Patents

Literature

38results about How to "Improve bag breaking efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

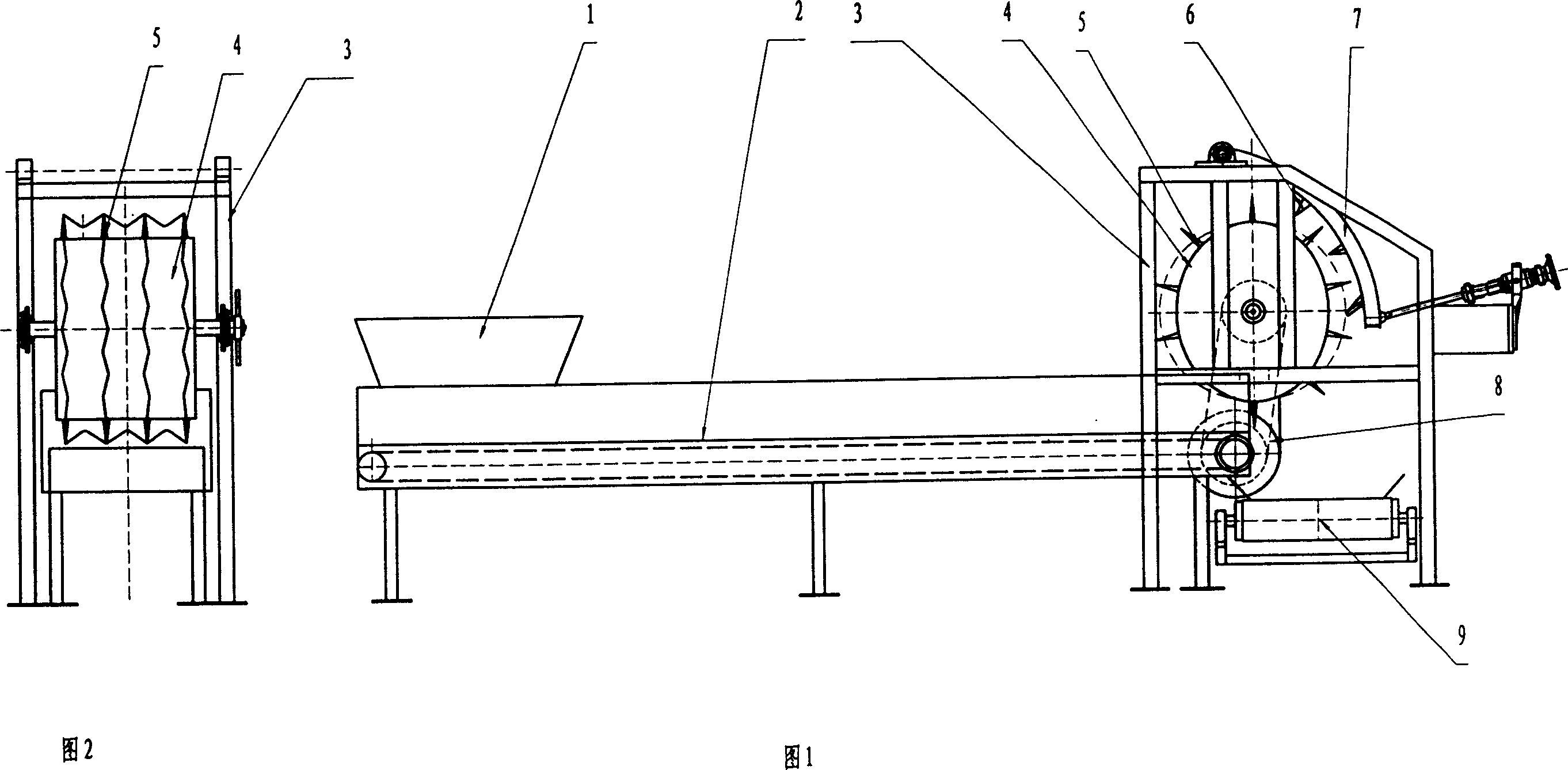

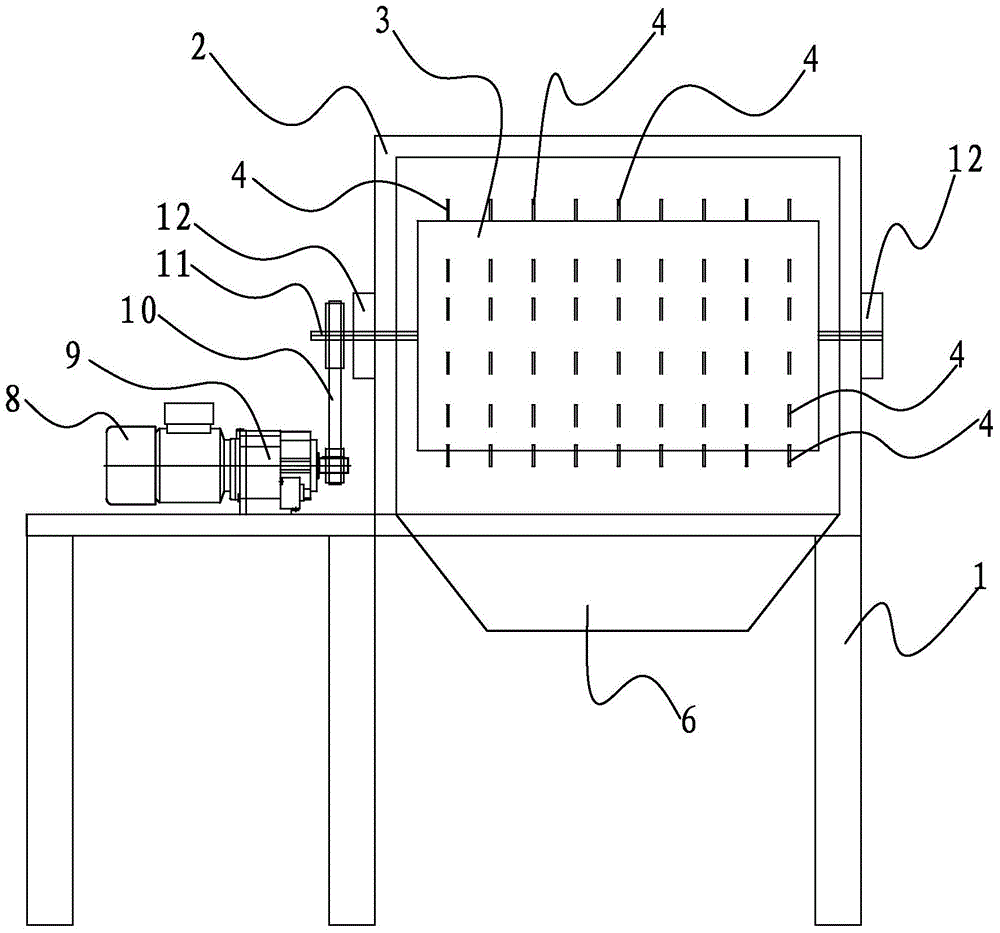

Garbage bag breaking machine

InactiveCN1944191AEffectively break openImprove processing efficiencyArticle unpackingGrain treatmentsFixed bearingEngineering

The present invention is garbage bag breaking machine, and belongs to the field of environment protecting machine technology. The garbage bag breaking machine includes a material conveying mechanism, one fixed bearing and one bag breaking mechanism. It features the bag breaking mechanism comprising material shifting rotary cutter fixed on hub and bag breaking fixed cutter, the power mechanism driving the material shifting rotary cutter and the tooth crossing installation of the material shifting rotary cutter and the bag breaking fixed cutter. The present invention has optimized structure, convenient operation, easy maintenance, high production efficiency and other advantages, and suitable for use in garbage bag breaking treatment.

