Recycling method for high-chlorine heavy metal sludge

A heavy metal sludge and recycling technology, applied in the granulation method of raw materials, chemical instruments and methods, sludge treatment and other directions, can solve the problems of easy oxidation failure, frequent regeneration, large processing capacity of ion exchangers, etc. The effect of realizing resource utilization and improving recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

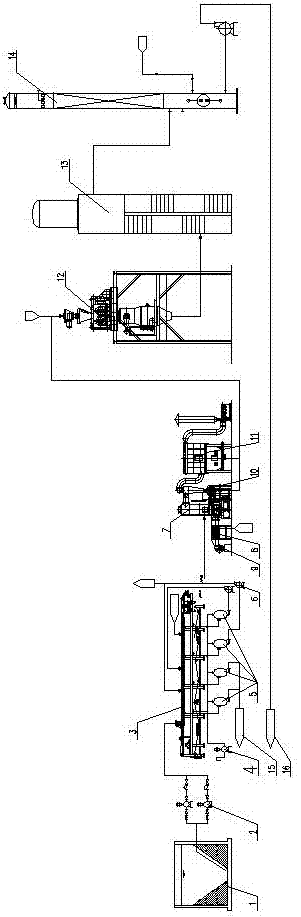

[0020] Such as figure 1 As shown, the invention discloses a resource treatment method for high-chlorinated heavy metal sludge

[0021] The method is characterized in that: comprising the steps of:

[0022] 1) Salt washing: The sludge pump 2 transports the high-chlorinated heavy metal sludge in the sludge concentration tank 1 to the vacuum belt dehydrator 3, and the cleaning water sprayed by the spray system on the top of the vacuum belt dehydrator The chlorinated heavy metal sludge is washed to obtain brine, and the amount of washing water is 3 to 7 times that of the high-chlorinated heavy metal sludge. At the same time, the water in the high-chlorinated heavy metal sludge is removed through the vacuum belt dehydrator 3 to obtain a moisture content of 30-50. % dewatered sludge;

[0023] Among them, the high chloride heavy metal sludge in the sludge thickening tank 1 has a water content of 85-90% and a chloride salt content of 15-25%.

[0024] 2) Drying: the dewatered sludge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com