Patents

Literature

92results about How to "Won't go off track" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

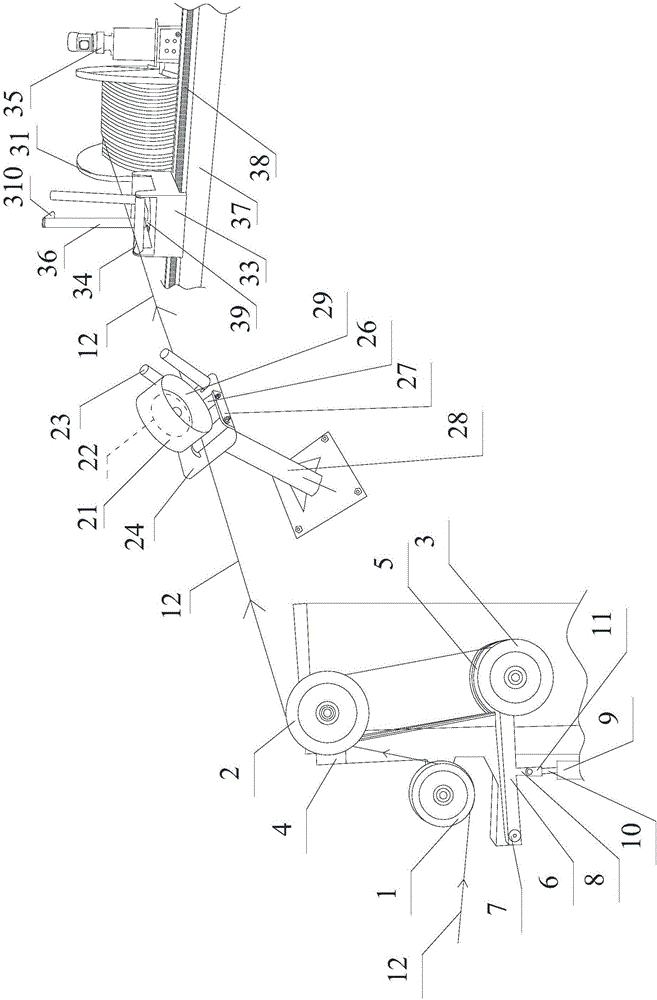

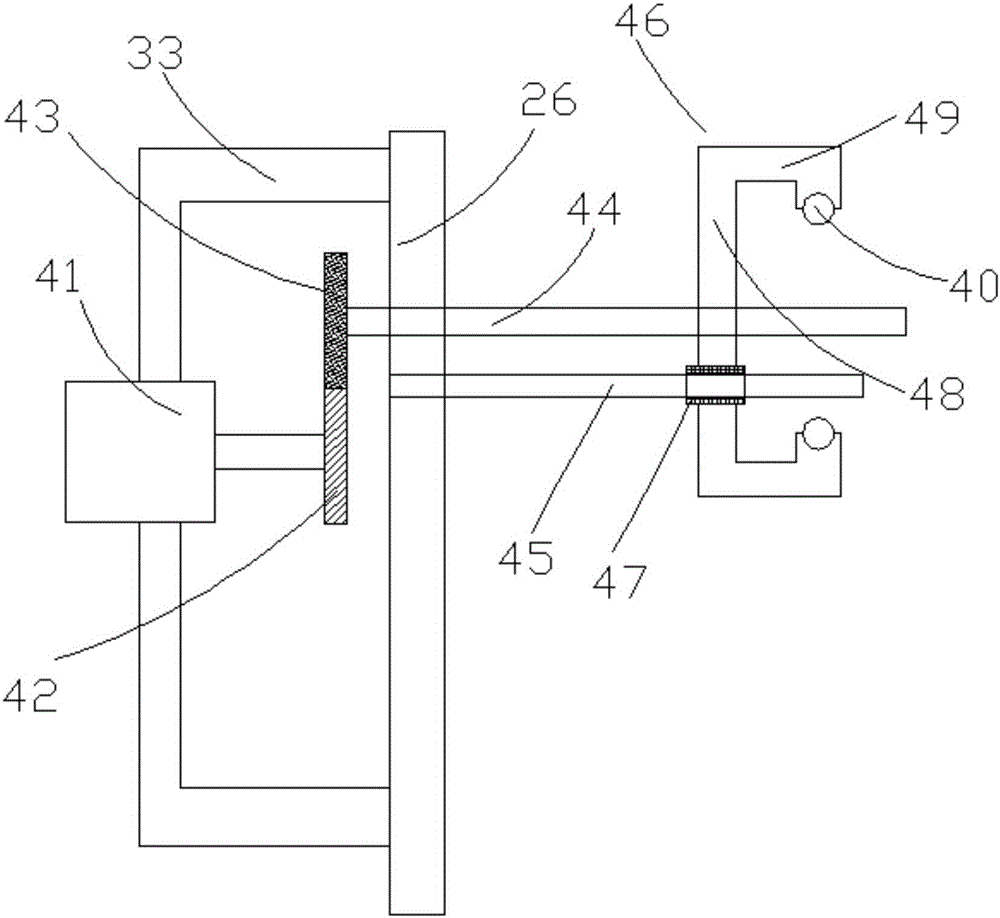

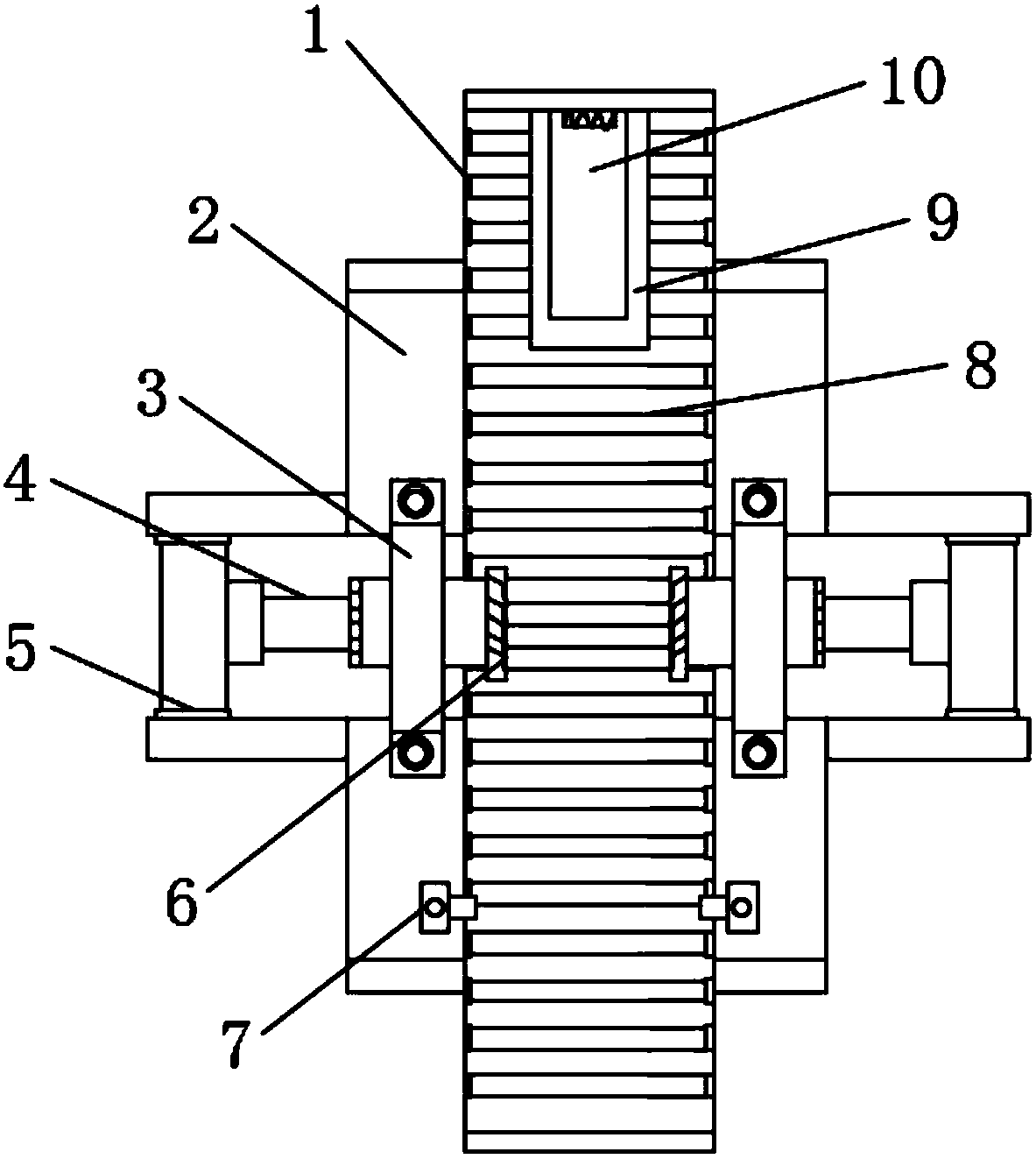

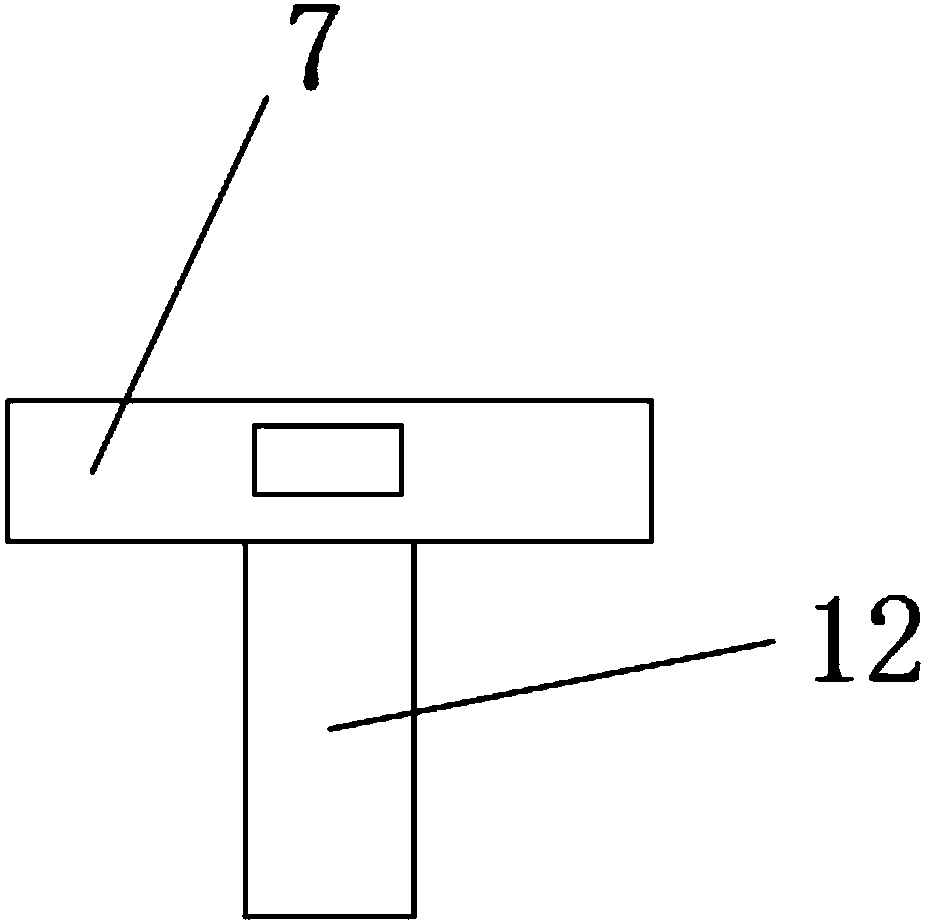

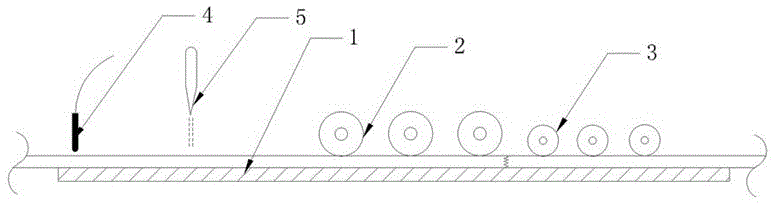

Drawbench

InactiveCN105000429APut an end to the situation where the tension adjustment is not in placeNot tiredFilament handlingEngineeringConductor Coil

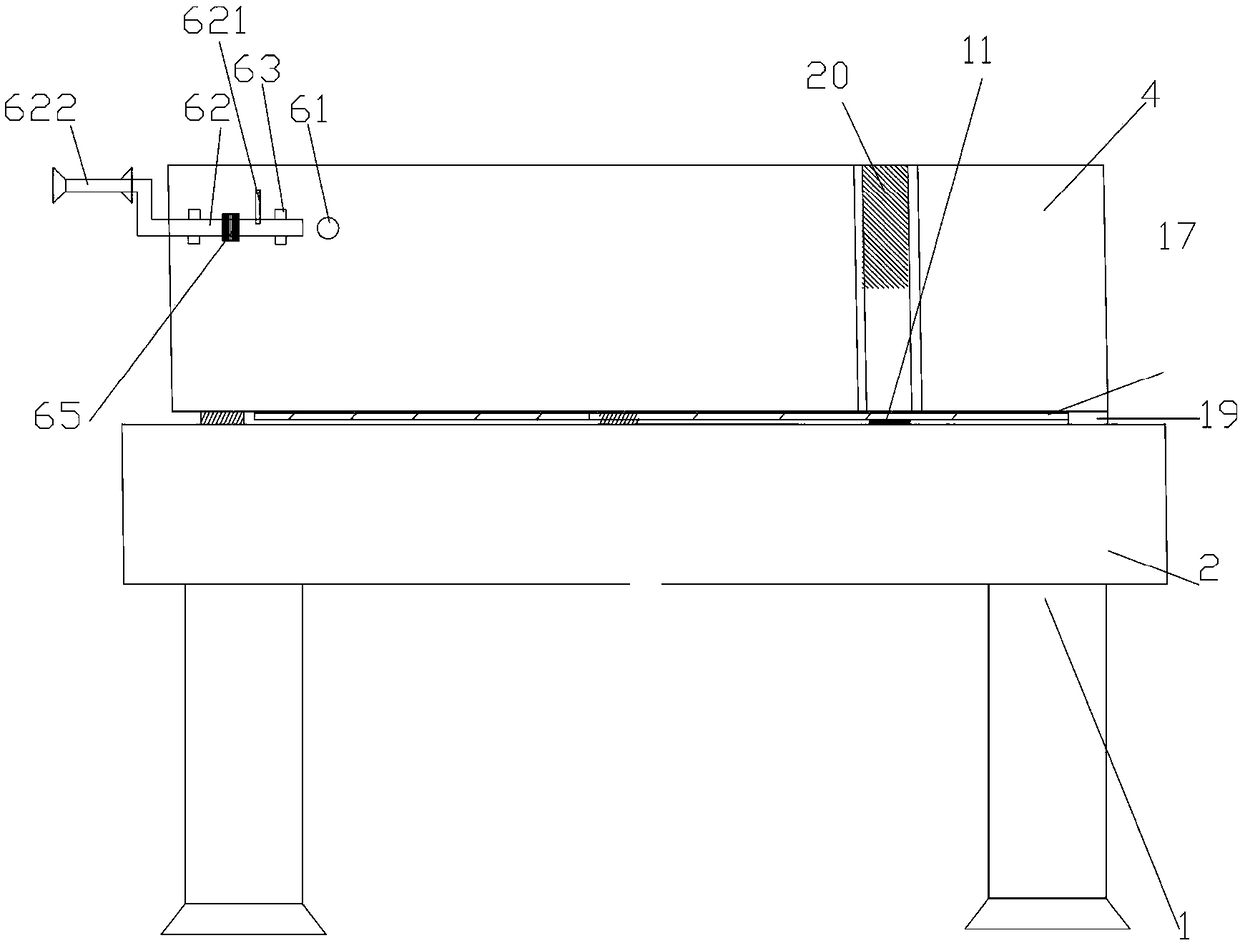

The invention discloses a drawbench which comprises a take-up tension regulating mechanism, a meter counter and a cable arranging frame. The take-up tension regulating mechanism is used for regulating the take-up tension during winding of a cable, the meter counter calculates the meters of the cable, and the cable arranging frame is used for guiding a to-be-wound cable to be wound on a cable winding frame. The cable arranging frame comprises a first rack and a mobile table movably arranged on the first rack. Two vertical columns parallel to each other and a transverse column vertical to the two vertical columns are arranged on the mobile table. The vertical columns and the transverse column are capable of rotating relative to the mobile table. The transverse column is located in front of the two vertical columns, so as to enable the transverse column to guide the to-be-wound cable to penetrate through the place between the two vertical columns to reach the cable winding frame. A guide rail parallel to the transverse column is arranged on the first rack, and the mobile table is clamped on the guide rail and can move along the guide rail. According to the drawbench provided by the invention, the cable can move orderly; the transverse columns can effectively reduce the friction force of the cable on the mobile table, ensure the normal walking of the cable, and also play a role in supporting the cable; the two vertical columns do not influence the walking of the cable, and can limit the cable on the mobile table very well.

