Method for recycling and reusing solid waste and glass prepared by using solid waste as raw material

A technology for solid waste and glass, which is applied in the field of glass and glass made from solid waste, and achieves the effects of low cost, high utilization rate, and simple and easy technological process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Directly use waste water to settle solid waste (hereinafter referred to as sediment) to melt glass, and the composition of the weight percentage of sediment includes: SiO 2 : 56.16%, Al 2 o 3 : 21.27%, CaO: 7.03%, Fe 2 o 3 : 0.42%, MgO: 0.31%, Na2 O: 7.42%, K 2 O: 0.12%, SO 3 : 5.32%, La 2 o 3 : 1.95%. The specific production method is as follows:

[0030] A planetary ball mill is used to grind the sediment until the powdery particles pass through a 16-mesh sieve. Put the ground sediment particles into an alumina crucible, heat them in a high-temperature furnace to 1350°C and 1400°C respectively, keep them warm for 1-2 hours, then pour them into a mold, and anneal them in an annealing furnace at 650-700°C1 -2h, cool down to room temperature with the furnace.

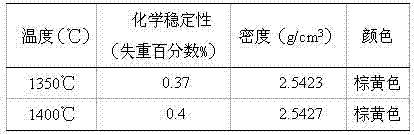

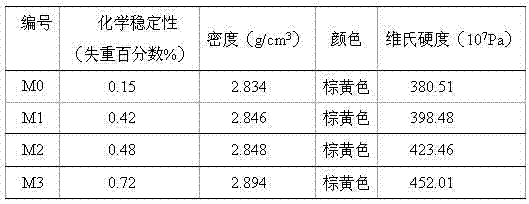

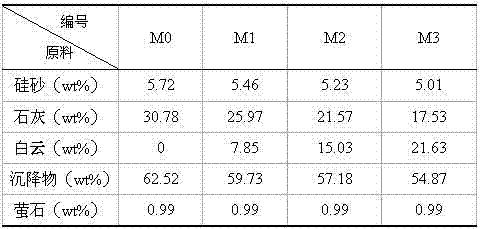

[0031] The performance indicators of the glass obtained at different melting temperatures are as follows:

[0032]

Embodiment 2

[0034] Directly use waste water to settle solid waste (hereinafter referred to as sediment) to melt glass, and the composition of the weight percentage of sediment includes (wt%): SiO 2 : 46.16%, Al 2 o 3 : 24.27%, CaO: 6.03%, Fe 2 o 3 : 0.45%, MgO: 0.32%, Na 2 O: 9.42%, K 2 O: 0.15%, SO 3 : 8.32%, La 2 o 3 : 1.96%, C u O: 0.98%, Ni 2 o 3 : 0.94%. The specific production method is as in Example 1, and the properties of the glass obtained are similar to those in Example 1.

Embodiment 3

[0036] Glass is manufactured according to the composition formula in Example 1. The difference is that the preparation method is: grind the sediment to powdery particles, heat the ground sediment particles to 1500° C., and keep the temperature for 1 hour. The obtained glass liquid is obtained by using water The quenching method is directly made into glass powder. The obtained glass powder can be used as a raw material for glass manufacturing, or as a raw material for other fields such as ceramic glaze and sintered glass-ceramics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com