Patents

Literature

65results about How to "Affect appearance quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

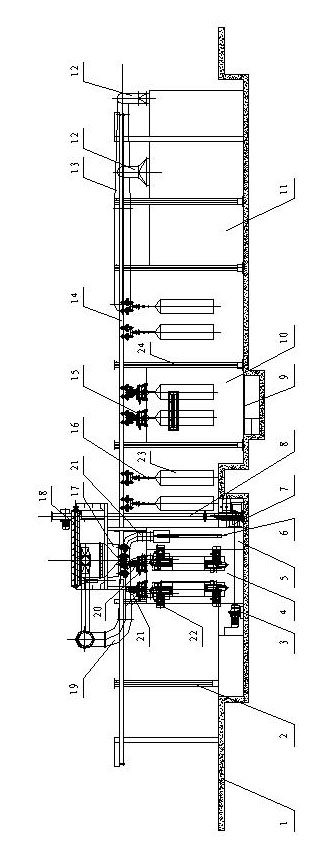

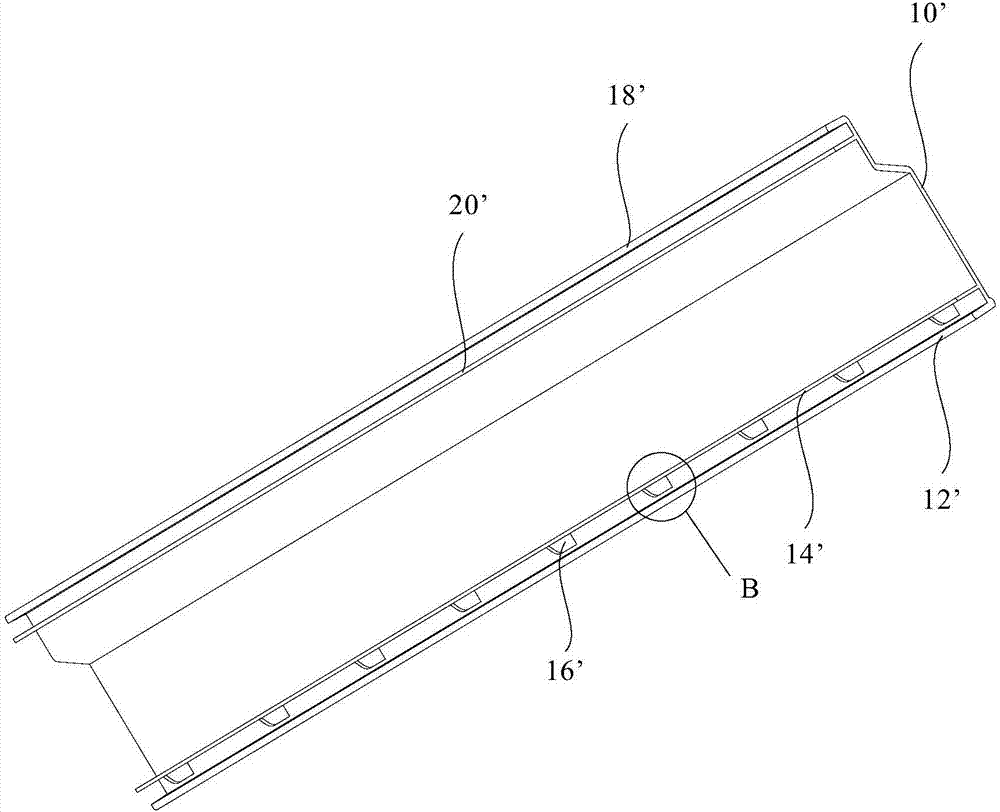

Hydraulic cylinder surface shot blasting, paint spraying and drying system and shot blasting, paint spraying and drying process thereof

InactiveCN101972726AIncrease productivityImprove cleanlinessSpraying apparatusPretreated surfacesHydraulic cylinderLacquer

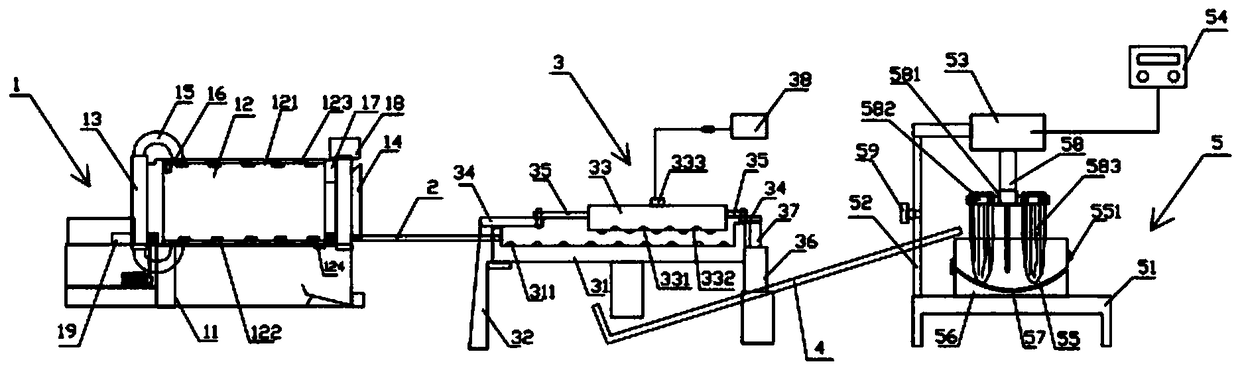

The invention relates to a hydraulic cylinder surface shot blasting, paint spraying and drying system and a shot blasting, paint spraying and drying process thereof, and the hydraulic cylinder surface shot blasting, paint spraying and drying system consists of a hanging chain conveying system, a shot blasting working position, a paint spraying working position, a drying working position, an overhauling working position, an unloading working position, a loading working position, a paint mixing room, an air compressor and an operating room. The shot blasting, paint spraying and drying process comprises the following process steps: loading of a piece, shot blasting, derusting and cleaning (10-15min), automatic paint spraying (3-5min), paint refinishing, leveling (5min), drying at 60-80 DEG C (30min), natural cooling and unloading of the piece. The hydraulic cylinder surface shot blasting, paint spraying and drying system has the advantages of high degree of mechanical and electrical automation, small occupied area, good safety performance, and high production efficiency, is not affected by weather and can ensure the cleanliness, the temperature, the illumination and the safety and sanitation standard required by the paint spraying environment; and the shot blasting, paint spraying and drying process is simple, safe, time-saving, environment-friendly and high in working efficiency and can obtain the good appearance quality of a paint film.

