Patents

Literature

38results about How to "Guaranteed not to warp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

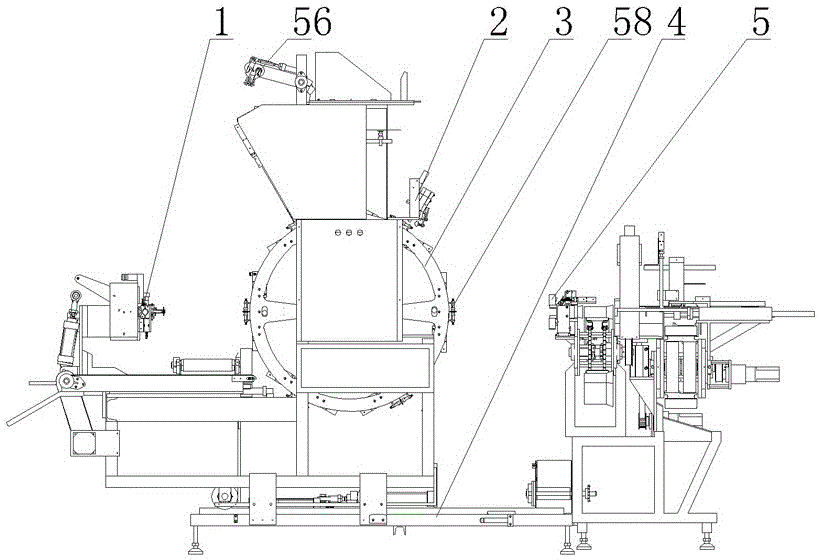

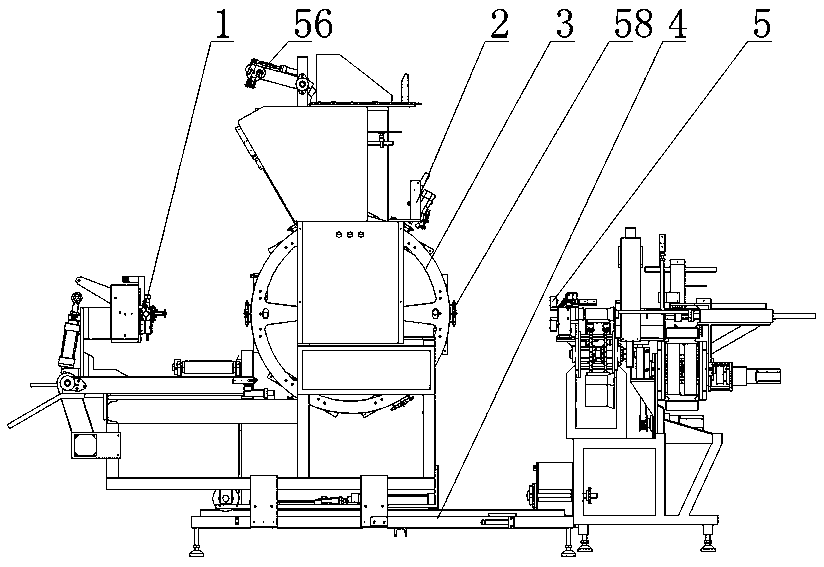

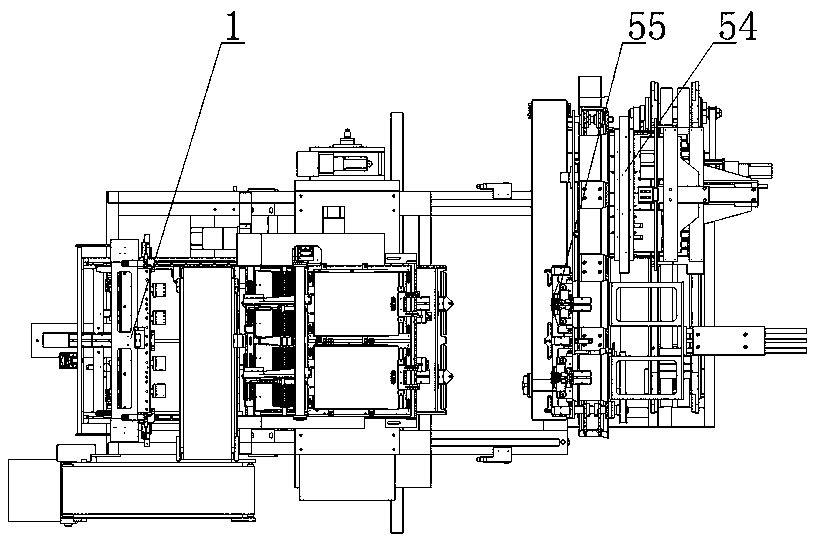

Roller-type fed material bagging machine

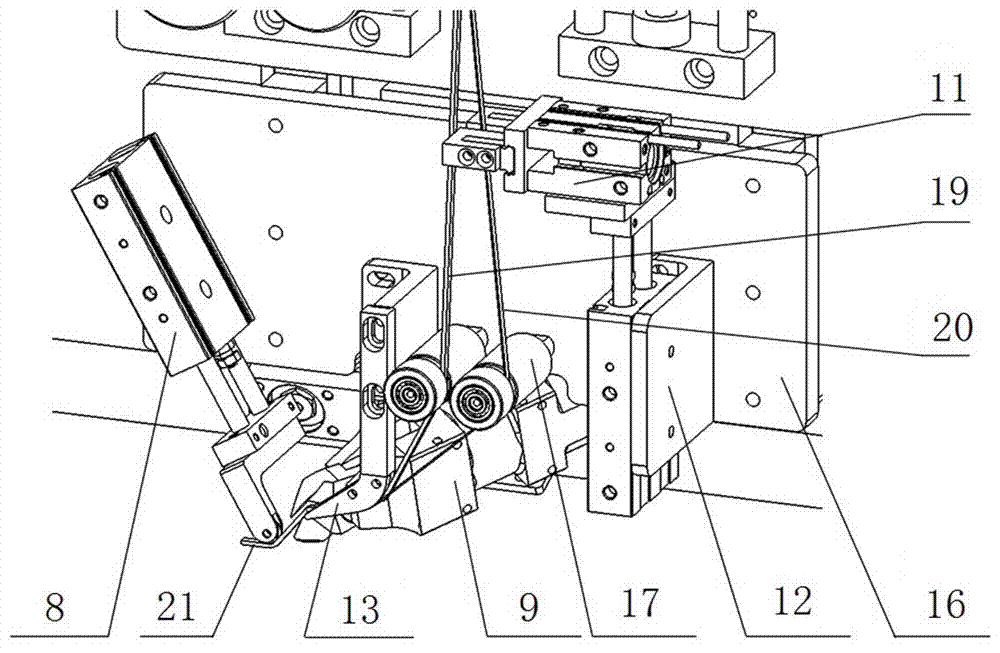

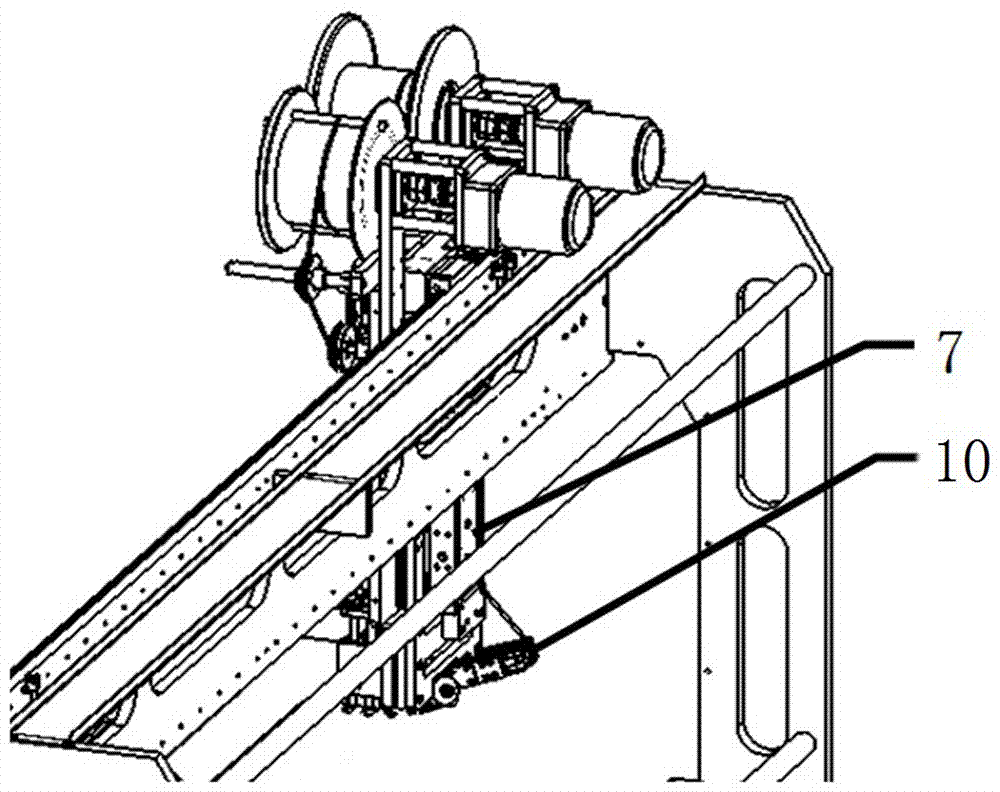

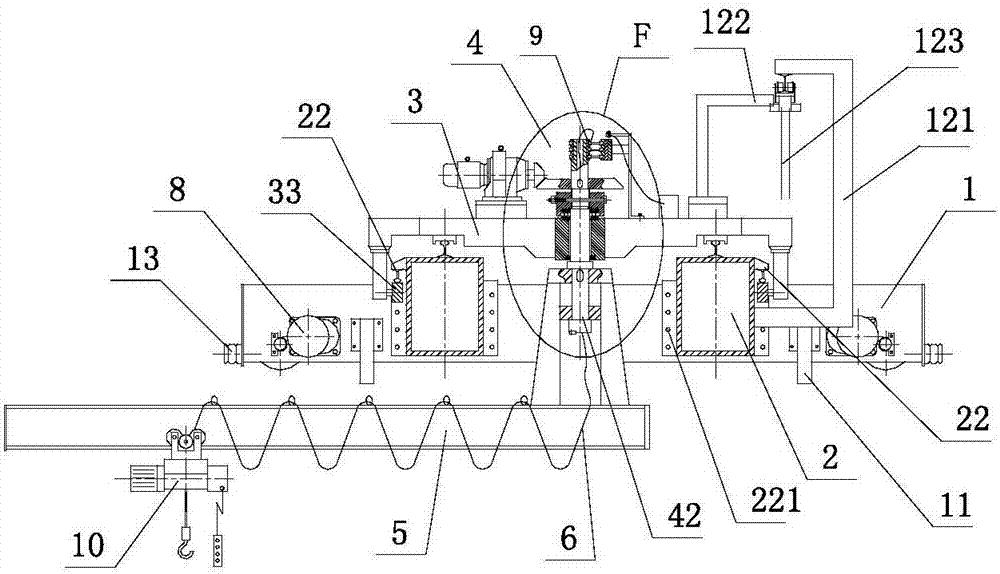

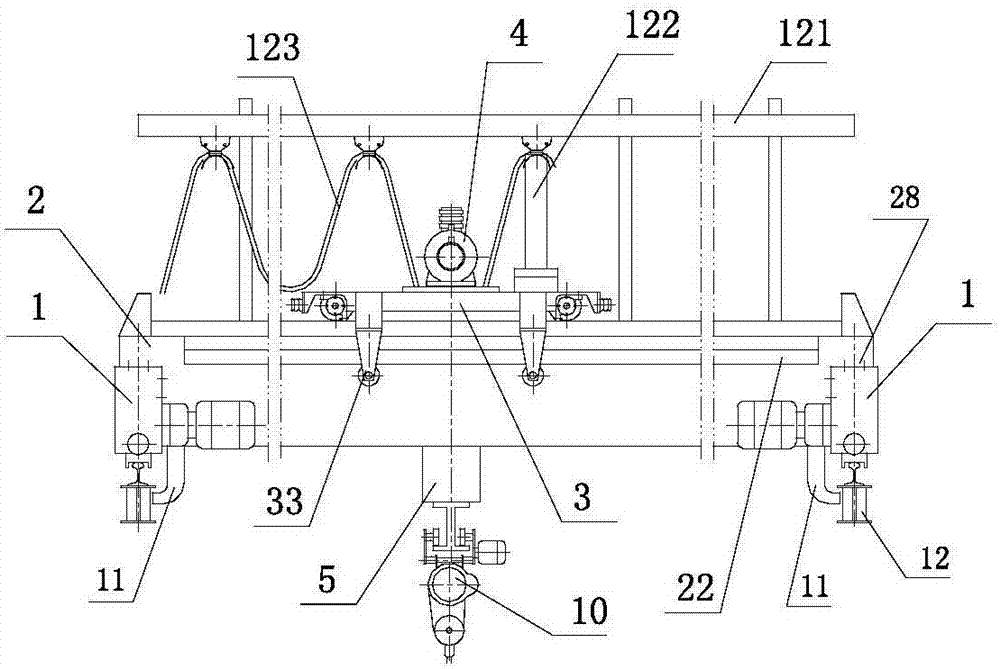

The invention discloses a roller-type fed material bagging machine which is provided with a rack and a roller. A bag feeding device and a heat sealing device are arranged on the outer side of the roller. Work grooves are evenly formed in the rollers. A bag propping mechanism is arranged at a feeding position of a material bagging machine and is provided with a bag propping frame. U-shaped bag propping rods are arranged on the two sides of the bag propping frame. Bag opening mechanisms are arranged at the work grooves. The roller-type fed material bagging machine is characterized in that packaging bag tensioning mechanisms are arranged on one sides of the U-shaped bag propping rods; a bag rubbing mechanism is arranged above the work grooves; and bag grabbing and pulling mechanisms are arranged at discharge outlets of the work grooves. By adoption of the bagging machine, tensioning of a bag opening during material feeding of a packaging bag is achieved, tilting-up or wrinkling of the two edges of the packaging bag is avoided, the two walls of the packaging bag can be rubbed open when the bag needs to be opened, and the bag opening effect is guaranteed; and before heat sealing, the bag opening of the packaging bag is pulled to be level, so that the bag opening after heat sealing is flat, and a good packaging effect is achieved.

Owner:WENZHOU RUIDA MACHINERY

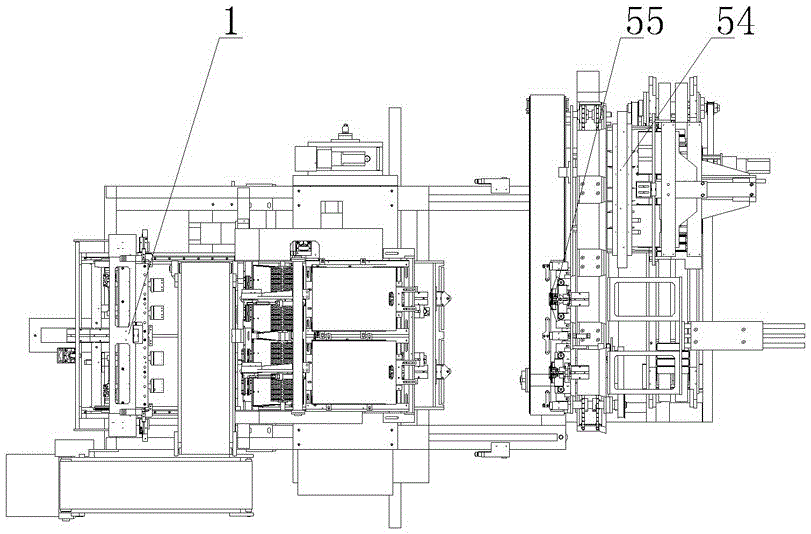

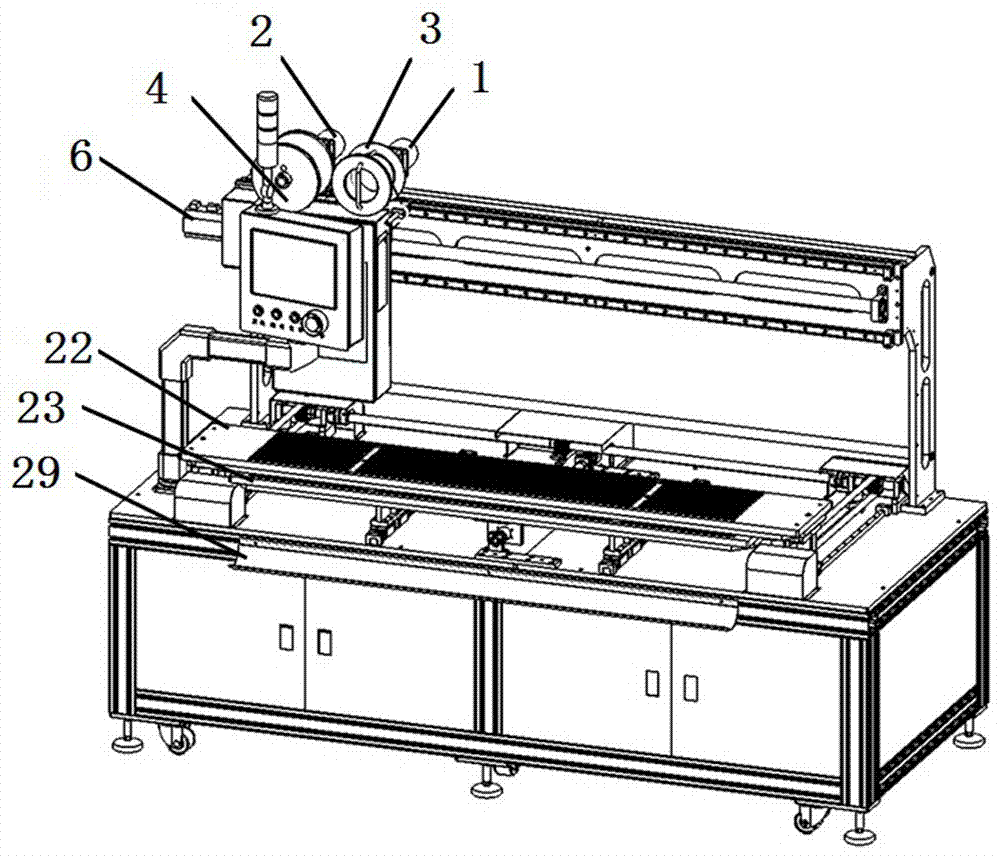

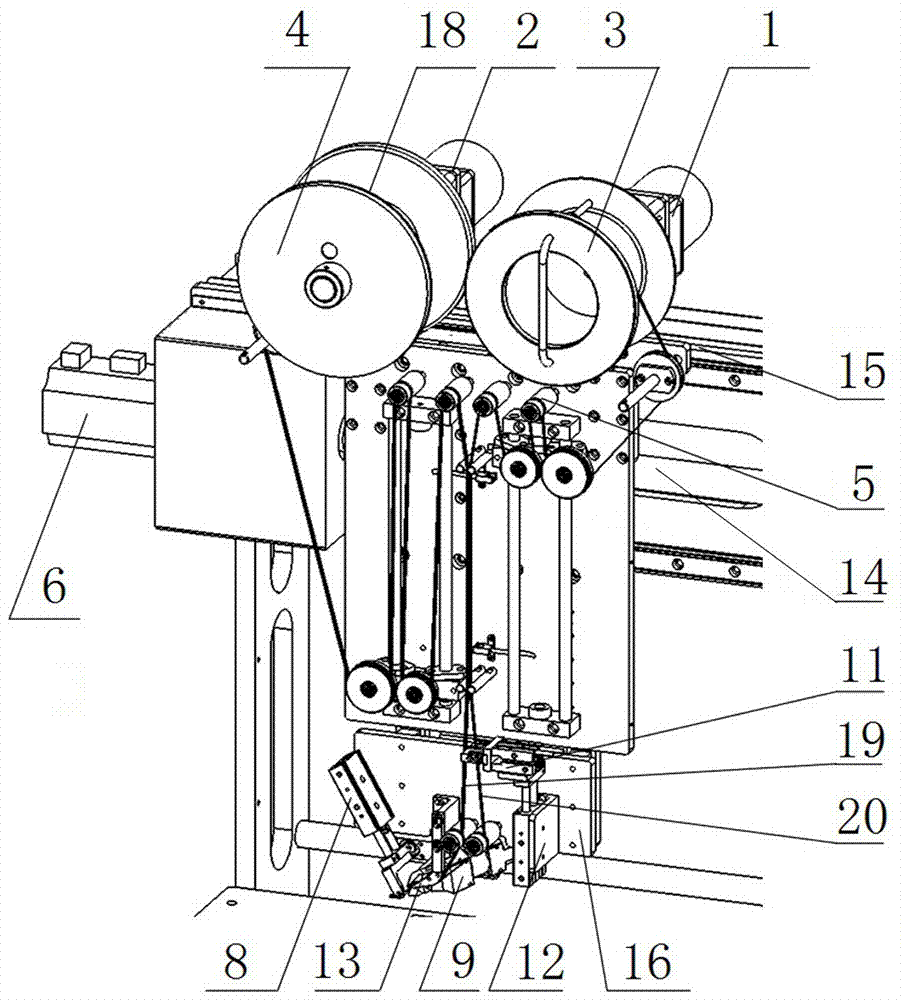

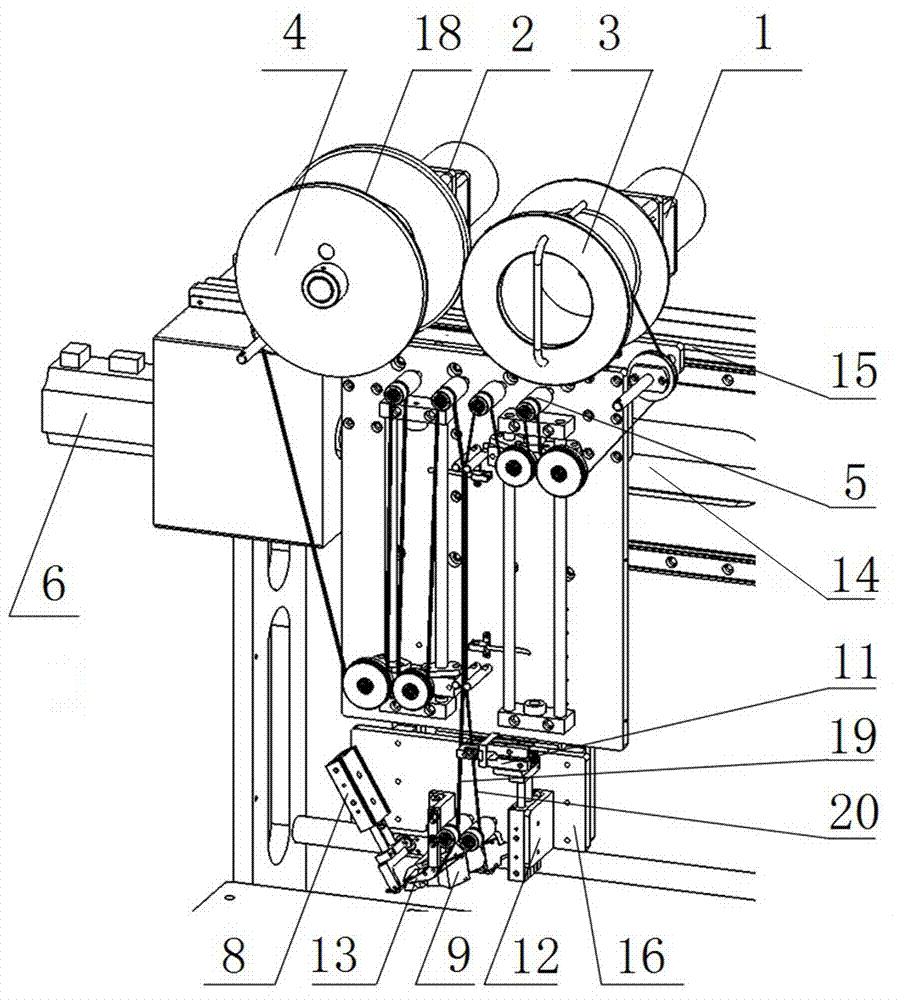

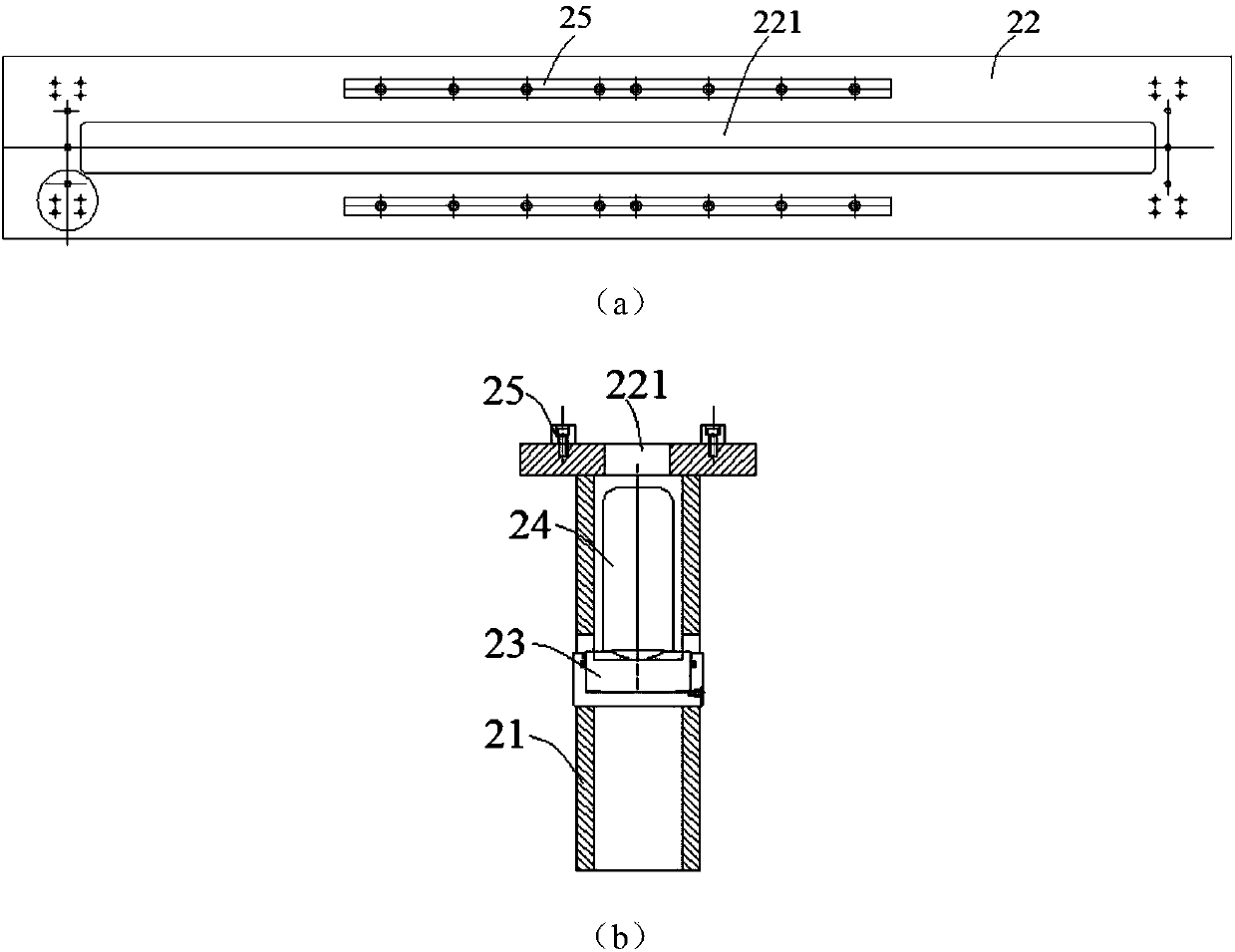

Gel strip pasting machine

ActiveCN107187923AEasy to take backImprove efficiencyArticle deliveryFinal product manufactureElectric machineEngineering

The invention provides a gel strip pasting machine comprising a gel strip pasting mechanism and a jig mechanism; the gel strip pasting mechanism comprises a winding motor, an unwinding motor, a winding disk, an unwinding disk, a plurality of tension regulating wheels, a gel strip pasting displacement motor, upper and lower gel strip pasting cylinders, a rolling pasting cylinder, gel strip cutting air shears, a gel strip cutting cylinder, a release paper clamping cylinder I, a release paper clamping cylinder II and a gel strip pasting slot; the jig mechanism comprises a jig I, a jig II, a jig I displacement motor, a jig II displacement motor, synchronizing wheels and belts; the jig I and the jig II are both provided with a plurality of parallel slots used for holding single plastic frames; and a material receiving trough is arranged below the jig mechanism, and parallel with the slots. The gel strip pasting machine provided by the invention has the advantages of good gel strip pasting effect, no shutdown during reloading, high efficiency, etc.

Owner:HEFEI BYAT AUTOMATIC TECH CO LTD

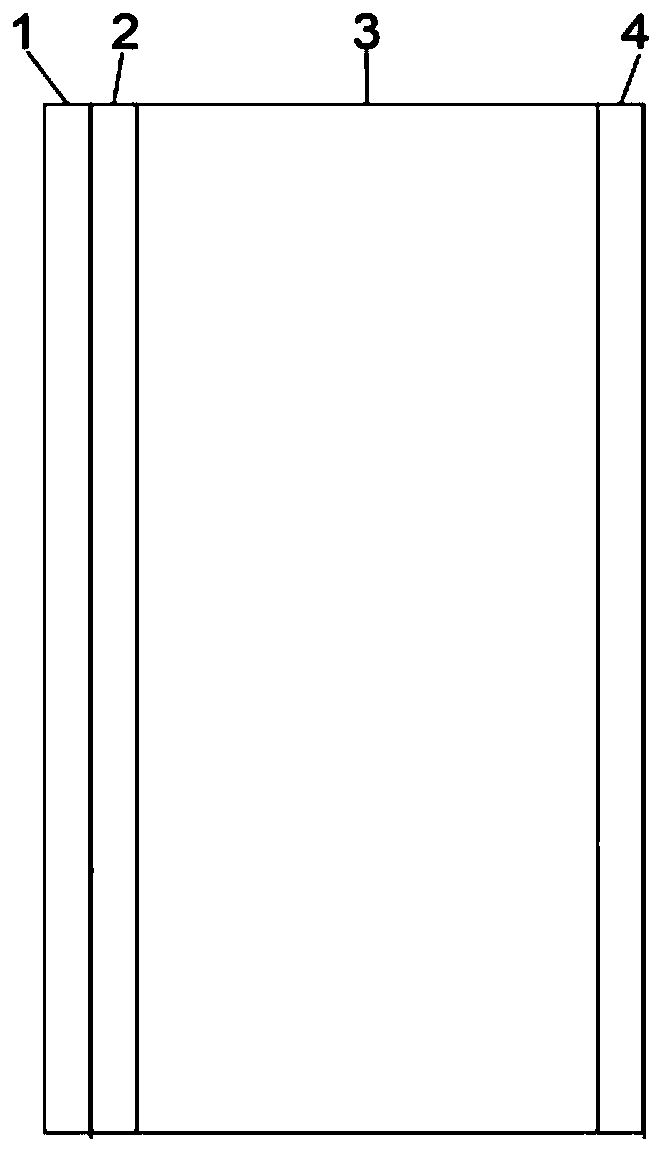

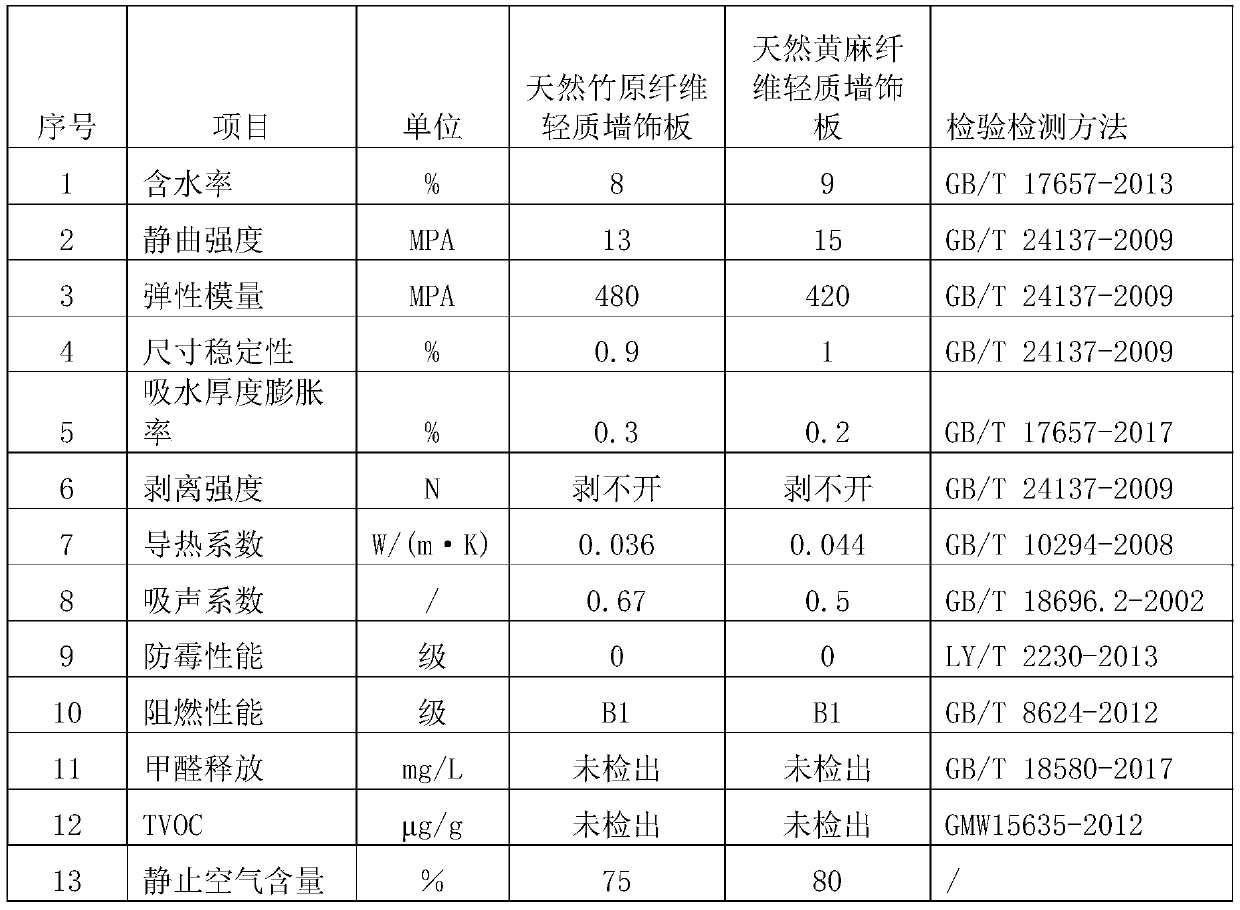

Light wall veneer and preparation method thereof

PendingCN111331990AMeet different aesthetic needsDemand constraintsCovering/liningsLamination ancillary operationsPolyesterPolymer science

The invention discloses a light wall veneer. The light wall veneer comprises a decorative surface layer and a natural fiber reinforced polypropylene plate layer; the decorative surface layer and the natural fiber reinforced polypropylene plate layer are bonded through a moisture curing reaction type polyurethane hot melt adhesive; the natural fiber reinforced polypropylene plate layer is composedof a transition layer, a middle layer and a balance layer, the natural fiber reinforced polypropylene plate layer is formed by: three-dimensionally interweaving 40-60% of natural fiber and 60-40% of polypropylene staple fiber to form a fiber felt, adhering the transition layer and the balance layer to two sides of the fiber felt respectively, and then conducting hot-pressing bonding; wherein the transition layer and the balance layer are polyester non-woven fabrics made of the same material, and the natural fiber reinforced polypropylene plate layer is bonded with the decorative surface layerthrough the transition layer. The natural fiber offcut used in the light wall veneer can be recycled by 100% after being opened, volatile pollutants cannot be generated in the production process, thelight wall veneer is environmentally friendly, and can meet different aesthetic requirements.

