Treatment method of arsenic wastewater

A treatment method and wastewater technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem that heavy metal sediments cannot be effectively separated and recovered, sludge is difficult to recover and Utilization, large amount of sludge and other problems, to achieve the effect of high chemical utilization rate and reaction efficiency, small chemical dosage, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

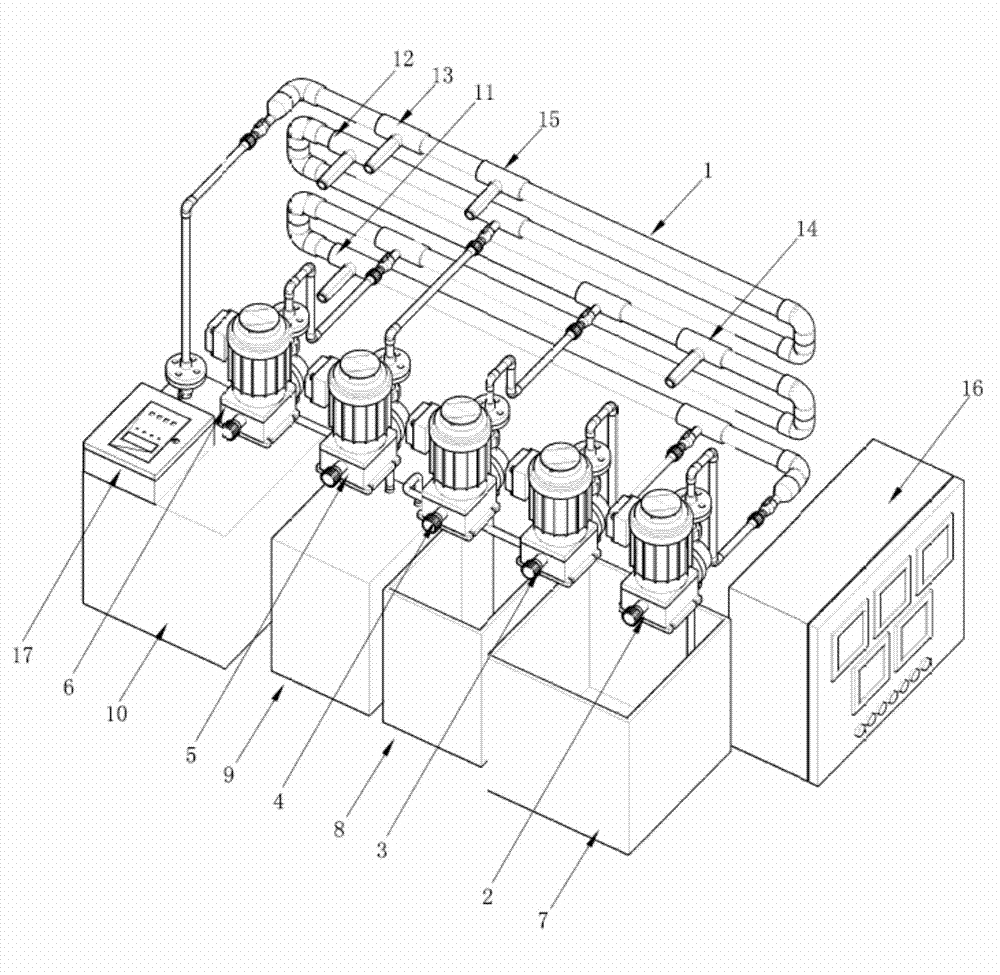

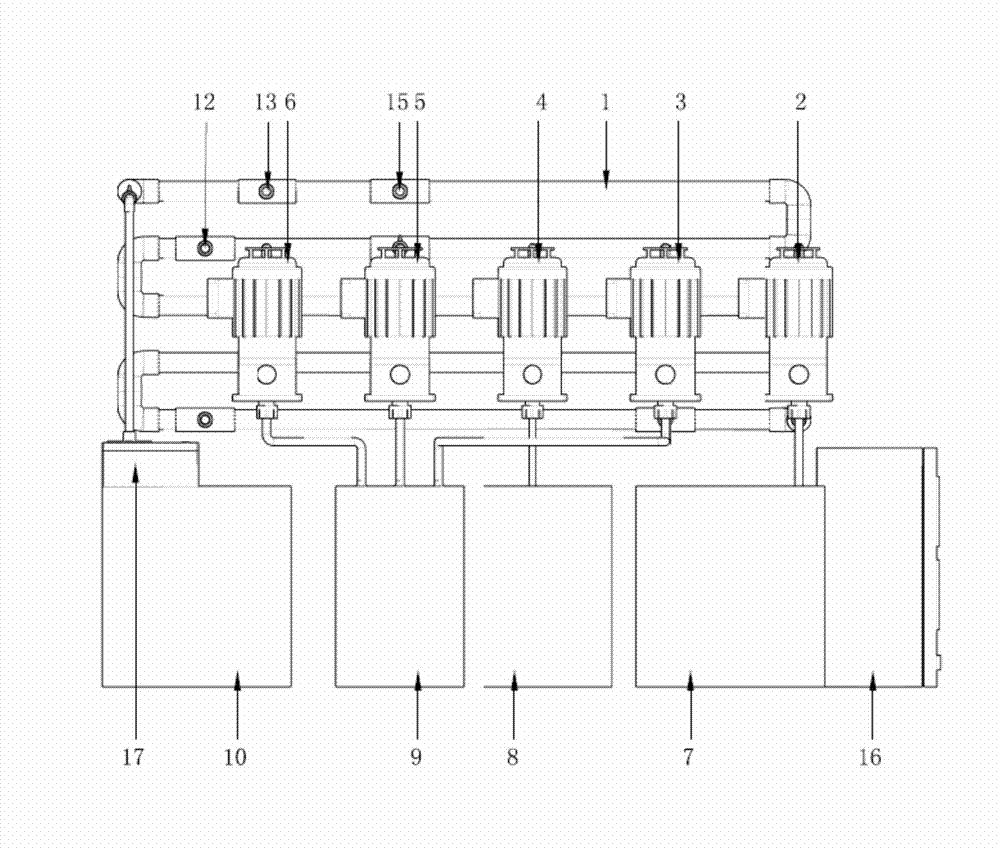

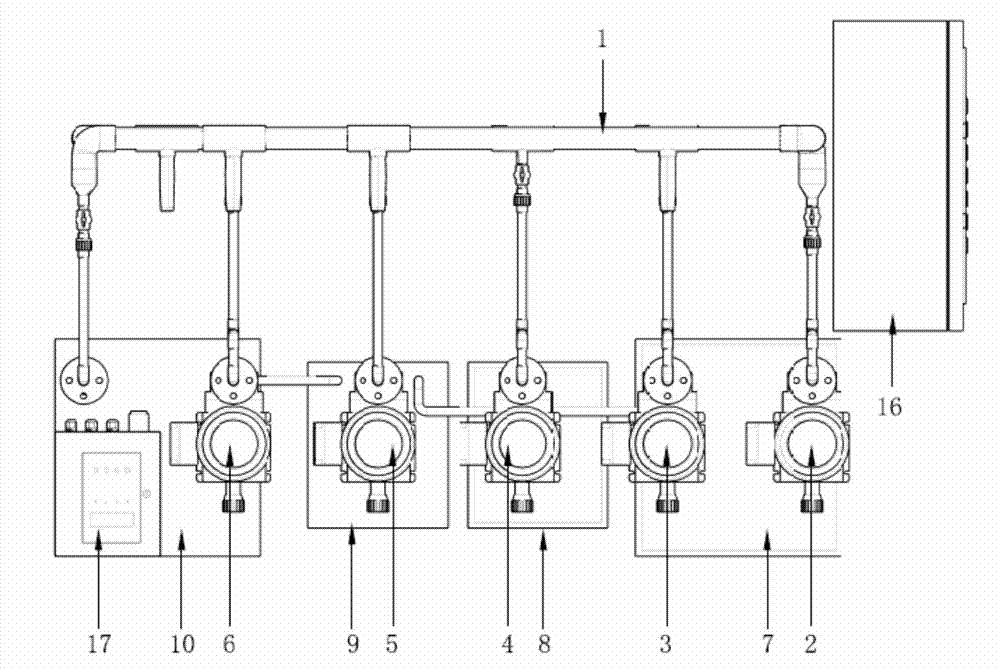

[0037] A kind of wastewater containing high concentration of arsenic and heavy metals to be treated, wherein the content of arsenic is 10000mg / L, the content of cadmium is 100mg / L, the content of copper is 50mg / L, the content of lead is 80mg / L, the pH of the wastewater is 8, and the present invention is adopted as Figure 4 The treatment method shown is to treat the arsenic-containing wastewater by adopting a continuous water inflow method, and the treatment volume is controlled at 500L / h, which specifically includes the following steps:

[0038] (a) pH adjustment: transport the waste water to be treated to the first adjustment tank, add concentrated sulfuric acid to the waste water to be treated, and adjust its pH value to below 5;

[0039] (b) Sulfurization and arsenic removal: Pass the pH-adjusted wastewater into a tubular arsenic removal continuous treatment device (referred to as the tubular arsenic removal device), and control the pH value of the reaction environment in ...

Embodiment 2