Owner:天津百利阳光环保设备有限公司

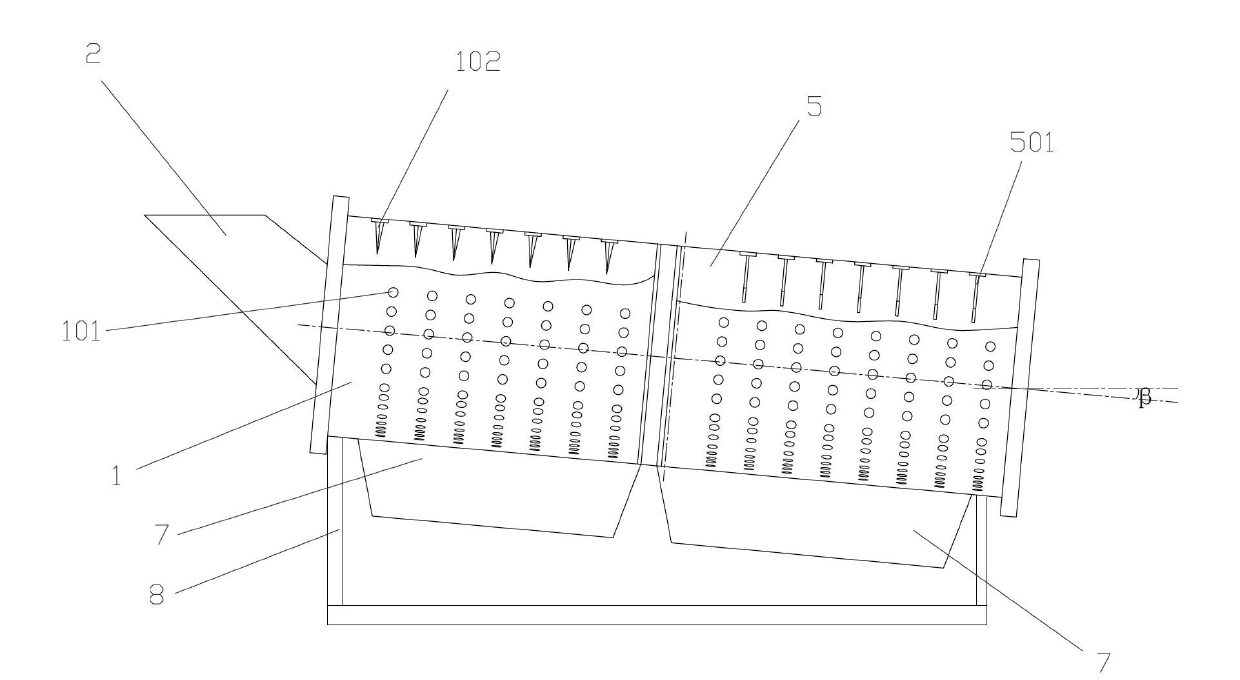

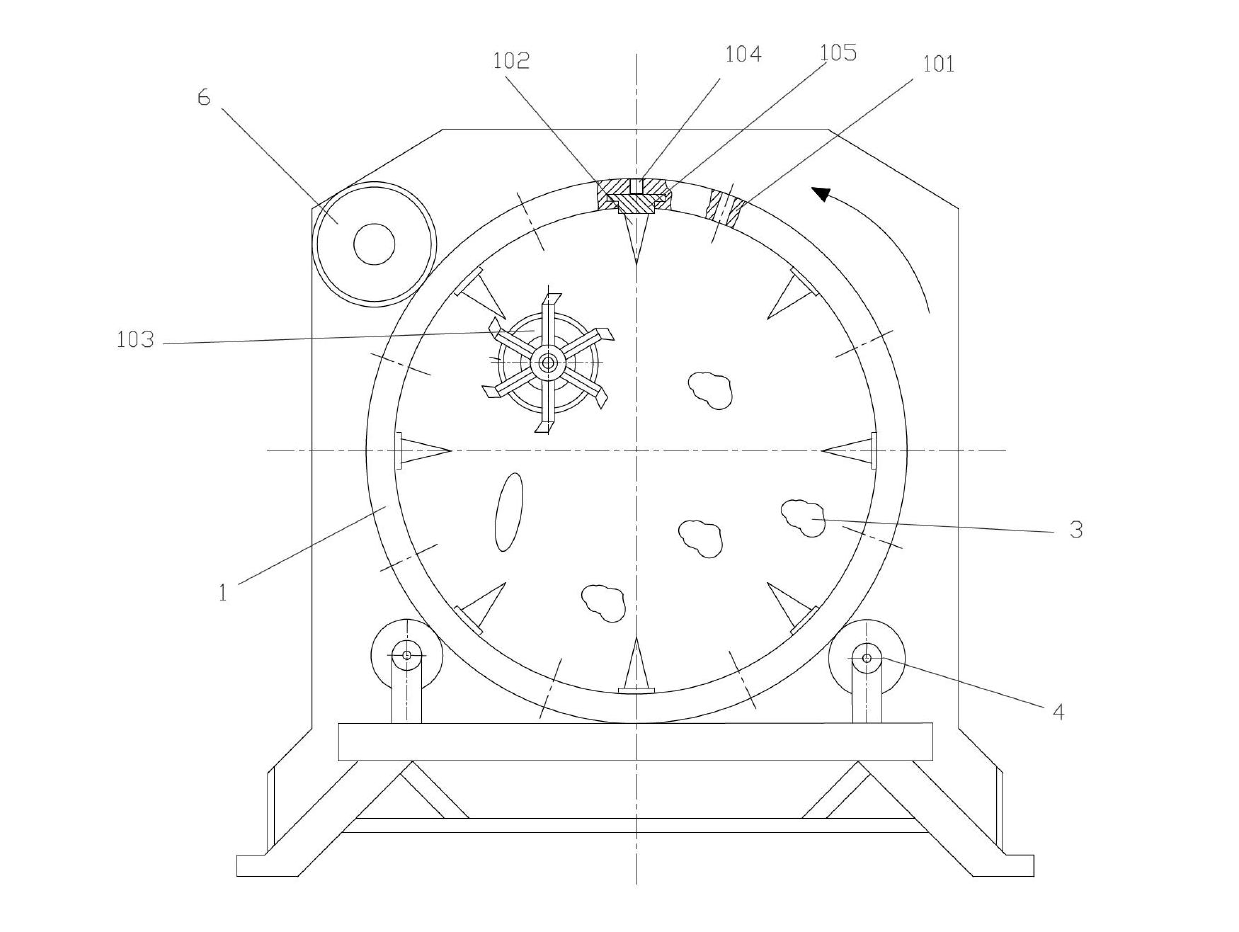

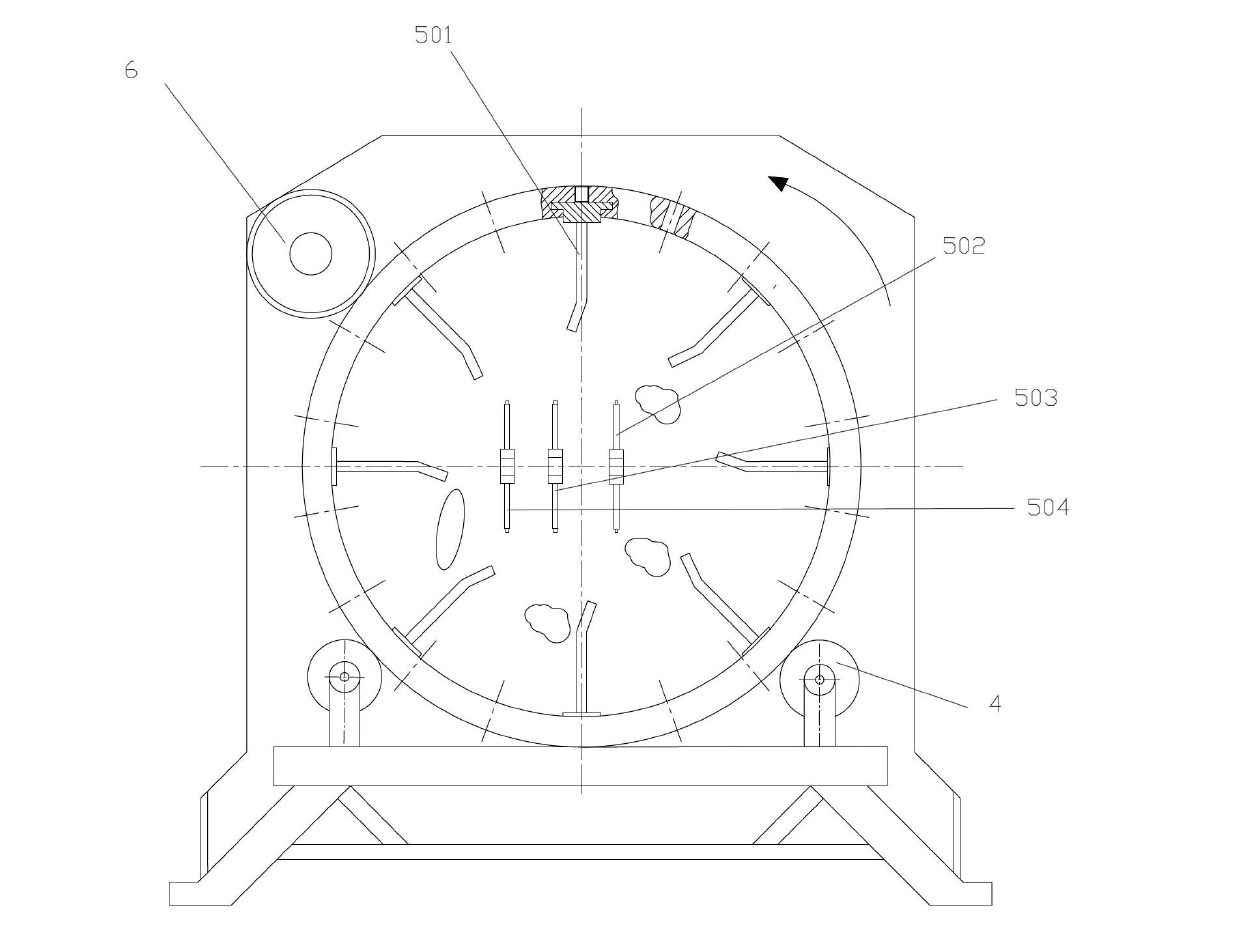

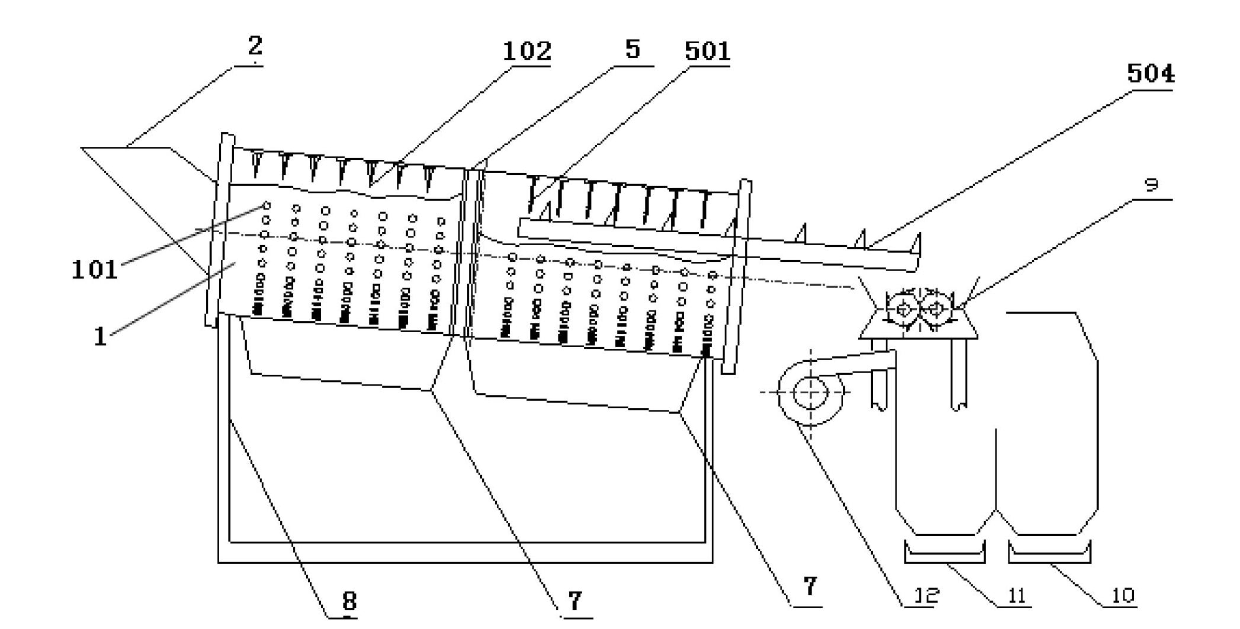

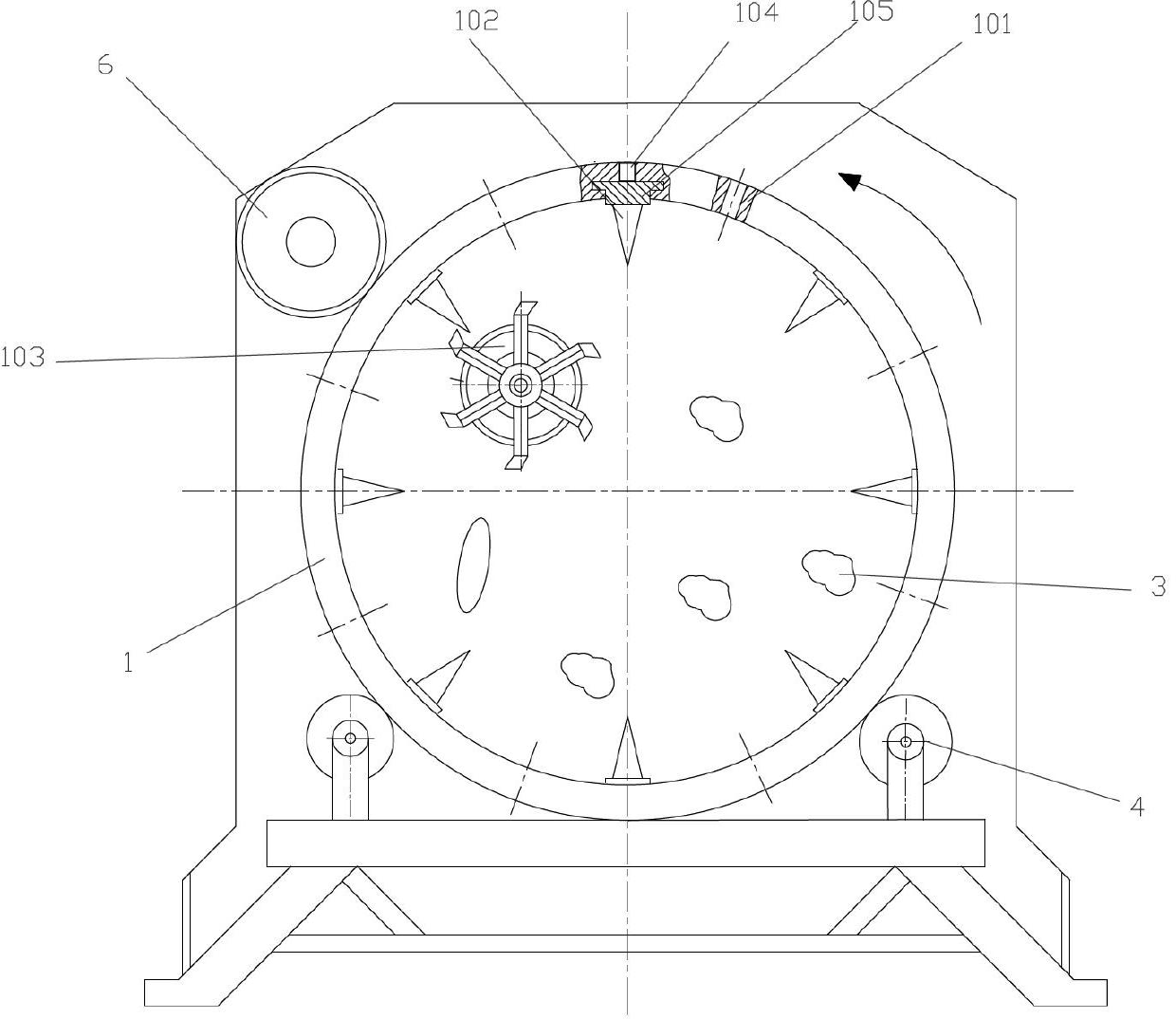

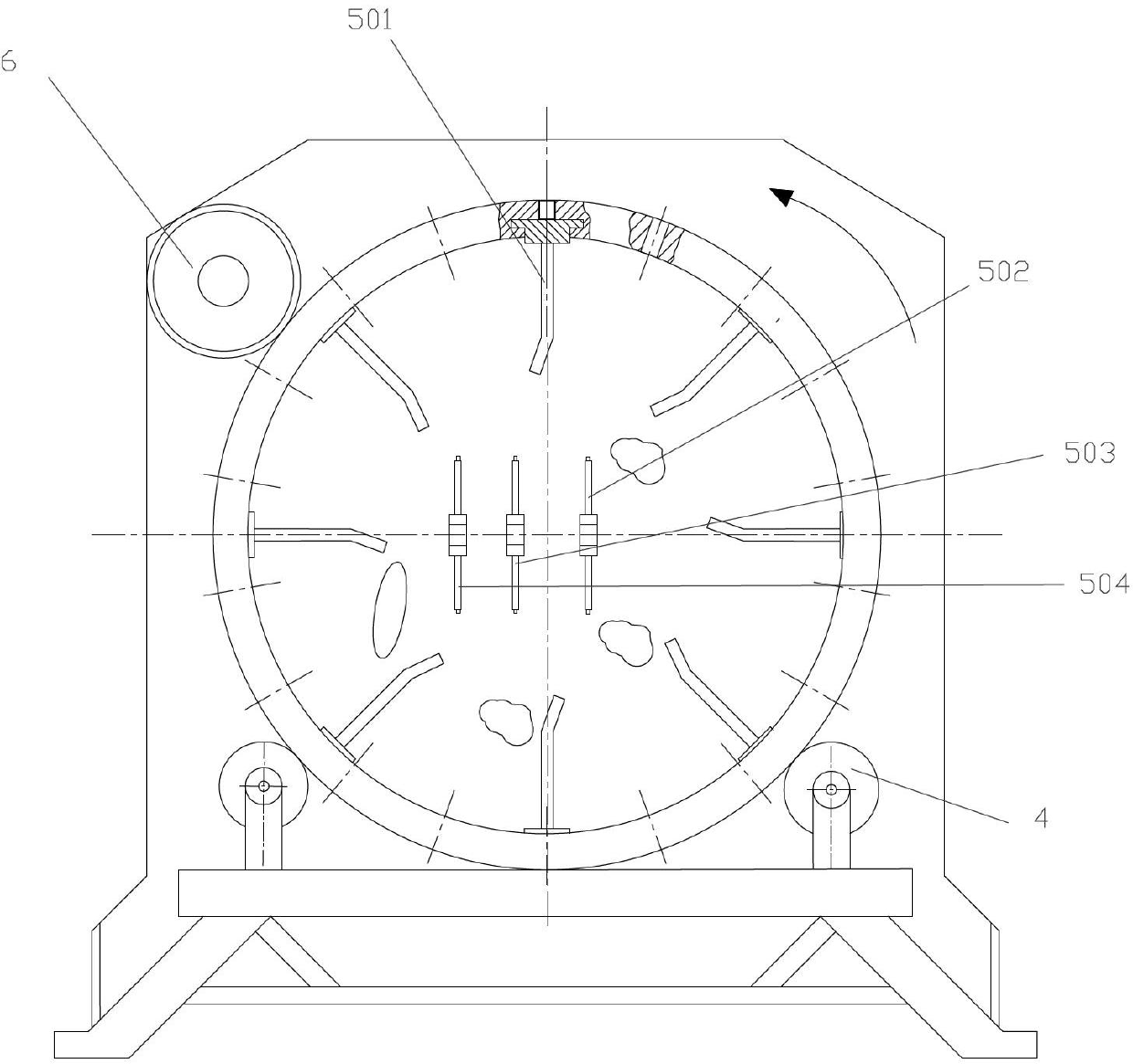

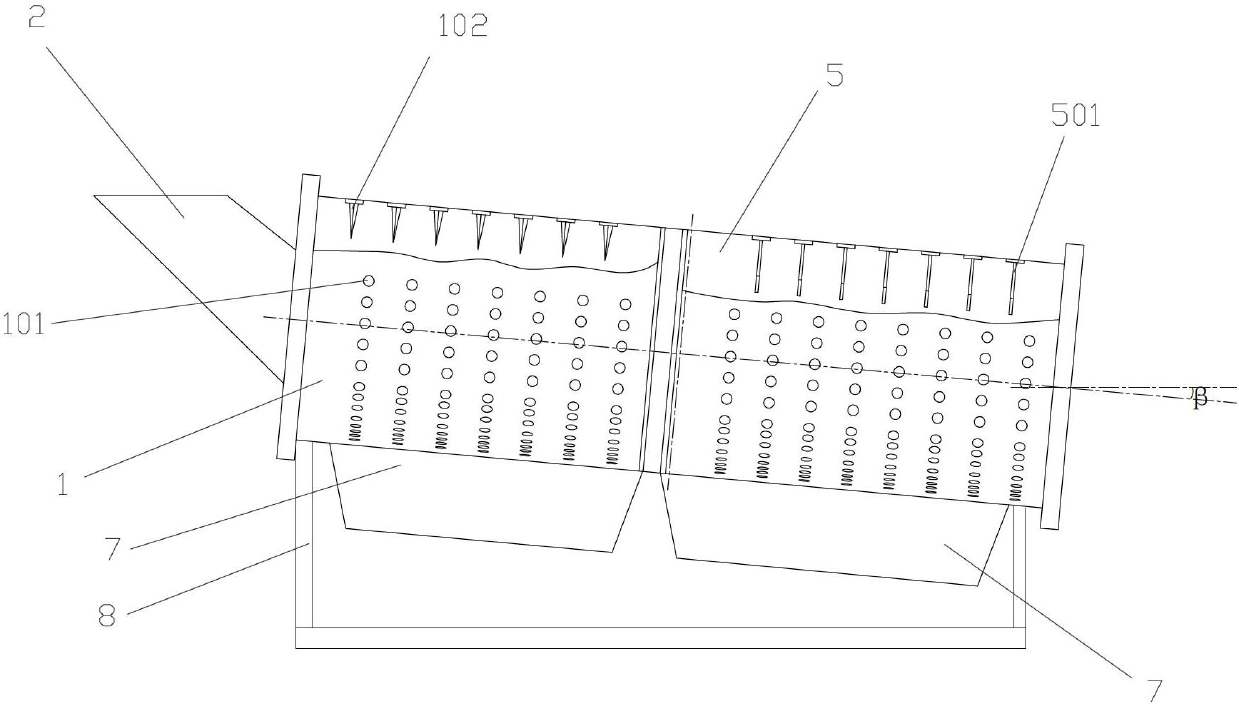

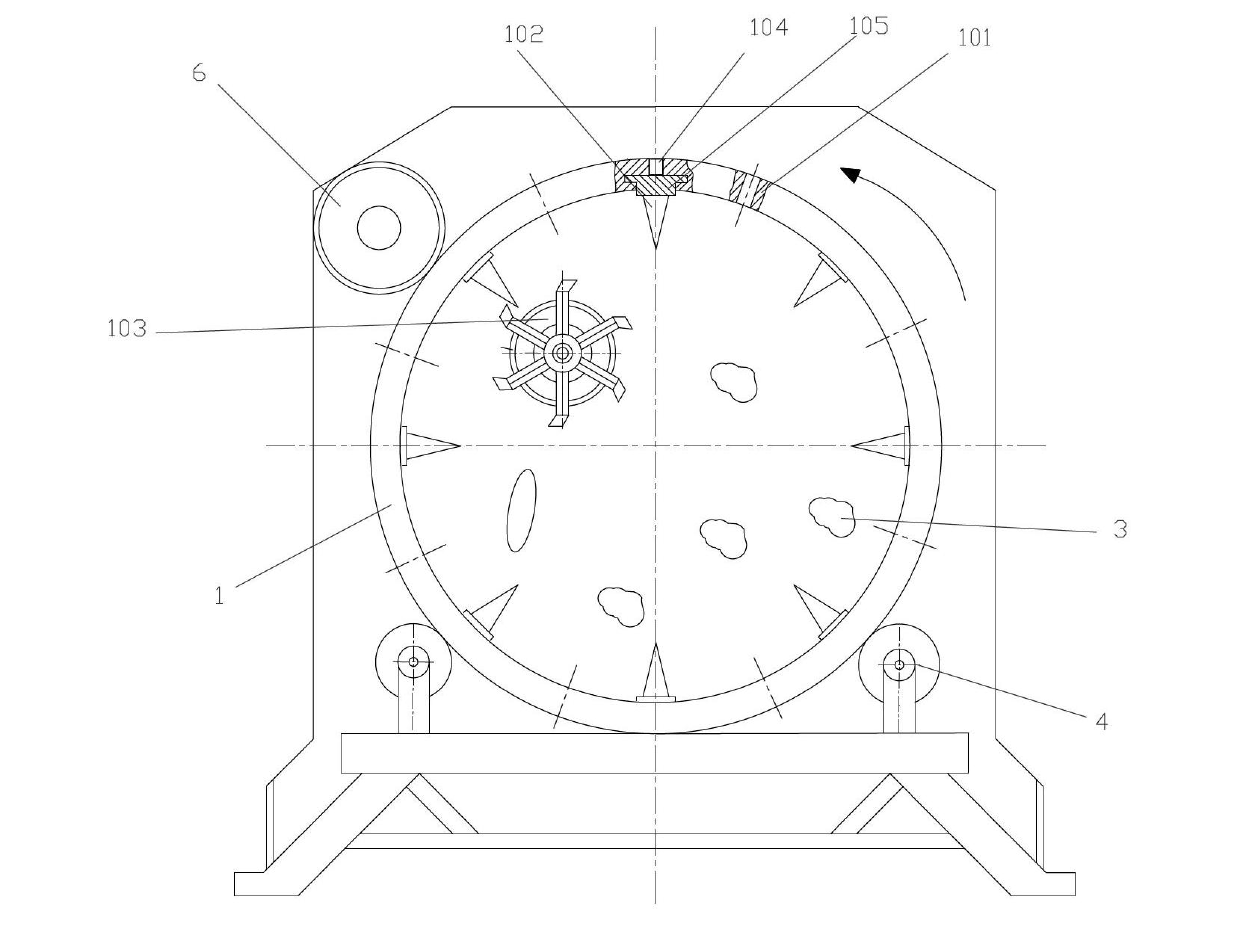

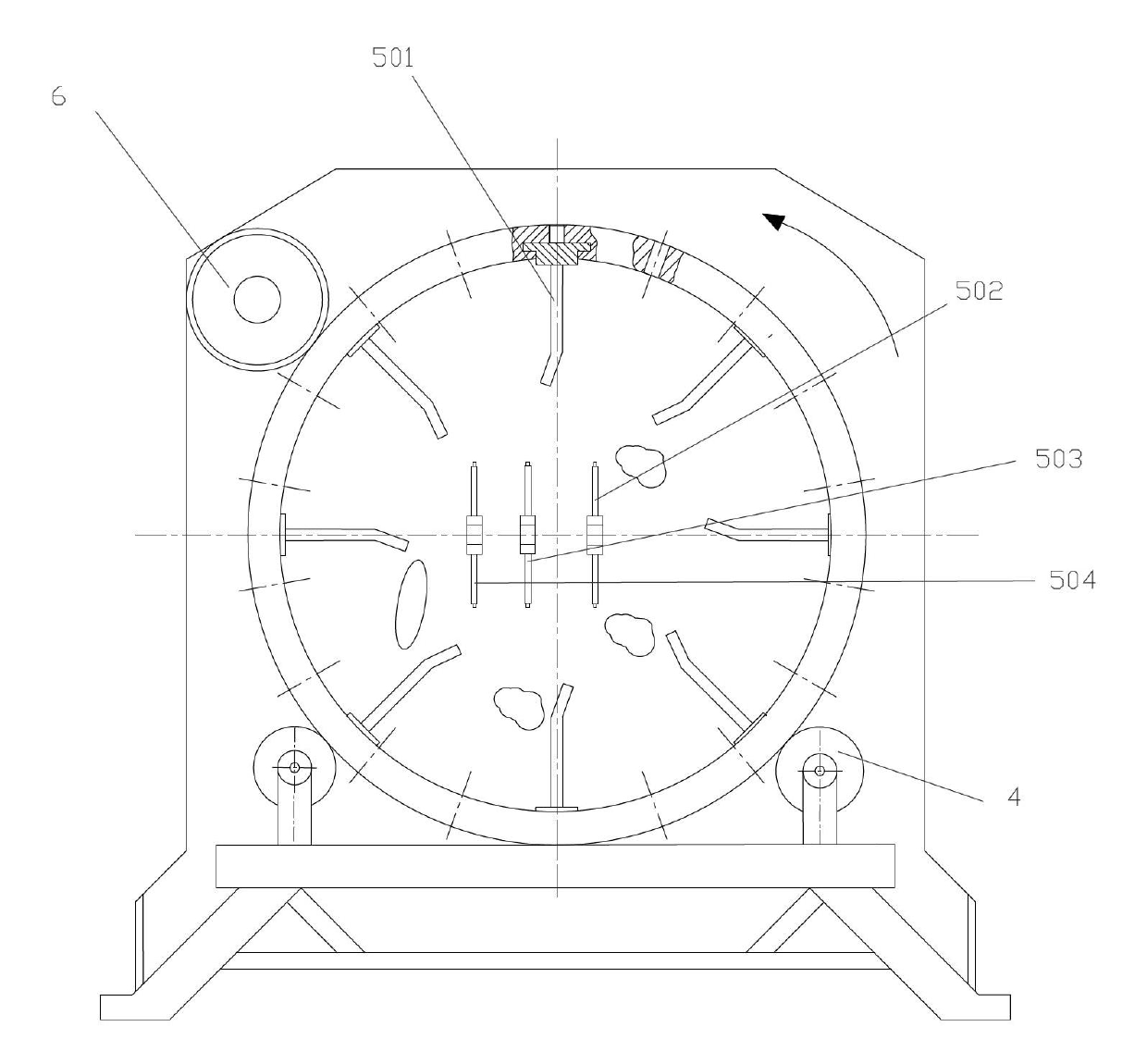

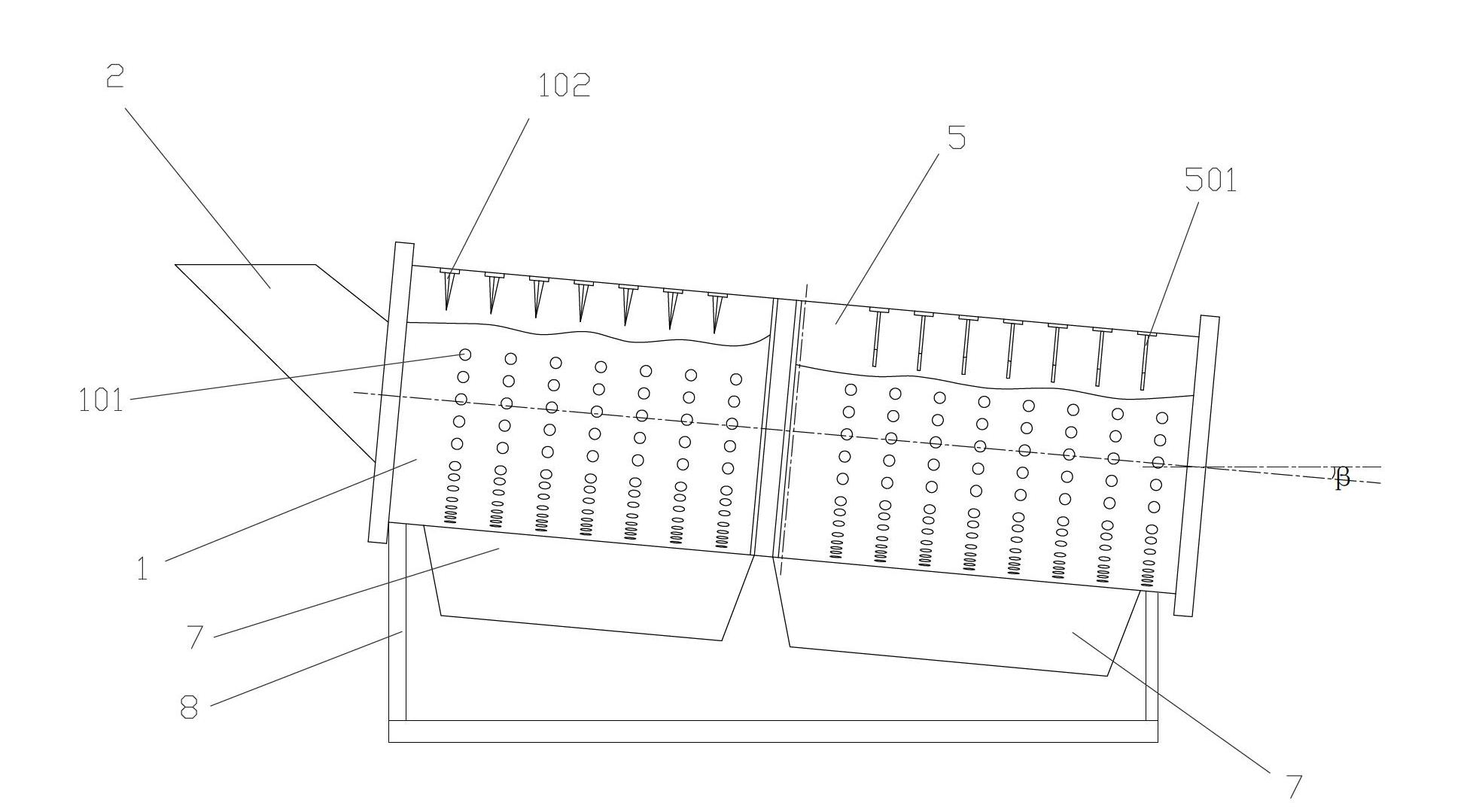

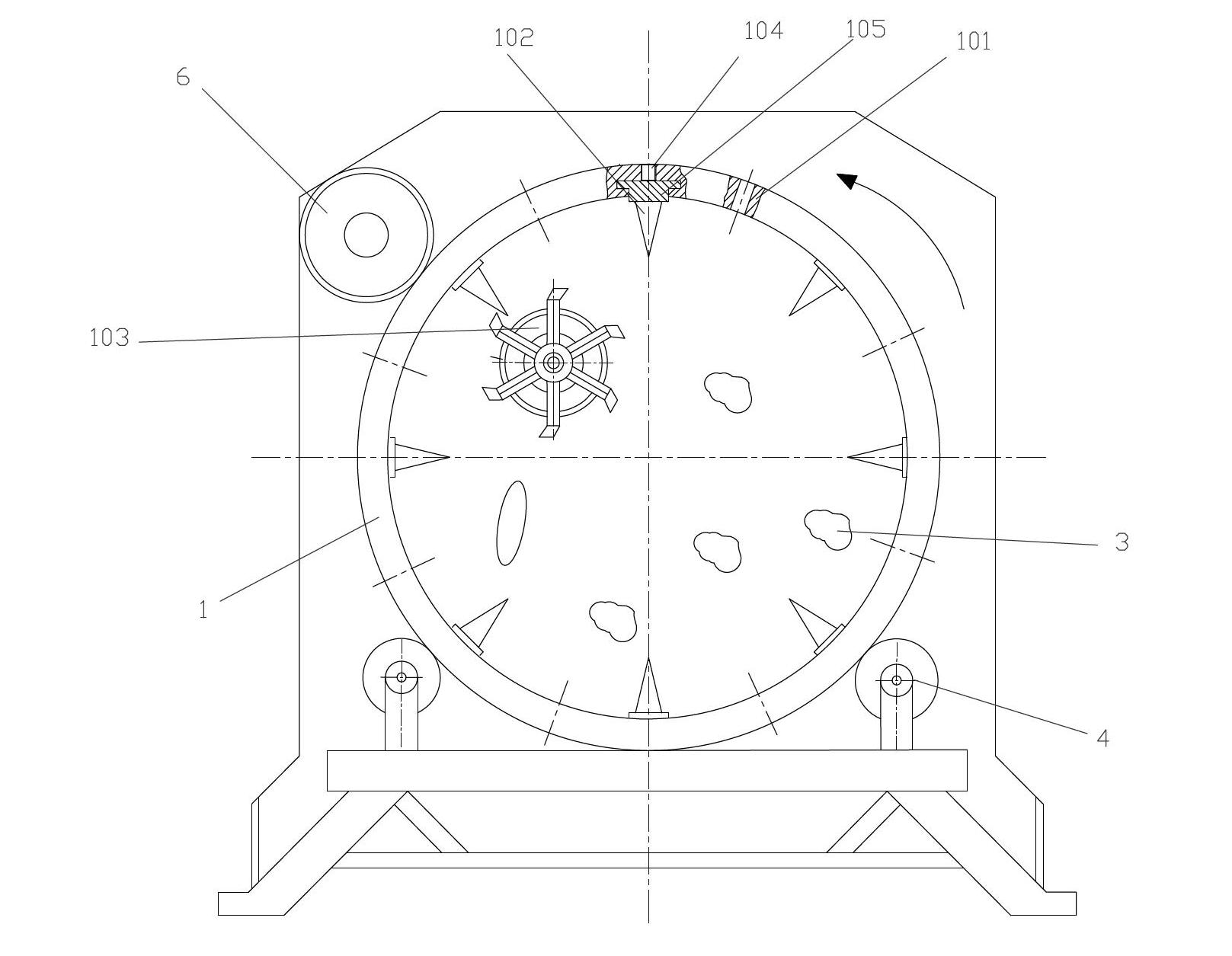

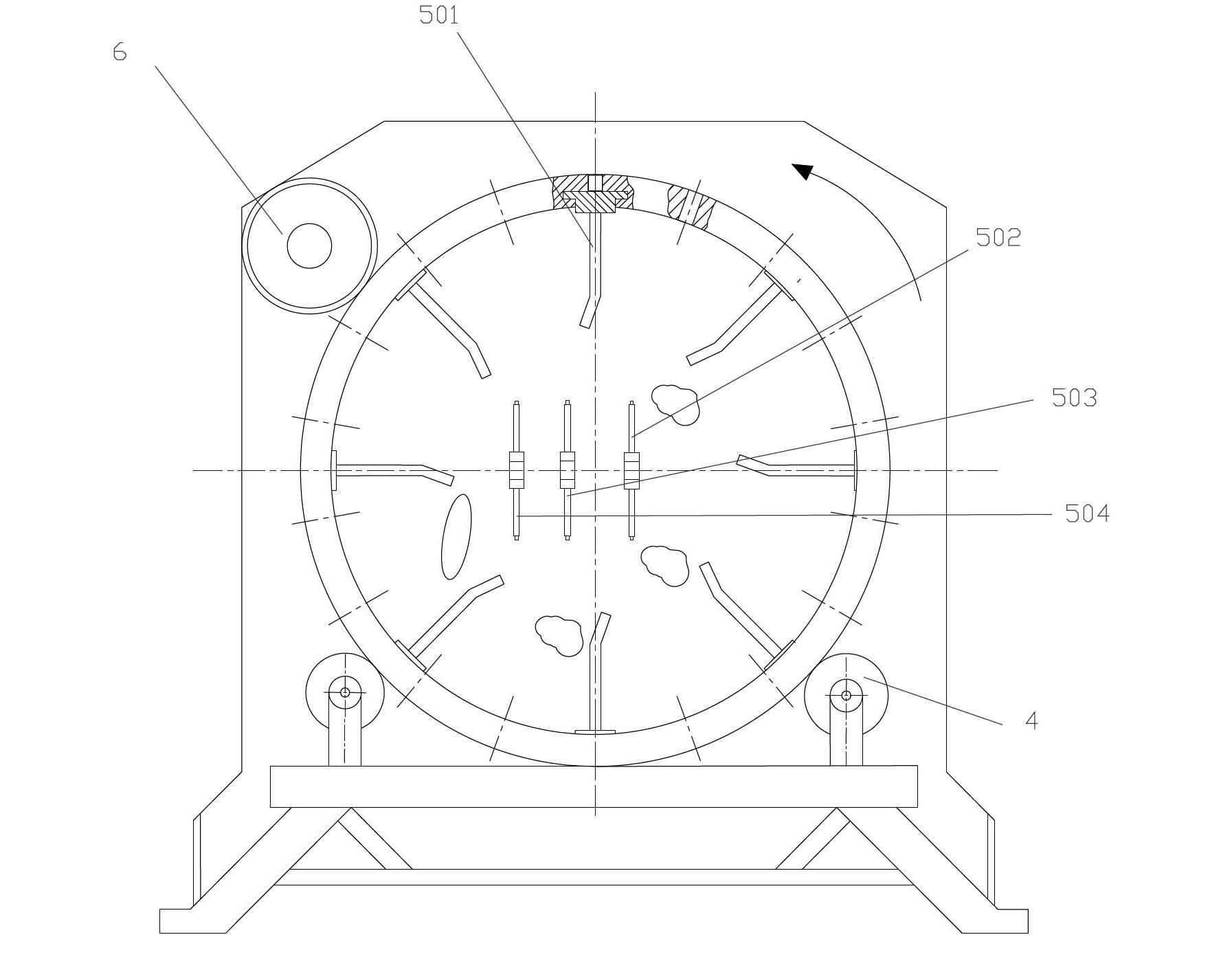

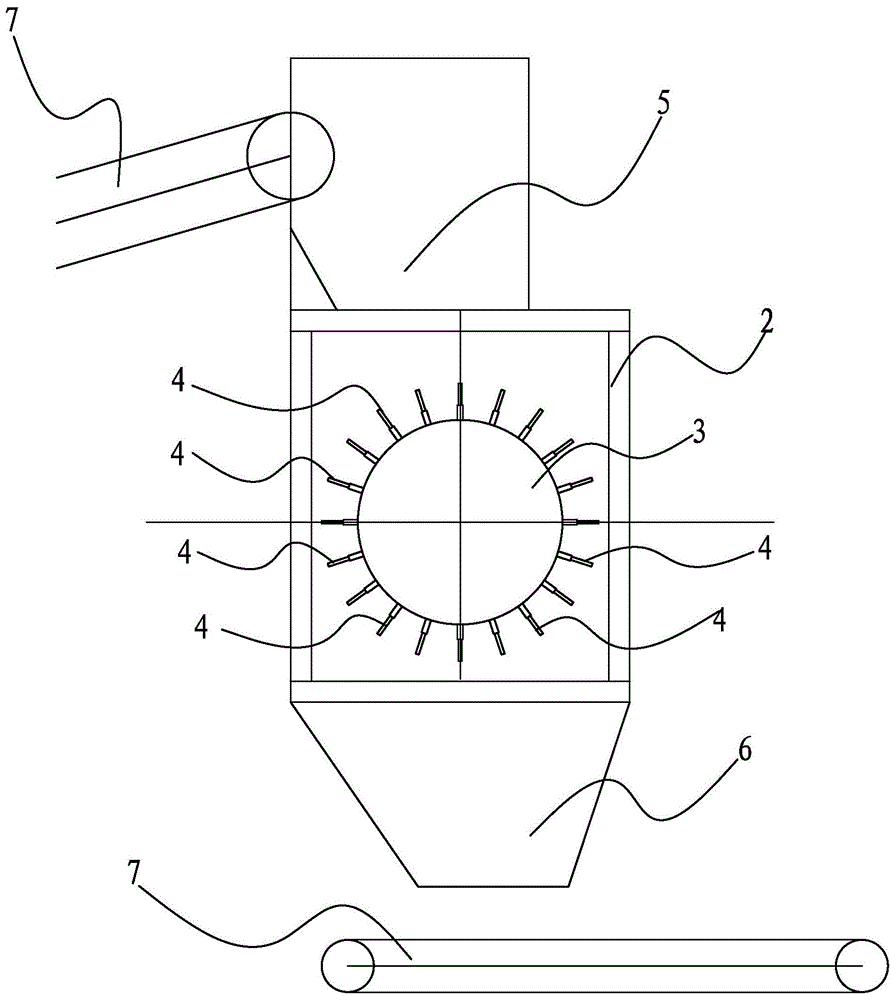

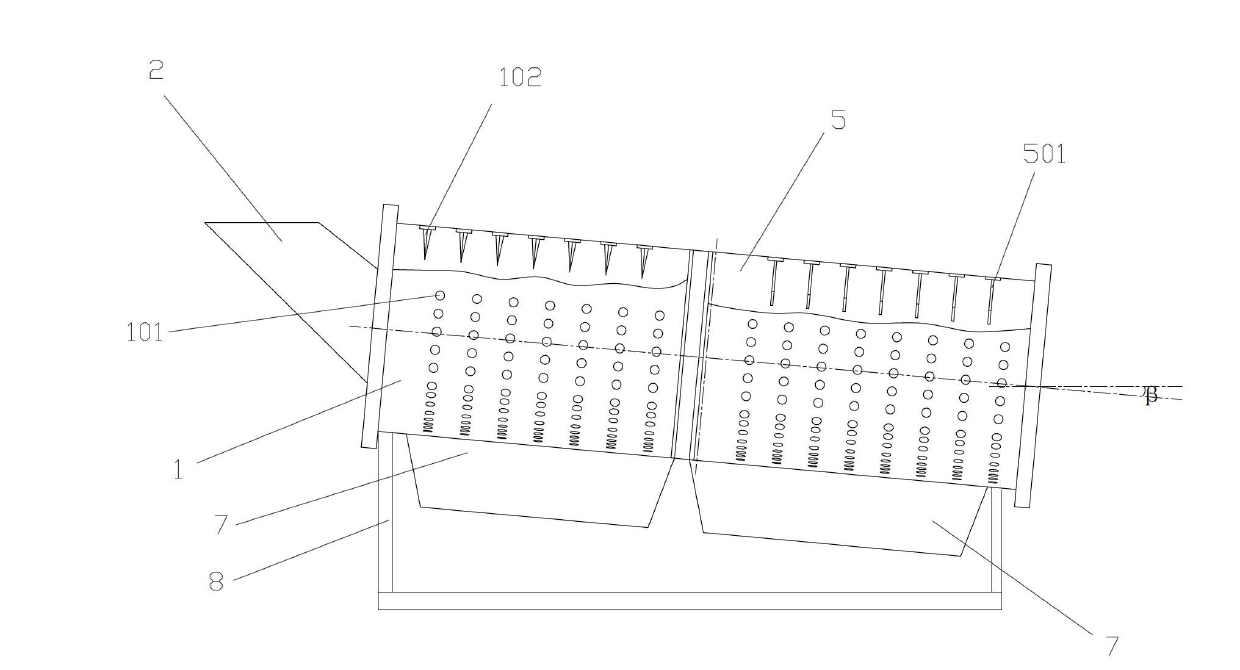

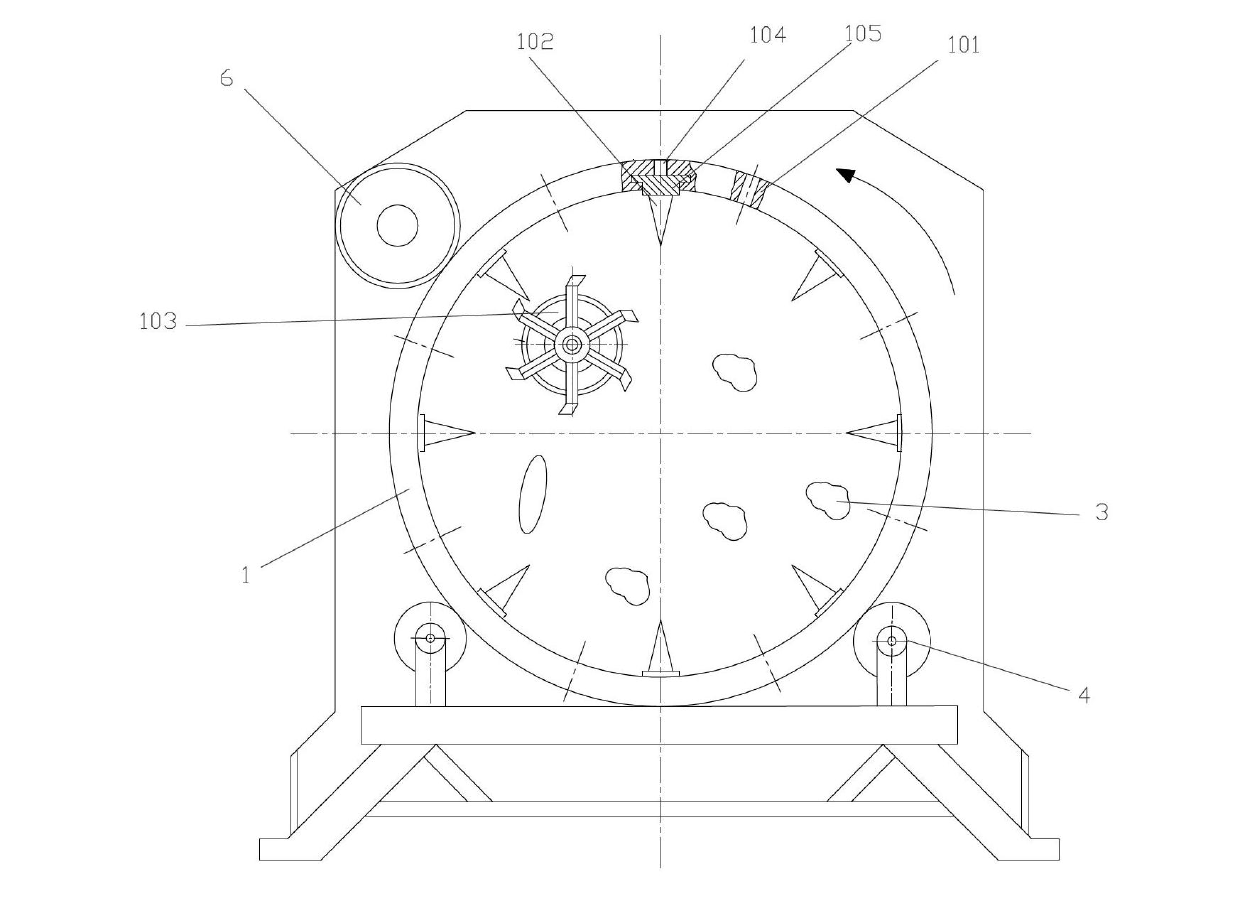

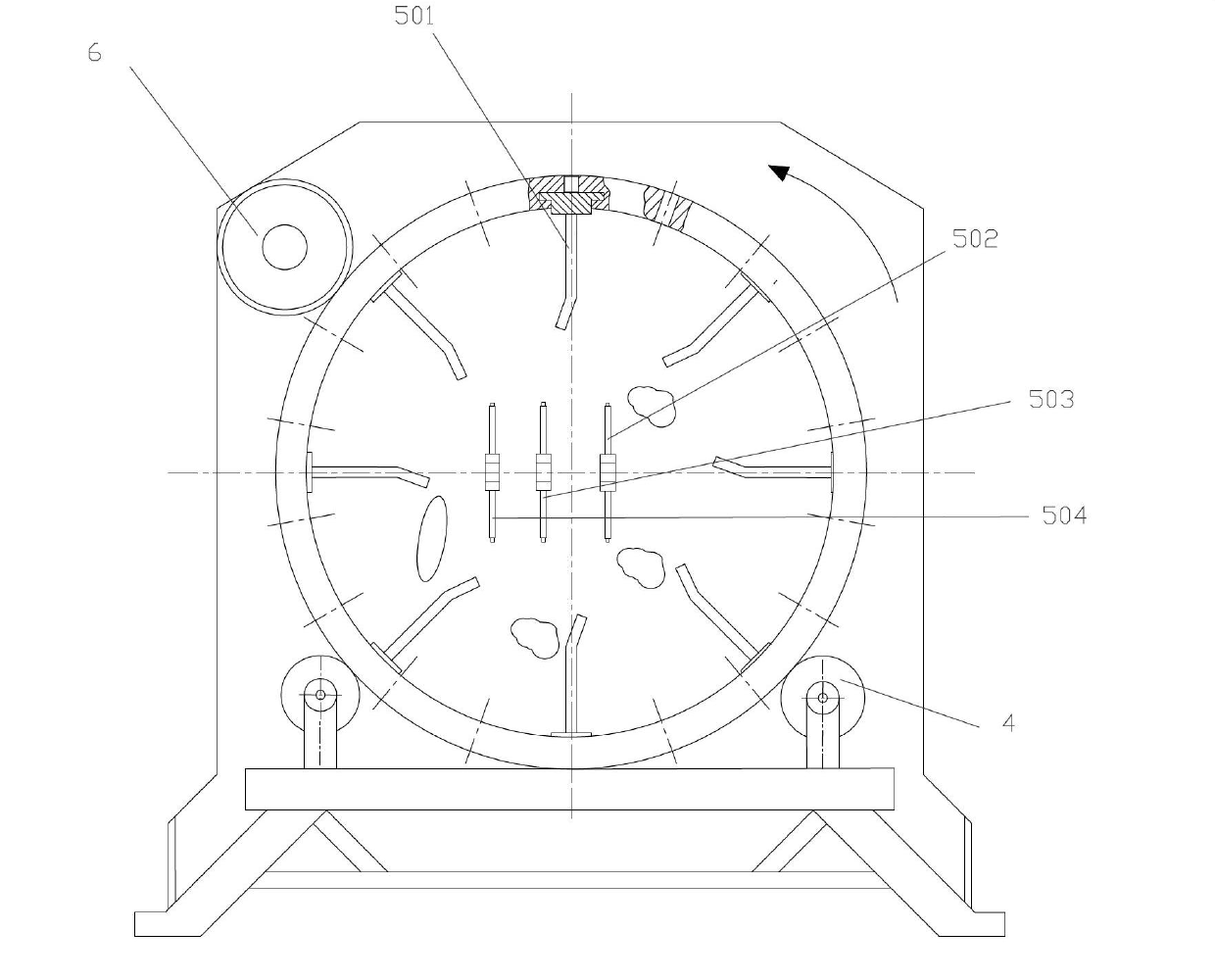

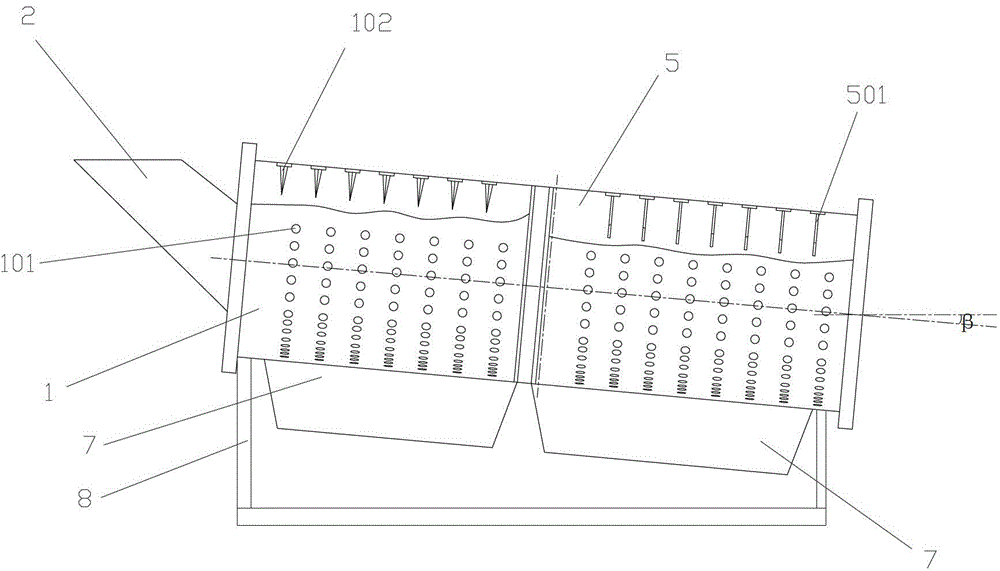

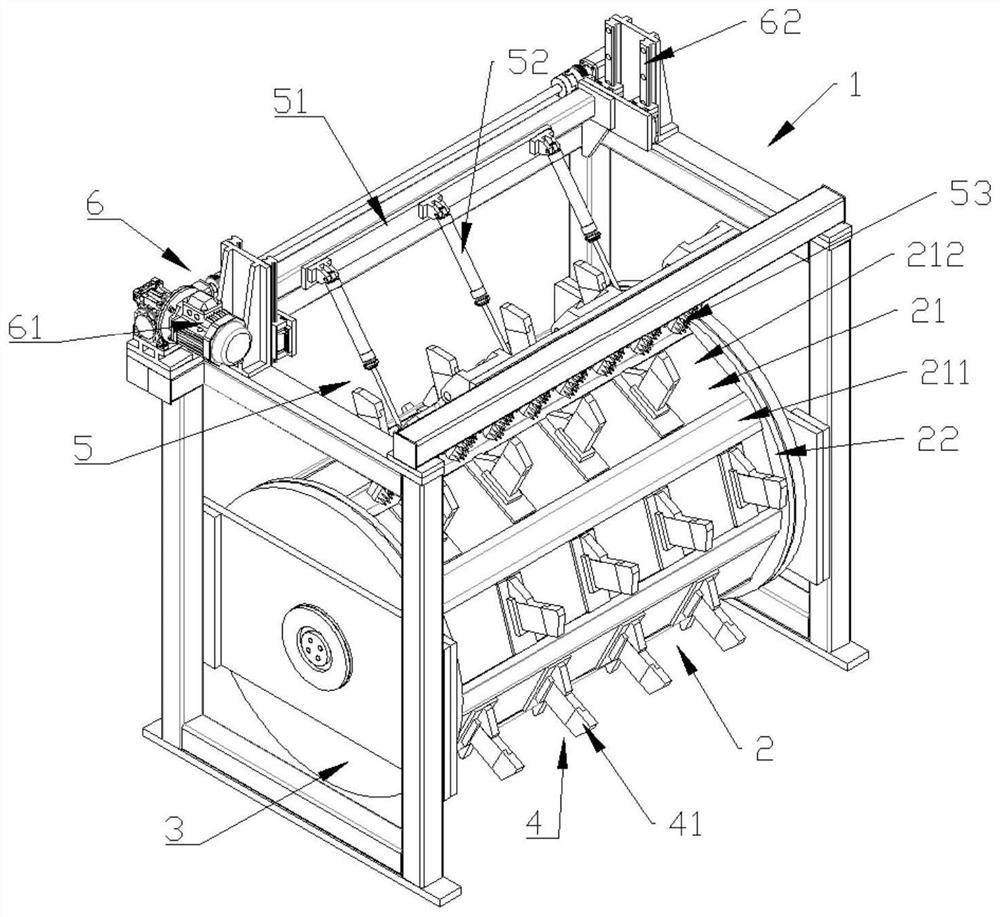

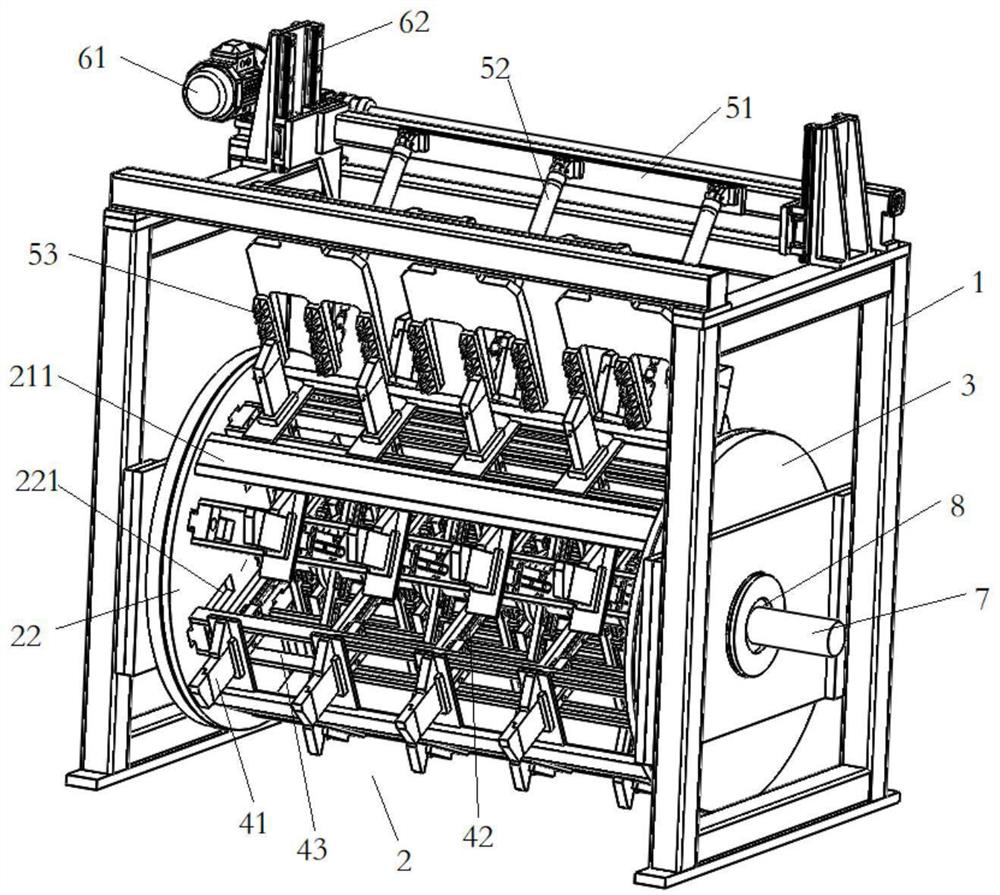

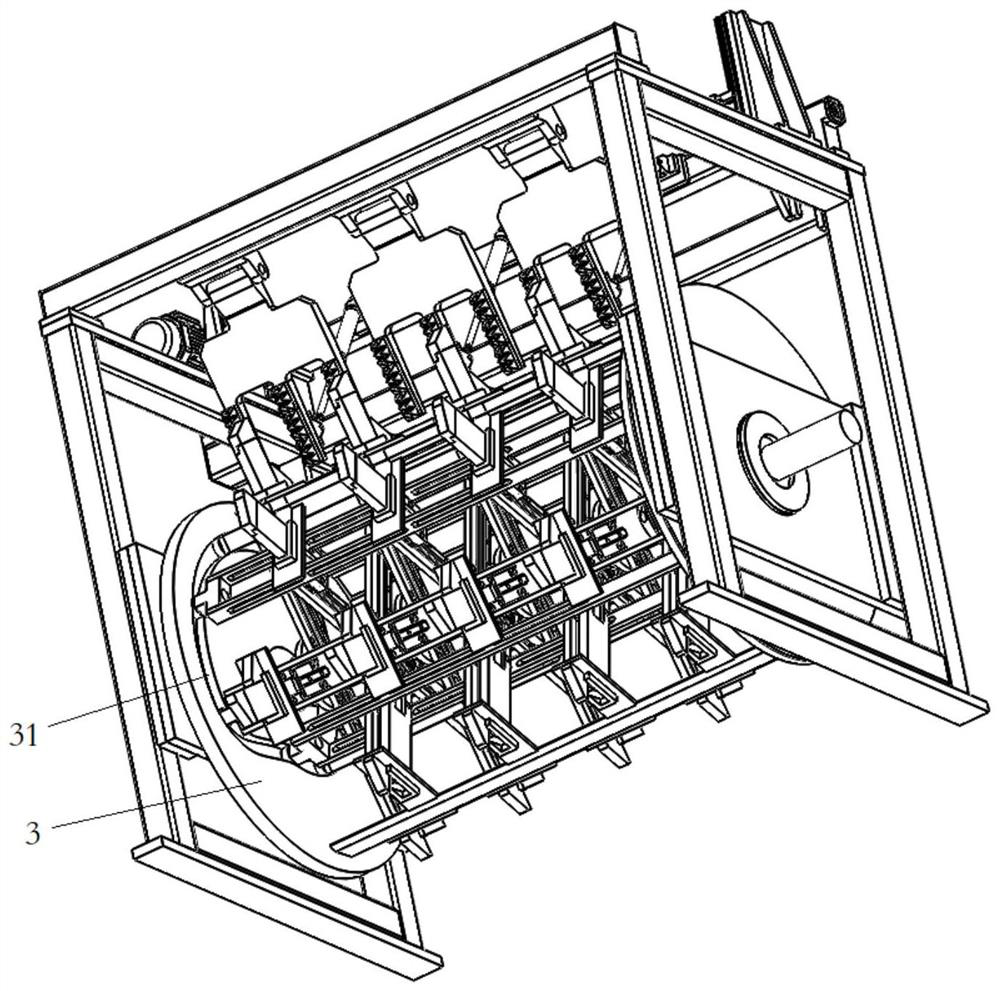

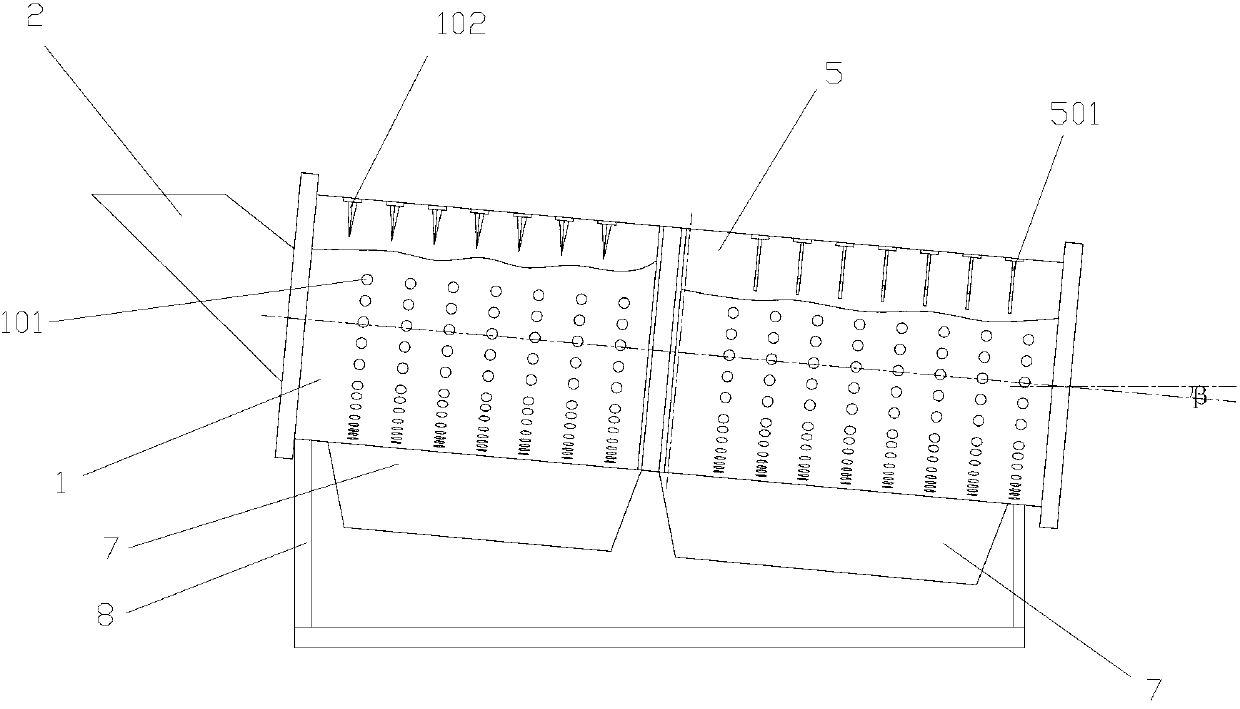

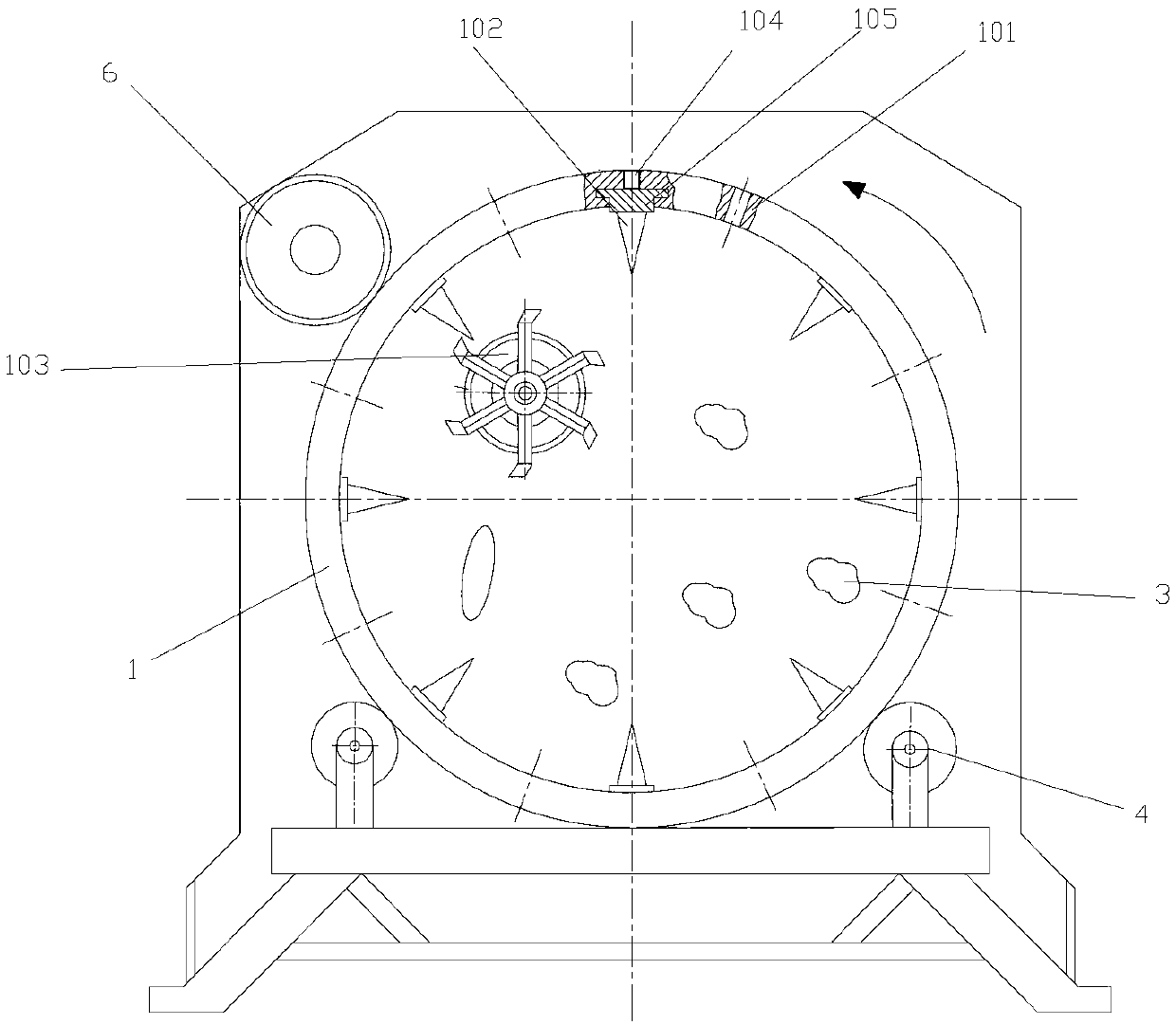

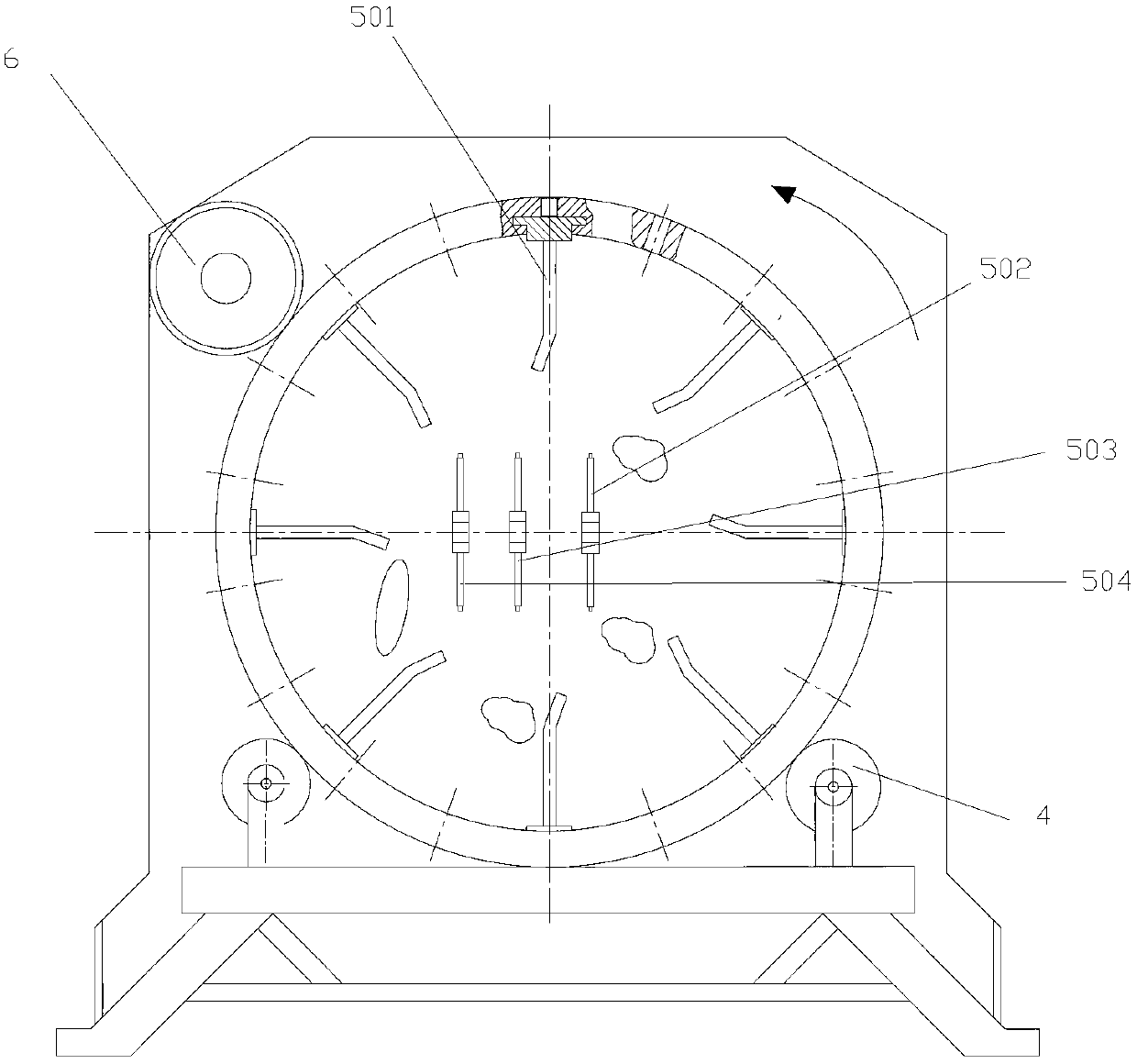

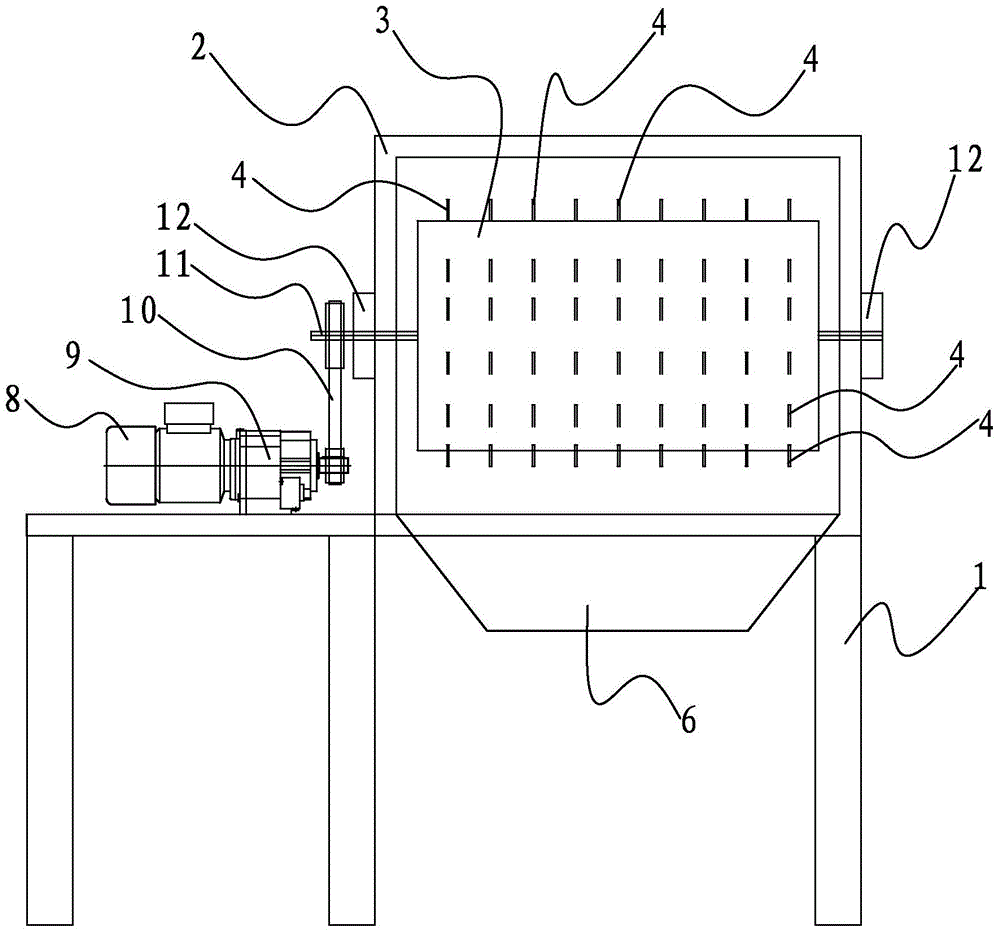

Two-section drum screen for municipal domestic waste

InactiveCN102671854ARealize sortingAchieve recyclingSievingScreeningDomestic wasteMunicipal solid waste

The invention discloses a two-section drum screen for municipal domestic waste. The two-section drum screen comprises a fixed stand, and a drum screen and a drum screen driving device which are arranged on the fixed stand, wherein the drum screen comprises a drum screen inlet section and a drum screen outlet section which are connected with each other; a feed port is formed at an inlet of the drum screen inlet section; an undersize collection device is arrange below the drum screen; a plurality of screen holes are formed in circumferential directions of the drum screen inlet section and the drum screen outlet section; a plurality of bag breaking knives are arranged on the circumferential inner wall of the drum screen inlet section; knife cleaning devices which are matched with the bag breaking knives are arranged in the drum screen inlet section; the peripheries of the drum screen inlet section and the drum screen outlet section are provided with hole cleaning devices for cleaning the screen holes; a plurality of strip-shaped object hanging devices are arranged on the circumferential inner wall of the drum screen outlet section; and three rows of hanging needle chains are arranged in the drum screen outlet section. According to the two-section drum screen, the functions of screening, bag breaking and strip-shaped object collection can be effectively achieved, and beneficial conditions are created for classification and recycling of the municipal domestic waste.