Owner:ANQING SUN & MOON CABLE

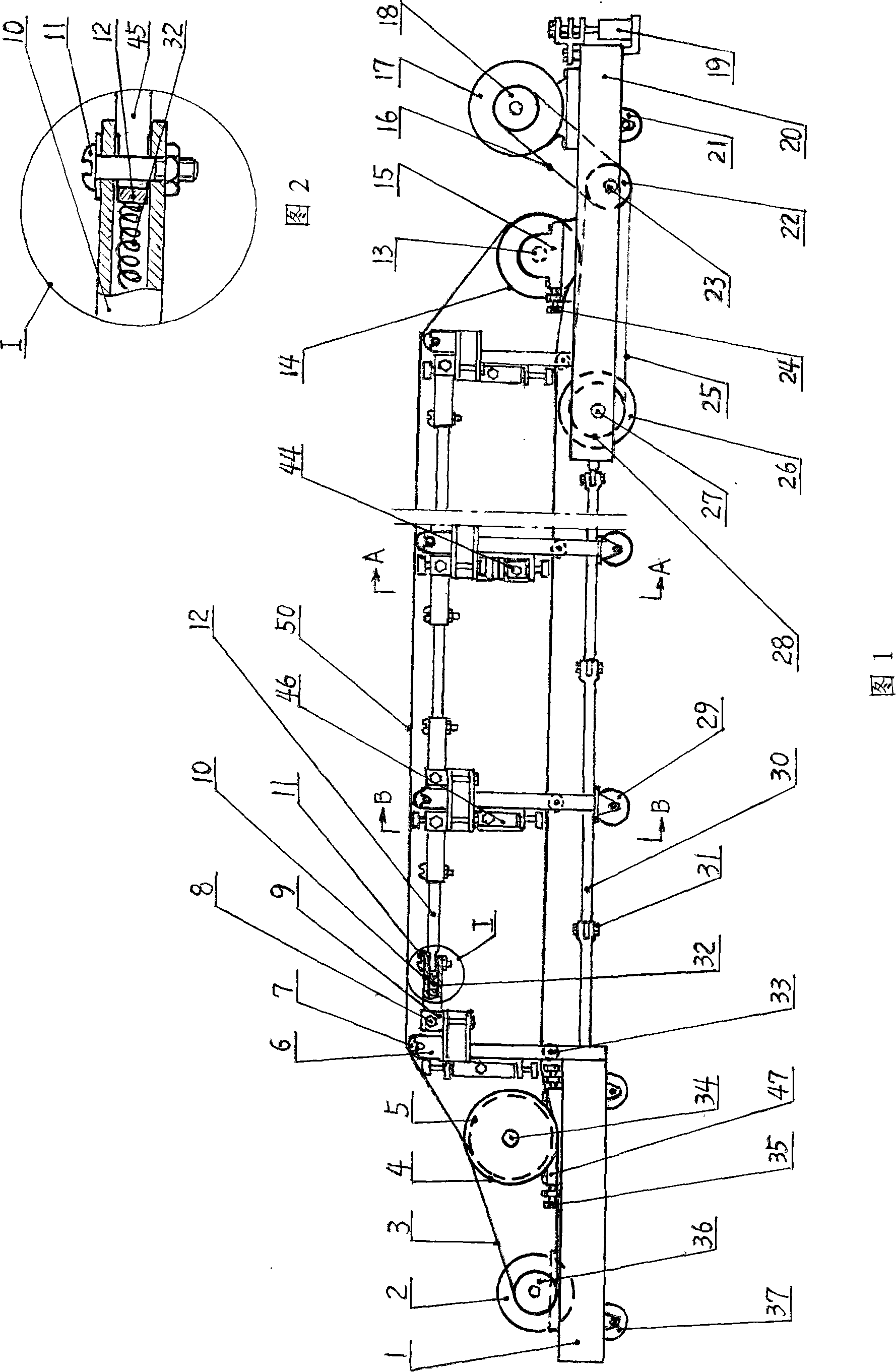

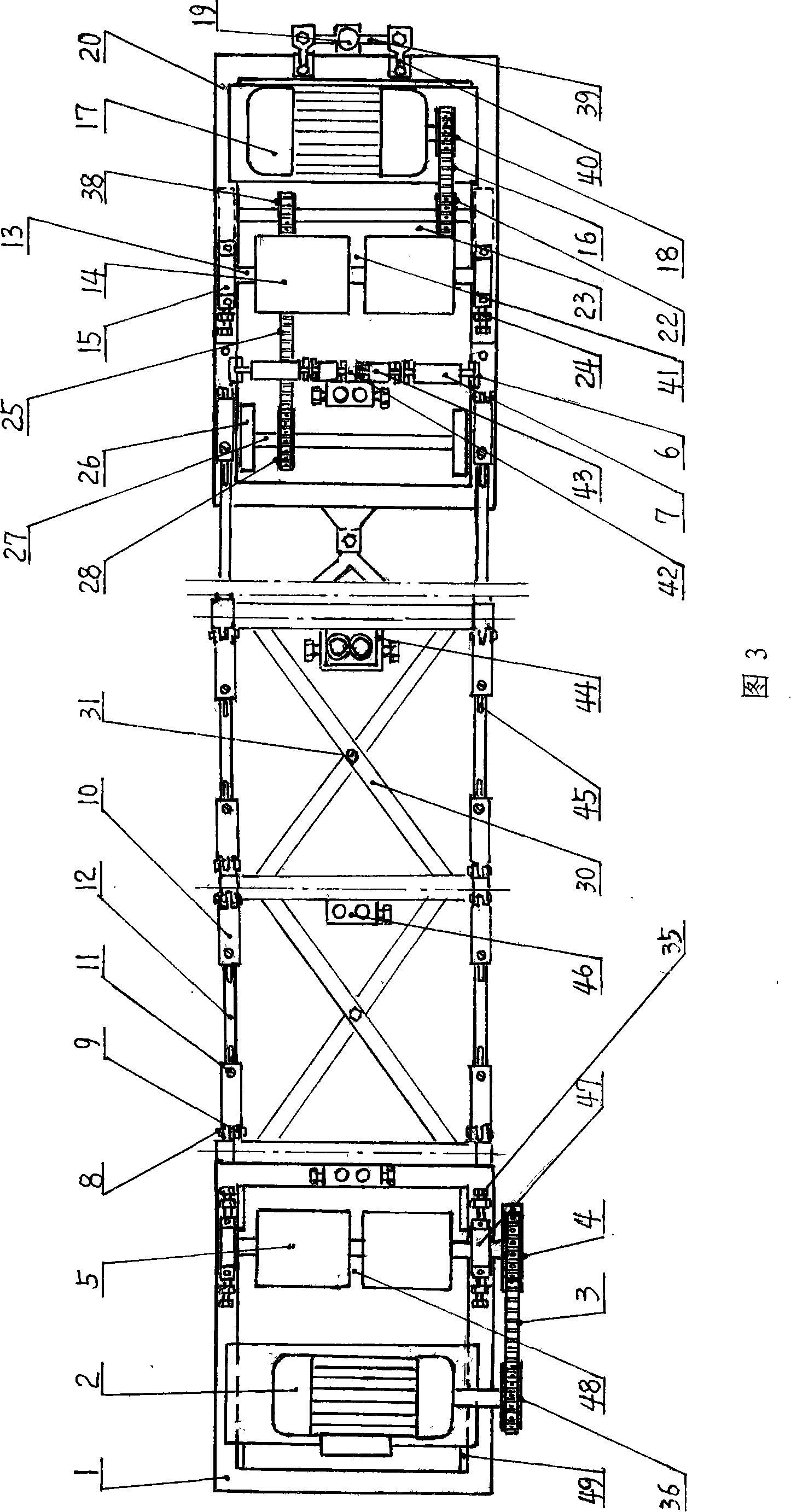

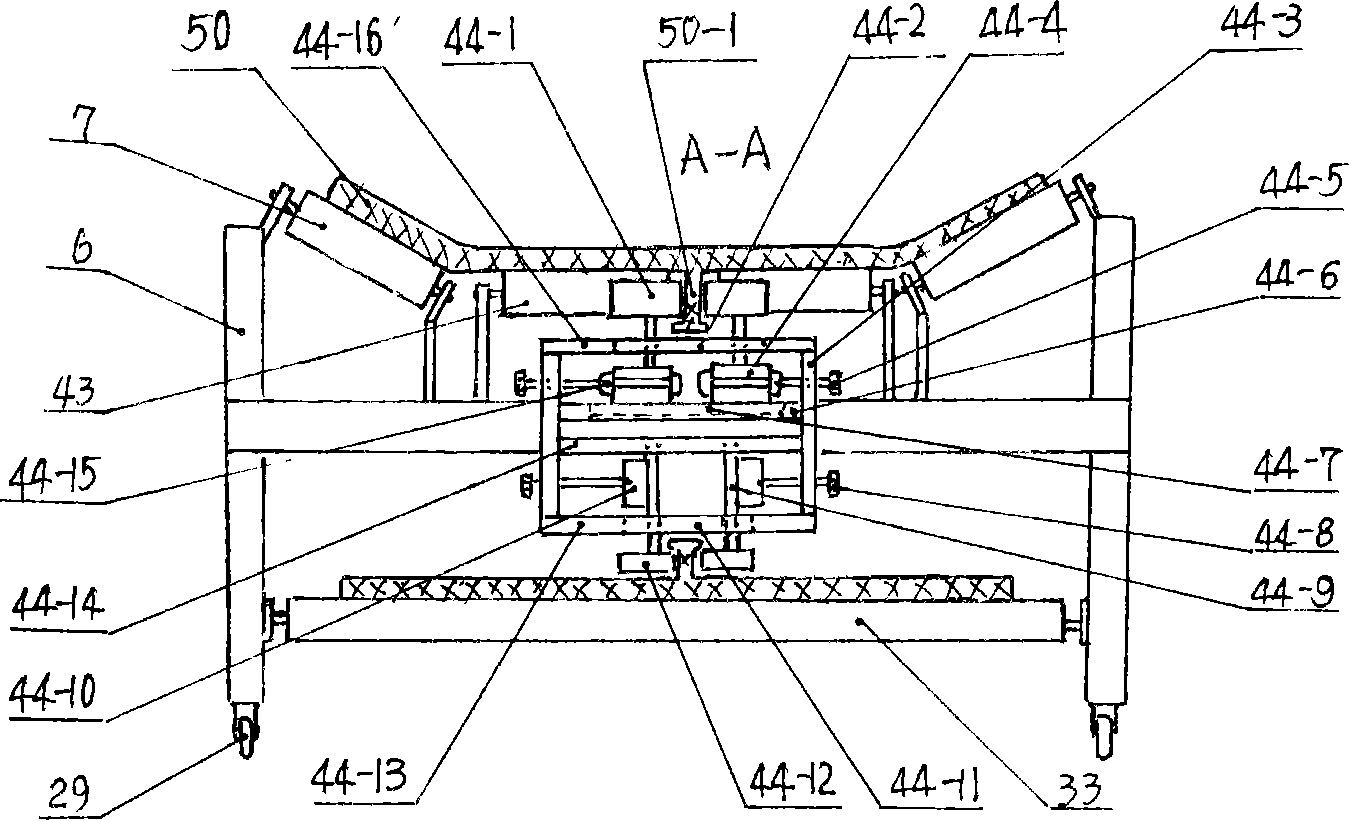

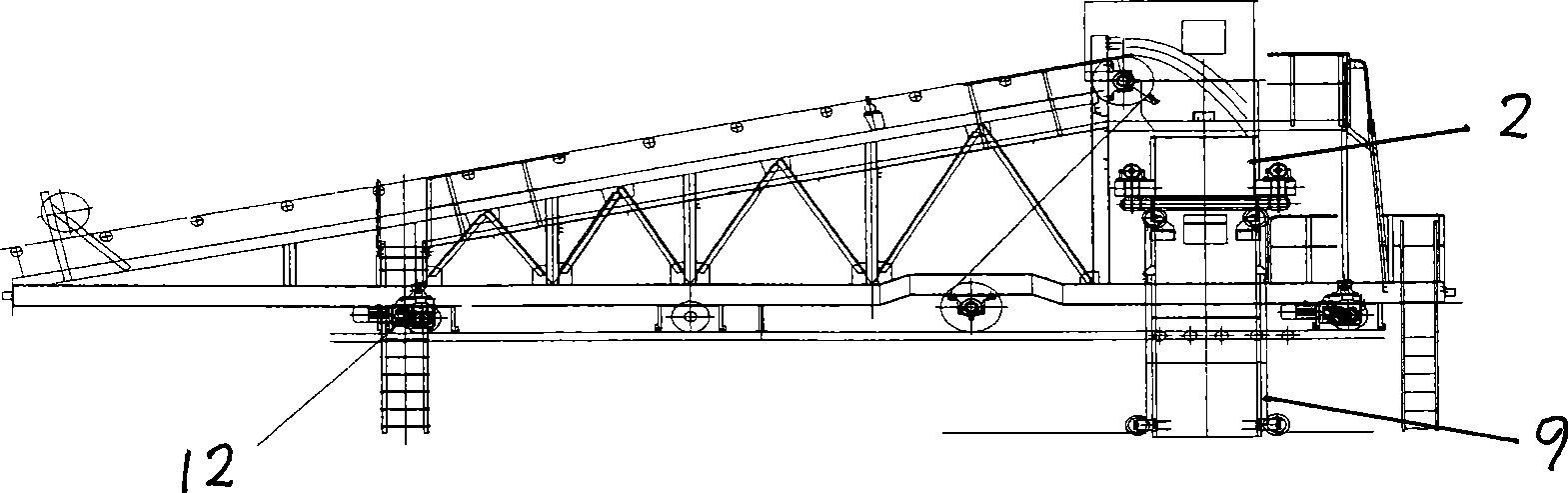

Multi-drive mobile adhesive tape conveyor capable of bending at will

The invention belongs to transportation machinery, in particular to an arbitrarily curved multi-drive mobile belt conveyor suitable for bulk material transportation, which consists of a head frame (1), a tail frame (20), a main motor (2), and a travel motor ( 17), idler frame (6), lower idler roller (33) and adhesive tape (50), a driving roller shaft (34 ), two driving drums (5) are fixed on the driving drum shaft (34), a driving drum groove (48) is left between the driving drums (5), and a machine head row wheel (37) is installed under the head frame (1) ;The belt conveyor can be bent at any number of points in the vertical and horizontal directions, and has strong adaptability; the belt will not deviate. Due to the multi-point drive, the tension of the belt is reduced, so the use level of the belt will be reduced, the initial investment cost will be reduced, and the use of the belt will be extended. Long life, improve transportation efficiency; it can move by itself and bend at will.

Owner:内蒙古瑞隆重工装备制造有限公司

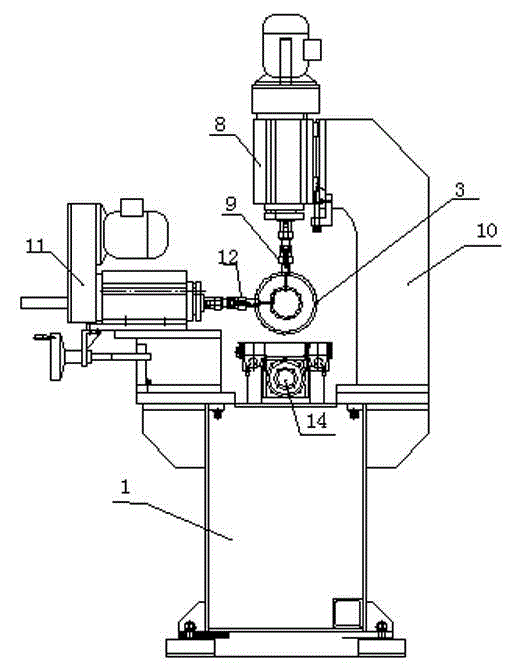

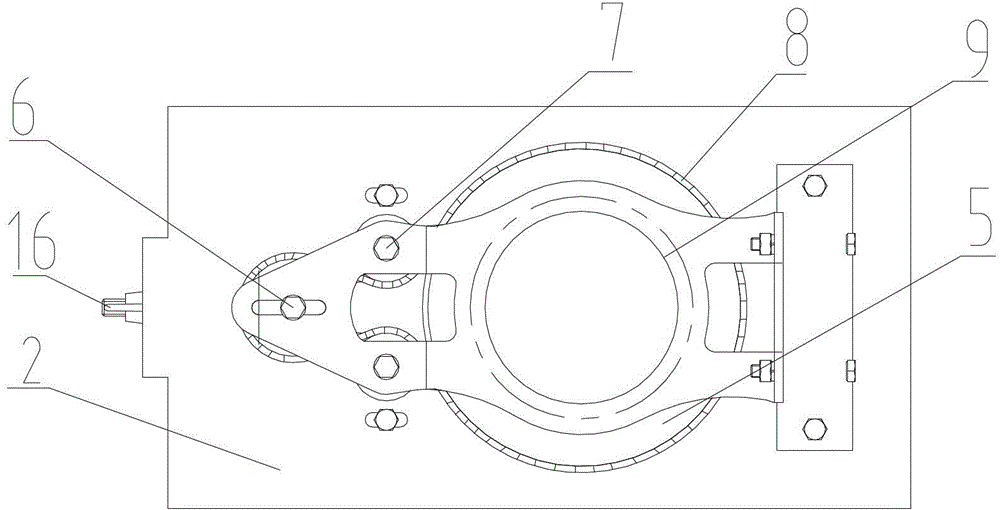

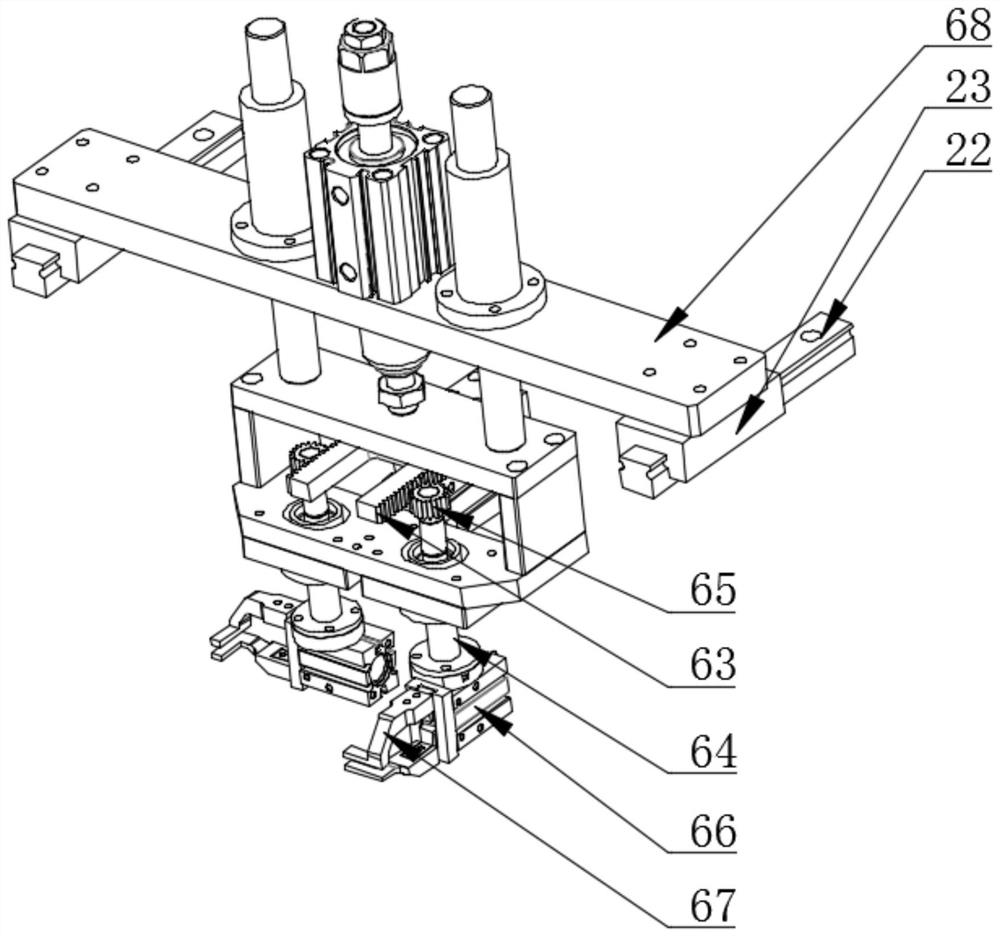

Valve lock clamp groove rolling device

The invention provides a valve lock clamp groove rolling device. The valve lock clamp groove rolling device comprises a driving mechanism, a first rolling wheel, a second rolling wheel, a valve support frame and a controller, wherein the controller is connected to a first driving device and is used for controlling the rotational speed of a first driving gear; the first rolling wheel and the second rolling wheel are symmetrically arranged at the two sides of one end of the valve support frame; the first rolling wheel is connected to the center of the first driving gear through a first transmission shaft; the second rolling wheel is connected to the center of a driven gear through a second transmission shaft; both the first rolling wheel and the second rolling wheel can make feed movements toward the valve support frame; a first ring button for preventing a valve from deviating and a rotating device for driving the valve to rotate are arranged on the valve support frame; and the controller is connected to the rotating device and is used for controlling the rotational speed of the rotating device. The valve lock clamp groove rolling device can be used for machining a lock clamp groove to obtain relatively good surface roughness, causes the surface of the lock clamp groove to be smooth and flat and prolongs the service life of the lock clamp groove.

Owner:安徽鼎立智能制造股份有限公司

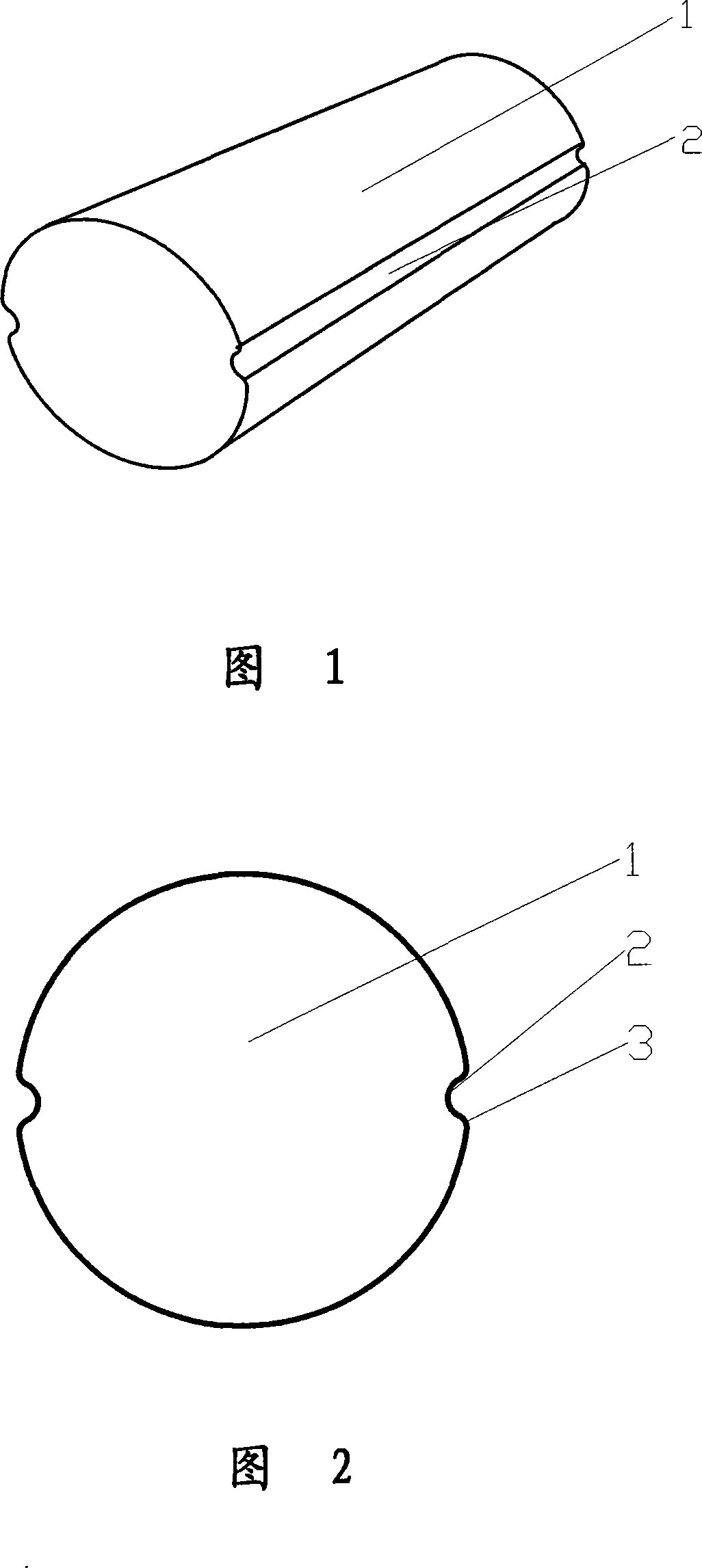

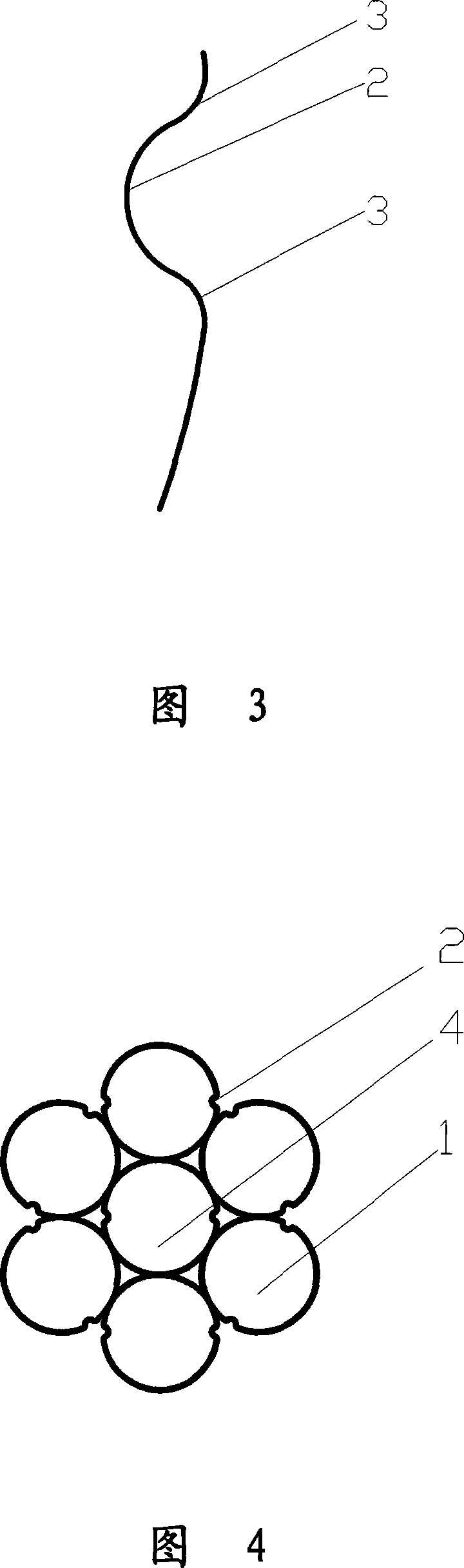

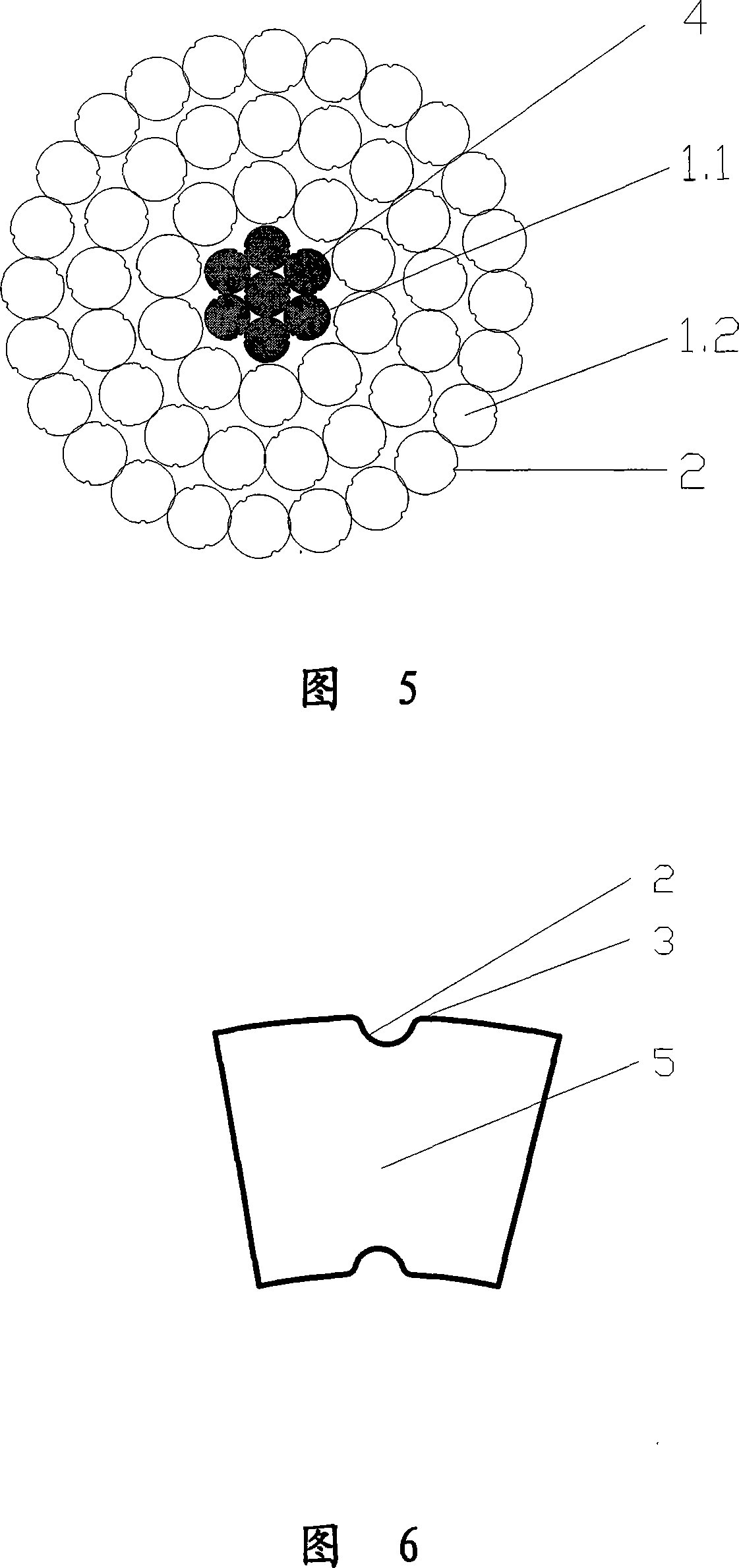

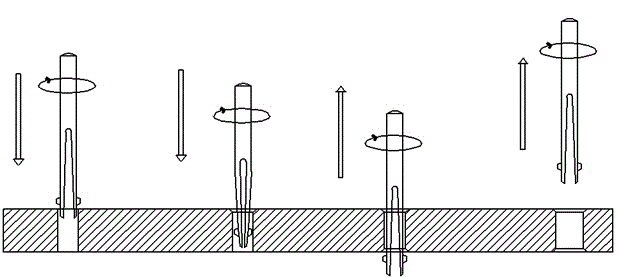

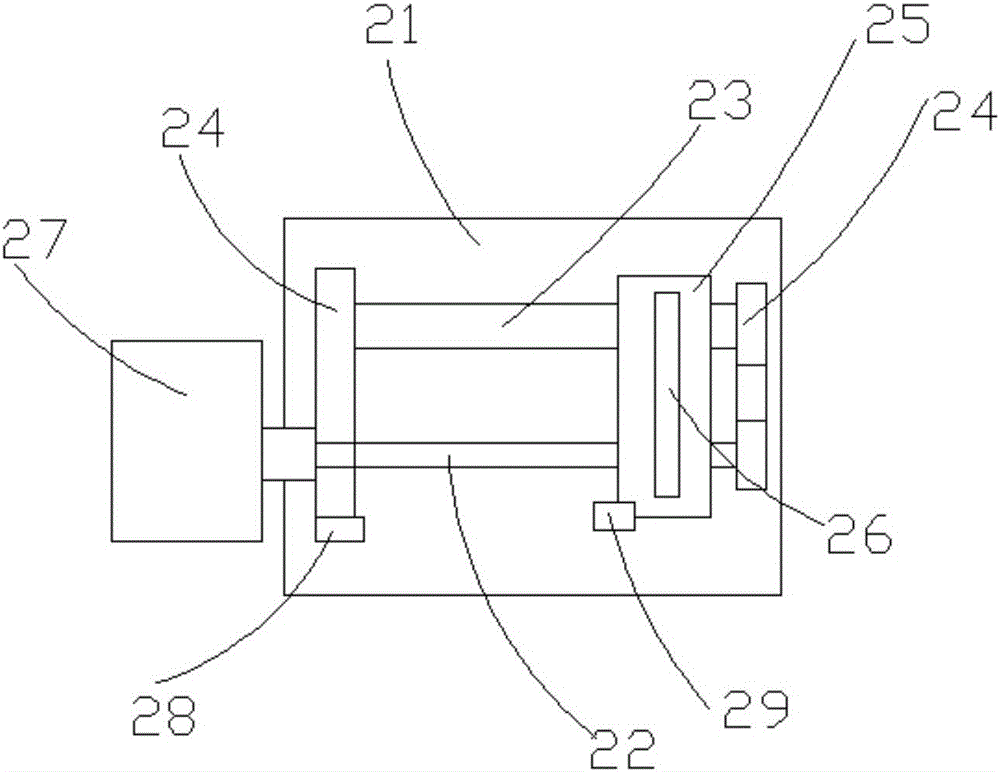

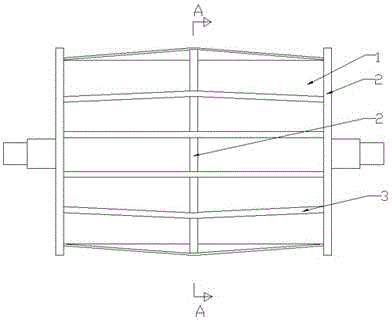

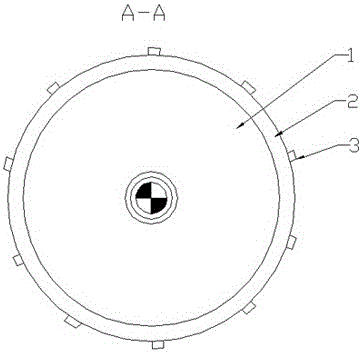

Electric cable and its conductor with recognition function, method and forming device for manufacturing the same

ActiveCN101131888AWill not affect the normal service lifeDoes not affect section shapeNon-insulated conductorsInsulated cablesElectrical conductorElectric cables

The present invention relates to a kind of cable conductor of recognition function, the preparation method of such a cable and conductor, and their forming device. The conductor has the characteristic of over one grooves on the single conductor surface extend along axial direction of the conductor. The grooves which can be formed through roller pressing are both easy in process and unique in recognition. It is very easy to recognize when the stolen cable being stored and sold, thus the evidence of stealing is provided. In addition, the grooves which are formed on the conductor surface by roller pressing can adapt to high speed of wire traveling. The cable production will have fast speed and high efficiency, and can run with wire twist simultaneously or before wire collection of single conductor. The present invention will not introduce obviously increase of production cost; the produced grooves are smooth and have good straightness which will not lead to snake-like grooves and eliminate point discharge or electric corona of the grooves. The mold of roller is easy to make, hard to wear and has a long service life, which specifically suits for the forming of various sizes of single conductor grooves.

