Garbage bag breaking machine with functions of bag breaking, avoiding and winding resisting

A bag breaking machine and garbage technology, applied in the field of machinery, can solve the problems of low bag breaking efficiency, slow manual bag breaking speed, and high labor consumption, and achieve ideal effect and high bag breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

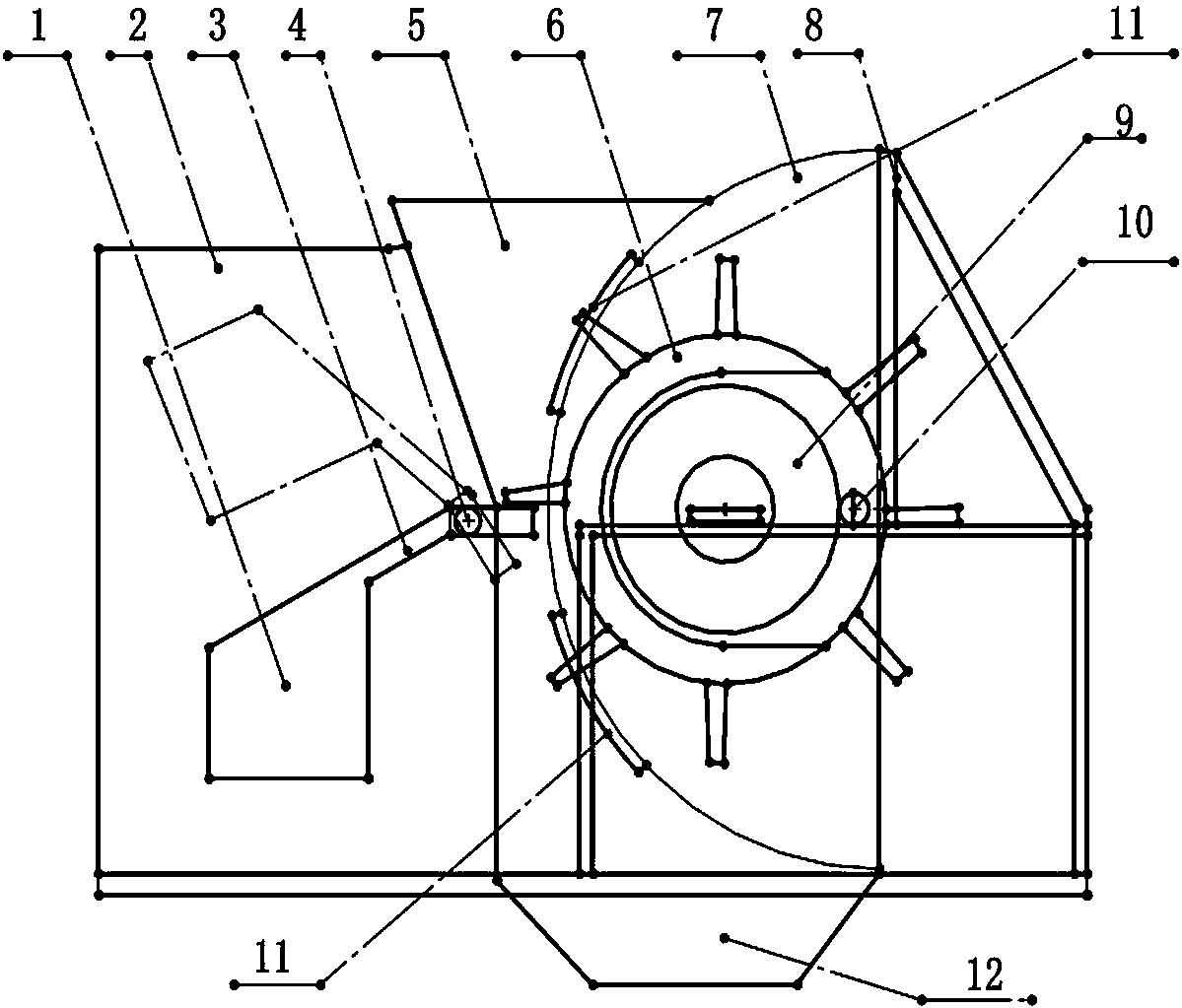

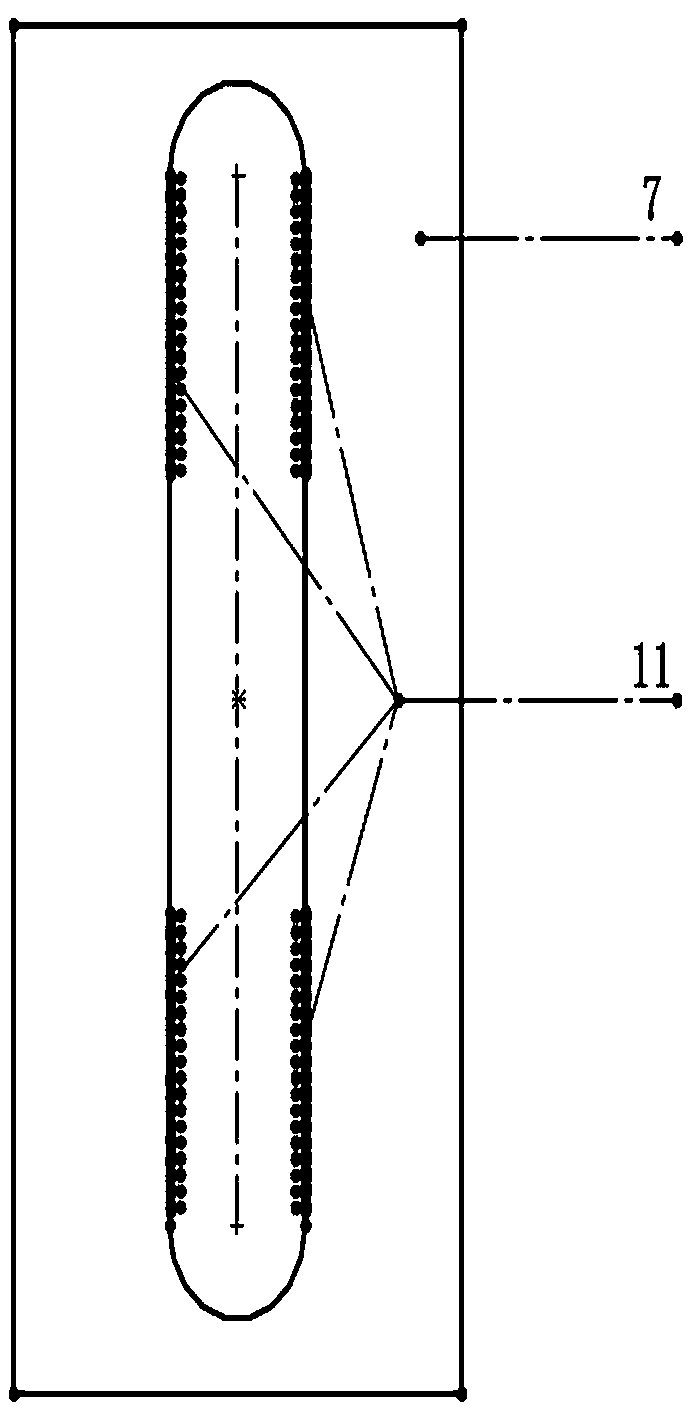

[0012] Embodiment 1: The present invention mainly consists of 1 fixed knife counterweight, 2 fixed knife frame boxes, 3 fixed knife limit support frames, 4 fixed knife combinations, 5 garbage inlet baffles, 6 moving knife combinations, and 7 moving knife counters. It is composed of winding knife guard box, 8 frames, 9 gear combinations, 10 reducer combinations, 11 circular arc anti-winding comb device, and 12 material guide grooves.

[0013] The fixed knife rest box 2 and the moving knife anti-winding knife protection box 7 are installed on the frame 8, and the garbage inlet baffle plate 5 is connected to the fixed knife rest box 2 and the moving knife anti-winding knife protection box 7; The movable knife combination 6, the gear combination 9, the reducer combination 10 and the lower end guide groove 12 are installed on the inner frame 8 of the knife box 7 to form a material channel; the fixed knife combination 4 and the fixed knife limit support are installed in the fixed kni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com