Owner:SHANGHAI SHENGFENG BUILDING MATERIAL TECH

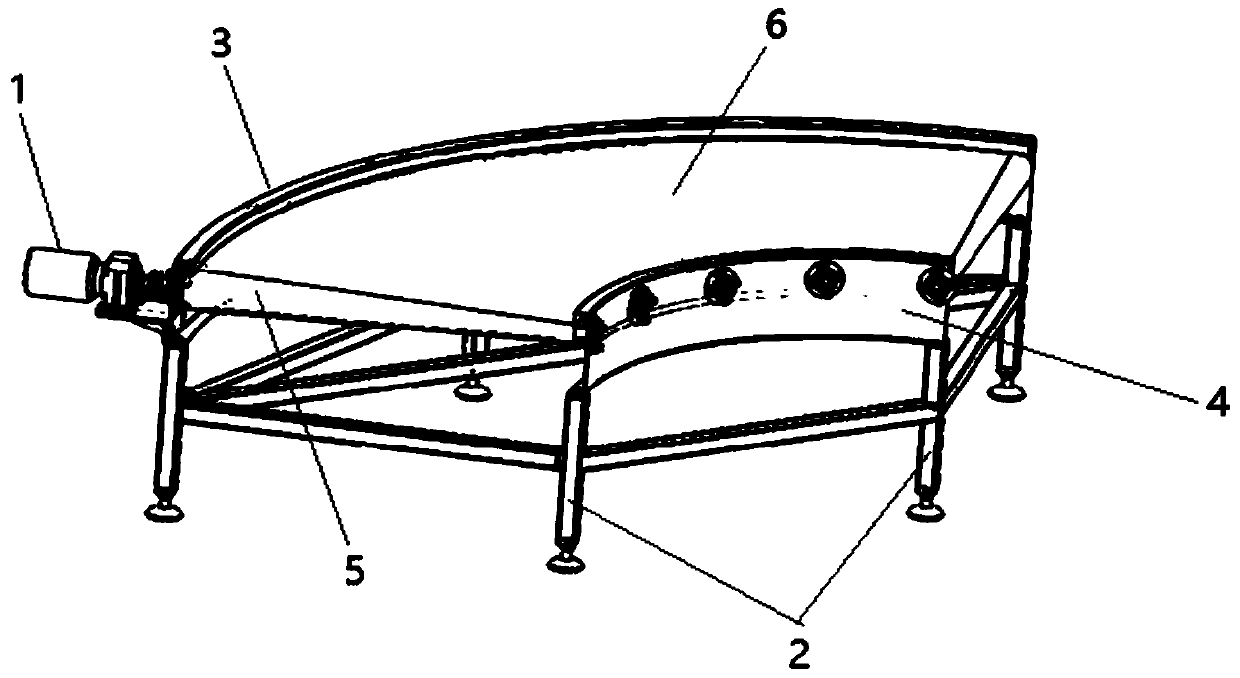

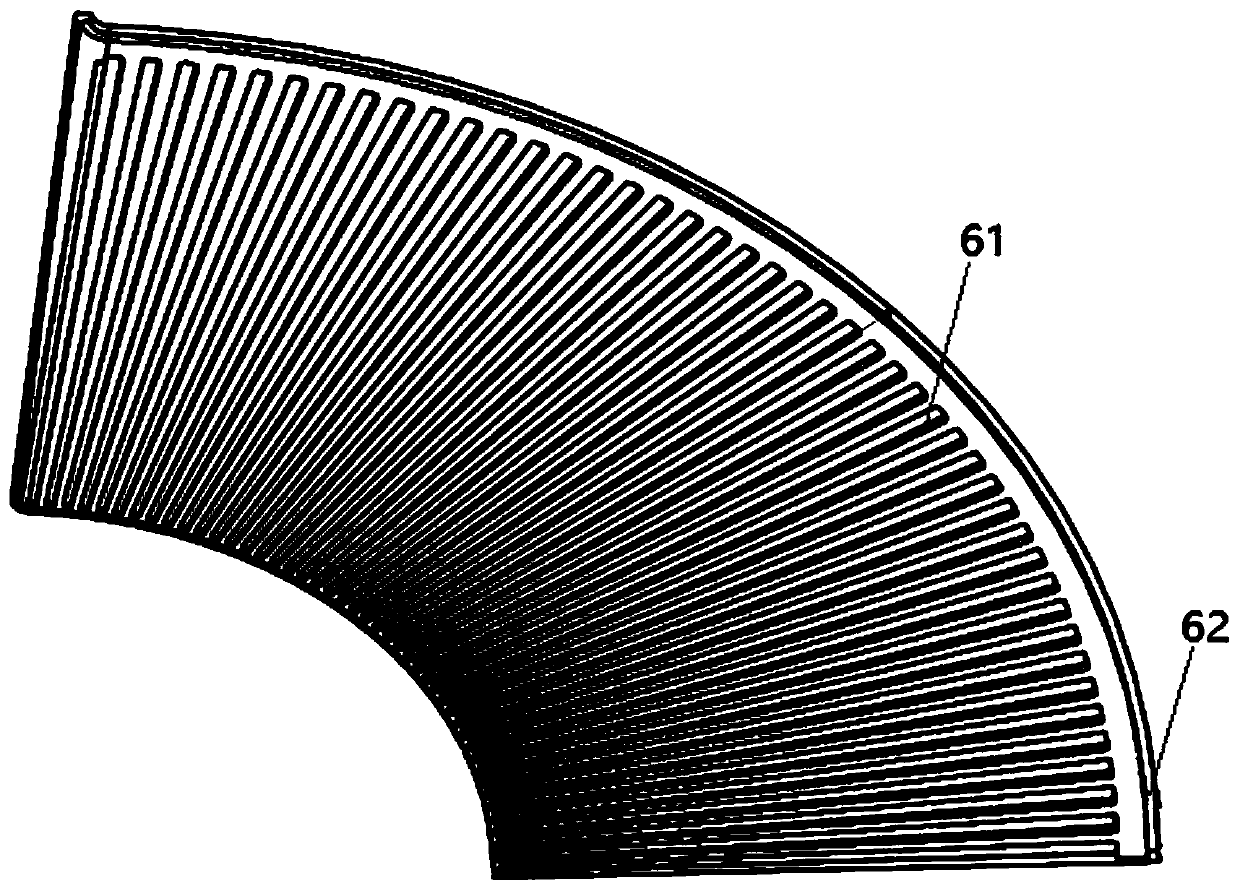

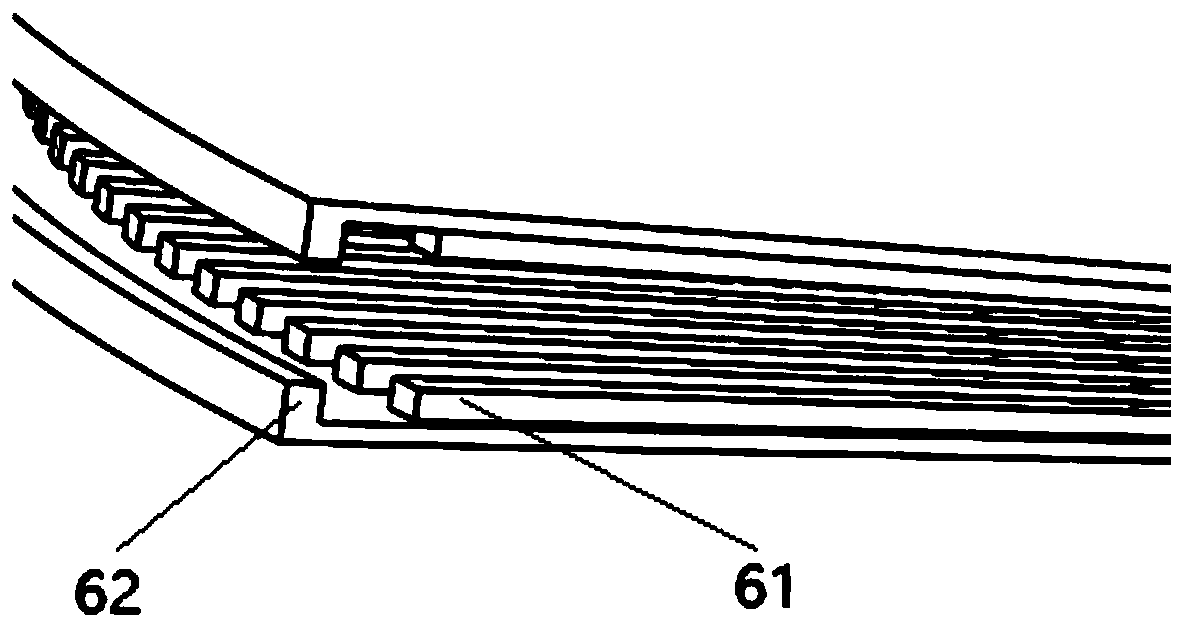

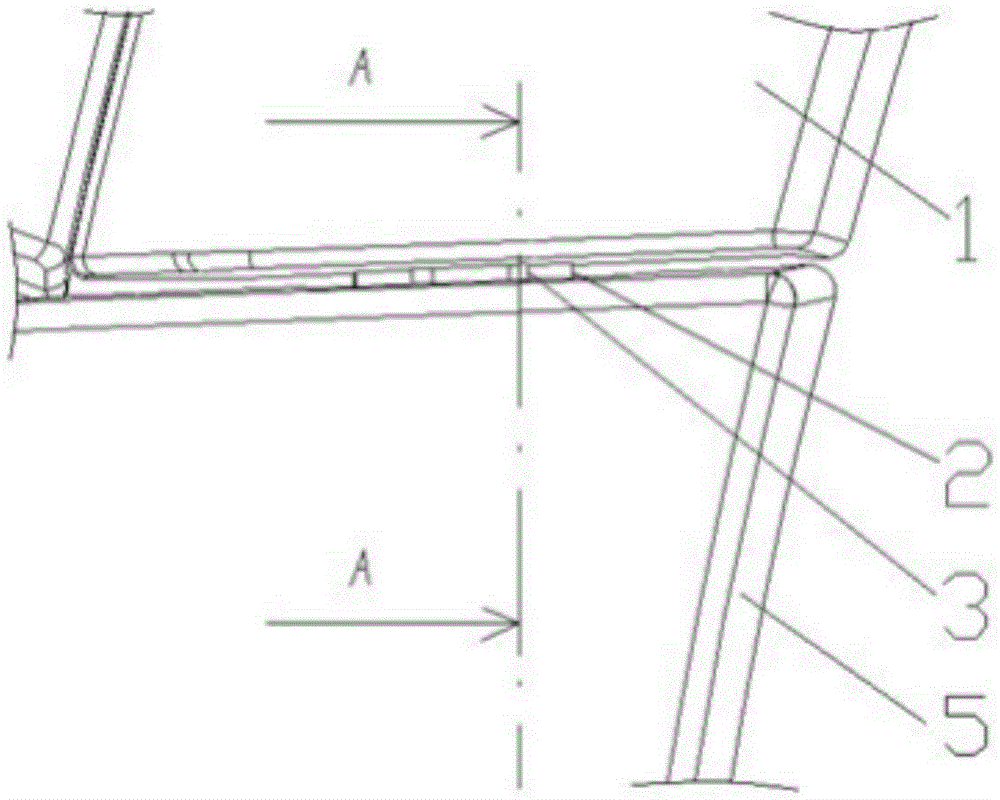

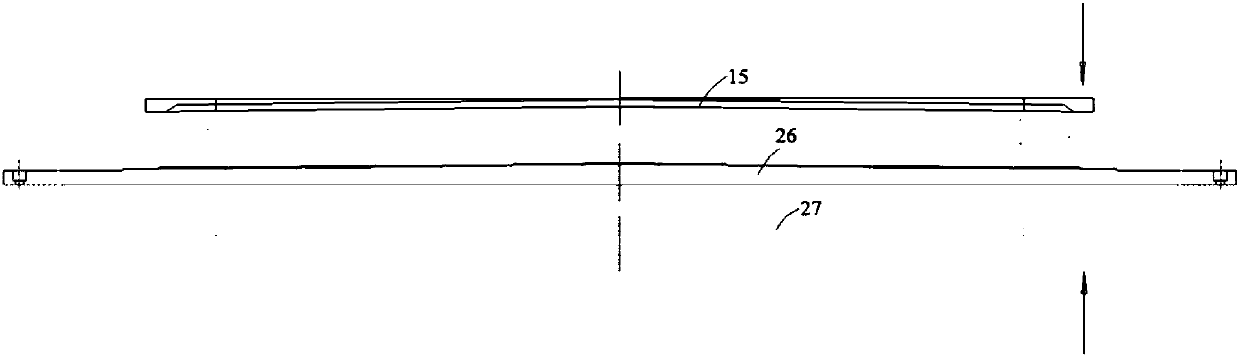

Turning conveyor and conveyor belt

The invention relates to a turning conveyor. The turning conveyor comprises a conveyor machine frame, a drive system, a fan-shaped conveyor belt and transmission guide shafts. The machine frame comprises a fan-shaped frame. The transmission guide shafts are arranged in the fan-shaped frame. Tooth grooves are formed in the axial surface of each transmission guide shaft. The invention further relates to a conveyor belt suitable for the turning conveyor mentioned above. Transverse racks are arranged on the inner surface of the conveyor belt and are meshed with the axial tooth grooves of the transmission guide shafts. The corresponding transmission guide shaft is connected with the drive system, and the fan-shaped conveyor belt is driven to cyclically rotate around the transmission guide shafts in the fan-shaped frame to be used for conveying goods; by means of gear transmission achieved through meshing of the tooth grooves of the transmission guide shafts and the racks of the fan-shaped conveyor belt, rotation of the conveyor belt can be easy, and the friction loss between the conveyor belt and the transmission shafts is greatly reduced; and meanwhile the conveyor belt is provided with longitudinal guide strips, a conveyor belt limiting mechanism is arranged on the machine frame, and the problem that transverse displacement and deviation are caused to the conveyor belt during curve operation is thoroughly solved through combination of the longitudinal guide strips and the conveyor belt limiting mechanism.

Owner:AA IND BELTING (SHANGHAI) CO LTD

Single-side frame rubber pasting mechanism

ActiveCN107215697AGuaranteed not to skewGuaranteed not to warpLabelling machinesArticle deliveryElectric machineEngineering

The invention provides a single-side frame rubber pasting mechanism suitable for rubber pasting of a single-side plastic frame. The single-side frame rubber pasting mechanism comprises a winding motor, an unwinding motor, a winding disc, an unwinding disc, multiple tension adjusting wheels, a rubber pasting displacement motor, a rubber pasting up-and-down air cylinder, a roll-pasting air cylinder, a rubber cutting air shear, a rubber cutting air cylinder, a release paper clamping air cylinder I, a release paper clamping air cylinder II and a rubber pasting groove. The single-side frame rubber pasting mechanism has the beneficial effects that after the rubber pasting mechanism reaches a rubber cutting position, a roll-pasting wheel continues to advance to finish roll-pasting of a rubber strip at the tail end, and it is guaranteed that the tail does not warp up; a discharging opening of the rubber pasting groove is provided with a guide groove, release paper and a silicon rubber strip are separated, and it is guaranteed that skew does not happen during rubber pasting.

