Garbage bag breaking machine and bag breaking method using it

A bag breaking machine and garbage technology, which is applied in the unsealing, packaging, transportation and packaging of objects, can solve the problems of low efficiency, heavy workload, and inability to effectively break bags, so as to save labor and reduce the cost of bag breaking , High bag breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

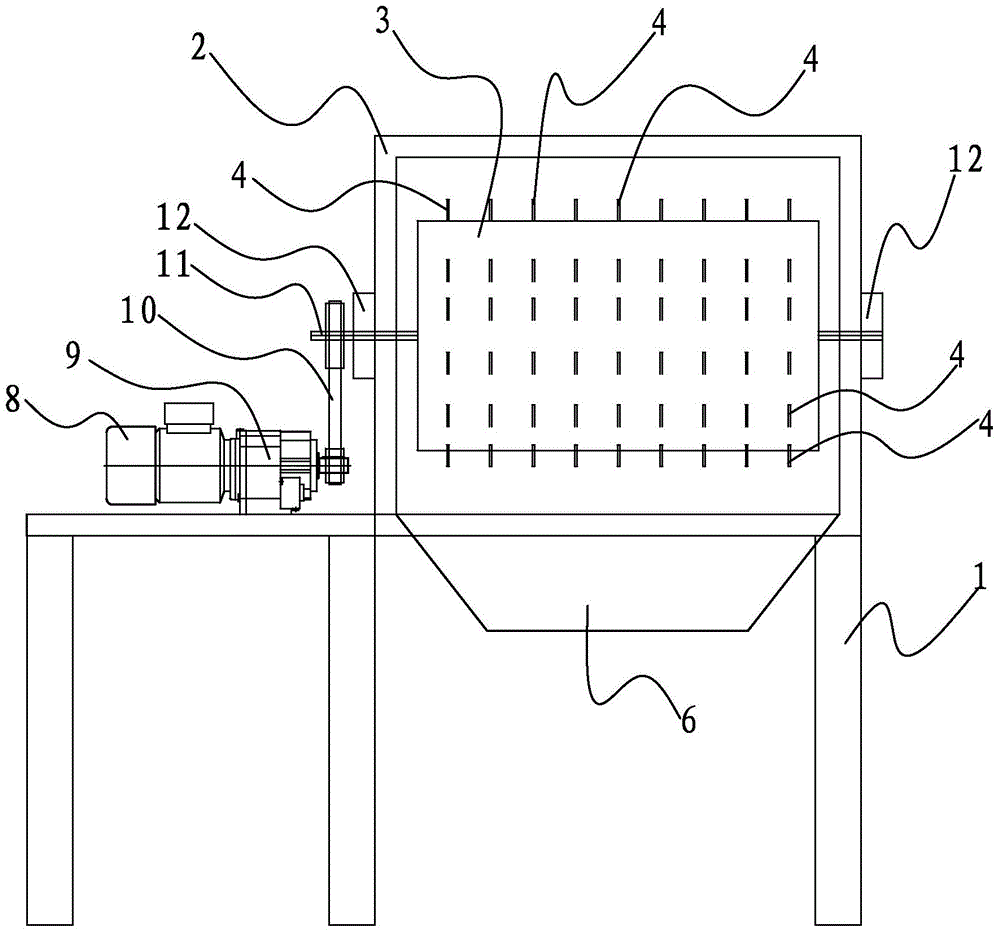

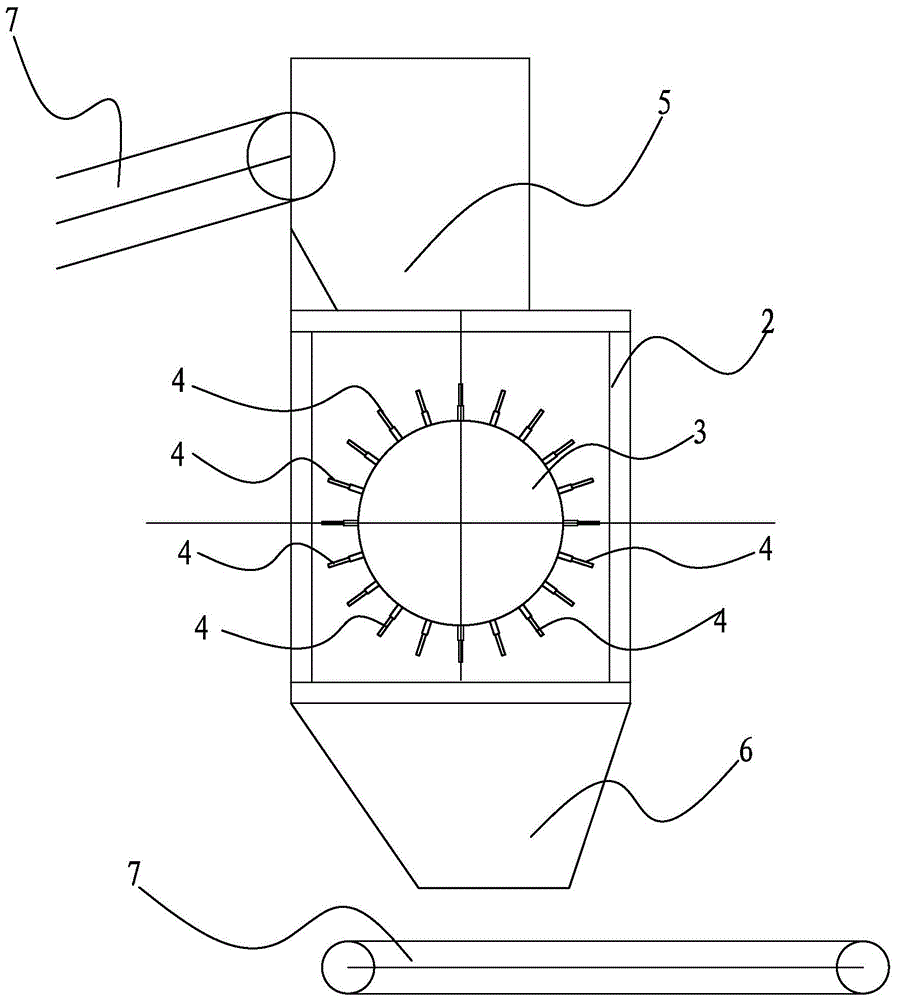

[0028] The following with attached figure 1 and figure 2 A garbage bag breaking machine of the present invention and a bag breaking method using it are further described in detail.

[0029] A garbage bag breaking machine of the present invention, please refer to figure 1 and figure 2 , comprising a bracket 1, a casing 2 arranged on the bracket 1, and a rotatable drum 3 with a rotational speed of at least 60 revolutions per minute arranged in the casing 2, and a gap is formed between the casing 2 and the drum 3 , the upper ring of the outer wall of the drum 3 is provided with at least ten rows of steel whip groups, each row of steel whip groups has at least five steel whips 4, the top of the housing 2 is provided with a feed port 5, and the bottom of the housing 2 A discharge port 6 is provided, and the drum 3 is connected with a driving device. Like this, during the process that the bagged garbage falls from the feed port 5, the driving device drives the drum 3 to rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com