rotary spray pendulum spray device 7 and a control System 8, the described rotary spray pendulum spray device 7 includes a chuck 9, an induction plate 10, a probe holder 11, an induction probe 12 and a rotary spray pendulum spray main part 13, the gearbox 1 and the motor 2 are connected by bolts and the internal Gears or belts work together; it is characterized in that the multi-pipe drill spray bar 3 is fixedly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com