Light wall veneer and preparation method thereof

A light-weight wall and decorative panel technology, applied in chemical instruments and methods, household walls, and other household appliances, can solve the problems of high hardness and brittleness, low toughness, toxic and harmful gases, etc., and achieve the effect of high toughness and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

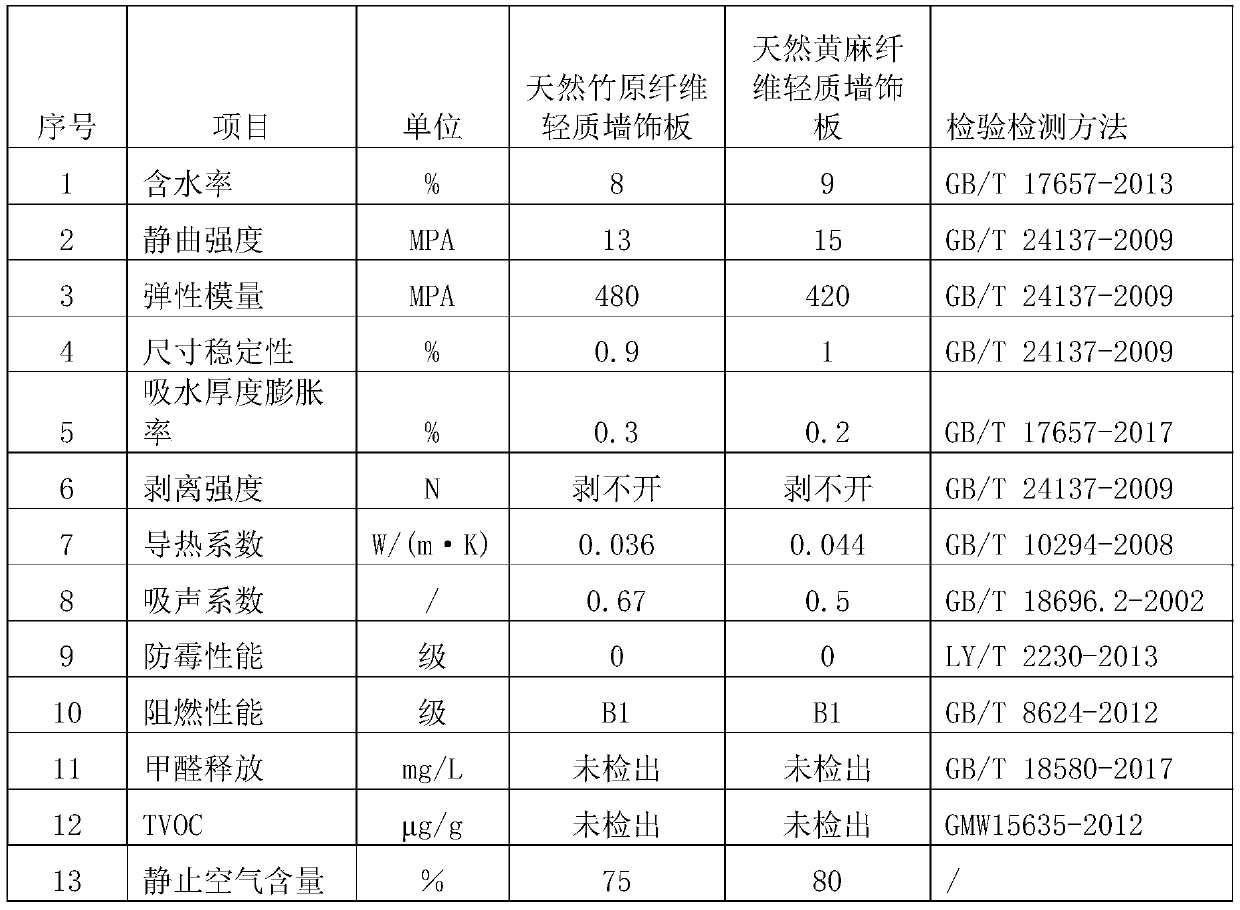

Embodiment 1

[0028] To prepare a natural bamboo fiber lightweight wall panel, the specific preparation process is as follows:

[0029] Step 1: Making natural bamboo fiber reinforced polypropylene ply

[0030] A. Feed the natural bamboo fiber and polypropylene staple fiber into the bale opening machine, mix them according to the mass ratio of 40% and 60% respectively, and then mix them for initial opening and fine opening, and then carding into upper and lower fiber webs through a carding machine. The fiber web is fed to the web-laying machine to be laminated into a fiber web of the required thickness, and then sent to the needle punching machine for pre-needling forming, and then the upper and lower main needle punches are performed to form a fiber mat.

[0031] B. Paste the polyester non-woven fabric of the same material on both sides of the fiber mat prepared above, and use a continuous contact flat press to first hot press at 180~200℃, and then cold press at 10~15℃;

[0032] In the hot pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com