Oil field oil sludge woven bag breaking device

A technology of sludge and woven bags, which is applied in the directions of packaging, transportation and packaging, and unsealing of packaged objects. It can solve the problems of high sludge viscosity and inability to flow out of sludge, and achieve the effects of accelerating separation, improving bag breaking efficiency, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

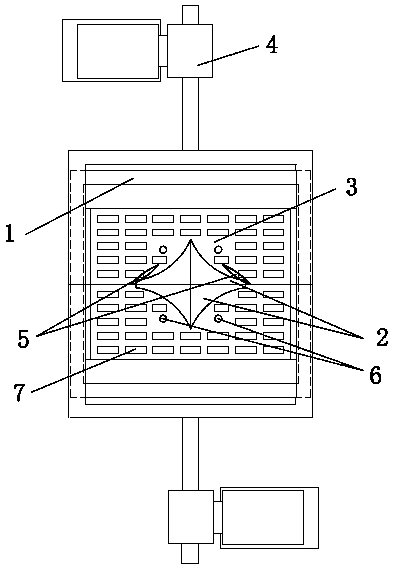

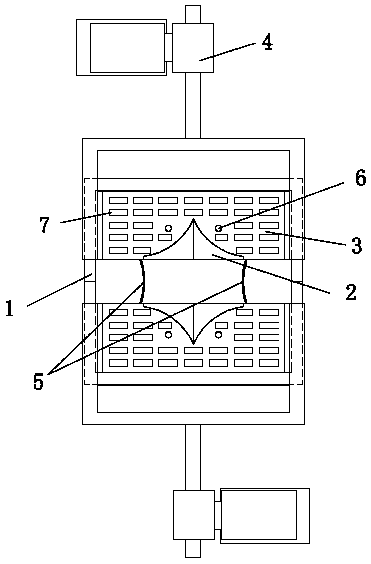

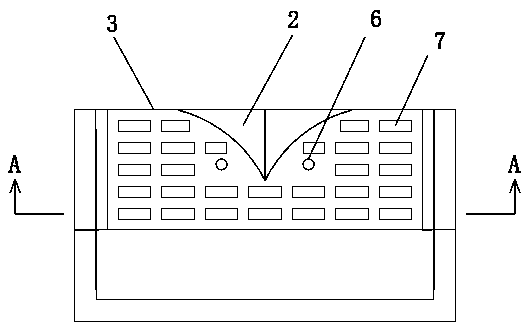

[0025] Such as figure 1 , figure 2 As shown, the oilfield sludge woven bag breaking device of the present invention includes a frame 1, on which a number of support plates 3 are arranged, and both sides of the support plate 3 are provided with slide rail grooves so that the support plate 3 can be moved along the Frame 1 is used for plane sliding. In this embodiment, there are two support plates 3, each of which is driven by an electric push rod 4, and the support plate 3 is driven by the electric push rod 4 to open and close along the frame 1 to make the sludge flow from the support plate. 3 falls between. The support plate 3 is provided with a mud discharge hole 7, most of the oily sludge falls from the space between the support plates 3, and the sludge falling on the support plate 3 falls from the sludge discharge hole 7. Since the support plate 3 is always in the reciprocating motion of opening and closing, the oily sludge can fall from the mud discharge hole 7 more smo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com