[0062] A kind of wastewater containing high concentration of arsenic and heavy metals to be treated, wherein the content of arsenic is 5000mg / L, the content of cadmium is 80mg / L, the content of copper is 30mg / L, the content of lead is 50mg / L, the pH of wastewater=6, adopt the present invention The treatment method for this arsenic-containing wastewater is treated by continuous water inflow, and the treatment volume is controlled at 1000L / h, which specifically includes the following steps:

[0063] (a) pH adjustment: step (a) of this example is the same as Example 1;

[0064] (b) Sulfurization and arsenic removal: Step (b) of this example is the same as that of Example 1;

[0065] (c) Solid-liquid separation: Step (c) of this example is the same as Example 1; the arsenic content in the effluent after centrifugation is 0.3 mg / L, the cadmium content is 0.8 mg / L, and the copper content is 0.4 mg / L. The lead content is 1.2 mg / L (see Table 2 below); it can be seen that the removal ...

Embodiment 3

[0072] A kind of wastewater containing high concentration of arsenic and heavy metals to be treated, wherein the content of arsenic is 1000mg / L, the content of cadmium is 10mg / L, the content of copper is 8mg / L, the content of lead is 20mg / L, the pH of wastewater=5, adopt the present invention The treatment method for this arsenic-containing wastewater is treated by continuous water inflow, and the treatment volume is controlled at 2000L / h, which specifically includes the following steps:

[0073] (a) pH adjustment: step (a) of this example is the same as Example 1;

[0074] (b) Sulfurization and arsenic removal: Step (b) of this example is the same as that of Example 1;

[0075] (c) Solid-liquid separation: Step (c) of this example is the same as Example 1; the arsenic content in the effluent after centrifugation is 0.4 mg / L, the cadmium content is 0.2 mg / L, and the copper content is 0.3 mg / L. The lead content is 0.5mg / L (see Table 3 below); it can be seen that the removal ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com