Finger joint device for bamboo piece jointing in length

A technology of bamboo slices and components, applied in mechanical equipment, sugarcane machining, etc., can solve problems such as uneven force, cumbersome manual splicing, poor splicing quality, etc., and achieve stable performance and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

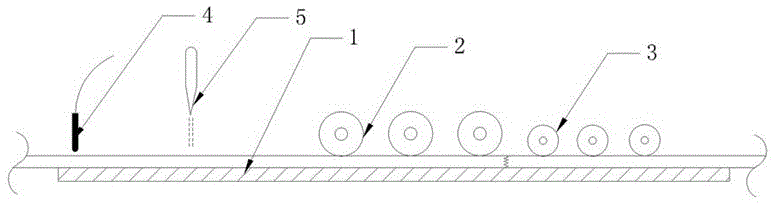

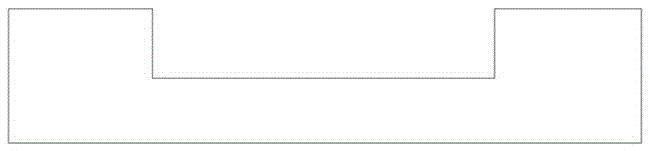

[0018] like figure 1 and figure 2 The shown finger-joint device for lengthening bamboo slices includes a glue spray assembly and a finger-joint assembly, the glue spray assembly is located in front of the finger-joint assembly, and the finger-joint assembly includes a bamboo slice groove 1, a traveling roller set and a delay roller set, The group of traveling rollers and the group of delaying rollers are located above the bamboo slot, and the group of traveling rollers and the group of delaying rollers respectively comprise two traveling rollers 2 and two delaying rollers 3. In this embodiment, one of the delaying rollers 3 is provided with an unconnected The reserved delay roller of the motor is also provided with a reserved traveling roller not connected to the motor in the traveling roller 2 . The radius of the delay roller 3 is 4cm, the radius of the travel roller 2 is 3cm, both the travel roller 2 and the delay roller 3 are driven by the motor, and the speed of the trav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com