Owner:WUXI JIANGNAN CABLE

Soil gas flux detector and determination method

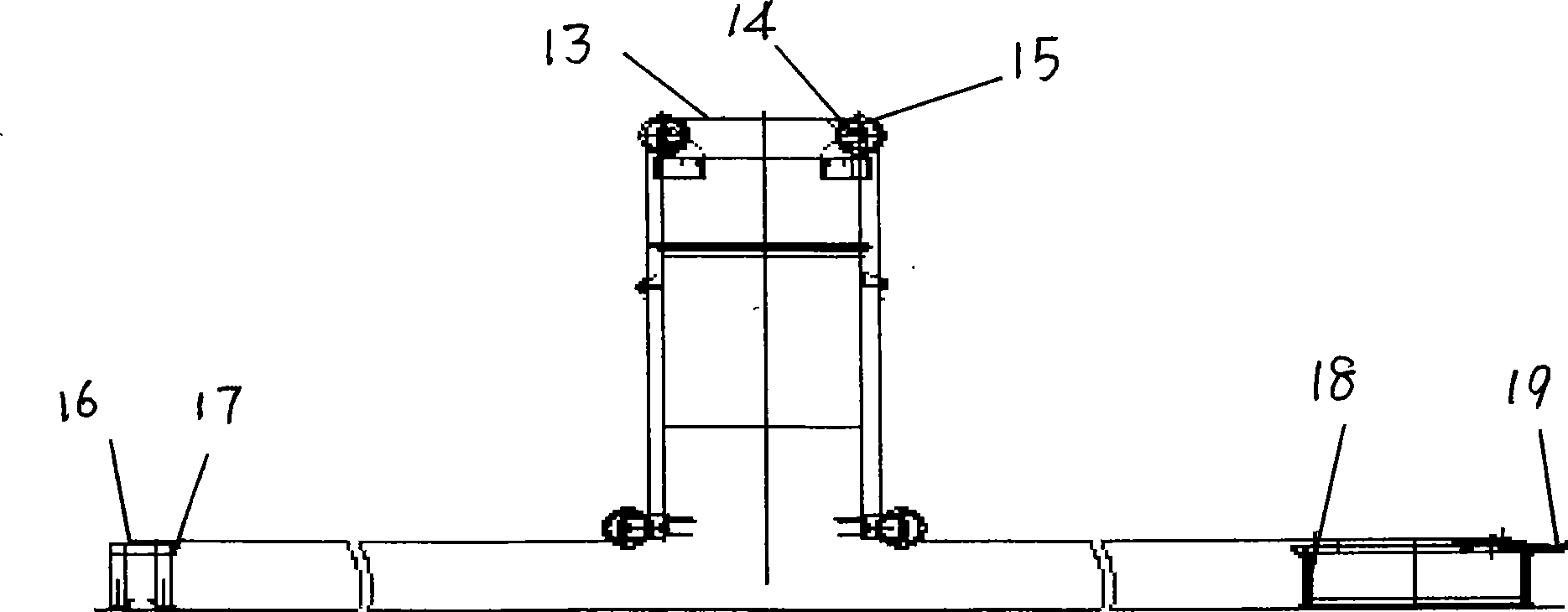

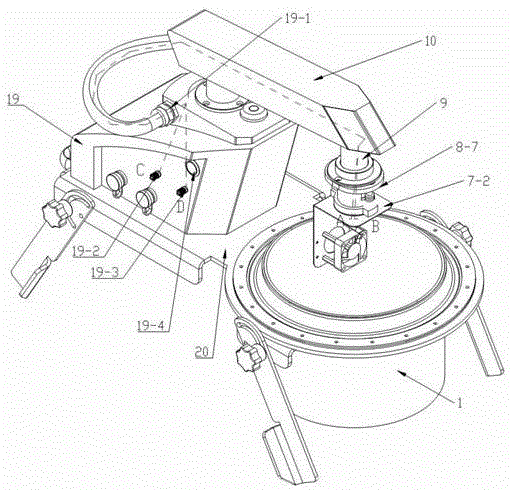

The invention relates to a soil gas flux detector comprising a soil ring (1), supporting legs (2), a pedestal (20), a gas chamber (7), a protective cover (8), a line passing shaft (9), and a control box (19). The flux detector is characterized in that a sealing ring (5) and a pressing ring (3) are arranged above the pedestal (20); the supporting legs (2) are arranged below the pedestal (20); supporting led slide grooves (16) and supporting leg rotation shafts (14) are arranged on the supporting legs (2); a buffering device (8-7) is arranged in the gas chamber (7), the protective cover (8), and the line passing shaft (9); and a return button (19-4) is arranged on the control box (19). With the device provided by the invention, problems such as exposed gas pipe and line, gas chamber offset, and large measuring error of soil gas flux detector can be solved.

Owner:北京萨维福特科技有限公司

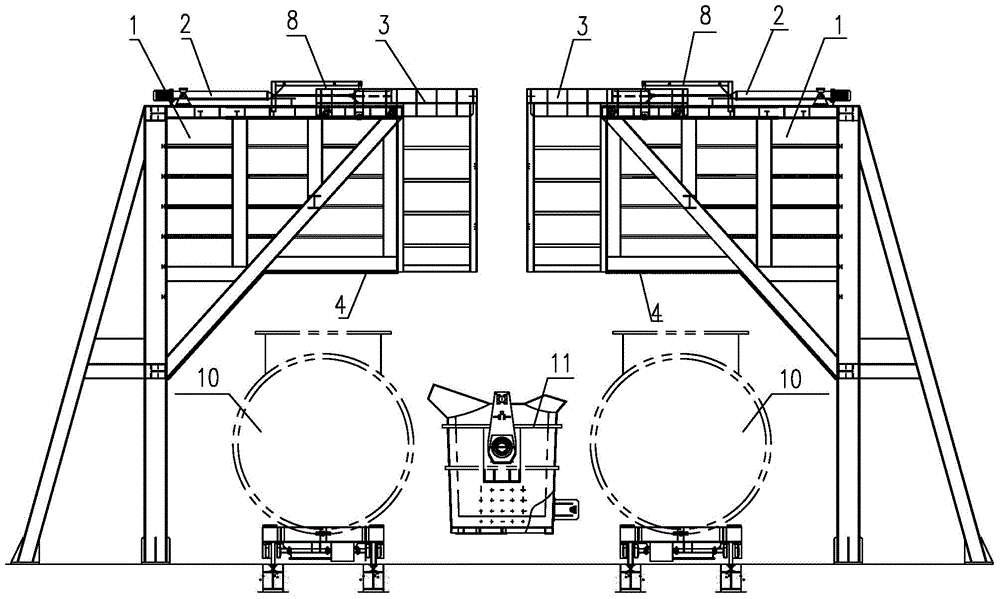

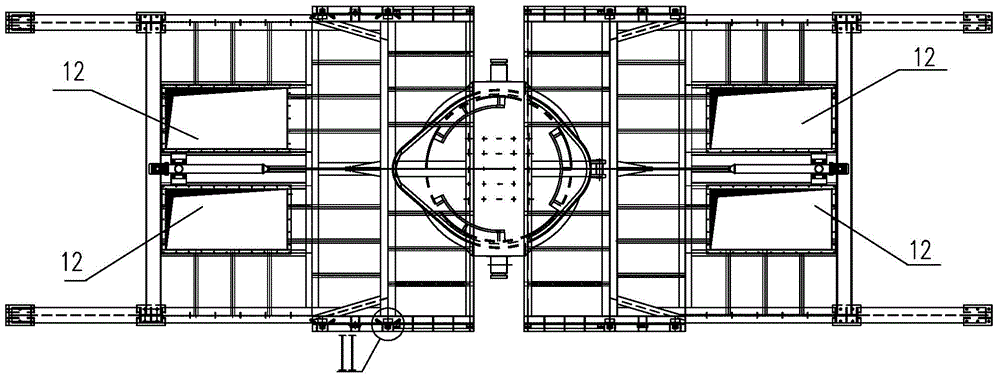

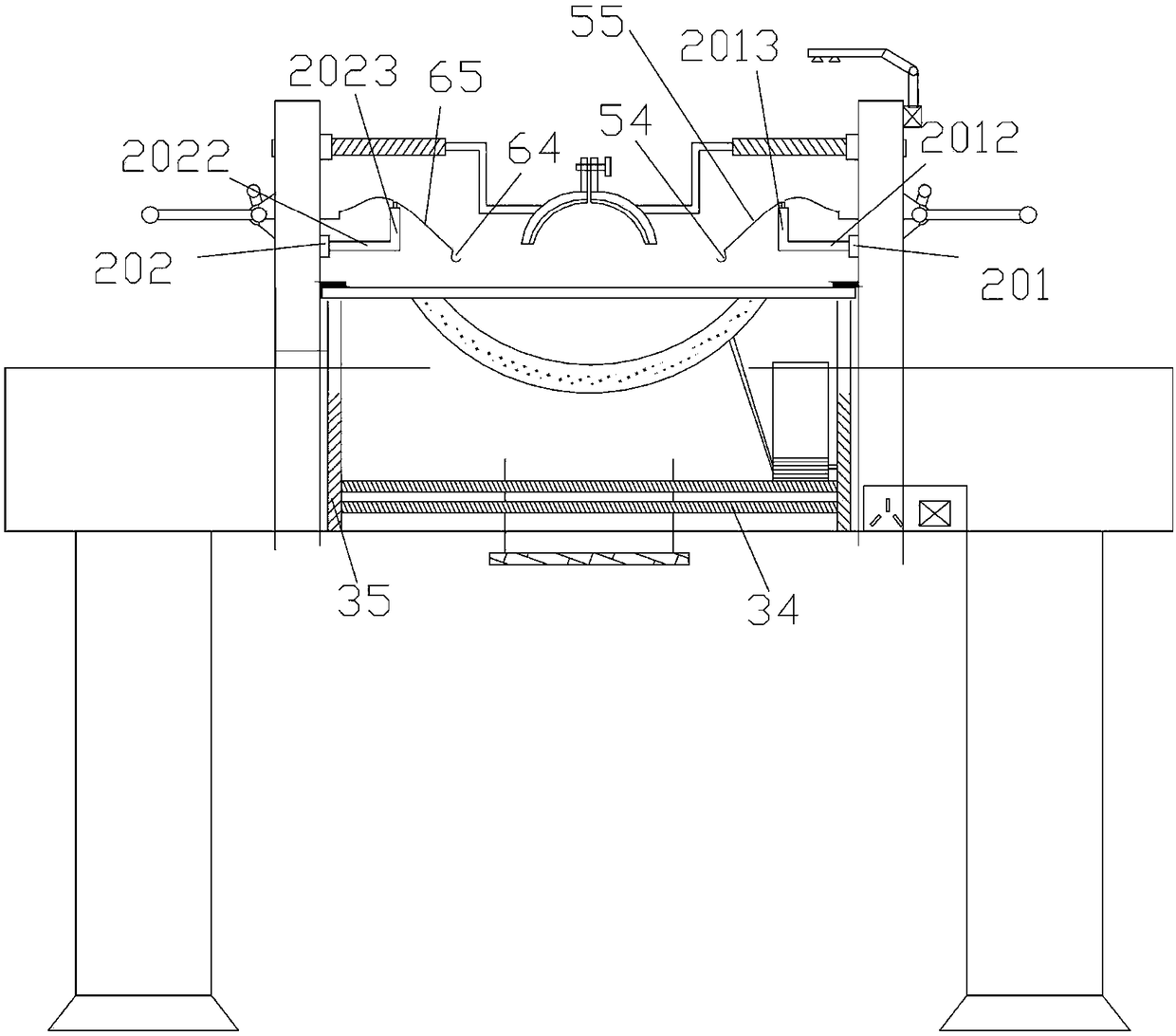

Dust removal device applicable to torpedo car

The invention discloses a dust removal device applicable to a torpedo car and mainly provides a dust removal device applicable to a torpedo car and good in dust removal effect. The dust removal device applicable to the torpedo car is of a symmetrical structure and at least comprises two fixed dust removal covers which are symmetrically arranged, wherein dust removal pipeline joints are formed in the fixed dust removal covers and connected with dust removal pipelines; fixed guide rails are also arranged on the fixed dust removal covers; a movable dust removal cover is arranged on each fixed dust removal cover; the movable dust removal covers are connected with bearing rollers; the bearing rollers are arranged on the fixed guide rails of the fixed dust removal covers; the movable dust removal covers are connected to pull-push power devices and travel control devices for controlling movement travel of the movable dust removal covers. Compared with the dust removal roof in the prior art, the dust removal device applicable to the torpedo car is short in distance from the torpedo car, small in area, strong in pertinence and capable of effectively removing smoke gas and particles and free of influence on the normal production in the dust removal process.

Owner:HUATIAN ENG & TECH CORP MCC

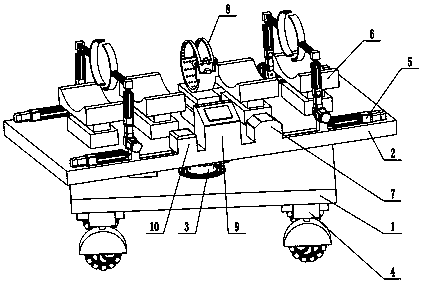

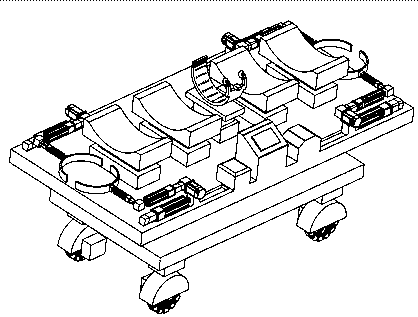

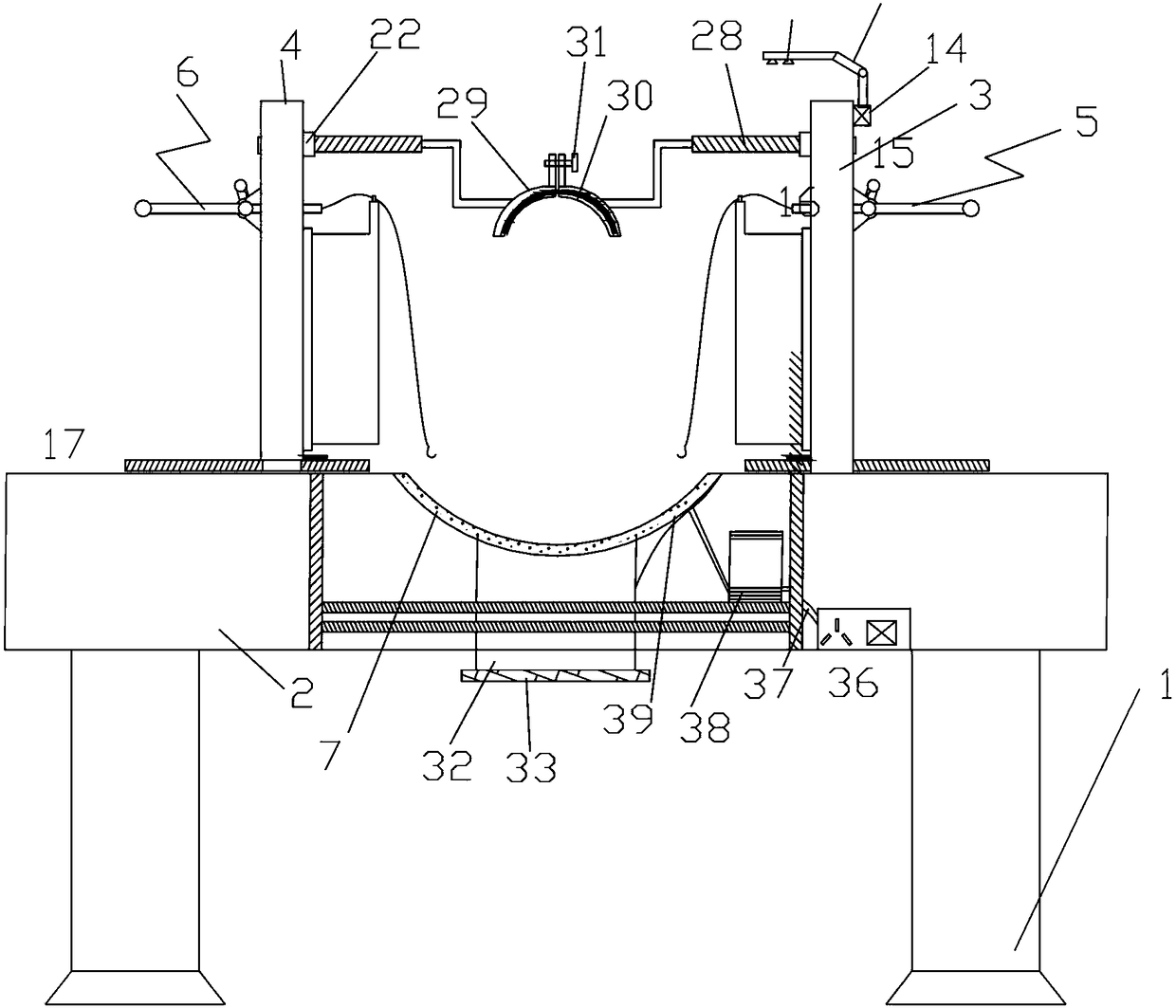

Automatic hot melting welding machine and welding method

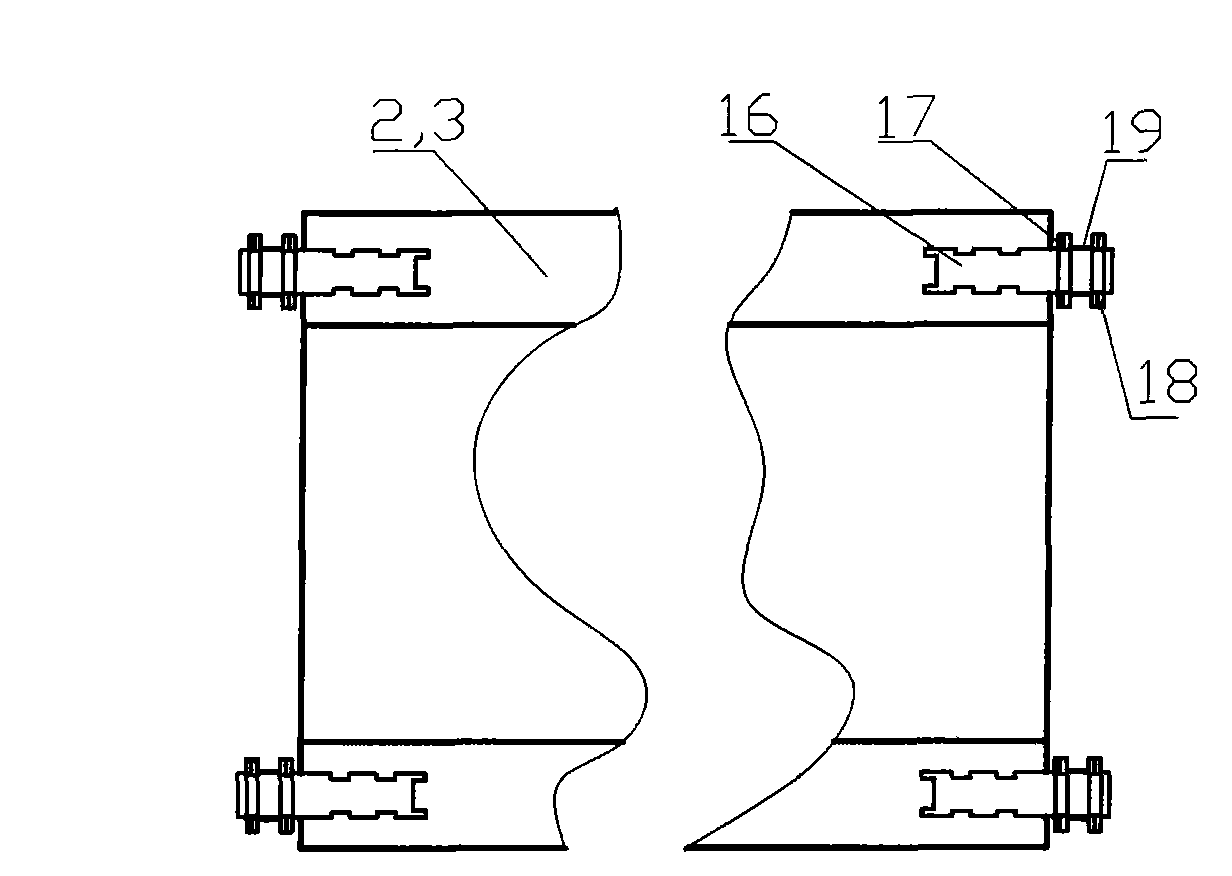

ActiveCN110315763AHigh degree of visualizationEasy to operatePipe connection arrangementsComputer moduleEngineering

The invention provides an automatic hot melting welding machine. The automatic hot melting welding machine comprises an upper bottom plate, a clamping unit, a supporting unit and a fixing devic, wherein the clamping unit is arranged on the upper bottom plate, the supporting unit is arranged on the upper bottom plate, the fixing device is arranged on the upper bottom plate and is positioned in themiddle of the supporting unit, a hot melting welding machine body and a console are arranged on the upper bottom plate, a controller is arranged in the console, a hot melting sleeve is attached to a pipeline to be welded through the fixing device, the hot melting welding machine is controlled to heat the hot melting sleeve through the console, the controller comprises an SSR, an SCR, a PLC and anAD acquisition module, and voltage and current signals are correspondingly collected, converted, displayed and heated and controlled through the SSR, the SCR, the PLC and the AD acquisition module. According to the automatic hot melting welding machine, a motor which is internally arranged in an upper arc plate is used for driving a gear C to rotate so as to drive the upper arc plate to slide in asliding groove A of a lower arc plate, and then the hot melting sleeve is driven to carry out complete sleeving on the pipeline to be welded.

Owner:TIANJIN JINENG PIPE

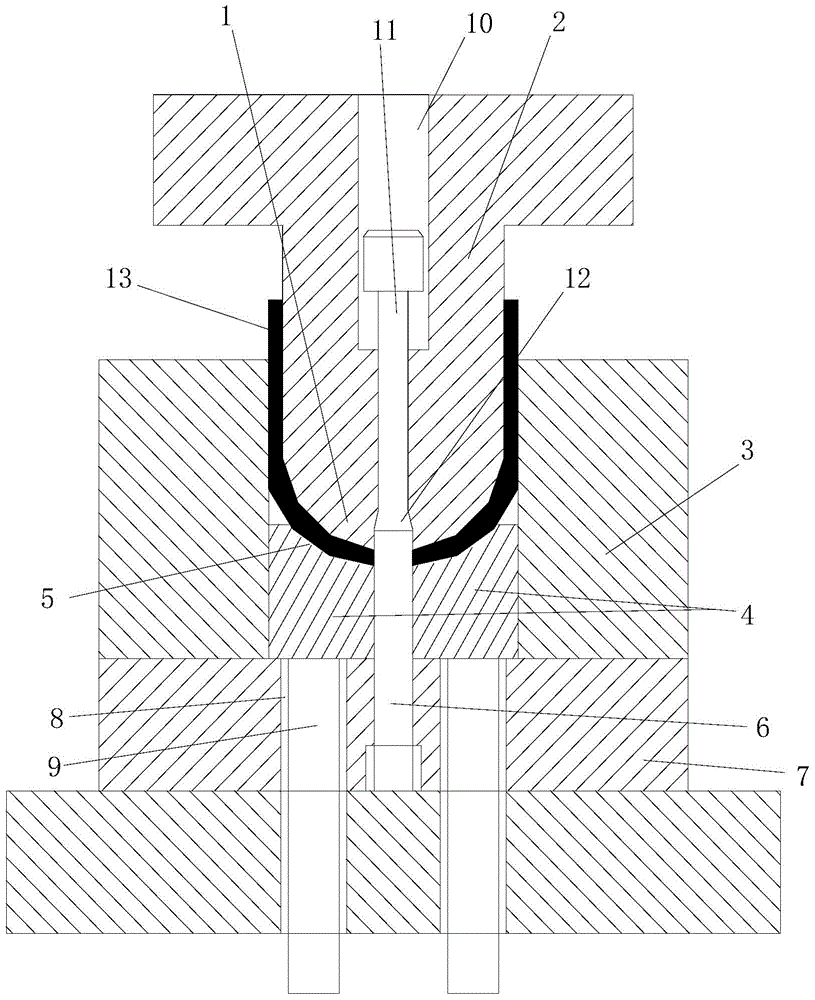

Arc-shaped plate bending device

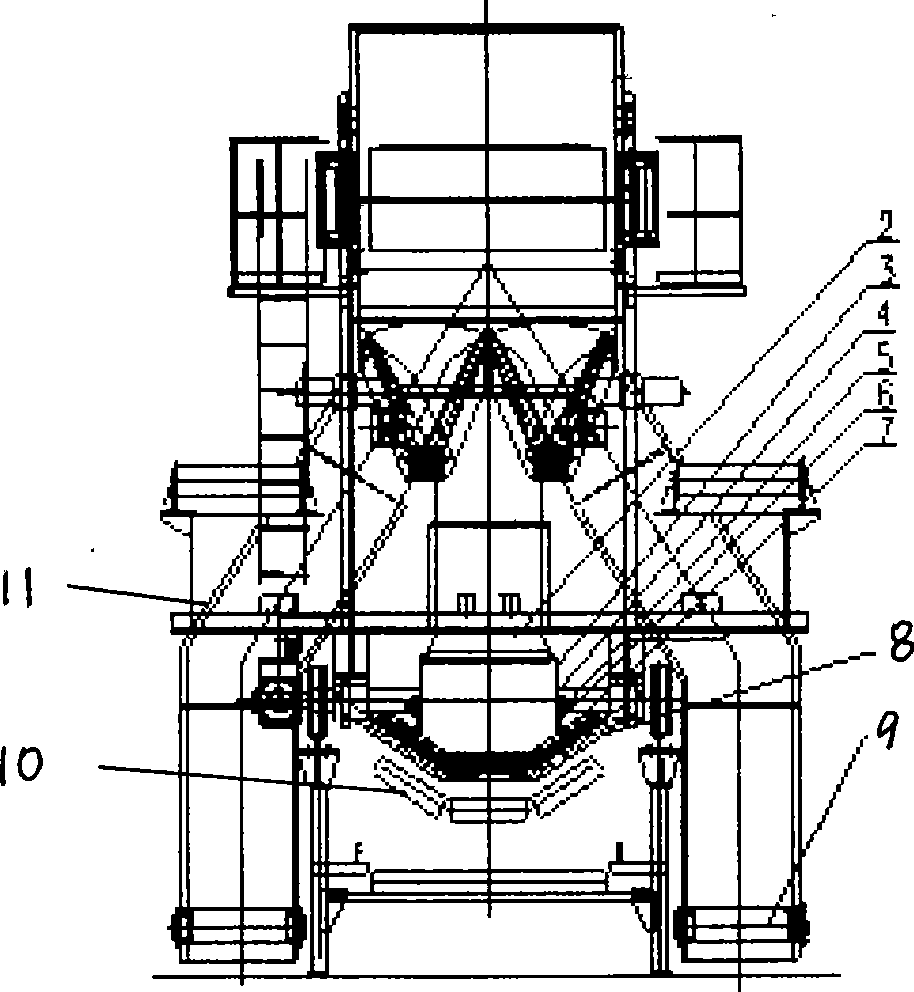

The invention belongs to the technical field of plate workpiece processing and particularly relates to an arc-shaped plate bending device which comprises a bent convex die, wherein the bent convex die is provided with arc-shaped molding die heads; a bent concave die is arranged below the bent convex die; the middle of the bent concave die is provided with a die cavity which penetrates through the upper and lower end surfaces of the bent concave die; the die cavity of the bent concave die is internally provided with two mutually independent lifting die heads capable of ascending to be flush with the upper end surface of the bent concave die; the tops of the lifting die heads are provided with arc-shaped concave surfaces which correspond to the arc-shaped molding die heads of the bent convex die. The arc-shaped plate bending device is simple in structure and reasonable in design; by virtue of the arc-shaped plate bending device, the bending of two semi-arc plates can be completed once, so that the working efficiency is high; in a bending process, plate blanks do not deviate and the bending quality is high.