Owner:四川川润环保能源科技有限公司 +1

Sorting and separation system for long-strip articles in urban domestic garbage

InactiveCN102671861AEfficient sortingEfficient separationSievingGas current separationFixed frameEngineering

The invention discloses a sorting and separation system for long-strip articles in urban domestic garbage, which comprises a two-sectional drum screen, a double-shaft shearing crusher, an air-blower, a collection device for fabrics and a collection device for plastics; the two-sectional drum screen comprises a fixed frame and a drum screen arranged on the fixed frame, and the drum screen comprises an entrance section of the drum screen and an exit section of the drum screen; a plurality of bag-breaking cutters are arranged on the inner wall of the entrance section of the drum screen; and a plurality long-strip article hanging devices are arranged in the exit section of the drum screen, a long-strip article collection device is arranged in the exit section of the drum screen, a rear end of the long-strip article collection device extends out of the exit section of the drum screen and extends to a feeding part on the upper end of the double-shaft shearing crusher, the air-blower is arranged on the discharging part of the double-shaft shearing crusher, and the collection device for fabrics and the collection device for plastics are arranged in the lower part of the double-shaft shearing crusher. According to the system, long-strip articles in garbage can be effectively selected for separation, and the system has reliable selection and high accuracy of separation.

Owner:四川川润环保能源科技有限公司 +1

Plastic wood prepared from mixed plastic in domestic garbage and wood powder, and preparation method of plastic wood

Owner:四川川润环保能源科技有限公司 +1

Garbage bag breaking device

The invention belongs to a garbage bag breaking device for breaking bags containing garbage and breaking garbage bags in a garbage treating process. According to the technical scheme of the garbage bag breaking device, a cover plate is arranged on the upper portion of a wheel hub in a covering mode; long moving cutters and short moving cutters are in eagle-beak-shaped hook shapes and are perpendicularly and fixedly arranged on the circumferential face of the wheel hub in rows; rectangular cutter blades perpendicularly arranged on the circumferential face of the wheel hub are arranged among the long moving cutters and the short moving cutters; fixed cutters are in eagle-beak-shaped hook shapes and are perpendicularly and fixedly arranged on the inner face of the cover plate; the inner faces of the hook shapes of the long moving cutters and the inner faces of the hook shapes of the short moving cutters stir the garbage bags, the inner faces of the hook shapes of the fixed cutters are opposite to the inner faces of the hook shapes of the long moving cutters and the inner faces of the hook shapes of the short moving cutters, and the fixed cutters are matched with the adjacent long moving cutters and the adjacent short moving cutters to shear the garbage bags. The technical problems that an existing garbage bag breaking device is poor in bag breaking efficiency of a bag breaking cutter, weak in capacity and poor in effect, material blocking and material hanging easily occur, and the existing garbage bag breaking device is complex in structure are solved.

Owner:QINGDAO UNIV OF SCI & TECH

Multi-component regenerated fuel based on domestic garbage and preparation method thereof

The invention discloses a multi-component regenerated fuel based on domestic garbage and a preparation method thereof, which are suitable for resource processing of solid wastes. The regenerated fuel is formed by mixing combustible components in the domestic garbage, coal liquefaction residues, agricultural solid wastes and calcium oxide in proportion, and specifically comprises the following components in percentage by mass: 62.5%-77.0% of the combustible components in the domestic garbage, 10.0%-20.0% of the coal liquefaction residues, 5.0%-14.0% of the agricultural solid wastes and 4.5%-7.5% of the calcium oxide. The preparation method comprises the following steps: firstly separating the combustible components from the domestic garbage; then performing drying, crushing and other pretreatment on the combustible components in the domestic garbage, the coal liquefaction residues and the agricultural solid wastes; further mixing all the components according to the ratio, and uniformlystirring; and finally shaping. The regenerated fuel has the advantages of higher calorific value, stable combustion and low secondary pollution, and can realize resource utilization of the urban domestic garbage and the industrial and the agricultural solid wastes.

Owner:四川川润环保能源科技有限公司 +1

Bag breaking machine for garbage disposal

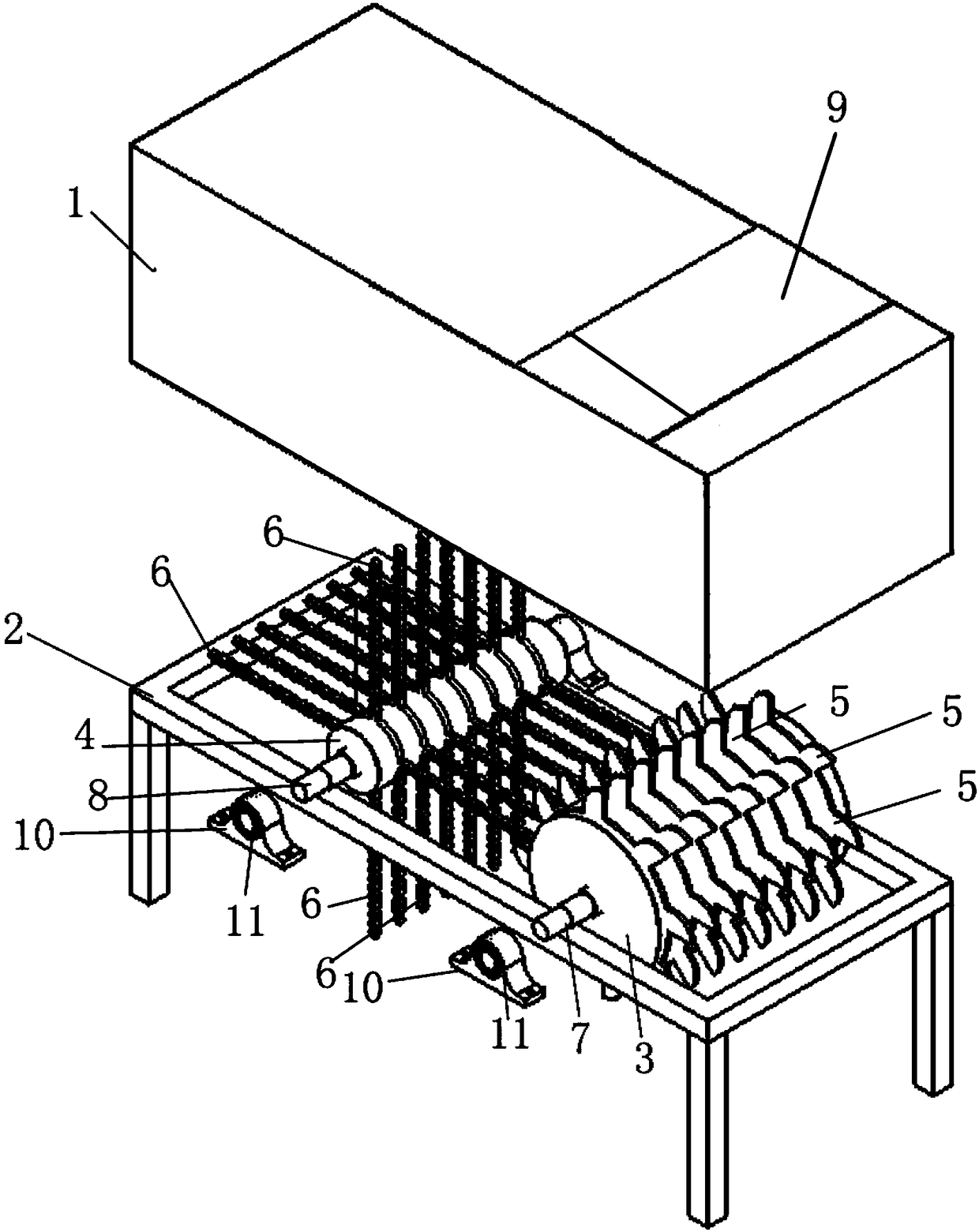

ActiveCN106362837AImprove bag breaking efficiencyAvoid wear and tearGrain treatmentsUnpacking by cuttingEngineeringMechanical engineering

The invention discloses a bag breaking machine for garbage disposal. The bag breaking machine for garbage disposal comprises a main support, a shell, a main roller and an auxiliary roller, wherein the main roller and the auxiliary roller are arranged on the main support in a rotating mode, the rotation direction of the main roller is opposite to that of the auxiliary roller, and at least five cutting device assemblies are arranged on the outer wall of the main roller in a surrounding mode. Each cutting device assembly comprises at least two cutting devices, and the cutting portion of each cutting device faces the auxiliary roller. At least three flexible slashing strip assemblies are arranged on the auxiliary roller in a surrounding mode. Each slashing strip assembly comprises at least two flexible slashing strips. The cutting device assemblies and the flexible slashing strip assemblies are arranged transversely in alternate and spaced modes, or, the minimum transverse interval between the outermost end of each cutting device assembly and the outermost end of the corresponding flexible slashing strip assembly is smaller than 5 cm, or, the outermost end of each cutting device assembly and the outermost end of the corresponding flexible slashing strip assembly are overlapped in the transverse direction but spaced in the longitudinal direction. A feed inlet is formed in the top of the shell, and the bottom end of the feed inlet is located above the main roller. The bag breaking machine for garbage disposal is simple in structure and high in bag breaking efficiency, achieves full mechanization, saves labor and reduces the garbage bag breaking cost.

Owner:郑雨童

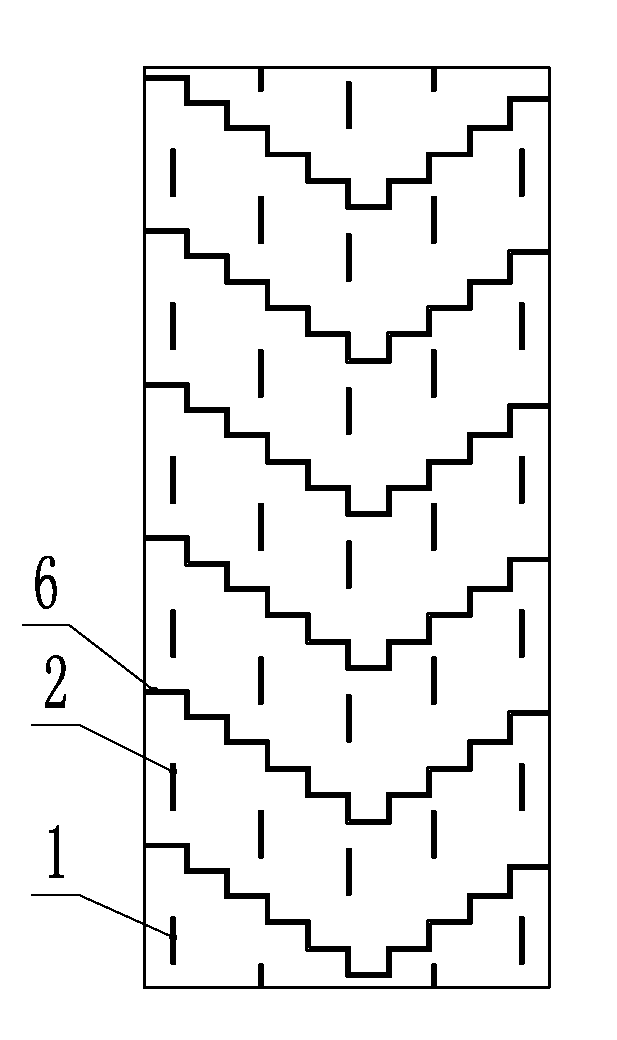

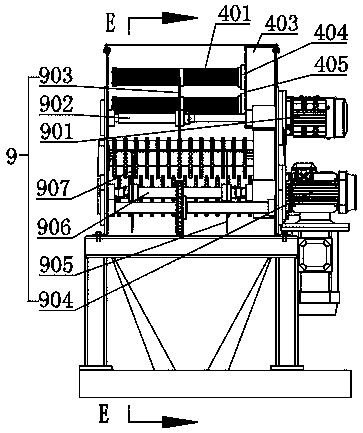

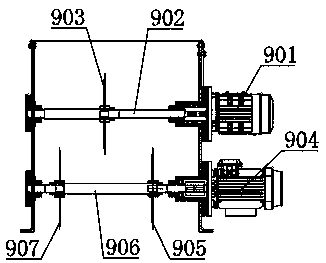

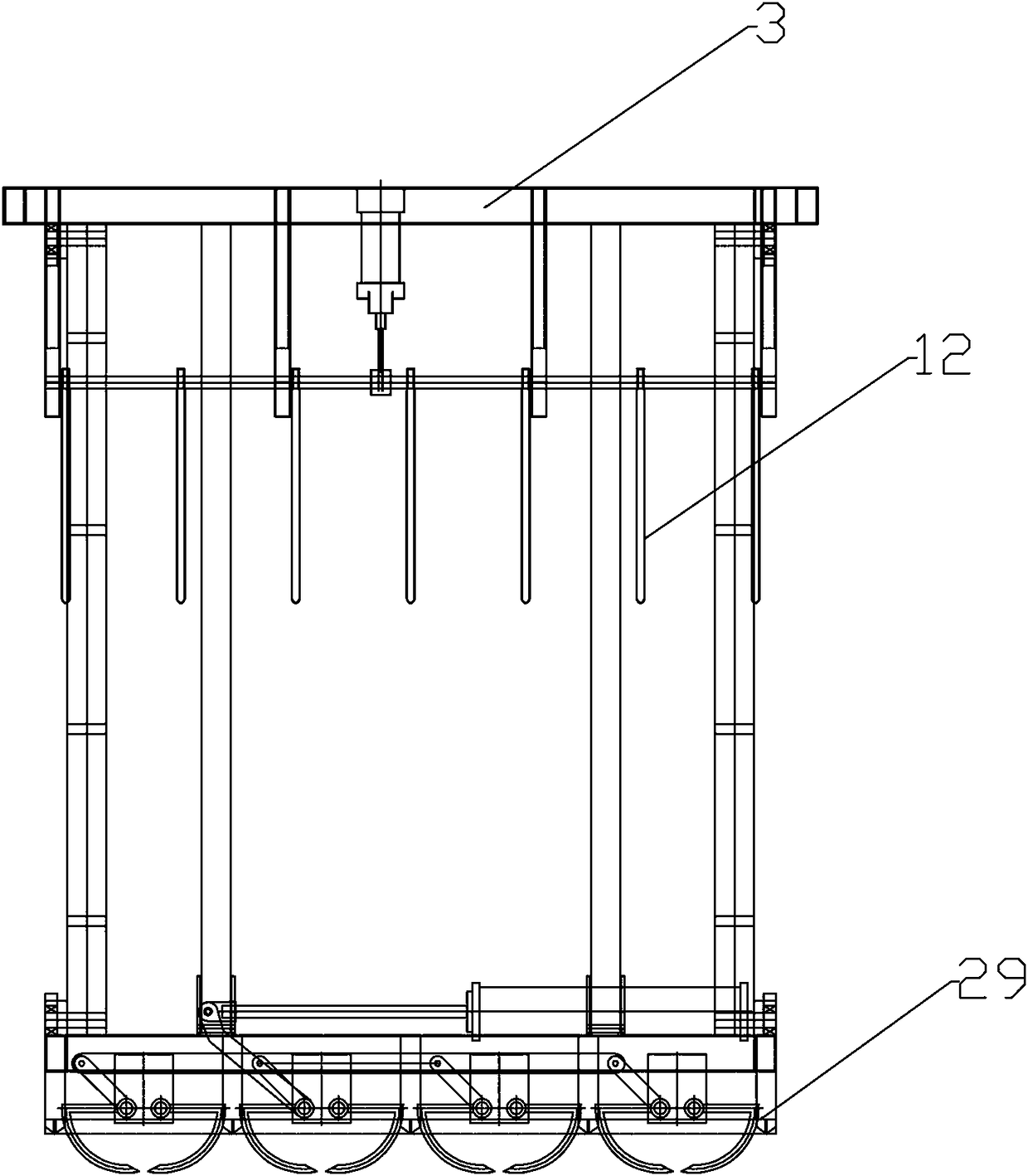

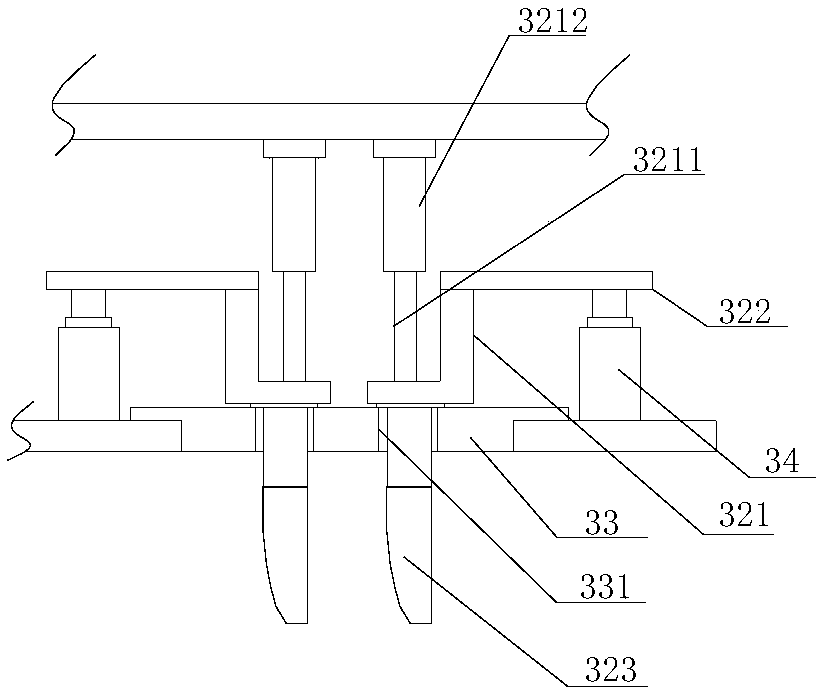

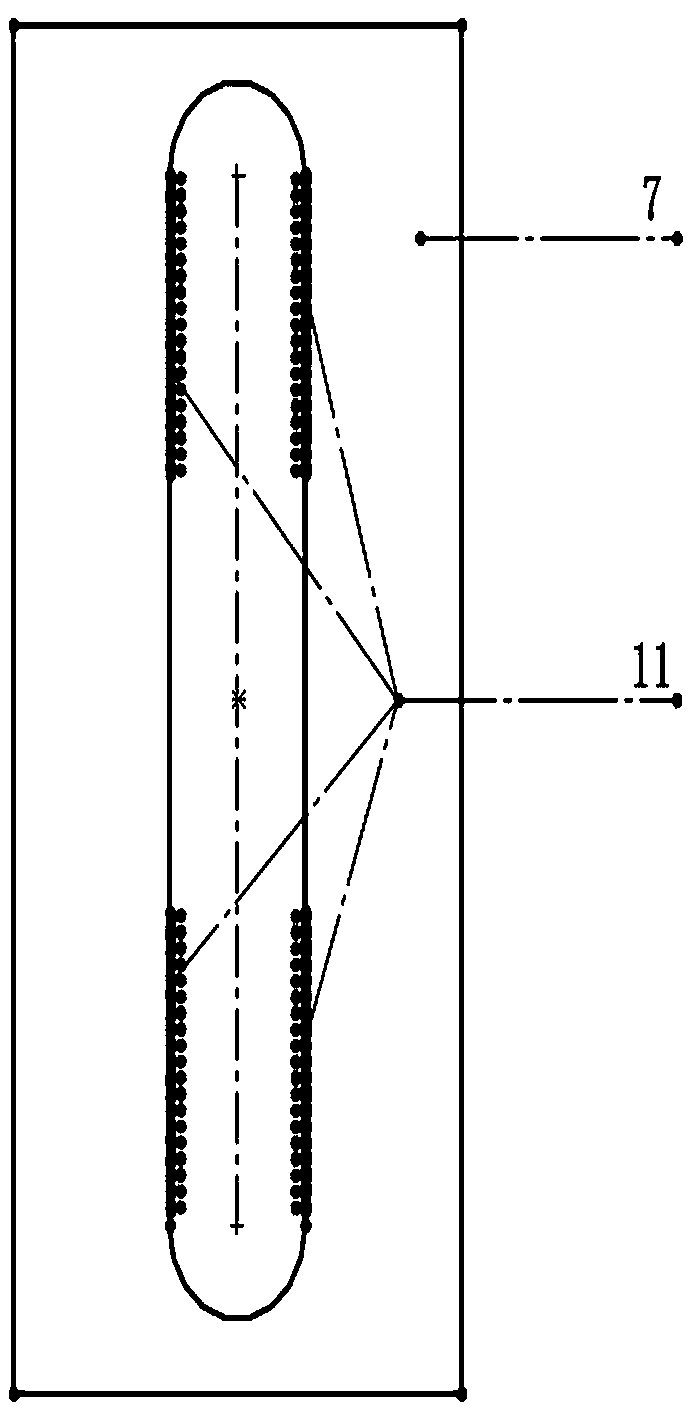

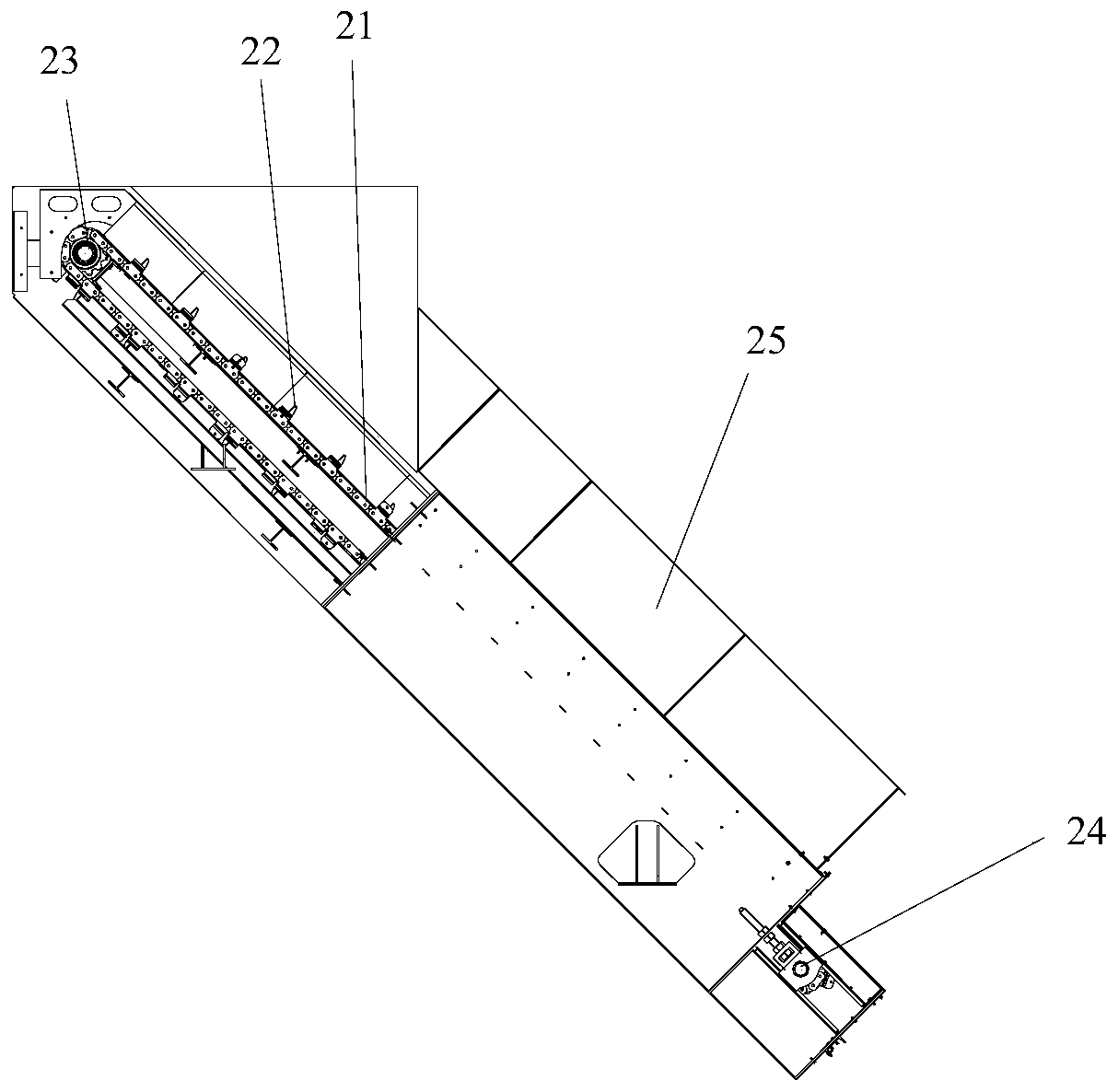

Ratchet chain type automatic bag breaking equipment

ActiveCN111332570AAvoid cloggingUnobstructed dischargeLoading/unloadingUnpacking by cuttingRatchetProcess engineering

The invention relates to the technical field of material unpacking equipment, and particularly discloses ratchet chain type automatic bag breaking equipment which comprises a base and a bag breaking bin. The bag breaking bin comprises a feeding opening and a waste bag discharging opening, the bag breaking bin is internally provided with a bag breaking mechanism close to the feeding opening, a waste bag extruding mechanism close to the waste bag discharging opening and a chain wheel mechanism penetrating through the feeding opening and the waste bag discharging opening, and the chain wheel mechanism is used for receiving material bags input from the feeding opening and conveying the material bags to the waste bag discharging opening; the bag breaking mechanism is used for cutting the material bags conveyed by the chain wheel mechanism, so that the material bags are unloaded; the waste bag extruding mechanism is used for smoothly discharging and recovering the empty material bags after unloading, rapid bag breaking of the material bags is achieved, the material bags are prevented from being blocked in the bag breaking bin, materials are smoothly discharged, blocking of the discharging opening due to winding of the waste material bags is effectively avoided, the outer side of the discharging opening can be sleeved with a waste bag collecting bag, and the waste bags are recycled ina centralized mode.

Owner:SHANDONG WANBANG PETROLEUM TECH CO LTD

Oil field oil sludge woven bag breaking device

The invention belongs to the technical field of oil sludge treatment and particularly relates to an oil field oil sludge woven bag breaking device. The device is characterized in that at least two supporting plates (3) are arranged on a rack (1) of the oil field oily sludge woven bag breaking device, each supporting plate (3) is provided with a bag breaking knife (2), each supporting plate (3) isprovided with an electric push rod (4), the supporting plates (3) are driven by the electric push rods (4) to do opening and closing movement along the rack (1) to enable oil sludge to fall off between the supporting plates (3), and arc-shaped elastic rods (5) are arranged between the supporting plates (3) and do compression upward protruding and loosening flattening movement along with the opening and closing movement of the supporting plates (3). The device is advantaged in that the device can improve bag breaking efficiency of oil sludge woven bags and accelerate separation of oil sludge and the woven bags, and is simple in structure and convenient to process and operate.

Owner:ZHE JIANG ECO ENVIRONMENTAL TECH CO LTD

Shield type urban garbage bag breaking machine

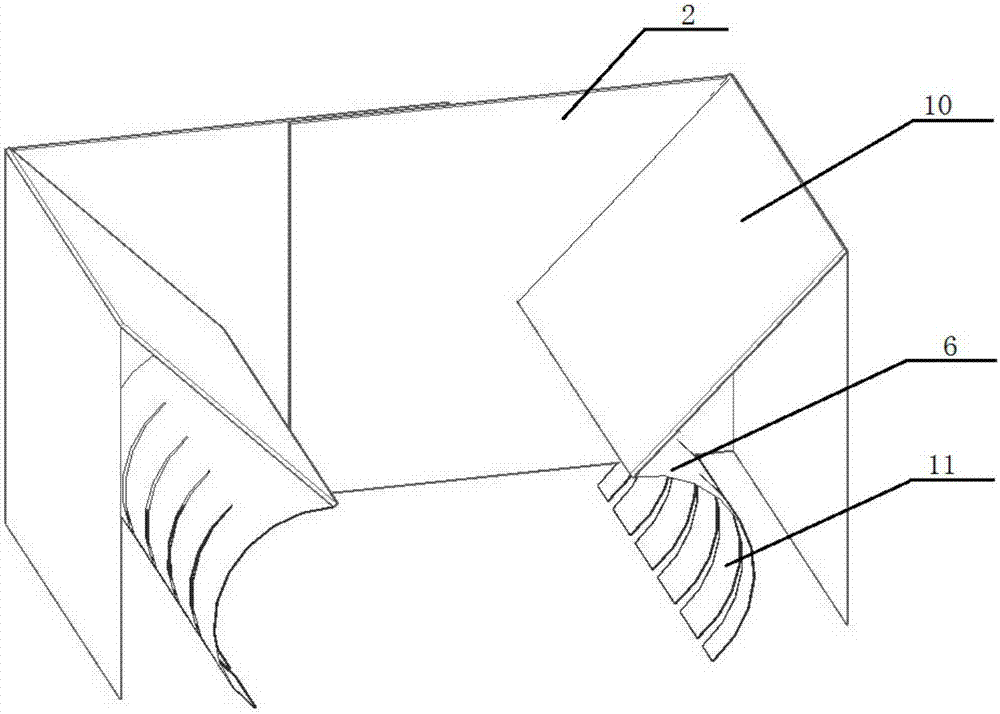

PendingCN109987298AReduce loadImprove bag breaking efficiencyBags openingEngineeringCounter rotation

The invention discloses a shield type urban garbage bag breaking machine. A bag breaking shield and rotating mechanism backward rotating cutting manner is adopted for bag breaking and segmenting, a screw device is used for conducting garbage extruding and draining, and then water is output in several streams. The processes of bag breaking, segmenting and water removing can be conducted at a time,bar-shaped garbage is not likely to being wound around a rotating shaft, cleaning is convenient and fast, the garbage treatment efficiency is greatly improved, and the outage rate is low.

