Multi-drive mobile adhesive tape conveyor capable of bending at will

A belt conveyor and multi-drive technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of high tensile force on the belt, low transportation efficiency, constant number of turns, etc., to extend the service life, The effect of improving transportation efficiency and reducing input costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

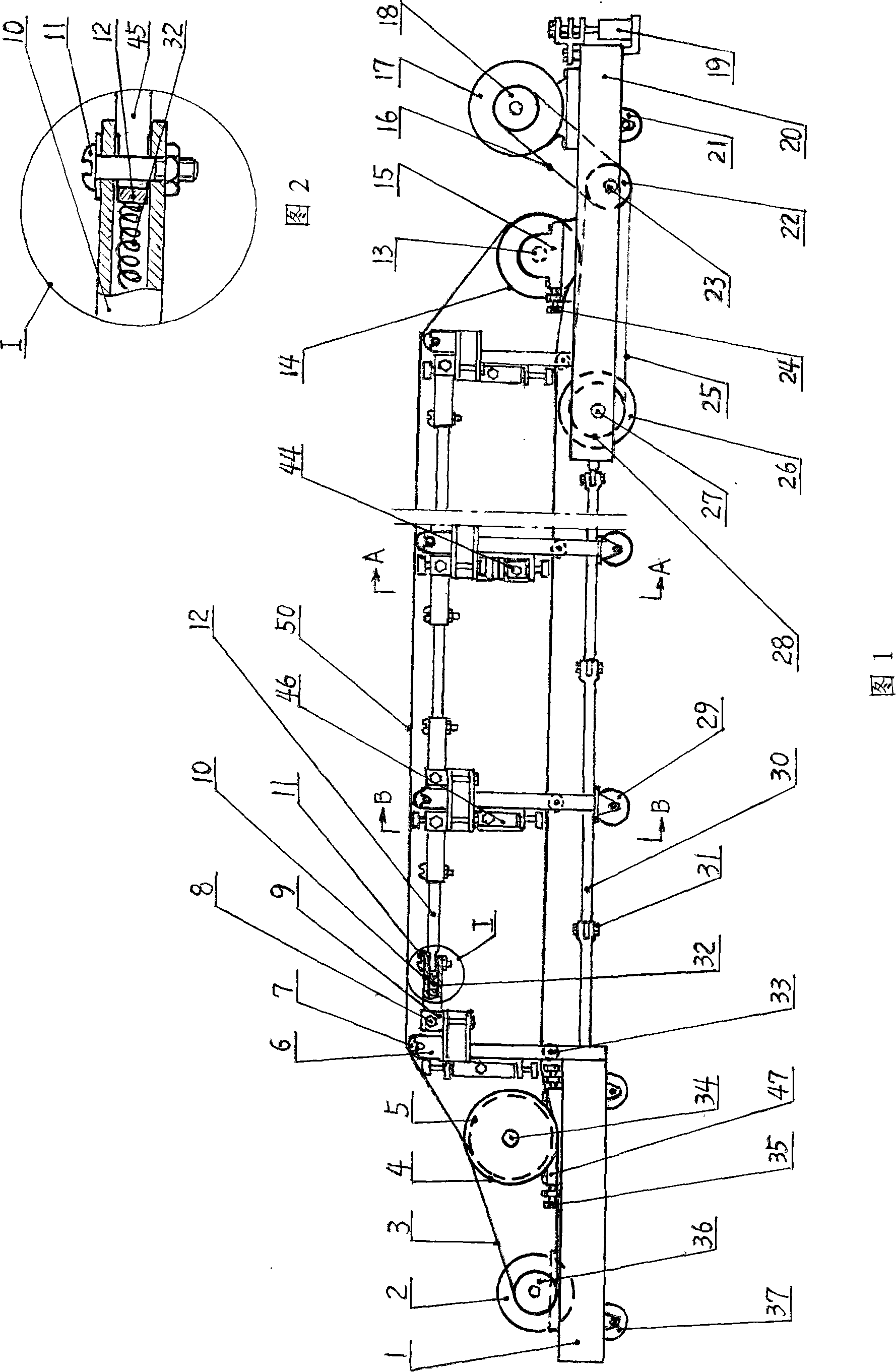

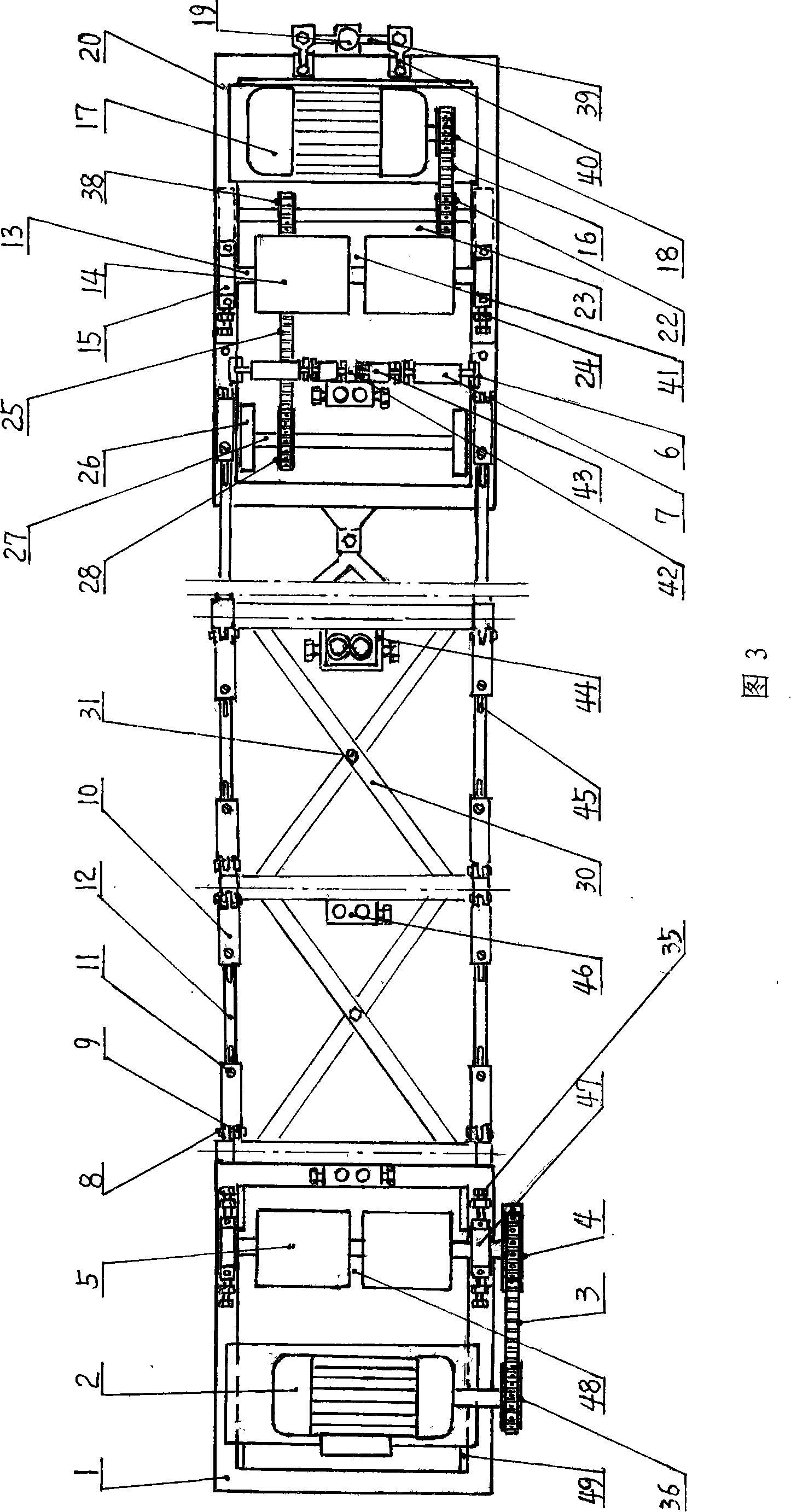

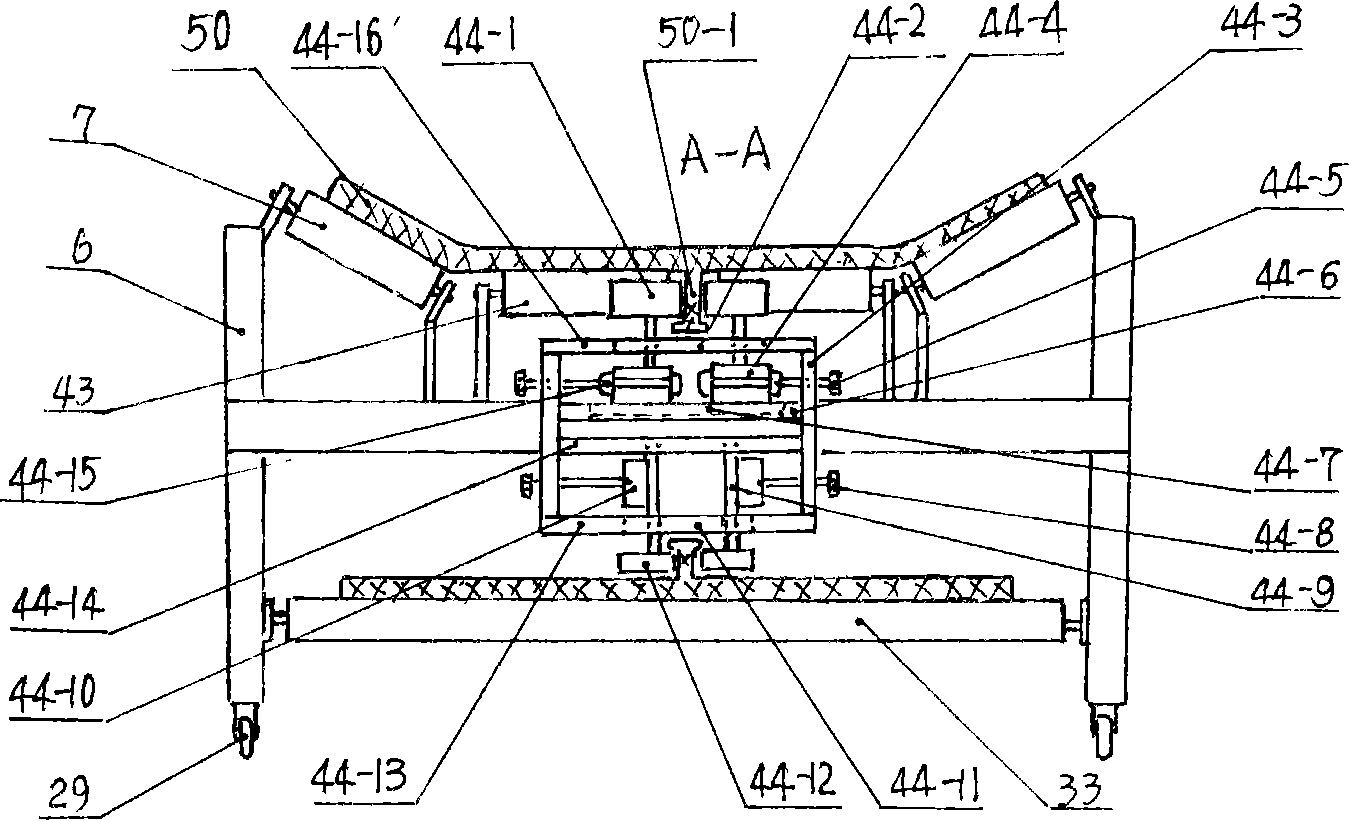

[0013] Referring to the accompanying drawings, an arbitrary bending multi-drive mobile belt conveyor is composed of a head frame 1, a tail frame 20, a main motor 2, a travel motor 17, an idler frame 6, a lower idler roller 33 and an adhesive tape 50. The feature is that a driving roller shaft 34 is movably installed in the two bearing seats 47 fixed on the head frame 1, two driving rollers 5 are fixed on the driving roller shaft 34, and driving roller grooves 48 are left between the driving rollers 5, The machine head row wheel 37 is installed under the machine head frame 1; a roller frame 6 is fixed at the left end of the machine head frame 1, and the lower part of the roller frame 6 is fixed with one end of the triangular lower link 30, and the tips of two adjacent triangular lower link rods 30 The lower connecting rod pin shaft 31 is used for flexible connection, and an upper connecting rod seat 9 is fixed on the upper part of the idler frame 6, and one end of the upper conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com