Owner:CHANGZHOU YINBAO NICKEL NETWORK

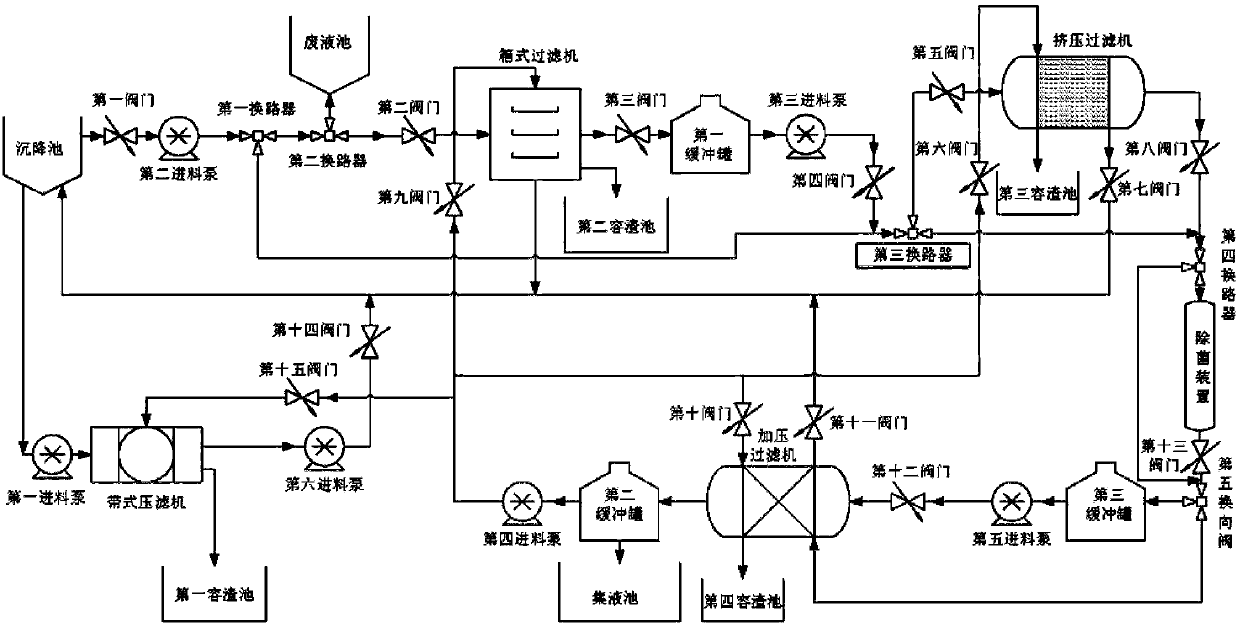

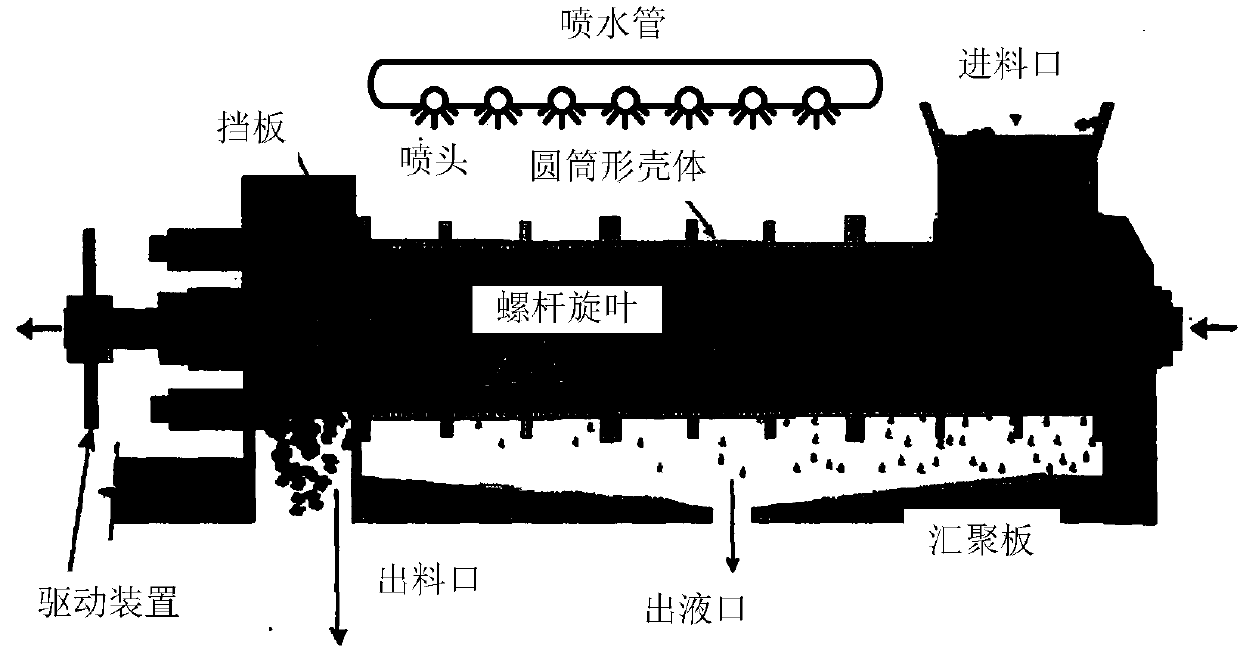

Chemical slurry squeezing filtration system

ActiveCN107670385ARealize processing and manufacturingFilter thoroughlyWater treatment parameter controlSpecific water treatment objectivesSlagFiltration

The invention discloses a chemical slurry squeezing filtration system. The system comprises one belt filter press, one box filter, one pressure filter, one squeezing filter, one sterilization device,one sedimentation tank, one waste liquid pool, one liquid collection pool, four slag storage tanks, three buffer tanks, six feeding pumps, five circuit switches and fifteen valves. The squeezing filter comprises a waster spray pipe, a cylindrical housing, screw vanes, a driving motor and a gathering plate. The screw vanes are arranged at intervals.

Owner:山东辰安化学有限公司

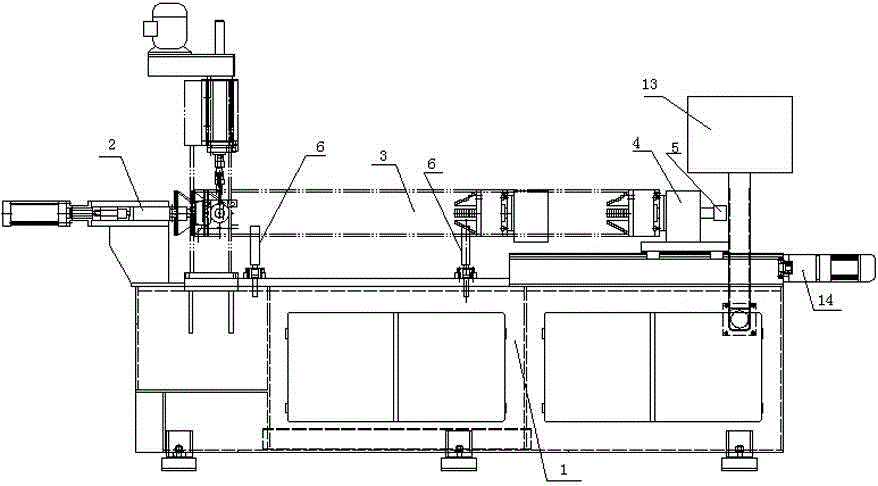

Numerically-controlled drilling and chamfering machine

InactiveCN104972156AGuaranteed accuracySolve the technical problem of unable to fall burrsPrecision positioning equipmentWork clamping meansDrill floorUltimate tensile strength

The invention provides a numerically-controlled drilling and chamfering machine. An electric control system is arranged on the side edge of a working platform. A support is arranged in the middle of the working platform. A first positioning and tightening device is arranged at one end of the working platform. A dividing plate is arranged at the other end of the working platform through a servo motor. A second tightening device is correspondingly arranged on the dividing plate. Two drill stands are arranged on the portion, located outside the first positioning and tightening device, of the working platform through supporting arms. The two drill stands are provided with drill jackets respectively. A numerically-controlled sliding table is arranged below the servo motor and the dividing plate. The first positioning and tightening device is a pneumatic positioning and tightening device. The two drill stands are perpendicular to each otheraccording to the relative positions. According to the numerically-controlled drilling and chamfering machine, the technical problem that chamfering and deburring of the orifice of an oil hole in the inner wall of a cylinder pipe cannot be achieved is solved, damage of an oil cylinder sealing piece and scratch of the inner wall of the oil cylinder are effectively prevented, and product quality is greatly improved; different requirements for machining of four oil holes, eight oil holes and the like can be met at a time; on the premise that drilling of a cylinder barrel is completed, the machining cycle is shortened, labor intensity is relieved, and working efficiency is improved.

Owner:湖北佳恒科技股份有限公司

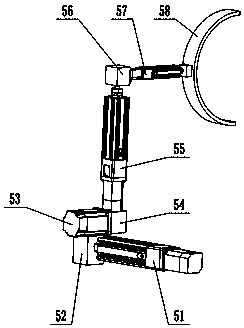

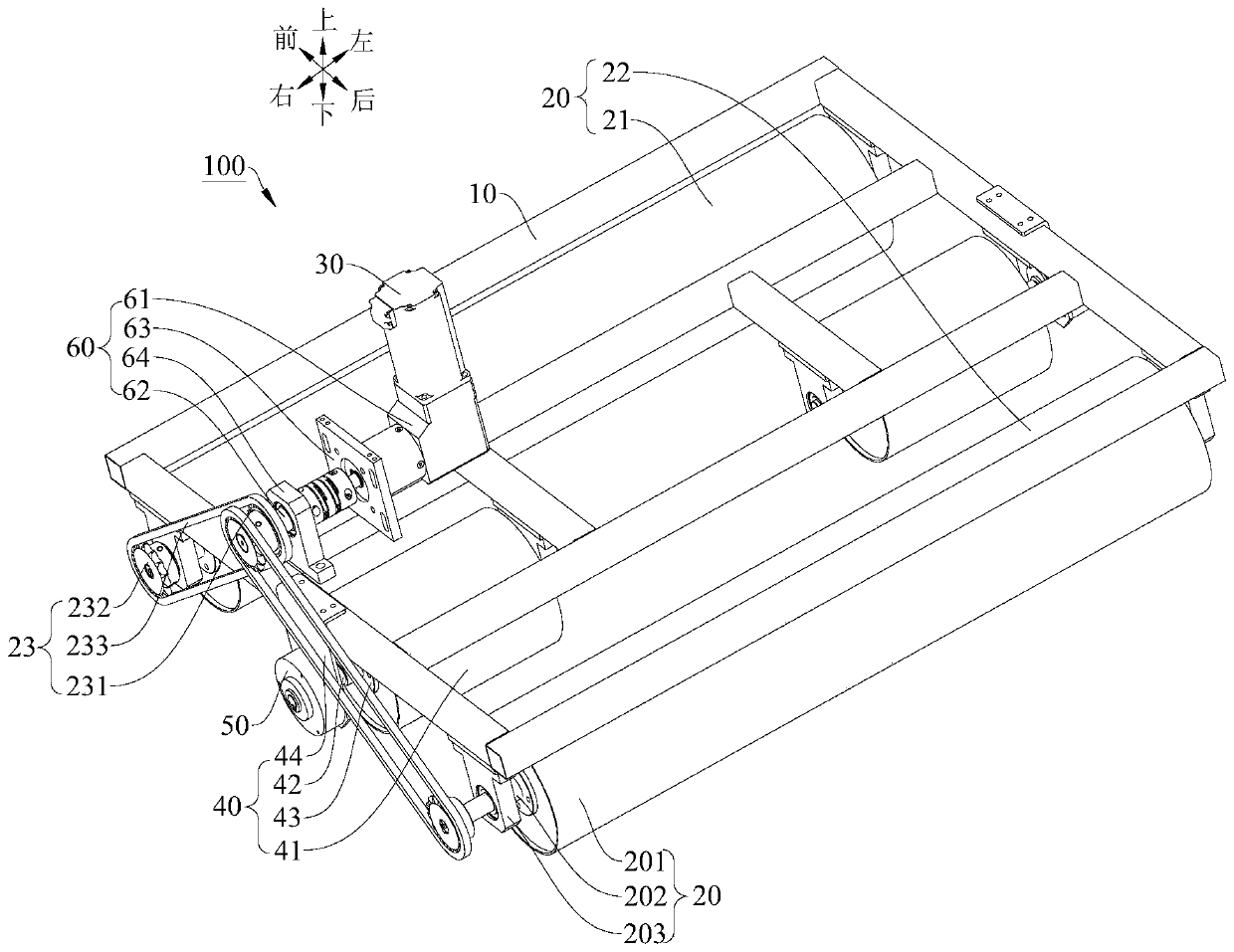

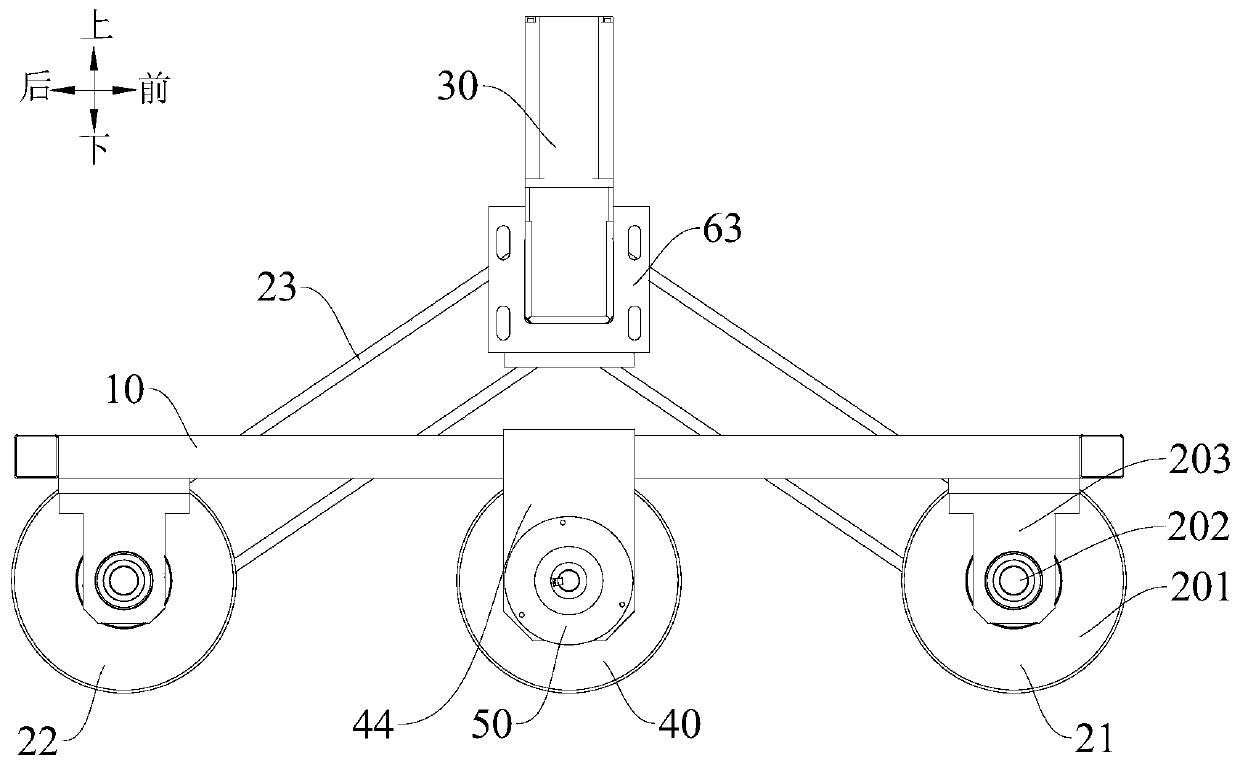

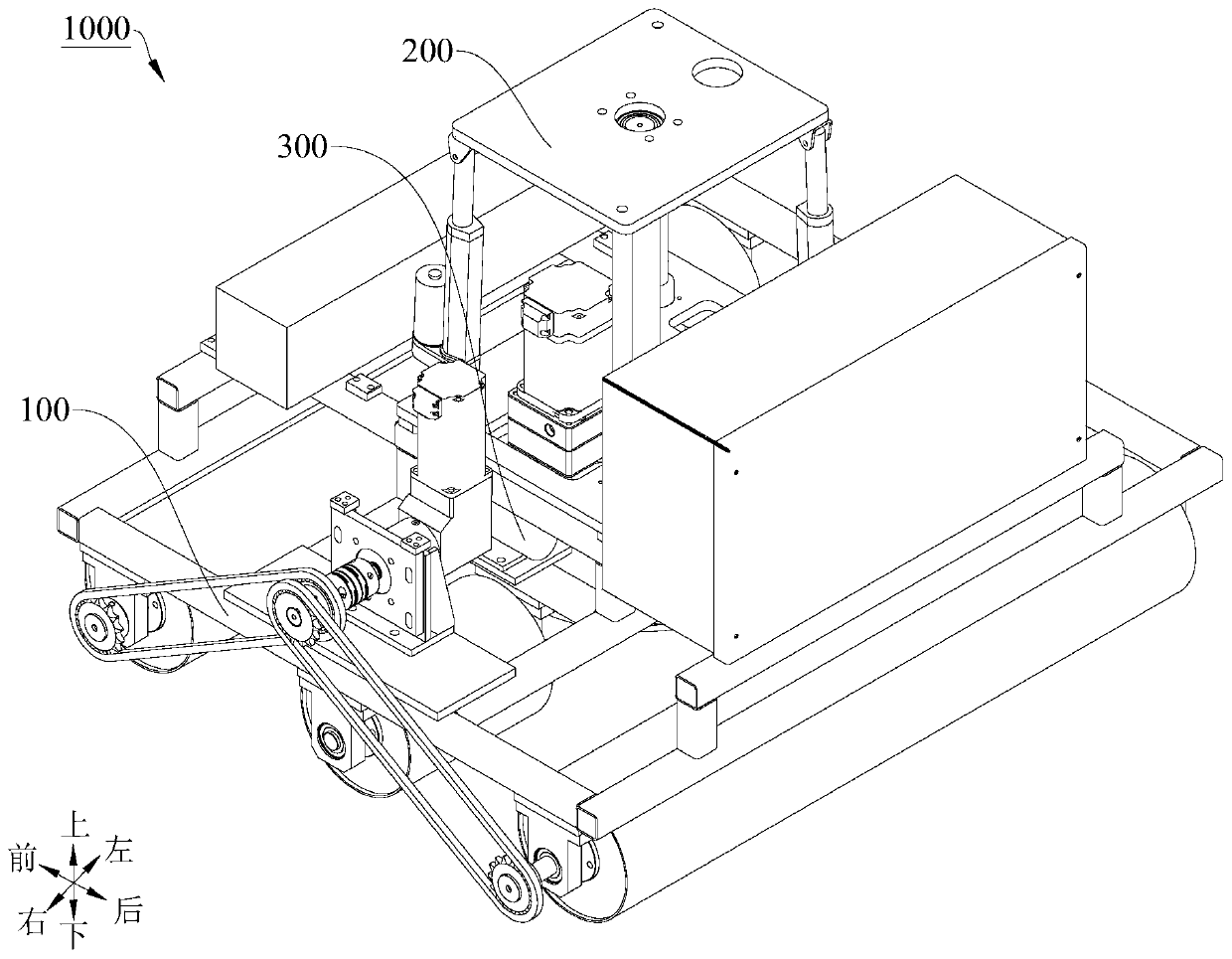

Deviation correction device and method of screeding robot and screeding robot

ActiveCN110593573ATroubleshoot deviation from normal direction of motionRealize automatic deviation correctionBuilding material handlingDrive wheelEngineering

The invention discloses a deviation correction device and method of a screeding robot and the screeding robot. The deviation correction device comprises a rack, a drive wheel, a drive part and deviation correction wheels. The drive wheel is rotationally arranged on the rack. The drive part is connected with the drive wheel so as to drive the drive wheel to rotate. At least the two deviation correction wheels are arranged and are arranged on the two sides of the rack, and damping devices are arranged at the shaft ends of the two deviation correction wheels. The damping devices are configured toapply preset resistance to all the deviation correction wheels when motion of the screeding robot is deviated, and therefore the motion deviation direction of the screeding robot is corrected. By means of the deviation correction device and method of the screeding robot and the screeding robot, the correction deviation wheels are additionally arranged on the two sides of the rack, the friction force between the correction deviation wheels on the two sides and the construction face is controlled through the damping devices, the problem that the screeding robot is deviated from the normal running direction is solved, and automatic deviation correction of the work direction of the robot is achieved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