Owner:中煤邯郸煤矿机械有限责任公司

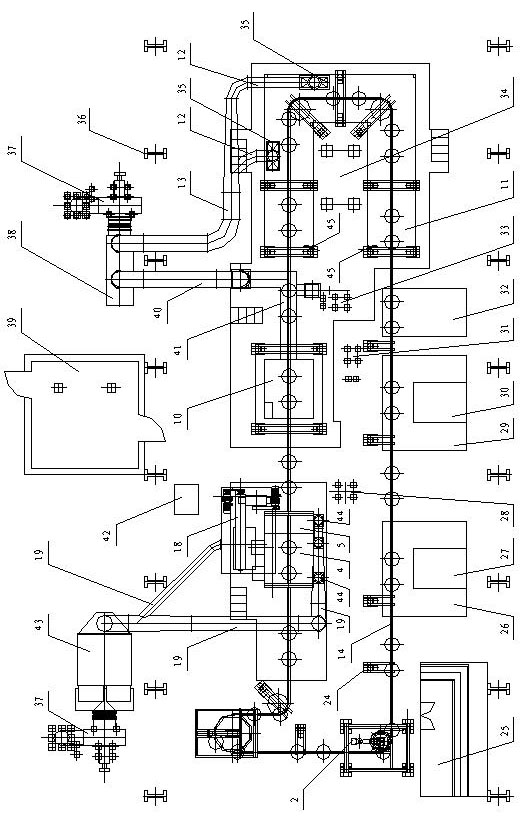

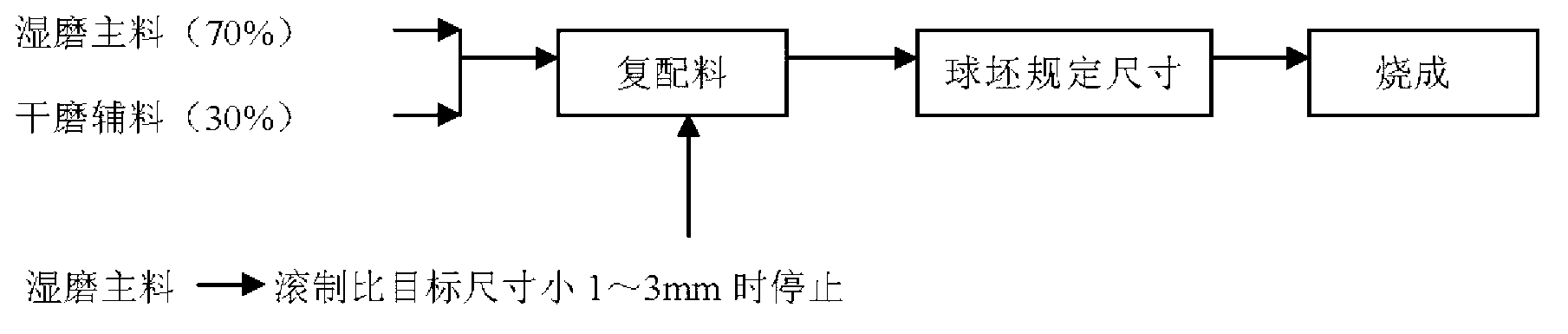

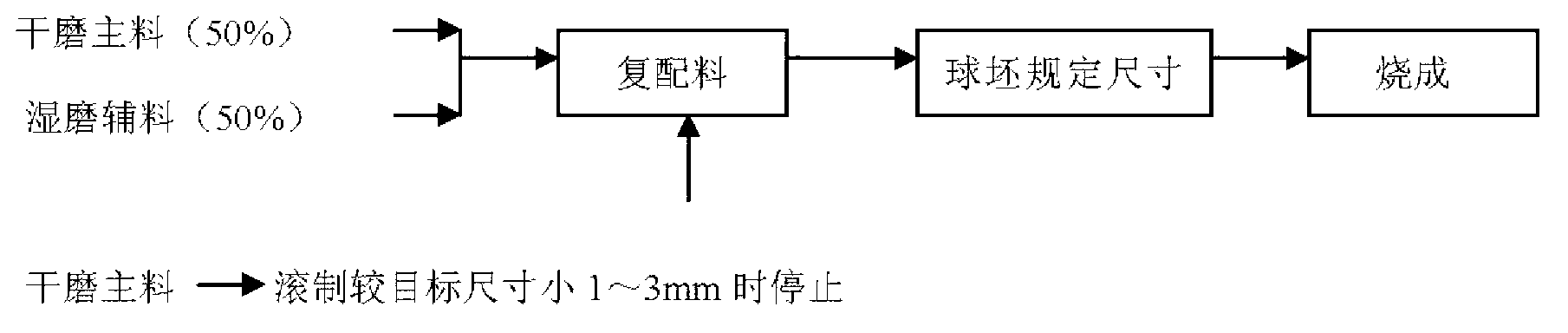

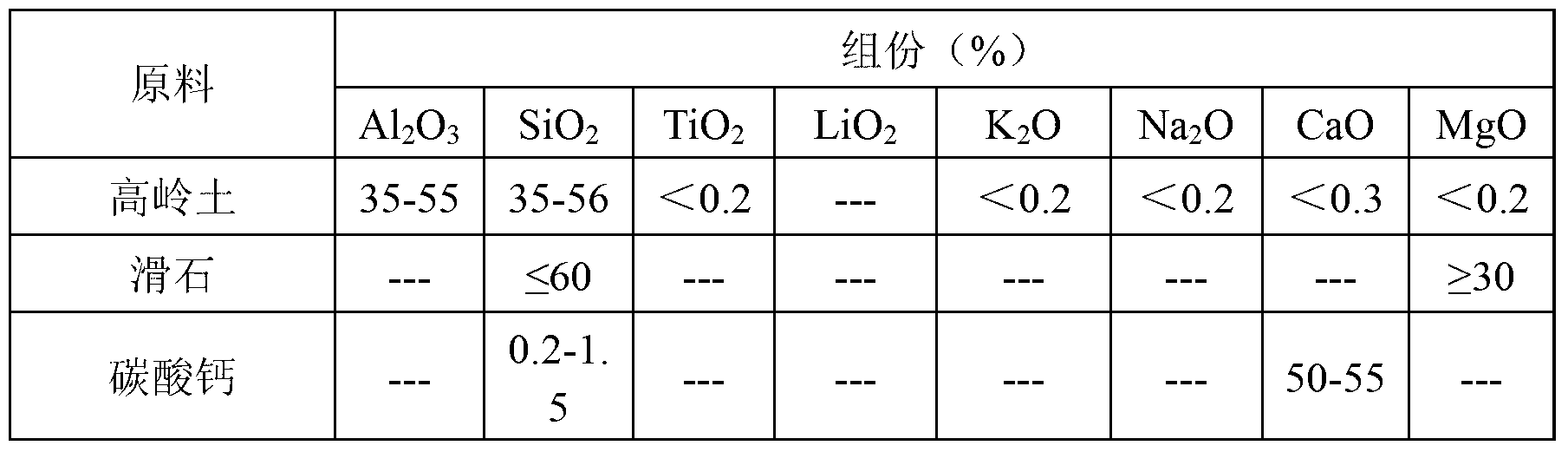

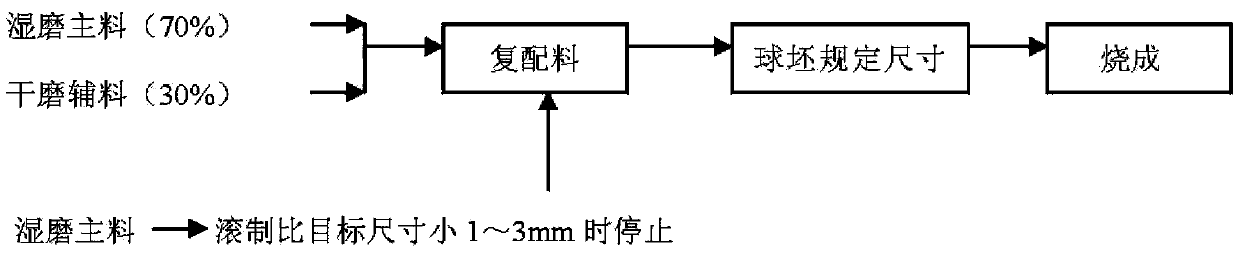

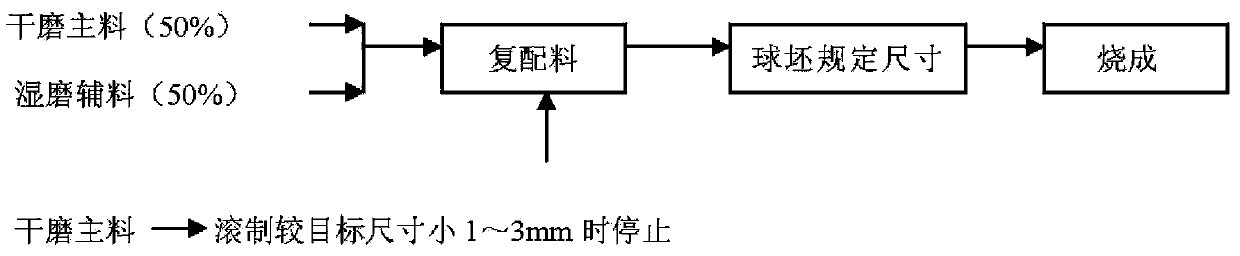

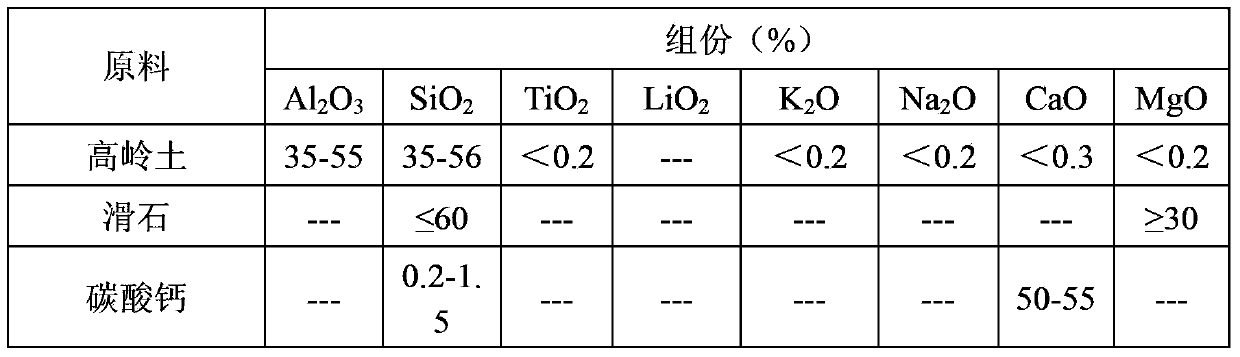

Method for improving appearance quality of inertial porcelain ball

The invention discloses a method for improving appearance quality of an inertial porcelain ball, and belongs to the technical field of novel materials. The method disclosed by the invention divides conventional ball-billet rolling process into two stages, wherein in the first stage, ingredients are grinded by a dry method or a wet method to roll the ball-billet till the size of the ball-billet is 1-3mm smaller than target size; and in the second stage, powder compounded by dry and wet grinding is adopted, and based on the ball-billet formed in the first stage, auxiliary materials are added to prepare compound powder based on the dry or wet grinded powder, and a novel surface wrapping layer is formed by rolling. Practices show that the method can solve the problem of ball layering in production of the inertial ball by the wet method ball-milling process and surface blistering after calcining. The method solves the problem that the degree of sphericity of the product in production of the inertial ball by the wet method ball-milling process is insufficient, and cracks are easy to generate after calcining. In addition, detection shows that the integral physical property of the product is further improved while the appearance quality of the inertial porcelain ball is improved at the same time.

