Turning conveyor and conveyor belt

A conveyor belt and conveyor technology, applied in the field of logistics conveyors, can solve the problems of excessive tension and easy wear, conveyor belt deviation, easy deviation, etc., to eliminate slippage, prolong service life, and reduce energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

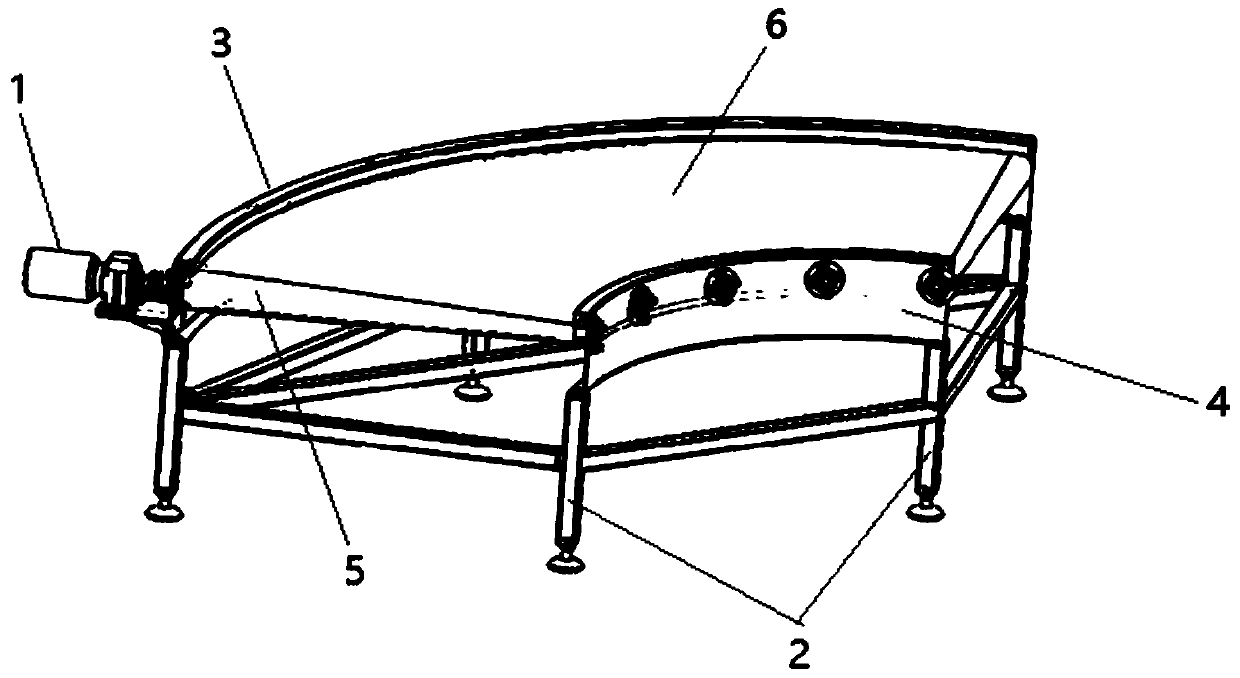

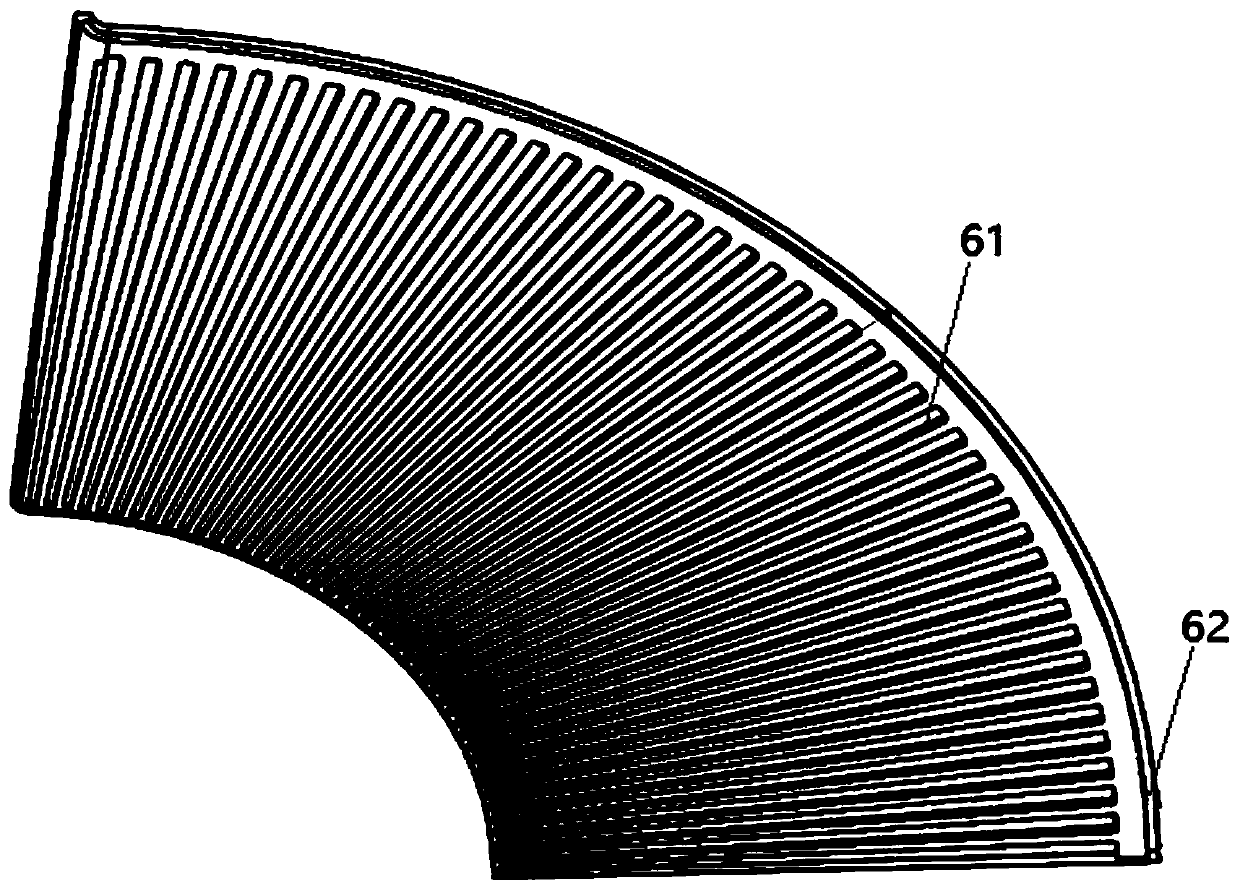

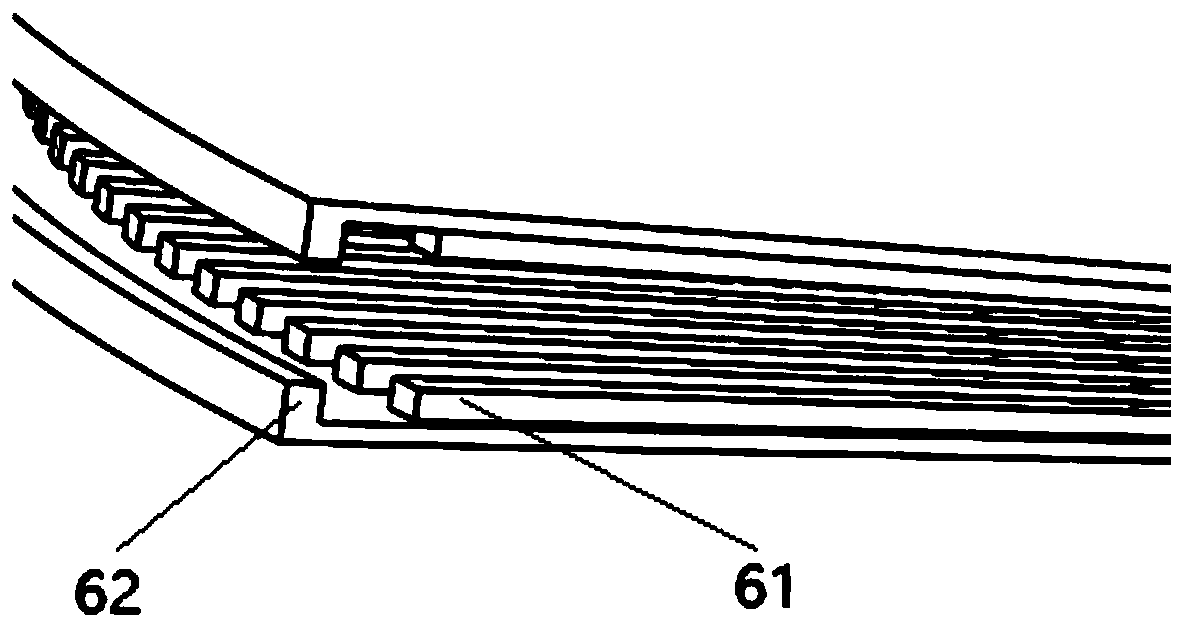

[0060] Embodiment 1, such as Figure 4 As shown, the belt pressing mechanism is arranged on the outer ring support 3 and the bead 7 opposite to the outer surface of the fan-shaped conveyor belt 6, and the bead 7 is arranged above the outer edge of the fan-shaped conveyor belt 6 to prevent the conveyor belt from upturning. The guide strip limit mechanism is a limit guide plate 8 arranged on the outer ring support 4 against the inner surface of the longitudinal guide bar 62, and the limit guide plate 8 is against the inner surface of the longitudinal guide bar 62, so that the conveying There is no lateral displacement of the belt, and it will not deviate inward.

Embodiment approach 2

[0061] Embodiment 2, such as Figure 5 As shown, the belt pressing mechanism is a pressure roller 9 arranged on the outer ring support 3 opposite to the outer surface of the fan-shaped conveyor belt 6, and the guide strip limit mechanism is arranged on the outer ring support 3 The position-limiting guide wheels 10 mortgaged on the inner side of the longitudinal guide bar 62 , the pressure wheels 9 and the position-limiting guide wheels 10 should be provided in multiple sets on the outer ring support 3 .

Embodiment approach 3

[0062] Embodiment 3, such as Image 6 As shown, the belt pressing mechanism is arranged on the outer ring support 3 and opposite to the outer surface of the fan-shaped conveyor belt 6. The bar limit mechanism is arranged on the outer ring support and mortgaged The limit guide wheels 10 on the inner side of the longitudinal guide bar 62, the limit guide wheels 10 should be provided with multiple groups on the outer ring support 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com