Shearing type bag breaking machine for bagged house refuse

A domestic waste and shearing technology, which is applied in the field of shearing bagged domestic waste bag breaking machines, can solve the problems such as the inability to sort valuable waste, the unsatisfactory bag breaking rate, and the inability to meet the treatment process. , to achieve high bag breaking efficiency, improve waste sorting efficiency, and achieve the effect of broken bag treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

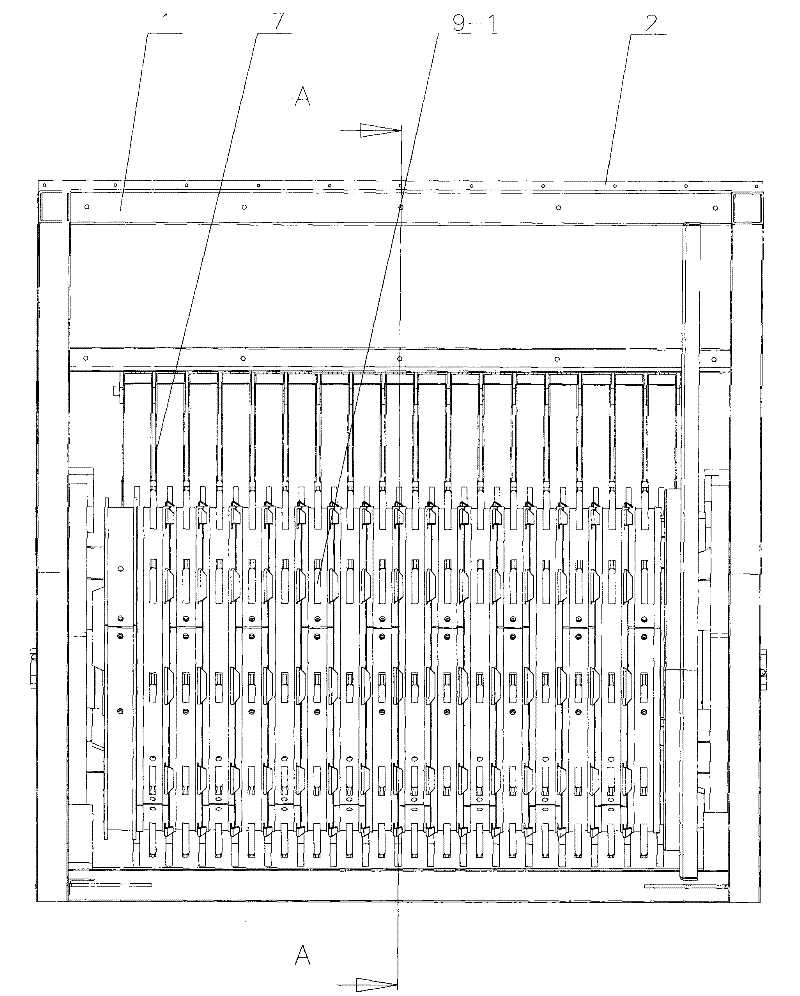

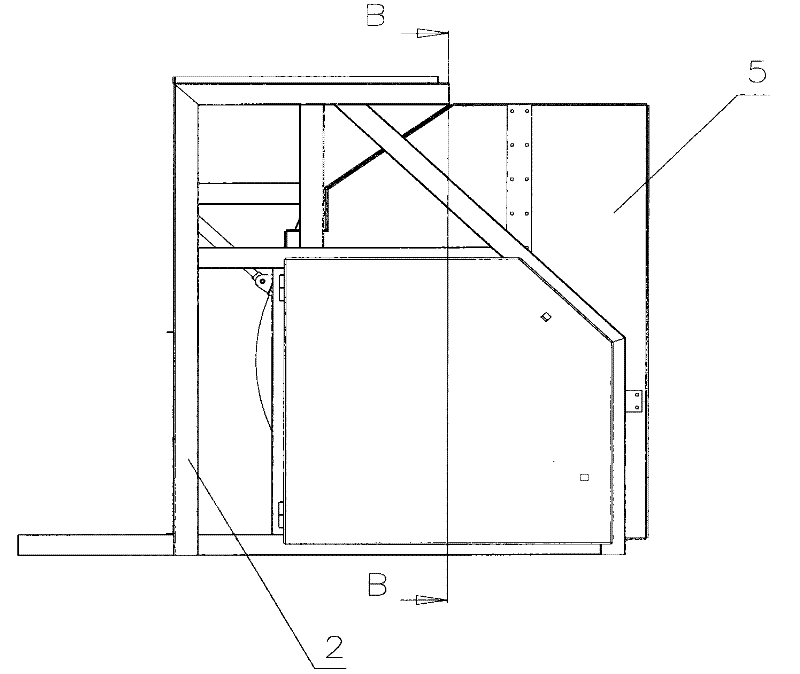

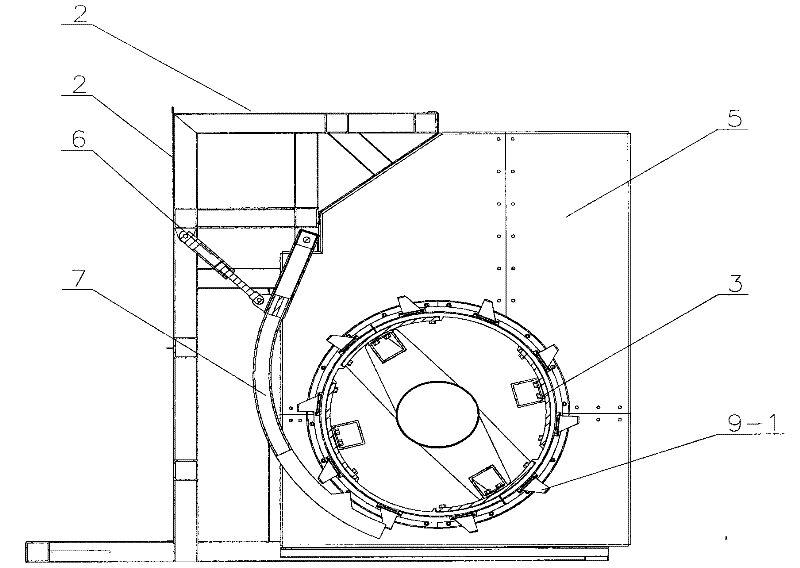

[0022] see figure 1 , The main structure of the present invention is composed of: main frame body 1, protective plate 2, rotating body 3, shearing body 4, fixed knife group, telescopic oil cylinder, driving hydraulic motor 13, motor fixing frame, hydraulic station.

[0023] The main frame body 1 is welded by high-quality square tubes, which has good rigidity and compact structure, and can withstand strong working loads when the system is working.

[0024] On the left and right sides of the main frame body 1, there is respectively a hydraulic motor fixing frame for supporting and fixing the hydraulic motor. The tailstock of the motor is connected with the fixed frame, and the shaft sleeve of the motor driving body and the rotating body 3 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com