Owner:广西大自然再生资源有限公司

Rubbish bag breaking machine and method for breaking bag by using same

ActiveCN103552715ASimple structureImprove bag breaking efficiencyArticle unpackingRevolutions per minutePlastic bag

The invention discloses a rubbish bag breaking machine and a method for breaking a bag by using the same. The rubbish bag breaking machine comprises a support, a casing and a roller, wherein the casing is arranged on the support; the roller is arranged in the casing and can rotate at a speed of at least 60 revolutions per minute; a gap is formed between the casing and the roller; at least ten rows of metal chain groups are arranged on the outer wall of the roller; each metal chain group comprises at least five metal chains; a feed port is formed in the top of the casing; a discharge port is formed in the bottom of the casing; and the roller is connected with a driving device. The rubbish bag breaking machine is simple in structure, high in bag breaking efficiency, fully mechanized and labor-saving, reduces the rubbish bag breaking cost, can break a plastic bag body into large fragments and can break up caked rubbish at the same time.

Owner:西安德兆环保科技有限公司

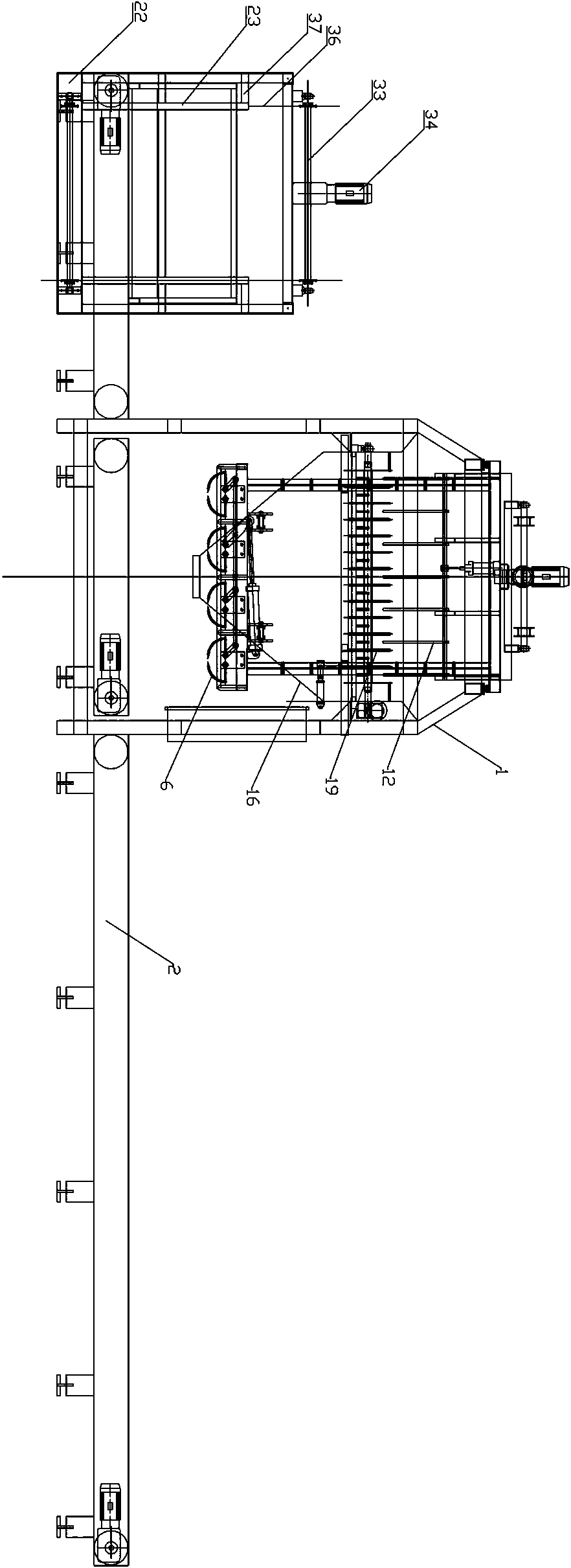

Automatic bag breaking machine and garbage classification device

PendingCN113581687ABag breaking fastImprove bag breaking efficiencyRefuse receptaclesBags openingStructural engineeringMechanical engineering

The invention relates to the technical field of bag breaking machines, and discloses an automatic bag breaking machine and a garbage classification device. The automatic bag breaking machine comprises a conveying mechanism, a cutting table, a collecting barrel and a clamping plate assembly. The conveying mechanism is used for conveying garbage bags. The cutting table comprises a containing box, a turning plate and a cutter, wherein the containing box is arranged at the tail end of the conveying mechanism; the cutter is slidably arranged at the bottom of the containing box so as to cut the garbage bag open; the turning plate is rotatably arranged at the bottom of the containing box and is configured to be capable of blocking the bottom opening of the containing box so as to bear a garbage bag; or after the garbage bag is cut open, the bottom opening of the containing box is opened. The collecting barrel is used for storing the cut garbage bag. The clamping plate assembly comprises a lifting rod and at least two clamping plates, wherein the lifting rod is arranged between the containing box and the collecting barrel in a sliding mode, and the at least two clamping plates are configured to be capable of getting close to each other so as to clamp a garbage bag; or the clamping plates are away from each other to release the garbage bag. The automatic bag breaking machine can quickly complete bag breaking of the garbage bags, so that the bag breaking efficiency is improved.

Owner:阿尔飞思(昆山)智能物联科技有限公司

Garbage bag breaking system

InactiveCN104401558AEffective splitConducive to sorting and recyclingBags openingUnpacking by cuttingEngineeringMechanical engineering

The invention discloses a garbage bag breaking system, which comprises a bag breaking tube, a cutting cutter and a motor and is characterized in that the inside of the bag breaking tube is in a tubular shape and is provided with a feeding opening and a discharging opening, a rotating shaft is arranged in the bag breaking tube, the cutting cutter is arranged on the rotating shaft, the motor is connected with the rotating shaft and drives the rotating shaft to rotate, so that the cutting cutter is driven to rotate in the bag breaking tube to cut a garbage bag, the cutting cutter comprises a main cutter and a sub cutter, the main cutter is arranged on the rotating shaft, and the outer end of the main cutter is hinged to the sub cutter. The garbage bag breaking system has the advantages that the rotating cutting cutter is used for cutting the garbage bag entering the bag breaking tube, the cutting cutter has a retreating and avoiding function, and can avoid heavy objects, large objects or substances different to break, the collision generated on the cutting cutter is avoided, the impact on the motor due to cutting cutter stagnation is avoided, the damage to the cutting cutter and the motor is reduced, the service life is prolonged, and the maintenance and overhaul cost is reduced.

Owner:四川洪春福环保设备有限公司

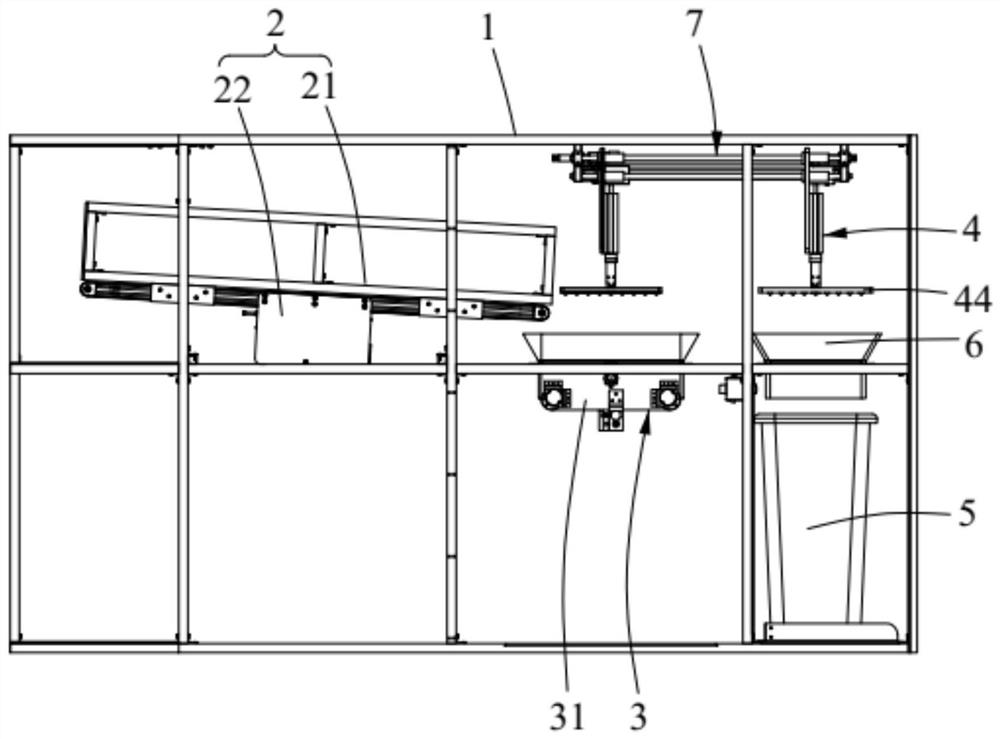

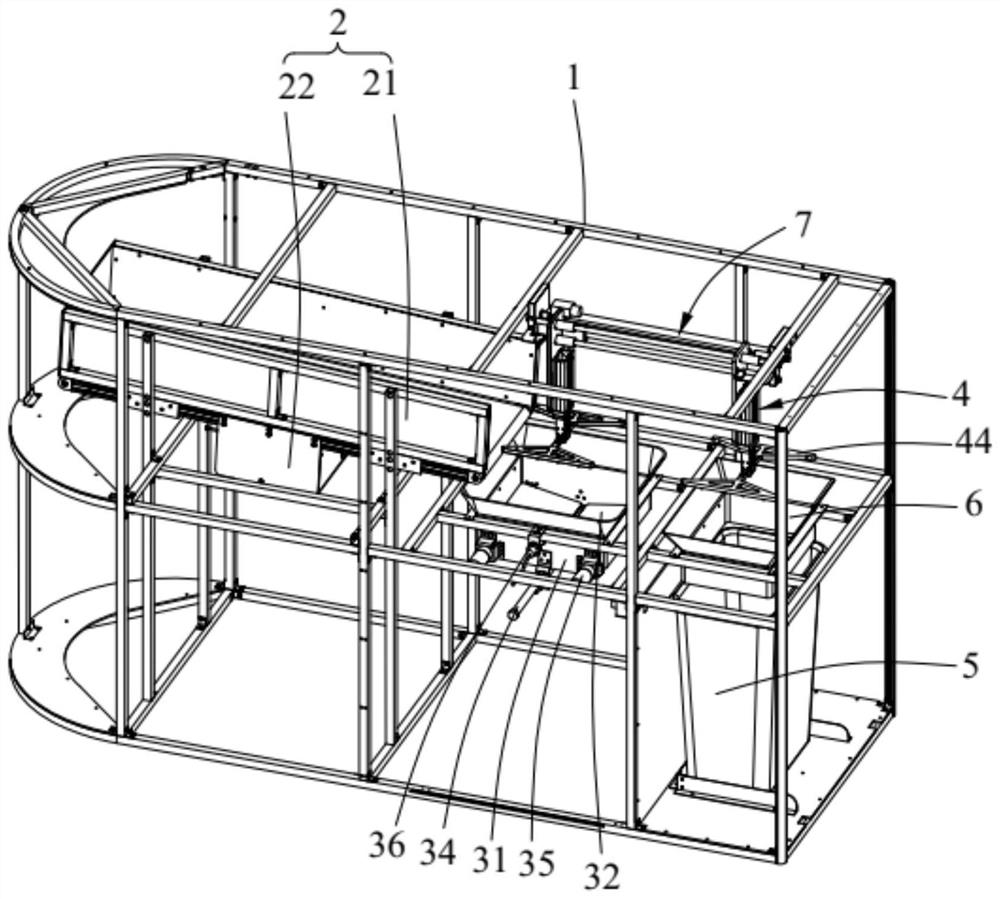

Full-automatic bag cutting machine

PendingCN108545272AImprove bag breaking efficiencyHigh degree of automationUnpacking by cuttingAutomation

The invention relates to a bag disassembling device, in particular to an automatic bag grabbing device, and discloses a full-automatic bag cutting machine. The full-automatic bag cutting machine comprises a rack, a conveying device, the bag grabbing device, a bag cutting device and an empty tray stacking device, wherein the conveying device, the bag grabbing device, the bag cutting device and theempty tray stacking device are arranged on the rack; the conveying device comprises a conveying belt and trays placed on the conveying belt, the bag grabbing device and the bag cutting device are located in the middle of the conveying belt, the empty tray stacking device is located on the tail end of the conveying belt, the bag cutting machine is high in bag breaking efficiency, materials in a material strip can be completely dumped, and the automation degree is high.

Owner:开封奥华机械有限公司

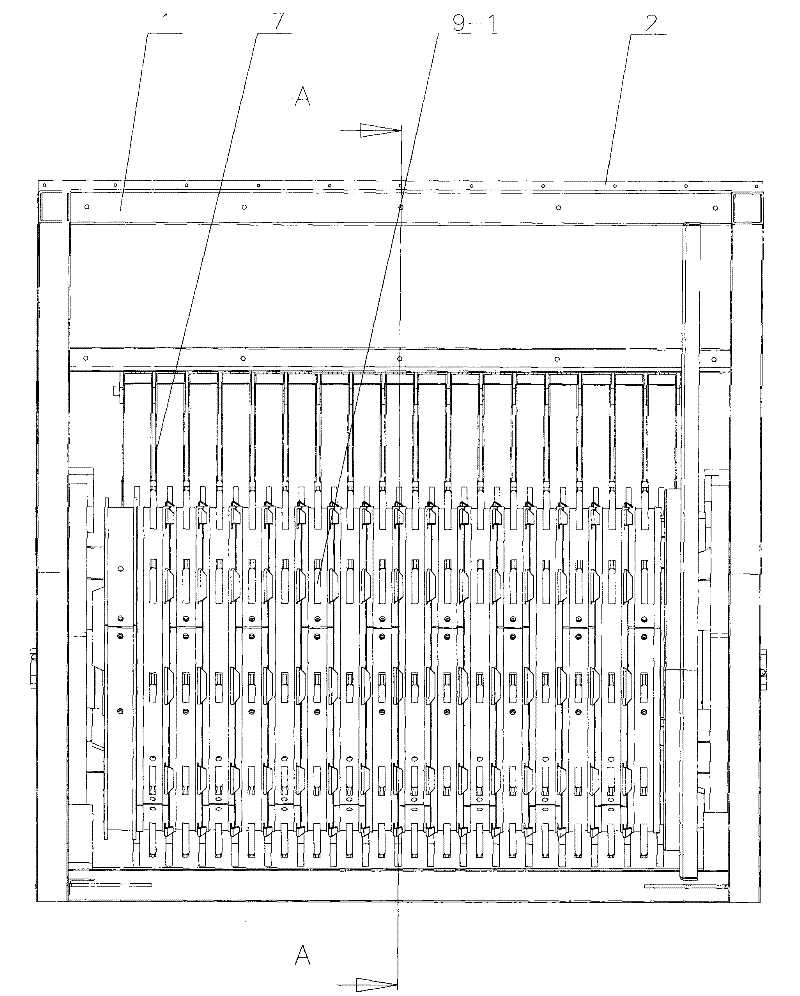

Garbage bag-breaking machine

InactiveCN106144092AGood bag breaking effectImprove bag breaking efficiencyUnpacking by cuttingKnife bladesEngineering

The invention discloses a garbage bag breaking machine, comprising a bag breaking knife, a main shaft, a body frame and a driving mechanism; Drive the rotation of the main shaft; the front side edge of the bag breaking knife is serrated, and the bottom is provided with a buckle part; the main shaft is evenly equipped with a plurality of circular fixed disks, and a plurality of circular fixed disks are fixed in parallel around the main shaft through the circular fixed disks. The blade fixing shaft; the bag breaking knife is fixed on the blade fixing shaft through the buckle parts, so that a blade group is formed between every two circular fixing disks, and all the bag breaking knives of each blade group are evenly distributed around the main shaft and The serrated front edges all point in the same direction as the spindle's rotation. The bag breaking effect of the invention is good, which can ensure the complete removal of all garbage bags; the bag breaking efficiency is high, the use performance is good, and it is not easy to be blocked; the design is scientific and reasonable, the operation is stable, and the service life is long.

Owner:中环环保设备股份有限公司

Formed fuel mixed with combustible garbage components and coal liquefaction residual and preparation method

InactiveCN102676265AHigh calorific valueEasy to storeBiofuelsSolid fuelsEnvironmental engineeringDomestic waste

The invention discloses a formed fuel mixed with combustible components in garbage and coal liquefaction residual and a preparation method, which are applicable to resource recycling of domestic garbage and coal liquefaction residual. The formed fuel is mixed by the following components in percent by weight: 62.0%-80.0% of combustible components in domestic garbage, 12.0%-28.0% of coal liquefaction residual and 8.0%-10.0% of desulfurizing agent. The preparation method comprises the following steps of: firstly sorting combustible components in the domestic garbage, and then drying and crushing the combustible components in the domestic garbage; then mixing the combustible components in the domestic garbage, the coal liquefaction residual and the desulfurizing agent according to the matching ratio, stirring uniformly; and finally forming. The formed fuel disclosed by the invention has the advantages that the heat value is high, the secondary pollution is low, the mechanical performance is excellent, the reduction and the harmlessness of the domestic garbage are realized, and meanwhile, the recycling of the domestic garbage and the coal liquefaction residual is realized.

Owner:四川川润环保能源科技有限公司 +1

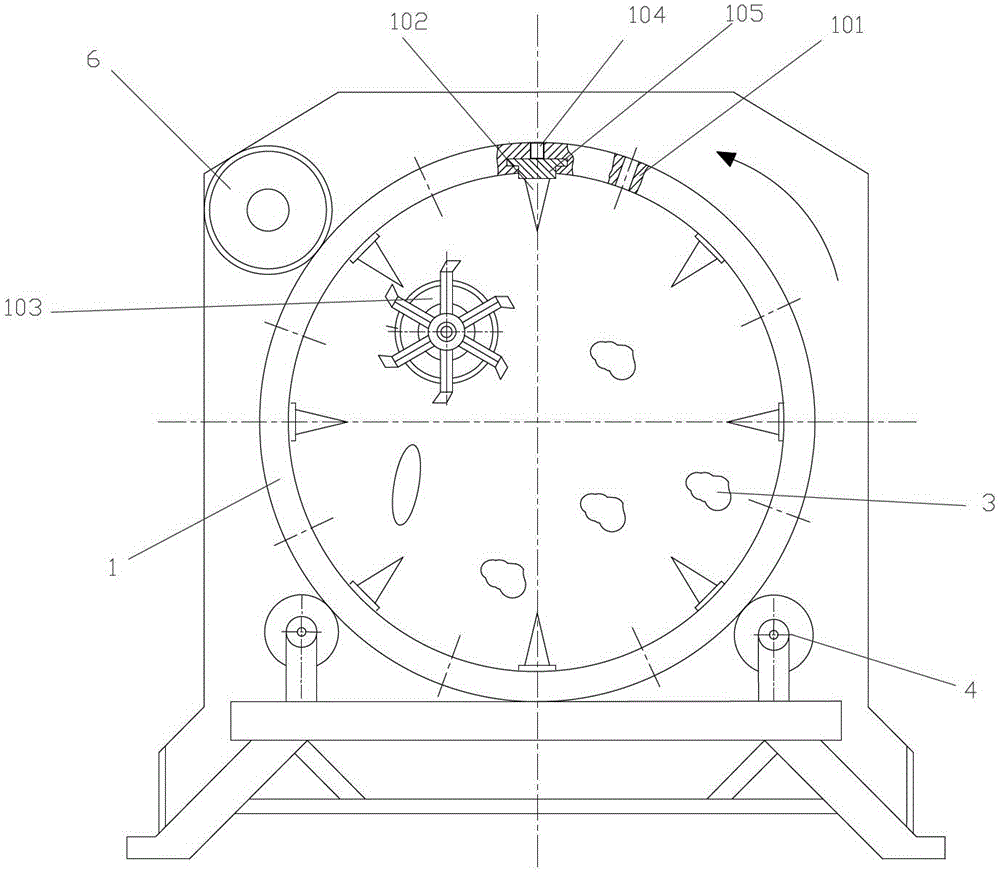

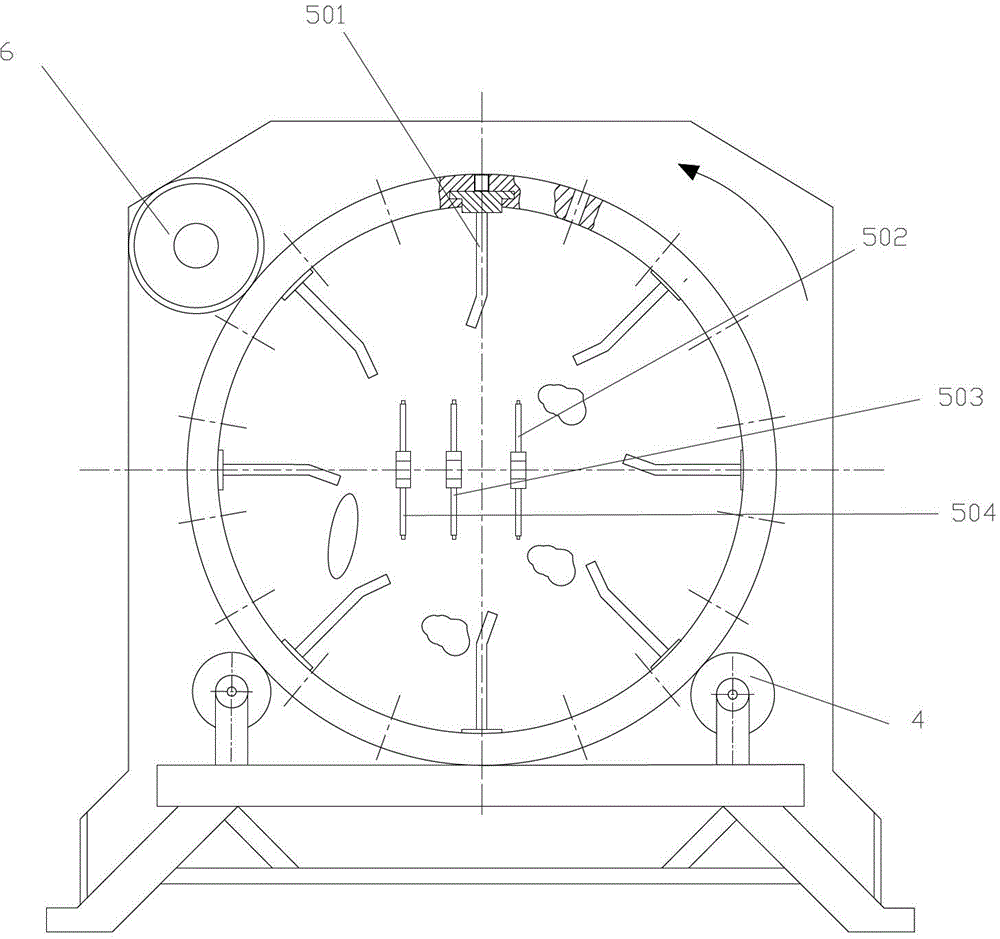

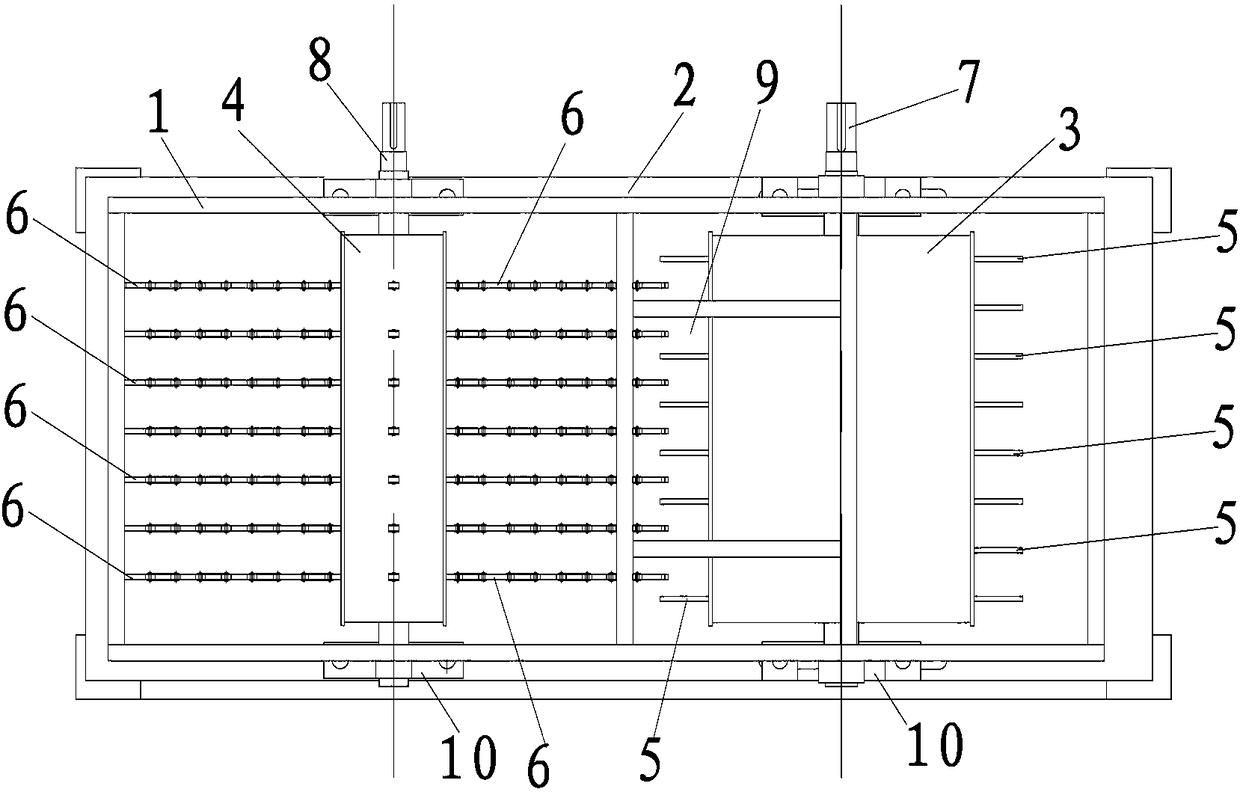

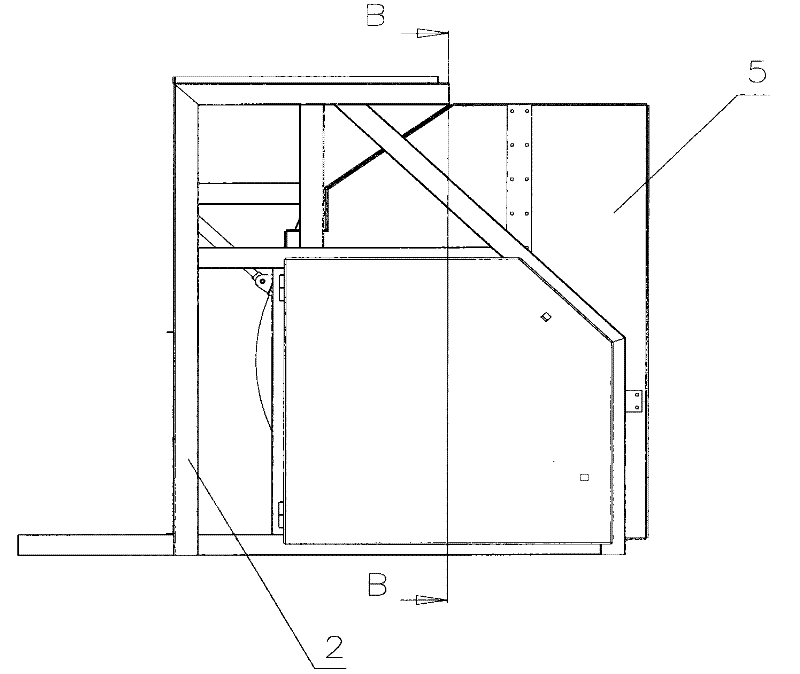

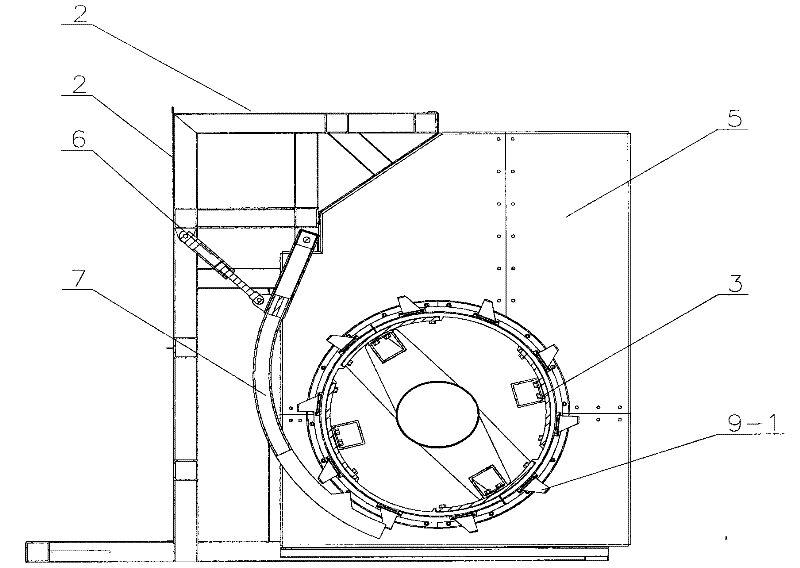

Two-section drum screen for municipal domestic waste

InactiveCN102671854BRealize sortingAchieve recyclingSievingScreeningDomestic wasteMunicipal solid waste