Owner:HEFEI BYAT AUTOMATIC TECH CO LTD

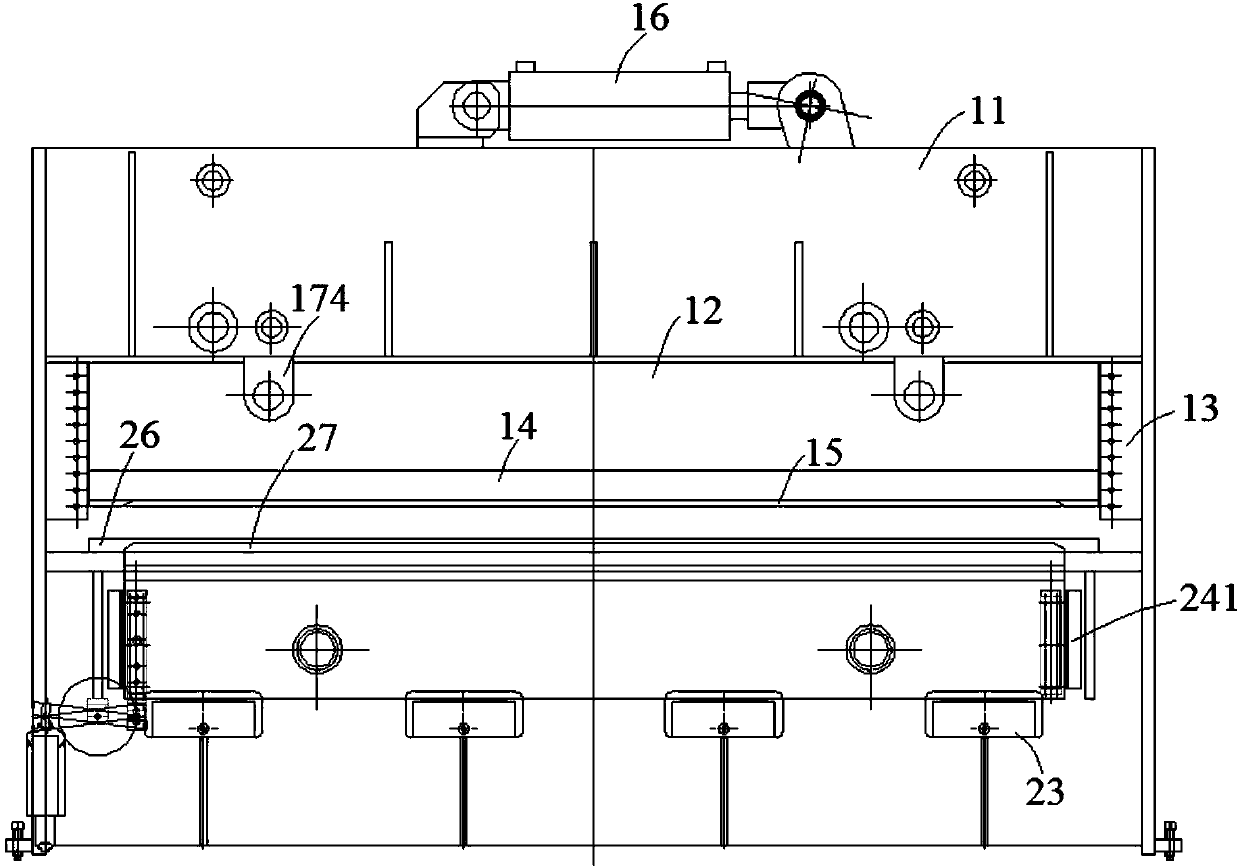

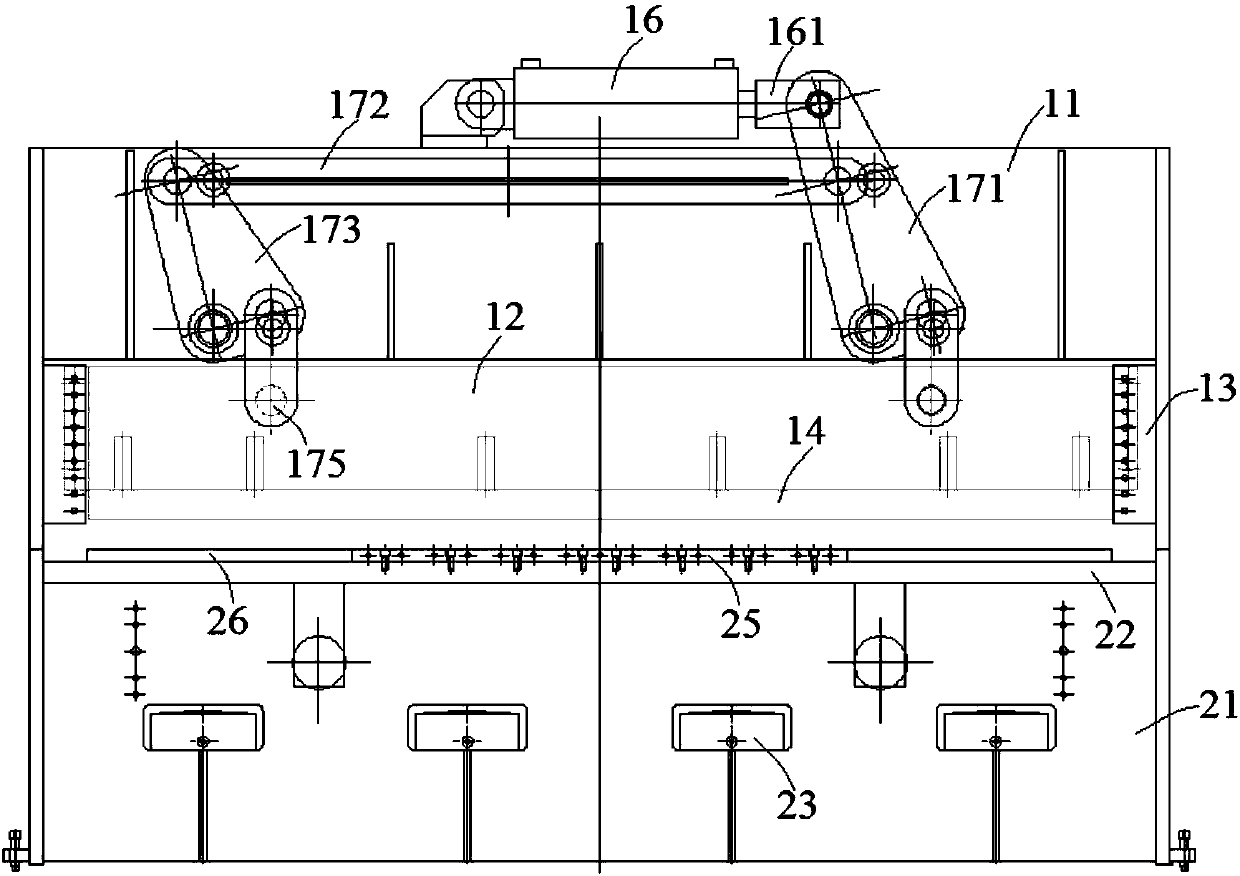

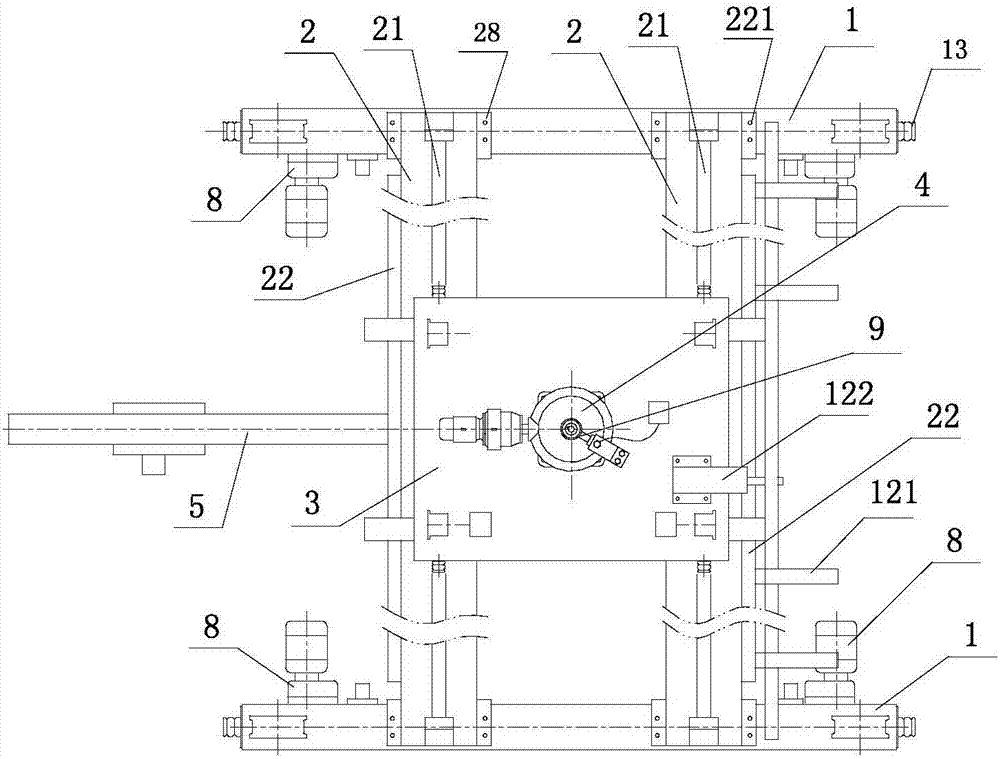

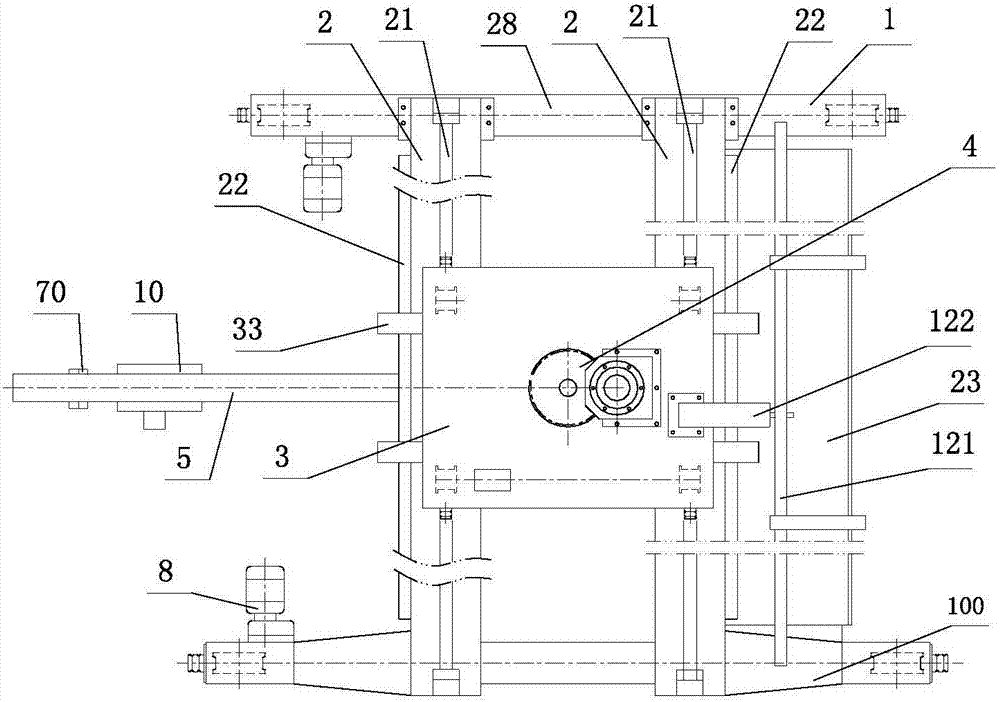

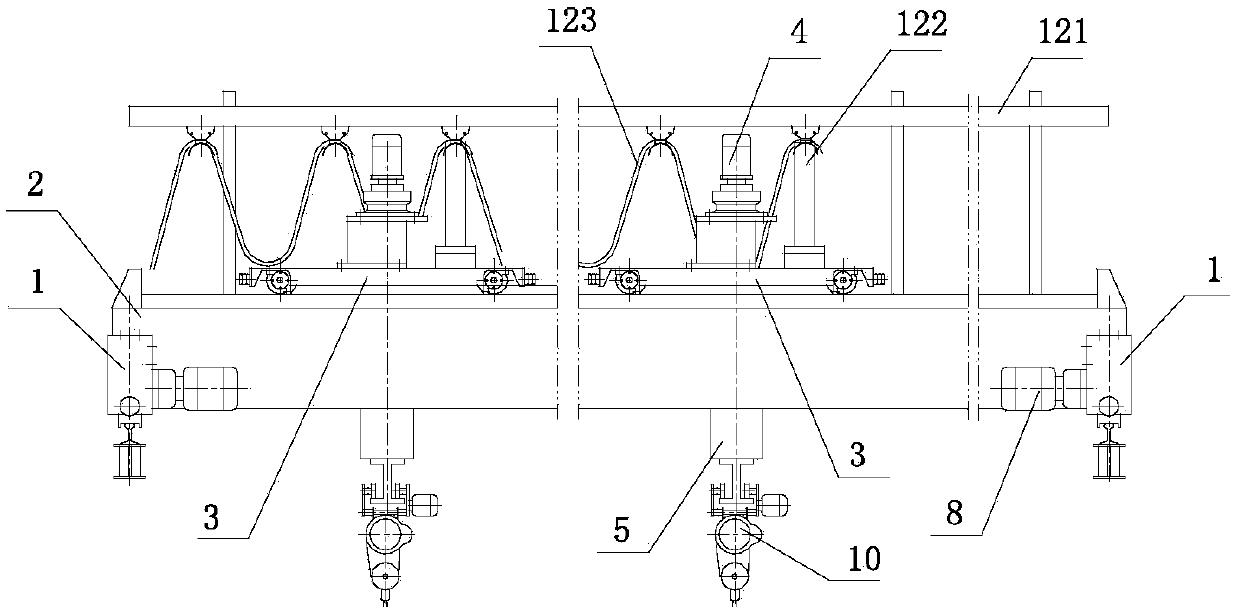

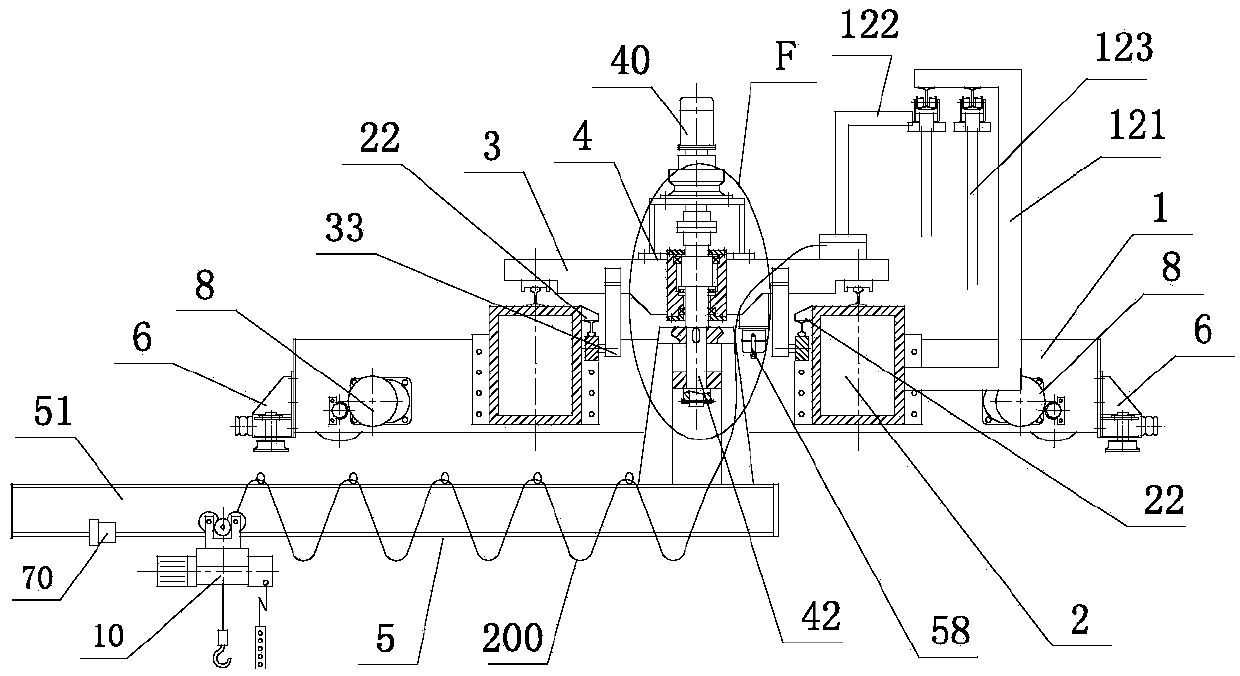

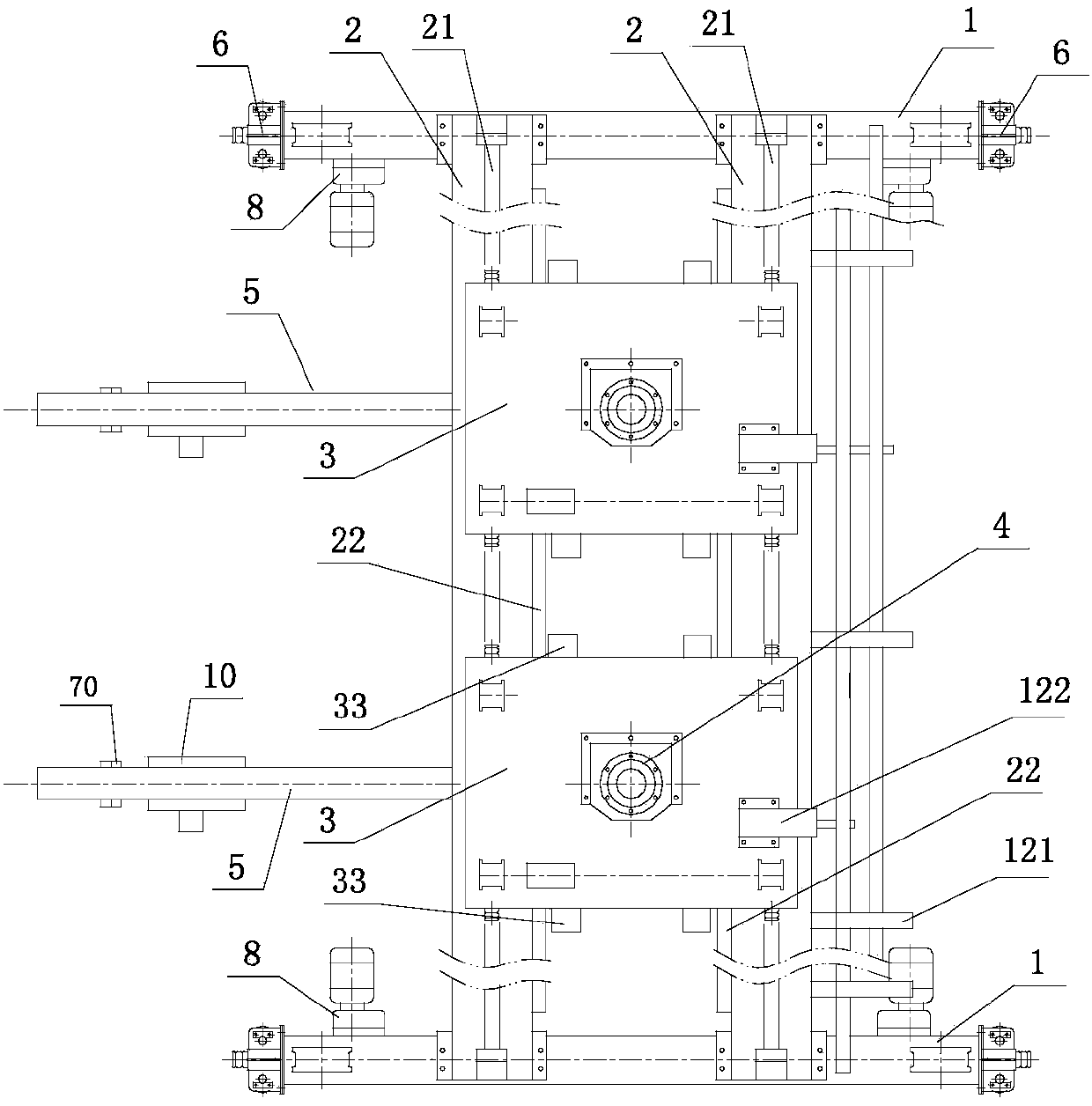

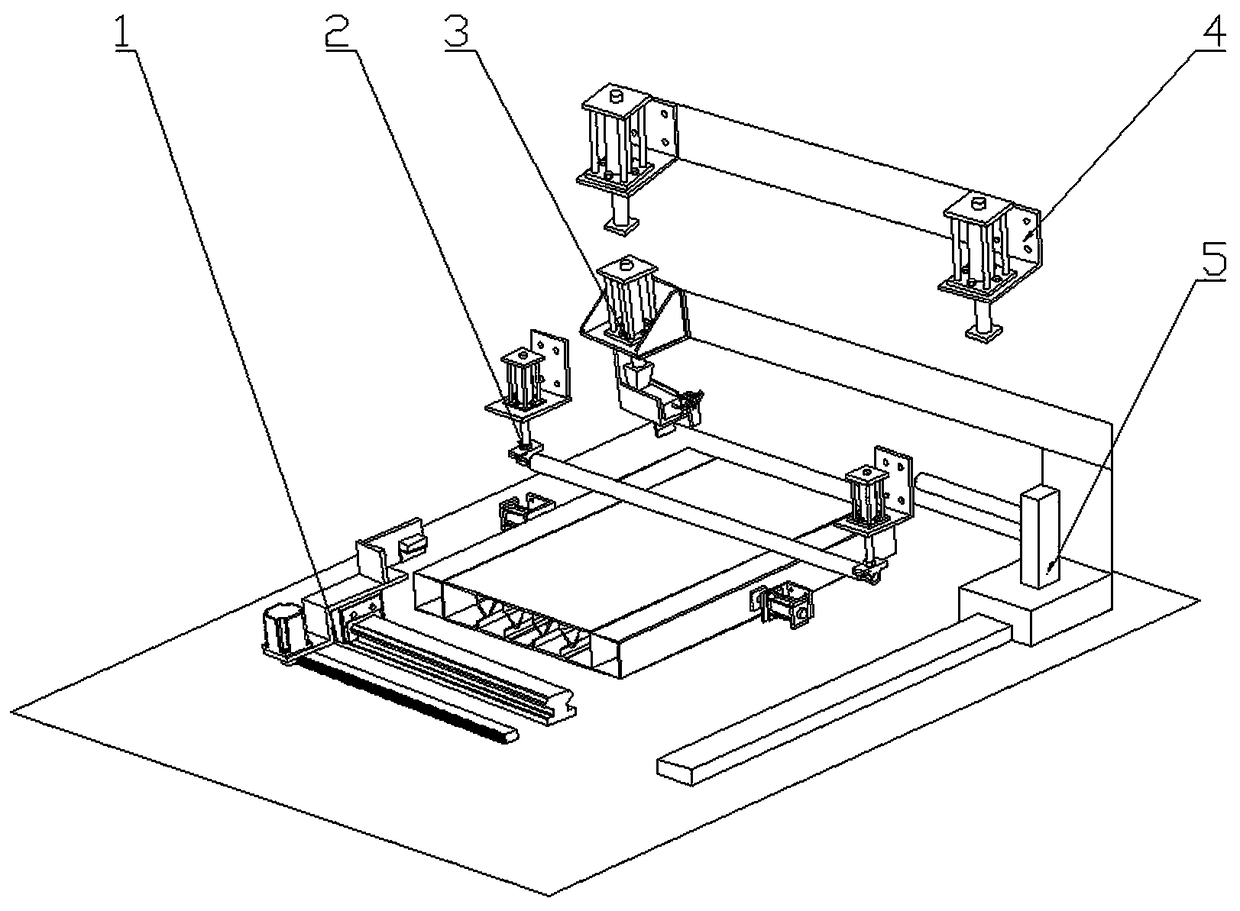

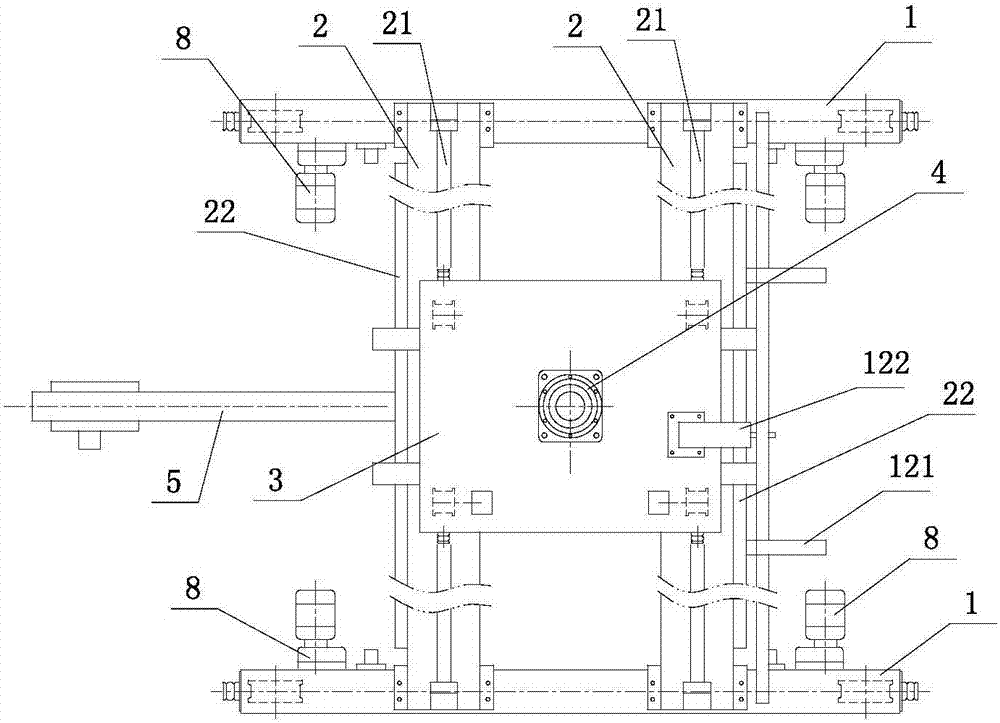

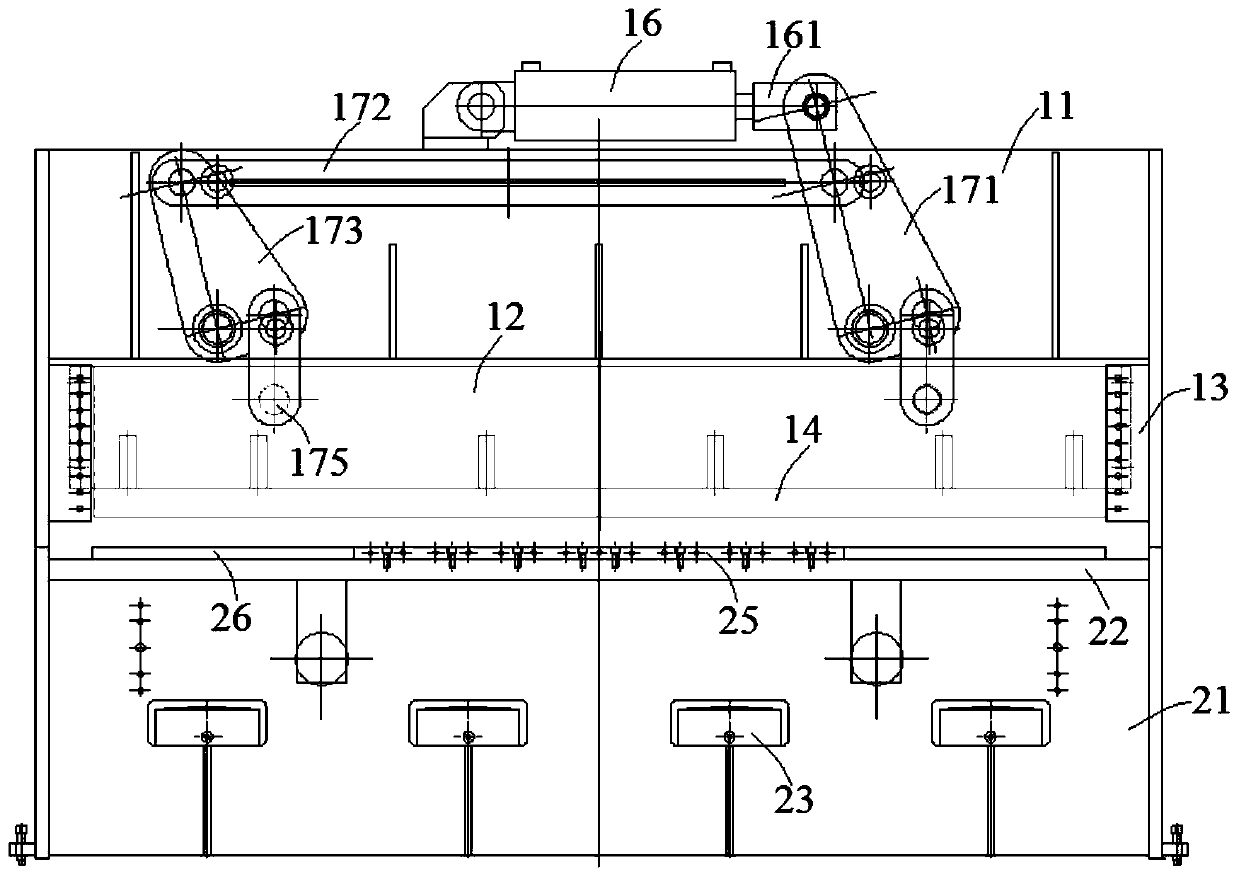

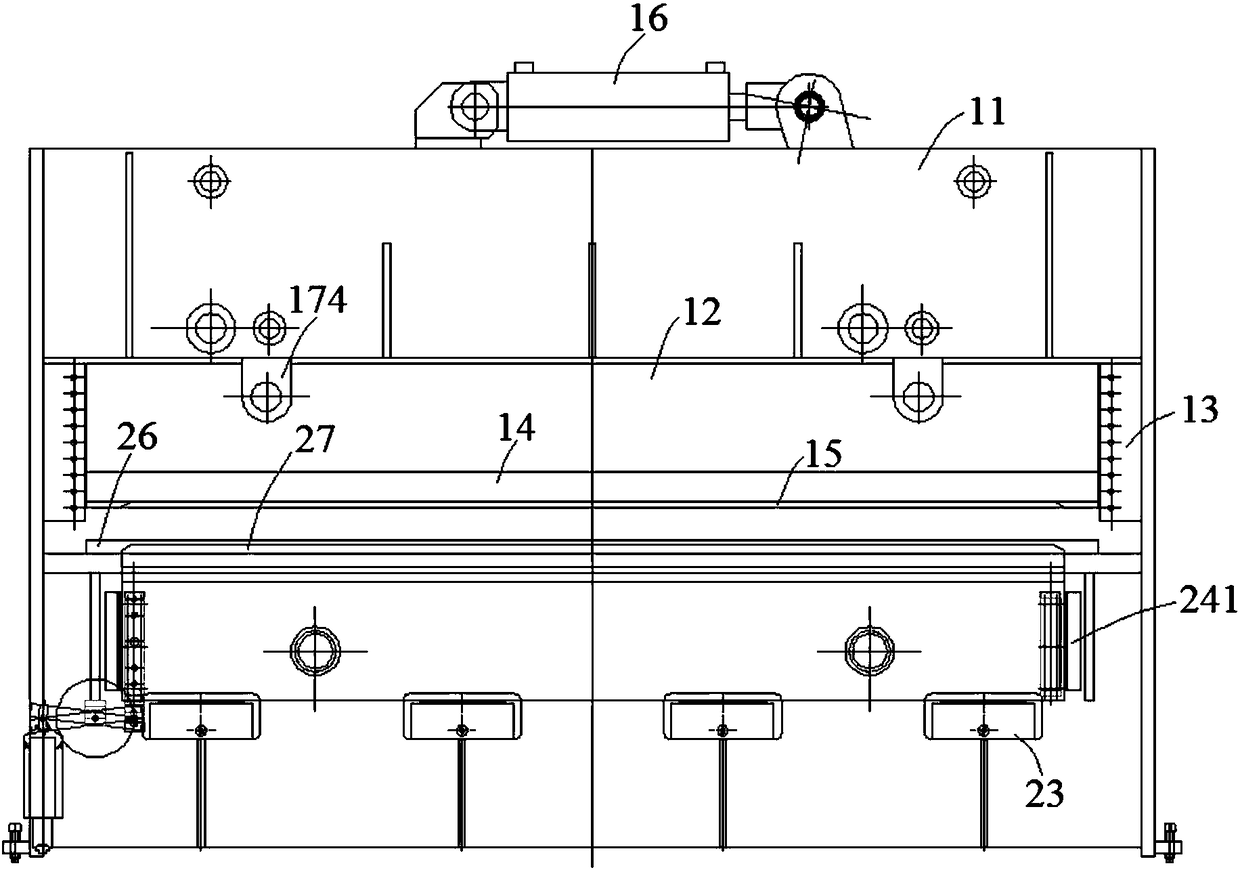

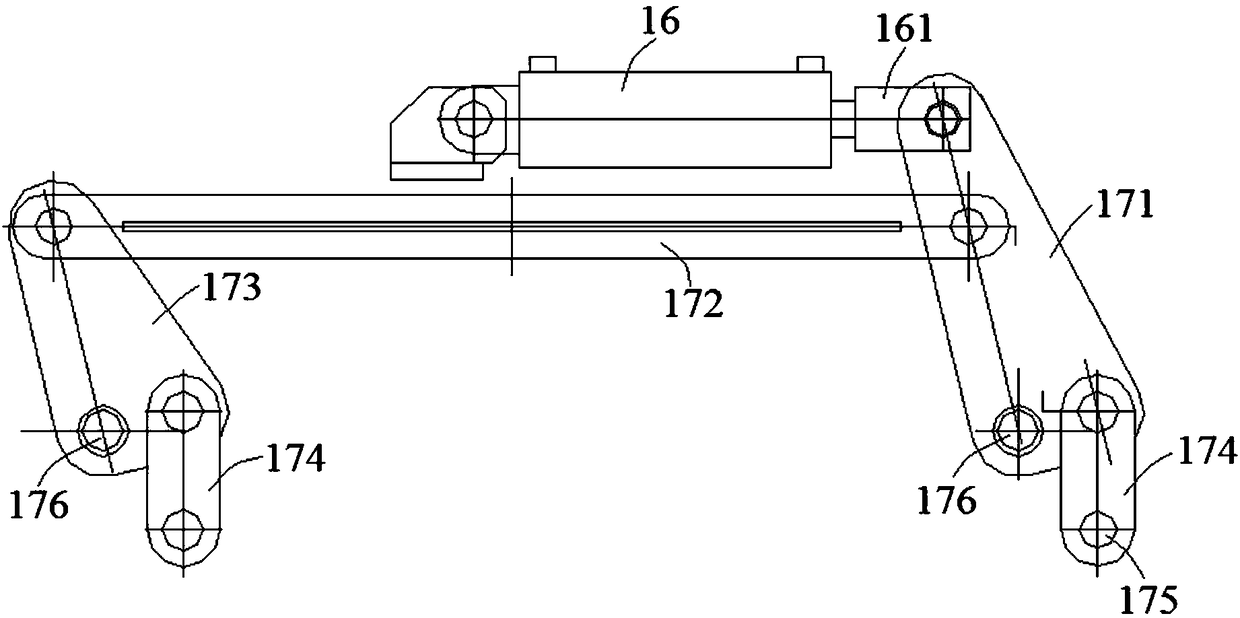

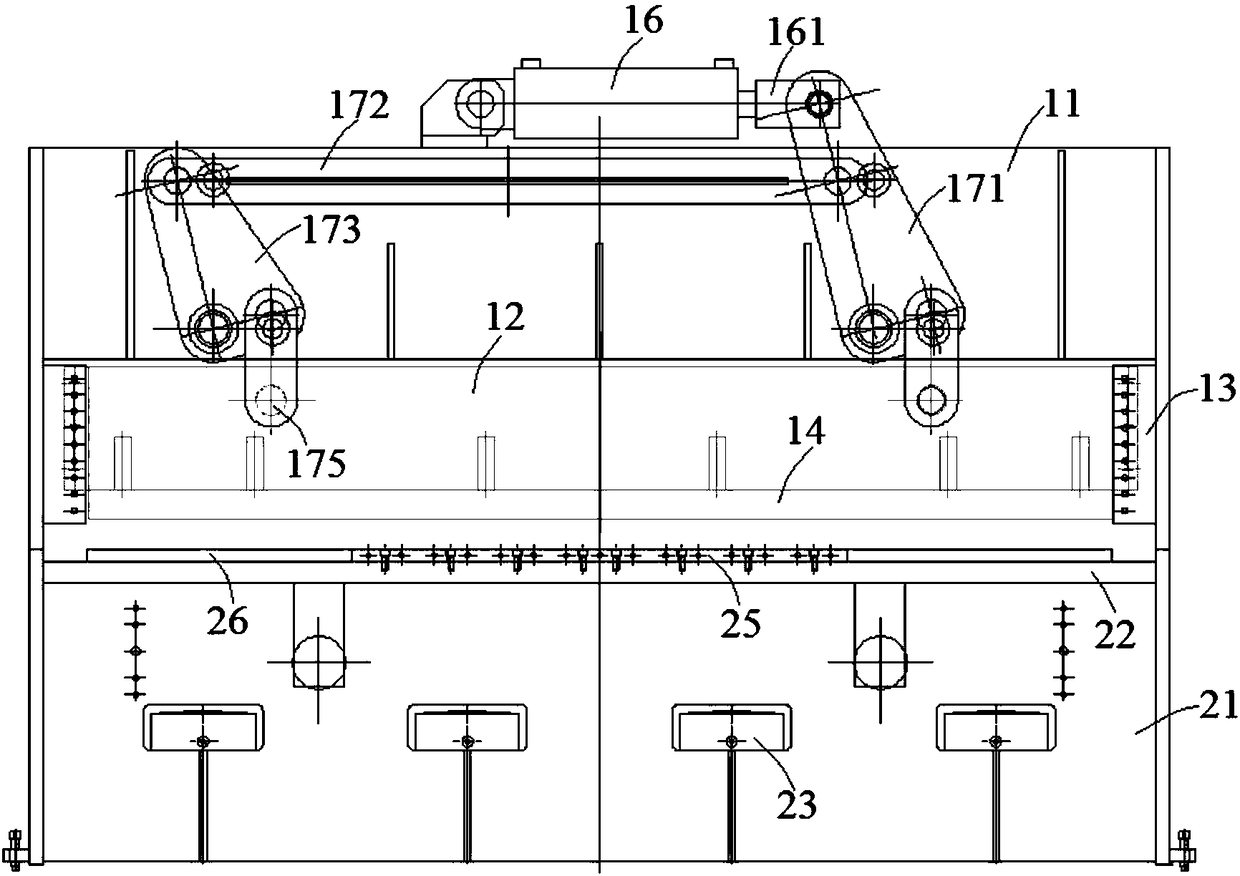

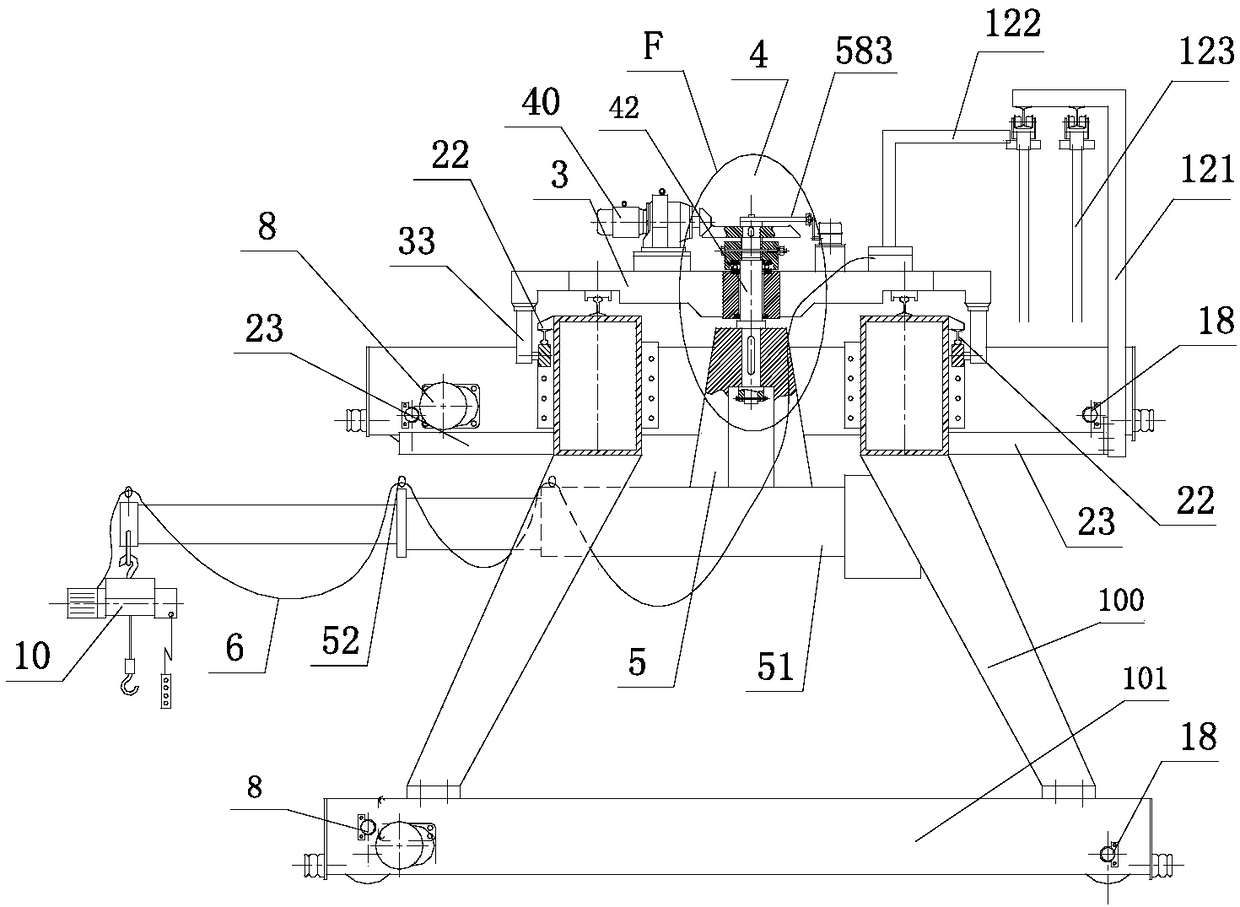

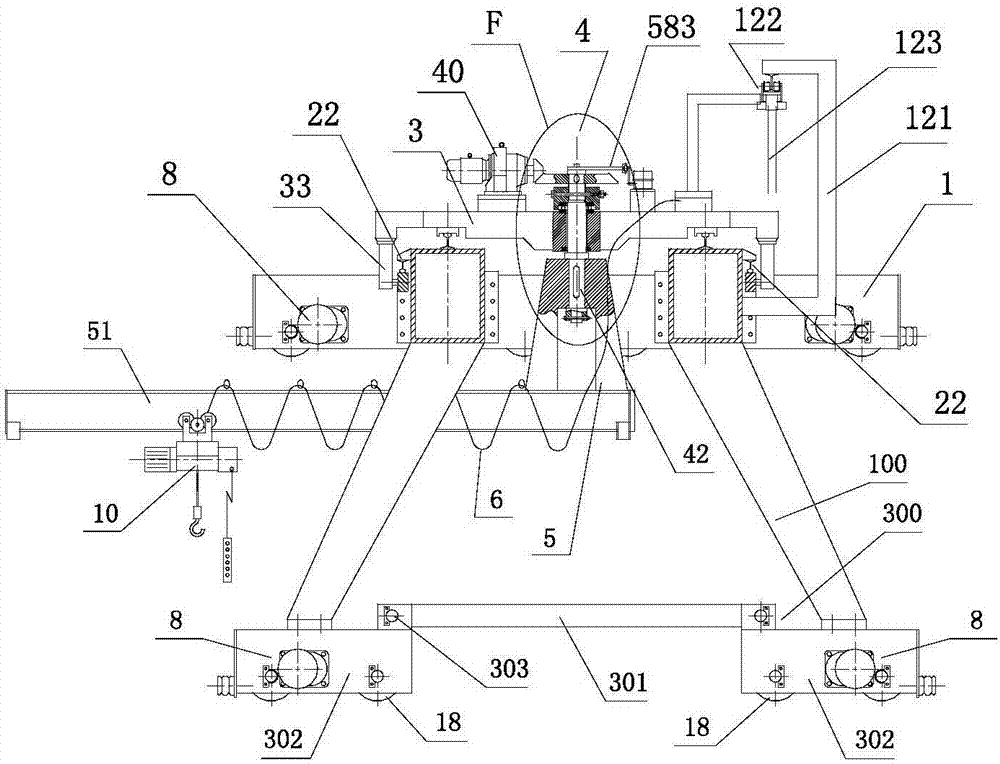

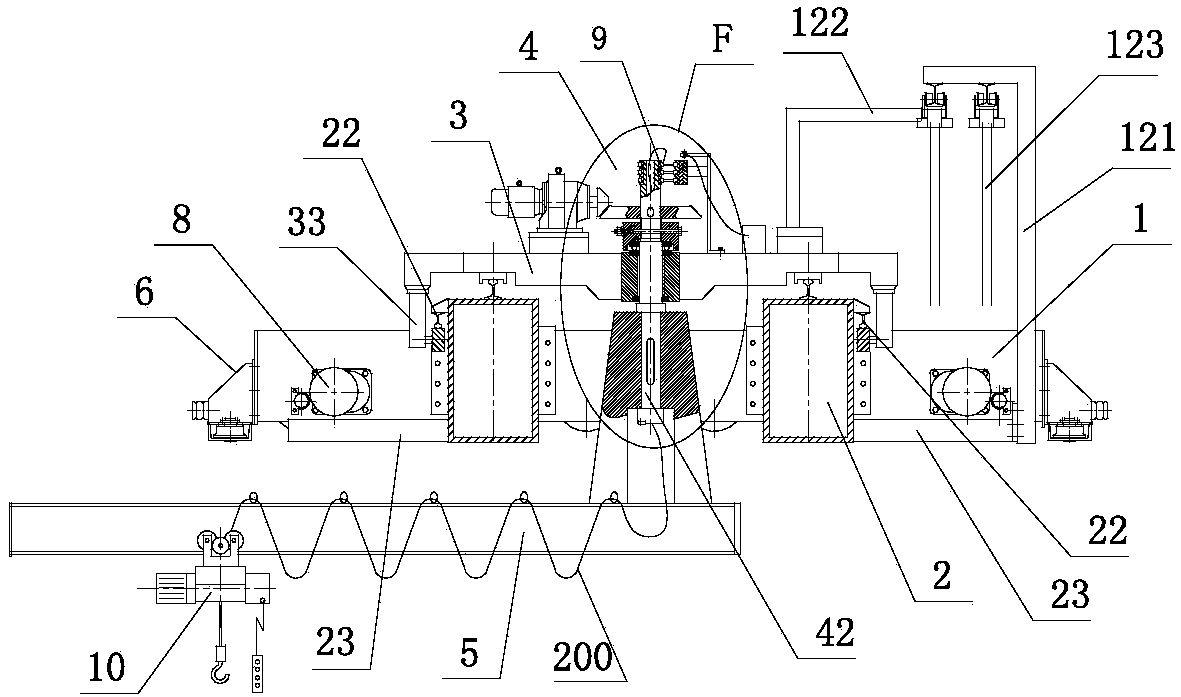

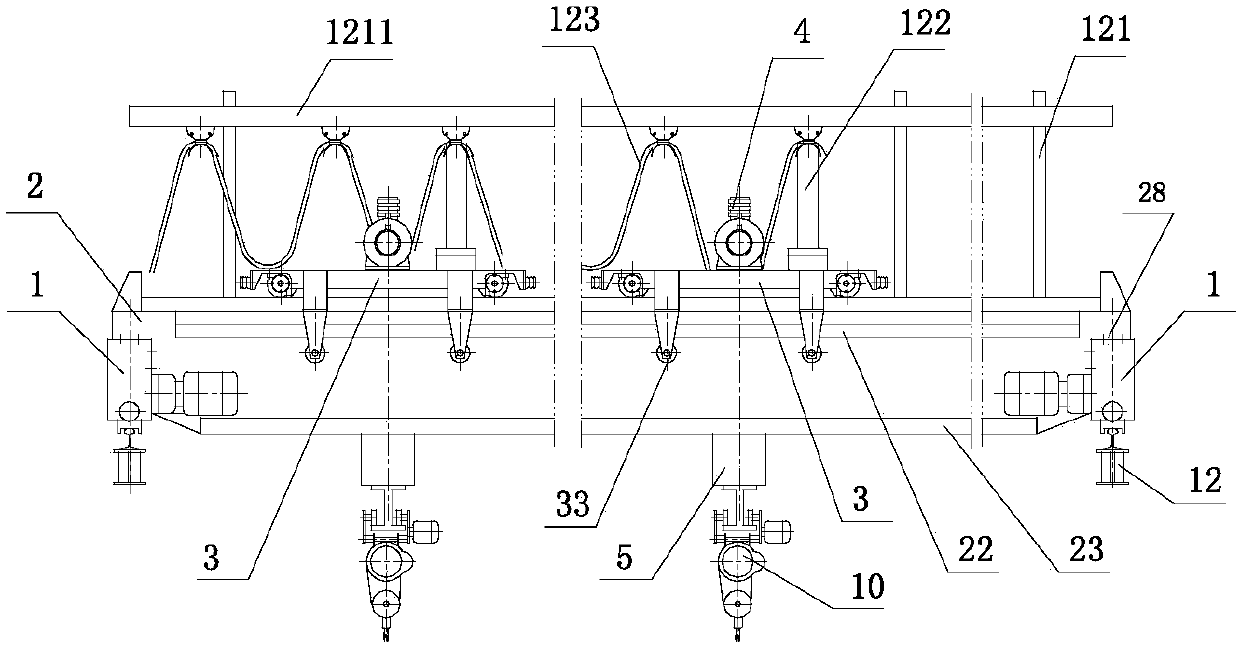

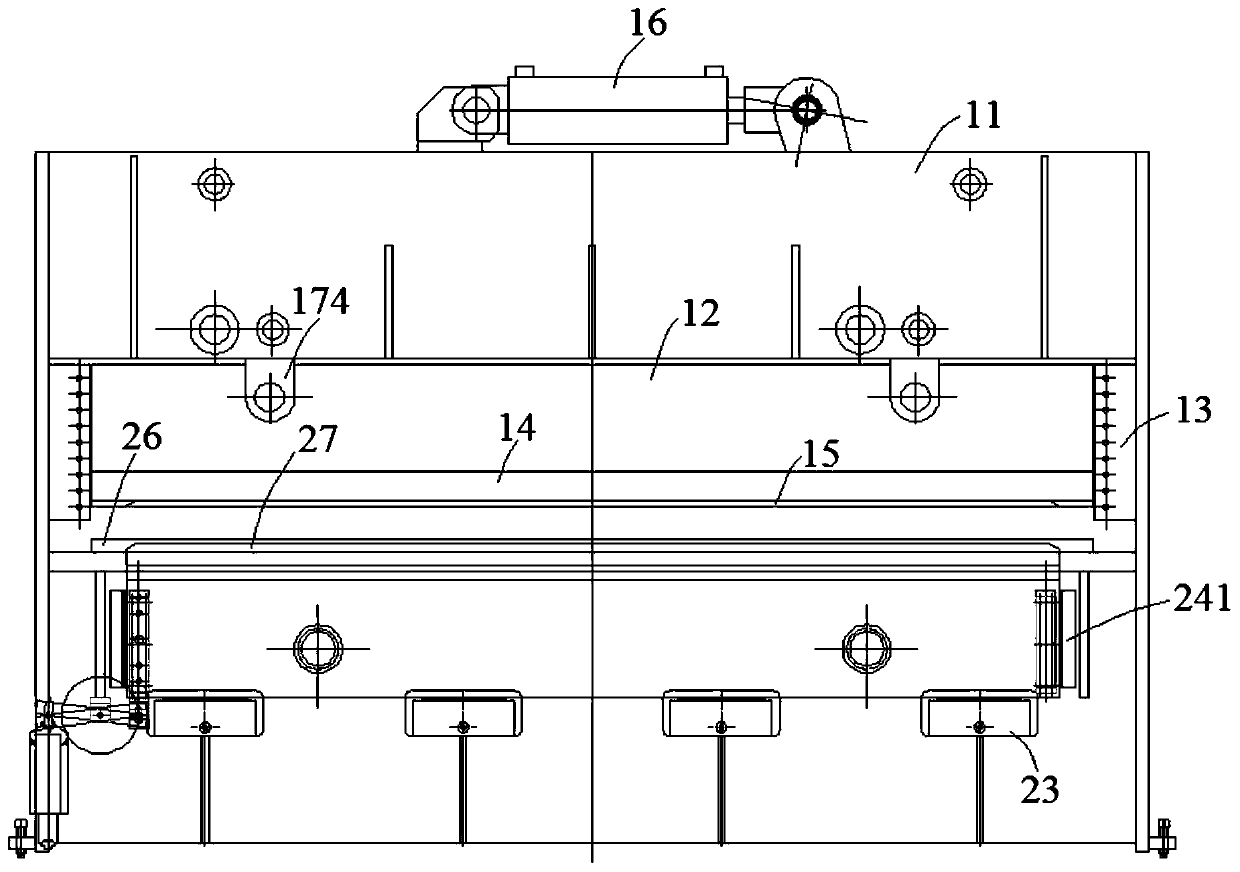

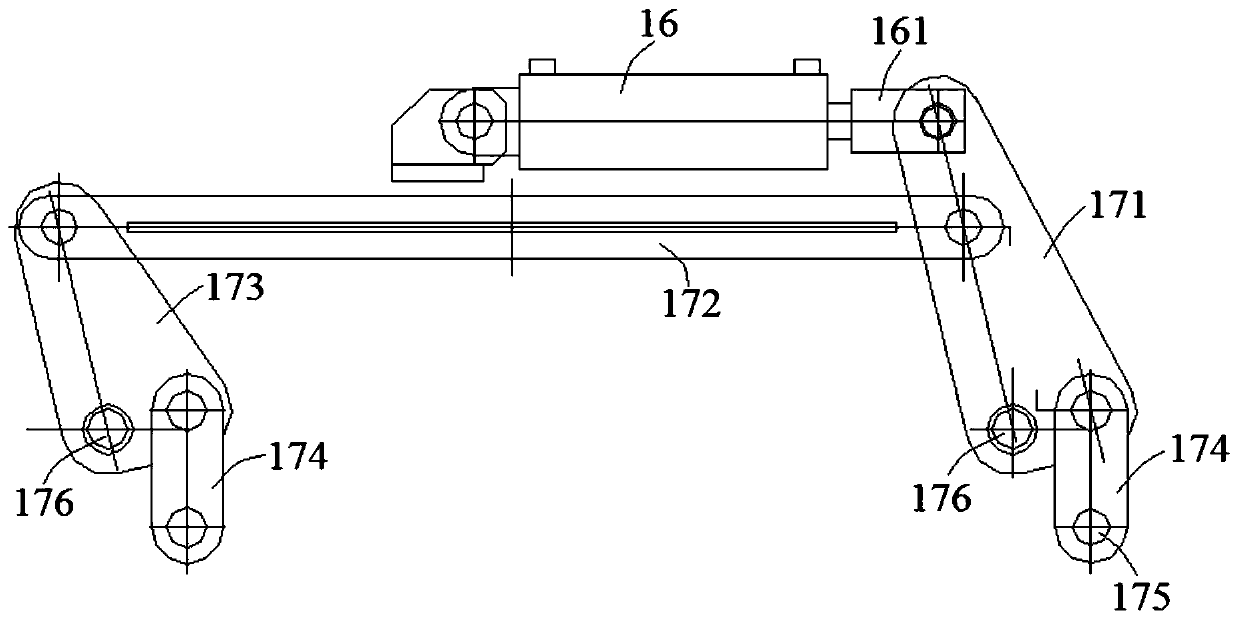

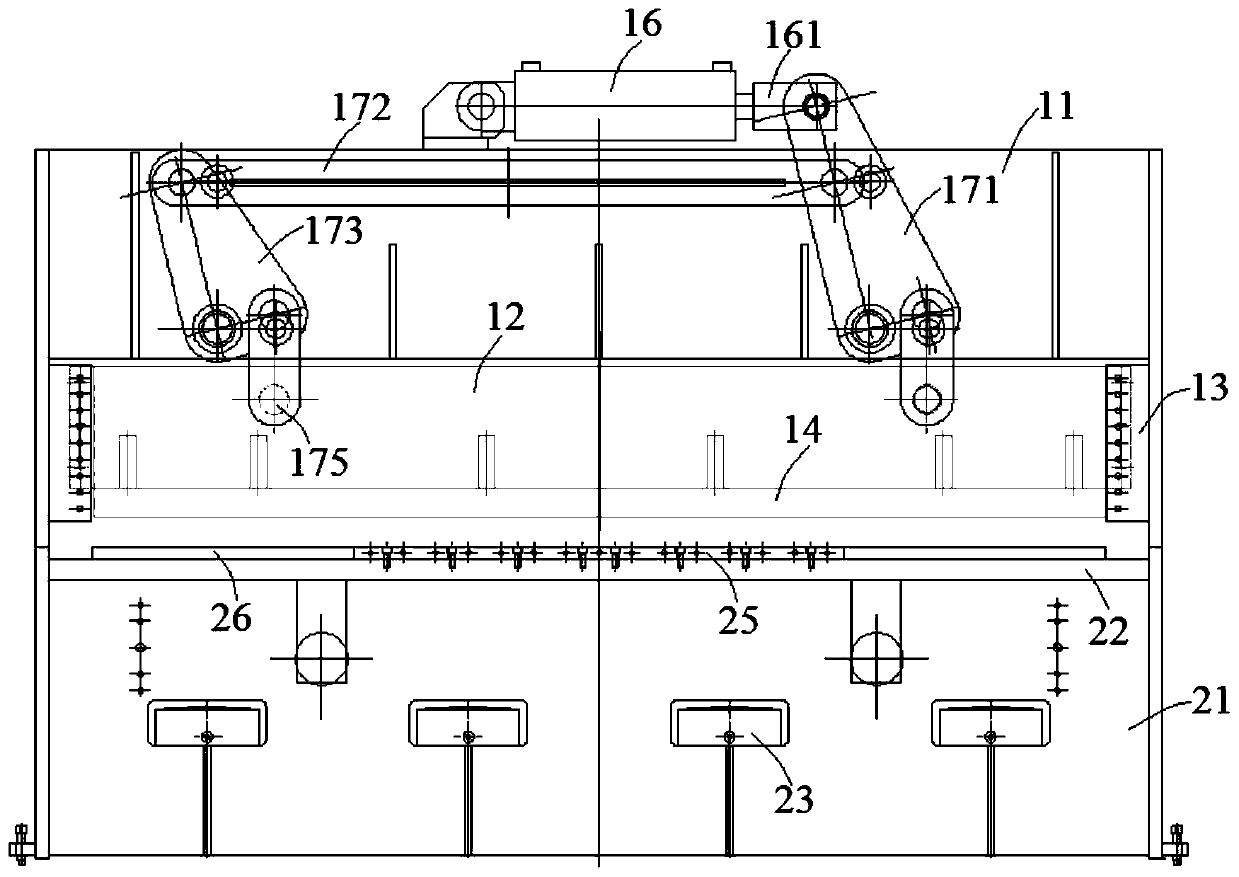

Low-cost container top plate hydraulic forming system

ActiveCN107931389AReduce financial burdenReduce procurement costsShaping toolsMetal-working feeding devicesEngineeringContainer tops

The invention discloses a low-cost container top plate hydraulic forming system and belongs to the field of hydraulic forming. The system comprises an upper box body, upper sliding blocks, upper molds, an upper main oil cylinder, a lower box body, lower main oil cylinders, lower sliding blocks and lower molds. The upper main oil cylinder is arranged at the upper part of the upper box body, and theupper sliding blocks are arranged at the lower part of the upper box body; the upper molds are fixed at the bottom of the upper sliding blocks, and a driving unit is arranged between the upper main oil cylinder and the upper sliding blocks; the upper main oil cylinder drives the upper sliding blocks to move in a vertical direction through the driving unit; and the lower sliding blocks are arranged in the lower box body, the lower portions of the lower sliding blocks are connected with the lower main oil cylinders, the upper portions of the lower sliding blocks are connected with the lower molds, and the lower main oil cylinders drive the lower sliding blocks to move in the vertical direction. The low-cost container top plate hydraulic forming system relates to a special machine designed for a container top plate structure, the cost of equipment purchasing is greatly reduced, and the economic burden of a small-and-medium-sized container top plate production enterprise is reduced.

Owner:安徽金大进重工机床有限公司

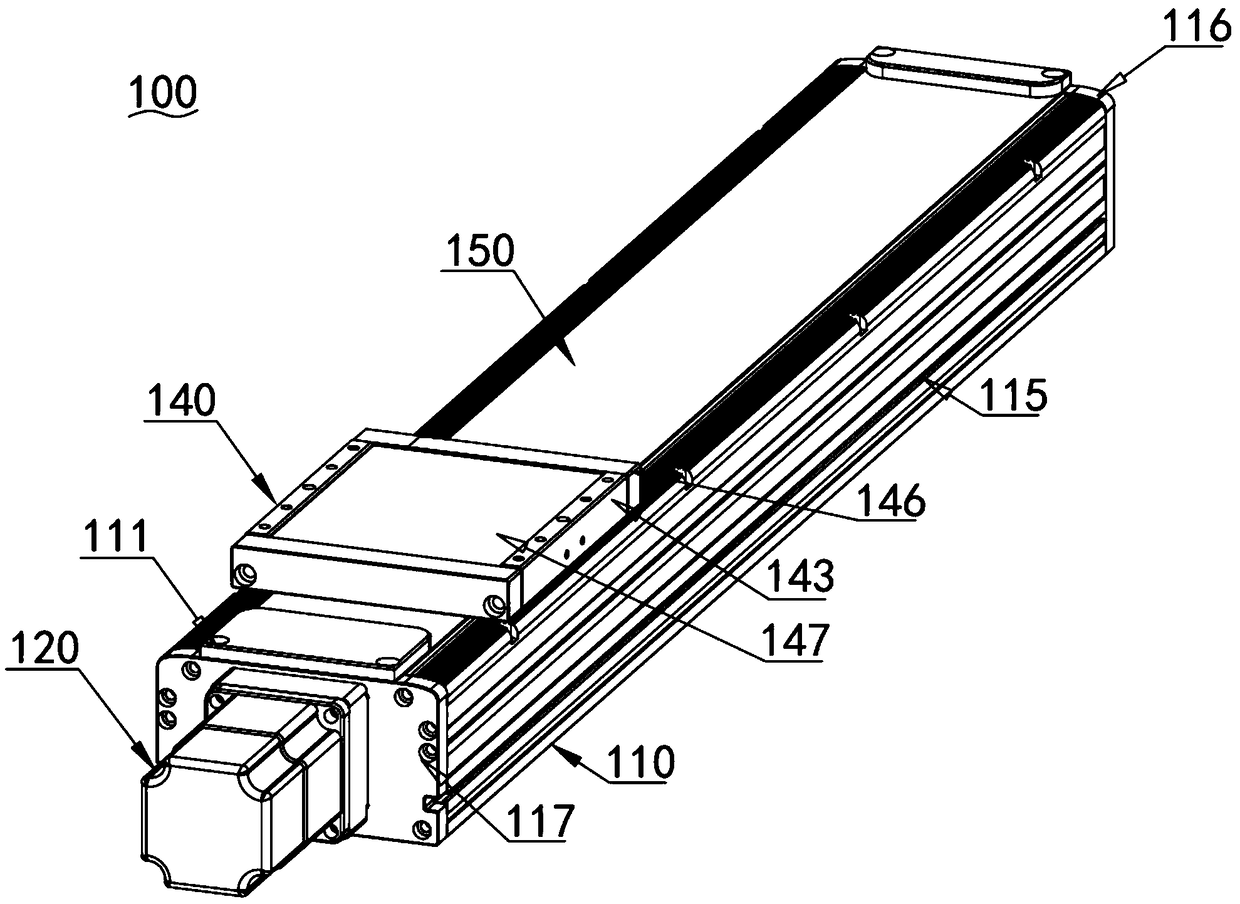

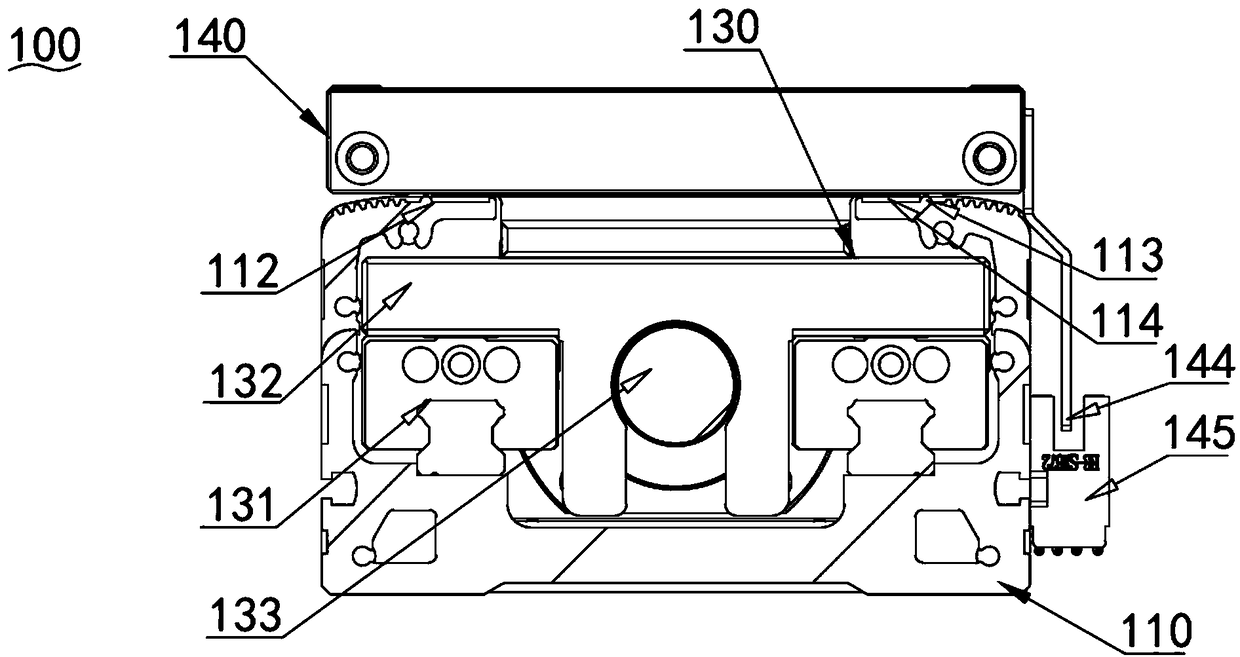

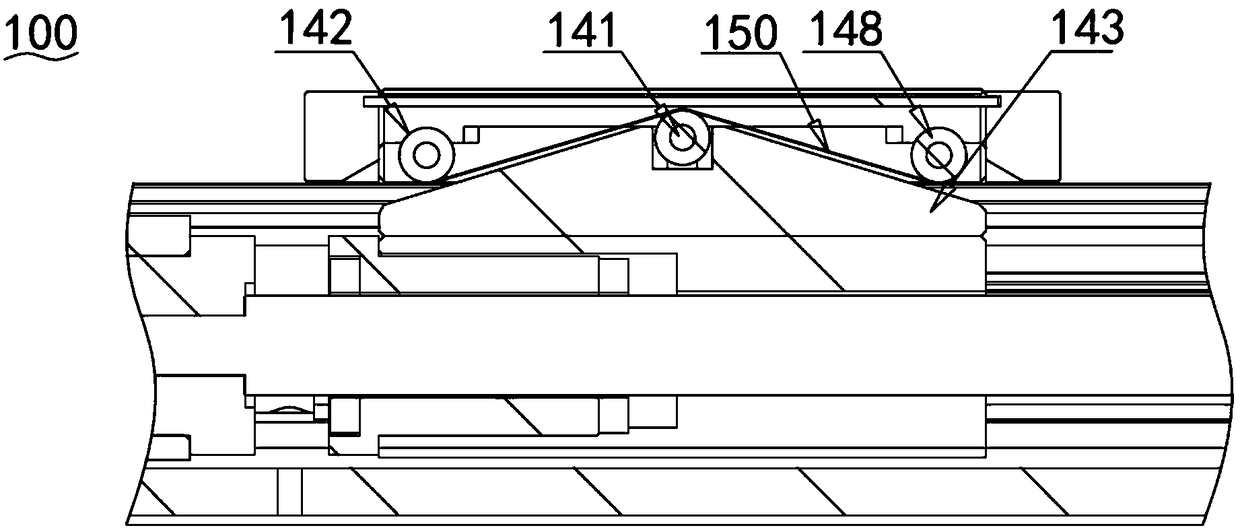

Totally-enclosed type linear module

The invention relates to the technical field of linear transmission, in particular to a totally-enclosed type linear module. The totally-enclosed type linear module comprises a base, a driving component, a transmission assembly and a transmission seat, wherein the driving component is arranged at one end of the base, the transmission assembly is arranged inside the base and is in driving connection with the driving component, the transmission seat is movably arranged to the transmission assembly, the side, provided with the transmission seat, of the base is provided with a sealing steel piece,two ends of the base are provided with pressing plates to fix the sealing steel piece to the surface of the base, the surface of the base is provided with positioning grooves, each positioning grooveis provided with a blocking edge, the blocking edge sides are provided with magnets to adsorb the sealing steel piece, the sealing steel piece penetrates into the transmission seat, the transmissionseat is internally provided with a lever to support the sealing steel piece up, and the positions, located on two sides of the lever, of the transmission seat are provided with roller shafts to pressthe sealing steel piece. According to the totally-enclosed type linear module, by means of the arrangements of the positioning grooves and the absorption actions of the magnets, the sealing steel piece is adsorbed to realize sealing transmission, the fact that the sealing steel piece keeps stable transmission in the high-efficiency transmission process can be guaranteed, the transmission efficiency is high, the stability is good, and the sealing strength is high.