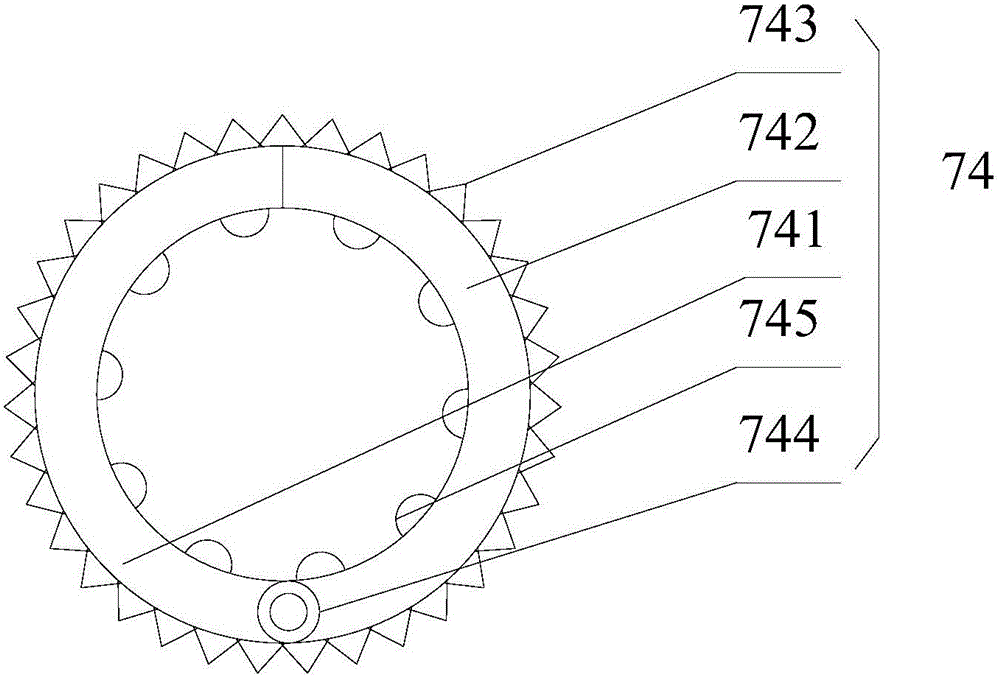

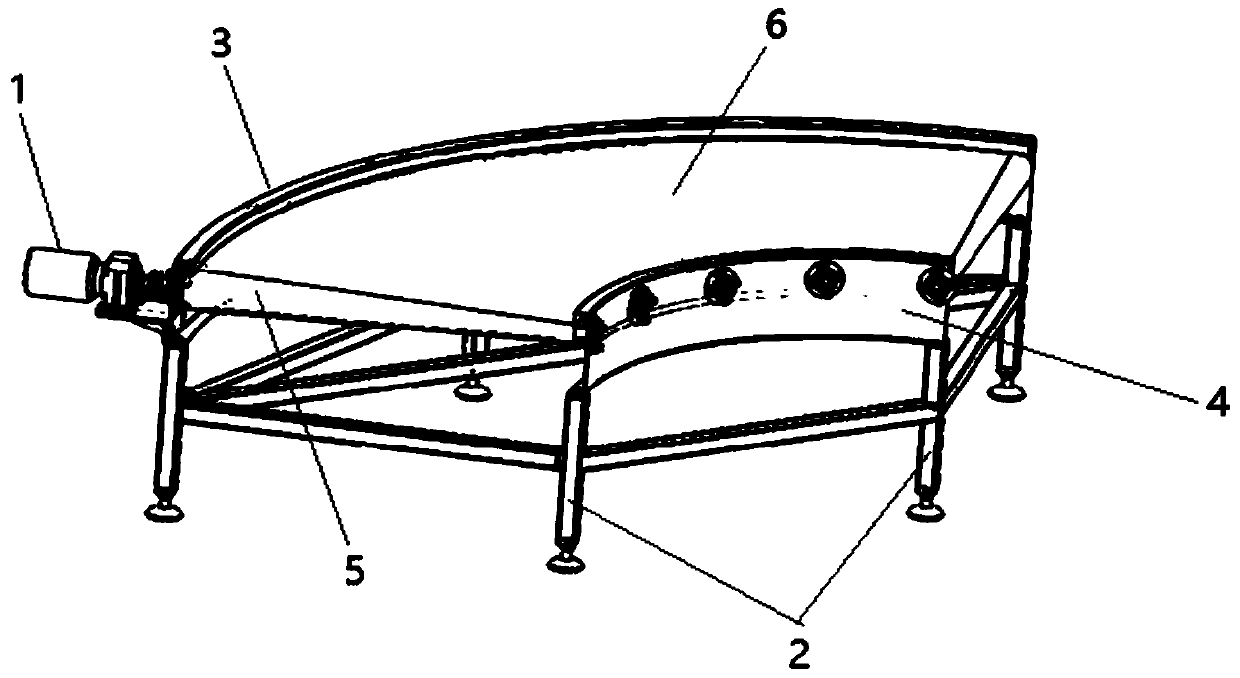

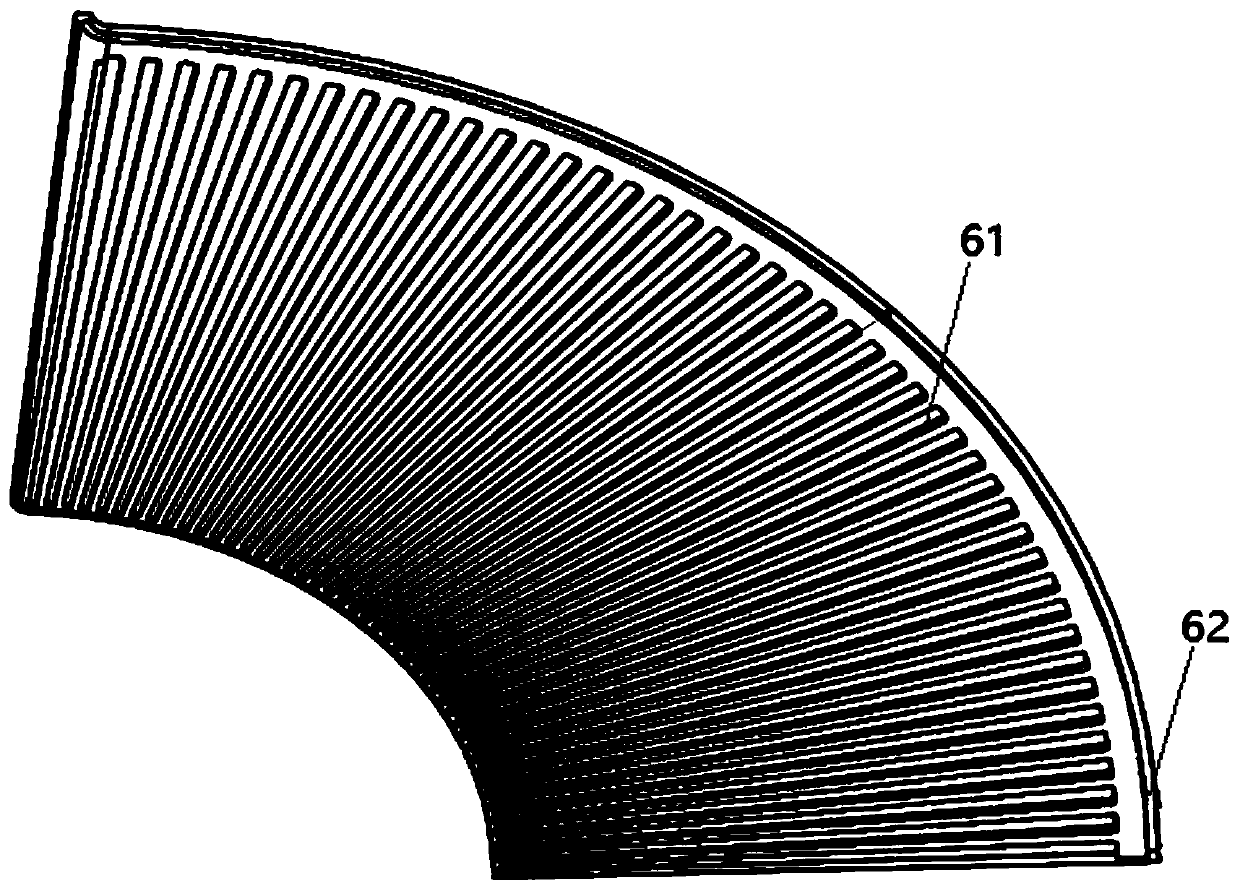

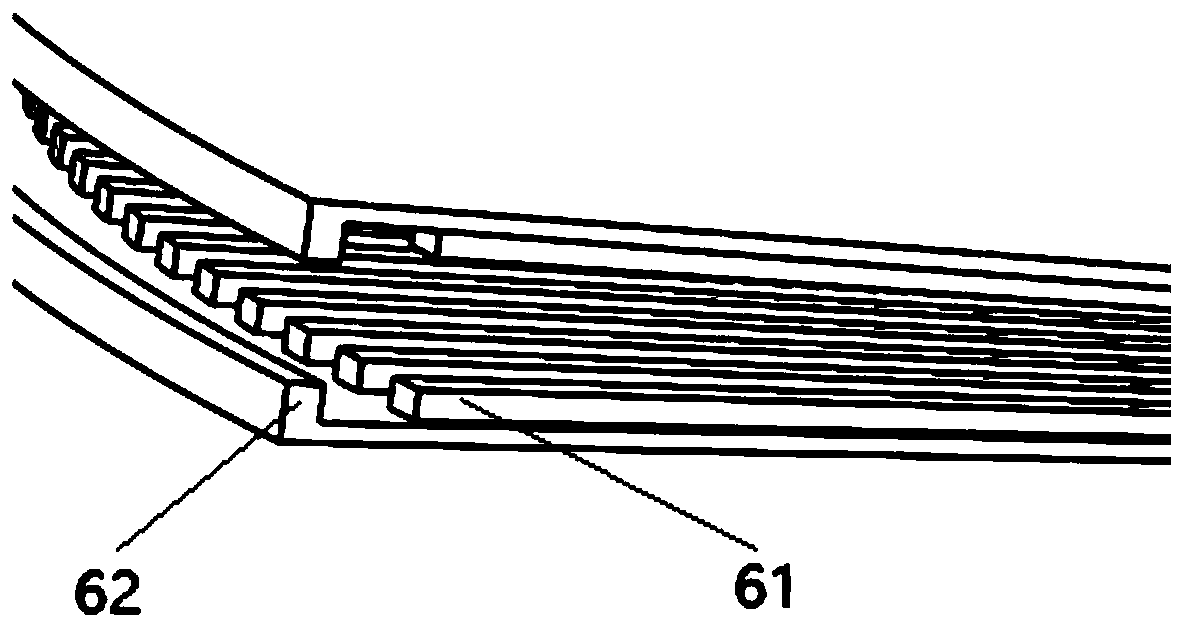

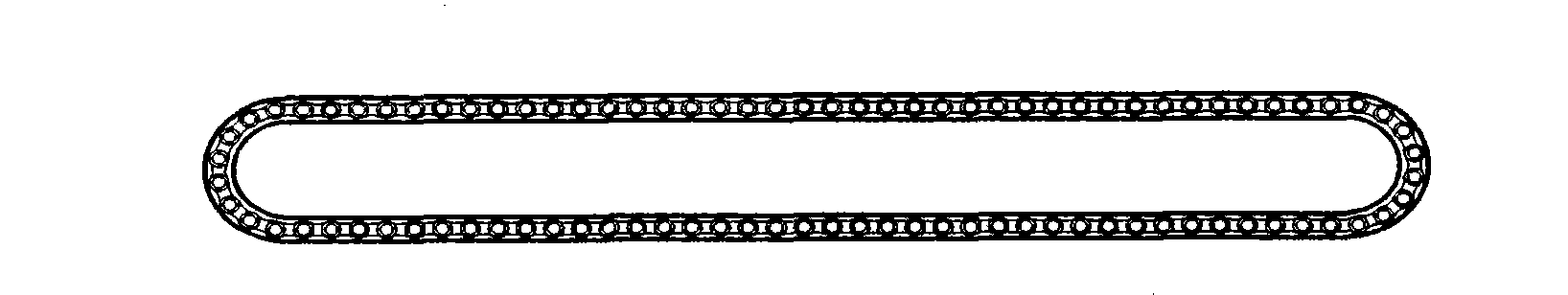

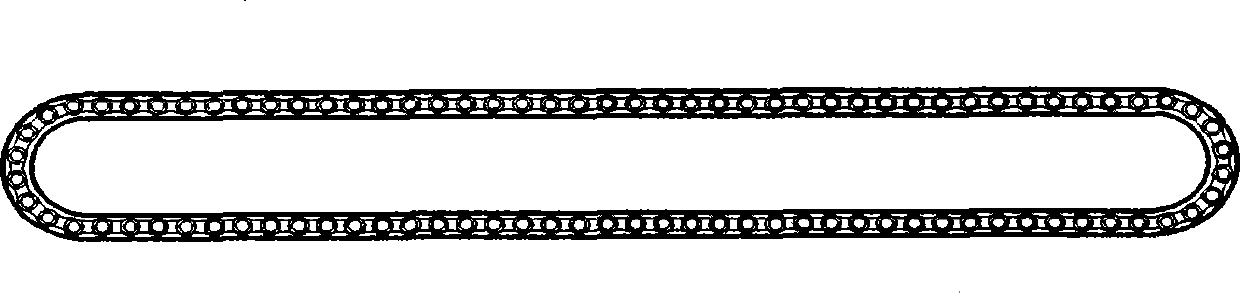

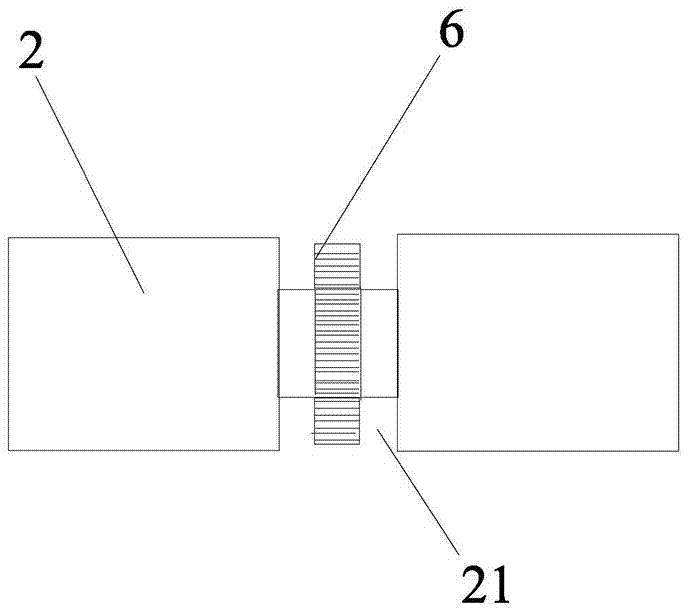

Turning conveyor and conveyor belt

The invention relates to a turning conveyor. The turning conveyor comprises a conveyor machine frame, a drive system, a fan-shaped conveyor belt and transmission guide shafts. The machine frame comprises a fan-shaped frame. The transmission guide shafts are arranged in the fan-shaped frame. Tooth grooves are formed in the axial surface of each transmission guide shaft. The invention further relates to a conveyor belt suitable for the turning conveyor mentioned above. Transverse racks are arranged on the inner surface of the conveyor belt and are meshed with the axial tooth grooves of the transmission guide shafts. The corresponding transmission guide shaft is connected with the drive system, and the fan-shaped conveyor belt is driven to cyclically rotate around the transmission guide shafts in the fan-shaped frame to be used for conveying goods; by means of gear transmission achieved through meshing of the tooth grooves of the transmission guide shafts and the racks of the fan-shaped conveyor belt, rotation of the conveyor belt can be easy, and the friction loss between the conveyor belt and the transmission shafts is greatly reduced; and meanwhile the conveyor belt is provided with longitudinal guide strips, a conveyor belt limiting mechanism is arranged on the machine frame, and the problem that transverse displacement and deviation are caused to the conveyor belt during curve operation is thoroughly solved through combination of the longitudinal guide strips and the conveyor belt limiting mechanism.

Owner:AA IND BELTING (SHANGHAI) CO LTD

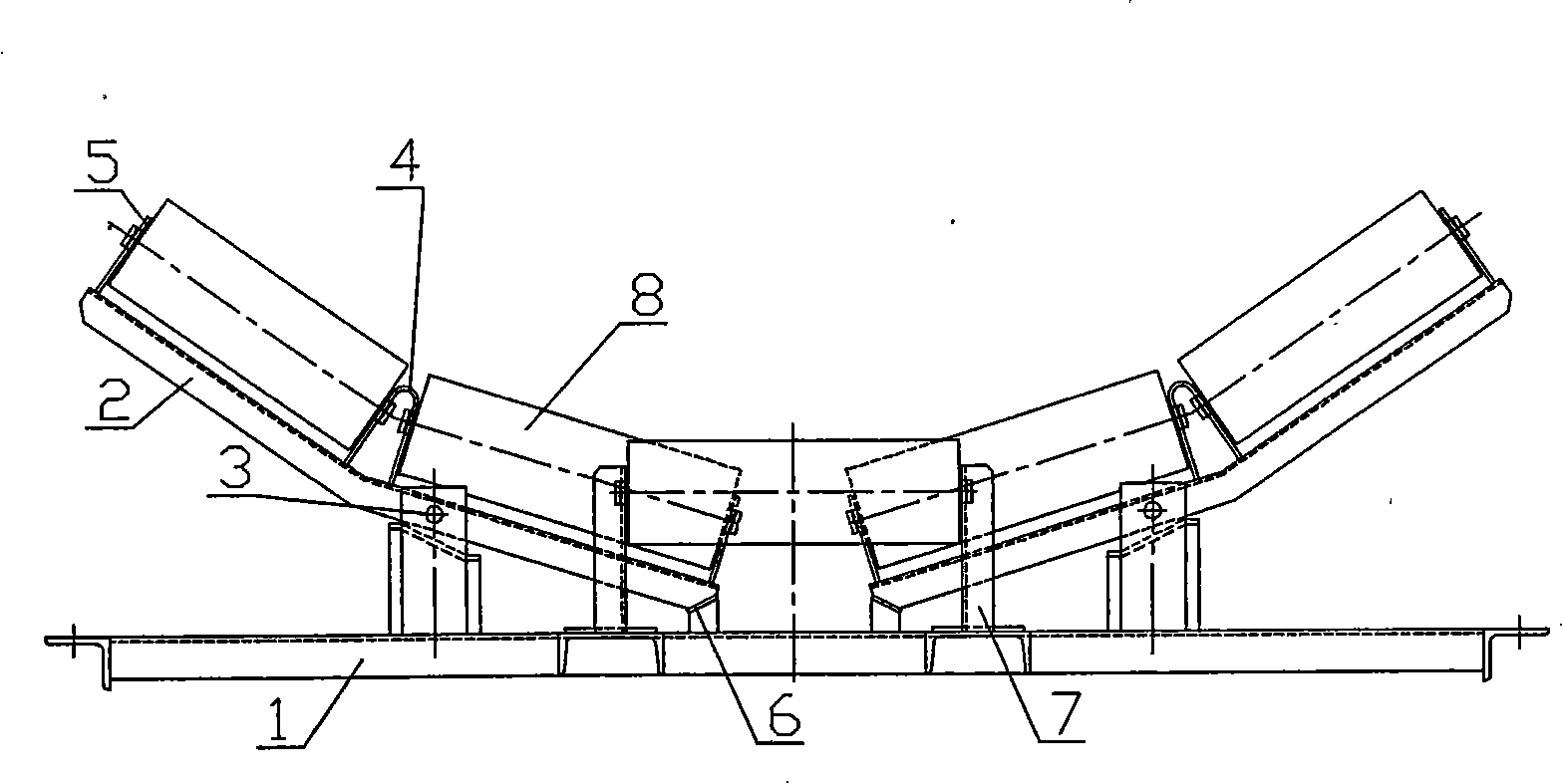

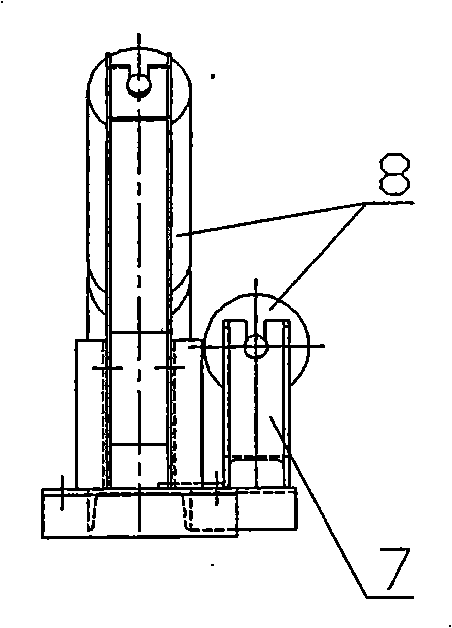

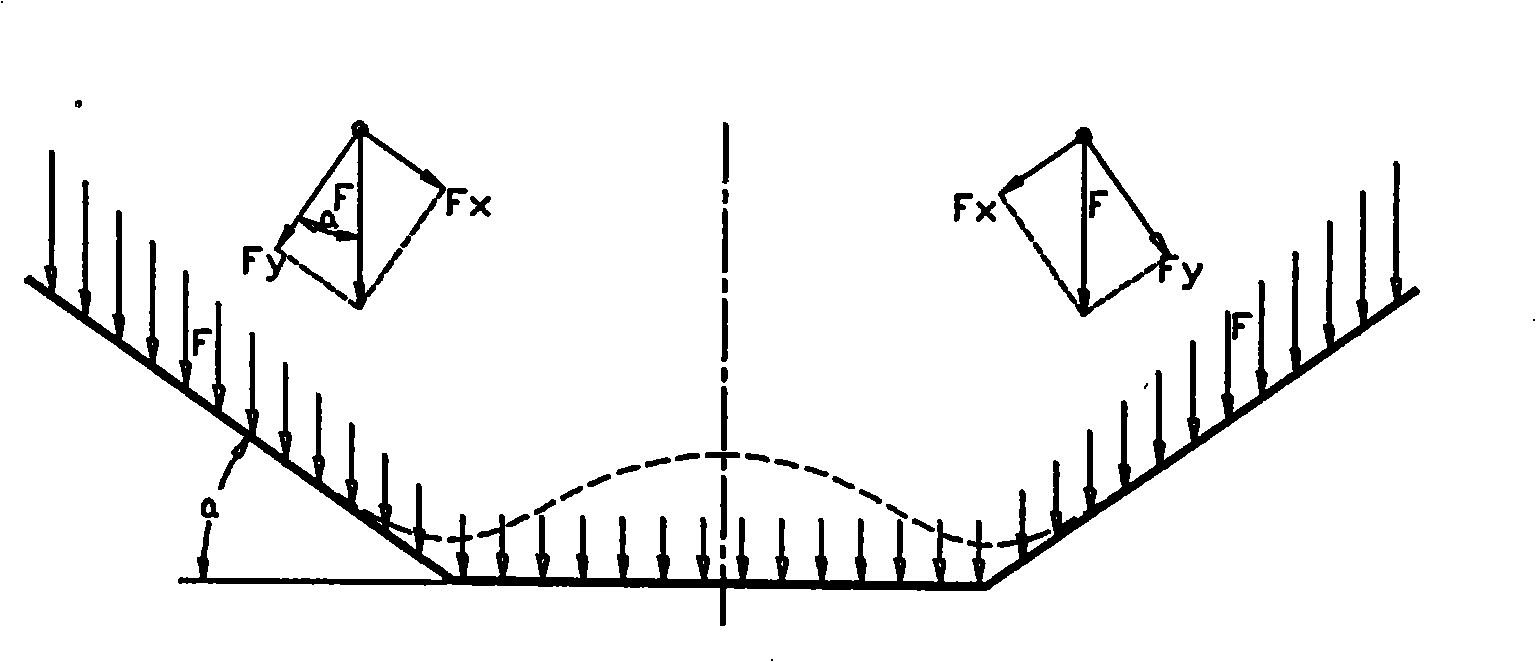

Conveyor belt self-adapting adjusting apparatus of belt conveyor

InactiveCN101301959AStrong adaptive adjustment abilityPrevent belt from drumming or lateral bucklingConveyorsRollersEngineeringConveyor belt

Owner:TIANJIN CHENGKE MECHANICAL & ELECTRICAL TRANSMISSION TECH

Heavy duty dumper

InactiveCN101462638AReduce shockReduce wearSupporting framesMechanical conveyorsRubber ringPower station

The invention provides a heavy-duty dumper, which aims to solve the problem that the prior dumper is only suitable for low-power sealing-tape machines and is not suitable for high-power belt conveyers used by large-scale enterprises such as large-scale power stations. The key points of the heavy-duty dumper comprise the following: the heavy-duty dumper is provided with a main belt and two side chutes which are connected with a hopper; a guide chute, a receiving buffer device and the main belt are arranged under the hopper in turn; the buffer device is provided with a buffer roller frame body and a buffer roller set; rubber rings are arranged on surfaces of buffer rollers; a driving running gear adopts a variable-frequency motor; a sealing device is arranged inside each side chute and consists of an adhesive tape provided with a framework, a bearing roller, a clamping device, a tensioning device, a support, a clamping device support and a tensioning device tailstock; the bearing roller is fixed on a chute body; the special adhesive tape provided with the framework passes by the bearing roller; and a sealing adhesive tape is arranged above a bin opening by which discharged materials of the chute pass and passes by two side walls and the upper part of the chute. The heavy-duty dumper is suitable for the belt conveyers which are operated in high power.

Owner:SHENYANG MINING MACHINERY GROUP

Deviation rectifying mechanism

ActiveCN105714479ACompliant with blankingAchieve fixationWork-feeding meansLinking machinesVisual inspectionEngineering

The invention relates to a deviation rectifying mechanism. The deviation rectifying mechanism comprises a linear guide rail component, a visual inspection component and a control chip, wherein two deviation rectifying components which are arranged vertically and symmetrically are arranged on the linear guide rail component; an opening component is arranged between the two deviation rectifying components; an uncoiling component is arranged at the end part of each deviation rectifying component; the control chip is connected with the linear guide rail component, the deviation rectifying components, the opening component and the visual inspection component. According to the deviation rectifying mechanism, the disadvantages in the prior art can be overcome; whether an upper garment piece is aligned with a lower garment piece can be inspected, and the garment pieces can be adjusted until the garment pieces are aligned; the labour cost is reduced; the overall work efficiency is improved.

