Process for extracting and separating coenzyme Q10 from mushroom dregs

A coenzyme and bacterial residue technology, applied in the field of chemical engineering, can solve the problems of low silica gel reuse times, large consumption of solvents, silica gel, and organic solvents, and achieve parameters that are easy to control, waste liquid output, and low cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Weigh 70g of the fungus residue (wherein, the mass percentage of coenzyme Q10 is 2.6%), fill it into the percolation column (Φ2.0×35cm) by wet method, and the accumulated volume is about 100mL after the filling is uniform, and soak at a constant temperature of 10°C 2h, make it fully swell, open the outlet valve of the percolation column, and at the same time continuously add n-hexane from the top of the column, control the flow rate at 2.5-3.0mL / min, until the volume of the percolation liquid collected is 530mL.

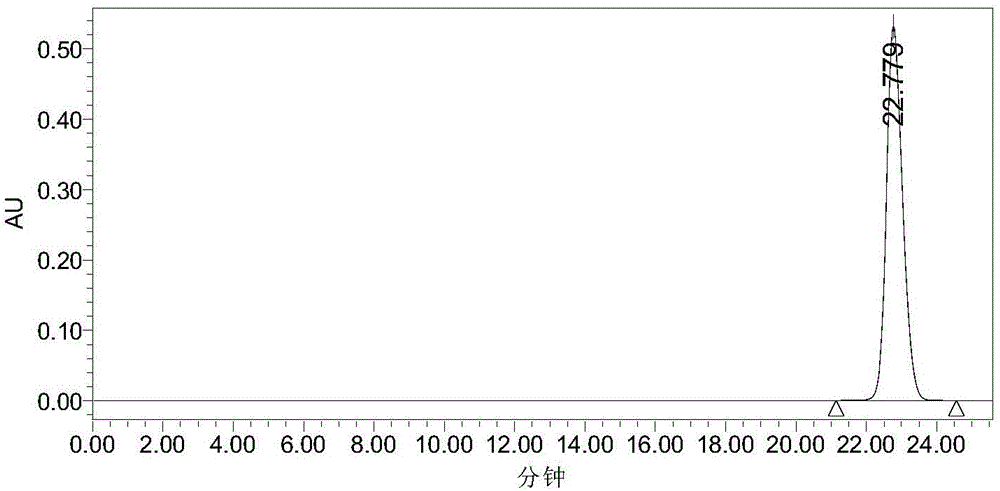

[0044] Repeat several times to collect enough percolation liquid as the raw material liquid for subsequent operations. After analysis, the solid concentration is 4.7mg / mL, the content of coenzyme Q10 is 72.1%, and the extraction rate is 98.7%.

[0045] (2) Concentrate the percolation solution to remove the solvent, add n-hexane to dissolve, and prepare a solution with a solid concentration of 300 mg / mL. Take 20ml of the solution, and carry out three-stage ...

Embodiment 2

[0048] (1) The method of operation is the same as in Example 1.

[0049] (2) Concentrate the percolation solution to remove the solvent, add n-hexane to dissolve, and prepare a solution with a solid concentration of 300 mg / mL. Take 20ml of this solution, and use an equal amount of N,N-dimethylformamide as the extractant for five-stage countercurrent extraction. After the extraction balance, analyze the n-hexane phase of the raffinate, the content of coenzyme Q10 in the n-hexane phase after the five-stage extraction is 94.3%, and the solid concentration is 205mg / mL, the total recovery rate of coenzyme Q10 in the five-stage countercurrent extraction of this extraction process is 89.4% .

[0050] (3) Concentrate the extracted raffinate, add acetone at 30°C until it is completely dissolved, the solid-to-liquid ratio is 1:25, then gradually lower the temperature to 5°C, cool and crystallize for 24 hours, filter, and wash with an appropriate amount of cold ethanol. After fully dra...

Embodiment 3

[0052] (1) The method of operation is the same as in Example 1.

[0053] (2) Concentrate the percolation solution to remove the solvent, add n-hexane to dissolve, and prepare a solution with a solid concentration of 300 mg / mL. Take 20ml of this solution, use an equal amount of N,N-dimethylformamide as the extractant, and n-hexane as the detergent, and perform six-stage fractional extraction. The specific process is: Fractional distillation extraction is divided into three stages of extraction section and three stages of washing section. The first stage enters the fractionation extraction system, and the last stage of the washing section merges with the raw material liquid and enters the extraction section together. The extraction phase and the washing phase are subjected to multi-stage countercurrent extraction. The primary outflow is the raffinate rich in coenzyme Q10. Analysis of the raffinate showed that the content of coenzyme Q10 in the n-hexane phase after extraction w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com