Owner:东莞希思克传动科技有限公司

Automobile wheel trim

InactiveCN105346477AReinforced tongueAvoid breakingVehicle componentsEngineeringMechanical engineering

Owner:CHONGQING LINZHOU MACHINERY MFG CO LTD

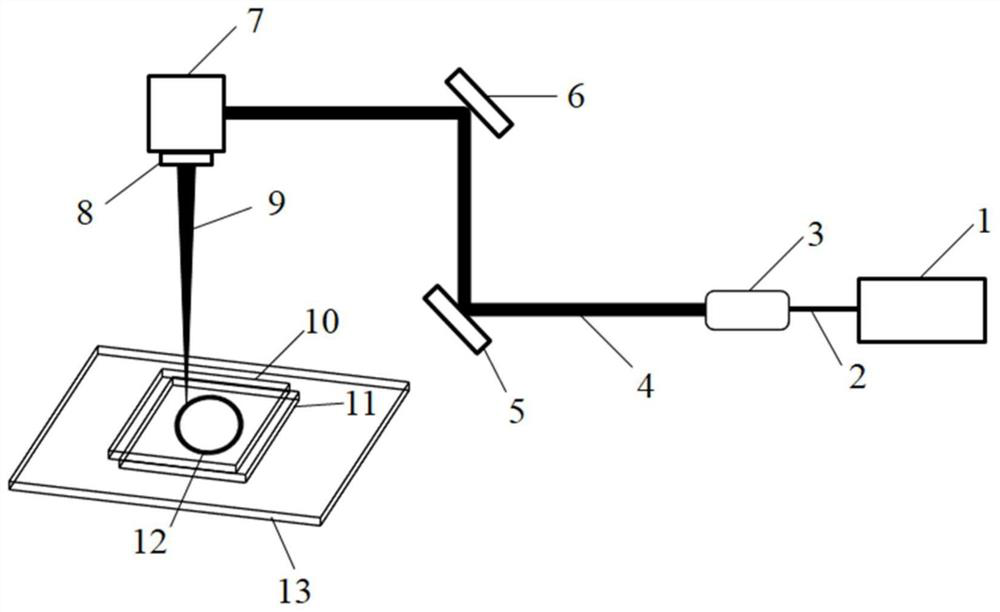

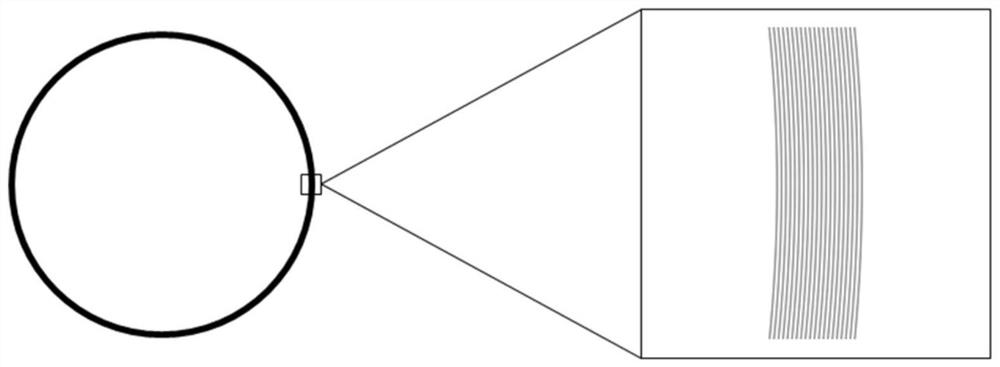

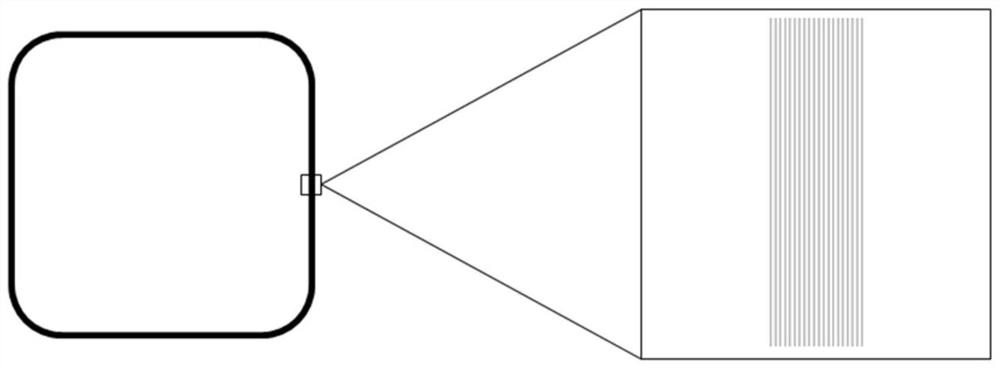

Femtosecond laser glass welding device and method

PendingCN113292233AFast scanningFast welding speedGlass reforming apparatusFemto second laserWeld seam

The invention discloses a femtosecond laser glass welding device and method. The method comprises the following steps of 1) dropwise adding a small amount of liquid on one piece of glass, then stacking another piece of glass, enabling the liquid to fill a gap of the to-be-welded glass, and enabling the gap to be reduced under the action of atmospheric pressure, 2) focusing a femtosecond laser beam with relatively high monopulse energy on the contact surface of the two pieces of glass to be welded, and scanning the laser focus at a high speed along a closed path by utilizing a scanning galvanometer to form a semitransparent welding seam at the contact part of the two pieces of glass, and (3) finally, using a femtosecond laser beam with low monopulse energy for low-speed scanning along the semitransparent weld joint, and achieving firmer welding finally. Through the first high-speed scanning, a glass gap can be uniformly reduced, and buckling deformation of two pieces of naturally stacked glass in a welding process is avoided; and a semitransparent microstructure can be pre-formed on the contact interface, so that light absorption during second scanning is enhanced, and the volume of a molten pool is enlarged. The femtosecond laser can be used for achieving sealing welding of glass with large gaps, and the method has the advantages of being high in welding speed, high in welding strength, stable and reliable in process and wide in application range.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

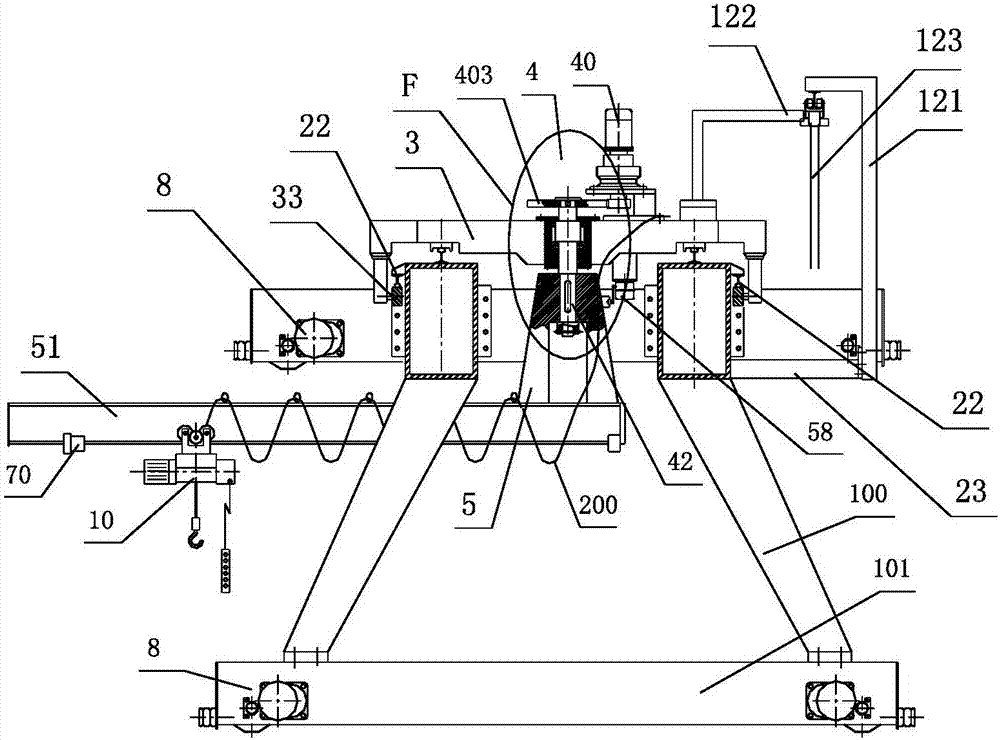

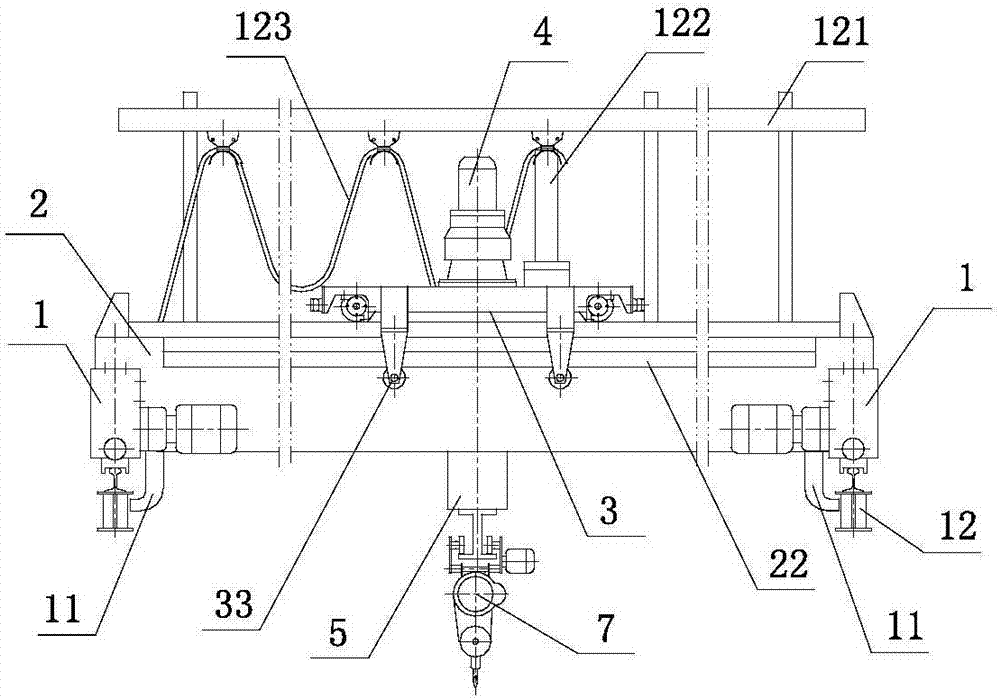

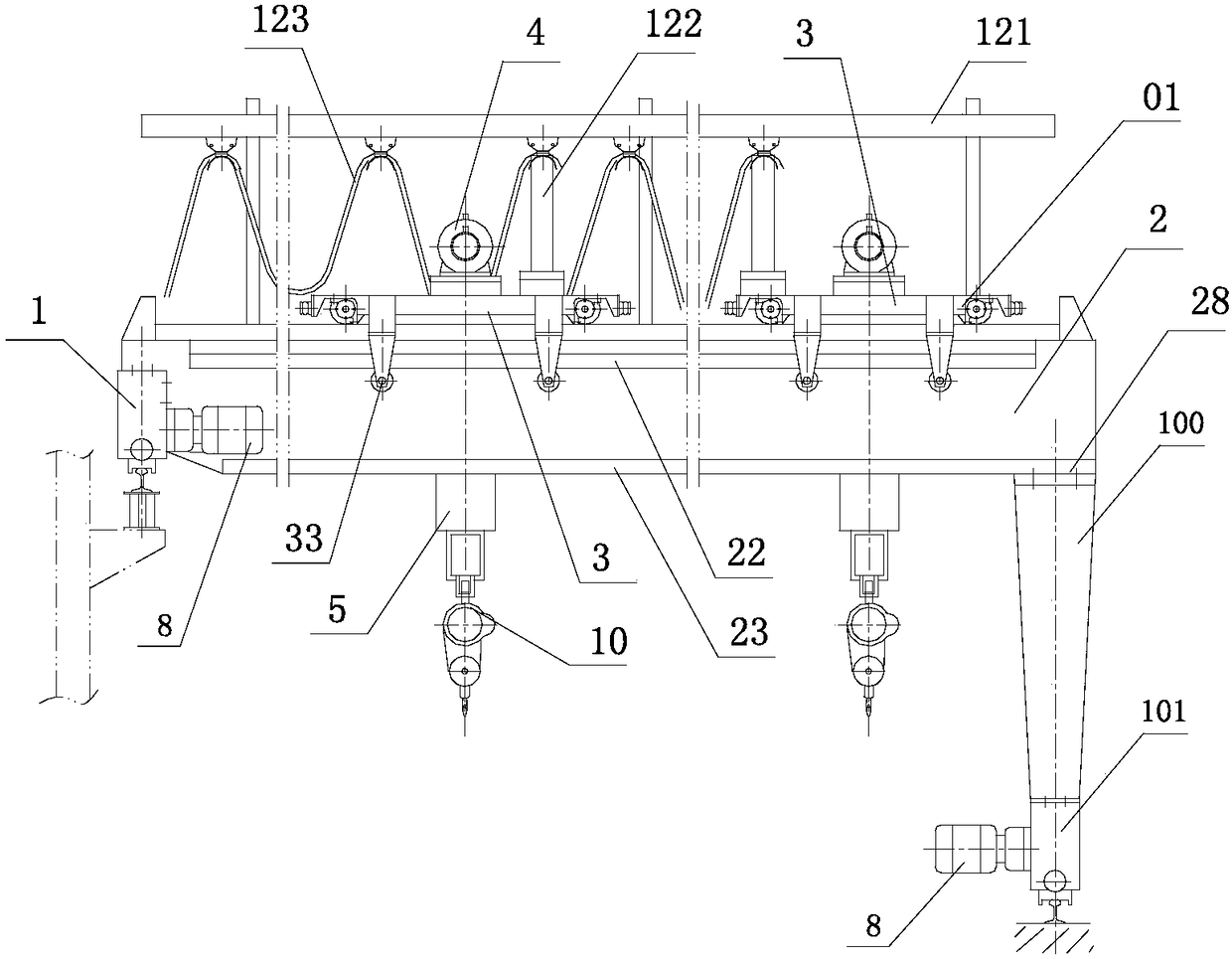

Bridge type cantilever crane with reaction wheel type running trolley and safety hooks

InactiveCN107352407AAccurate requirements for rotational speedPrevent speedingLoad-engaging girdersTravelling cranesDrive wheelBridge type

This application discloses a bridge-type cantilever crane with a trolley running on reverse rollers and a safety hook. It includes two end girders and two main girders to form a double-girder bridge structure; The running trolley is connected to the track above the beam; both ends of the end beam are equipped with a cart driving device with wheel rims and gear teeth and an anti-tipping device; steel rails are set on the outside of the main beam; both sides of the running trolley are connected with anti-rolling device The device runs on the rails; the two active wheel groups on the running trolley are driven independently; the running trolley is equipped with a rotating mechanism; the thrust bearing in the rotating mechanism is connected to the upper part of the bearing seat; the lower part of the boom shaft in the rotating mechanism is connected to the cantilever The components are connected, and the upper part is connected to the collector slip ring; the electric hoist is installed on the cantilever component and can move back and forth horizontally along the cantilever beam; the cantilever beam is under the main beam and can rotate at any angle on the horizontal plane.