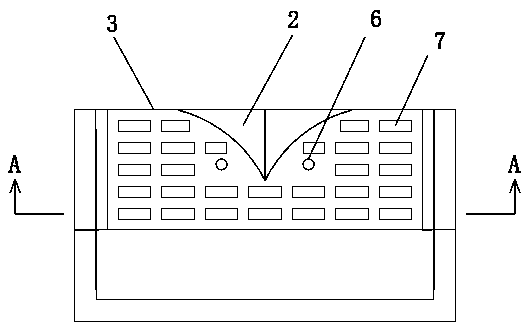

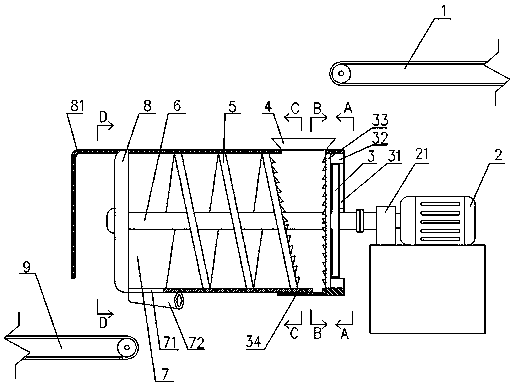

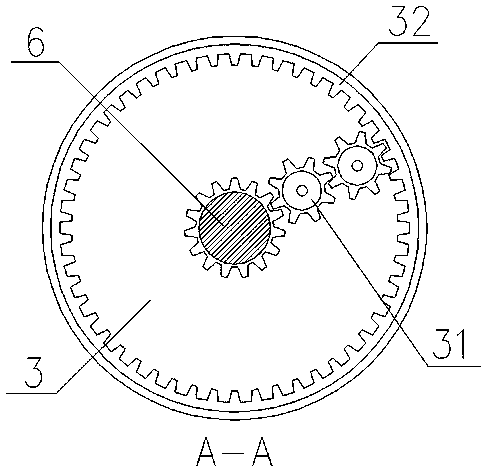

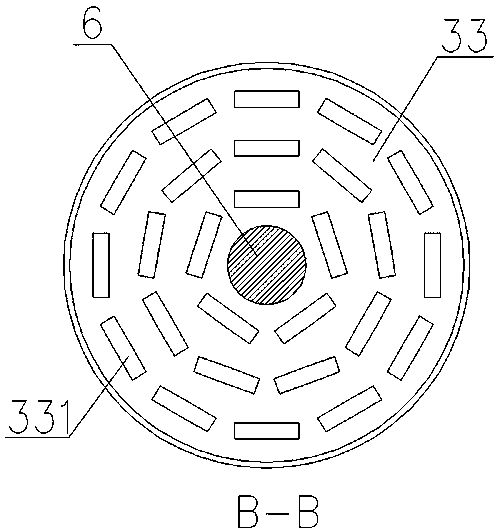

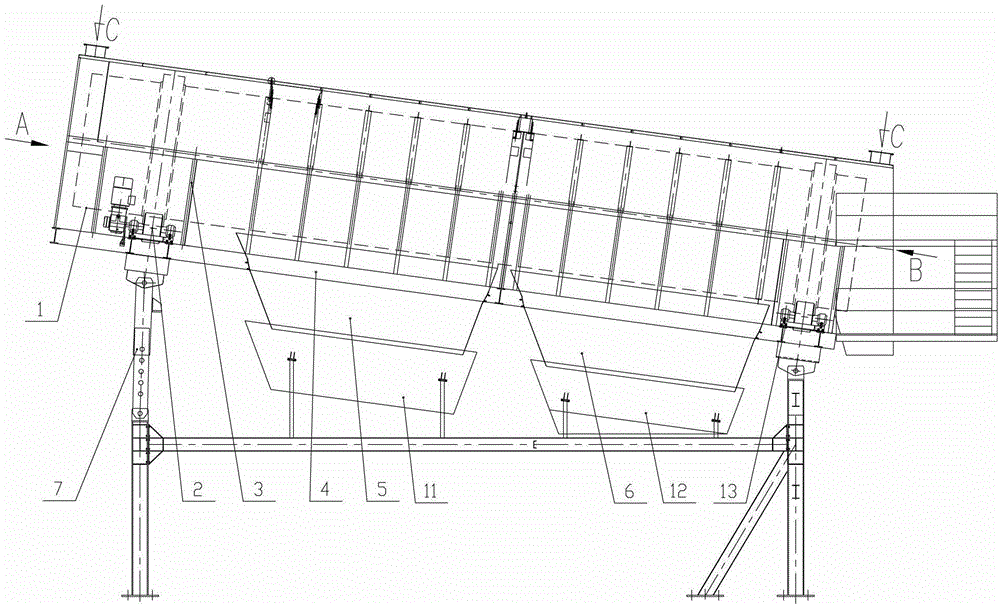

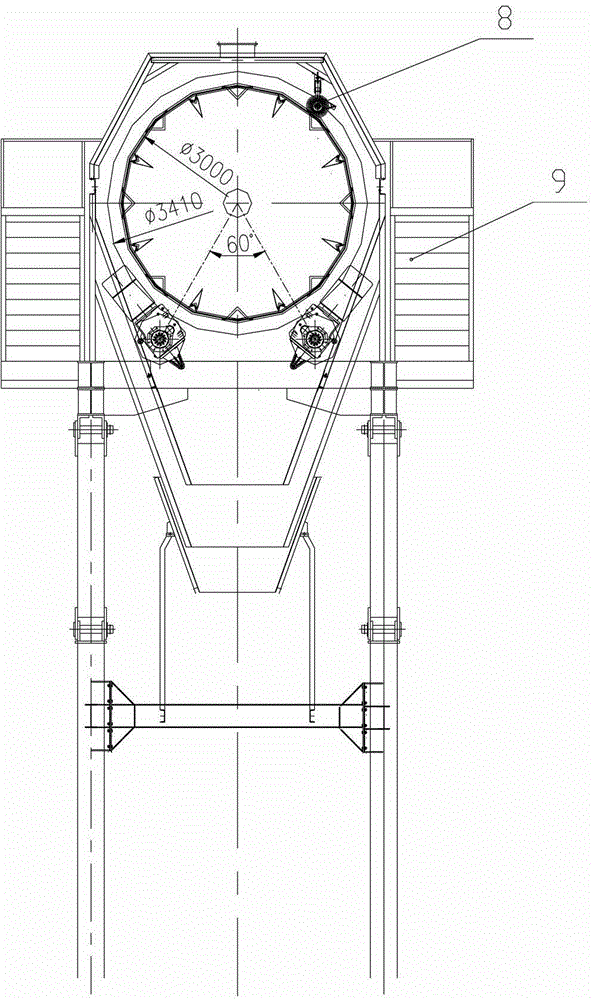

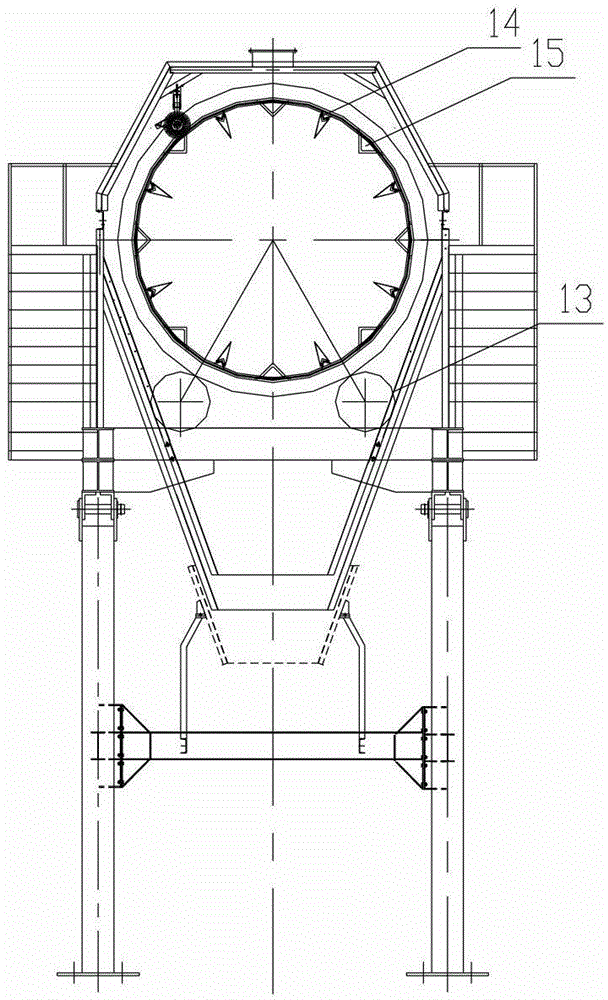

A two-sectional drum screen for municipal solid waste comprises a fixed rack (8), and a drum screen and a drum screen driving device (4) that are installed on the fixed rack (8). The drum screen comprises a drum screen entrance section (1) and a drum screen exit section (5) that are connected to each other. A feeding port (2) is installed at an entrance of the drum screen entrance section (1). A screen underflow collection device (7) is disposed below the drum screen. Several screen holes (101) are disposed on circumferential directions of the drum screen entrance section (1) and the drum screen exit section (5). Several bag breaking cutters (102) are installed on a circumferential inner wall of the drum screen entrance section (1), and cutter cleaning devices (103) fitting the bag breaking cutters (102) are disposed in the drum screen entrance section (1). A hole cleaning device (6) for cleaning the screen holes (101) is disposed on peripheries of the drum screen entrance section (1) and the drum screen exit section (5). Several strip object hanging devices (501) are installed on a circumferential inner wall of the drum screen exit section (5), and three rows of hanging needle chains (502, 503, 504) are installed in the drum screen exit section (5). Therefore, functions of screening, bag breaking, and strip object collection are effectively achieved, and a beneficial condition is created for classification and recycling of municipal solid waste.

Owner:四川川润环保能源科技有限公司 +1

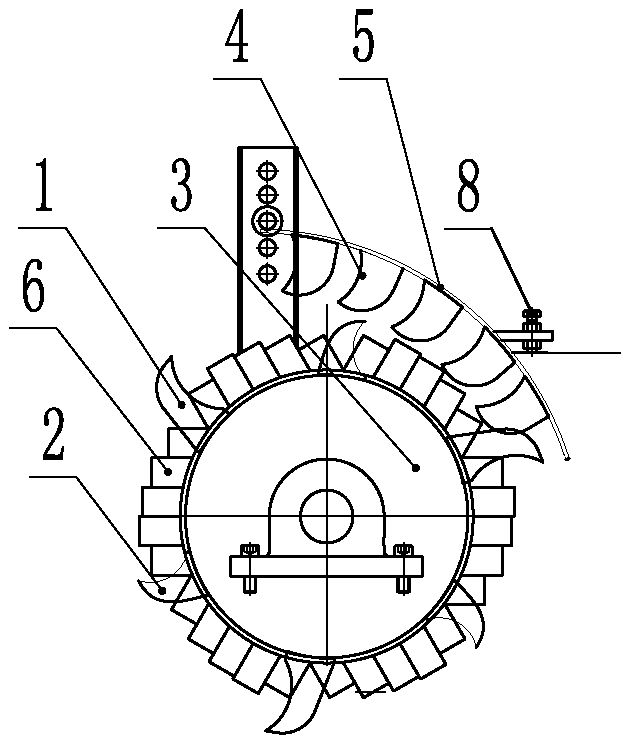

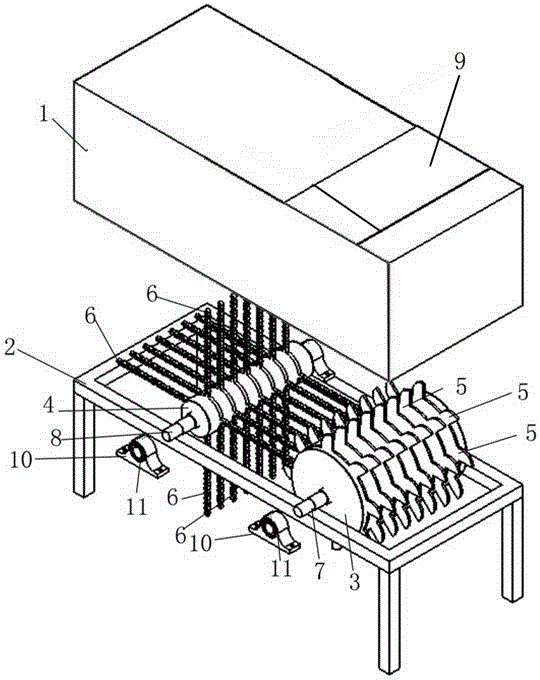

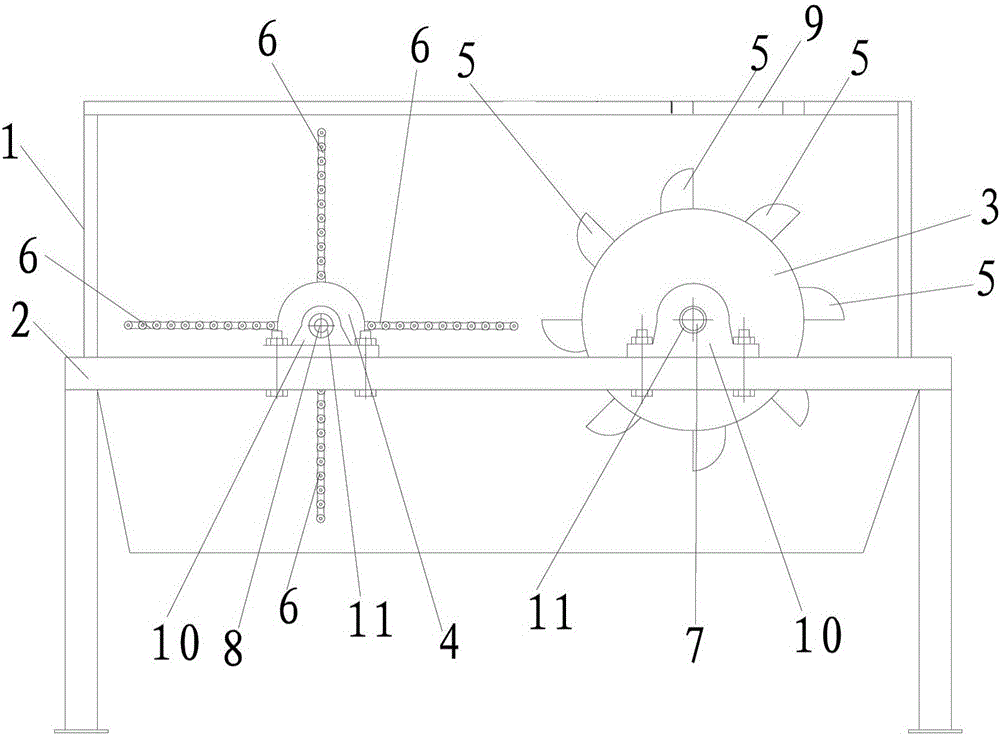

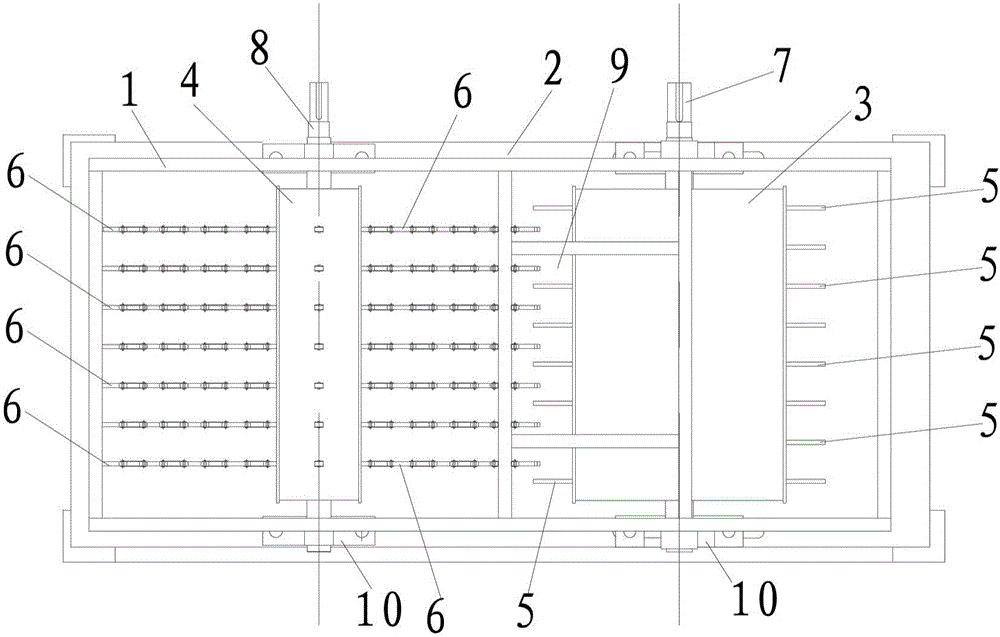

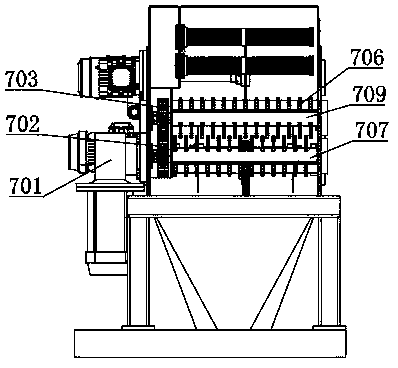

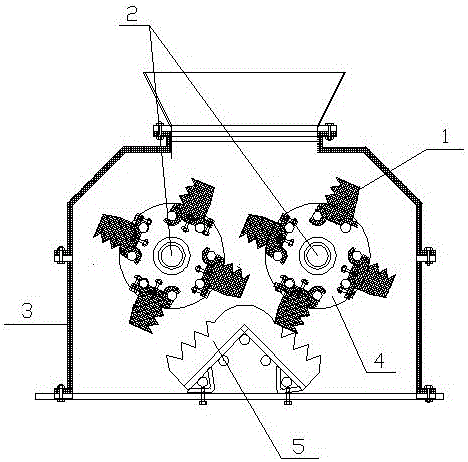

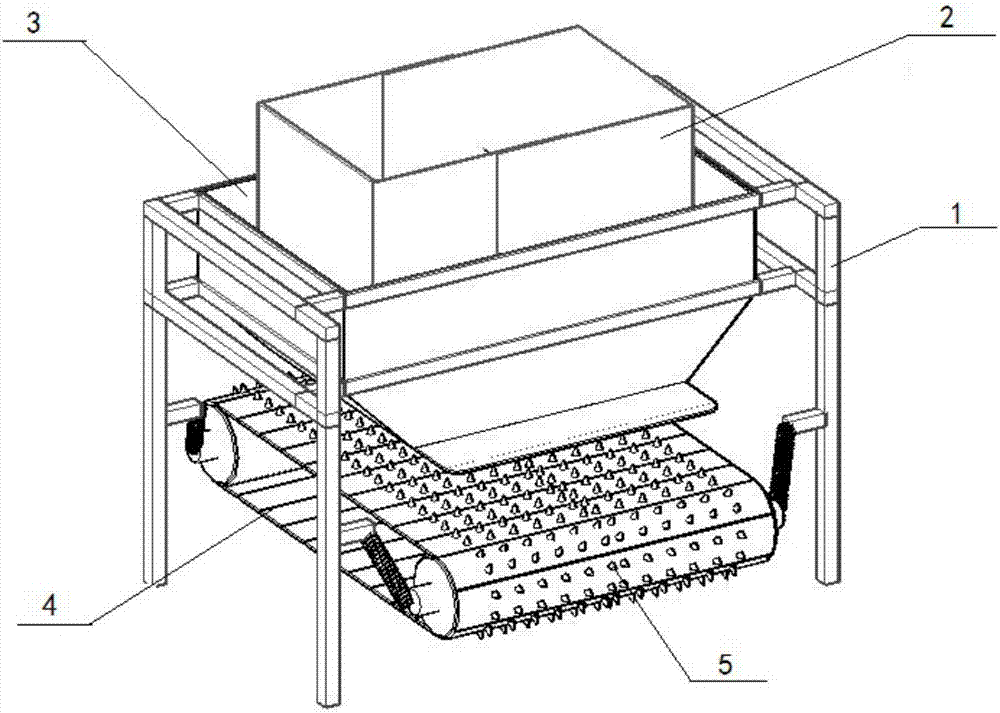

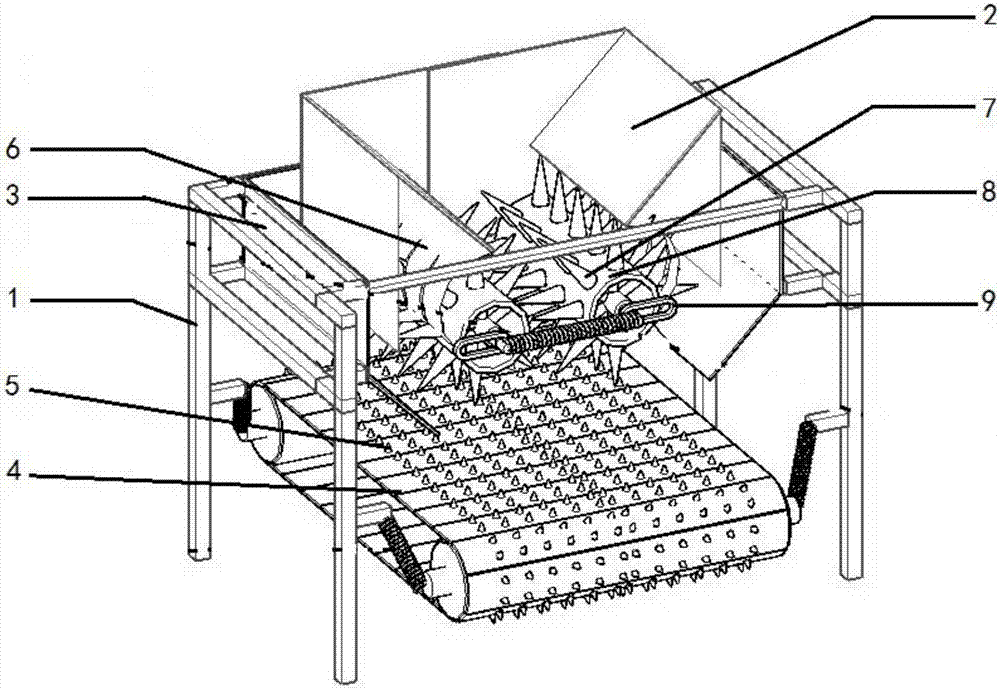

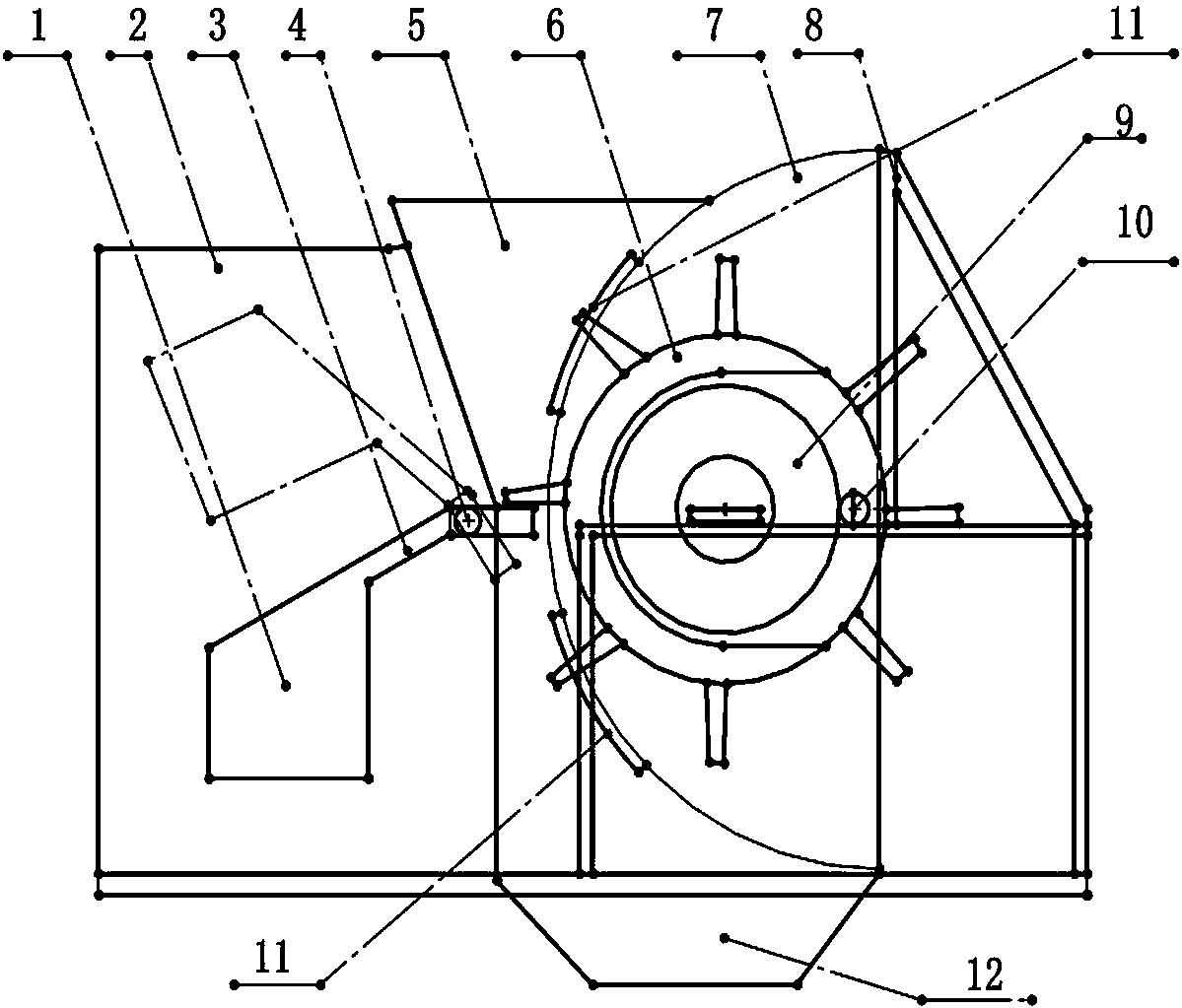

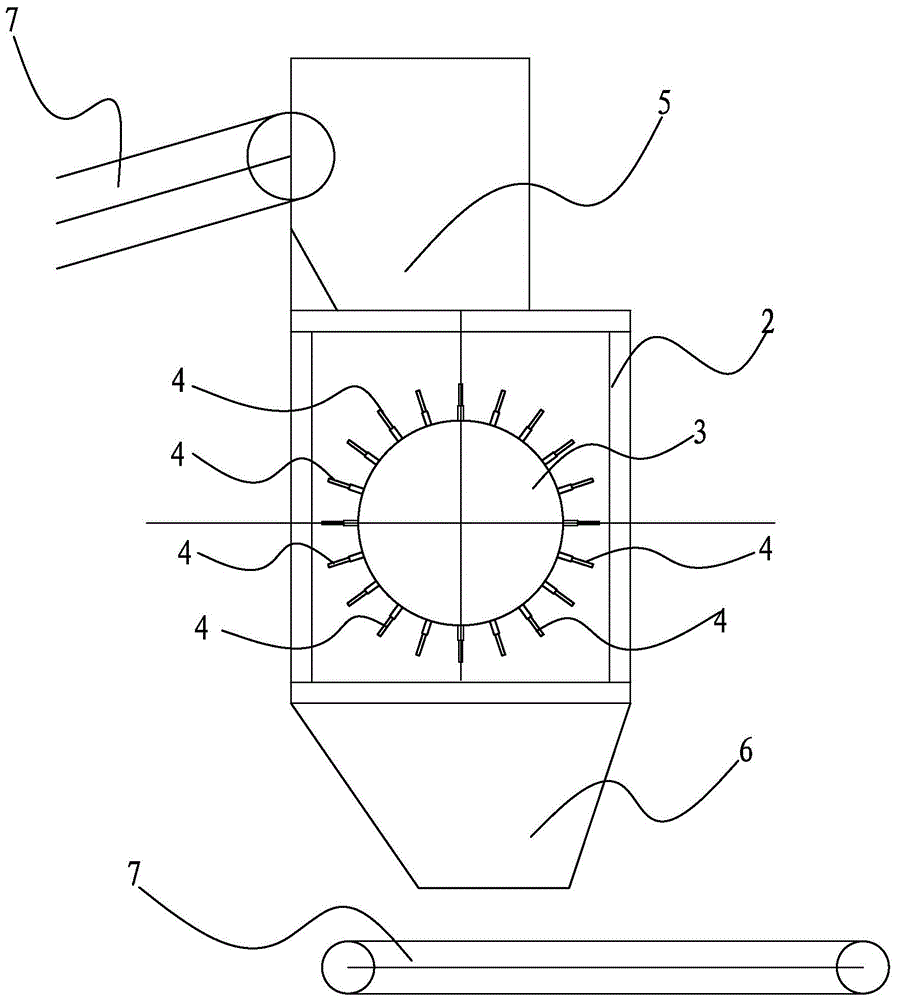

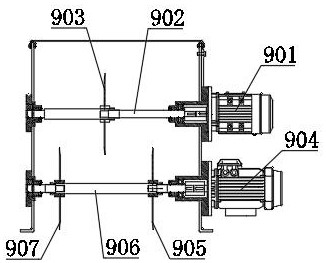

Movable shaft double-wheel bag breaking machine

InactiveCN107344643ANot easy to hangEasy to disassembleUnpacking by cuttingForeign matterJoint action

The invention belongs to the field of garbage sorting, and particularly relates to a movable shaft double-wheel bag breaking machine. The movable shaft double-wheel bag breaking machine comprises a support, a box above the support, two bag breaking wheels, two feeding baffles, a chain plate conveyor and a motor. The bag breaking wheels and the feeding baffles are located in the box, the chain plate conveyor is located below the box, and the bag breaking wheels are arranged between the two feeding baffles. Bag breaking cones are arranged on the peripheries of the bag breaking wheels, and bag breaking short cones are arranged on the surface of a conveying belt of the chain plate conveyor. The two bag breaking wheels are driven by the motor to rotate in the opposite directions, and a conveying wheel of the chain plate conveyor is driven by the motor to rotate. The movable shaft double-wheel bag breaking machine is simple in structure and uniform in feeding, the feeding height is not limited, and the phenomenon of jamming is not likely to happen. Foreign matter is not prone to being hung on the bag breaking cones, and detachment is convenient. Due to the unique movable shaft design, hard objects capable of being directly recycled cannot be damaged. Under the joint action of the bag breaking wheels rotating in the opposite directions and the chain plate conveyor with the bag breaking short cones at the lower portion, the bag breaking efficiency is greatly improved.

