Hydraulic machine tool for one-time forming blind waves of container blind-wave top plate

A container and blind wave technology, applied in the field of hydraulic presses, can solve the problems of high procurement costs and reduce equipment procurement costs, and achieve the effects of reducing procurement costs, reducing economic burden, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

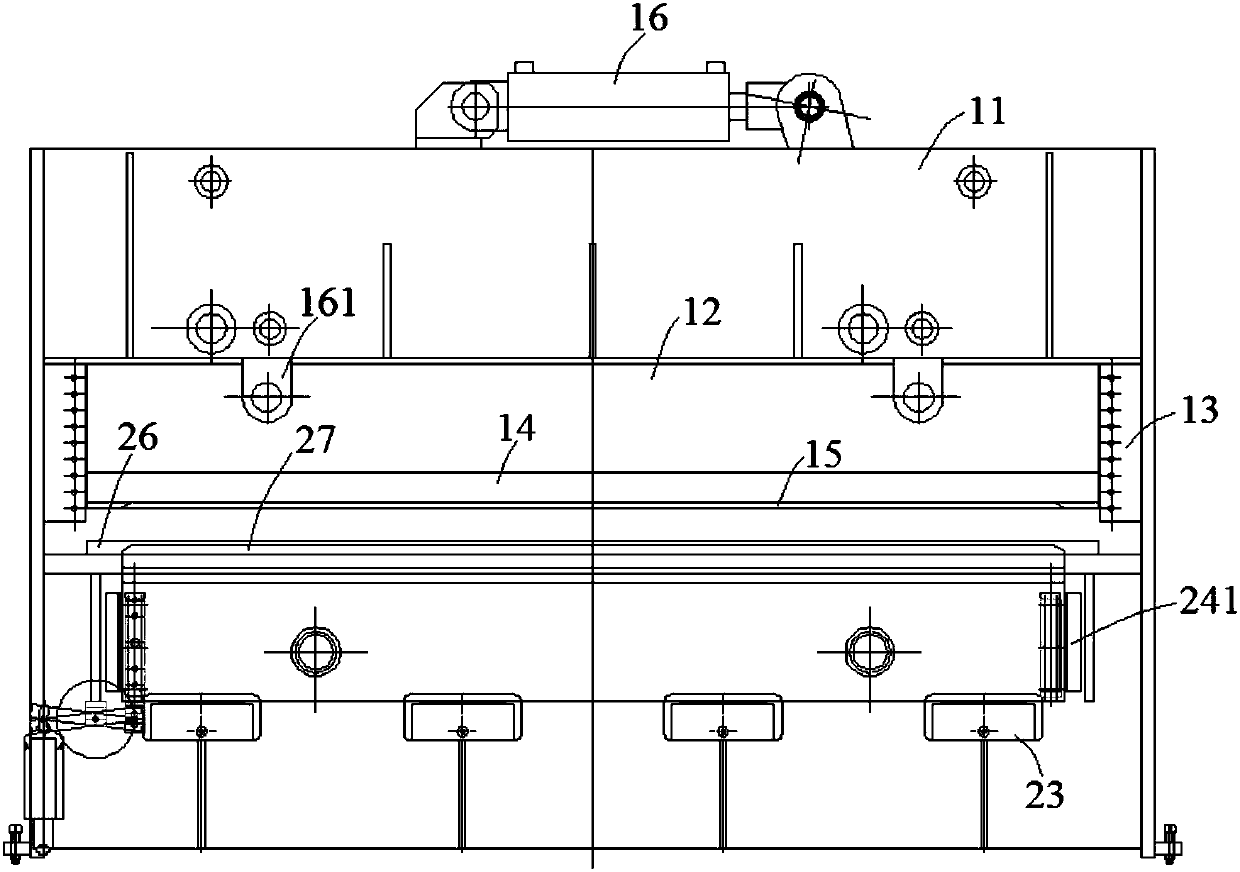

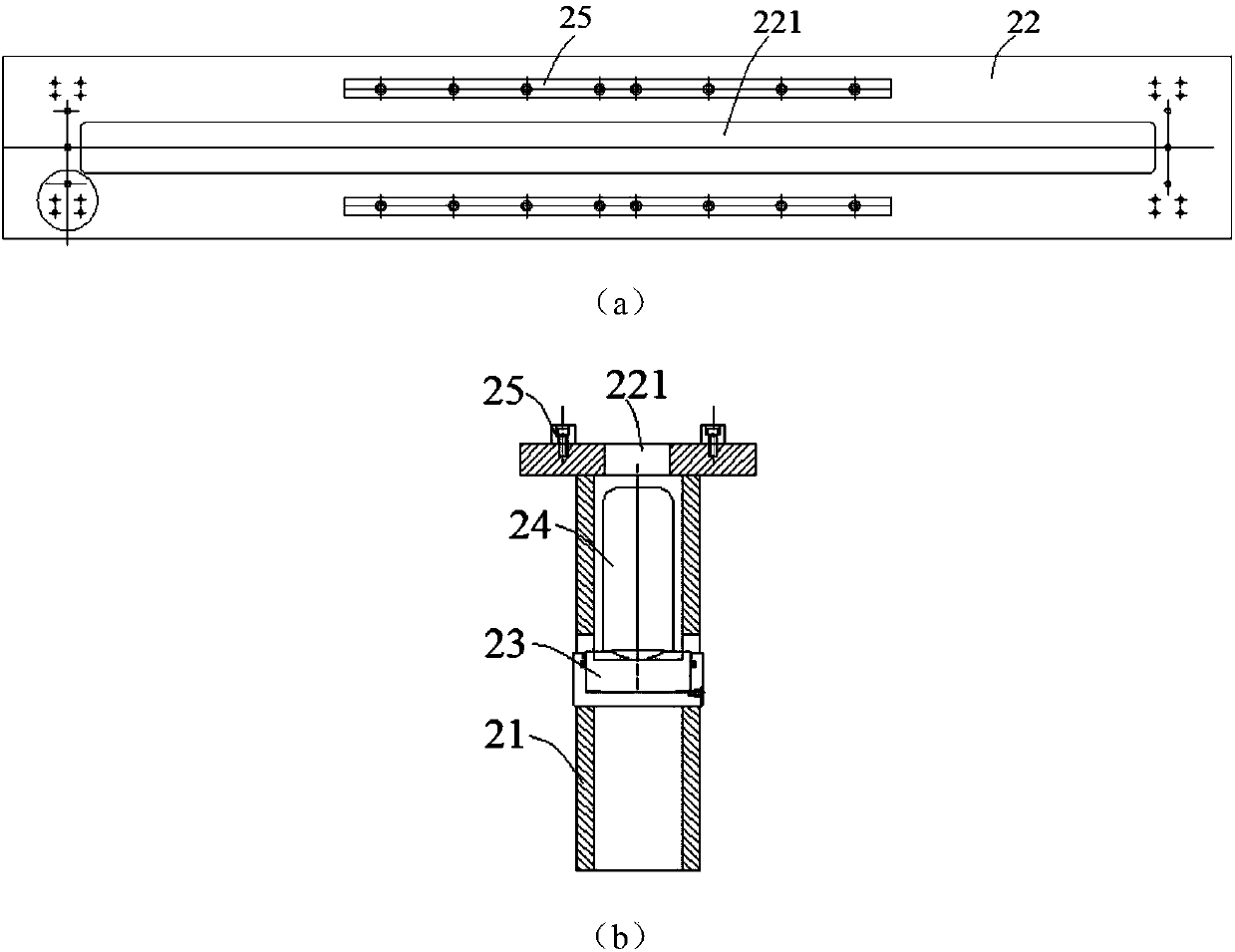

[0038] combine figure 1 , a hydraulic machine tool for forming a blind wave at one time on the container blind wave roof of the present embodiment, comprising an upper box body 11, an upper slider 12, an upper mold 15, an upper main oil cylinder 16, a lower box body 21, a lower main oil cylinder 23, a lower Slide block 24 and lower mold 27. Described upper master oil cylinder 16 is arranged on upper box body 11 tops, and upper slide block 12 is arranged on upper box body 11 bottoms, and upper mold base 14 is arranged at the bottom of upper slide block 12, and upper mold base 15 is fixed on upper mold base 14.