Owner:卢统华

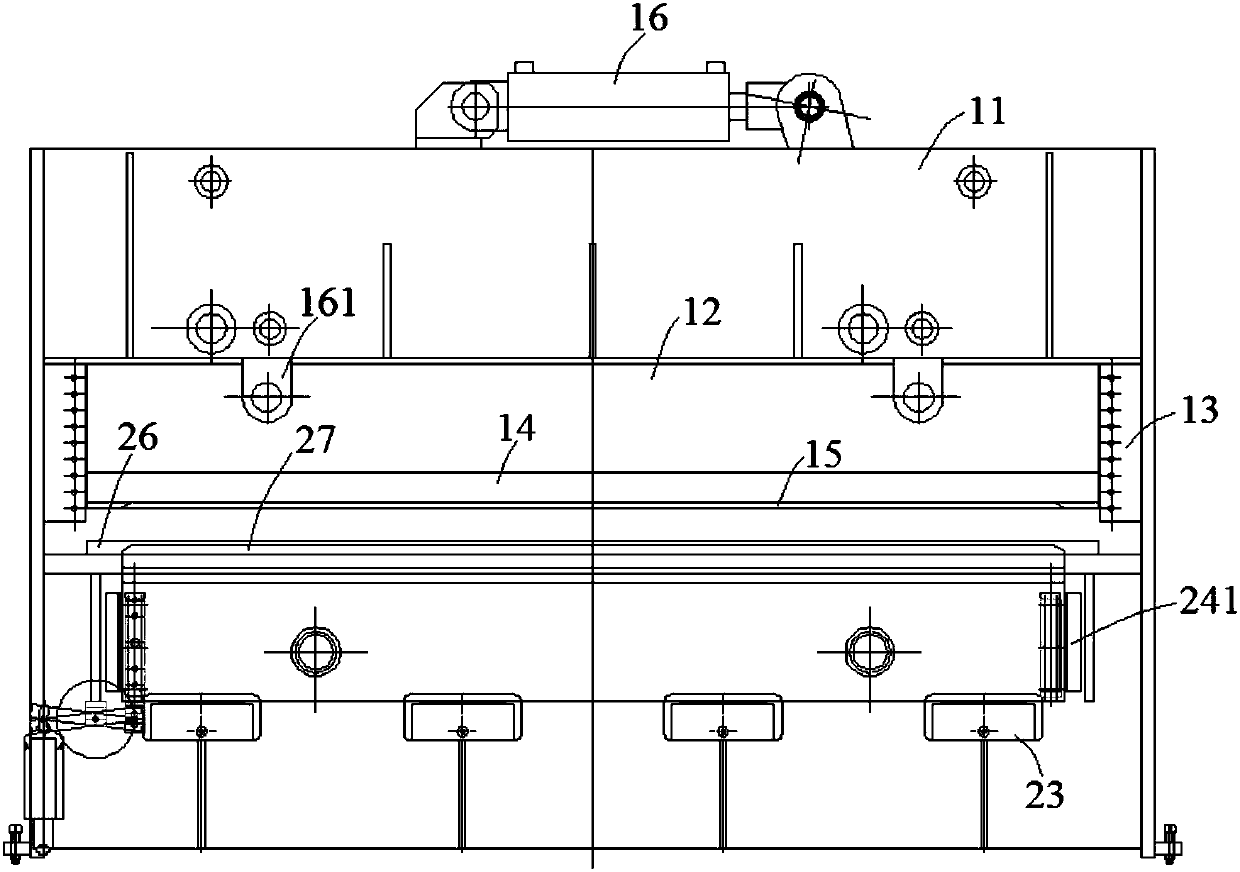

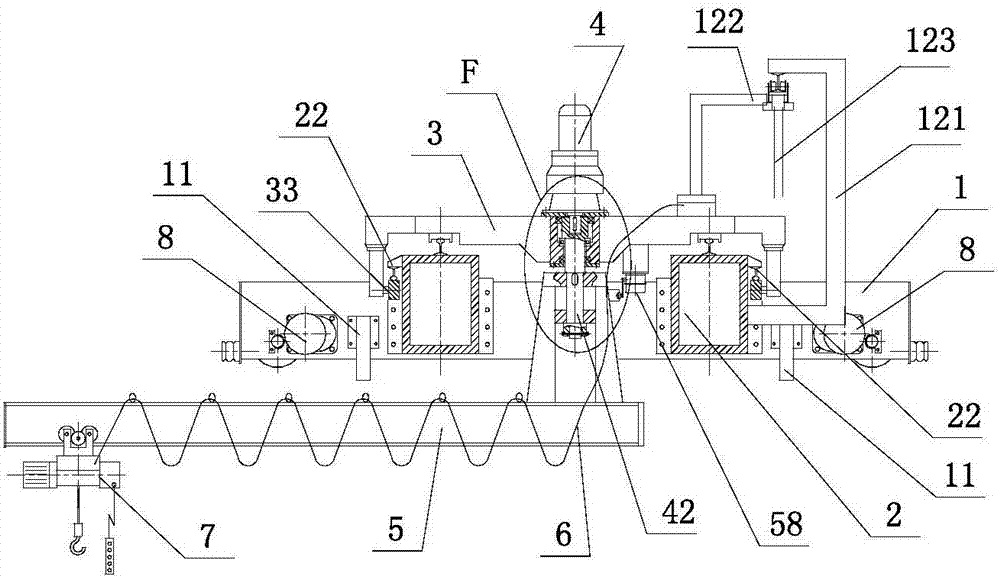

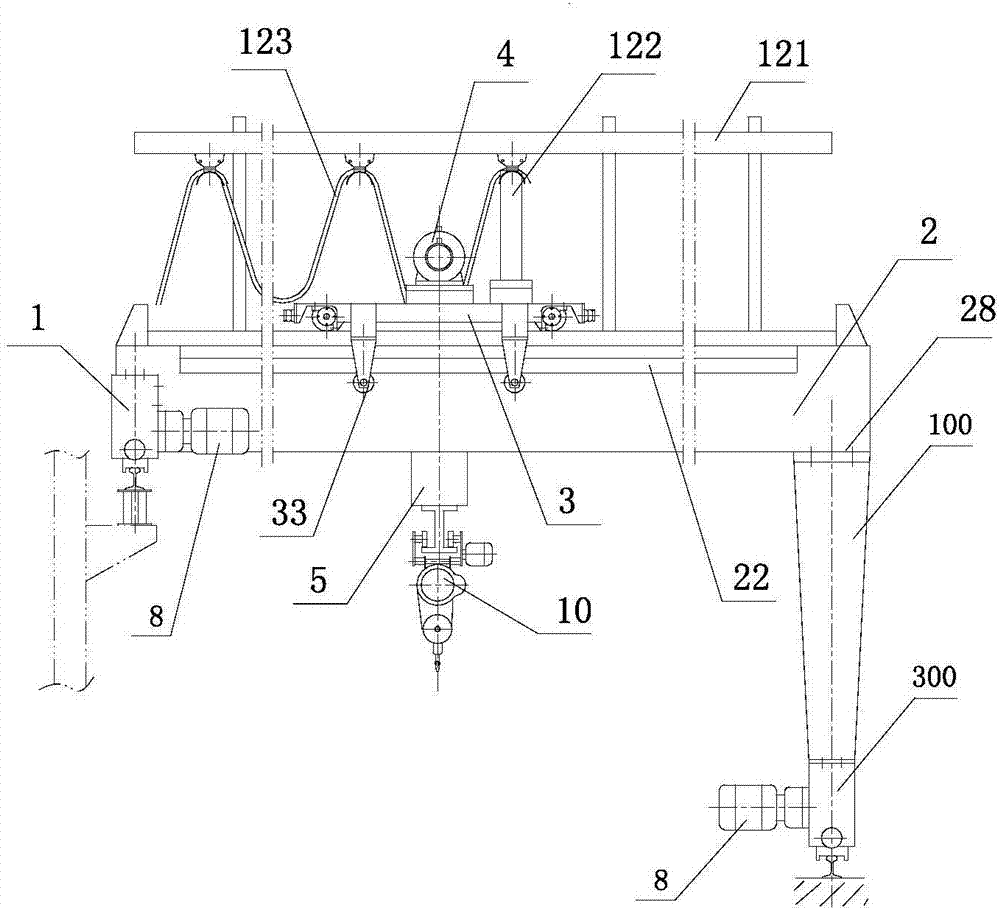

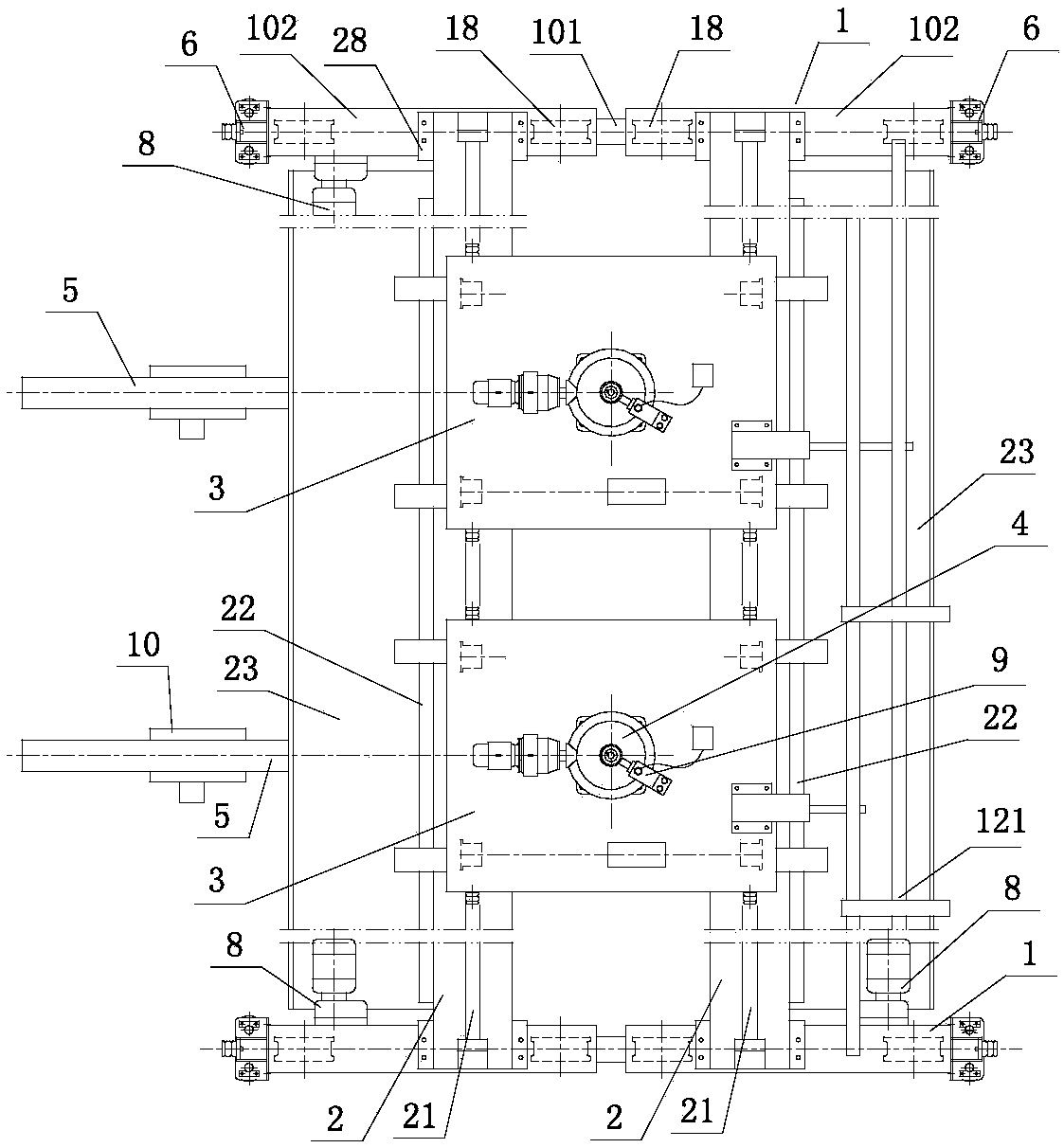

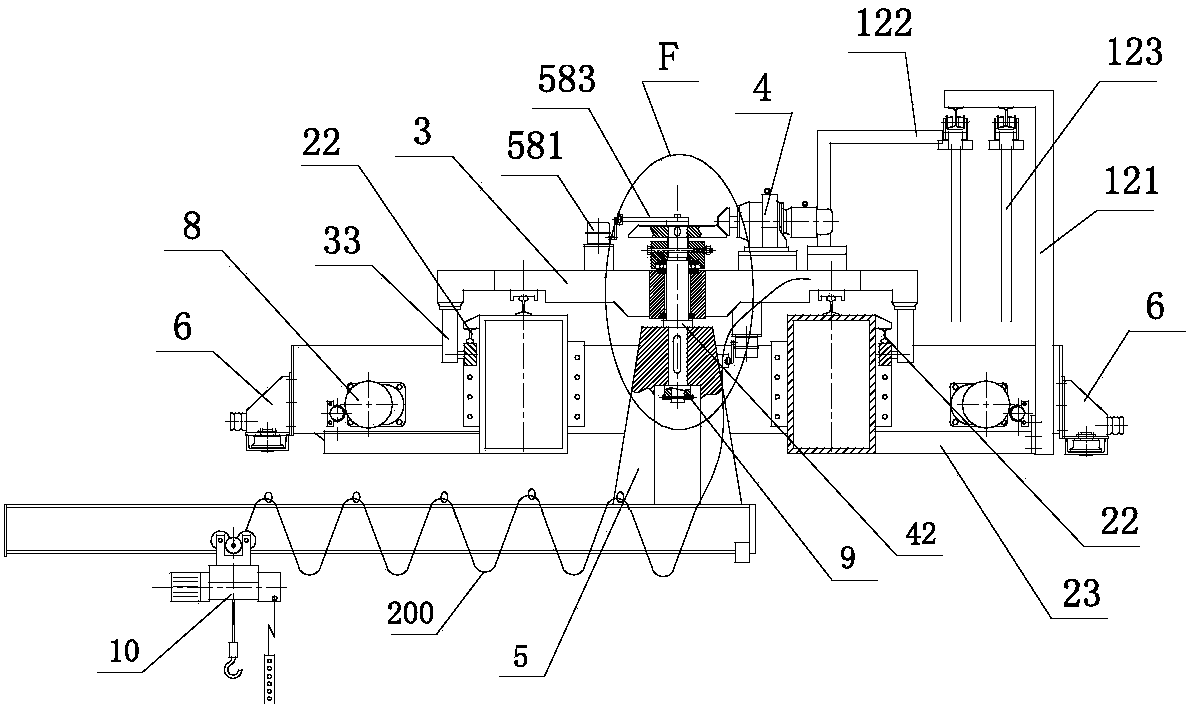

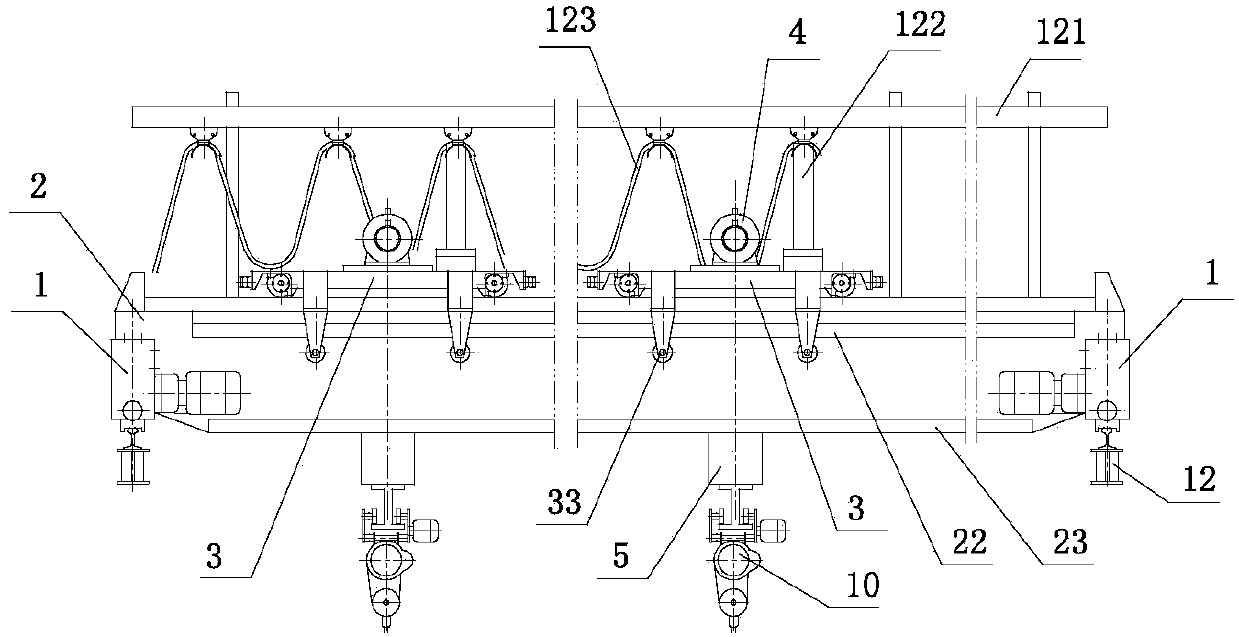

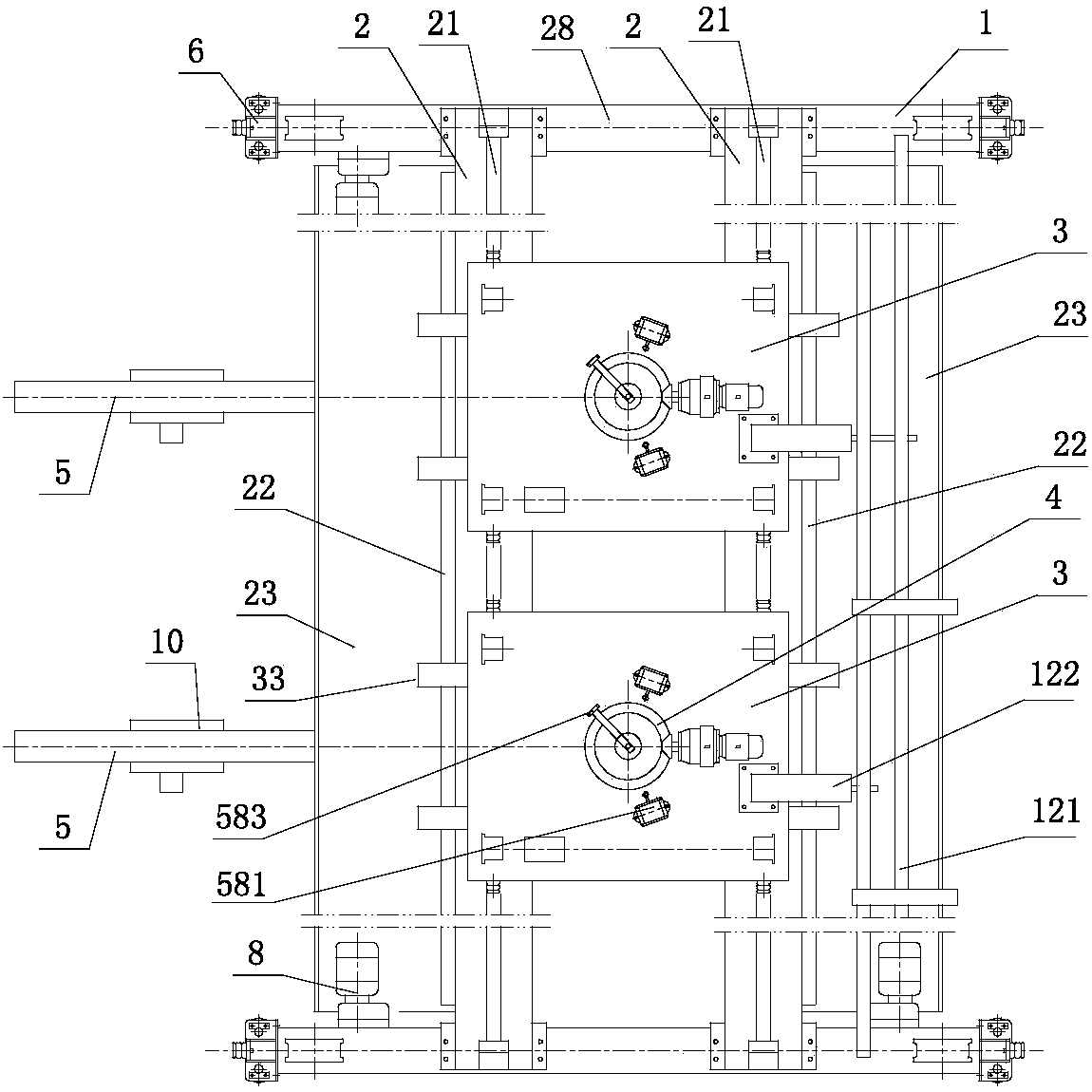

Hydraulic machine tool for one-time forming blind waves of container blind-wave top plate

ActiveCN107931388AReduce financial burdenReduce procurement costsMetal-working feeding devicesPositioning devicesEngineeringContainer tops

The invention discloses a hydraulic machine tool for one-time forming blind waves of a container blind-wave top plate, and belongs to the technical field of hydraulic machines. The machine tool comprises an upper box body, upper sliding blocks, upper molds, an upper main oil cylinder, lower main oil cylinders, lower sliding blocks and lower molds, the upper main oil cylinder is arranged at the upper part of the upper box body, the upper sliding blocks are arranged at the lower part of the upper box body, the upper molds are fixed at the bottom of the upper sliding blocks, and the upper main oil cylinder drives the upper sliding blocks to move in the vertical direction; the lower sliding blocks are arranged in the lower box body, the lower portions of the lower sliding blocks are connectedwith the lower main oil cylinders, and the upper portions of the lower sliding blocks are connected with the lower molds, and the lower main oil cylinders drive the lower sliding blocks to move in thevertical direction; and a rear material blocking device is arranged on one side of the lower box body, and the rear material blocking device is used for dragging the plate to move in a horizontal direction. The hydraulic machine tool relates to a special machine designed for a container top plate structure, the cost of equipment purchasing is greatly reduced, and the economic burden of a small-and-medium-sized container top plate production enterprise is reduced.

Owner:安徽金大进重工机床有限公司

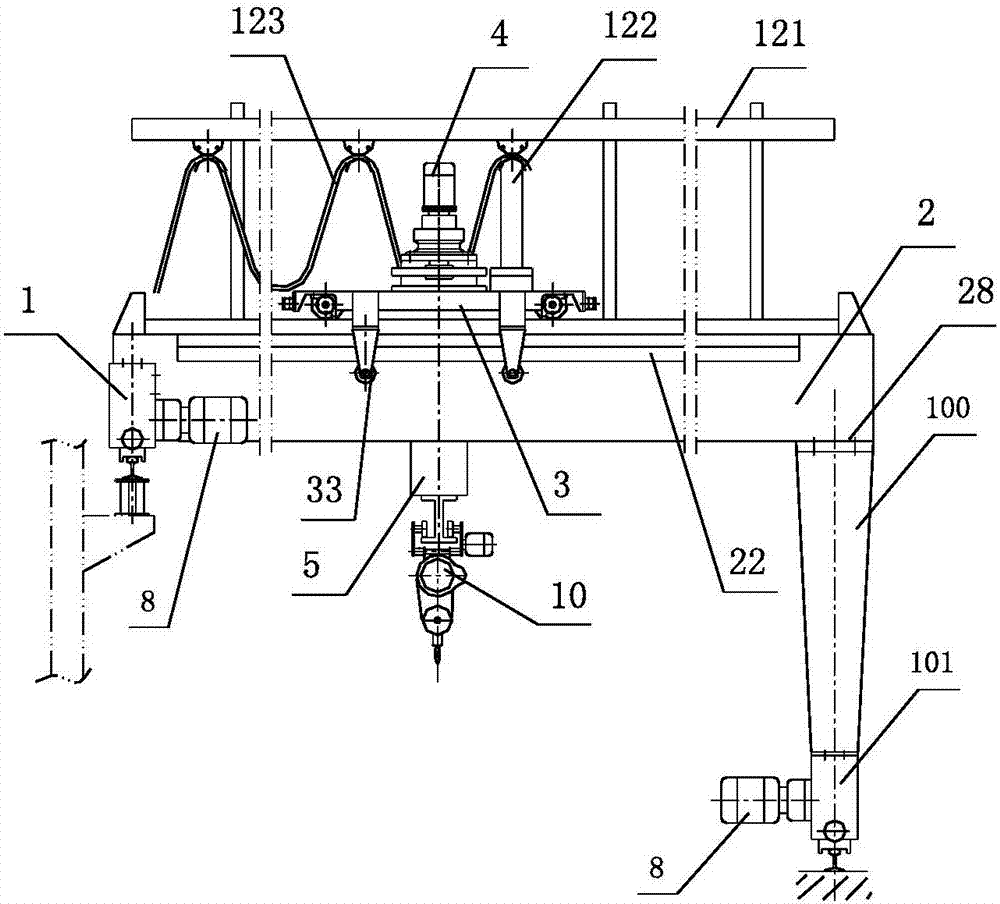

Semi-portal cantilever crane with reverse-rolling-wheel travelling trolley and exposed drive

InactiveCN107352453AImprove efficiencyGuaranteed uptimeLoad-engaging girdersTravelling gearGear driveDevice form

This application discloses a semi-gantry cantilever crane with anti-roller running trolley and open transmission, including a half-gantry composed of an end beam, two main beams, and a leg frame; the leg frame includes a ground beam ;The outer side of one of the main girders is equipped with a walking platform and a pick-up frame, and a hanging cable is installed on the pick-up rack; the running trolley is connected to the track above the main girder; rails are set on the outside of the main girder; both sides of the running trolley are connected The anti-roller device is hooked to run on the rail; the running trolley adopts a "three-in-one" reducer and a driving device connected with a floating shaft; the running trolley is equipped with a rotating mechanism with open gear transmission; the boom in the rotating mechanism The shaft is connected with the cantilever member; the cantilever member is equipped with a rotation limit device; the electric hoist is installed on the cantilever member and can move back and forth along the cantilever beam horizontally; the cantilever beam is under the main beam and can rotate; the cantilever end connection position of the cantilever beam is adjustable car gear.

Owner:卢统华

Cantilever crane with two travelling trolleys and anti-tipping end beams

InactiveCN107867634AImprove efficiencyEasy to cooperate with liftingTravelling cranesTravelling gearCouplingCantilever

This application discloses a cantilever crane with two running trolleys and end girder anti-tipping, including two end girders and two main girders; Two running trolleys are connected on the track; both ends of the end beam are equipped with a cart driving device and a horizontal wheel device; the inner side of the main beam is equipped with a steel rail and the tread faces downward; two sets of anti-rolling wheel devices are connected to each side of the running trolley. The anti-roller device is lapped on the rail; the active wheel groups on the running trolley are connected by spline sleeve couplings; the running trolley is equipped with a rotating mechanism; the driving device in the rotating mechanism passes through the coupling and the boom Shaft connection; the lower end of the boom shaft is connected to the cantilever member; the cantilever member is provided with a rotation limit device; the cantilever beam is equipped with an electric hoist and can move back and forth horizontally along the cantilever beam; the cantilever beam is placed under the main beam and can rotate; the cantilever beam The car block device is connected on the top and the position is adjustable.

Owner:福州市鼓楼区奇韵通自动化设备有限公司

A low-cost container roof hydroforming system

ActiveCN107931389BReduce financial burdenReduce procurement costsShaping toolsMetal-working feeding devicesEngineeringContainer tops

The invention discloses a low-cost container top plate hydraulic forming system and belongs to the field of hydraulic forming. The system comprises an upper box body, upper sliding blocks, upper molds, an upper main oil cylinder, a lower box body, lower main oil cylinders, lower sliding blocks and lower molds. The upper main oil cylinder is arranged at the upper part of the upper box body, and theupper sliding blocks are arranged at the lower part of the upper box body; the upper molds are fixed at the bottom of the upper sliding blocks, and a driving unit is arranged between the upper main oil cylinder and the upper sliding blocks; the upper main oil cylinder drives the upper sliding blocks to move in a vertical direction through the driving unit; and the lower sliding blocks are arranged in the lower box body, the lower portions of the lower sliding blocks are connected with the lower main oil cylinders, the upper portions of the lower sliding blocks are connected with the lower molds, and the lower main oil cylinders drive the lower sliding blocks to move in the vertical direction. The low-cost container top plate hydraulic forming system relates to a special machine designed for a container top plate structure, the cost of equipment purchasing is greatly reduced, and the economic burden of a small-and-medium-sized container top plate production enterprise is reduced.