Owner:辽宁省能源研究所有限公司

A garbage disposal bag breaking machine

ActiveCN106362837BWon't go off trackImprove bag breaking efficiencyGrain treatmentsUnpacking by cuttingEngineeringMechanical engineering

The invention discloses a bag breaking machine for garbage disposal. The bag breaking machine for garbage disposal comprises a main support, a shell, a main roller and an auxiliary roller, wherein the main roller and the auxiliary roller are arranged on the main support in a rotating mode, the rotation direction of the main roller is opposite to that of the auxiliary roller, and at least five cutting device assemblies are arranged on the outer wall of the main roller in a surrounding mode. Each cutting device assembly comprises at least two cutting devices, and the cutting portion of each cutting device faces the auxiliary roller. At least three flexible slashing strip assemblies are arranged on the auxiliary roller in a surrounding mode. Each slashing strip assembly comprises at least two flexible slashing strips. The cutting device assemblies and the flexible slashing strip assemblies are arranged transversely in alternate and spaced modes, or, the minimum transverse interval between the outermost end of each cutting device assembly and the outermost end of the corresponding flexible slashing strip assembly is smaller than 5 cm, or, the outermost end of each cutting device assembly and the outermost end of the corresponding flexible slashing strip assembly are overlapped in the transverse direction but spaced in the longitudinal direction. A feed inlet is formed in the top of the shell, and the bottom end of the feed inlet is located above the main roller. The bag breaking machine for garbage disposal is simple in structure and high in bag breaking efficiency, achieves full mechanization, saves labor and reduces the garbage bag breaking cost.

Owner:郑雨童

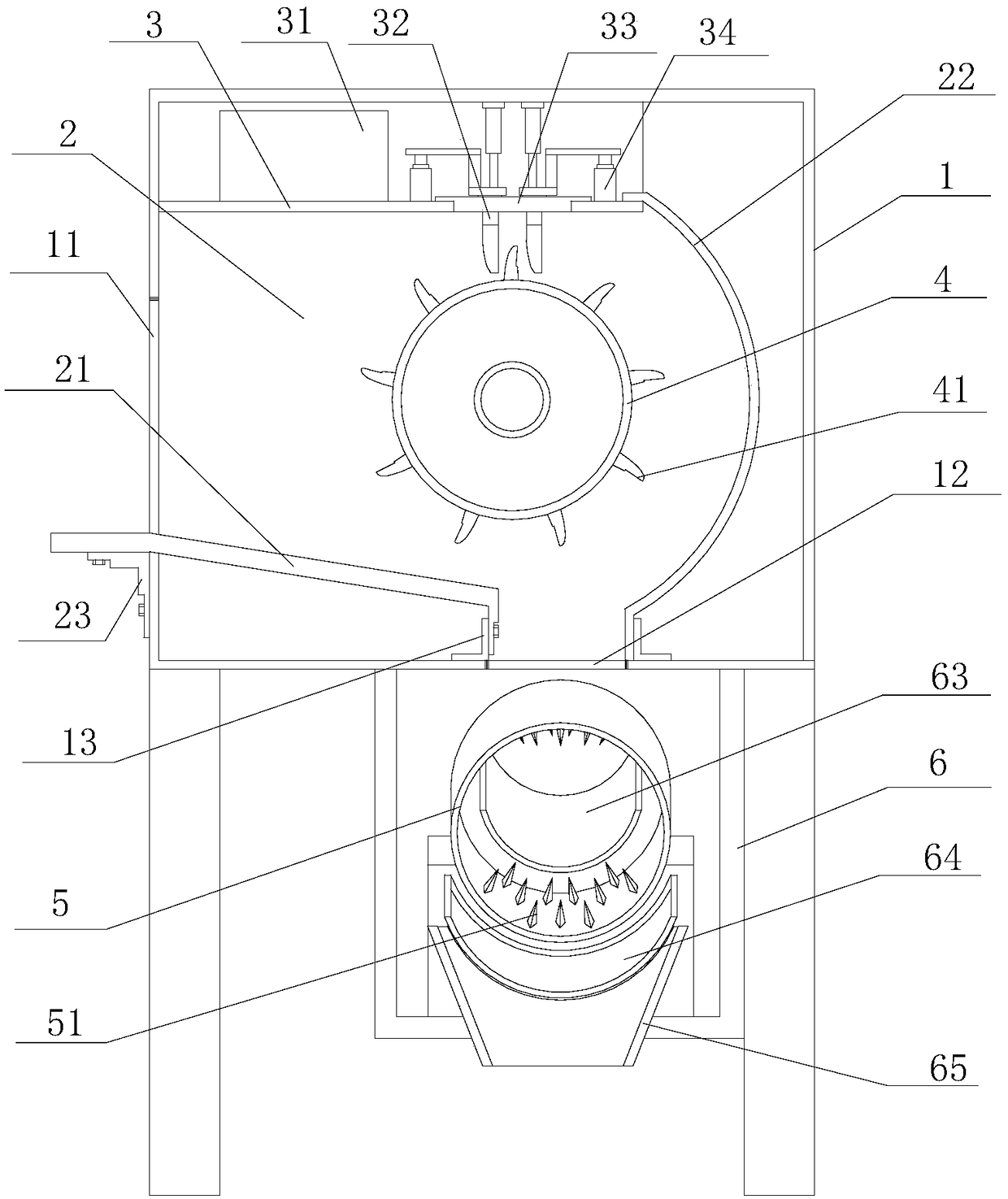

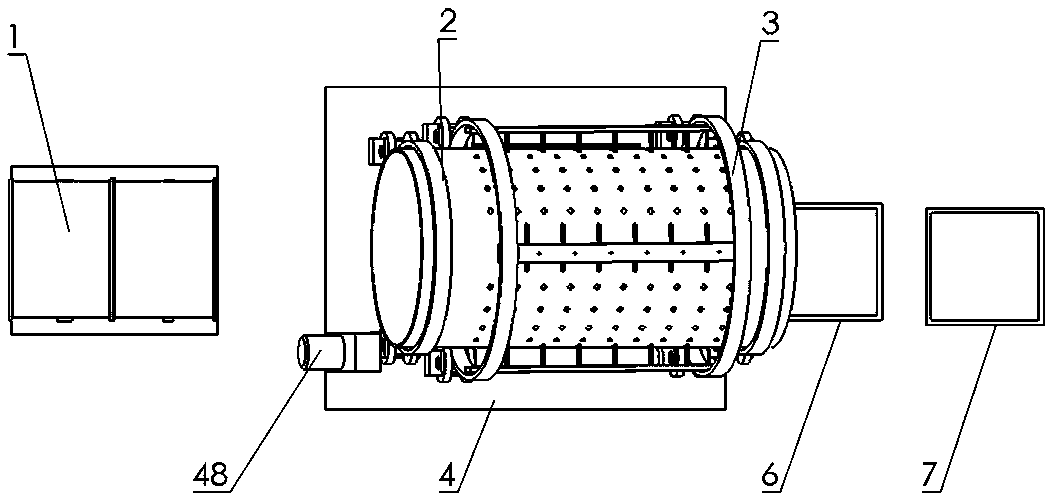

Organic garbage pretreatment bag breaking device

PendingCN108639481AAvoid entanglementClean up in timeSolid waste disposalUnpacking by cuttingForeign matterEngineering

The invention discloses an organic garbage pretreatment bag breaking device which comprises a crate, a first bag breaking chamber, a clearing box, a smashing roller, a bag breaking drum and a second bag breaking chamber. The crate is provided with the first bag breaking chamber. A first feeding opening is formed in one side of the crate. The smashing roller is arranged in the first bag breaking chamber. A first smashing cutter is arranged on the periphery of the smashing roller. The clearing box is arranged above the smashing roller. A clearing partition plate is arranged in the clearing box.Two clearing cutter assemblies distributed symmetrically are arranged below the clearing partition plate. A first discharging opening is formed below the first bag breaking chamber and communicates with the second bag breaking chamber. The bag breaking drum is arranged in the second bag breaking chamber. A smashing portion is arranged in the bag breaking drum. The bag breaking drum is installed inan oblique shape. The smashing roller and the bag breaking drum are adopted for cooperating to carry out secondary bag breaking, the bag breaking efficiency can be improved, meanwhile, the clearing cutter assemblies are arranged on the smashing roller, and the situation that foreign matters are wound around the smashing roller can be avoided.

Owner:ZHEJIANG MINGJIA ENVIRONMENTAL PROTECTION TECH CO LTD

Garbage bag breaking machine with functions of bag breaking, avoiding and winding resisting

InactiveCN108328036AImprove bag breaking efficiencyGood effectBags openingUnpacking by cuttingEngineeringFiber

A garbage bag breaking machine with functions of bag breaking, avoiding and winding resisting mainly comprises a frame, a fixed knife rest box, a fixed knife combination, a fixed knife balance weight,a fixed knife limiting support frame, a movable knife winding resisting protection box, a movable knife combination, a gear combination, a speed reducer combination, a garbage inlet baffle, an arc winding resisting knife device and a guiding groove; the arrangement position of the fixed knife combination and the rotation position of the movable knife combination are arranged in a staggered manner, and the movable knife combination rotates to a garbage position on the fixed knife combination and then continues rotating to break bagged garbage; the movable knife combination rotates downwards, the fixed knife combination rotates around a shaft to avoid hard substances under the effect of the hard substances, and the fixed knife combination resets automatically under the effect of the fixed knife balance weight; a winding resisting carding tool device with a certain arc is designed on the movable knife winding resisting protection box; and when the movable knife combination rotates to thearc winding resisting carding tool device, fiber substances on the movable knife combination will be hooked onto the arc winding resisting carding tool device, and winding of the fiber substances tothe movable knife combination is prevented.

Owner:乌审旗恒泰固体废弃物处理研究所 +1

Winding-free heavy bag breaking machine

PendingCN113320785AAvoid entanglementImprove bag breaking efficiencyBags openingForeign matterStructural engineering

The invention provides a winding-free heavy bag breaking machine. The bag breaking machine comprises a roller, a rack, telescopic bag breaking tooth assemblies and a bag breaking cutter. The roller is connected with a rotary driving device to realize rotation. The rack is used for supporting the roller. The multiple telescopic bag breaking tooth assemblies are installed on the roller, each telescopic bag breaking tooth assembly comprises multiple bag breaking teeth, and the bag breaking teeth can stretch out of or retract into the roller in the radial direction of the roller. The bag breaking cutter is installed on the machine frame and used for being matched with the bag breaking teeth to break bags. The winding-free heavy bag breaking machine has the advantages that foreign matter winding after bag breaking can be avoided, the bag breaking efficiency is improved, and the maintenance frequency is reduced.

Owner:山东恒创环境科技有限公司

Multi-component regenerated fuel based on domestic garbage and preparation method thereof

The invention discloses a multi-component regenerated fuel based on domestic garbage and a preparation method thereof, which are suitable for resource processing of solid wastes. The regenerated fuel is formed by mixing combustible components in the domestic garbage, coal liquefaction residues, agricultural solid wastes and calcium oxide in proportion, and specifically comprises the following components in percentage by mass: 62.5%-77.0% of the combustible components in the domestic garbage, 10.0%-20.0% of the coal liquefaction residues, 5.0%-14.0% of the agricultural solid wastes and 4.5%-7.5% of the calcium oxide. The preparation method comprises the following steps: firstly separating the combustible components from the domestic garbage; then performing drying, crushing and other pretreatment on the combustible components in the domestic garbage, the coal liquefaction residues and the agricultural solid wastes; further mixing all the components according to the ratio, and uniformlystirring; and finally shaping. The regenerated fuel has the advantages of higher calorific value, stable combustion and low secondary pollution, and can realize resource utilization of the urban domestic garbage and the industrial and the agricultural solid wastes.

Owner:四川川润环保能源科技有限公司 +1

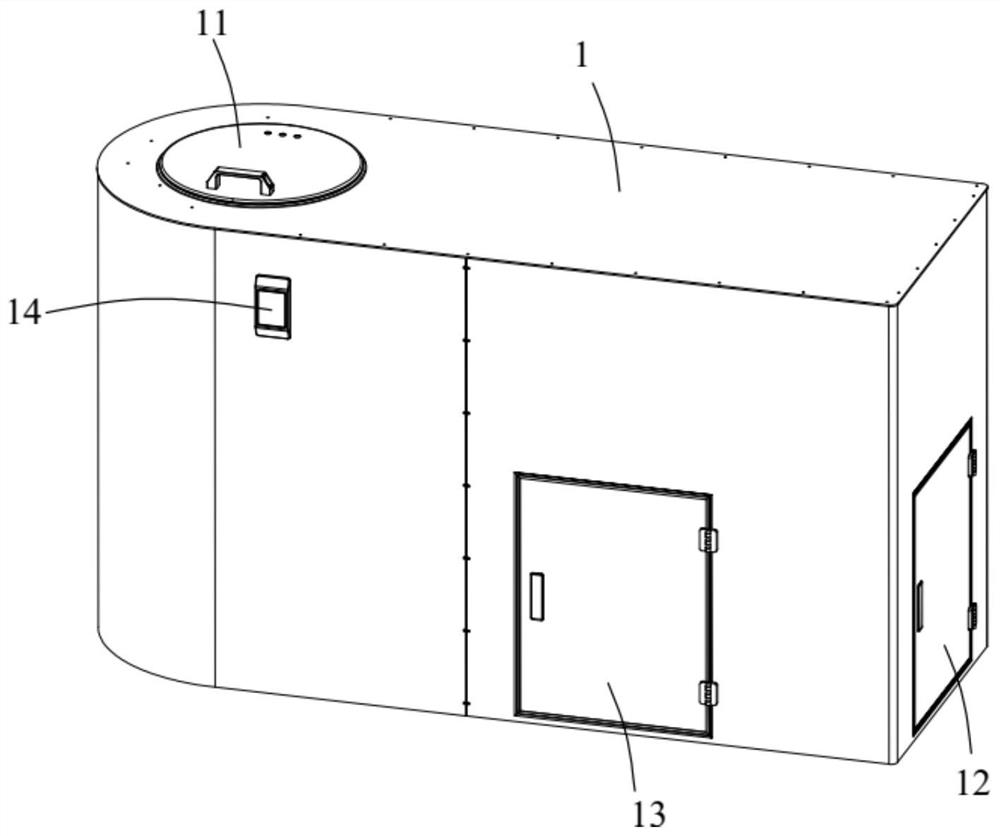

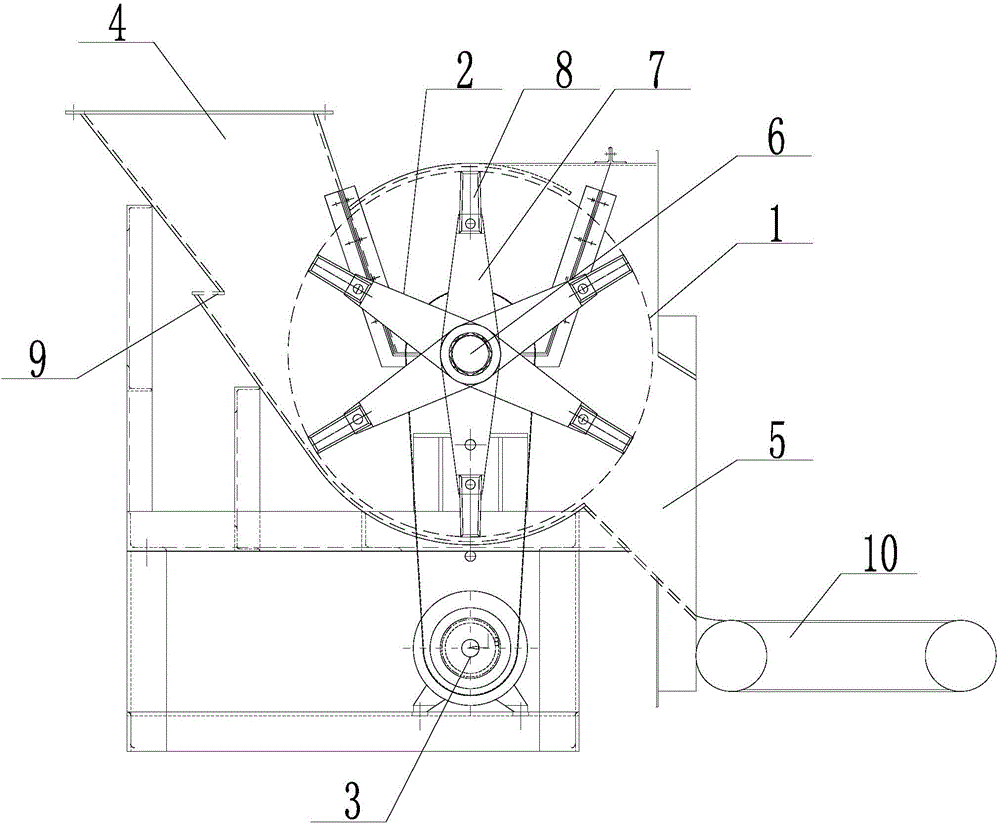

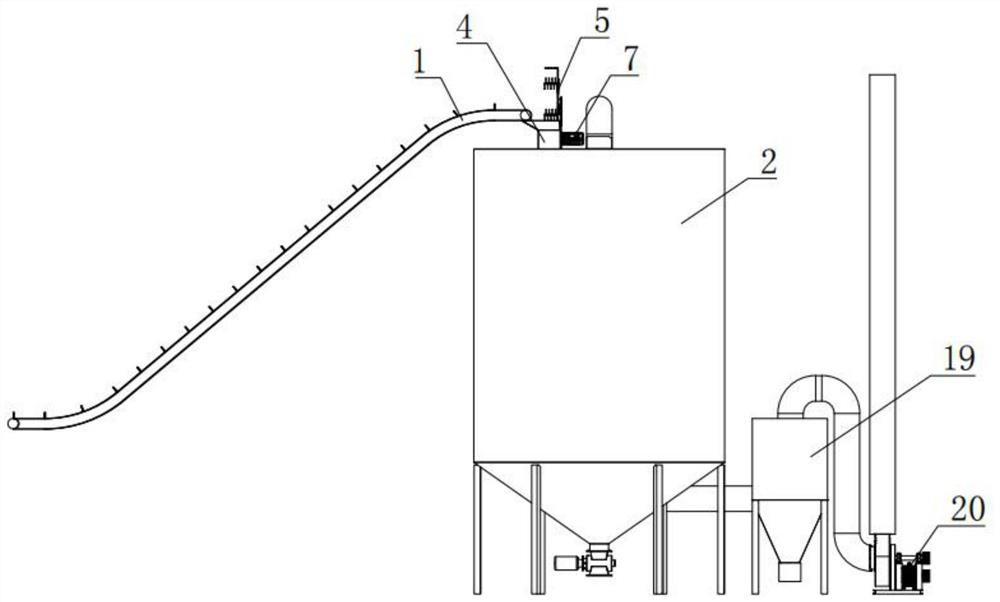

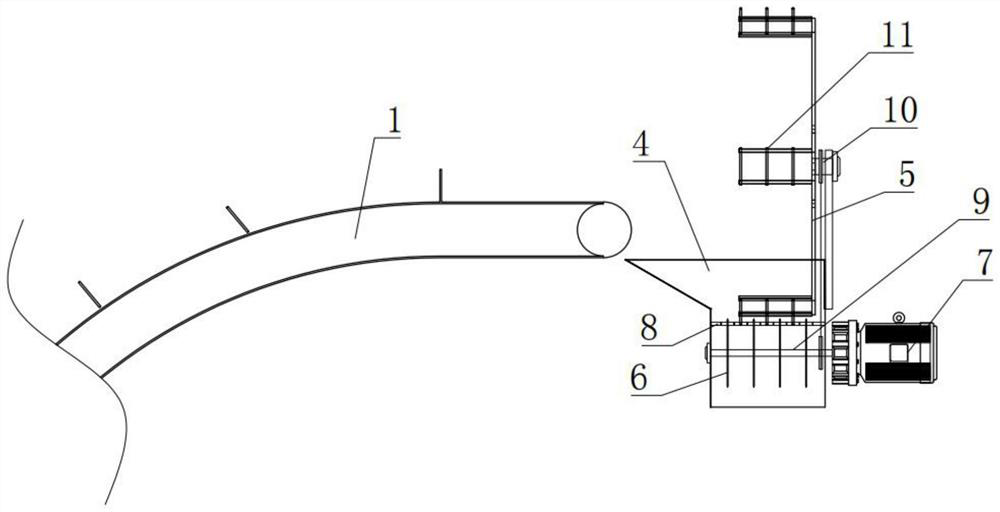

Automatic bagged material feeding device and feeding machine comprising same

ActiveCN113911485ARealize automatic feedingAvoid safety hazardsConveyorsBags openingRotating discLeather belt

The invention discloses an automatic bagged material feeding device and a feeding machine comprising the same. The automatic bagged material feeding device comprises a material conveying belt, a material bin and a bag breaking mechanism, the bag breaking mechanism comprises a feeding chamber, a bag clearing rotating disc, a bag breaking piece and a driving mechanism, the feeding chamber is of a structure with the two ends open, the bottom end of the feeding chamber communicates with the material bin, the section of the upper half portion of the feeding chamber is in a trapezoid shape, the section of the lower half portion of the feeding chamber is in a square shape, the discharging end of the material conveying belt is located above the feeding chamber, the bag clearing rotary disc is coaxially provided with a second connecting shaft, the second connecting shaft is connected with the feeding chamber through a rotary disc support, and the second connecting shaft is connected with the driving mechanism through a belt; and the bag clearing rotating disc is provided with bag claws in the circumferential direction of the bag clearing rotating disc, wherein the bag claws are used for bringing out empty bags in the feeding chamber when the bag clearing rotating disc rotates. According to the automatic feeding device, automatic feeding, bag breaking and bag clearing are achieved, manual carrying and bag opening are not needed, and potential safety hazards are effectively avoided.