Owner:王贤虎

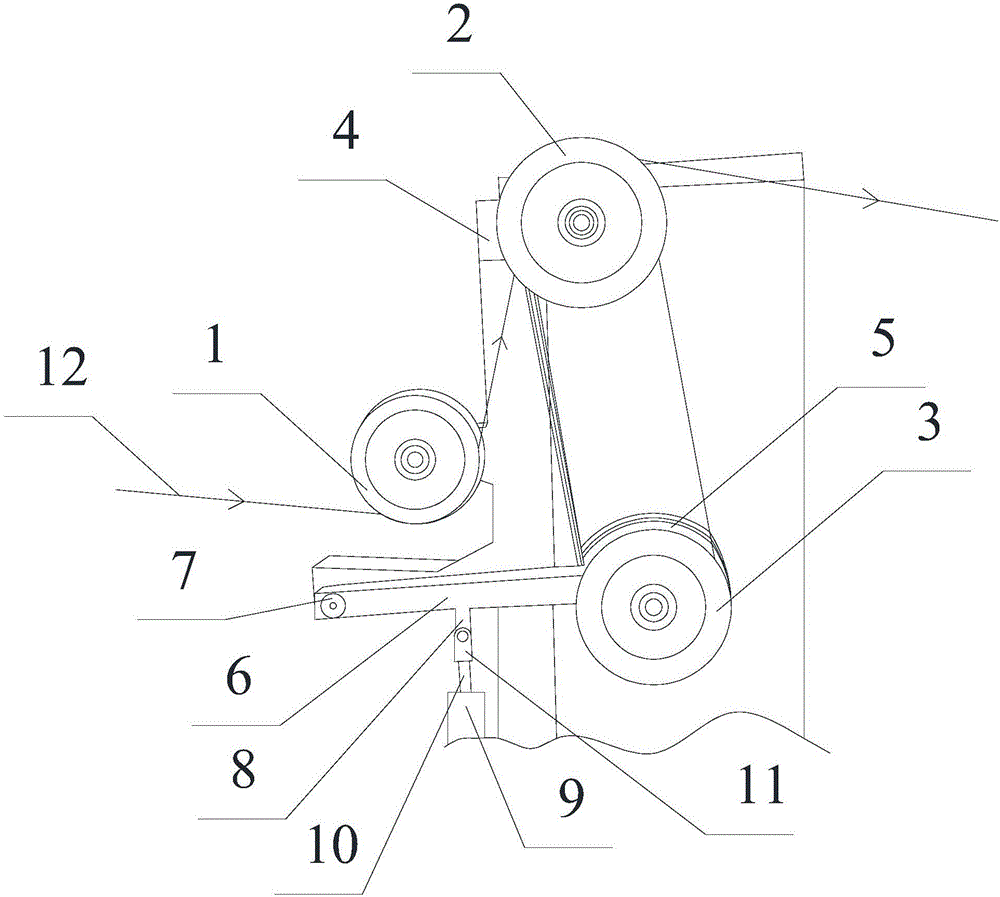

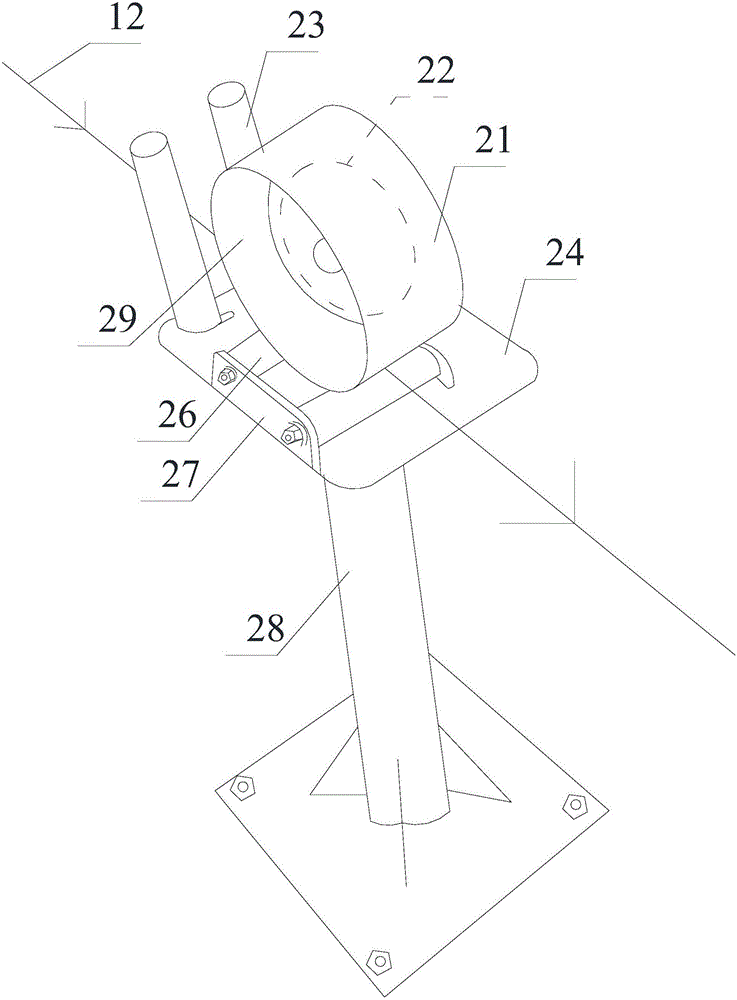

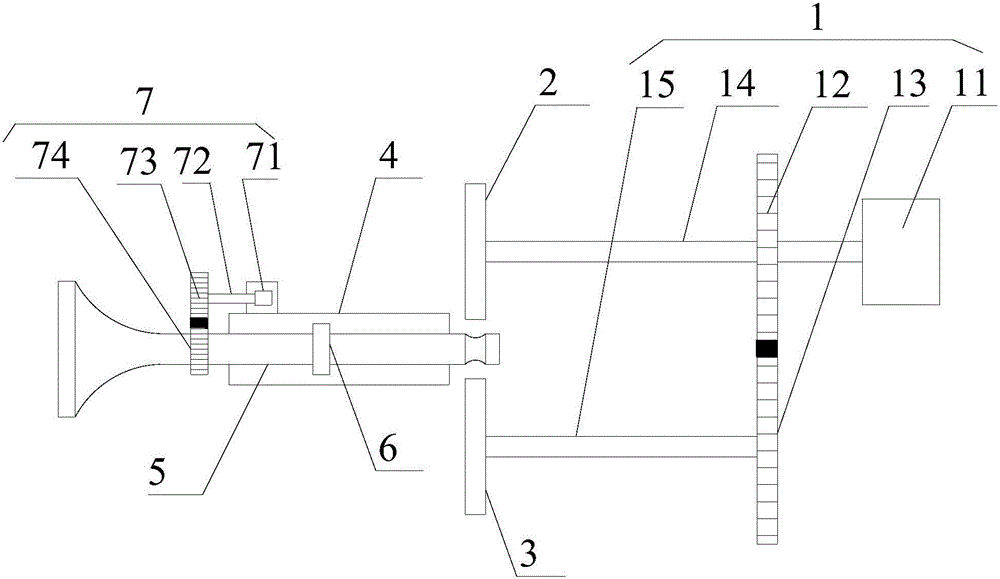

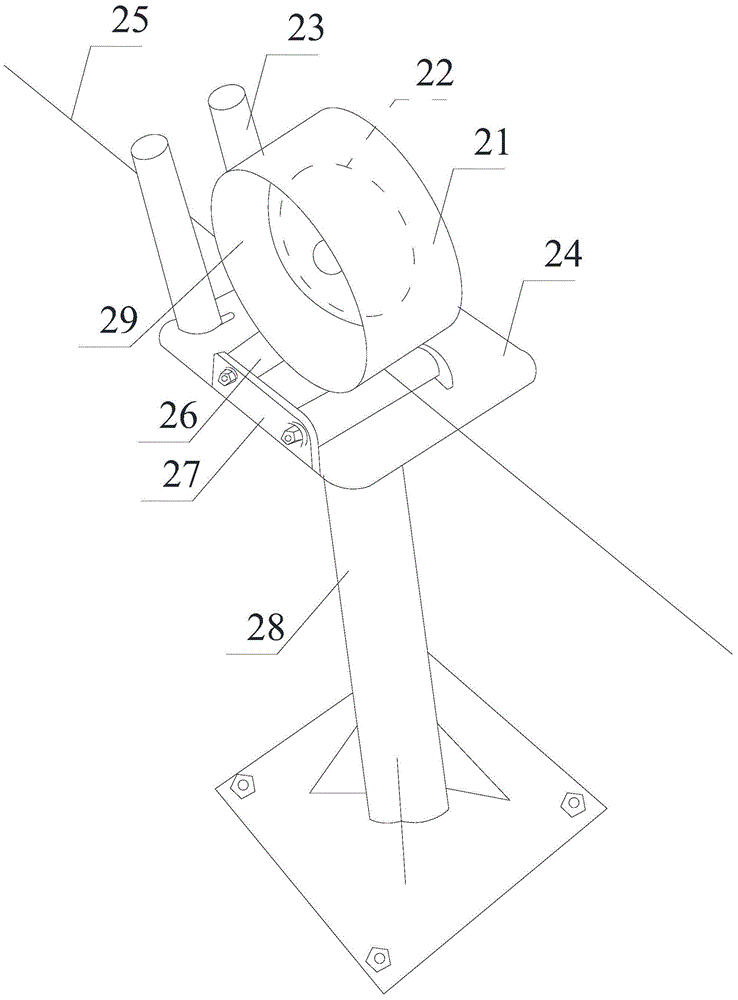

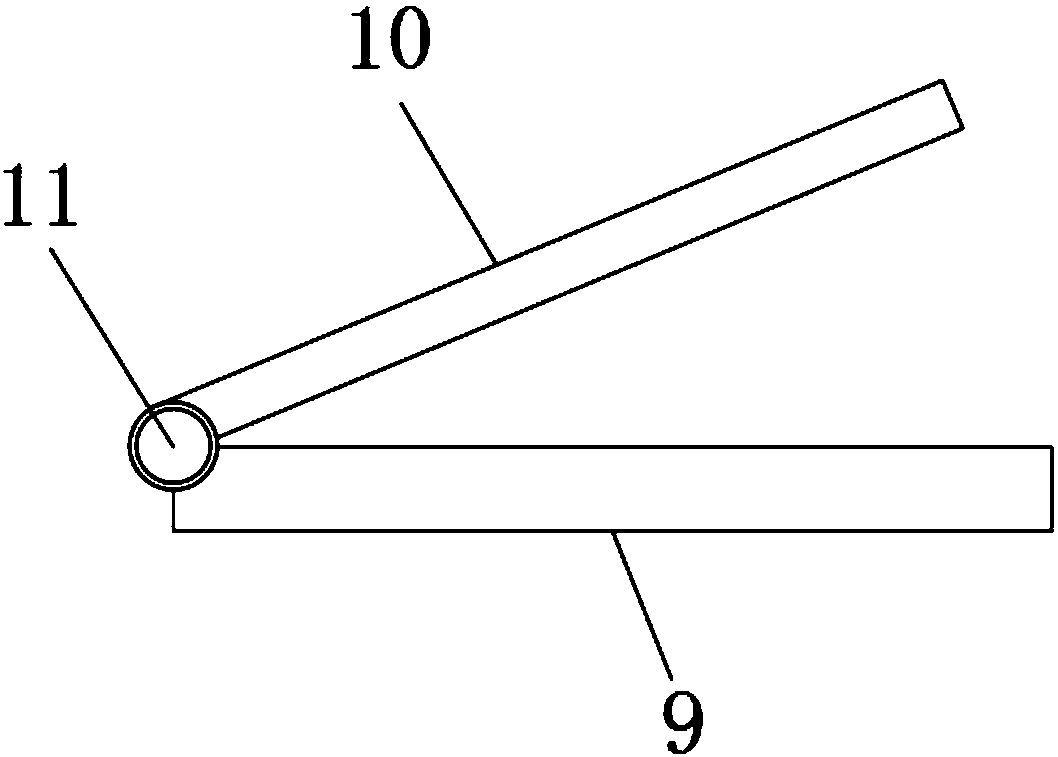

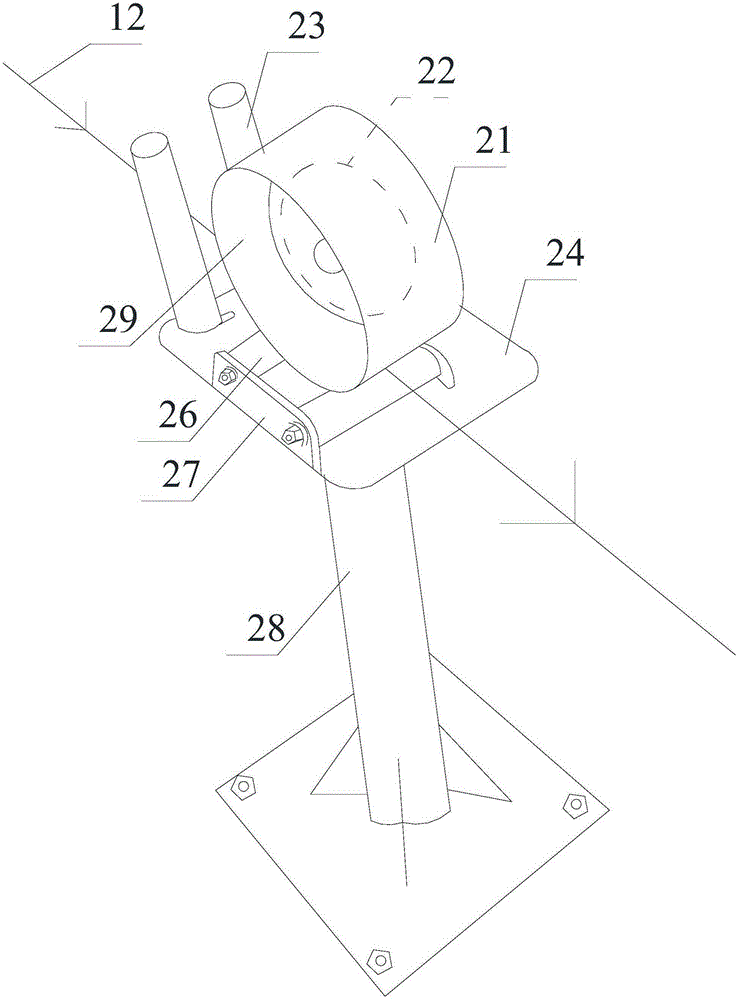

Length counter and length counting method thereof

The invention discloses a length counter and a length counting method thereof. The length counter comprises a pedestal, and a length counting device installed on the pedestal. The length counting device comprises a rolling wheel, a gear counter and at least one auxiliary wheel. The rolling wheel and the auxiliary wheel are superposed up and down; a cable for length counting penetrates between the rolling wheel and the auxiliary wheel superposed up and down, and drives the rolling wheel to rotate. The gear counter and the rolling wheel are coaxially fixed; the gear counter records the number of turns of the rolling wheel. According to the invention, the gear counter is fixed to the rolling wheel, and rotates with the rolling wheel, and accordingly, the number of turns of the rolling is completely right, and the length counting precision is improved; the length counter has a simple structure, is easy to operate, and can operate once the cable for length counting drives the rolling wheel to rotate; the length counter is simple to operate, does not require especially professional technical personnel for operation, and is easy to popularize on a production line. The invention also discloses a length counting method of the length counter.

Owner:ANQING SUN & MOON CABLE

Belt slipping prevention device of belt conveyor drum

InactiveCN105035652AIncrease coefficient of frictionIncrease frictionConveyorsFriction forceBelt conveyor

The invention discloses a belt slipping prevention device of a belt conveyor drum and relates to the technical field of belt conveyor drums. The belt slipping prevention device of the belt conveyor drum is characterized in that metal rings are mounted on the surface of the drum and a plurality of strengthening ribs are welded on the metal rings. The belt slipping prevention device achieves the target of prolonging the service life of the belt conveyor drum while improving the friction force of the belt conveyor drum.

Owner:LIUZHOU MEINA MACHINERY

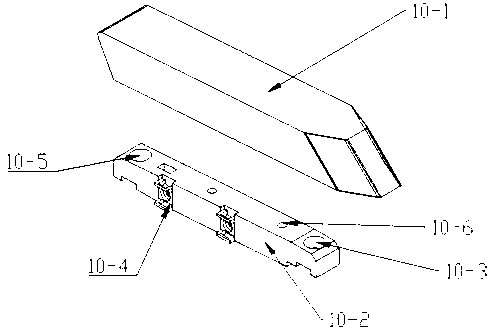

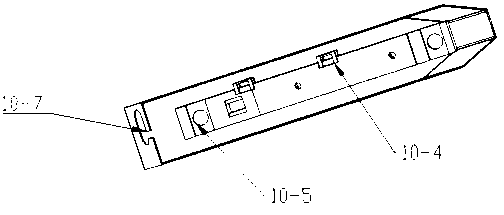

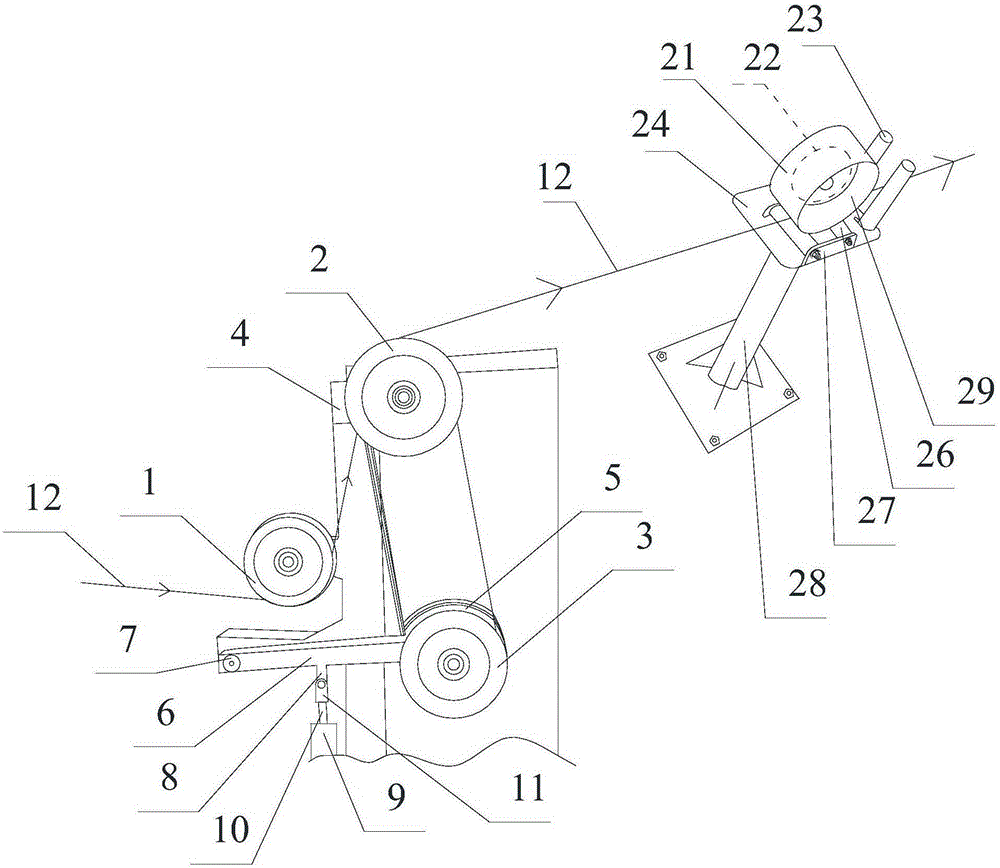

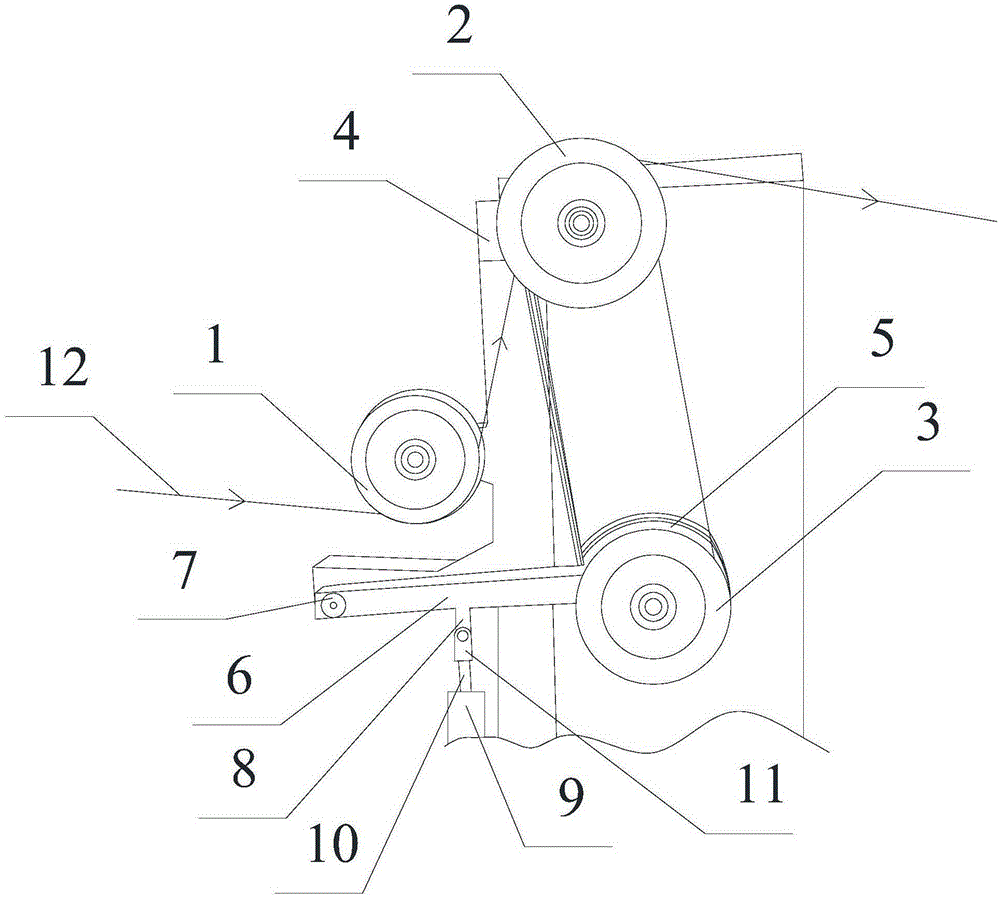

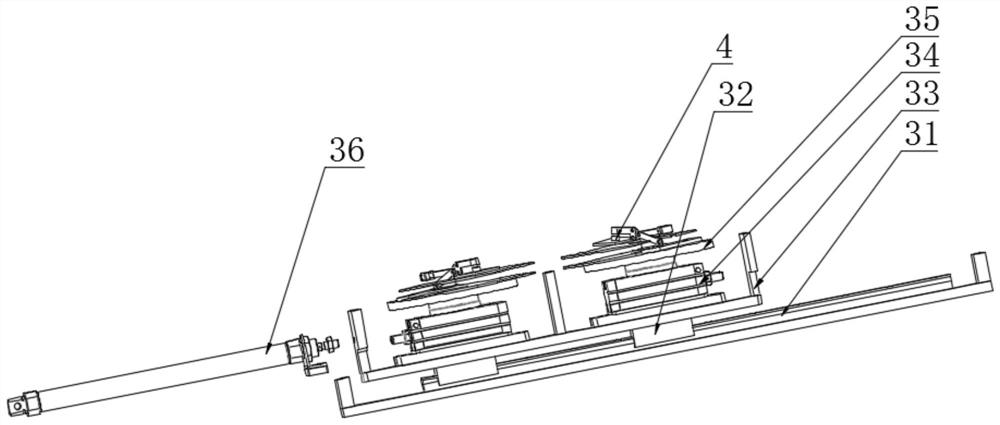

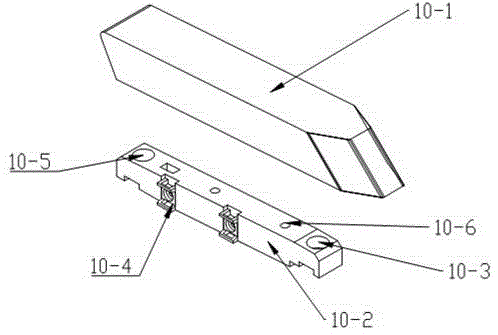

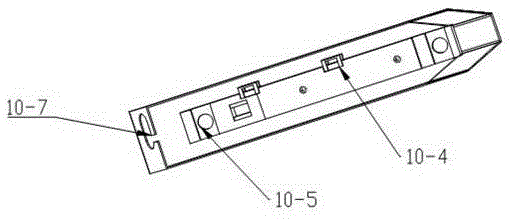

Auxiliary mechanism of wire drawing machine

The invention discloses an auxiliary mechanism of a wire drawing machine. The auxiliary mechanism comprises a meter counter and a creel stand. The meter counter is used for calculating the meter number of cables; and the creel stand is used for leading cables to be wound on a cable winding frame. The meter counter comprises a base and a meter counting device mounted on the base. The meter counting device comprises a rolling wheel, a gear counter and at least one auxiliary wheel. The rolling wheel and the auxiliary wheel are vertically stacked; the cables to be counted the meter number penetrate through the rolling wheel and the auxiliary wheel, which are vertically stacked; and the cables to be counted the meter number walk to drive the rotation of the rolling wheel. The gear counter and the rolling wheel are coaxially fixed; and the gear counter records the rotating circle number of the rolling wheel. The auxiliary mechanism has the following advantages: the gear counter is fixed on the rolling wheel, and rotates along with the rolling wheel, so that the rotating circle number of the rolling wheel is absolutely correct, and the meter counting precision is improved; and the auxiliary mechanism is simple in structure, is easy to operate, can drive the rotation of the rolling wheel by only needing the walking of the cables to be counted the meter number, and is simple in operation.

Owner:ANQING SUN & MOON CABLE

Material clamping mechanism used for groover

InactiveCN107745423ARealize automatic transportationTenoning is convenientDovetailed workDetentStaging operation

The invention discloses a clamping mechanism for a tenoning machine, which comprises an operating bottom platform, a transmission platform is arranged on the top of the operation bottom platform, and rollers are connected to the inner side of the transmission platform for equidistant rotation, and the top of the transmission platform One side is provided with a lower splint, the top of the lower splint is rotatably connected to an upper splint by an indexing spring, the beam is fixed on the operating platform through a strut, and the other side of the top of the operating platform is rotatably connected to it by a rotating shaft With bayonet. In the present invention, the clamping mechanism for the tenoning machine, firstly, a roller is arranged on the inner side of the transmission platform, and the automatic transportation of the wood can be realized through the rotation of the roller; secondly, the upper splint, the lower splint and the indexing spring The composed splint mechanism can clamp the wood to facilitate the tenoning of the wood, and the clamping support plate and bayonet pin can further fix the wood to prevent the wood from wandering when tenoning.