Owner:安徽金大进重工机床有限公司

Cantilever crane with lifting trolley and balanced end beams and capable of rotating by any angles

InactiveCN107954336AEasy to liftAccurate requirements for rotational speedTravelling cranesTravelling gearStops deviceEngineering

This application discloses a cantilever crane with a lifting trolley and a balanced end beam that can rotate at any angle. It includes a double-girder bridge frame with two end beams and two main beams; ;A lifting trolley and a running trolley are connected to the track above the main beam; the end beam is composed of a balanced end beam and a connecting rod; one end of the balanced end beam is connected to the driving device of the cart, and the other end is connected to the passive wheel set; Horizontal wheel device; the outer side of the main beam is equipped with rails; both sides of the running trolley are connected with anti-roller devices, and the anti-rolling wheel devices are hooked and run on the rails; There is a rotating mechanism; the lower end of the boom shaft is connected to the cantilever member, and the upper end is connected to the collector slip ring; the electric hoist is installed on the cantilever member; the car stop device is connected to the cantilever beam; the cantilever beam is located under the main beam and can rotate at any angle on the horizontal plane.

Owner:福州市鼓楼区奇韵通自动化设备有限公司

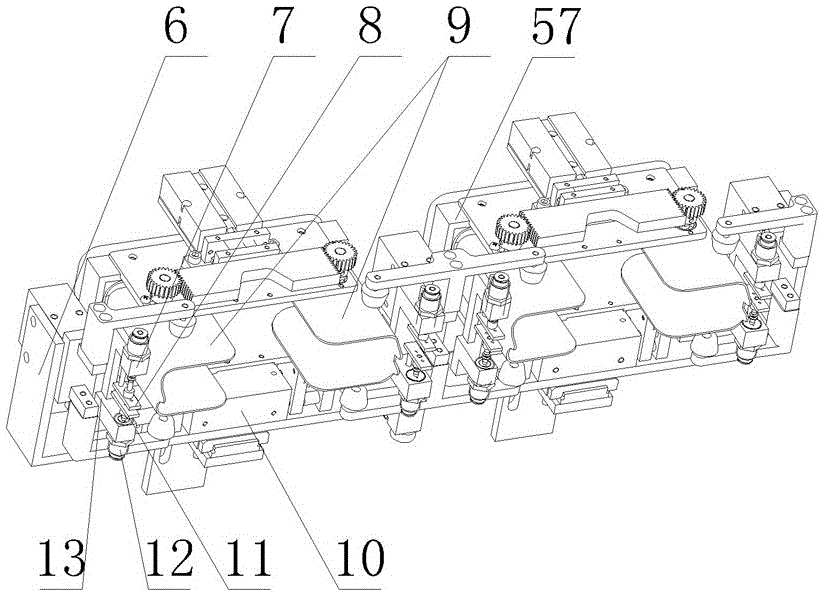

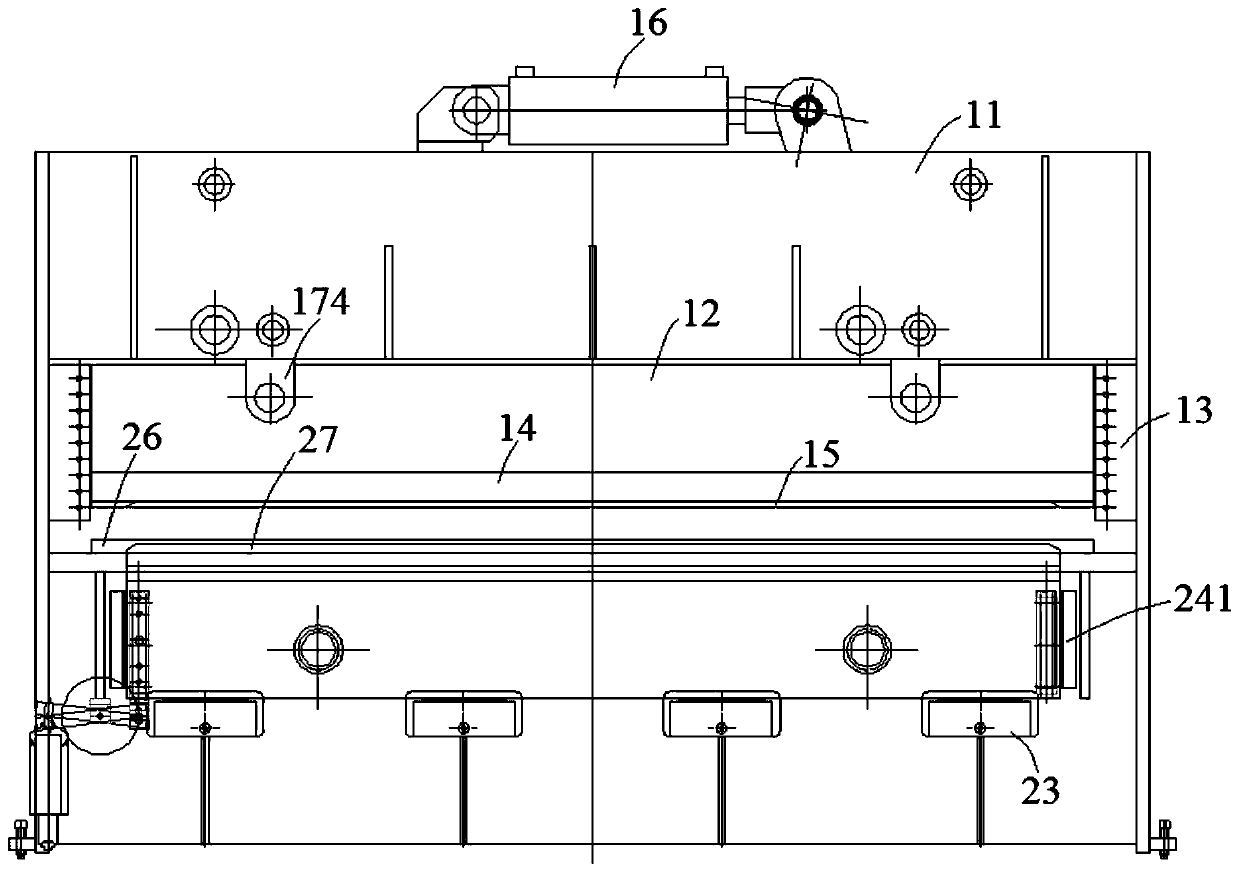

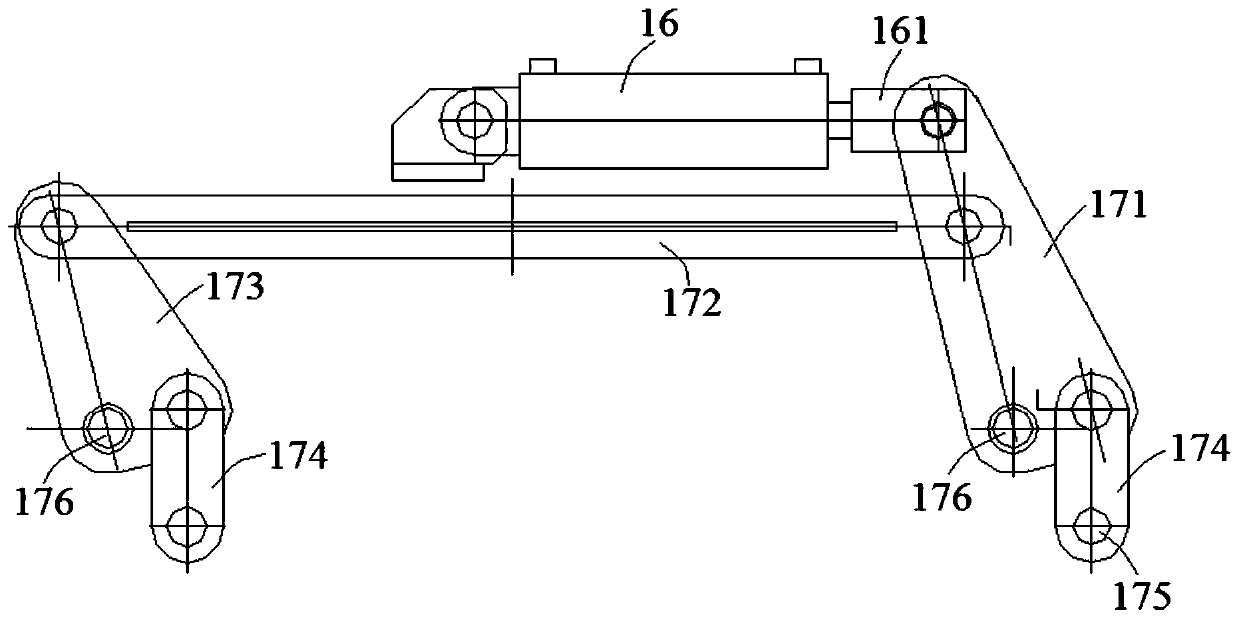

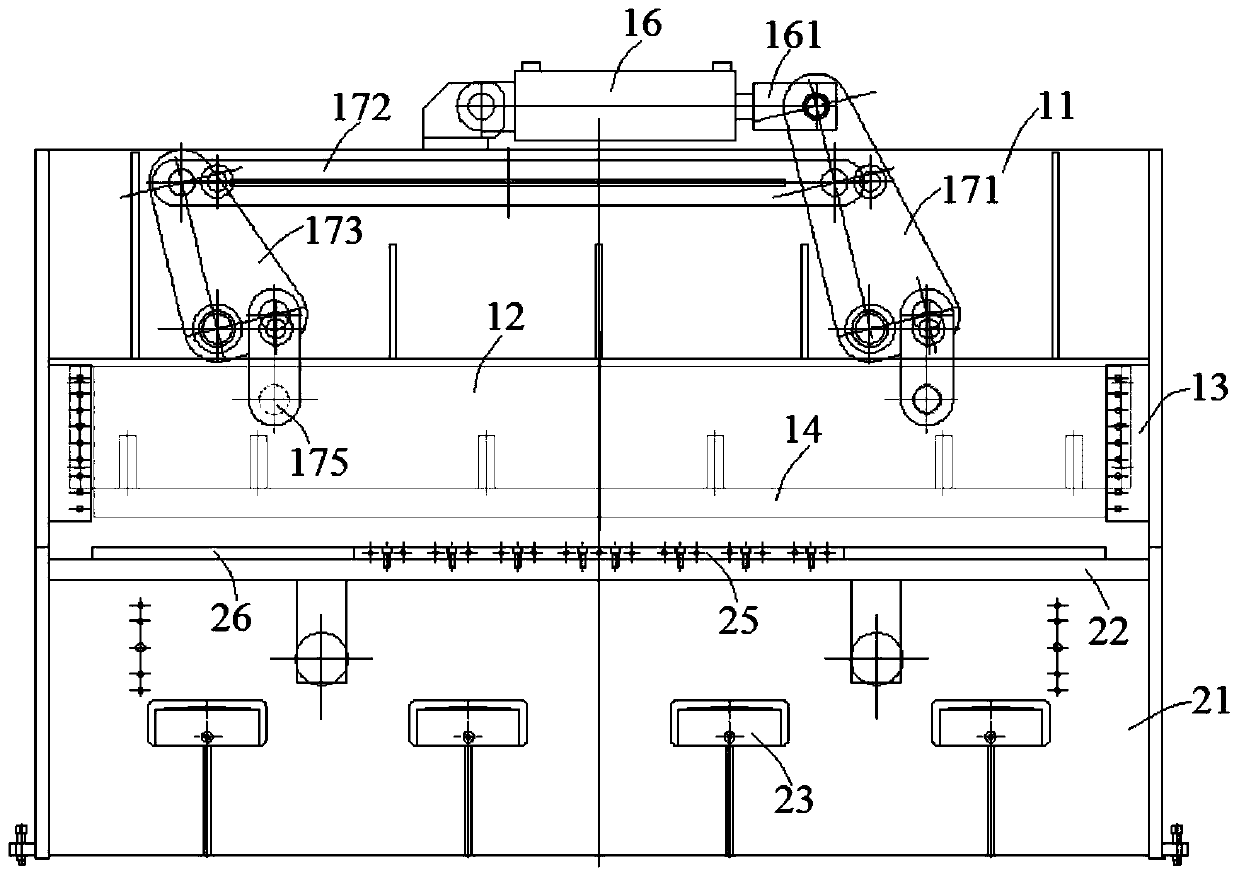

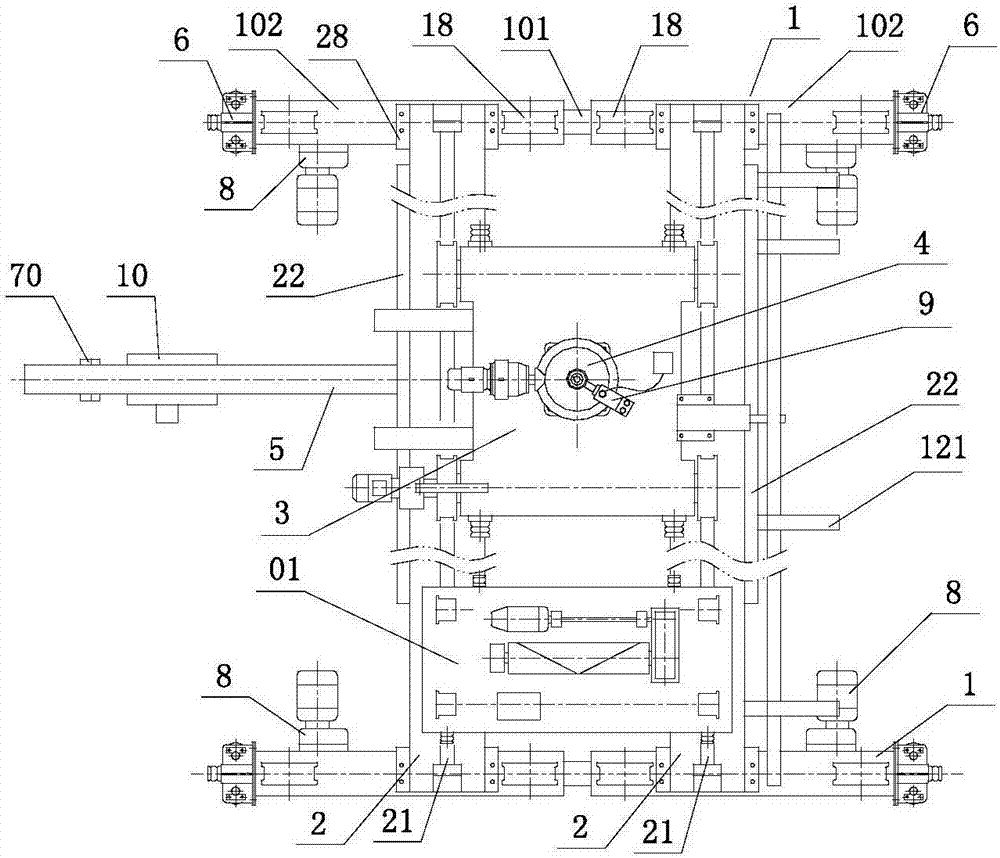

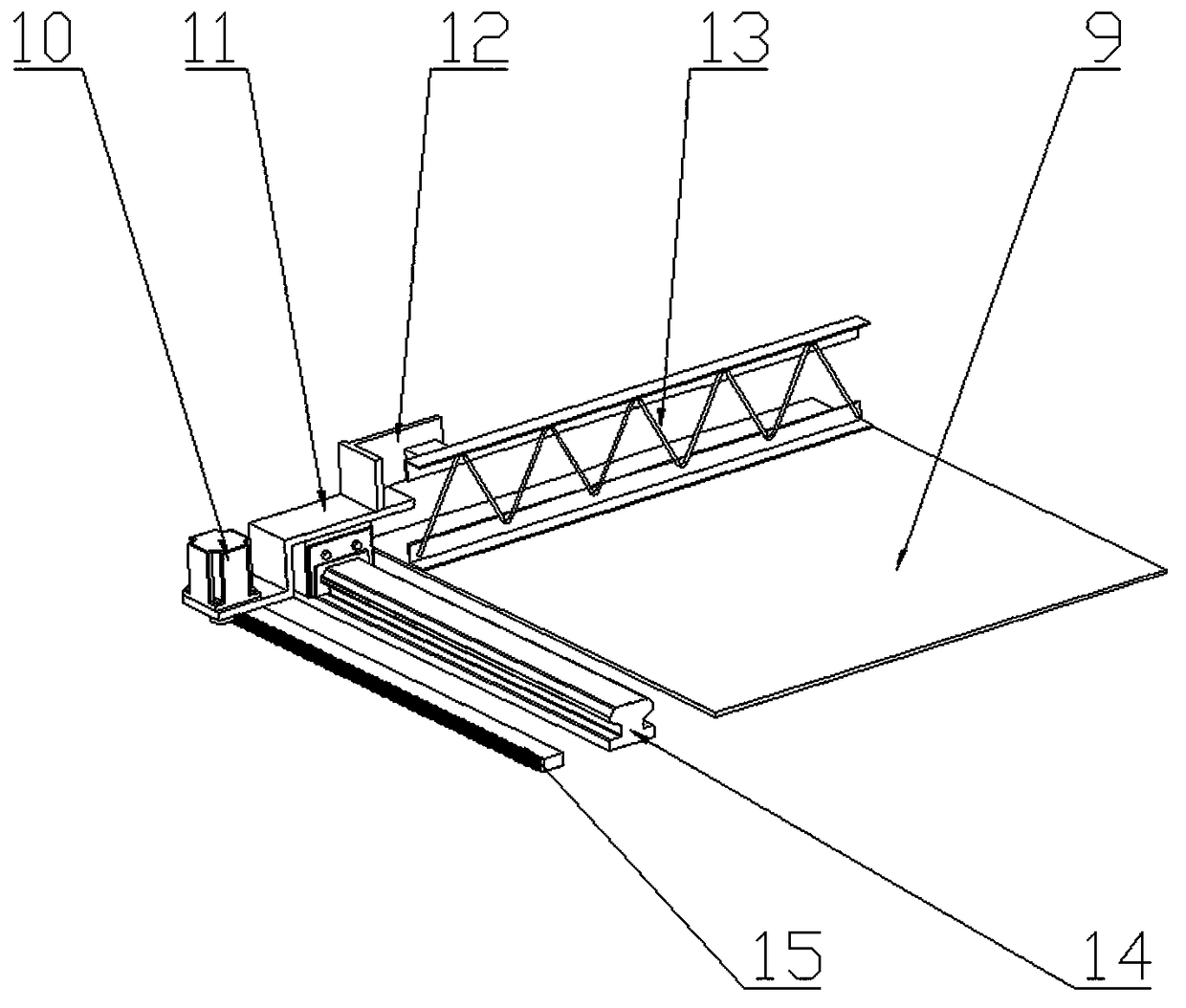

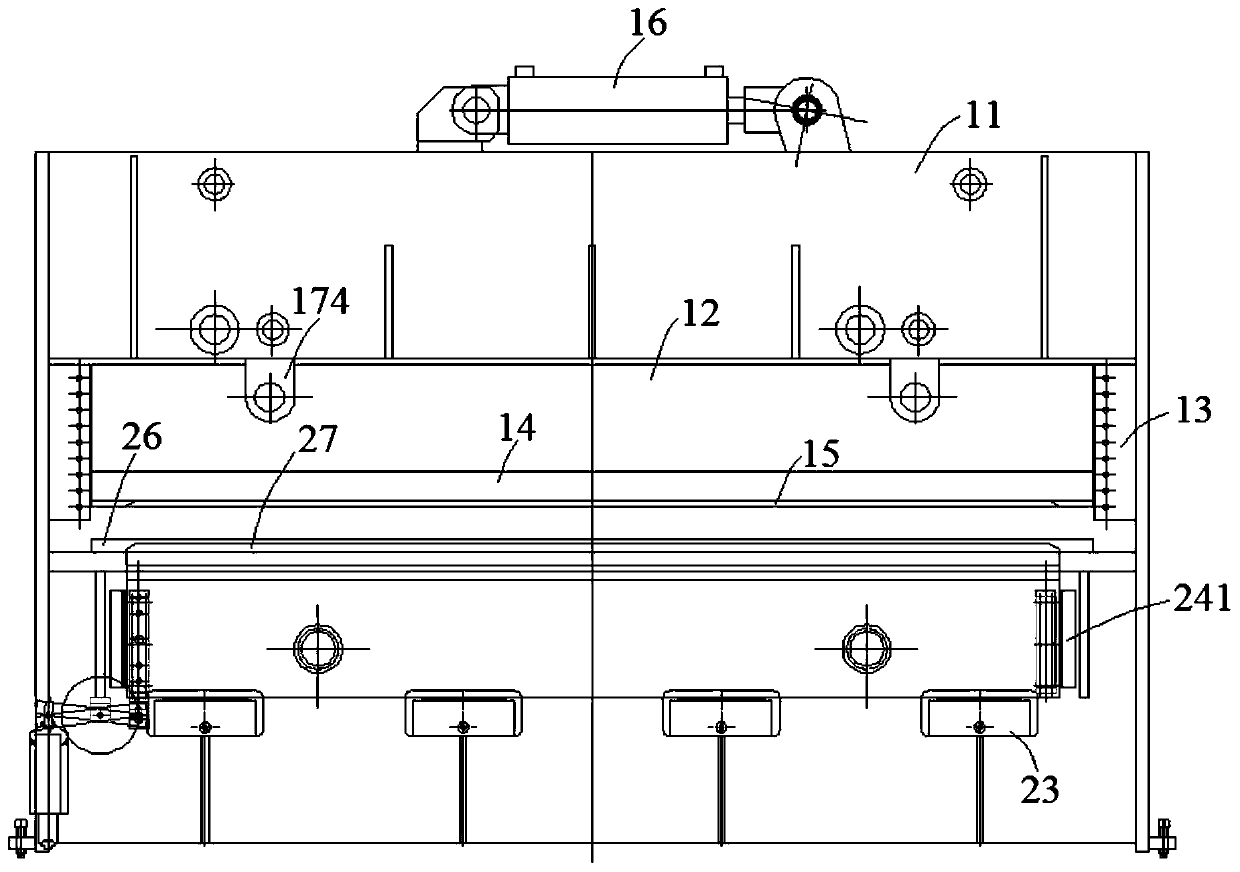

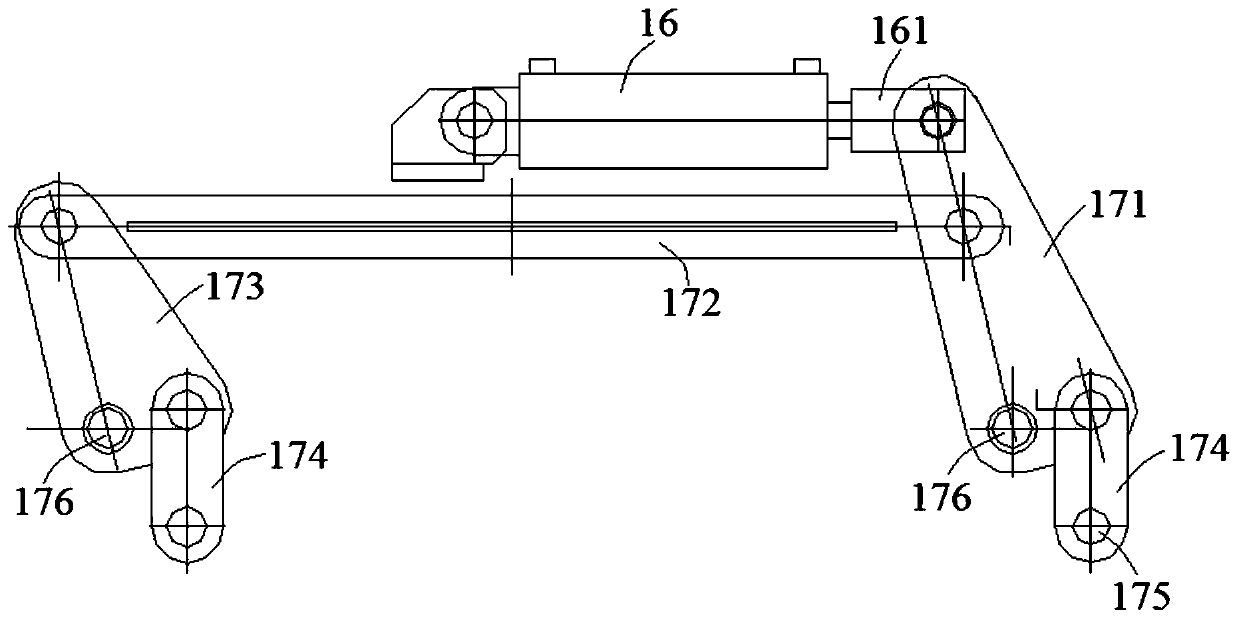

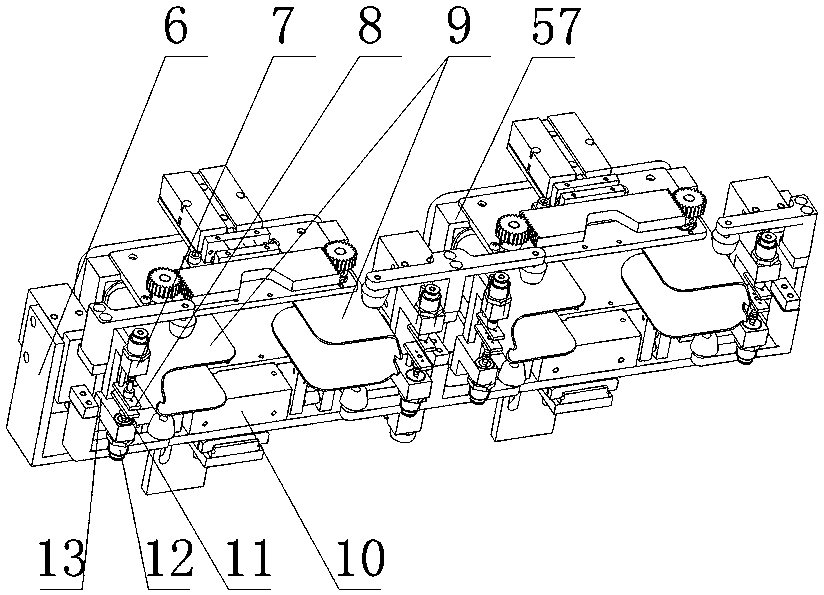

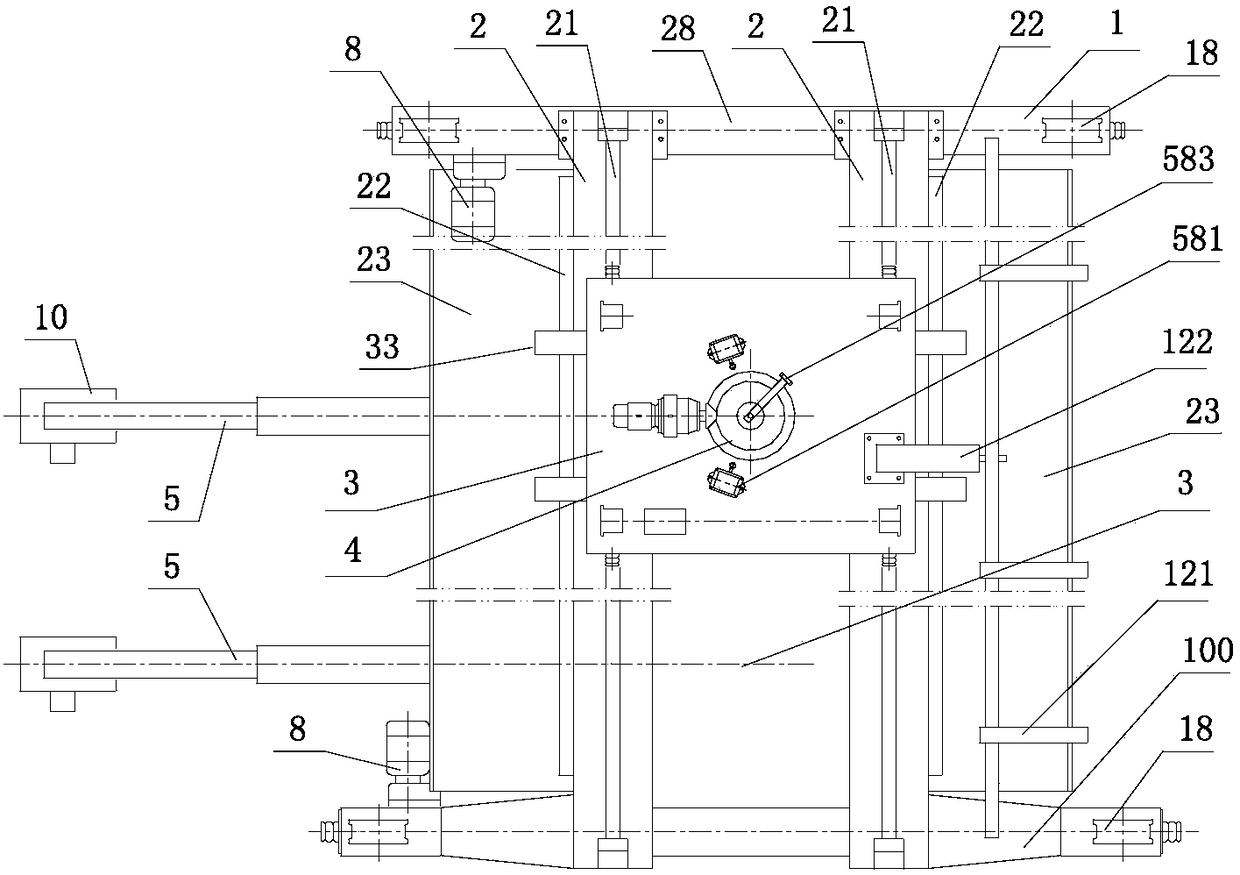

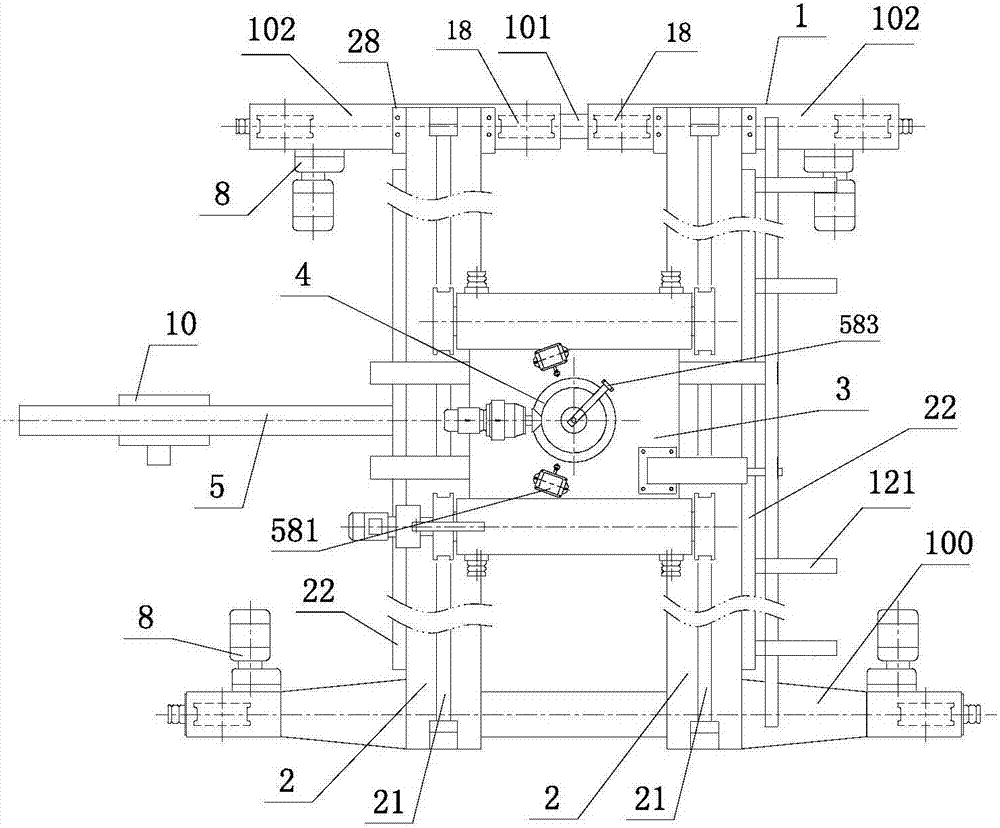

Control method of multi-cavity steel component assembling and positioning mechanism

ActiveCN109048166AIncrease productionImprove qualityWelding/cutting auxillary devicesAuxillary welding devicesDrive motorEngineering

The invention relates to a control method of a multi-cavity steel component assembling and positioning mechanism, and belongs to the technical field of multi-cavity steel component assembling equipment. The mechanism comprises a square tube positioning and pressing frame. Two ends of the square tube positioning and pressing frame are provided with square tube positioning and pressing pieces connected with the square tube positioning and pressing frame in a displacement mode. An electromagnet is arranged at a front end of an end primary positioning piece. A lower end of the end primary positioning piece is provided with an end primary positioning piece guide rail which is in sliding connection with the end primary positioning piece. A driving motor is arranged at the rear end of the end primary positioning piece. A rack guide rail parallel to the end primary positioning piece guide rail is arranged below the driving motor. The rack guide rail is movably engaged with the drive motor. Thelower end of a displacement cylinder is provided with a lock pressing piece which is movably contacted. Two ends of a pressing roller are provided with bearing seats which are movably sleeved with the pressing roller. Pressing cylinders are arranged on the bearing seats. According to the control method of the multi-cavity steel component assembling and positioning mechanism, the method has the advantages of being compact in structure, accurate in positioning and integrated in assembling and welding; and the machining precision of the multi-cavity steel components is improved, and the machining period is shortened.

