Application of a kind of crystalline silicon cutting waste in the preparation of colored glass and the resulting product

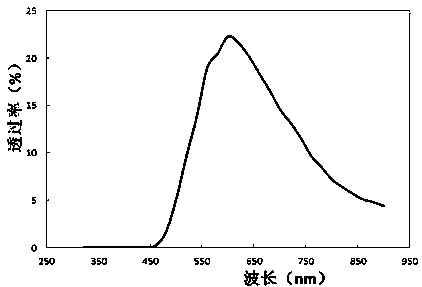

A technology of cutting waste and crystalline silicon, which is applied to the new application field of crystalline silicon cutting waste in the preparation of ultraviolet-absorbing color glass and crystalline silicon cutting waste, which can solve the problems of insufficient utilization of waste, complicated preparation process, and high cost, and achieve reduction Effects of stockpiling and environmental protection, high chemical stability, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

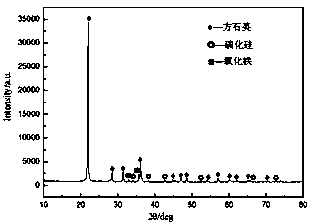

[0045] The design composition of colored glass is (wt%): silicon dioxide: 54.10%, sodium oxide: 21.47%, calcium oxide: 11.71%, iron oxide: 4.50%, aluminum oxide: 1.95%, magnesium oxide: 3.90%, nitric acid Sodium: 1.17%, Antimony Trioxide: 0.20%, Calcium Fluoride: 1.00%.

[0046] The preparation method of colored glass is:

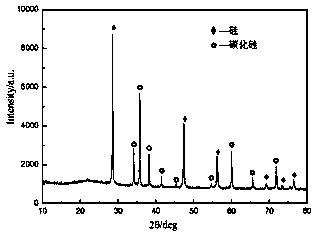

[0047] (1) Pretreatment of cutting waste: Put the cutting waste into a high-temperature furnace, heat it up to 300°C for 2 hours in an air atmosphere, and then raise it to 1450-1500°C for 2 hours to complete the pretreatment. After pretreatment, the pretreated cutting waste was added to a planetary ball mill, ground for 30 minutes at a speed of 250 r / min, and then passed through a 200-mesh sieve for subsequent use.

[0048] (2) According to the design and composition of colored glass, 60g of pretreated cutting waste is used as raw material, and silicon dioxide, sodium carbonate, calcium oxide, aluminum oxide, magnesium oxide, sodium nitrate, antimony triox...

Embodiment 2

[0052] The design composition of colored glass is (wt%): silicon dioxide: 74%, sodium oxide: 6.41%, calcium oxide: 8%, iron oxide: 6.16%, aluminum oxide: 1%, magnesium oxide: 2%, nitric acid Sodium: 1.20%, antimony trioxide: 0.20%, calcium fluoride: 1.03%.

[0053] The preparation method of colored glass is:

[0054] (1) Pretreatment of cutting waste: Put the cutting waste into a high-temperature furnace, heat it up to 300°C for 2 hours in an air atmosphere, and then raise it to 1450-1500°C for 2 hours to complete the pretreatment. After pretreatment, the pretreated cutting waste was added to a planetary ball mill, ground for 30 minutes at a speed of 250 r / min, and then passed through a 200-mesh sieve for subsequent use.

[0055] (2) According to the design and composition of colored glass, 49.3g of pretreated cutting waste is used as raw material, and silicon dioxide, sodium carbonate, calcium oxide, aluminum oxide, magnesium oxide, sodium nitrate, antimony trioxide, and cal...

Embodiment 3

[0058] The design composition of colored glass is (wt%): silicon dioxide: 55.87%, sodium oxide: 20.47%, calcium oxide: 11.16%, iron oxide: 4.65%, aluminum oxide: 1.86%, magnesium oxide: 3.72%, nitric acid Sodium: 1.12%, antimony trioxide: 0.19%, calcium fluoride: 0.96%.

[0059] The preparation method of colored glass is:

[0060] (1) According to the design and composition of colored glass, 40g of untreated cutting waste is used as raw material, and silicon dioxide, sodium carbonate, calcium oxide, aluminum oxide, magnesium oxide, sodium nitrate, antimony trioxide, and calcium fluoride are added as raw materials. Raw materials, the weight percentage of each raw material is as follows: cutting waste: 35.26%, silicon dioxide: 0%, sodium carbonate: 46.72%, calcium oxide: 10.58%, aluminum oxide: 1.76%, magnesium oxide: 3.53%, sodium nitrate : 1.06%, antimony trioxide: 0.18%, calcium fluoride: 0.91%.

[0061] (2) Put the cutting waste into the planetary ball mill, grind for 30 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com