Owner:高邮市鑫顺机械制造有限公司

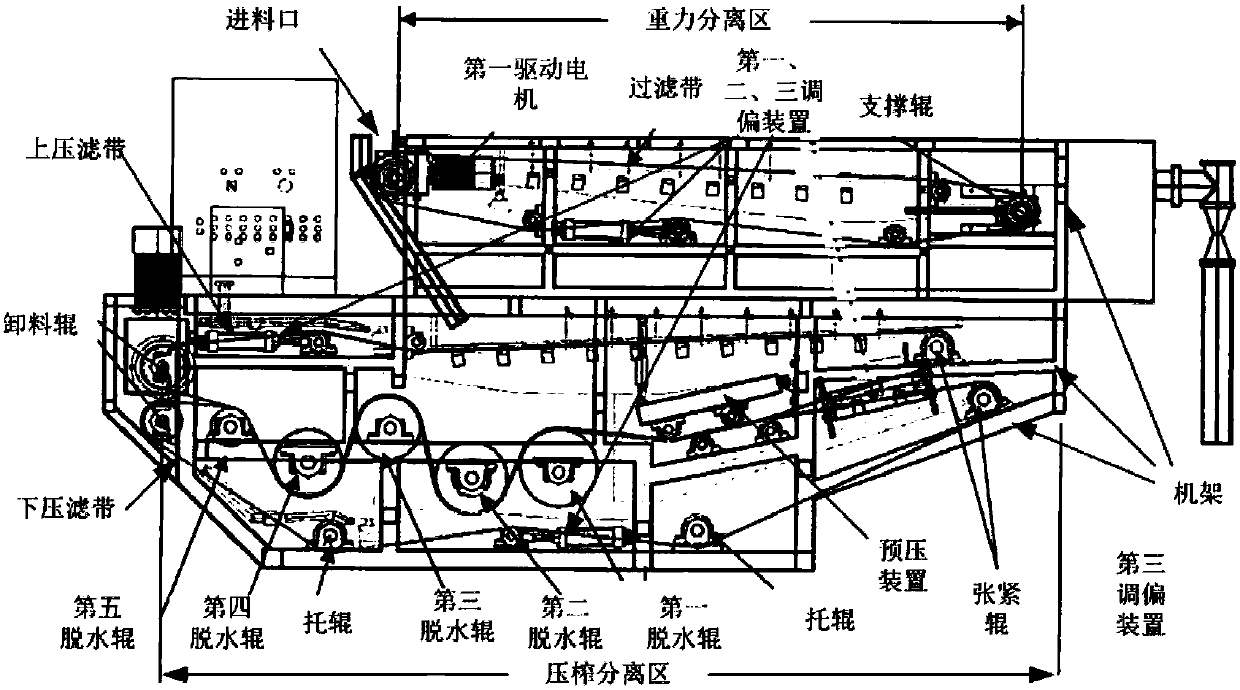

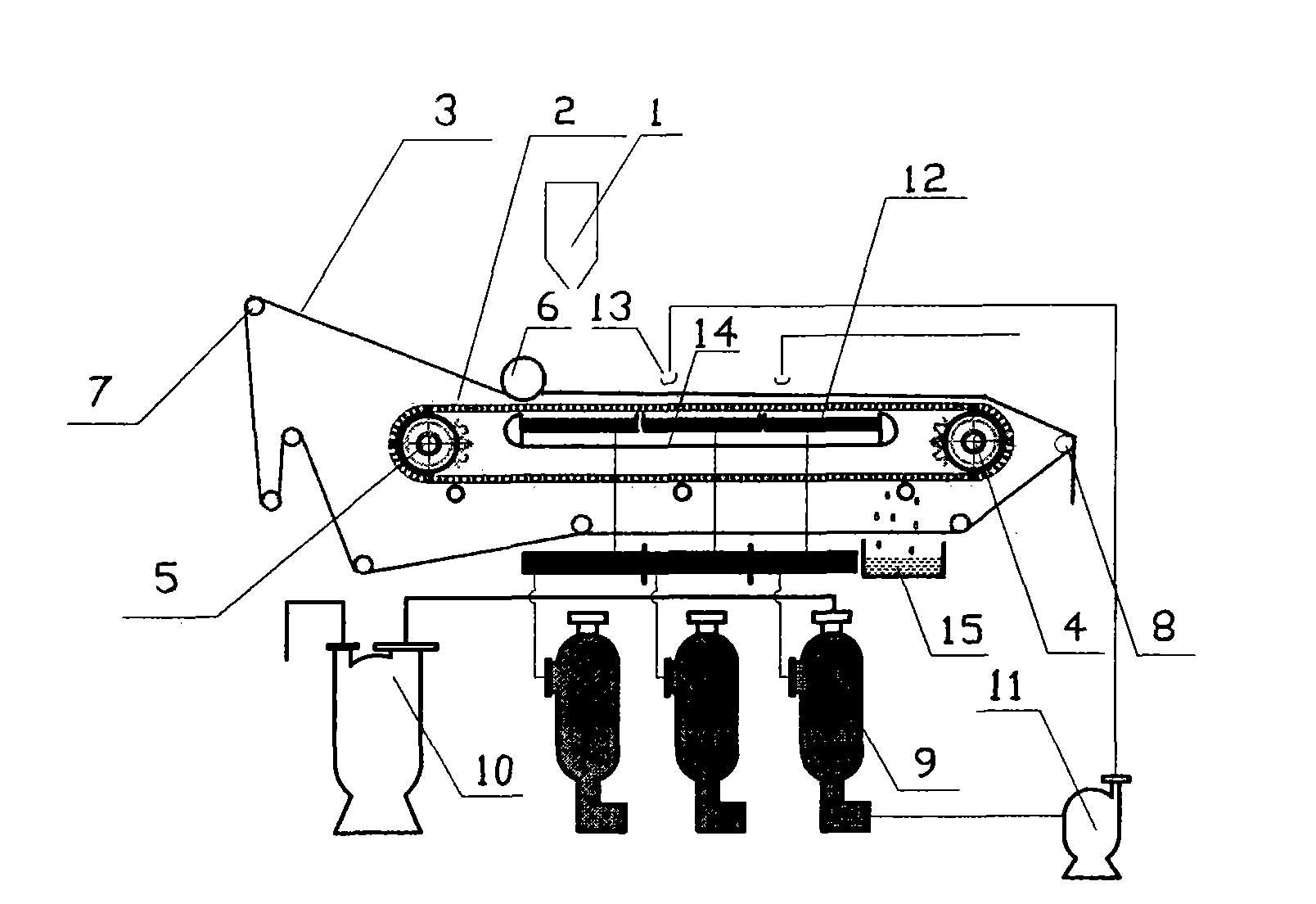

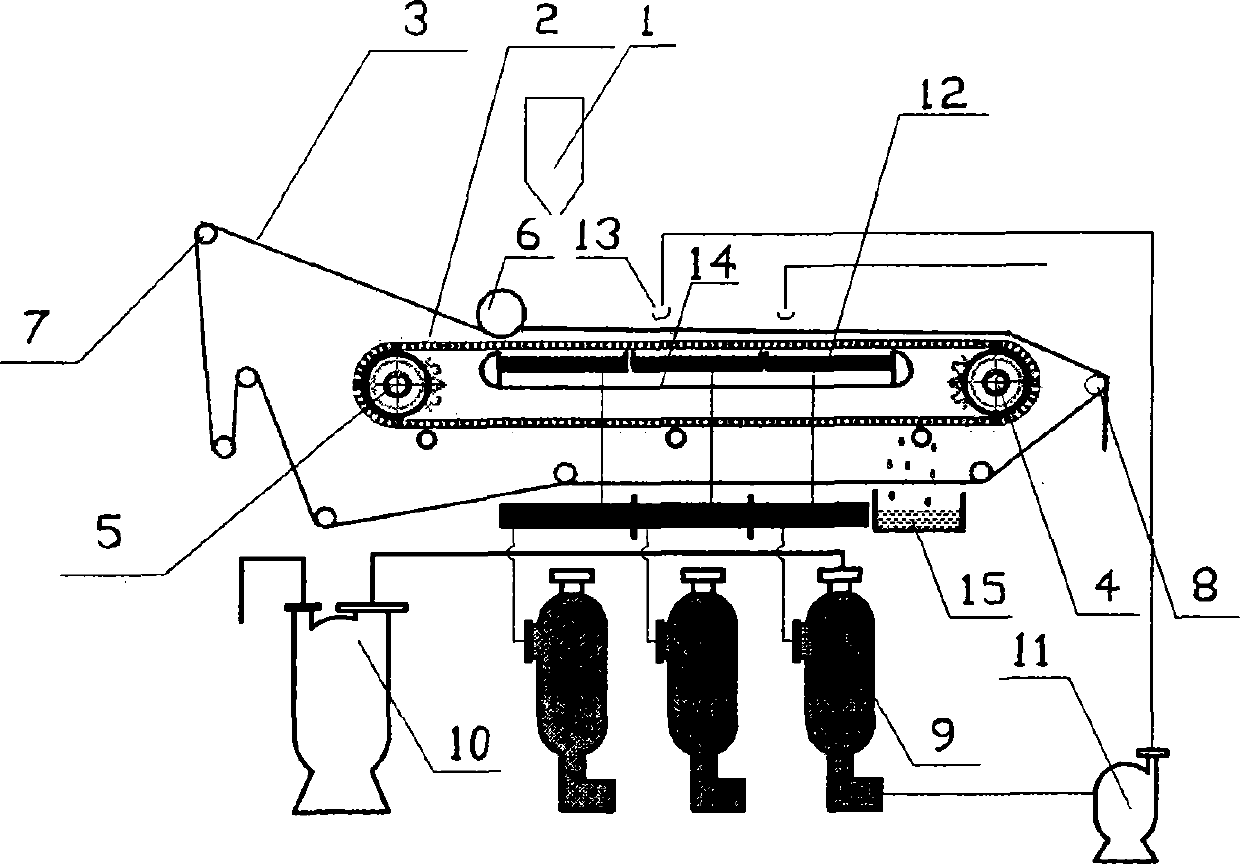

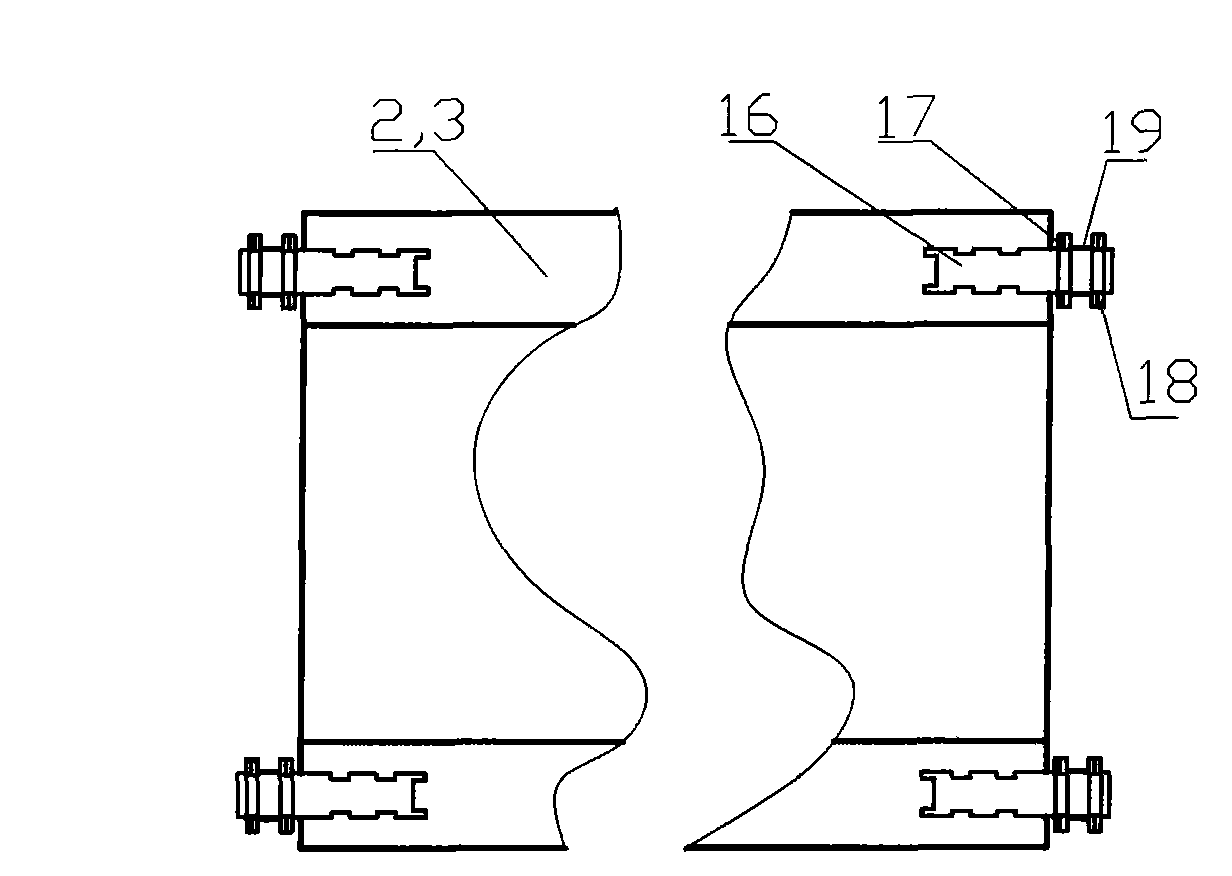

Double-belt non-deflection rubber belt vacuum filter

InactiveCN102091459ASimple structureEasy system maintenanceMoving filtering element filtersSprocketEngineering

The invention belongs to the field of solid-liquid separation equipment and particularly relates to a double-belt non-deflection rubber belt vacuum filter. The double-belt non-deflection rubber belt vacuum filter comprises a rubber belt (2), a filter cloth belt (3), rubber belt driving / driven wheels (4, 5), filter cloth belt driving / driven wheels (6, 7, 8), a vacuum box (12) and a gas-liquid separator (9), wherein the working surface of the filter cloth belt (3) is attached to the rubber belt (2); the rubber belt driving / driven wheels (4, 5) are in matched connection with the rubber belt (2);the filter cloth belt driving / driven wheels (6, 7, 8) are in matched connection with the filter cloth belt (3); the vacuum box (12) is fixed below the rubber belt; the gas-liquid separator (9) is provided with a vacuum pump (10); an inlet of the gas-liquid separator (9) is communicated with the vacuum box (12) through a pipeline; the end parts of the two sides of the rubber belt (2) and the filter cloth belt (3) are both provided with a chain wheel transmission mechanism; and the filter cloth belt driving / driven wheels (6, 7, 8) and the rubber belt driving / driven wheels (4, 5) adopt chain wheels meshed with the chain wheel transmission mechanisms. A system is convenient to maintain. The double-belt non-deflection rubber belt vacuum filter has a low cost and high transmission performance and guidance performance. The phenomenon of deflection of the rubber belt and the filter cloth belt can be effectively prevented.

Owner:丹东长城环境设备有限公司

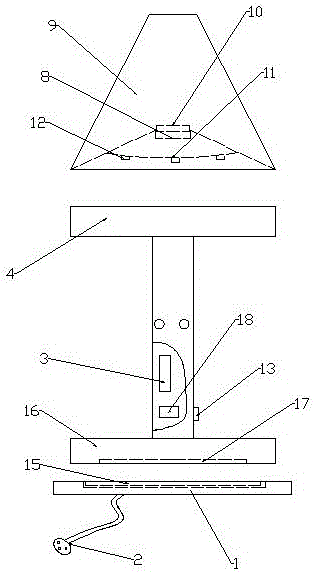

Intelligent wireless charging magnetic suspension table lamp

InactiveCN106195745APrevent deviationWon't go off trackElectrical apparatusElectroluminescent light sourcesInductive chargingMagnetic levitation

The invention discloses an intelligent wireless charging magnetic suspension table lamp which comprises a charging base. A plug is mounted at the lower end of the charging base. A first transmitting coil is arranged at the upper end of the charging base and connected with the plug. A table lamp base is arranged above the charging base. A first receiving coil is arranged at the lower end of the table lamp base and connected with a controller. A lithium battery is arranged in the table lamp base and connected with the controller. A magnetic suspension lamp base is arranged at the upper end of the table lamp base. A permanent magnet I is annularly arranged on the upper end face of the magnetic suspension lamp base. A plurality of wireless transmitting coils are symmetrically mounted at the position, in the permanent magnet I, of the magnetic suspension lamp base. A Hall sensor is mounted at the center position of the magnetic suspension lamp base. The wireless transmitting coils are connected with the output end of the controller. The Hall sensor is connected with the input end of the controller. A permanent magnet II is arranged above the magnetic suspension lamp base. A lampshade is clamped on the permanent magnet II through a locating ring and provided with a wireless receiving coil. The wireless receiving coil is connected with illumination lamps in the lampshade. The price is low, and the structure is simple.

Owner:ZHONGYUAN ENGINEERING COLLEGE

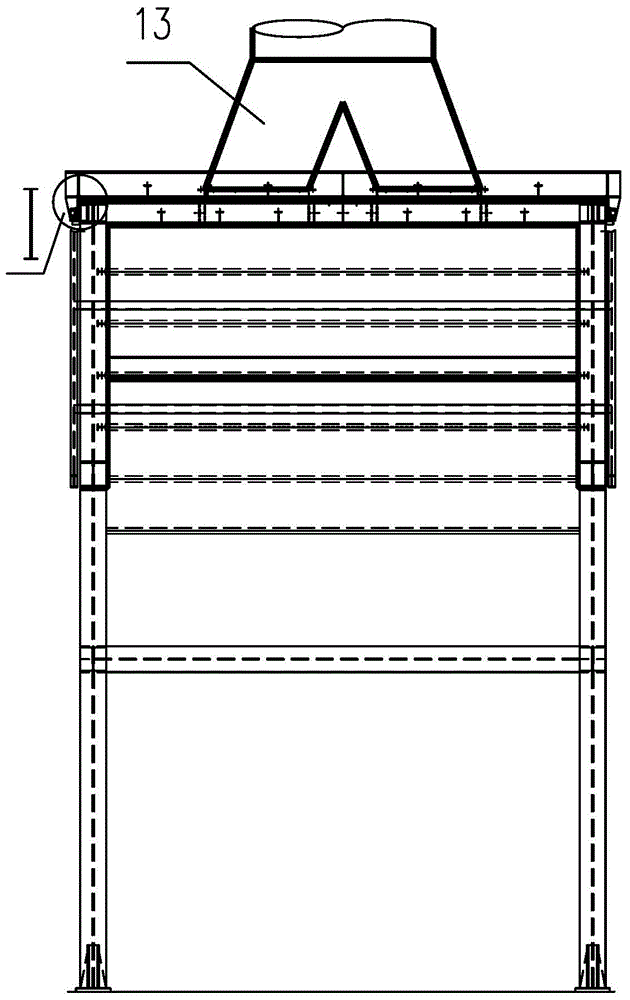

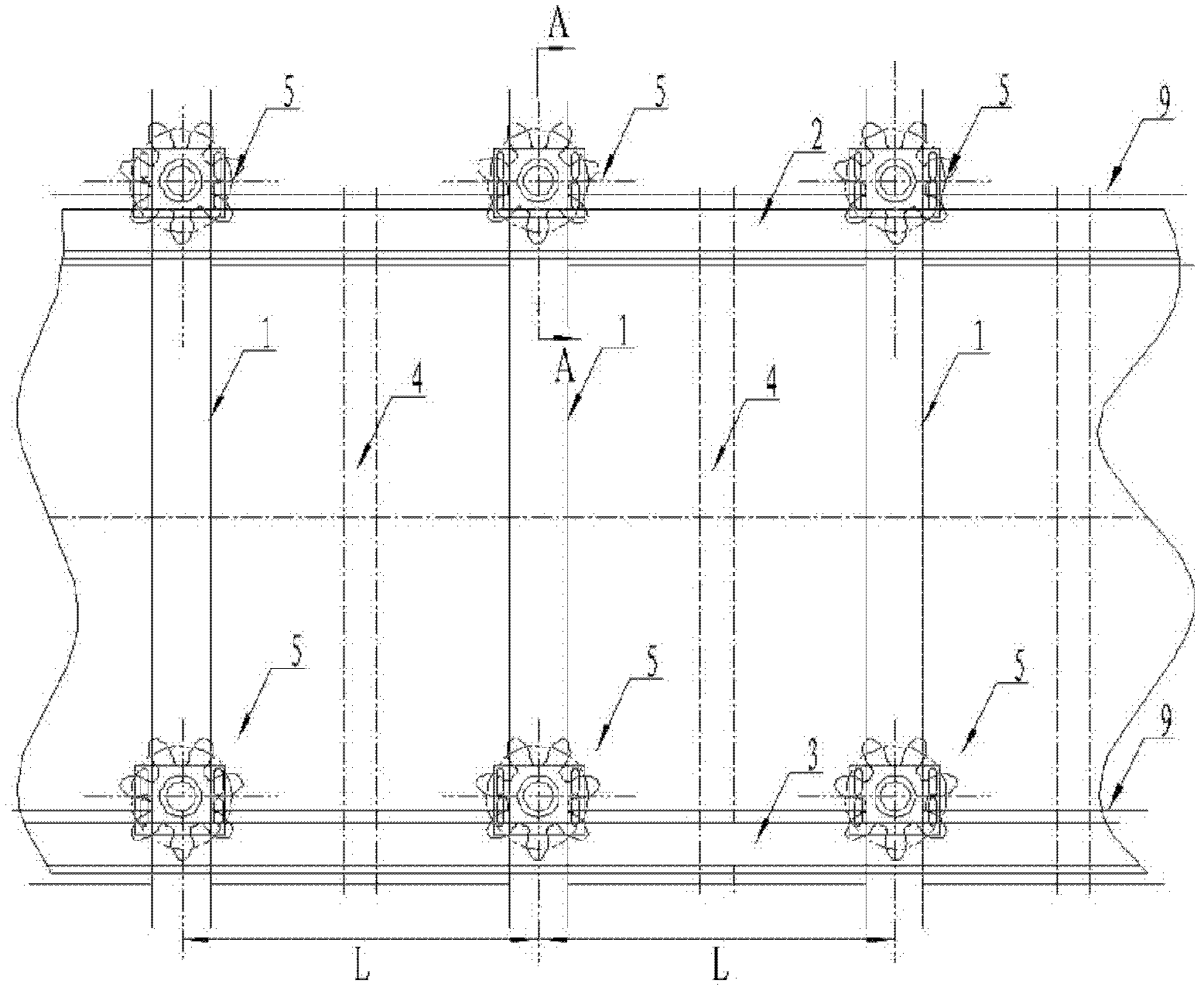

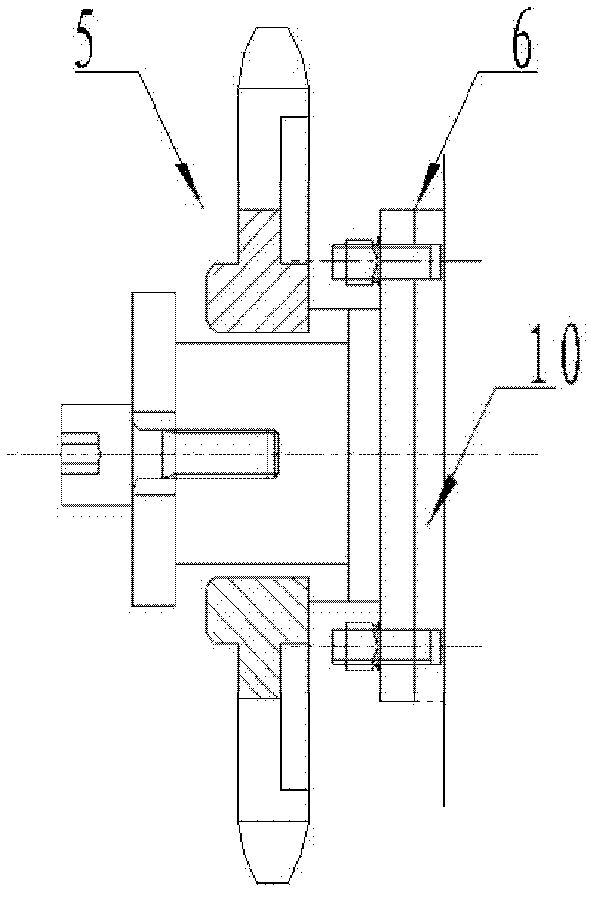

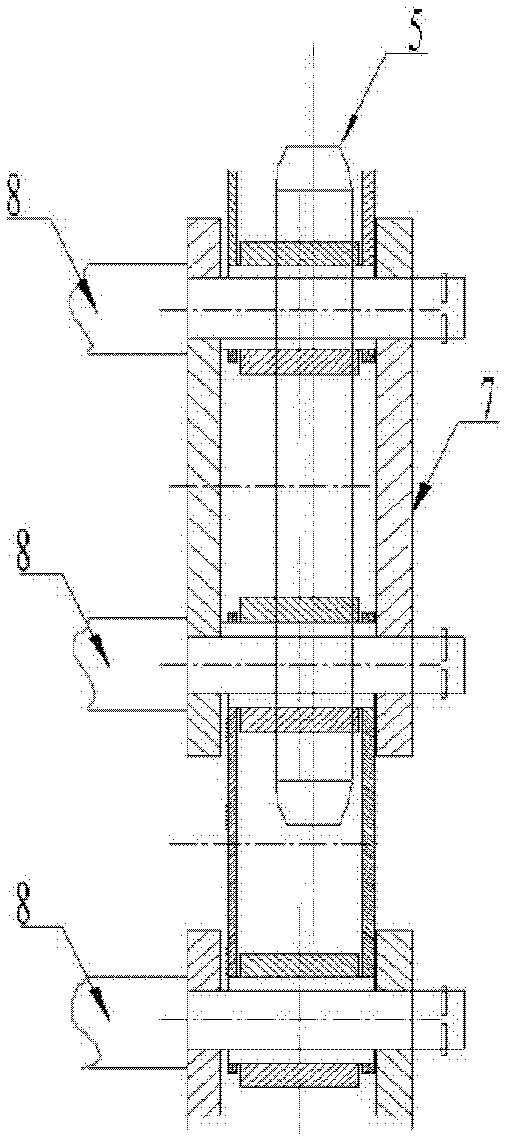

Method for preventing net belt of belt type drying machine from deviating and belt type drying machine

The invention discloses a method for preventing the net belt of a belt type drying machine from deviating. The belt type drying machine comprises a framework (1), a pair of tracks, two chains (7), a net belt support rod (8) and a net belt, wherein the tracks are fixed on the framework (1); the net belt support rod (8) is connected between two chains (7) and is paved on the track together with the chains (7); and the net belt is paved on the net belt support rod (8) and supported by the net belt support rod (8). The method comprises the step that the positioning wheels (5) meshed with the chains (7) are arranged along the tracks. The invention further provides the belt type drying machine for preventing the net belt from deviating. According to the technical scheme, when the belt type drying machine runs, the positioning wheels arranged along the tracks can be meshed with the chains, and thus the chains can be guided to operate along the tracks. Therefore, the chains are prevented from deviating from the tracks due to the expansion of the net belt support rod, and thus the deviation of the net belt is avoided.

Owner:PANZHIHUA IRON AND STEEL +3

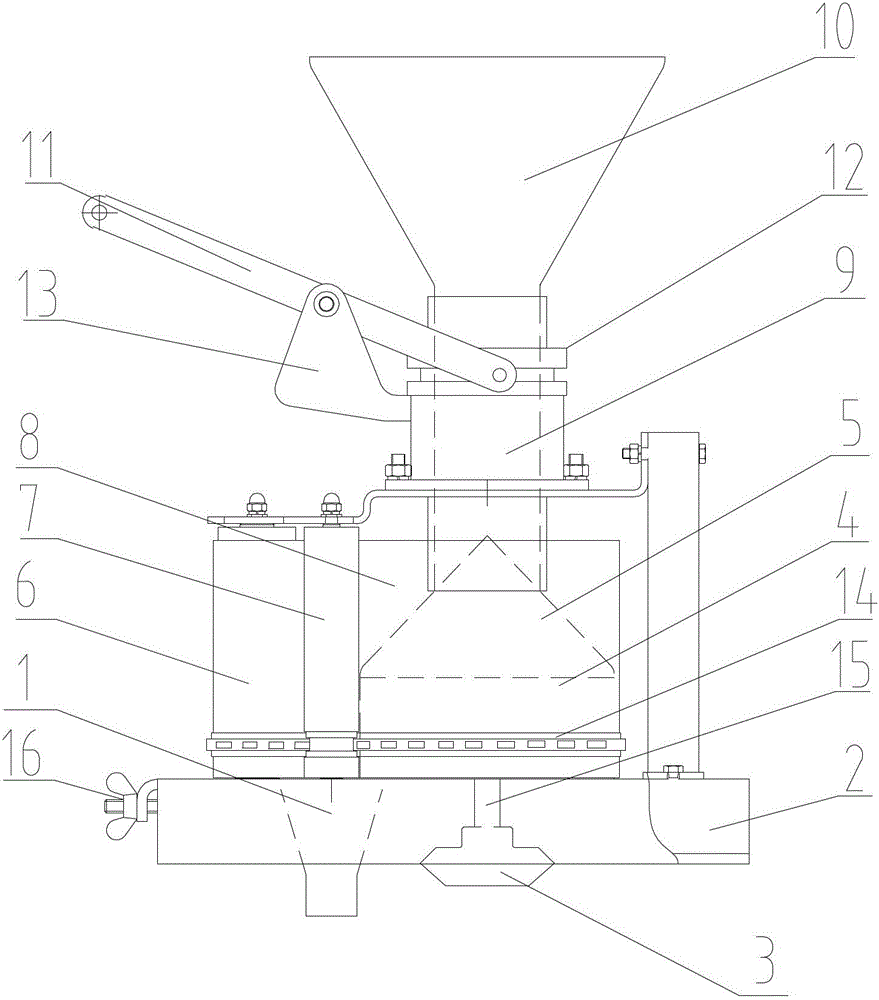

A kind of unit row seeding machine

ActiveCN103283360BEvenly distributedAchieve the purpose of self-purificationSeed depositing seeder partsSeederAgricultural engineering

The invention relates to the field of agricultural machinery equipment, and in particular relates to a seed metering single body for a plant-to-row drill seeder with high sowing efficiency. The seed metering single body comprises a seed metering deice and a seed storing device which are fixedly arranged on a machine body, wherein the seed metering device comprises an installing base, a seed metering opening is formed in one side of the installing base, a machine drives a rotating bevel gear, the upper part of the bevel gear is sequentially provided with a cone base and a hollow cone which are linked with the bevel gear, a tensioning roller is arranged at one side of the cone, the seed metering opening is formed between the cone and the tensioning roller, and a driving woven belt is packed outside the cone and the tensioning roller; the seed storing device comprises a glass seed storing sleeve and a seed storing hopper, and the lower part of the seed storing sleeve is tightly clamped with the top end of the cone. The seed metering single body provided by the invention has the advantages of being simple in structure, even in seeding, high in self-cleanliness, and small in seed damage.