Owner:浙江东南网架股份有限公司

Cantilever crane with reverse roller travelling trolley

InactiveCN107352452AGuaranteed uptimeEnsure that the rail does not warpLoad-engaging girdersTravelling gearLap jointEngineering

This application discloses a cantilever crane with a trolley running on reverse rollers, which includes a bridge structure composed of two end girders and two main girders; There is a track, and the running trolley is connected to the track; a steel rail parallel to the above track and with the tread facing down is set above the outer side of the main beam; two sets of anti-rolling wheel devices are connected to each side of the running trolley through adjusting gaskets, and the anti-rolling wheel devices are connected to each other. Connected to the rail; there is a rotating mechanism in the center of the running trolley; the boom shaft in the rotating mechanism is connected to the cantilever component; a rotation limit device is set between the cantilever component and the running trolley; a set is installed at each end of the two end beams A cart driving device and a safety hook with shaft-connected wheels; an electric hoist is connected to the cantilever member, and the electric hoist can move back and forth horizontally along the cantilever beam; the cantilever beam is placed under the two main beams and can rotate.

Owner:卢统华

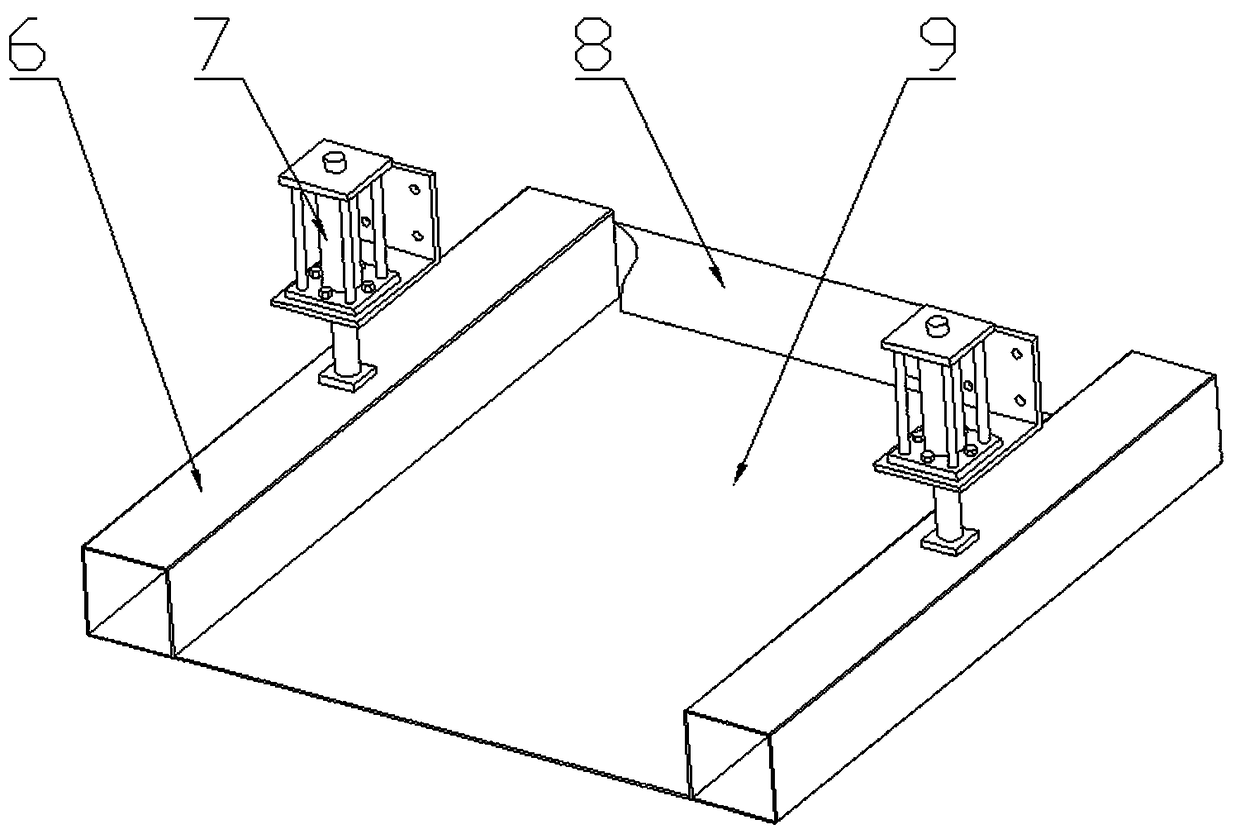

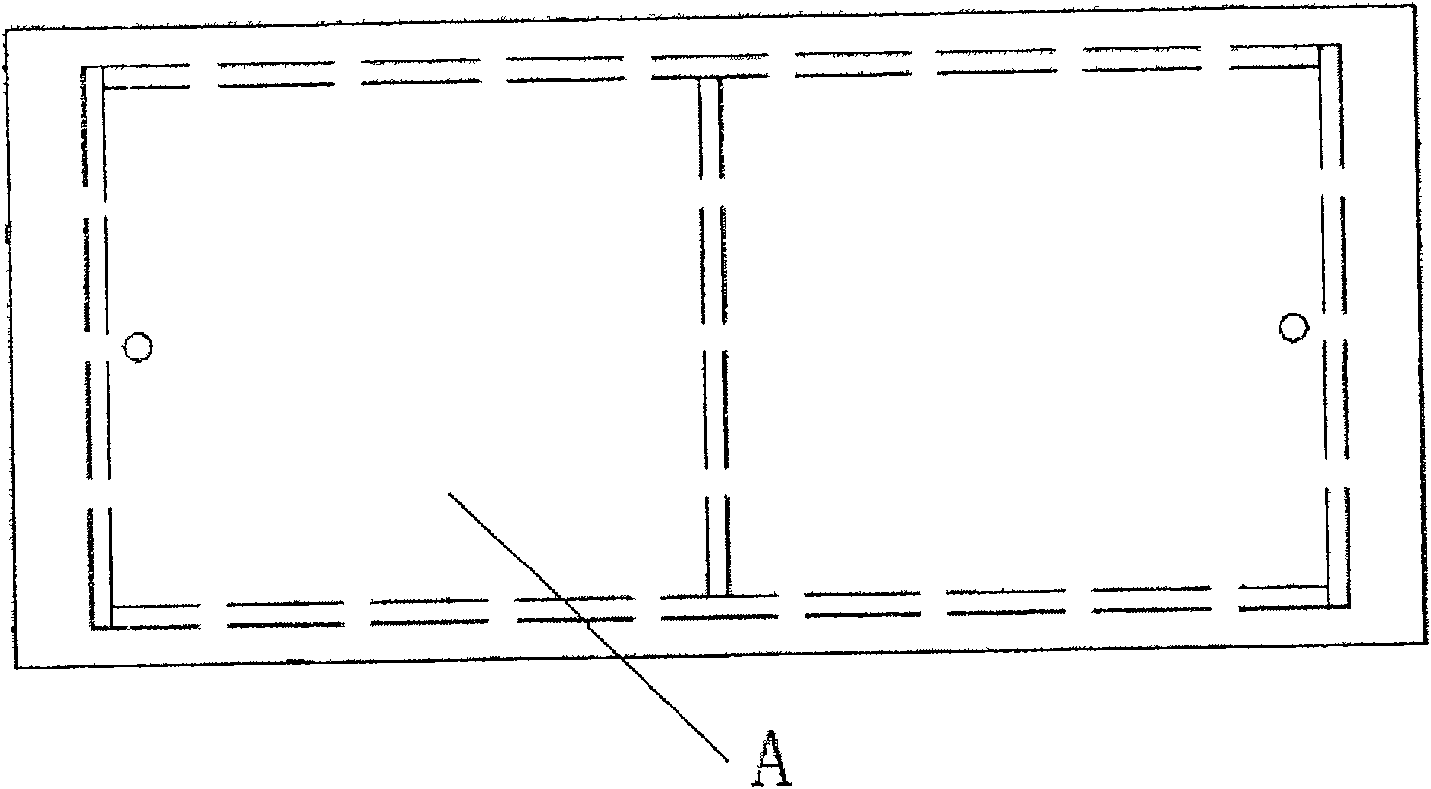

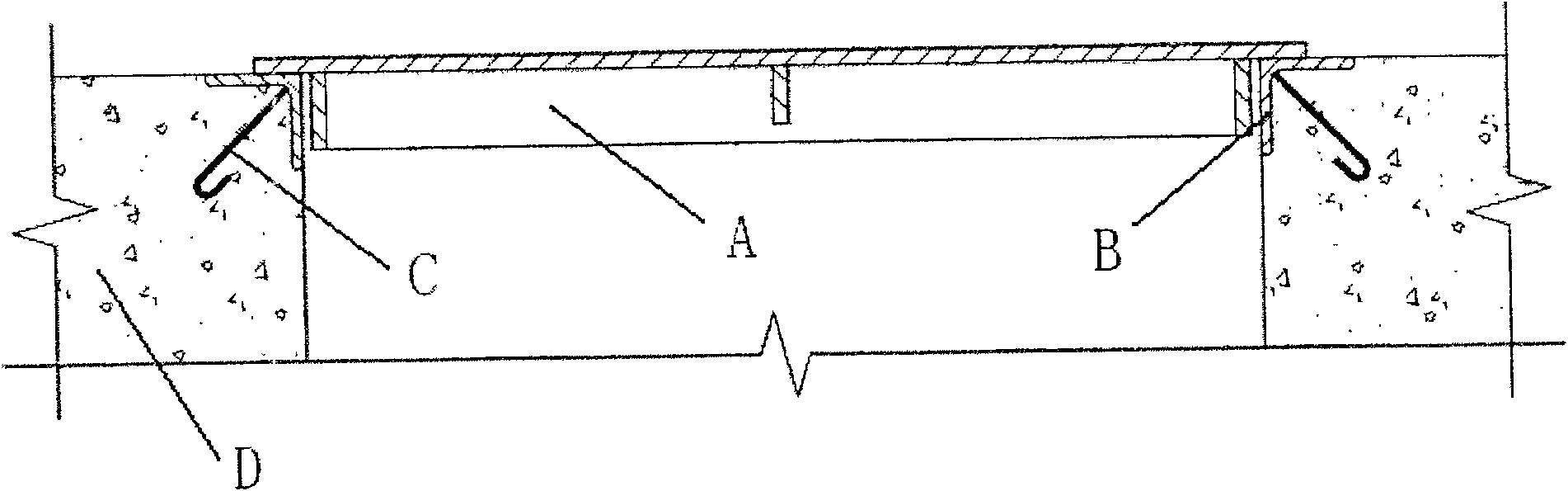

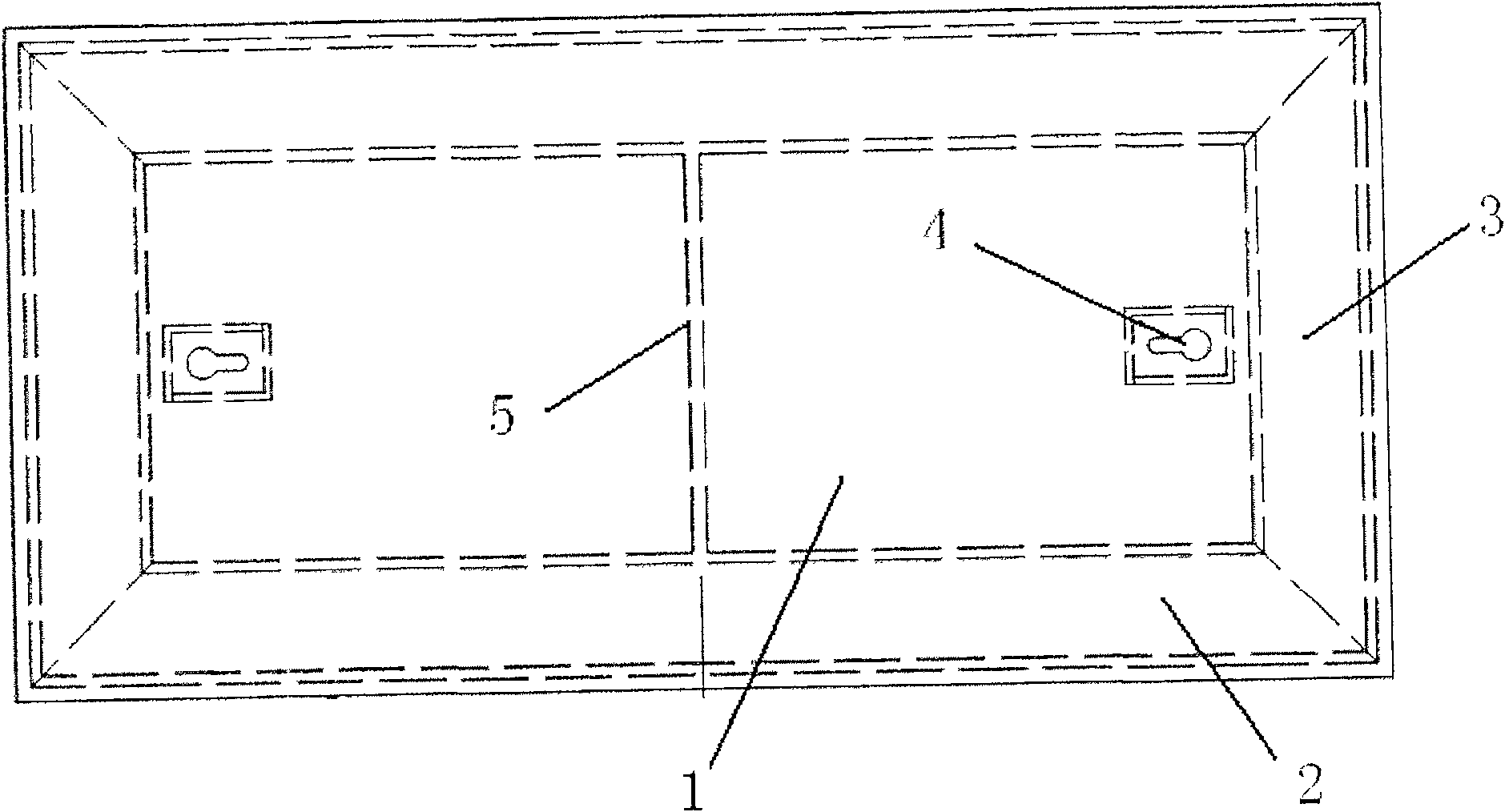

Trench steel cover board component

InactiveCN100577927CAvoid tripping and fallingGuaranteed not to warpArtificial islandsUnderwater structuresRear quarterAgricultural engineering

The invention discloses a trench steel cover plate component, which comprises a corner protector and a cover plate which is arranged on the corner protector and is characterized in that: the corner protector is a sunk corner protector; the sinking height of the corner protector is equivalent to the thickness of the cover plate; the corner protector is a group of angle irons which are respectively fixed on the trench surface and the subsidence surface; the cover plate comprises two supports which are arranged on the corner protector, two ribbon strips which are connected with the supports, and a top plate which is fixed on the supports and the ribbon strips; the top plate is provided with a key hole the lower part of which is provided with a collection box; a drainage hole is arranged on the collection box; and the collection box is movably connected with the top plate or a bottom plate or a side plate of the collection plate is detachably connected with other parts at the bottom of the collection box. The trench steel cover plate component can guarantee that the cover plate is parallel to the ground, has good bending rigidity, flexural capacity and surface evenness, and has low steel amount. Moreover, the cover plate is convenient to open and reset, and dust and small sundries falling from the key hole can be collected.

Owner:YANSHAN UNIV

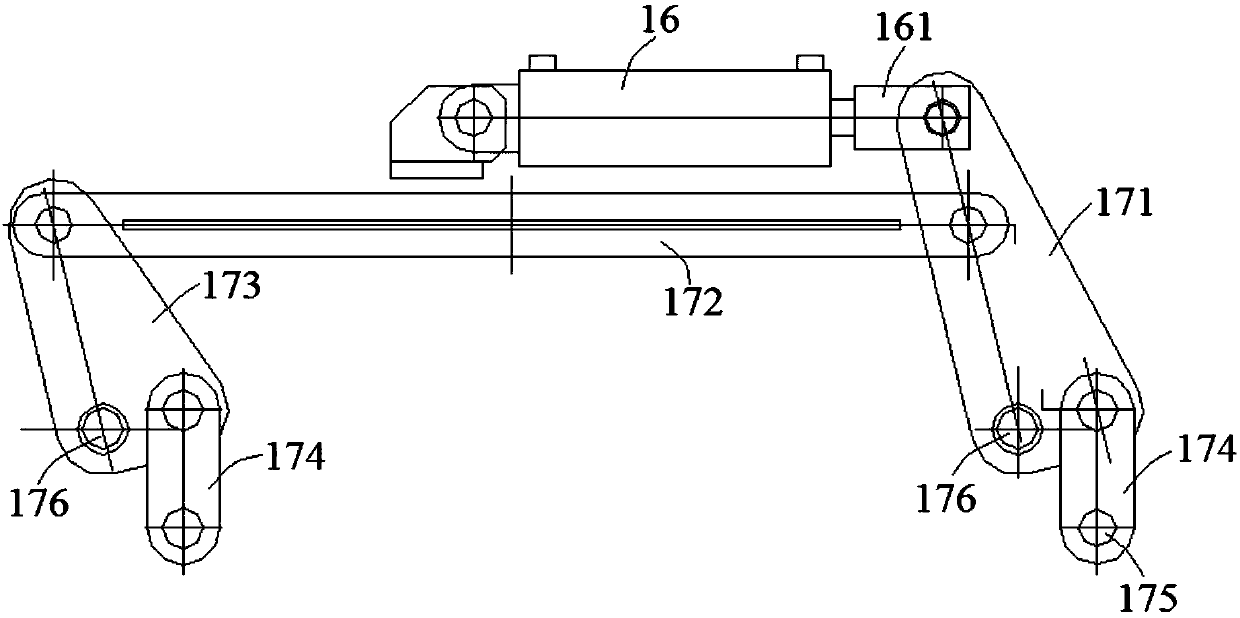

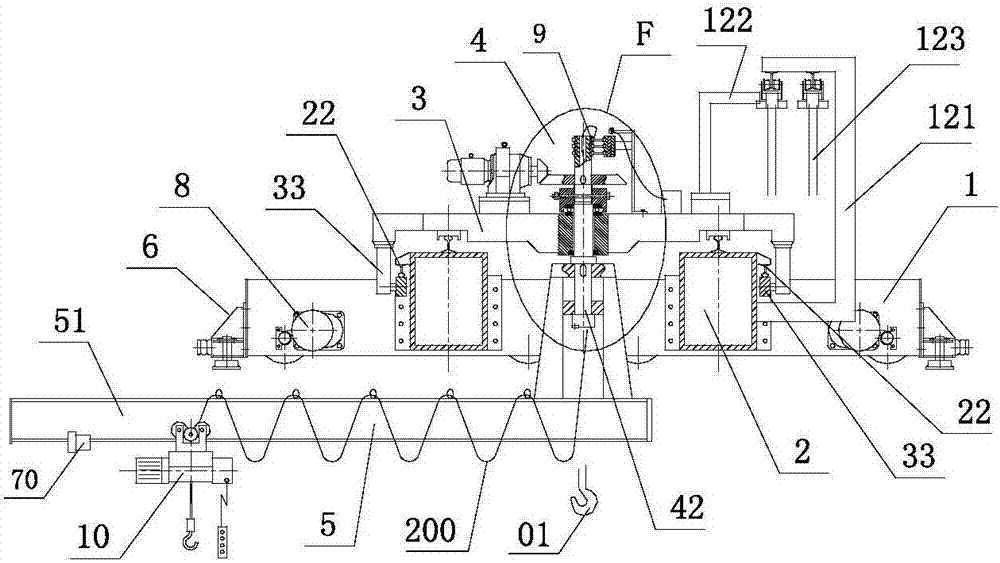

A Manufacturing Method of Blind Wave Roof with Reduced Processing Cost

ActiveCN108160794BReduce financial burdenReduce processing costsShaping toolsManufacturing technologyMotor drive

The invention discloses a blind wave top plate manufacturing method capable of reducing machining cost, and belongs to the technical field of blind wave top plate manufacturing. The blind wave top plate manufacturing method comprises the manufacturing steps that 1, a continuous coil steel is uncoiled, and is discharged to be a steel plate of a certain length; 2, the to-be-moulded steel plate is placed on an edge pressing ring on a worktable; 3, a piston of an upper main oil cylinder moves horizontally, and two vertical connection rods drive an upper mould to move downwards to closely press theto-be-moulded steel plate; 4, a lower mould is driven to move vertically by a lower main oil cylinder, and a blind wave is formed on the to-be-moulded steel plate in one step; 5, motors drive lead screws to rotate; slide bases sleeving the two lead screws move horizontally, and a baffle finger drives the steel plate to move to be subjected to moulding operation of a next blind wave; and 6, the moulded steel plate is subjected to positioning and trimming treatment sequentially. According to the manufacturing technique provided by the invention, the special machine designed for the blind wave top plate structure is used; equipment purchasing cost is greatly reduced; and financial load of middle and small container top plate manufacturing enterprises is alleviated.

Owner:安徽金大进重工机床有限公司

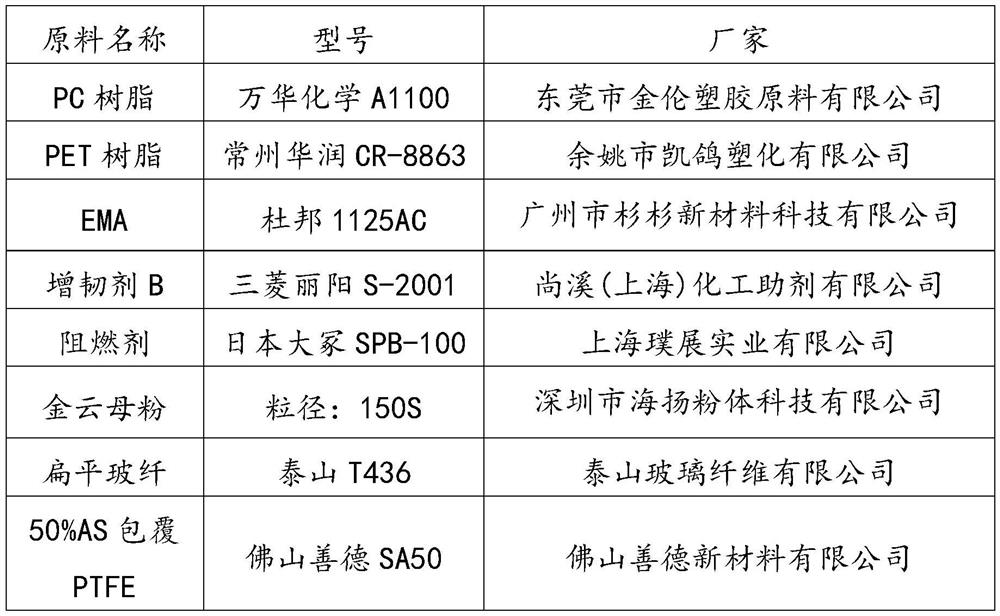

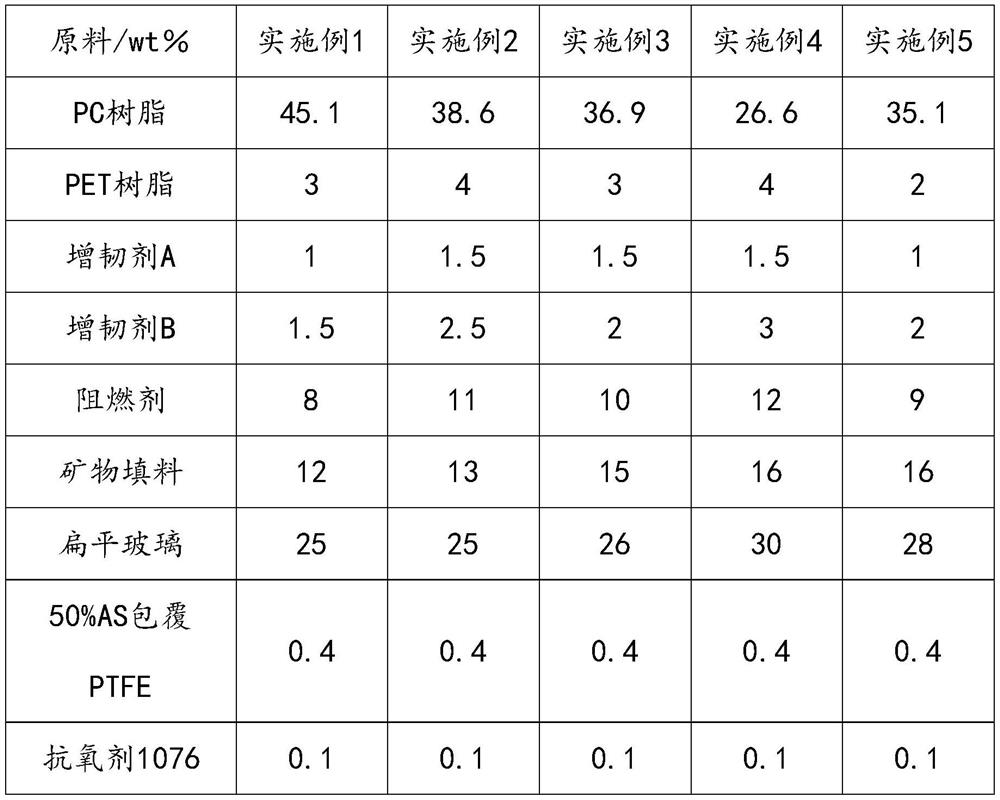

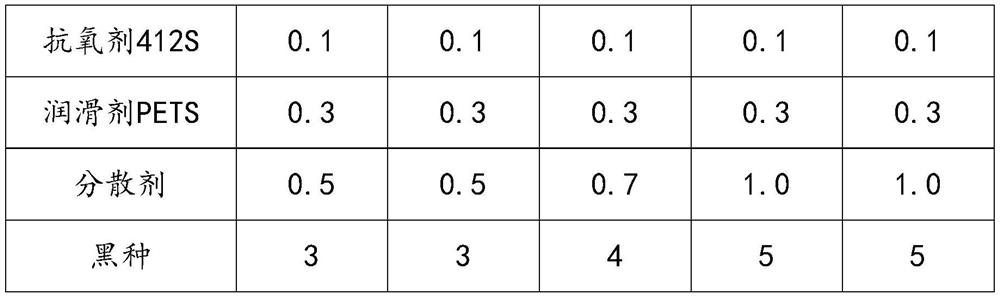

Halogen-free low-warpage low-linear-expansion-coefficient extrusion-grade thin-wall flame-retardant polycarbonate composite material and preparation method thereof

ActiveCN113292838ASolve warpingSolve the problem of large expansion rate at high and low temperaturesGlass fiberPolymer science

The invention relates to the field of polycarbonate resin composite materials, and discloses a halogen-free low-warpage low-linear-expansion-coefficient extrusion-grade thin-wall flame-retardant polycarbonate composite material and a preparation method thereof. The halogen-free low-warpage low-linear-expansion-coefficient extrusion-grade thin-wall flame-retardant polycarbonate material is prepared from the following components in percentage by mass: 25.9 to 46.5 percent of PC (polycarbonate) resin, 2 to 4 percent of PET (Polyethylene terephthalate) resin, 8 to 12 percent of a flame retardant, 1 to 1.5 percent of a flexibilizer A, 1.5 to 3 percent of a flexibilizer B, 12 to 16 percent of a mineral filler, 25 to 30 percent of glass fibers, 0.2 to 0.5 percent of an anti-dripping agent, 0.1 to 0.3 percent of a main antioxidant, 0.1 to 0.3 percent of an auxiliary antioxidant, 0.1 to 0.5 percent of a lubricant, 0.5 to 1 percent of a dispersing agent and 3 to 5 percent of a black seed. The linear expansion coefficient of the material can be reduced, warpage deformation of the material can be prevented, meanwhile, the problems of thin-wall flame retardance and toughness balance of the material are solved, the preparation method is simple in process and high in efficiency, the production cost can be greatly saved, and industrial production is easy.

Owner:GUANGDONG JUSHI CHEM CO LTD

Container top plate hydraulic-forming method

ActiveCN108115961AReduce equipment procurement costsReduce financial burdenShaping toolsMetal-working feeding devicesPistonSteel plates

The invention belongs to the technical field of container top plate manufacturing and discloses a container top plate hydraulic-forming method. The method includes steps: firstly, a to-be-formed steelplate is put on a side pressing ring on a workbench; secondly, a piston of an upper main oil cylinder moves horizontally to drive a main swing rod to rotate around a fulcrum axially while a cross beam drives an auxiliary swing rod to rotate around a fulcrum axially, two perpendicular connecting rods are driven to move downwards vertically, and then an upper mould moves downwards to tightly pressthe to-be-formed steel plate; thirdly, a lower main oil cylinder drives a lower mould to move upwards vertically to realize one-time forming of bind waves on the to-be-formed steel plate; fourthly, amotor drives screw rods to rotate, a slide seat sleeving the two screw rods moves horizontally, and a retainer drives the steel plate to move to perform next blind wave forming operation. A special machine designed aiming at the container top plate structure is adopted for the forming process, equipment purchase cost is sharply reduced, and economic burden of small-and medium-sized container top plate production enterprises is relieved.