Owner:JINGANG NEW MATERIALS

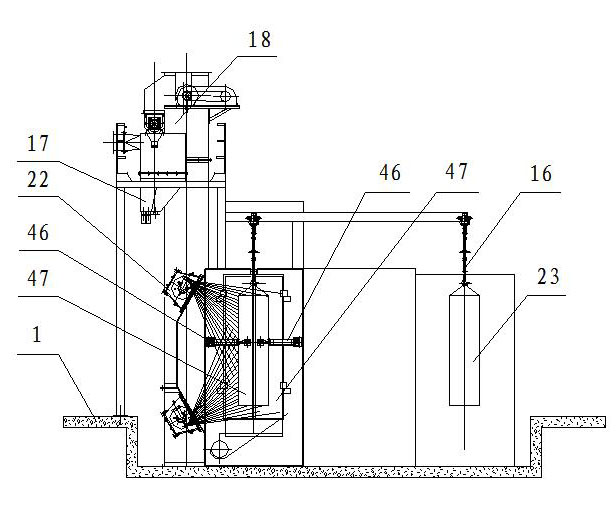

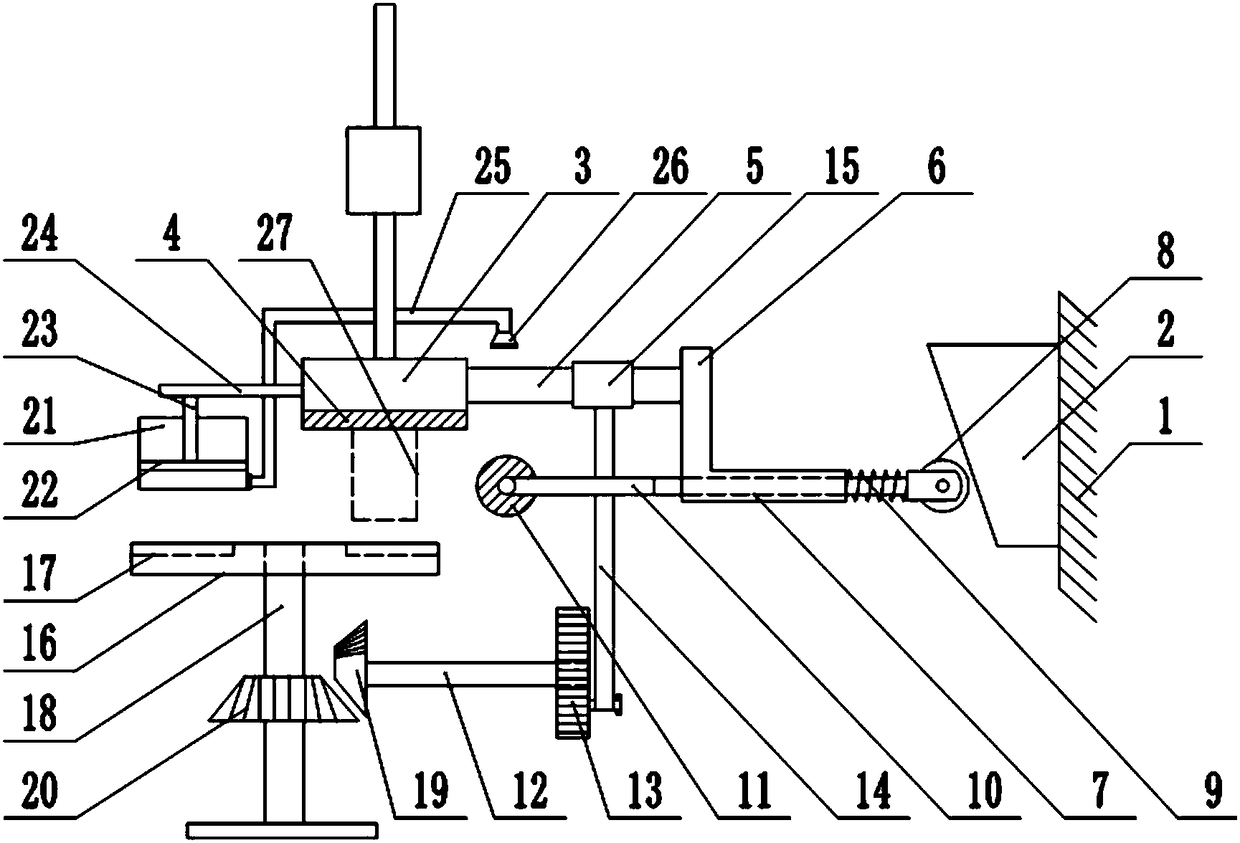

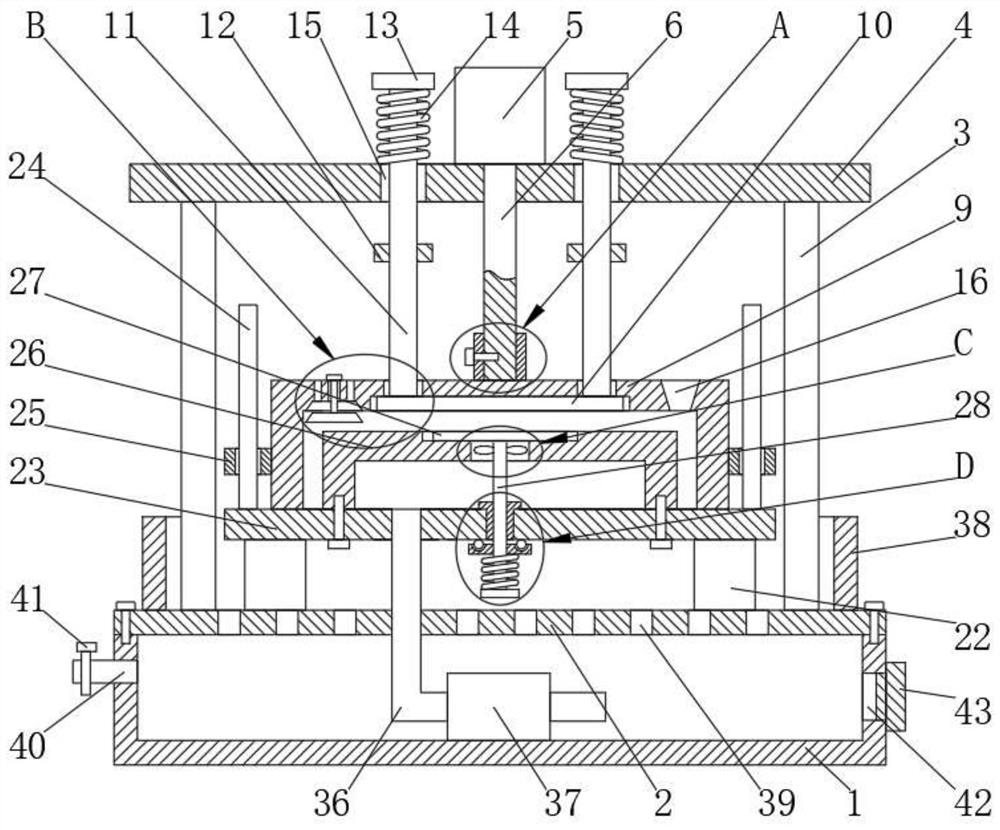

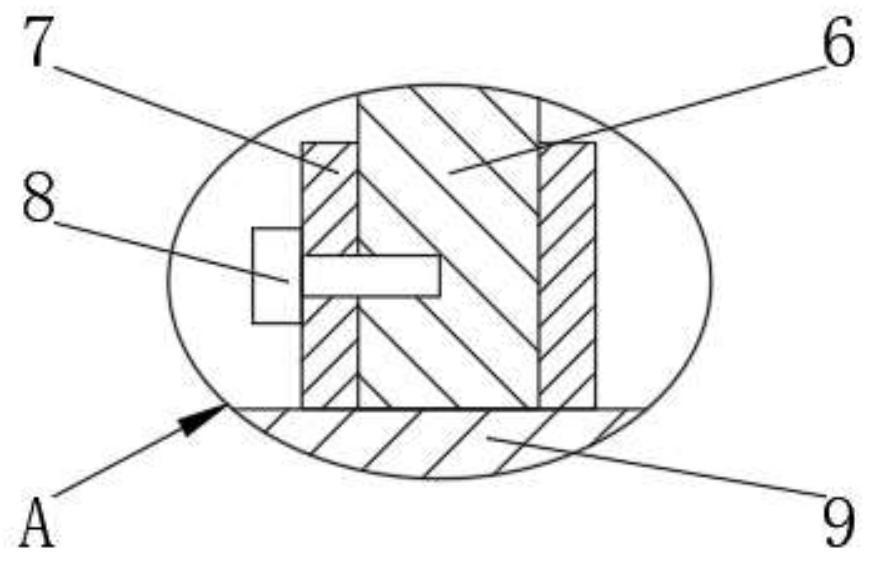

Valve element grinding equipment

InactiveCN108500779AEnsure consistencyAvoid Oversanding ProblemsGrinding drivesSeat surface grinding machinesDrive shaftEngineering

The invention relates to valve element grinding equipment. The valve element grinding equipment comprises a wedge-shaped block and a fixing plate. A first magnet is arranged on the fixing plate. A first connecting rod is fixedly connected with the fixing plate. An L-shaped rod is fixedly connected with the other end of the first connecting rod. A penetrating through hole is formed in the L-shapedrod. A first supporting rod is slidably connected into the through hole. One end of the first supporting rod penetrates through the through hole and is connected with a roller. The roller abuts against the wedge-shaped block. A supporting spring is arranged on the first supporting rod in a sleeving mode. A grinding roller is fixedly connected with the other end of the first supporting rod. A driving shaft is arranged under the grinding roller. A driving plate is fixedly connected with the driving shaft coaxially. A driving rod is rotationally connected with the eccentric position of the driving plate. A first connecting rod is connected with the other end of the driving rod. A first bevel gear is fixedly connected with the driving shaft coaxially and is a sector gear. A transfer plate is arranged under the fixing plate. A vertical shaft is fixedly connected with the transfer plate and coaxially and fixedly connected with a second bevel engaged with the first bevel gear. The grinding time of the equipment is uniform.

