A garbage disposal bag breaking machine

A technology of garbage disposal and bag breaking machine, which is applied in grain processing, packaging, cutting and unsealing, etc., and can solve problems such as blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

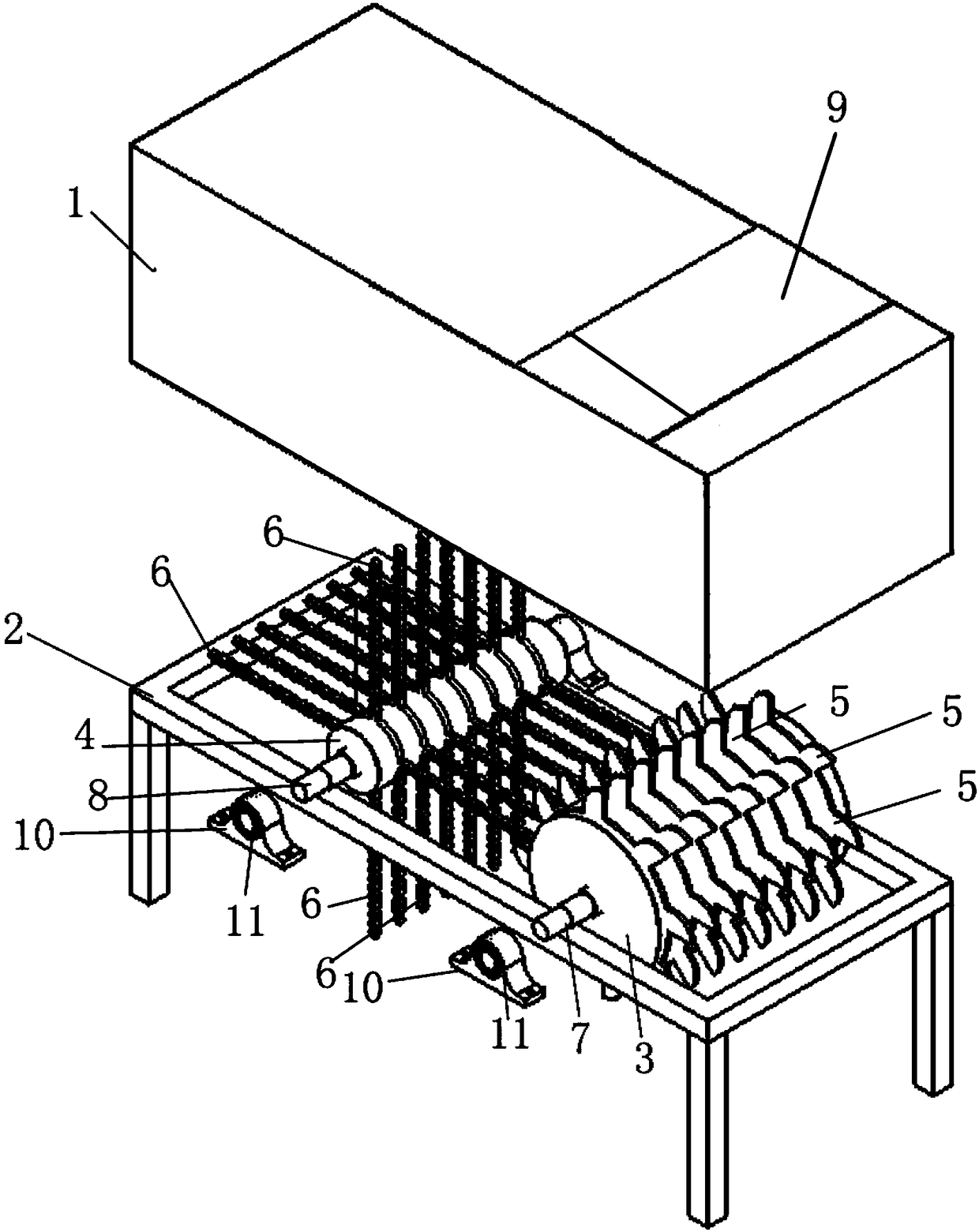

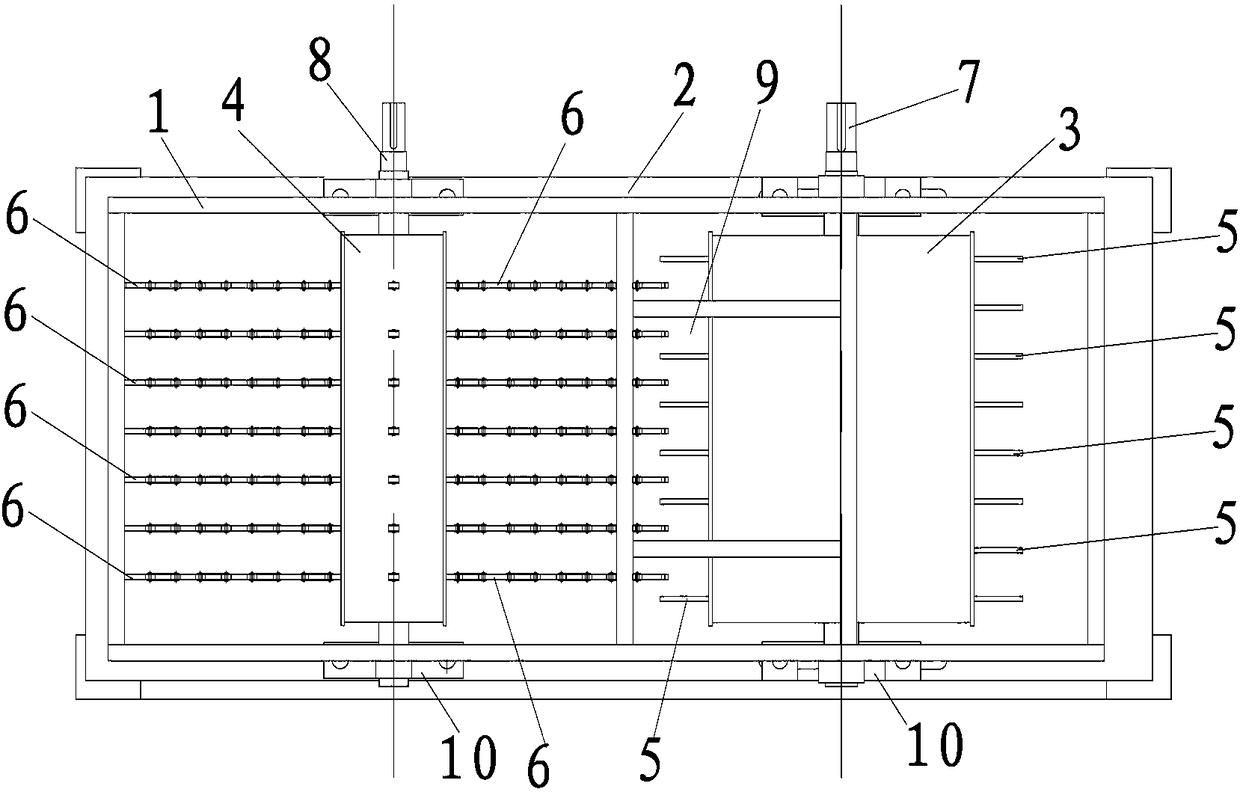

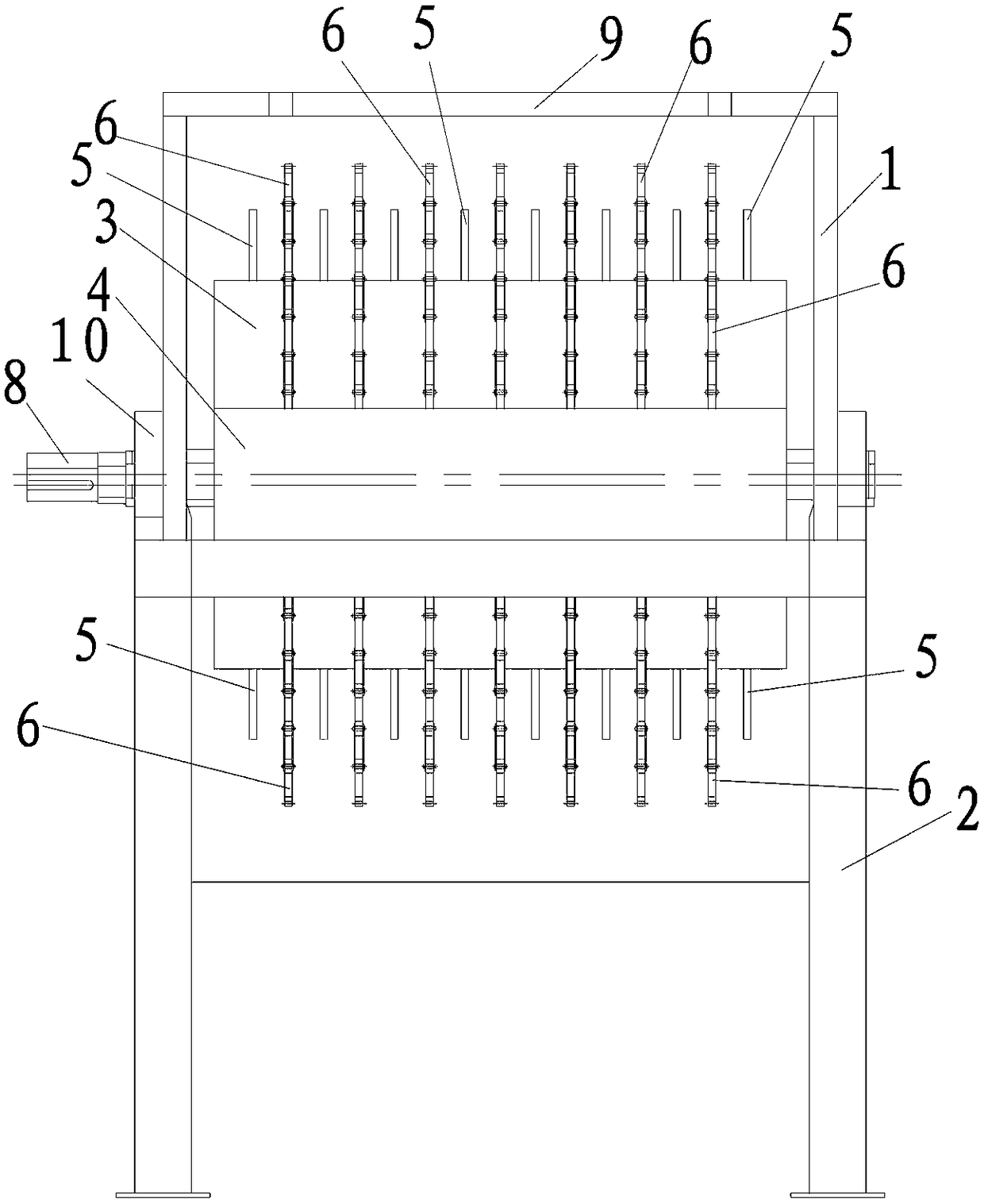

[0027] Below in conjunction with the drawings Figure 1 to Figure 3 The garbage disposal bag breaking machine of the present invention will be further described in detail.

[0028] The garbage disposal bag breaking machine of the present invention, please refer to Figure 1 to Figure 3 The relevant figures include a main body bracket 2, a casing 1 arranged on the main body bracket 2, and a main roller 3 and a sub-roller 4 arranged in the casing 1 with a rotational speed of at least 300 revolutions per minute. The main roller 3 is axially parallel to the auxiliary roller 4 and is detachably and rotatably arranged on the main body support 2. The auxiliary roller 4 and the main roller 3 are respectively arranged on the left and right sides of the main body support 2 in the housing 1 A gap is formed between the casing 1 and the main roller 3 and the auxiliary roller 4, the rotation direction of the main roller 3 and the auxiliary roller 4 is opposite to each other, and the outer wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com