Owner:安徽金大进重工机床有限公司

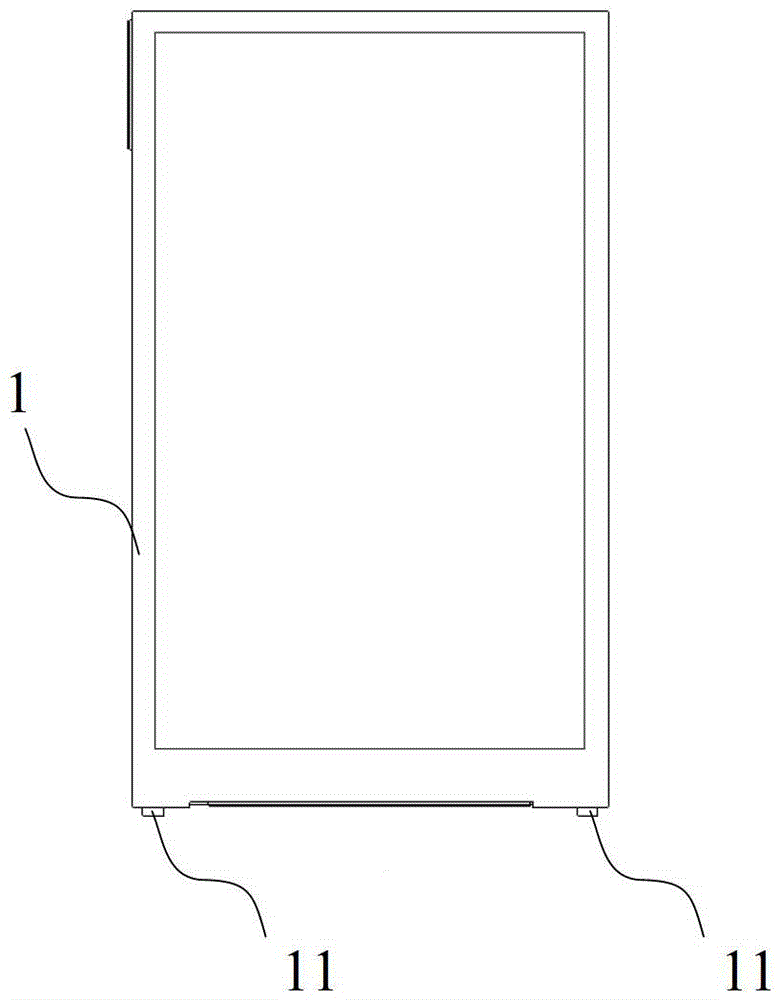

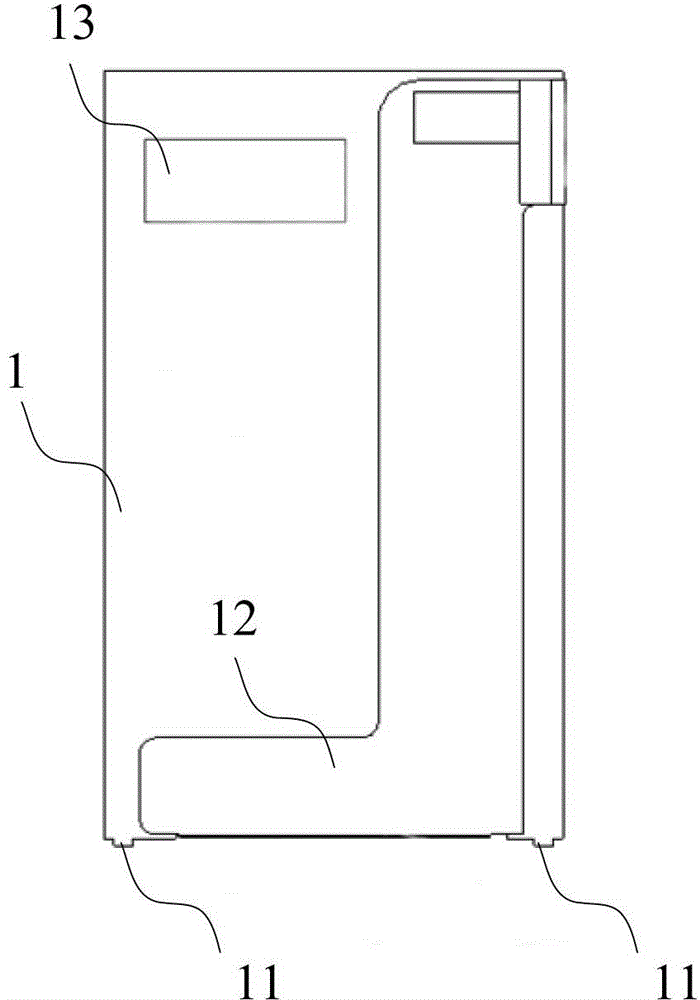

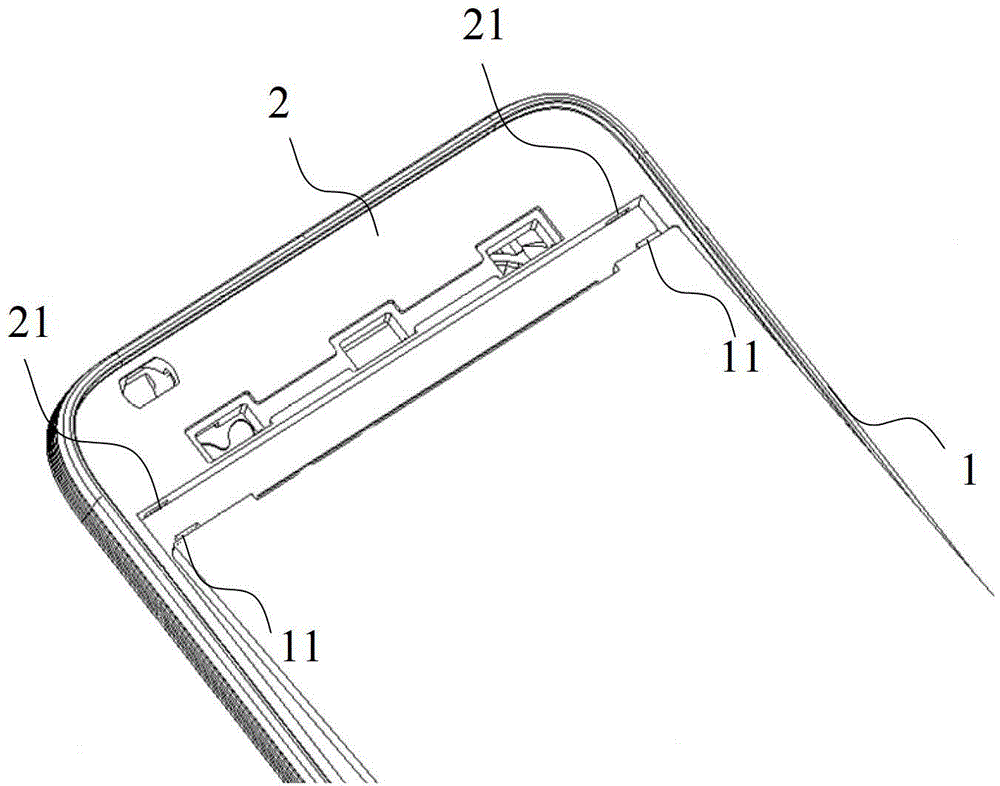

mobile terminal

ActiveCN102904993BGuaranteed not to warpImprove detachabilityTelephone set constructionsComputer terminalTouchscreen

Owner:HUAQIN TECH CO LTD

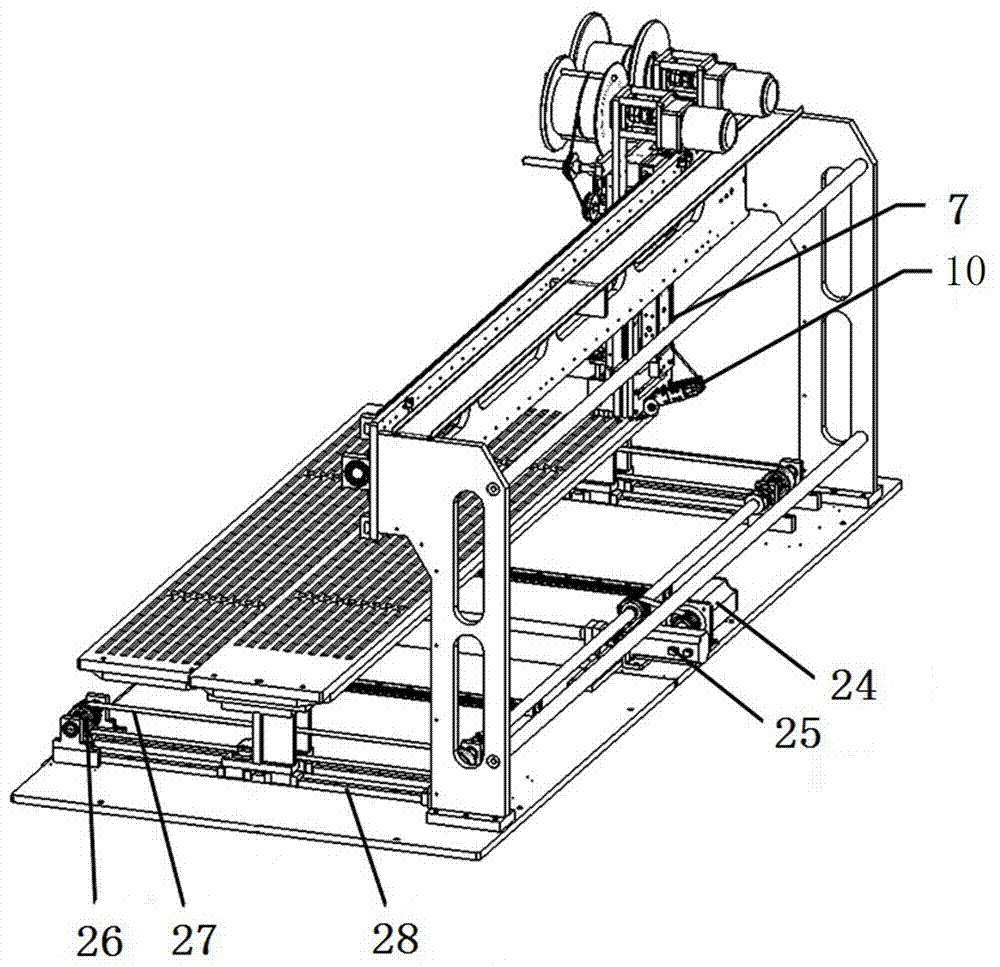

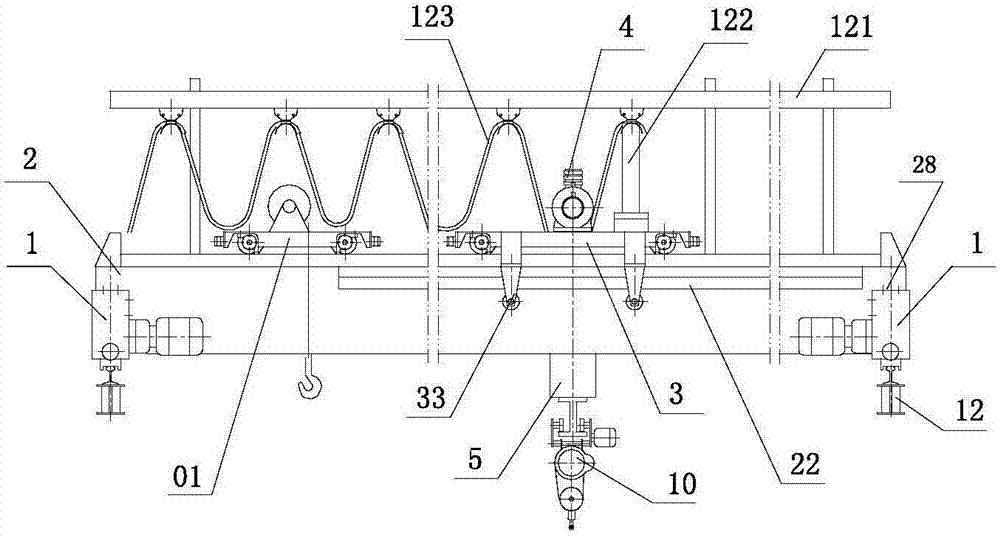

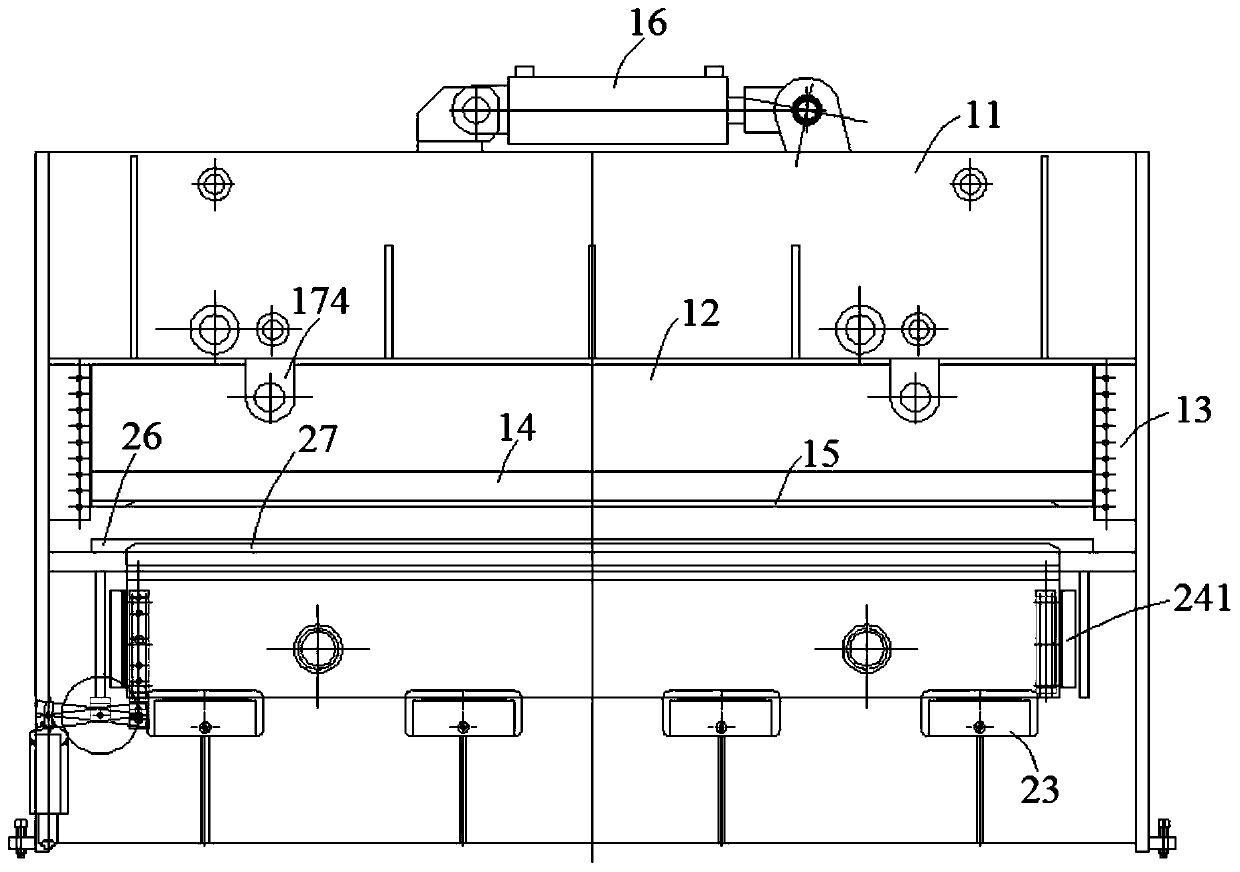

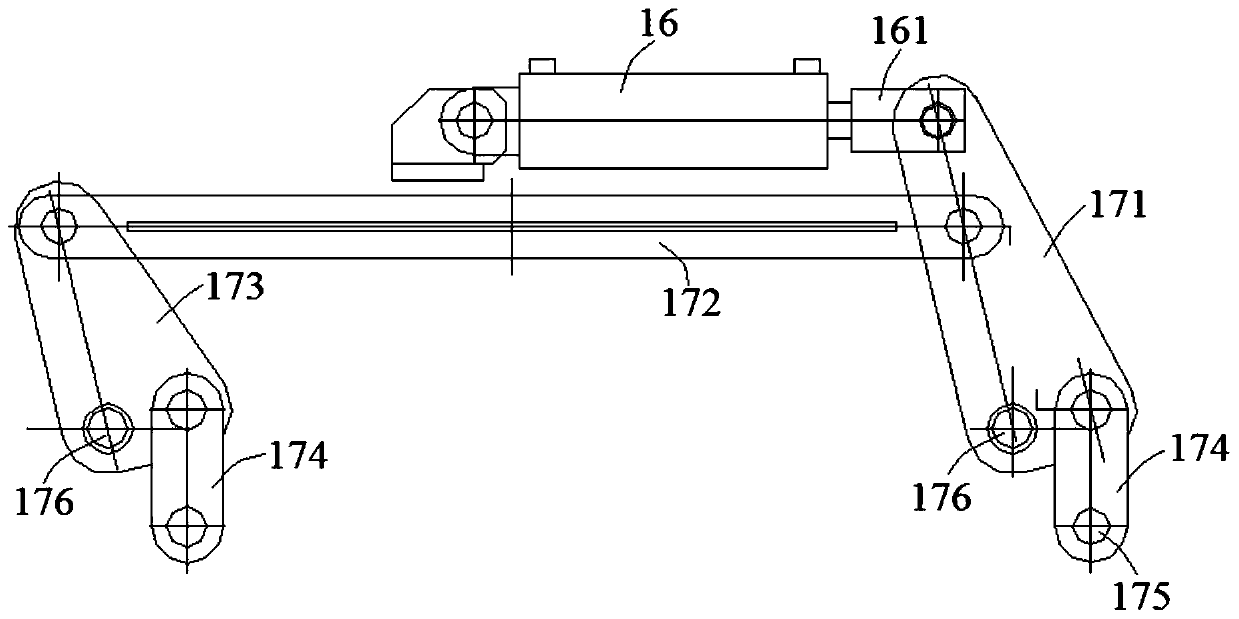

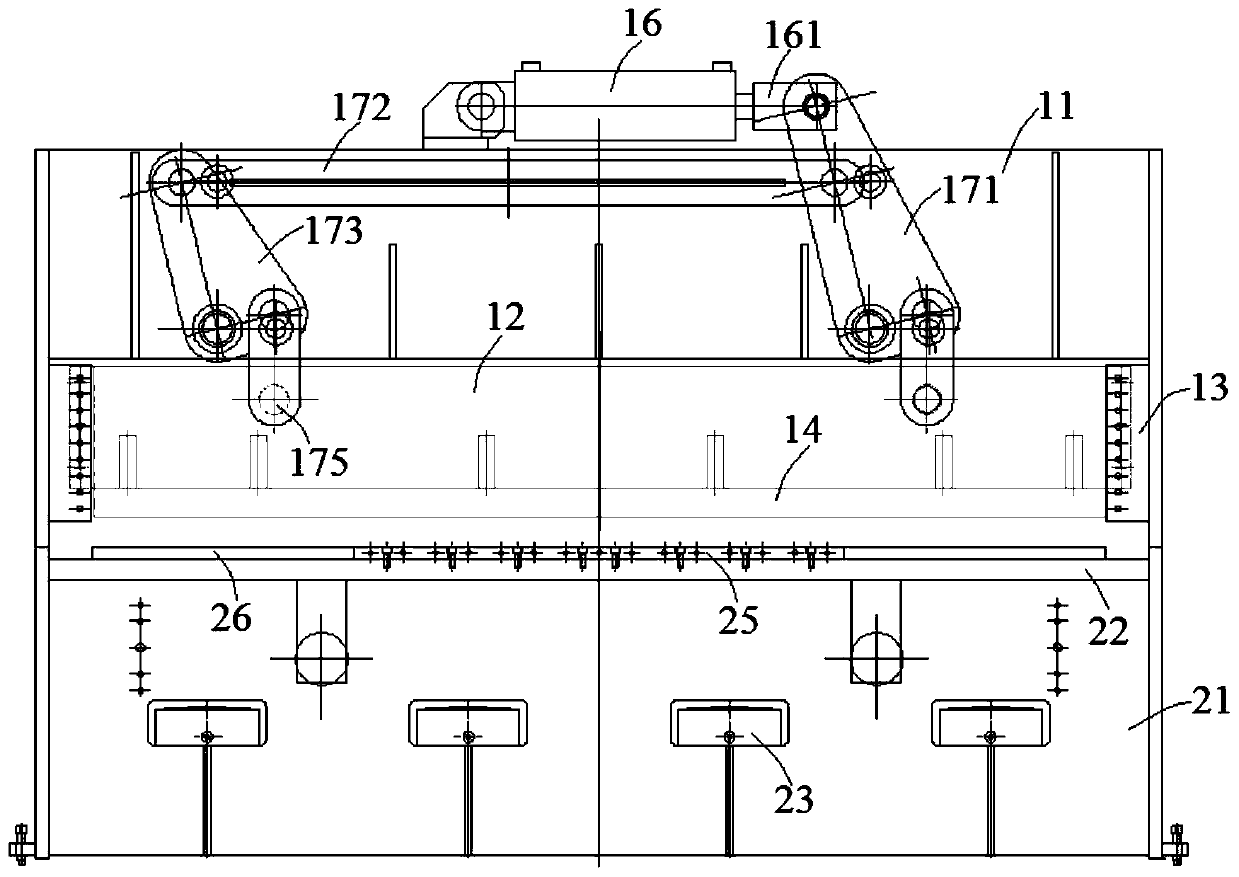

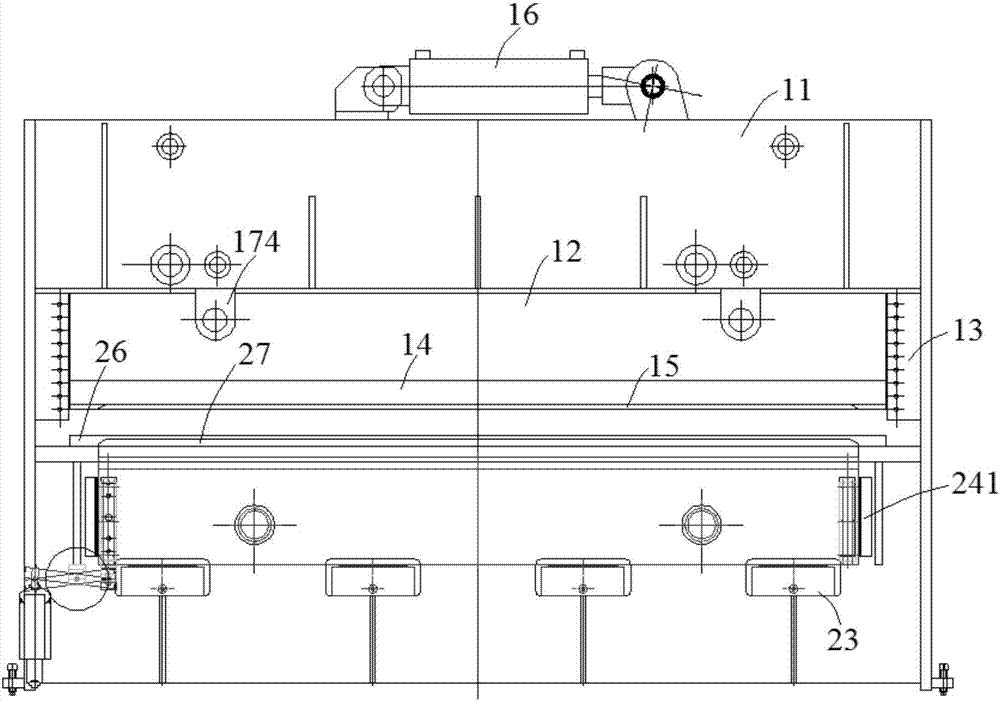

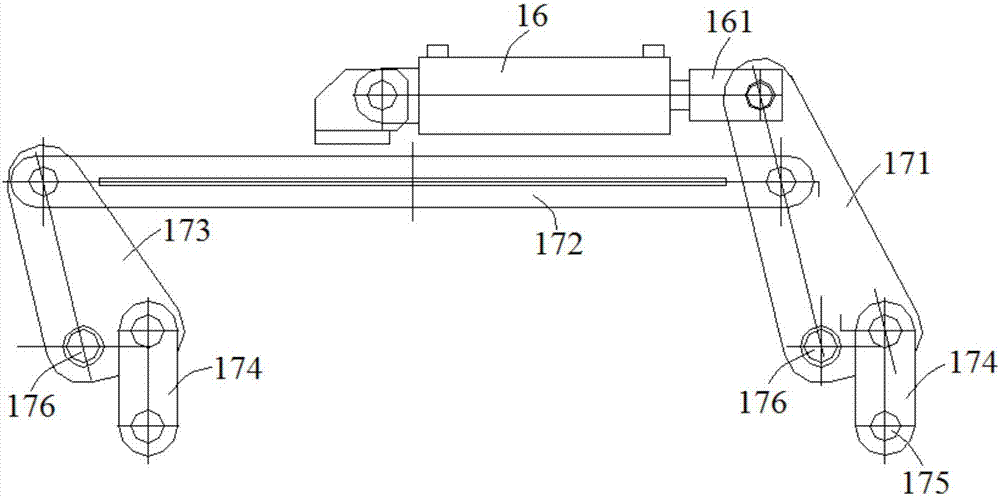

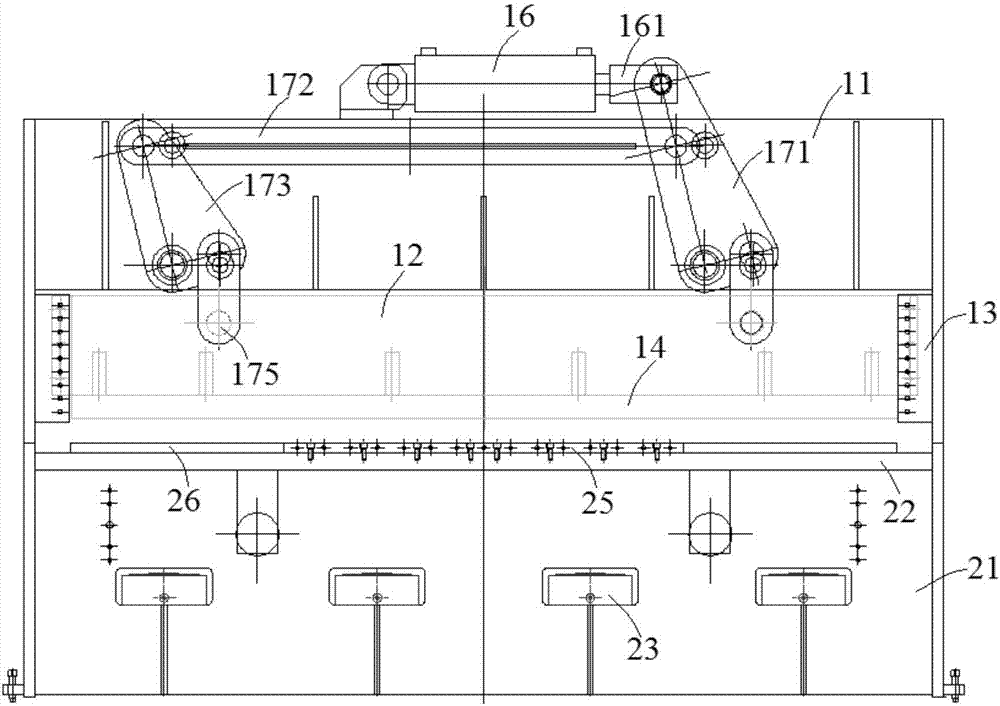

Roller feeding bagging machine

The invention discloses a roller-type fed material bagging machine which is provided with a rack and a roller. A bag feeding device and a heat sealing device are arranged on the outer side of the roller. Work grooves are evenly formed in the rollers. A bag propping mechanism is arranged at a feeding position of a material bagging machine and is provided with a bag propping frame. U-shaped bag propping rods are arranged on the two sides of the bag propping frame. Bag opening mechanisms are arranged at the work grooves. The roller-type fed material bagging machine is characterized in that packaging bag tensioning mechanisms are arranged on one sides of the U-shaped bag propping rods; a bag rubbing mechanism is arranged above the work grooves; and bag grabbing and pulling mechanisms are arranged at discharge outlets of the work grooves. By adoption of the bagging machine, tensioning of a bag opening during material feeding of a packaging bag is achieved, tilting-up or wrinkling of the two edges of the packaging bag is avoided, the two walls of the packaging bag can be rubbed open when the bag needs to be opened, and the bag opening effect is guaranteed; and before heat sealing, the bag opening of the packaging bag is pulled to be level, so that the bag opening after heat sealing is flat, and a good packaging effect is achieved.

Owner:WENZHOU RUIDA MACHINERY

Half-portal crane with two travelling trolleys and telescopic cantilever beams

InactiveCN108263969AImprove efficiencyEasy to cooperate with liftingTrolley cranesTravelling gearCantilevered beamIdler-wheel

The invention discloses a half-portal crane with two travelling trolleys and telescopic cantilever beams. A half-portal is composed of an end beam, two main beams and a supporting leg frame; tracks atthe upper portions of the two main beams are connected with the two travelling trolleys; the outer side of each main beam is respectively provided with a steel rail parallel to the track; the two sides of the travelling trolleys are respectively connected with two sets of reverse idler wheel devices, the reverse idler wheel devices hook the steel rails to run; the travelling trolleys are providedwith rotating mechanisms; the lower ends of suspension bar shafts of the rotating mechanisms are connected with cantilever components, and the upper ends of the suspension bar shafts are connected with safe rulers; the cantilever beams in the cantilever components are telescopic beams and composed of multiple sections of bushing beams; the head of each bushing beam is connected with a cable hanger; the tail end of each cantilever beam is connected with an electric block; the cantilever beams are located at the lower portions of the main beams and can stretch out of a workshop to work, and canrotate at any angle in a horizontal plane.

Owner:福州市鼓楼区奇韵通自动化设备有限公司

Half-portal crane with reverse roller travelling trolley

InactiveCN107352416AGuaranteed uptimeEnsure that the rail does not warpLoad-engaging girdersTravelling cranesDrive wheelLap joint

This application discloses a semi-gantry crane with a trolley running on reverse rollers, which includes an end girder, two main girders, and a leg frame, which form a half-gantry; There are tracks above the two main beams, and the running trolley is connected to the tracks; the end beam is composed of a balanced end beam and a connecting rod; the lower beam of the outrigger frame is formed by connecting a balanced ground beam and a connecting beam through a connecting shaft; The end beam and the balance ground beam are connected with the driving device of the cart and the passive wheel group; the side rails are set on the outer side of the main beam; the steel rails are set on the outer side of the main beam; There is a rotating mechanism; the lower end of the boom shaft in the rotating mechanism is connected to the cantilever member, and the upper end is connected to a safety ruler; an electric hoist is installed on the cantilever member and can move back and forth horizontally along the cantilever beam; the cantilever beam is placed under the main beam and can rotate.

Owner:卢统华

A special hydraulic press for container roof

ActiveCN107953591BReduce financial burdenReduce procurement costsShaping toolsMetal-working feeding devicesManufacturing enterprisesMachine design

The invention discloses a special hydraulic press for a container ejector plate, and belongs to the technical field of hydraulic presses. The special hydraulic press comprises an upper box body, an upper slide block, an upper mould, an upper main oil cylinder, a lower box body, a lower main oil cylinder, a lower slide block and a lower mould, wherein the upper main oil cylinder is arranged on theupper part of the upper box body; the upper slide block is arranged on the lower part of the upper box body; the upper mould is fixedly arranged on the bottom of the upper slide block; a drive unit isarranged between the upper main oil cylinder and the upper slide block; the upper main oil cylinder drives the upper slide block to move in the vertical direction through the drive unit; the lower slide block is arranged inside the lower box body; the lower part of the lower slide block is connected with the lower main oil cylinder, and the upper part of the lower slide block is connected with the lower mould; the lower main oil cylinder drives the lower slide block to move in the vertical direction; a rear baffle device is arranged at one side of the lower box body; and the rear baffle device pulls a board to horizontally move in a direction. The special hydraulic press is a special machine designed for the container ejector plate, so that equipment purchasing cost is greatly reduced, and economical burden of small and medium-sized container ejector plate manufacturing enterprises is reduced.

Owner:安徽金大进重工机床有限公司

Special hydraulic press for container ejector plate

ActiveCN107953591AReduce financial burdenReduce procurement costsShaping toolsMetal-working feeding devicesEngineeringMachine design

The invention discloses a special hydraulic press for a container ejector plate, and belongs to the technical field of hydraulic presses. The special hydraulic press comprises an upper box body, an upper slide block, an upper mould, an upper main oil cylinder, a lower box body, a lower main oil cylinder, a lower slide block and a lower mould, wherein the upper main oil cylinder is arranged on theupper part of the upper box body; the upper slide block is arranged on the lower part of the upper box body; the upper mould is fixedly arranged on the bottom of the upper slide block; a drive unit isarranged between the upper main oil cylinder and the upper slide block; the upper main oil cylinder drives the upper slide block to move in the vertical direction through the drive unit; the lower slide block is arranged inside the lower box body; the lower part of the lower slide block is connected with the lower main oil cylinder, and the upper part of the lower slide block is connected with the lower mould; the lower main oil cylinder drives the lower slide block to move in the vertical direction; a rear baffle device is arranged at one side of the lower box body; and the rear baffle device pulls a board to horizontally move in a direction. The special hydraulic press is a special machine designed for the container ejector plate, so that equipment purchasing cost is greatly reduced, and economical burden of small and medium-sized container ejector plate manufacturing enterprises is reduced.

Owner:安徽金大进重工机床有限公司

Crane with two travelling trolleys and with cantilever beams capable of rotating at any angle

InactiveCN107867639AImprove efficiencyEasy to cooperate with liftingTravelling cranesTravelling gearCantilevered beamGear drive

This application discloses a crane with two running trolleys and a cantilever beam that can rotate at any angle, including a double-girder bridge frame composed of two end beams and two main beams; The electric frame and hanging cable are connected outside the walking platform; two running trolleys are connected to the track above the main girder; the end girder is composed of a balanced end girder and a connecting rod; The beam is connected with an anti-tipping device; both sides of the running trolley are connected with anti-roller devices, and the anti-rolling device hooks on the rails on the outer side of the main beam to run; the running trolley is driven by a ZSC reducer; the running trolley is equipped with a rotating mechanism; the rotating mechanism The lower end of the boom shaft is connected to the cantilever member, and the upper end is connected to the current collector slip ring; the electric hoist is installed on the cantilever beam in the cantilever member; the cantilever beam is located under the main beam and can be extended outside the workshop, and can be rotated at any angle on the horizontal plane .

Owner:福州市鼓楼区奇韵通自动化设备有限公司

Bridge cantilever crane with two travelling trolleys and anti-tipping end beams

InactiveCN107867635AImprove efficiencyEasy to cooperate with liftingTravelling cranesTravelling gearThrust bearingEngineering

This application discloses a bridge-type cantilever crane with two running trolleys and anti-tipping end girders, including two end girders and two main girders to form a double-girder bridge frame; the outer sides of the two main girders are equipped with walking platforms , where one of the walkways is connected to the electric frame and the hanging cable; the track above the main girder is connected to two running trolleys; Both sides are connected with anti-roller devices, and the anti-roller devices are hooked and run on the rails outside the main girder; the running trolley adopts a drive device connected with a "three-in-one" reducer and a floating shaft; the thrust bearing in the rotating mechanism on the running trolley is connected to the The upper part of the bearing seat; the lower end of the boom shaft is connected to the cantilever member, and the upper end is connected to the safety ruler; two travel switches are connected to the running trolley; the electric hoist is installed on the cantilever member and can move back and forth along the cantilever beam; the cantilever beam is located under the main beam and Can rotate.

Owner:福州市鼓楼区奇韵通自动化设备有限公司

A method for hydraulically forming a container roof

ActiveCN108115961BReduce financial burdenReduce procurement costsShaping toolsMetal-working feeding devicesWave formEngineering

The invention belongs to the technical field of container top plate manufacturing and discloses a container top plate hydraulic-forming method. The method includes steps: firstly, a to-be-formed steelplate is put on a side pressing ring on a workbench; secondly, a piston of an upper main oil cylinder moves horizontally to drive a main swing rod to rotate around a fulcrum axially while a cross beam drives an auxiliary swing rod to rotate around a fulcrum axially, two perpendicular connecting rods are driven to move downwards vertically, and then an upper mould moves downwards to tightly pressthe to-be-formed steel plate; thirdly, a lower main oil cylinder drives a lower mould to move upwards vertically to realize one-time forming of bind waves on the to-be-formed steel plate; fourthly, amotor drives screw rods to rotate, a slide seat sleeving the two screw rods moves horizontally, and a retainer drives the steel plate to move to perform next blind wave forming operation. A special machine designed aiming at the container top plate structure is adopted for the forming process, equipment purchase cost is sharply reduced, and economic burden of small-and medium-sized container top plate production enterprises is relieved.

Owner:安徽金大进重工机床有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com