Owner:CHONGQING QIANYAN MACHINERY CO LTD

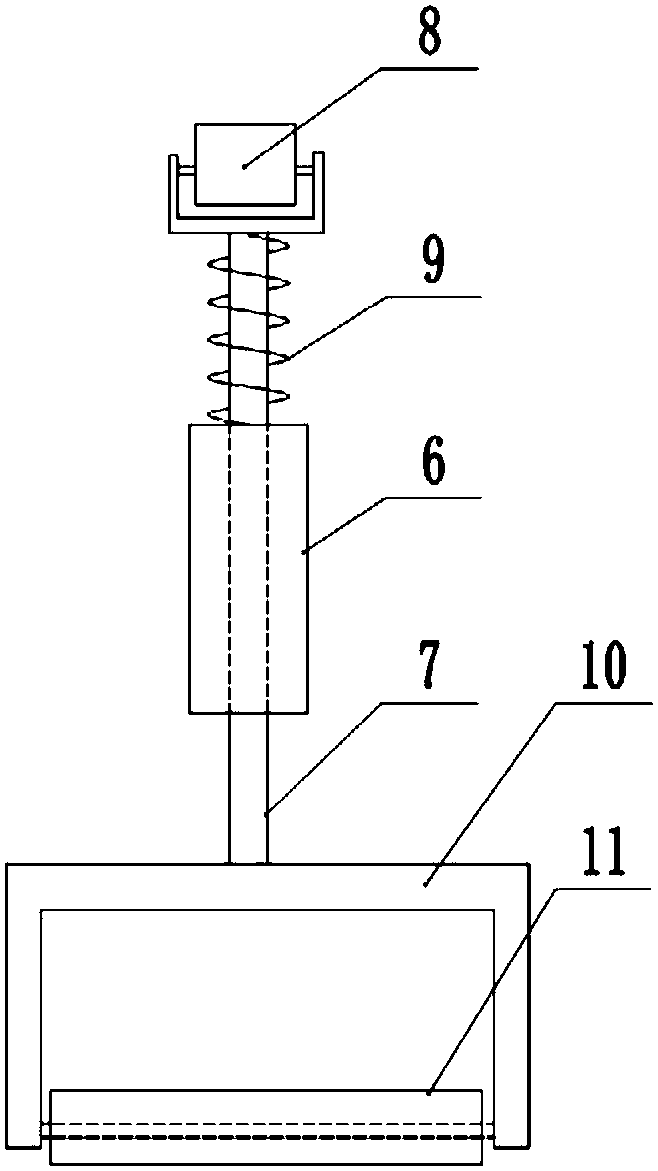

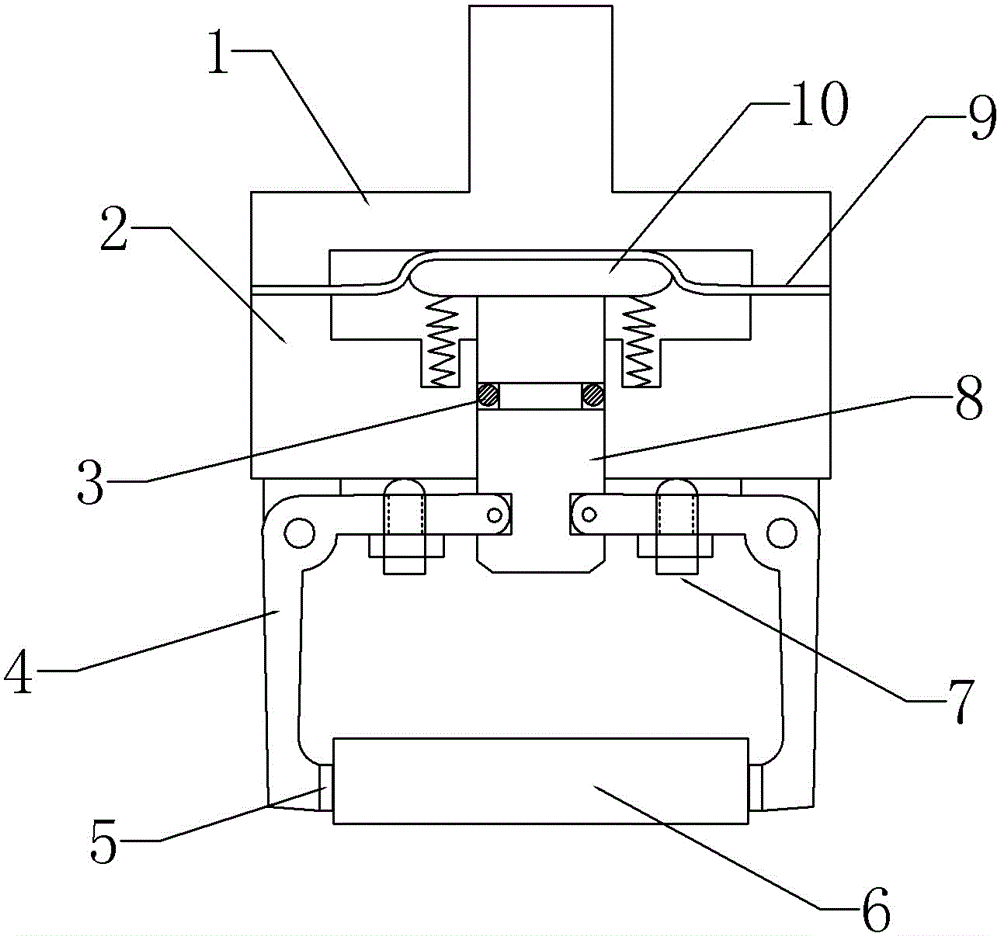

Power-on mechanism

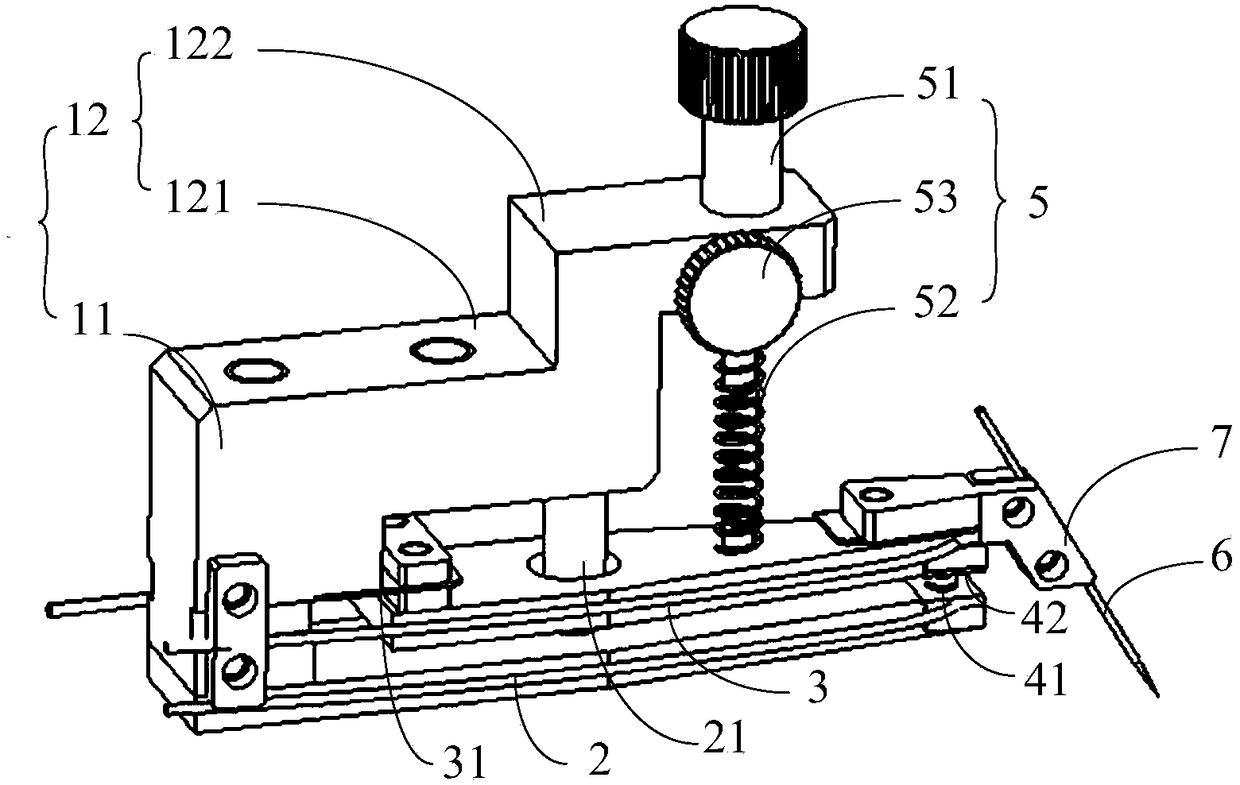

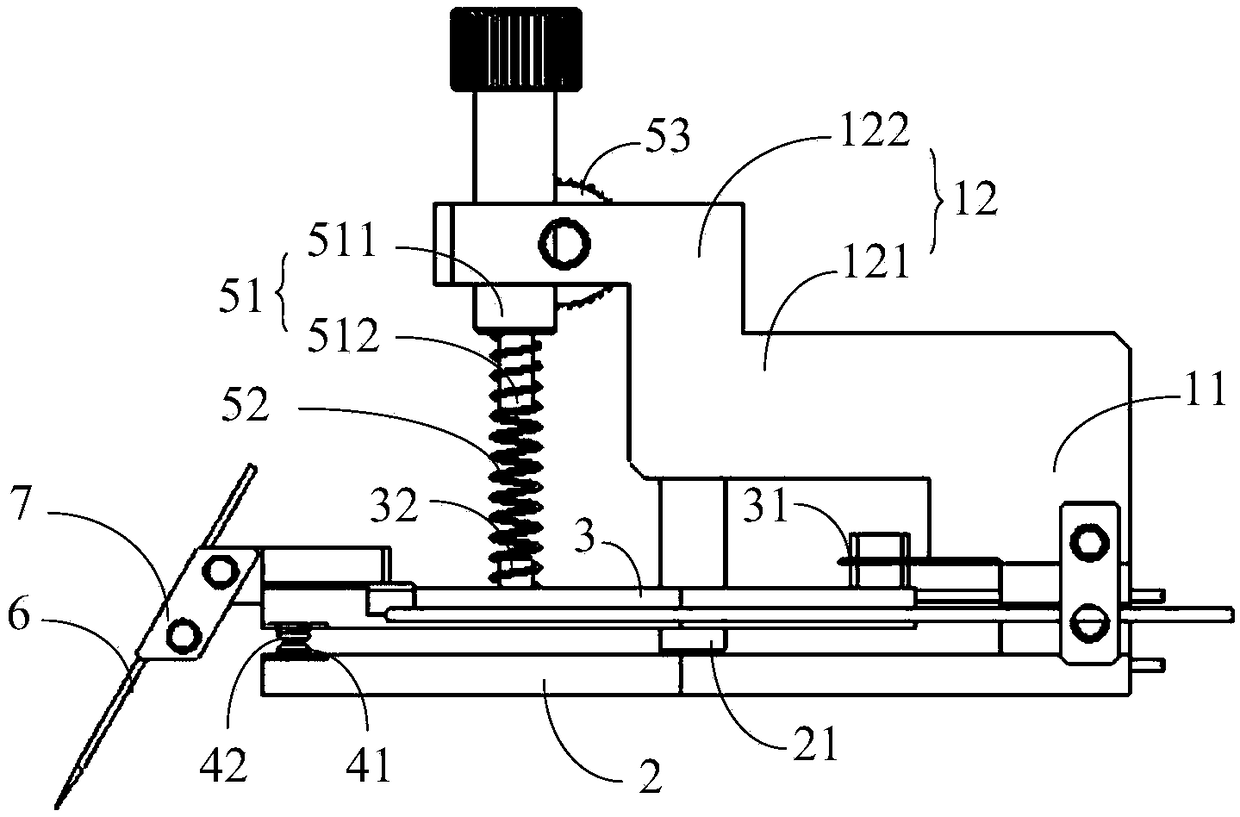

InactiveCN109387773AContact force adjustableOvercome abutmentPrinted circuit testingTest powerElectricity

The invention provides a power-on mechanism, belonging to the chip test power-on technical field. The power-on mechanism comprises a base, a static insulating plate, a movable insulating plate, an elastic component, and a power-on probe. The base comprises a support part and a cantilever part. The static insulating plate is connected with the supporting part and has a first conductive sheet. The movable insulating plate is connected with the support part and has a second conductive sheet arranged opposite to the first conductive sheet. The movable insulating plate has a movement stroke relative to the static insulating plate so as to make the second conductive sheet come into contact with or separate from the first conductive sheet. The elastic component is connected with the cantilever part and abuts with the movable insulating plate in a force-adjustable manner, so that the first conductive sheet and the second conductive sheet are in contact with each other. The power-on probe is connected to an end of the second insulating plate remote from the support part. The power-on mechanism provided by the embodiment of the invention can provide protection to chips during the testing process, prevent the power-on probe from generating indentation on the chips, and ensure the chip quality.

Owner:HISENSE BROADBAND MULTIMEDIA TECH

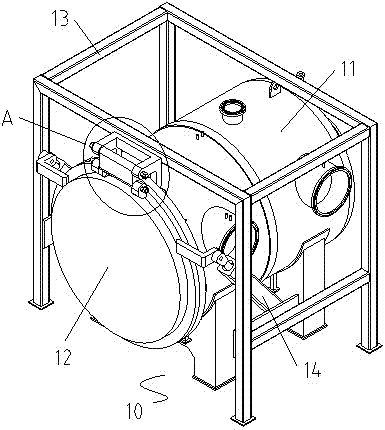

Tea leaf stir-frying integrated device

InactiveCN108174938AAffect qualityQuality improvementPre-extraction tea treatmentWater vaporEngineering

The present invention discloses a tea leaf stir-frying integrated device. The tea leaf stir-frying integrated device comprises an enzyme-deactivating device, a tea rolling device and a tea stir-fryingdevice. An enzyme-deactivating cylinder is provided with a cylindrical screen to form a double-layer structure with an annular cavity; the inner wall of the enzyme-deactivating cylinder is provided with leaf guiding threads for conveying small waste tea leaves; leaf guiding plates used for exporting tea leaves is arranged in the screen; a breather pipe is arranged in a center of a rolling and pressing plate of the tea rolling device; a plurality of air nozzles are arranged on the rolling and pressing surface of the rolling and pressing plate; the breather pipe communicates with the air nozzles; the breather pipe is connected with a steam source; a stir-frying device of the tea stir-frying device comprises three clamping tools, three kneading brooms and a fixed disk; the fixed disk sleevesa rotary shaft; the clamping tools are fixed on the fixed disk; and the kneading brooms are arranged on the clamping tools. In an enzyme-deactivation process, small tea leaves are separated to prevent subsequent burning by stir-frying and resource waste; in a tea rolling process, an appropriate amount of water vapor is inflated into a tea disk according to dry and wet state of the tea leaves to prevent the tea leaves from being crushed; and the stir-frying tea leaves are bright, pure in mouthfeel, and beautiful in appearance.

Owner:四川省朝阳天成茶叶有限公司

Processing method for preventing dry lemon slices from browning

InactiveCN104489058AKeep the natural flavorEnsure safetyFruits/vegetable preservation by dehydrationBrowningProcess engineering

The invention discloses a processing method for preventing dry lemon slices from browning. The processing method comprises the steps of cutting fresh lemons into slices with the thickness of 3mm-4mm, and carrying out heat pump drying on the slices at 45-50 DEG C for 10-12 hours. According to the processing method provided by the invention, no additive is added, and the prepared dry lemon slices are nature, high in nutrients, strong in flavor and long in guarantee period.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI

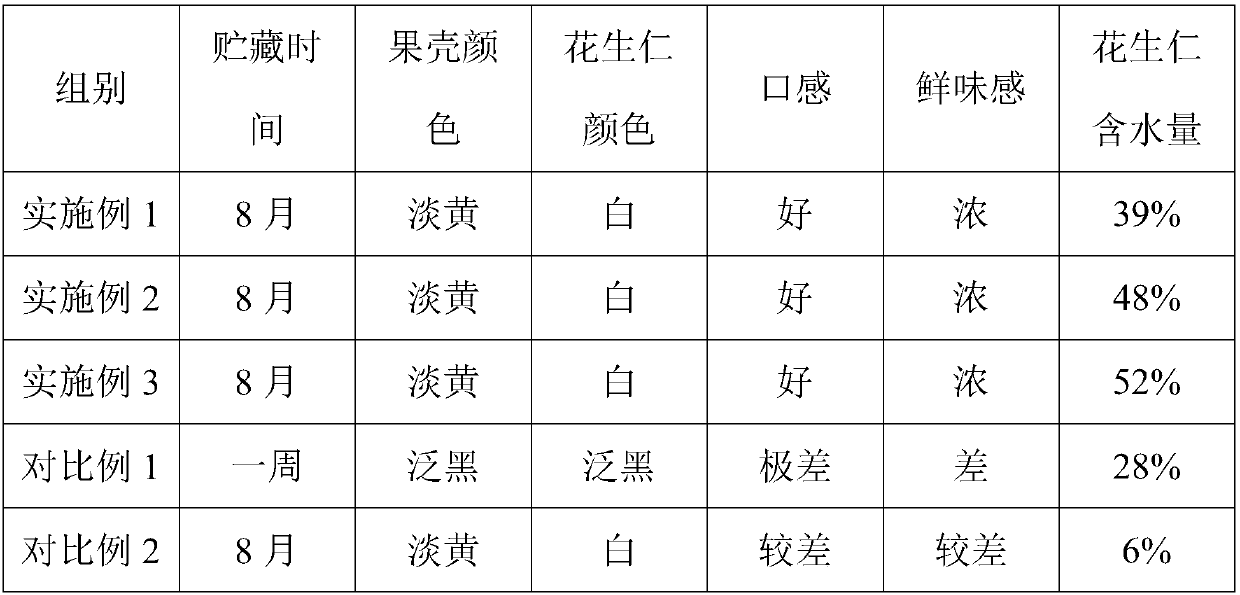

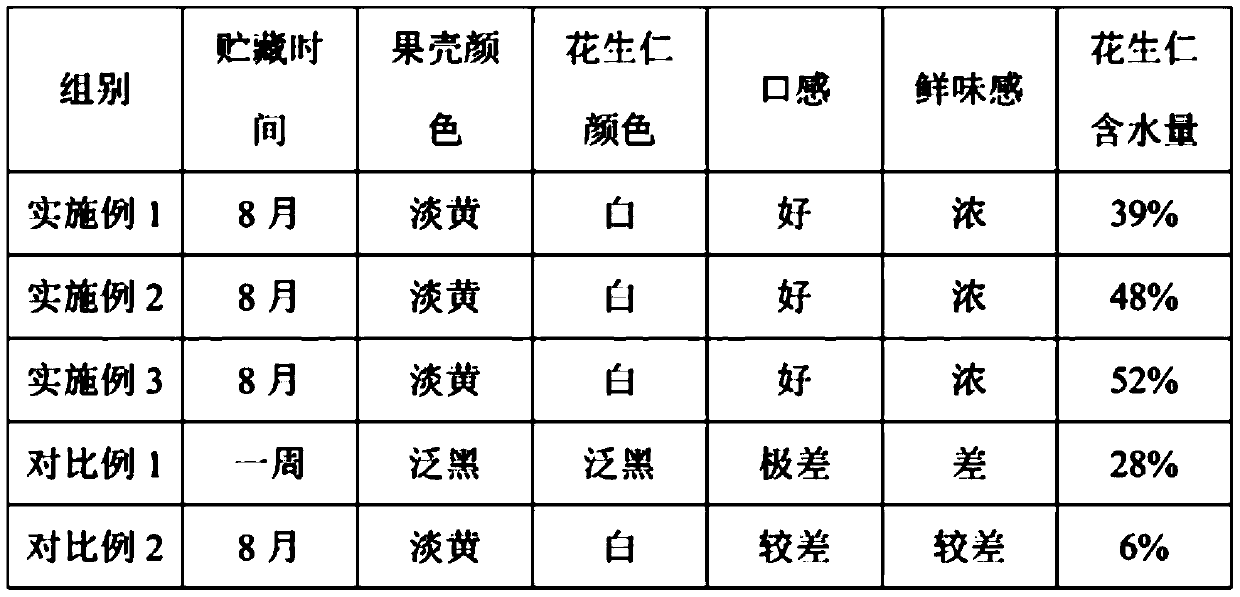

Method for storage and fresh-keeping of fresh peanuts

ActiveCN107712037AAffect appearance qualityGuaranteed tasteFruit and vegetables preservationSeed preservation by freezing/coolingHuman healthChemical preservatives

The invention discloses a method for storage and fresh-keeping of fresh peanuts, belonging to the technical field of food processing. The method comprises the following steps: subjecting fresh peanutsto sterilization and disinfection; drying the shells of the treated fresh peanuts to control the water content of the shells of the treated fresh peanuts to be no more than 8% and the water loss rateof peanut kernels to be no more than 5%; and storing the fresh peanuts in an environment with a humidity of no less than 85% and a temperature of 3 to 5 DEG C. The method provided by the invention does not need preservative treatment of the fresh peanuts with food preservatives, so harm caused by the toxicity of chemical preservatives can be avoided, and the method is favorable for human health and environmental protection, retains the original color, fragrance and taste and nutritional components of the peanuts, overcomes inconvenience and troubles caused by traditional process, solves problems in traditional delicious water-cooked peanuts, meets the demands of vast consumers and has good market application prospects.

Owner:JIANGXI ACAD OF AGRI SCI

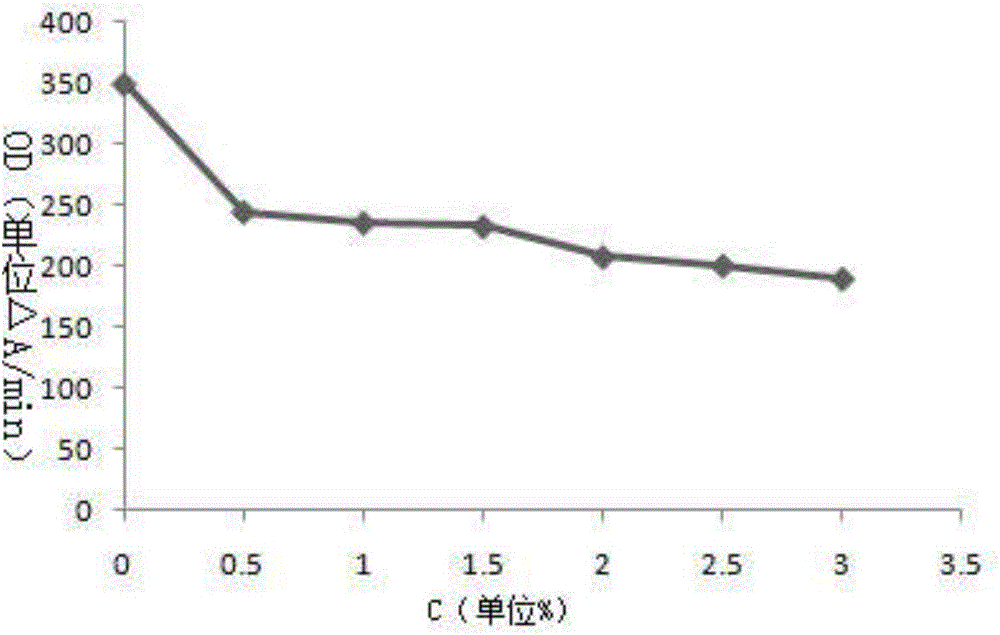

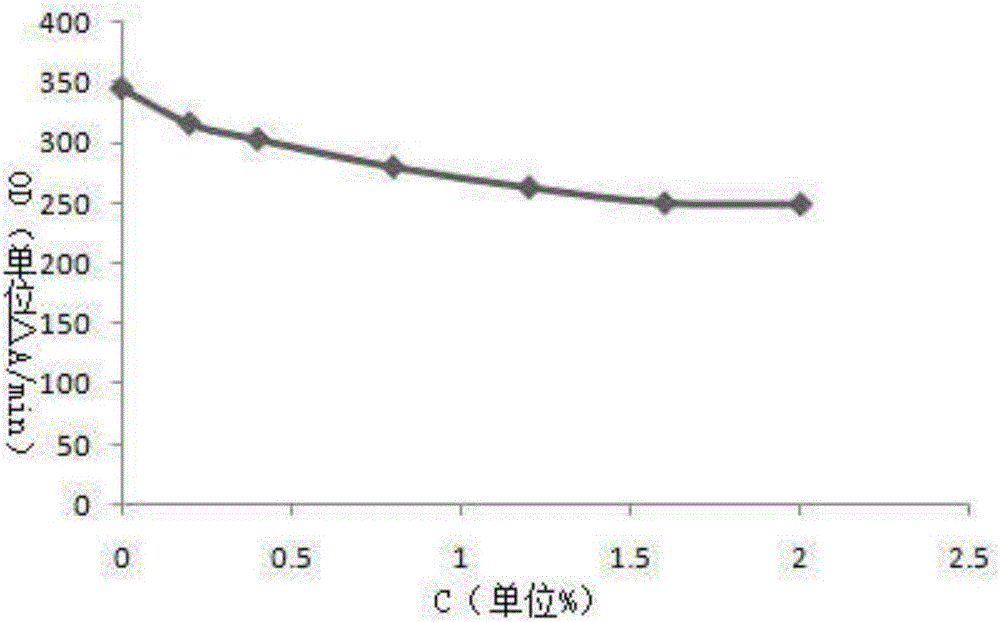

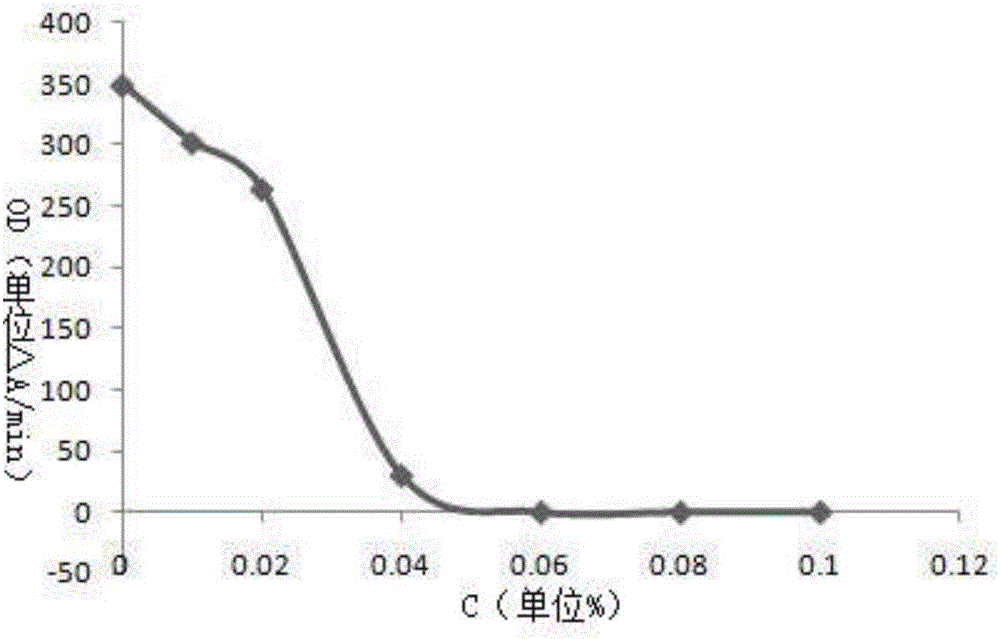

Sulfur-free processing method for Bulbus Fritillariae Thunbergii

InactiveCN106309883AAffect appearance qualityControl appearance qualityInorganic non-active ingredientsPlant ingredientsVitamin CEnzyme inhibition

The invention belongs to the technical field of processing of traditional Chinese medicines, and particularly relates to a sulfur-free processing method for Bulbus Fritillariae Thunbergii. The sulfur-free processing method for Bulbus Fritillariae Thunbergii comprises the following steps: A, liquid preparation: adding vitamin C, sodium chloride and citric acid in purified water to obtain a polyphenol oxidase sulfur-free inhibitor for subsequent use; B, soaking: soaking screened Bulbus Fritillariae Thunbergii in the polyphenol oxidase sulfur-free inhibitor for 15-60 minutes, wherein the polyphenol oxidase sulfur-free inhibitor completely covers the Bulbus Fritillariae Thunbergii during soaking; C, air-drying: draining water of the soaked Bulbus Fritillariae Thunbergii, and drying the Bulbus Fritillariae Thunbergii in an oven by hot air at the temperature of 50-70 DEG C for 100-120 minutes; and D, storing: storing the dried Bulbus Fritillariae Thunbergii in a sealing bag. The sulfur-free processing method for Bulbus Fritillariae Thunbergii has the advantages that the vitamin C, the sodium chloride, the citric acid and the like are used as main enzyme inhibition ingredients to inhibit activity of the polyphenol oxidase, activity of PPO is inhibited to prevent the circumstance that the appearance quality is affected by browning of raw herbal materials, after being soaked in the inhibiting liquid, the Bulbus Fritillariae Thunbergii is dried,, and therefore, good internal quality and appearance quality can be achieved.