Owner:QINGDAO AGRI UNIV +1

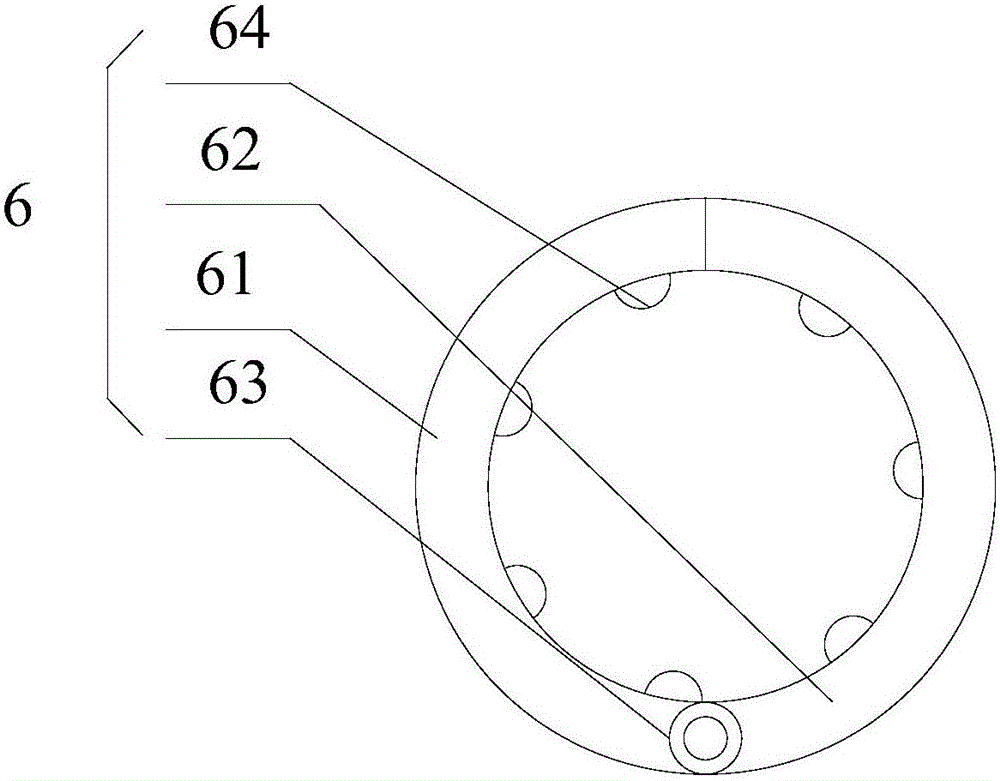

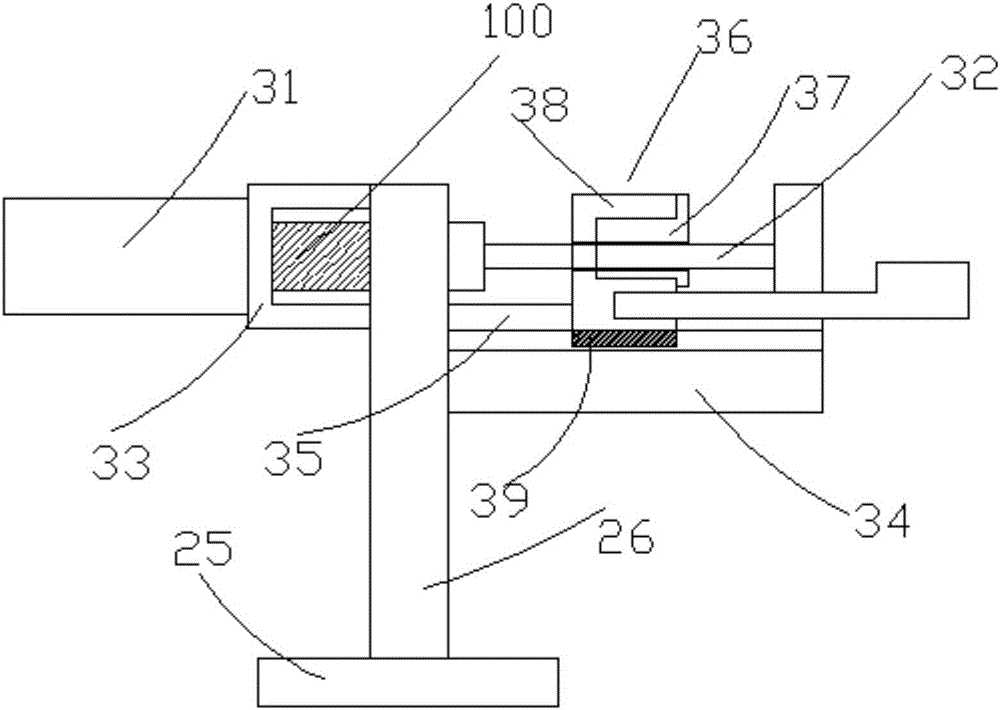

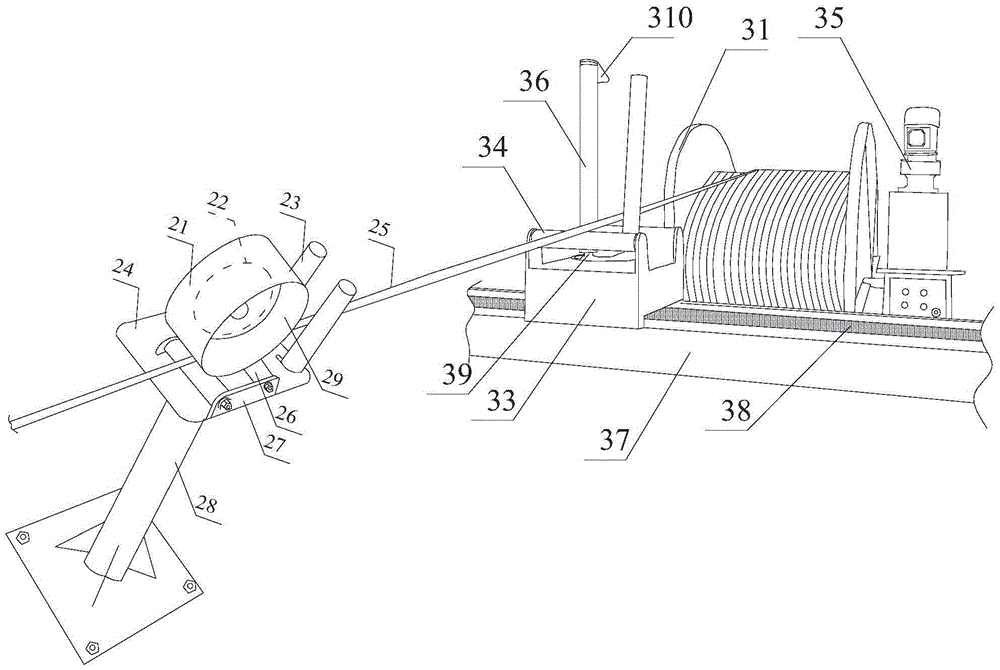

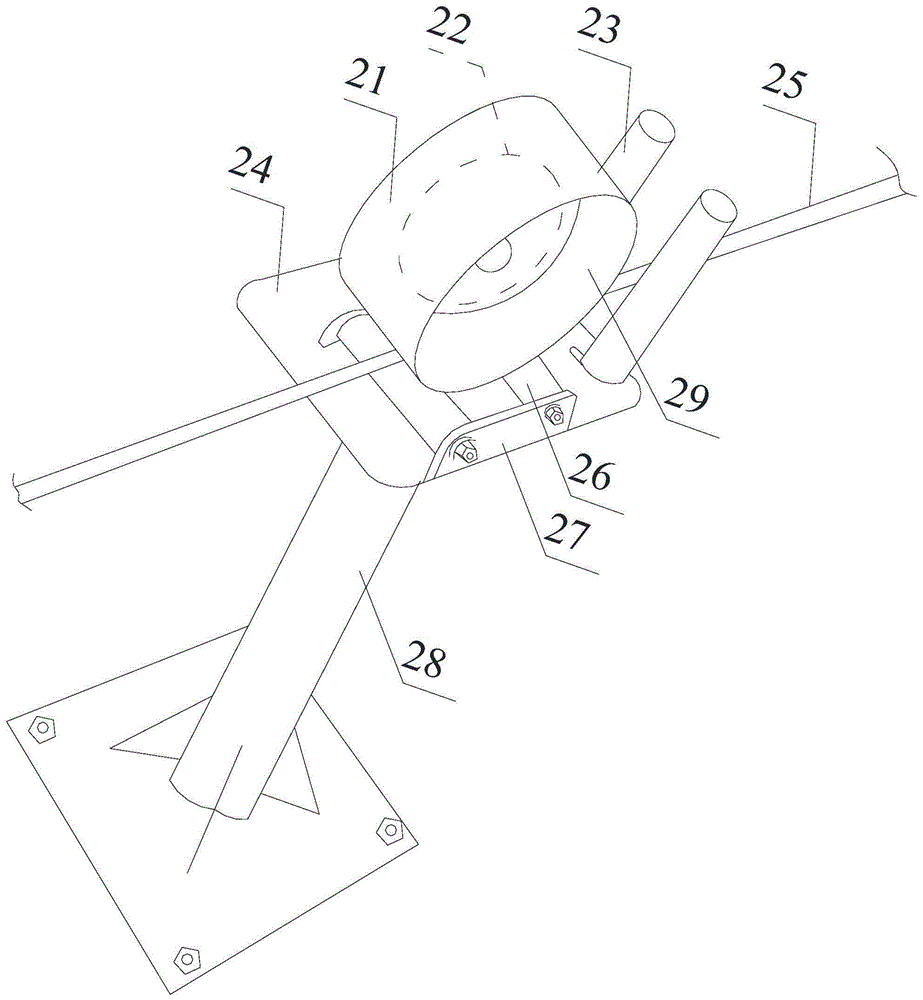

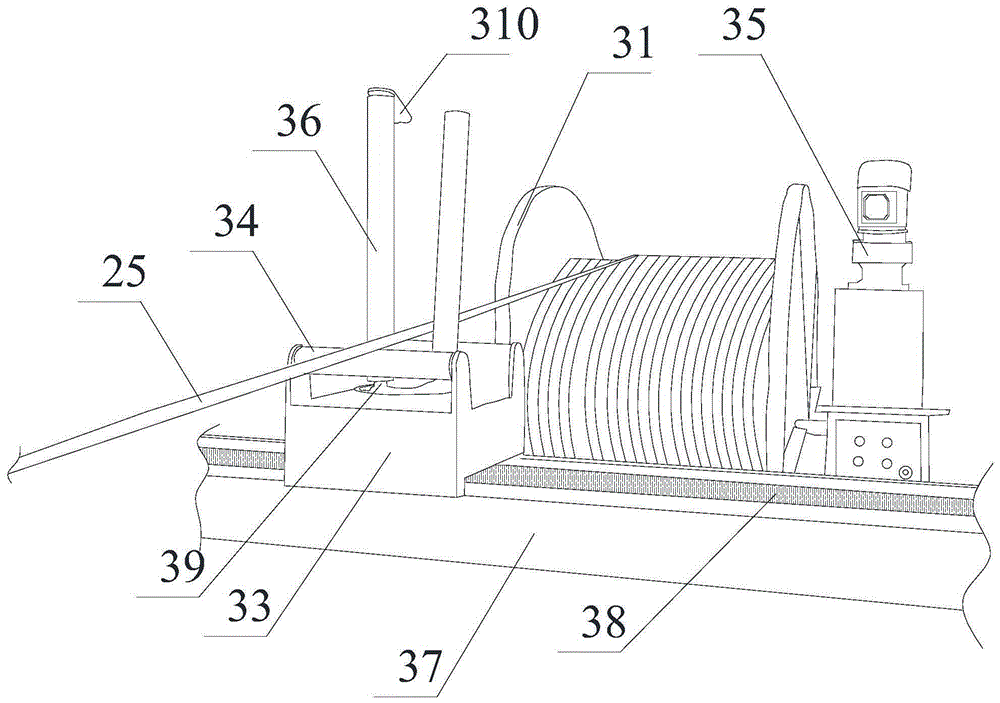

Auxiliary tool for drawing machine

InactiveCN105180755APut an end to the situation where the tension adjustment is not in placeNot tiredMetal working apparatusMechanical measuring arrangementsEngineeringConductor Coil

The invention discloses an auxiliary tool for a drawing machine, comprising a take-up tension regulation mechanism for regulating the take-up tension of the cable during the winding, and a meter recorder recording the meters of the cable. The take-up tension regulation mechanism comprises a transmission wheel, a fixed wheel, a moving wheel, a framework and a regulation assembly. The transmission wheel and the fixed wheel perform self-rotation relative to the framework; the moving wheel is movably installed on the framework through the adjustment assembly; the moving wheel can move relative to the framework while performing self-rotation relative to the framework; the circumferential end surfaces of the three wheels are provided with annular grooves; and the annular groove is coaxially positioned with the corresponding wheel. The meter recording device of the meter recorder comprises a rolling wheel, a gear counter, and at least one auxiliary wheel. The rolling wheel is stacked with the auxiliary wheel; the cable, the meter of which is to be recorded, passes through between the rolling wheel and the auxiliary wheel which are stacked, and walking of the cable drives the rolling wheel to rotate; the gear counter is coaxially fixed with the rolling wheel; and the gear recording device records the rotation turns of the rolling wheel.

Owner:ANQING SUN & MOON CABLE

Double-belt non-deflection rubber belt vacuum filter

InactiveCN102091459BWon't go off trackGuarantee stabilityMoving filtering element filtersVapor–liquid separatorSprocket

Owner:丹东长城环境设备有限公司

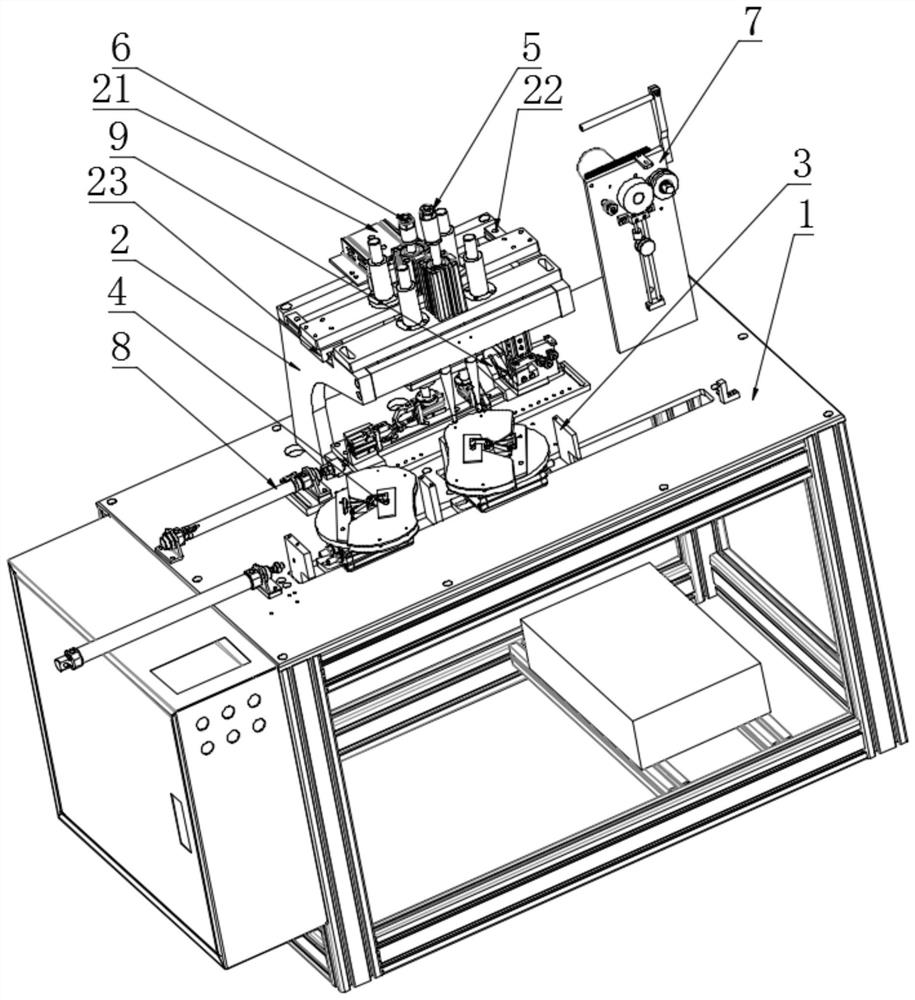

N95 mask double-station strap spot welding machine

PendingCN111907067AReduce equipment costsReduce labor costsDomestic articlesProtective garmentEngineeringSpot welding

The invention relates to an N95 mask double-station strap spot welding machine, and belongs to the field of N95 mask strap spot welding machines. The device comprises a workbench, a support and a positioning device which are fixedly connected are arranged on the workbench; a welding device and a movable strap clamping device are arranged on the support, and a strap pulling device connected with the workbench is arranged below the strap clamping device; and the positioning device comprises a first sliding guide rail fixed to the workbench, a first sliding block which is slidably connected is arranged on the first sliding guide rail, a supporting frame is arranged on the first sliding block, two rotating air cylinders which are parallel are arranged on the supporting frame, and positioning tools which are fixedly connected are arranged on the rotating air cylinders. Compared with the prior art, the machine has the beneficial effects that firstly, two welding stations are arranged on onepositioning device, that is, two welding stations are arranged on one strap welding machine, and only one person is needed for one welding station, so that the equipment cost and the labor cost of anenterprise are reduced, and the efficiency is improved.

Owner:烟台思壮智能科技有限公司

Medical apparatus for muscle retraction

The invention discloses a medical apparatus for muscle retraction. The medical apparatus for the muscle retraction comprises a base, a workbench arranged at the top end of the base, and a left vertical plate and a right vertical plate which are arranged on the workbench, wherein strip-shaped sliding slots are formed in the left vertical plate and the right vertical plate; a first traction device is arranged on the left vertical plate; a second traction device is arranged on the right vertical plate; a first sliding component and a second sliding component are arranged inside the strip-shaped sliding slots. The medical apparatus for the muscle retraction is easy to operate, muscles can be pulled slowly through the traction devices, and the muscle pulling width is adjusted, so that smooth operation of surgery is guaranteed; in addition, the sliding components can be adjusted up and down to adjust the muscle pulling height, so that requirements of the surgery are met and the progress of the surgery is greatly accelerated.

Owner:杨四九

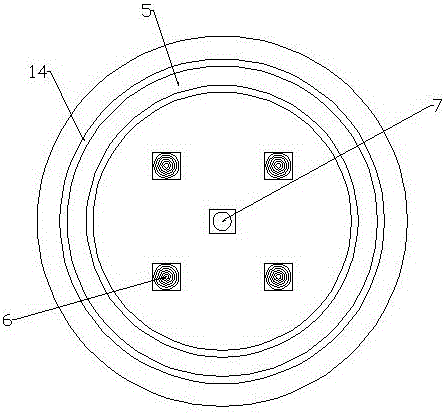

Soil gas flux measuring instrument and its measuring method

ActiveCN103235105BUndisturbedNot easy to interfereEarth material testingObservational errorMeasuring instrument

The invention relates to a soil gas flux detector comprising a soil ring (1), supporting legs (2), a pedestal (20), a gas chamber (7), a protective cover (8), a line passing shaft (9), and a control box (19). The flux detector is characterized in that a sealing ring (5) and a pressing ring (3) are arranged above the pedestal (20); the supporting legs (2) are arranged below the pedestal (20); supporting led slide grooves (16) and supporting leg rotation shafts (14) are arranged on the supporting legs (2); a buffering device (8-7) is arranged in the gas chamber (7), the protective cover (8), and the line passing shaft (9); and a return button (19-4) is arranged on the control box (19). With the device provided by the invention, problems such as exposed gas pipe and line, gas chamber offset, and large measuring error of soil gas flux detector can be solved.

Owner:北京萨维福特科技有限公司

Finger joint device for bamboo piece jointing in length

PendingCN106808540AImprove performanceDoes not cause stressCane mechanical workingFinger jointMechanical engineering

A finger joint device for bamboo piece jointing in length comprises a glue spray assembly and a finger joint assembly. The glue spray assembly is located in front of the finger joint assembly. The finger joint assembly comprises a bamboo piece groove, an advancing rolling wheel assembly and a delay rolling wheel assembly. The advancing rolling wheel assembly and the delay rolling wheel assembly are located above the bamboo piece groove. The advancing rolling wheel assembly comprises two advancing rolling wheels, and the delay rolling wheel assembly comprises two delay rolling wheels. The radius of each delay rolling wheel is 3 / 4-1 / 2 that of each advancing rolling wheel, the advancing rolling wheels and the delay rolling wheels are all driven by a motor, and the rotation speed of the advancing rolling wheels and the rotation speed of the delay rolling wheels are the same; and the lowest point of the advancing rolling wheels and the lowest point of the delay rolling wheels are located in the same horizontal line. According to the finger joint device for bamboo piece jointing in length, by the adoption of the different linear speeds between the advancing rolling wheels and the delay rolling wheels, extrusion of two bamboo pieces is completed; in this way, the problem that the extrusion strength is too large or too small is avoided by the adoption of the strength temperature during extrusion, and the performance of the jointed bamboo pieces is stable; and besides, batched continuous production can be achieved, and the production efficiency is high.

Owner:TAOJIANG FENGHE ZHIHUI BAMBOO IND CO LTD

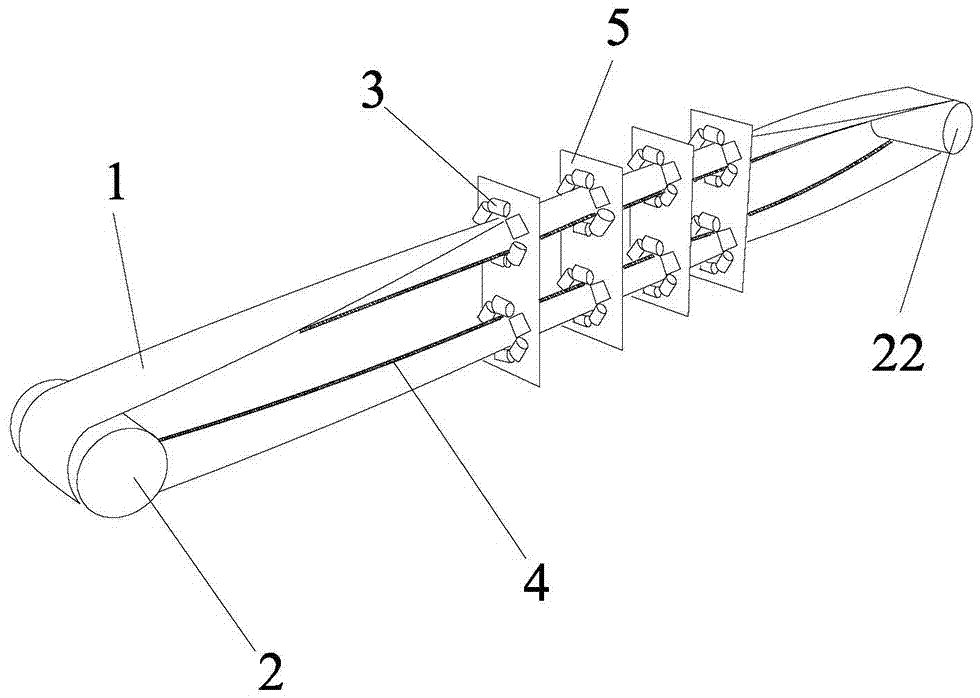

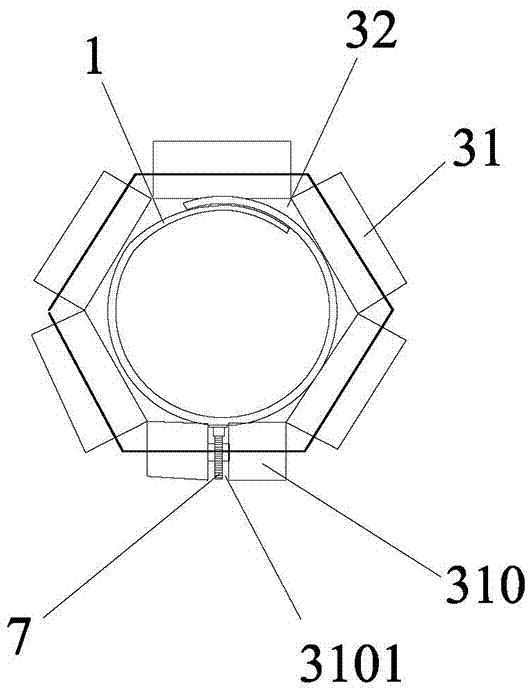

Pipe belt conveyor free of deviation adjusting and work method of pipe belt conveyor

The invention discloses a pipe belt conveyor free of deviation adjusting and a work method of the pipe belt conveyor. The pipe belt conveyor comprises a conveying rubber belt, a main driving shaft, a driven shaft, a chain, fixing blocks, large gears, small gears and a plurality of carrier roller sets. The conveying rubber belt is arranged on the main driving shaft and the driven shaft in a sleeving manner. The large gears are arranged on the main driving shaft. The chain is fixed to the back of the conveying rubber belt. The conveying rubber belt penetrates the multiple carrier roller sets. The carrier roller sets are arranged on the fixing blocks. Each carrier roller set is in a hexagon shape formed by splicing a plurality of carrier rollers. Each carrier roller set is provided with a hollow space containing the conveying rubber belt for the conveying rubber belt to be encircled by one circle to pass, and the small gears are arranged on the lowest carrier rollers of the carrier roller sets. The large gears and the small gears are engaged with the chain. The pipe belt conveyor can solve the problem of rubber belt deviation of the pipe belt conveyor and is simple in design.

Owner:XIAMEN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com