Owner:广西贵港和乐门业有限公司

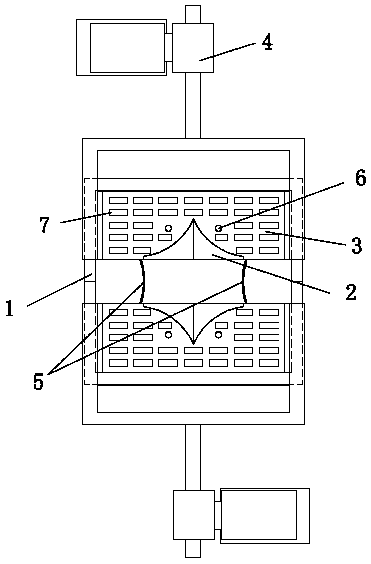

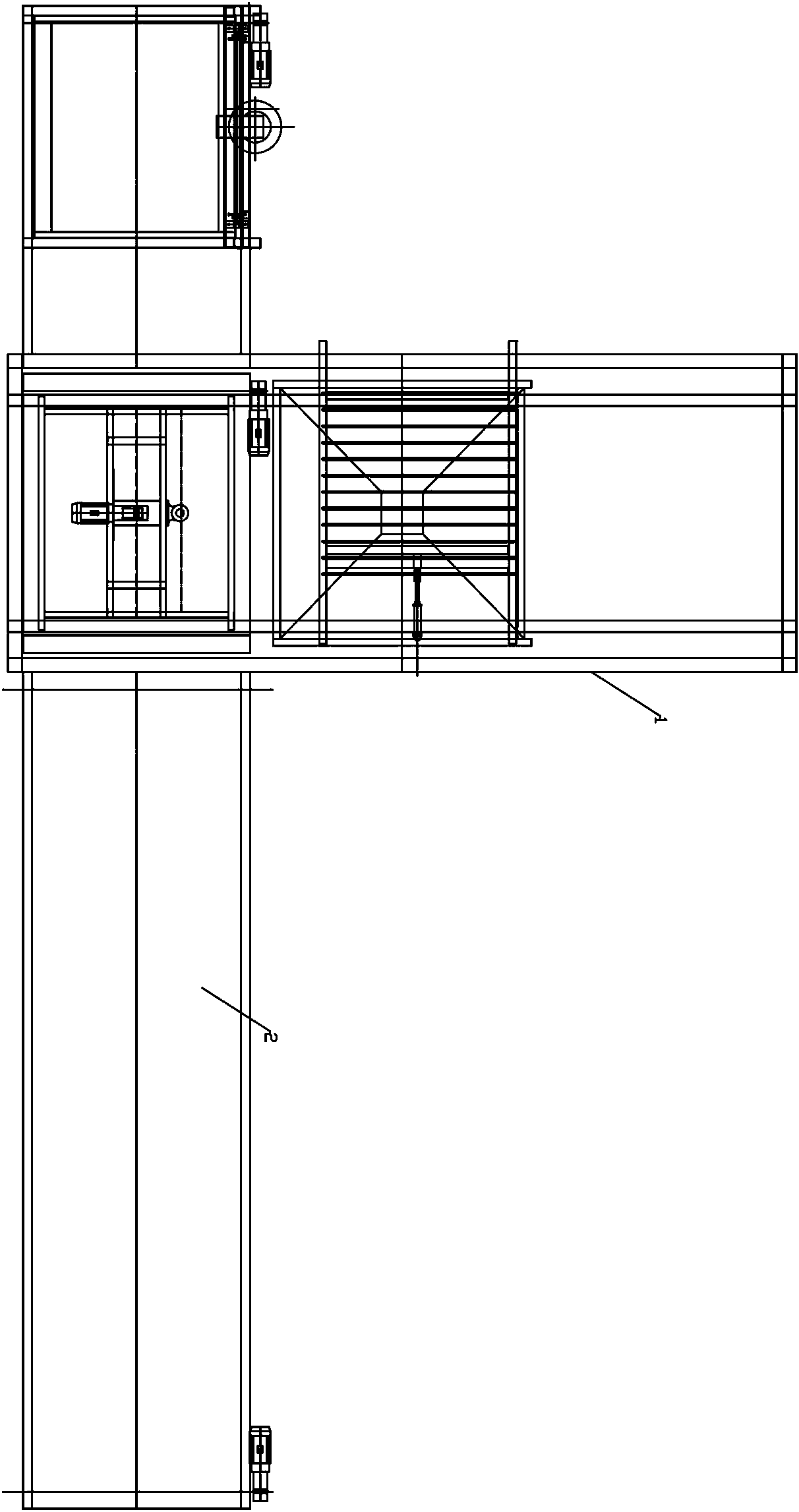

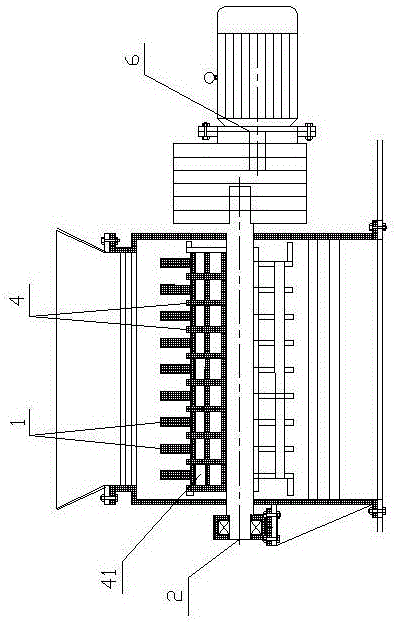

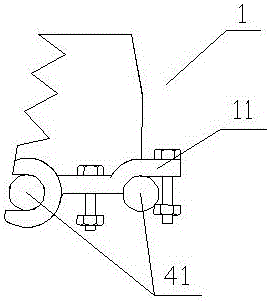

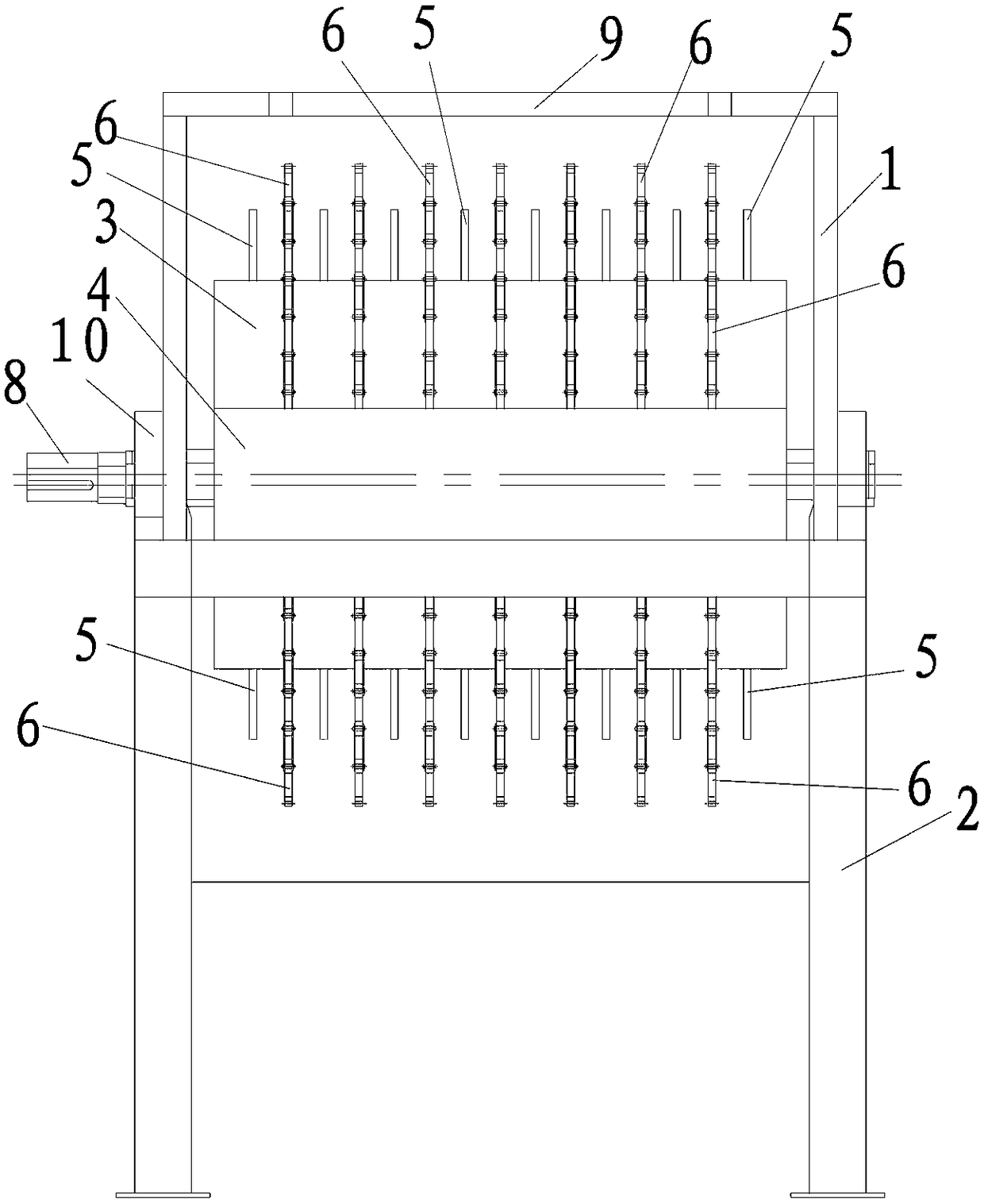

Bag breaking device and domestic waste sorting line with it

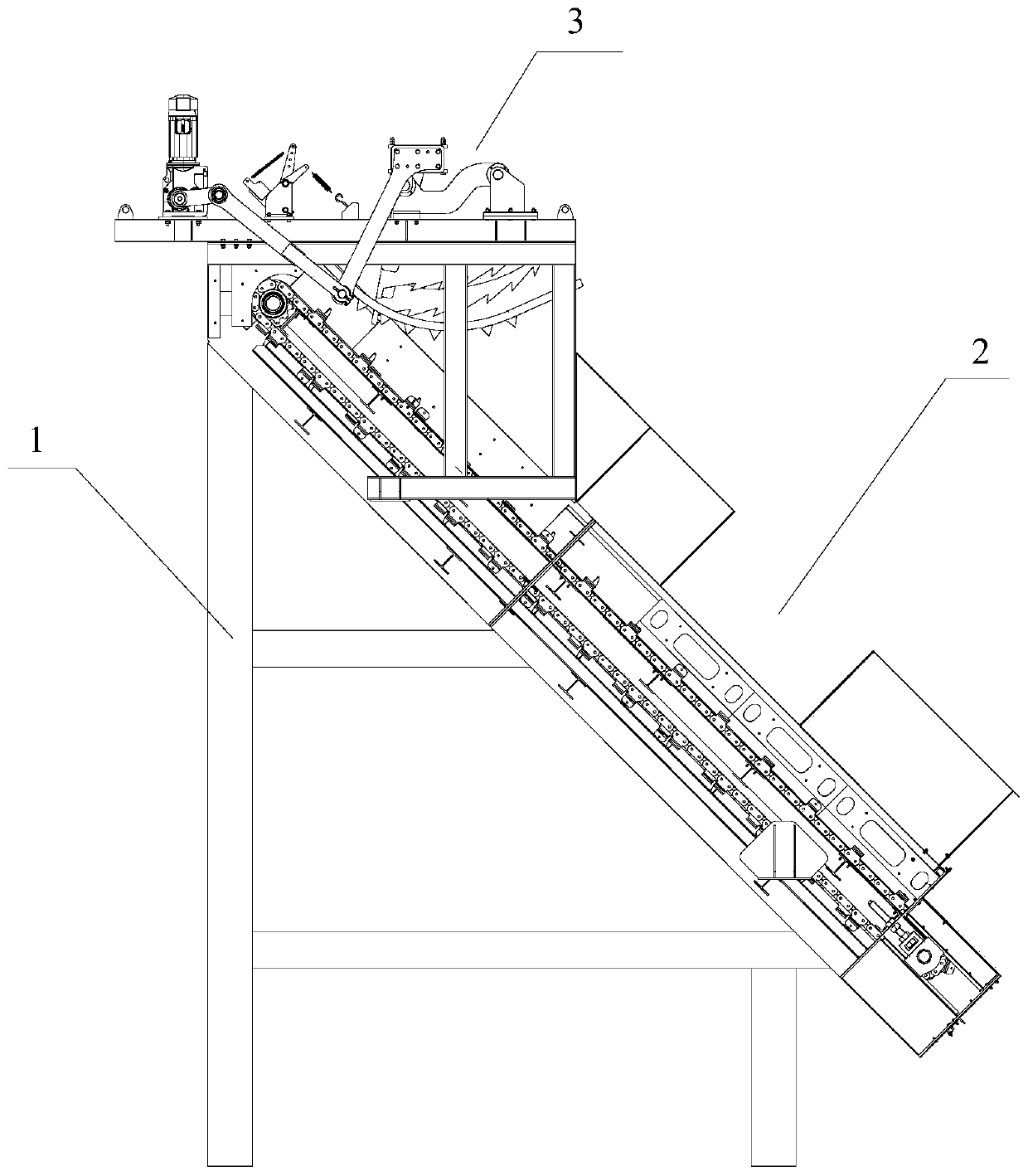

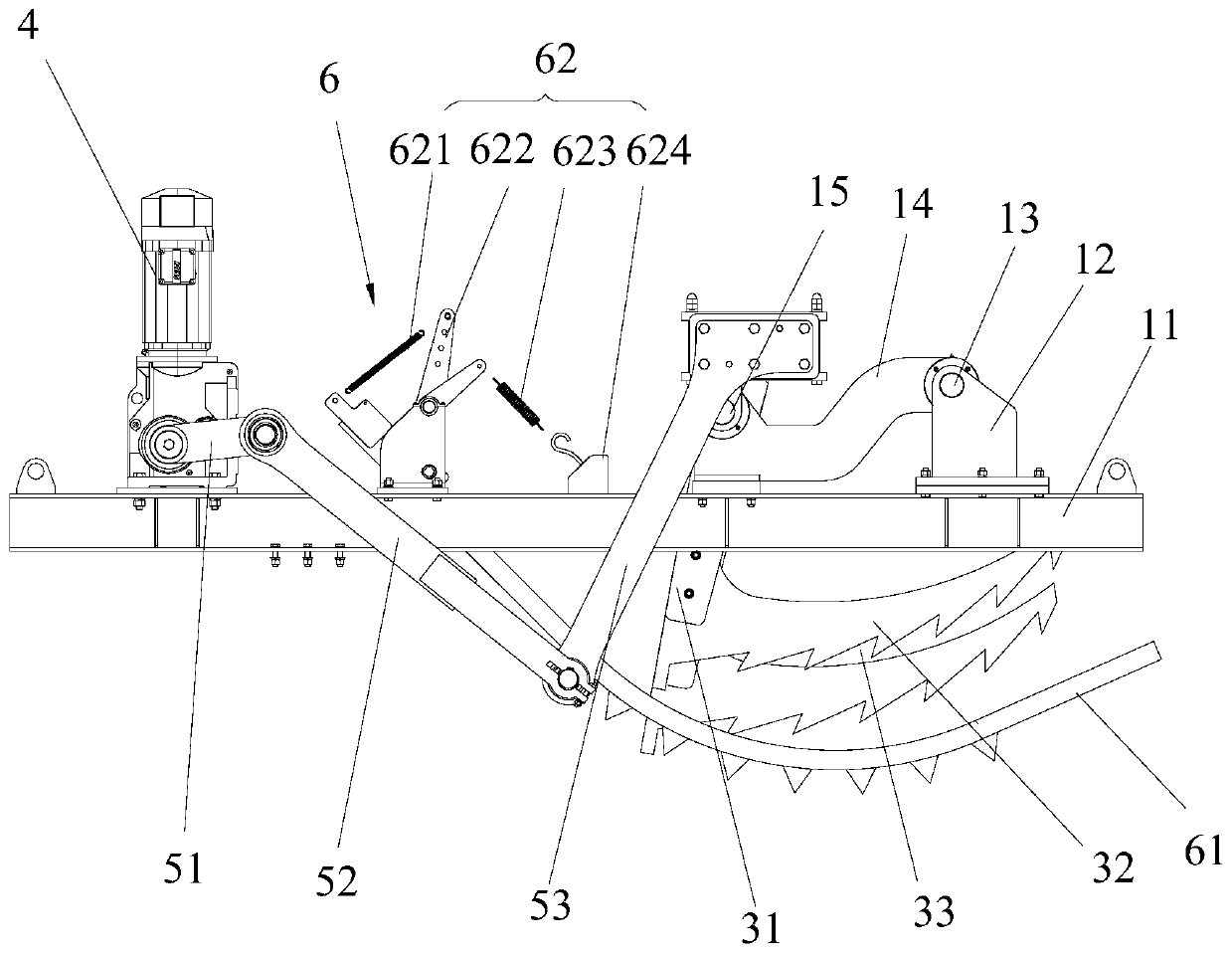

ActiveCN107902184BReduce wearReduce tanglingBags openingUnpacking by cuttingStructural engineeringConveyor belt

The invention discloses a bag breaking device and a domestic garbage sorting line with the same. The bag breaking device comprises a supporting frame, and a scraper machine and a bag breaking mechanism that cooperates with the scraper to form a differential to shear broken bags are disposed on the supporting frame; the bag breaking mechanism is provided with a corresponding first driver, and the first driver drives the bag breaking mechanism to swing back and forth through an eccentric mechanism; and the scraper includes a second driver and a conveyor belt, and the second driver drives the conveyor belt and materials to be separated on the conveyor belt to be delivered online. According to the bag breaking device and the domestic garbage sorting line with the same, the blade teeth of the bag breaking device is driven to swing back and forth under the action of the eccentric mechanism, and a differential movement is formed between the blade teeth of the bag breaking device and the scraper; the differential movement is used to achieve the effect of tearing and cutting the broken bags, and the efficiency of the bag breaking is improved; in addition, the blade teeth of the bag breakingmechanism are driven by the eccentric mechanism during the cutting process, the change of the cutting angle during the bag breaking process helps to reduce the wear of blades of the bag breaking mechanism, and the reciprocating swing cutting process greatly reduces the problems of material blocking and material winding in the bag breaking process.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

Garbage bag breaking machine and bag breaking method using it

ActiveCN103552715BReduce the cost of broken bagsEasy accessArticle unpackingEngineeringSimple machine

The invention discloses a garbage bag breaking machine and a bag breaking method using the same, wherein the garbage bag breaking machine includes a bracket, a casing arranged on the bracket, and a rotatable rotating speed of at least 60 revolutions per minute arranged in the casing. The drum has a gap between the shell and the drum. At least ten rows of steel whips are arranged on the outer wall of the drum, and each row of steel whips has at least five steel whips. The top of the shell is provided with A material inlet, a material outlet is arranged on the bottom of the housing, and the roller is connected with a driving device. The garbage bag breaking machine of the present invention has the advantages of simple structure, high bag breaking efficiency, complete mechanization, labor saving, reduced garbage bag breaking cost, capable of breaking plastic bags into large fragments and breaking up agglomerated garbage.

Owner:西安德兆环保科技有限公司

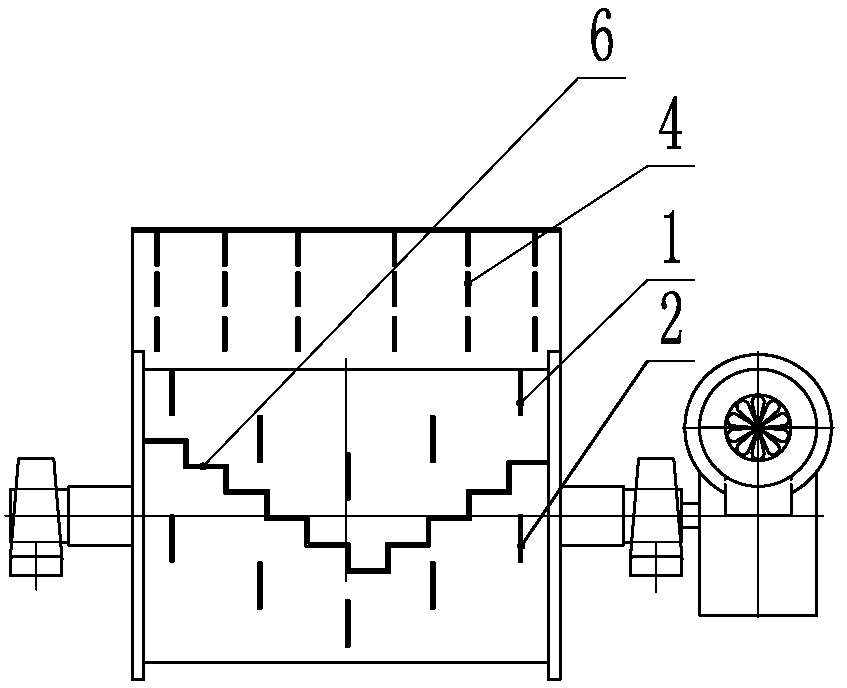

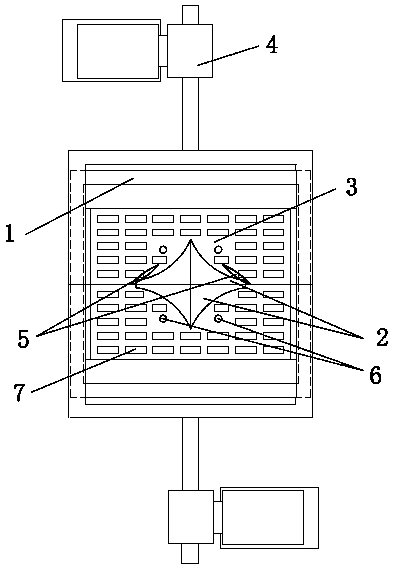

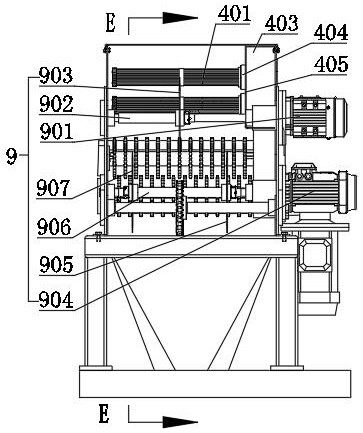

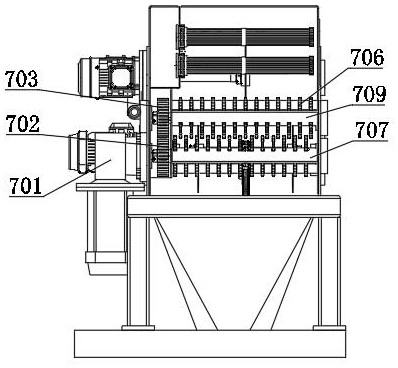

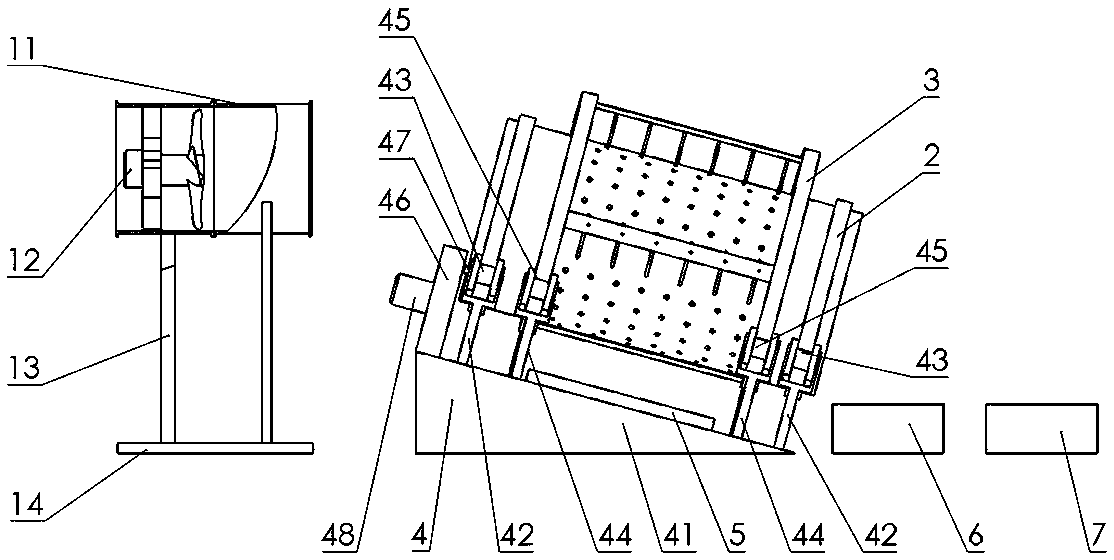

Shearing type bag breaking machine for bagged house refuse

ActiveCN102079408BTurn waste into treasureBaggage crackingArticle unpackingHydraulic motorEngineering

The invention discloses a shearing type bag breaking machine for bagged house refuse, which comprises a main frame body and also comprises a rotating body, wherein the rotating body consists of an A-group and a B-group rotating sub-bodies with same structures; the A-group and the B-group rotating sub-bodies are separately and crossly arranged, and connected through a transition shaft to form the rotating body, an interval is arranged between an arc plate of the A-group rotating sub-bodies and an arc plate of the B-group rotating sub-bodies; shearing bodies are fixedly connected to the arc plates along the circumferential directions, shearing tool bits are arranged on the shearing bodies; the shearing tool bits on the A-group rotating sub-bodies and the shearing tool bits on the B-group rotating sub-bodies are in staggered arrangement; shaft sleeves of the A-group and the B-group rotating sub-bodies are respectively connected with a hydraulic motor fixedly connected with the main framebody; and the rear part of the rotating body is provided with a stationary tool set which is in staggered arrangement with the shearing tool bits. The shearing type bag breaking machine has the advantages of compact structure and high bag-breaking efficiency.

Owner:天津百利阳光环保设备有限公司

A kind of ratchet chain type automatic bag breaking equipment

ActiveCN111332570BAvoid cloggingUnobstructed dischargeLoading/unloadingUnpacking by cuttingRatchetProcess engineering

Owner:SHANDONG WANBANG PETROLEUM TECH CO LTD

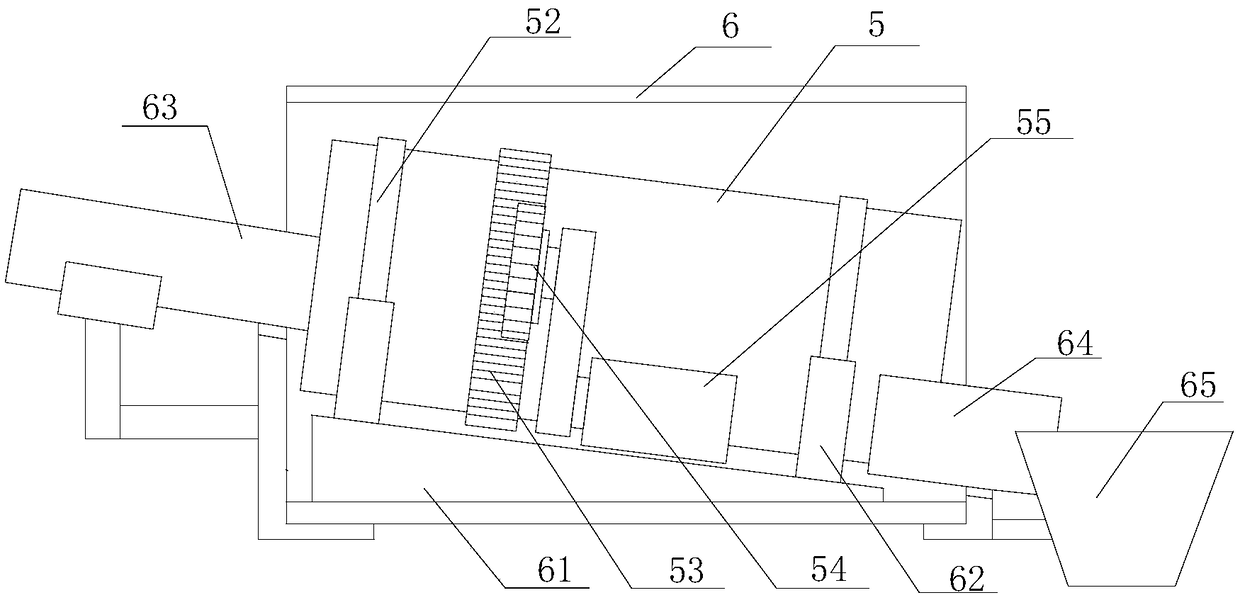

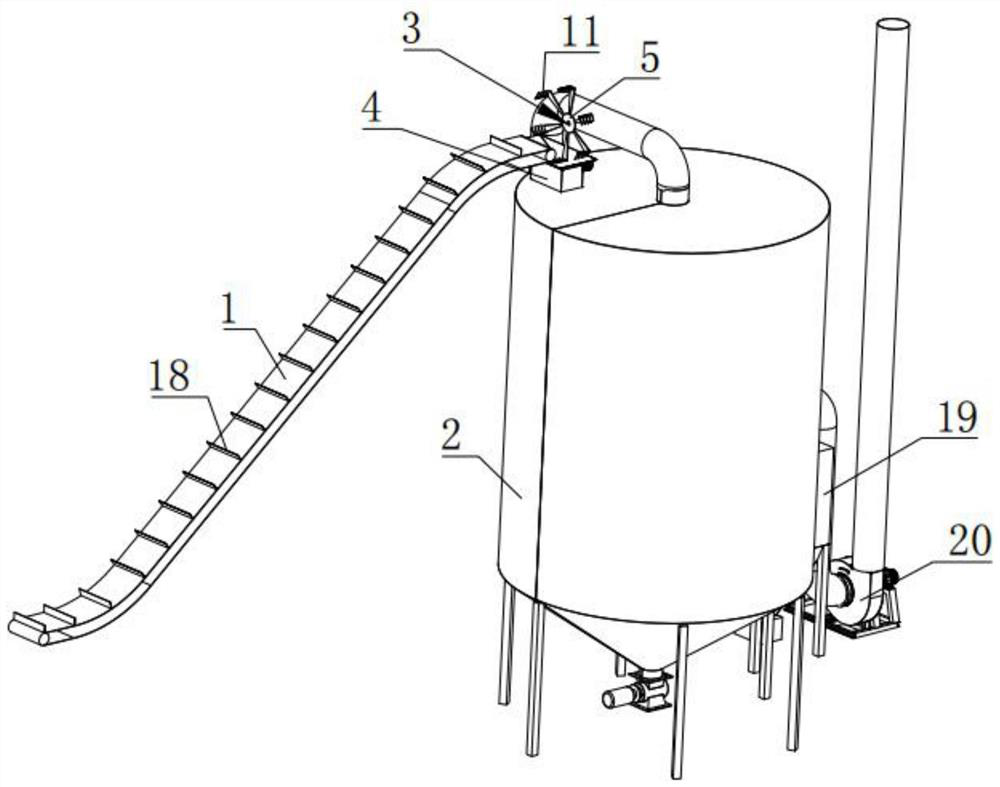

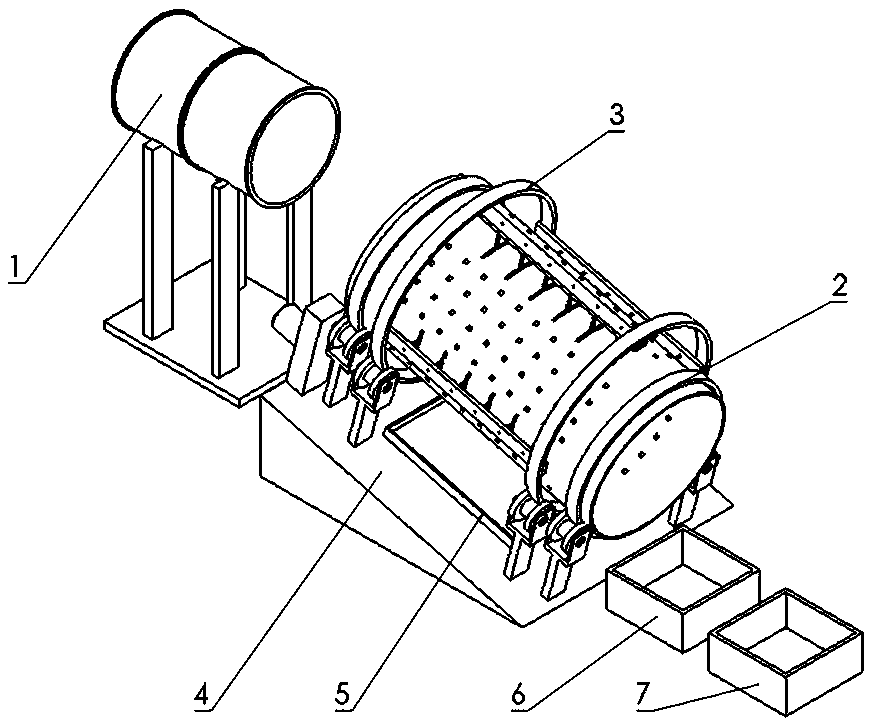

A compound drum bag breaking device for bagged domestic garbage

The invention discloses a combined roller bag breaking device for household garbage in bags. The bag breaking device belongs to the field of environment protection equipment and comprises a draught fan assembly, an inner roller, an outer rolling ring and a base assembly. The inner roller is sleeved with the outer rolling ring. The inner roller and the outer rolling ring are each supported by a rolling wheel supporting mechanism on the base assembly. The outer rolling ring is provided with bag breaking nails, and the bag breaking nails are inserted in kidney-shaped holes in the inner roller. The draught fan assembly is arranged at the end, with the inclined face higher, of the base assembly. The wind direction of an axial flow draught fan directly faces the upper side face of the inner wall of the inner roller. When the household garbage in bags is placed therein through the high end of the inner roller, a speed reduction motor drives the inner roller to rotate; the bag breaking nails drive the outer rolling ring to rotate; and meanwhile, the bag breaking nails are inserted into and pulled out of the kidney-shaped holes in a reciprocating manner, so that the garbage bags are punctured, under the wind action of the axial flow draught fan, the garbage bags fall off the bag breaking nails, and garbage is collected through a special collection box. By means of the combined roller bag breaking device, the bag breaking effect is enhanced; bag breaking efficiency is improved; and the combined roller bag breaking device is simple in structure and great in practicability.

Owner:黄山市开发投资集团有限公司

Composite multi-stage bag breaking screening machine in friction drive mode

Owner:北京科林皓华环境科技发展有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com