Owner:ZHEJIANG CHINESE MEDICAL UNIVERSITY

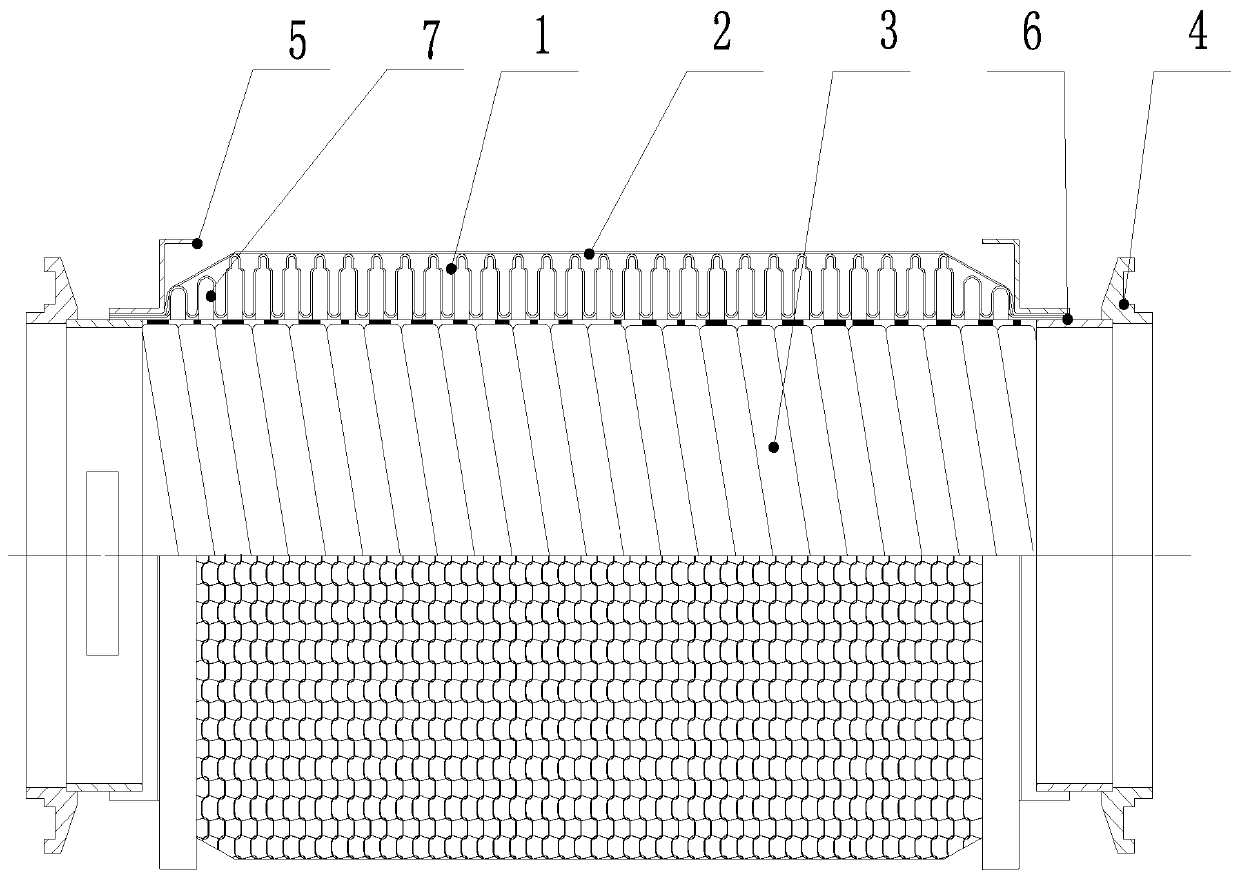

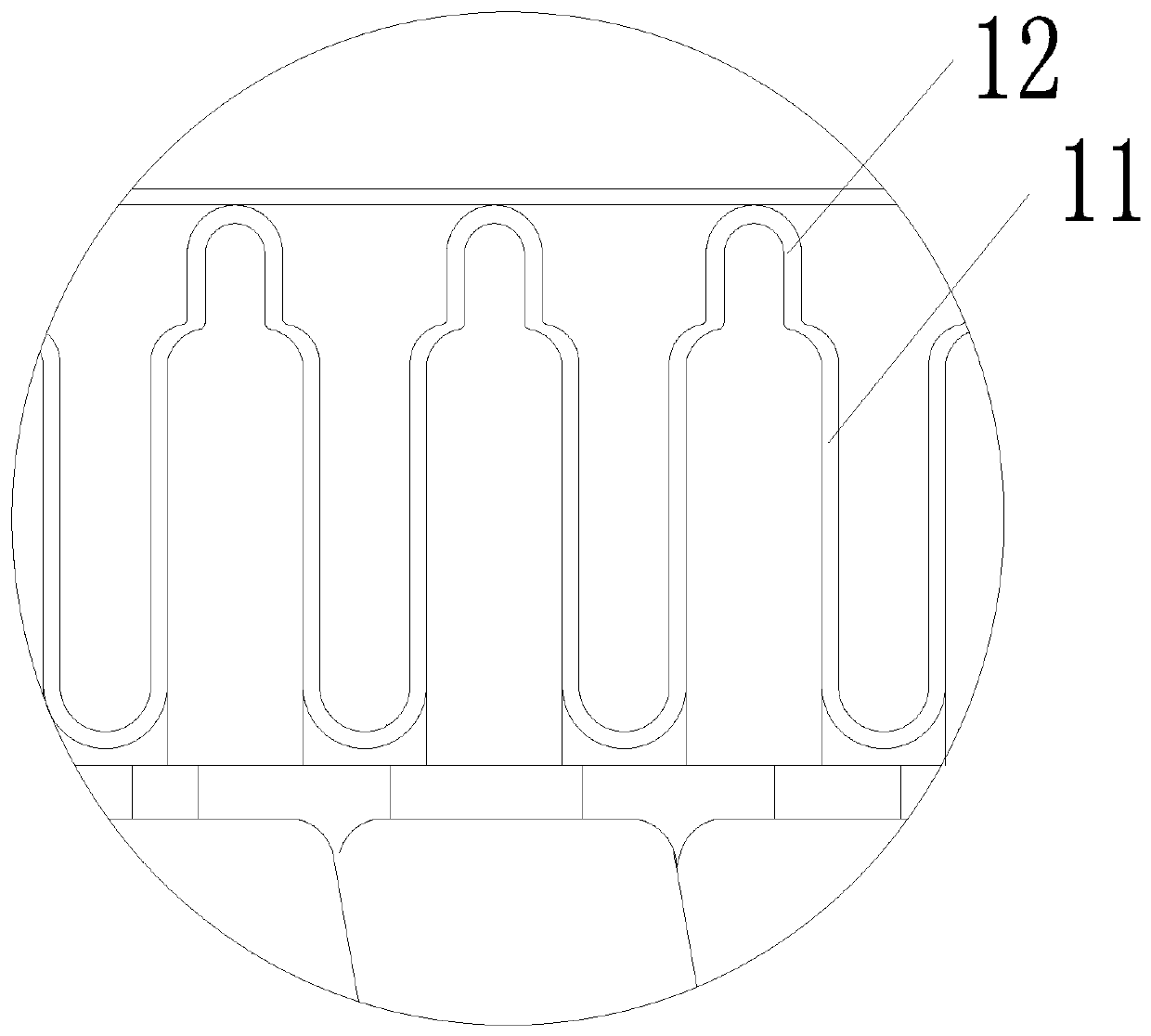

Novel corrugated pipe for automobile and manufacturing process thereof

PendingCN111535913AAvoid overstretchingReduce heat transferExhaust apparatusSilencing apparatusMechanical engineeringCommercial vehicle

The invention relates to a novel corrugated pipe for an automobile and a manufacturing process thereof. The novel corrugated pipe for the automobile comprises a metal corrugated pipe body with two straight edge sections at two ends, wherein a metal winding pipe is embedded in the inner wall of the metal corrugated pipe body; and a fish pattern net uniformly covers the outside of the metal corrugated pipe body. The novel corrugated pipe for the automobile has the advantages of high flexibility, heat-insulation performance, corrosion-resistant performance, good sealing performance and long service life. A main body corrugated pipe and the winding pipe have good high-temperature-resistant and corrosion-resistant performance; the fish pattern net, a Z-shaped outer ring and a joint break through the process scheme that a traditional corrugated pipe carbon steel workpiece joint for a commercial vehicle needs paint spraying; work procedures of joint phosphorization, paint spraying, salt spraytests and the like are omitted; the production and manufacturing cost is reduced; and the problems that the joint gets rusty because of paint falling in the use process by a user, and the appearancequality is influenced are solved. The metal corrugated pipe, the fish pattern net and the metal winding pipe adopt special assembly processes; a product is enabled to have a certain telescopic allowance; the installation state of the product is also controlled; the fracture of the product caused by excessive deformation is effectively prevented; and the service life of the product is prolonged.

Owner:常州市常联波纹管有限公司

Preparation method of quick-frozen Lycium barbarum

The invention discloses a preparation method of quick-frozen Lycium barbarum. The method is characterized by comprising the following steps: cooling ice water; draining; quick-freezing. The prepared quick-frozen Lycium barbarum has bright red color, color consistency, no individual adhesion and uniform size; the preparation method effectively maintains the color and flavor of Lycium barbarum, and extends the storage period; and the bacterial colony count / g is less than or equal to 10000, and fecal coliform (MPN / 100 g) is less than 3. The preparation method of quick-frozen Lycium barbarum effectively solves the problem of serious effective component loss in storage process, retains the nutritional ingredients to the maximum and keeps the appearance and quality of the quick-frozen Lycium barbarum the same to the fresh ones, so as to ensure that people can always eat fresh Lycium barbarum.