[0039] The piston of the upper master oil cylinder 16 moves in the horizontal direction, driving two vertical connecting rods 161 to move in the vertical direction, and the upper slider 12 is connected with the vertical connecting rods 161 and also moves in the vertical direction. The guide rail 13, the upper slider 12 moves in the vertical direction along the upper g...

Embodiment 2

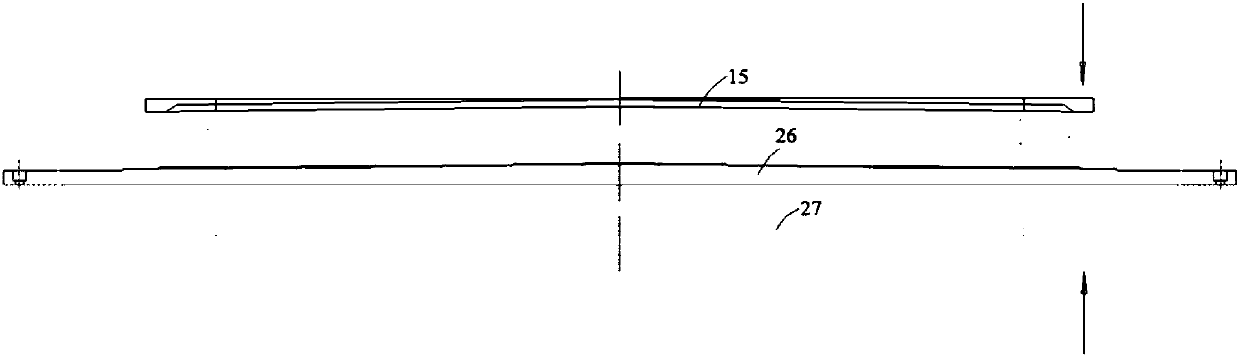

[0044] combine image 3 , Figure 4 , Figure 5 and Figure 6 , the hydraulic machine tool for one-time forming blind wave of container blind wave top plate of this embodiment is basically the same as embodiment 1, and its difference is that: this embodiment further optimizes the design of upper die 15, lower die 27 and blank holder 26 , specifically: the upper die 15 is set as a die, and threaded holes are set around the die cavity, and the die is inserted into the threaded holes by bolts to be connected with the upper die base 14 at the bottom of the upper slide block 12 . The lower die 27 is a convex die, and threaded holes are arranged along the length direction of the lower die 27, and the lower die 27 is inserted into the threaded holes by bolts to be connected with the lower block 24. The upper die 15, the blank holder 26 and the lower die 27 are all designed with a large arc surface along the length direction.

[0045] It is worth noting that, in the initial design...

Embodiment 3

[0047] combine Figure 7 , a hydraulic machine tool for one-time blind wave roof forming of a container blind wave roof in this embodiment is basically the same as embodiment 2, the difference is that in this embodiment, a back gauge is also provided on one side of the lower box 21 plate moving direction device, the back gauge device pulls the plate to move horizontally in one direction. The back gauge device includes a motor 31, a rear support plate 32, a screw rod 33, a sliding seat 341, a finger 346, a front support plate 36 and a sprocket 37, and the front support plate 36 is connected to the lower box 21 through a screw 361 , said screw rod 33 is provided with two, and two screw rods 33 are straddled in parallel between the front support plate 36 and the rear support plate 32, and one end of one of the screw rods 33 is connected with the motor 31, and the other end is provided with a chain Wheel 37; Another screw mandrel 33 one ends also are provided with sprocket wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com