Owner:宁夏天瑞产业集团现代农业有限公司

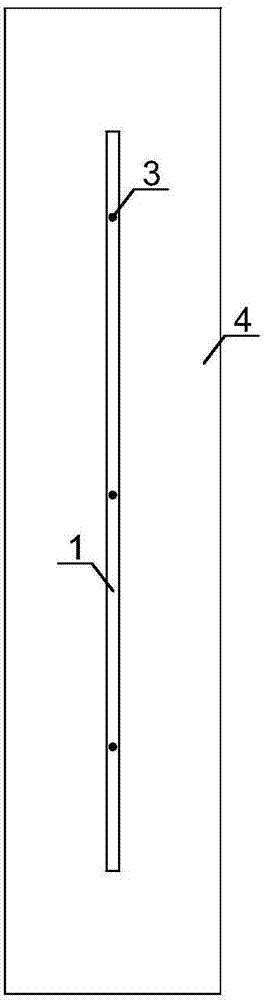

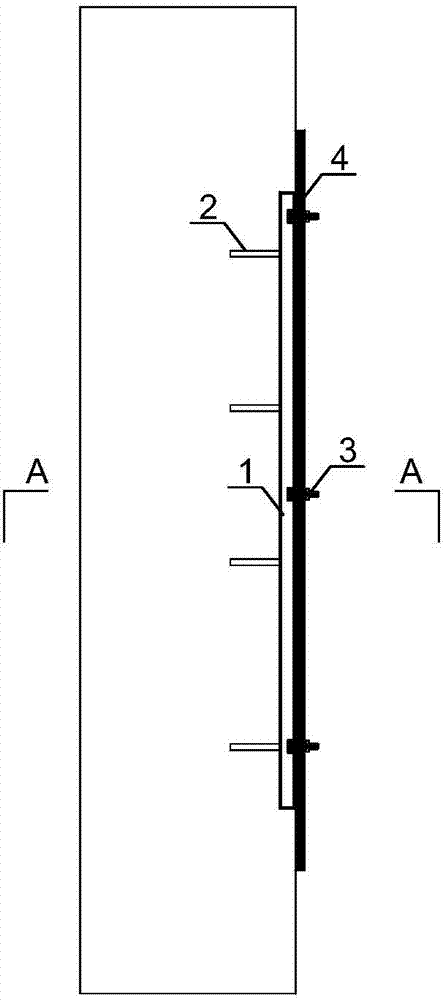

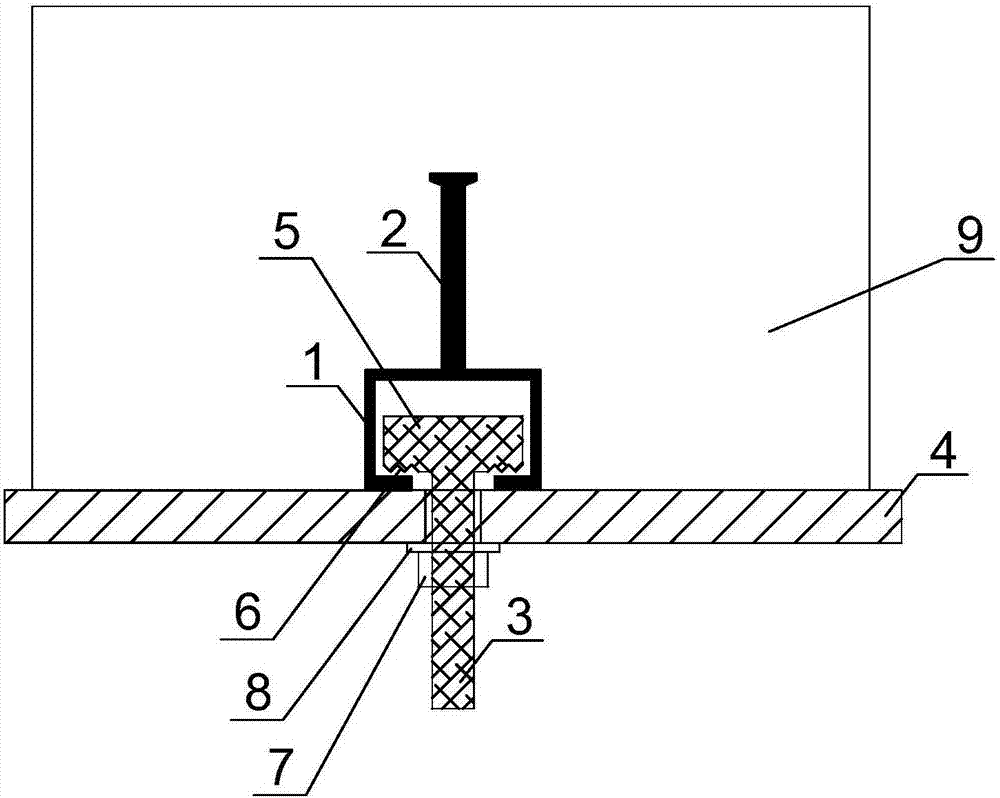

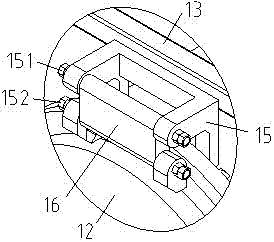

Pre-embedded type supporting base of cable bracket and mounting method for pre-embedded type supporting base

PendingCN107202199AImprove installation qualityPrecise positioningPipe supportsPre embeddingScrew cap

The invention discloses a pre-embedded type supporting base of a cable bracket and a mounting method for the pre-embedded type supporting base. The pre-embedded type supporting base comprises C-shaped steel, wherein a bolt is arranged at an opening side of C-shaped steel; a screw cap at one end of the bolt is arranged inside the C-shaped steel; a pre-embedded reinforcing part is arranged on the outer wall at the other side, opposite to the opening, of the C-shaped steel; and a molding board is further arranged at the opening side of the C-shaped steel. When the pre-embedded type supporting base of the cable bracket is mounted, the molding board is tightly connected with the supporting base through a bolt, so that the pre-embedded type supporting base is prevented from quality problems such as displacement as a result of structural construction reasons and structure staggering, which affect concrete appearance quality and supporting base mounting quality. According to the pre-embedded type supporting base disclosed by the invention, mounting quality is improved, so that the pre-embedded type supporting base is positioned accurately and firmly. Through bolt connecting, mounting working efficiency is effectively improved, mounting is more professional and programmed, construction cost is reduced and construction quality is improved, so that the pre-embedded type supporting base is suitable for construction of the pre-embedded type supporting bases of various cable brackets.

Owner:MCC5 GROUP CORP SHANGHAI

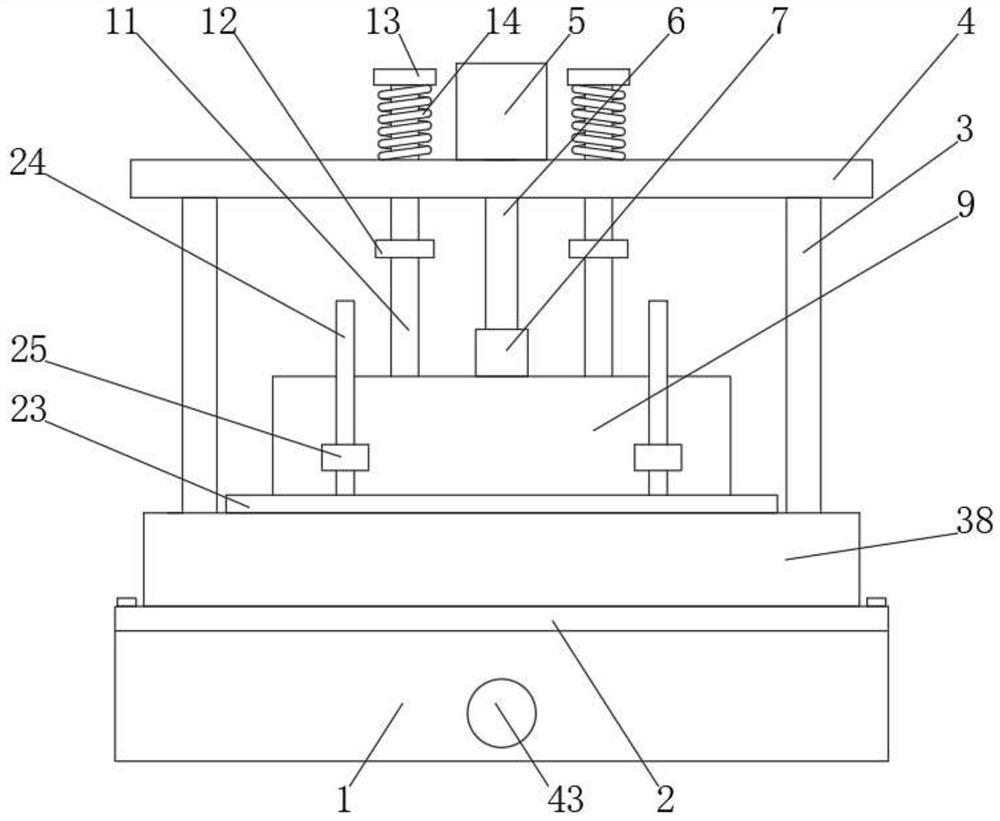

Injection mold for battery box shell of electric vehicle

InactiveCN113334694AEasy to disengageReduce wasteDomestic articlesElectric-vehicle batteryElectrical battery

The invention belongs to the field of electric vehicles, and particularly relates to an injection mold for a battery box shell of an electric vehicle. The injection mold comprises a water tank, wherein the upper end of the water tank is connected with a box cover through screws; a support column is welded to the upper end of the box cover; a mounting plate is welded to the upper end of the support column; an air cylinder is fixedly mounted at the upper end of the mounting plate; an air cylinder rod is arranged at the lower end of the air cylinder, and the air cylinder rod is sleeved with the mounting plate in a sliding manner; a connecting sleeve fixedly sleeves the outer side of the lower end of the air cylinder rod; an upper mold base is welded to the lower end of the connecting sleeve; a pressing plate is connected to the lower end of the upper mold base in a sliding manner; and a hanging rod is welded to the upper end of the pressing plate, and the hanging rod is sleeved with the upper mold base in a sliding manner. A water pump is arranged at the lower end of a water inlet pipe, the water pump sucks water into a convex mold, the water enters the convex mold to jack up a top plate, the water is injected between a battery box and the convex mold for pressurization, and the battery box is separated from the convex mold, so that the battery box is separated from the convex mold more conveniently.

Owner:杨施旅

Spraying equipment for propaganda slogans

ActiveCN113522587AQuick changeImprove spraying efficiencySpraying apparatusDrying gas arrangementsElectric machineryStructural engineering

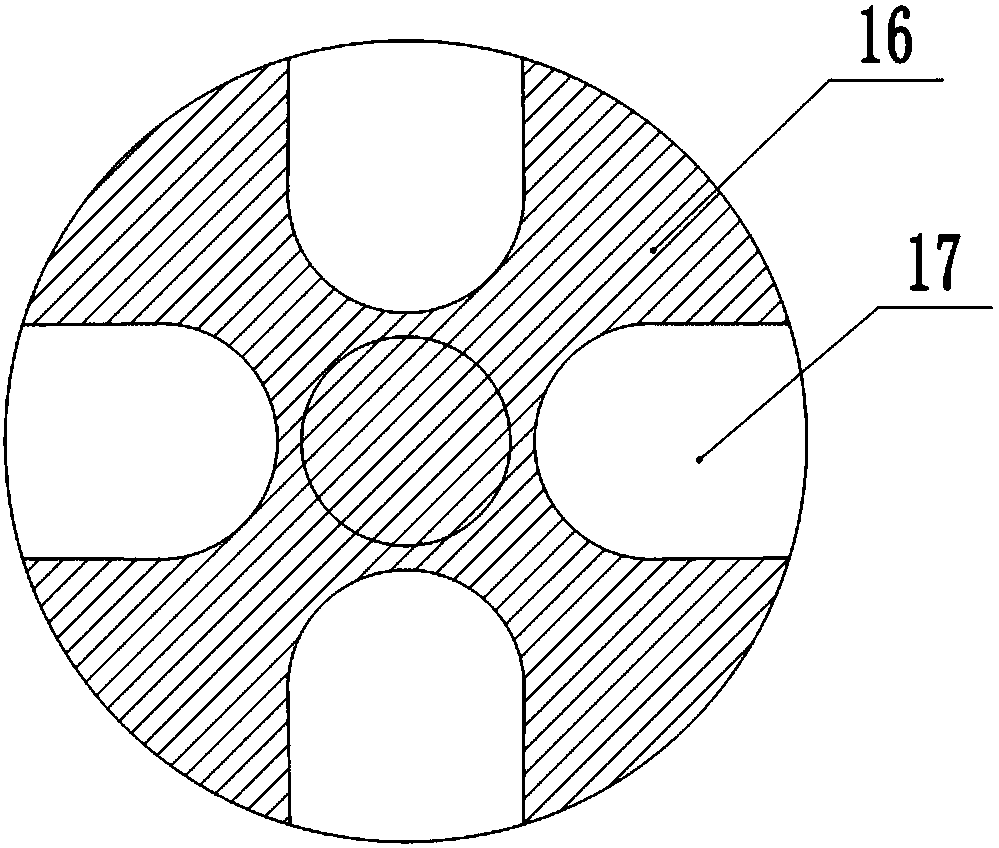

The invention discloses spraying equipment for propaganda slogans. The spraying equipment comprises a base, a mechanical arm is installed at the upper end of the base, a spraying mechanism for replacing and spraying paint is arranged on the base, the spraying mechanism comprises a supporting plate fixedly connected to the upper end of the base, a fixing block is fixedly connected to the upper end of the supporting plate, a circular cavity is formed in the fixing block, a conveying disc is rotationally connected to the inner wall of the circular cavity in a sealed mode, a first conveying pipeline and a second conveying pipeline are symmetrically arranged in the conveying disc, a feeding pipe is in threaded connection with the top of the circular cavity, a motor for driving the circular cavity to rotate is installed on the side wall of the fixing block, a collecting cover is installed on the side wall of the mechanical arm, and a circular ring is fixedly connected to the side wall of the collecting cover. By arranging the spraying mechanism and a control mechanism, a paint spraying pipe can be quickly replaced when different paints are sprayed on the wall surface, and compared with the prior art, the spraying can be carried out without firstly cleaning a nozzle, so that the spraying efficiency is improved.

Owner:南通松鼠文化传媒有限公司

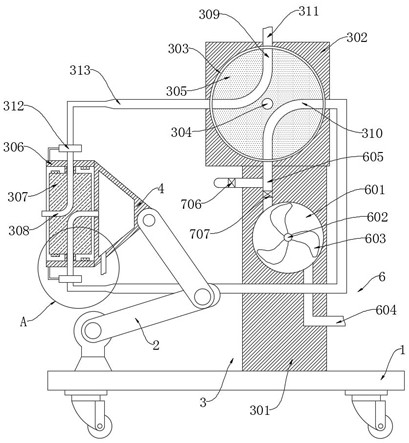

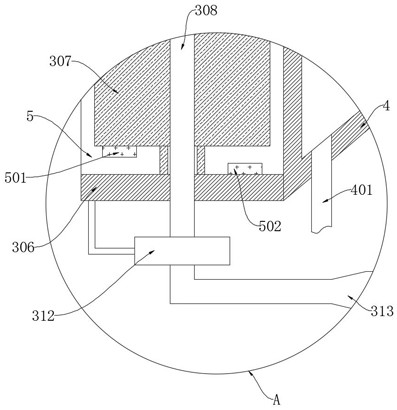

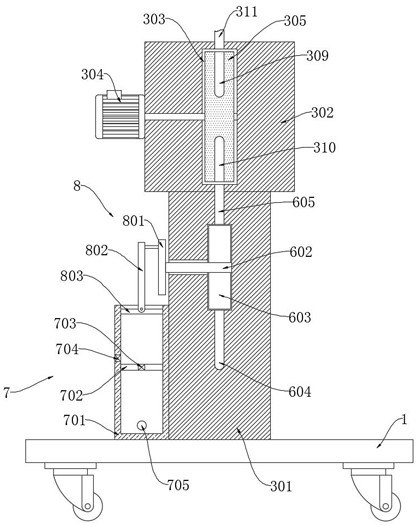

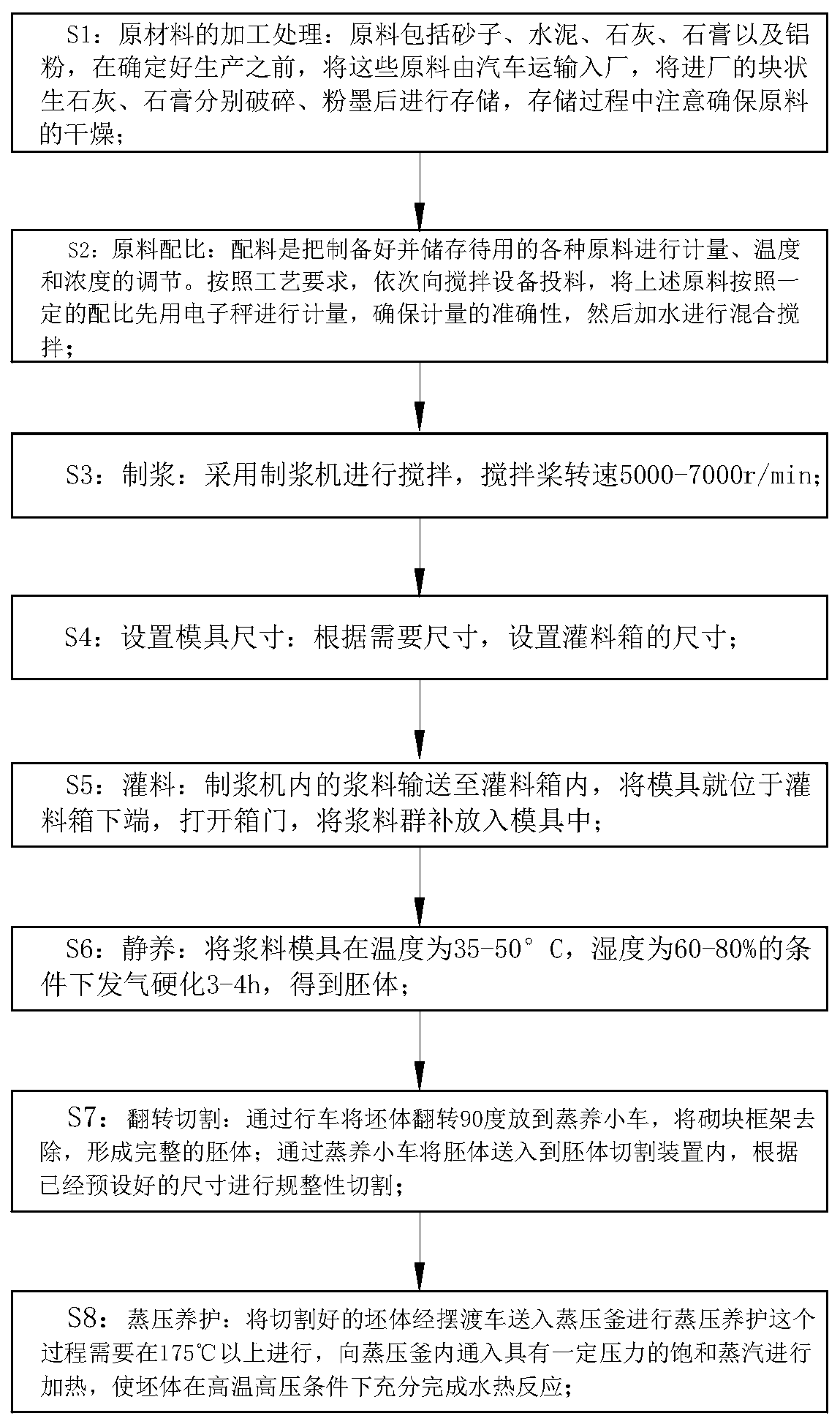

Method for producing ALC plates in multiple lengths

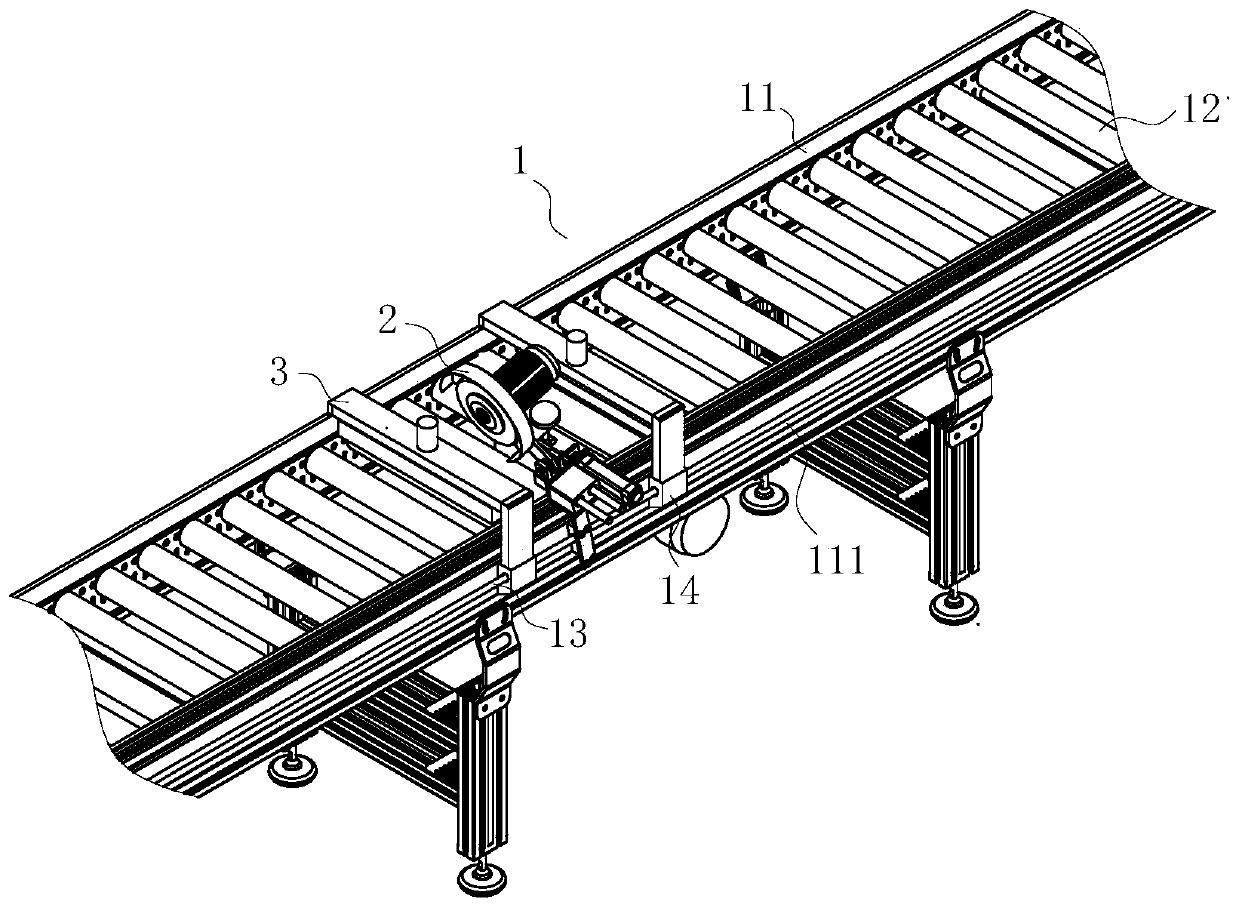

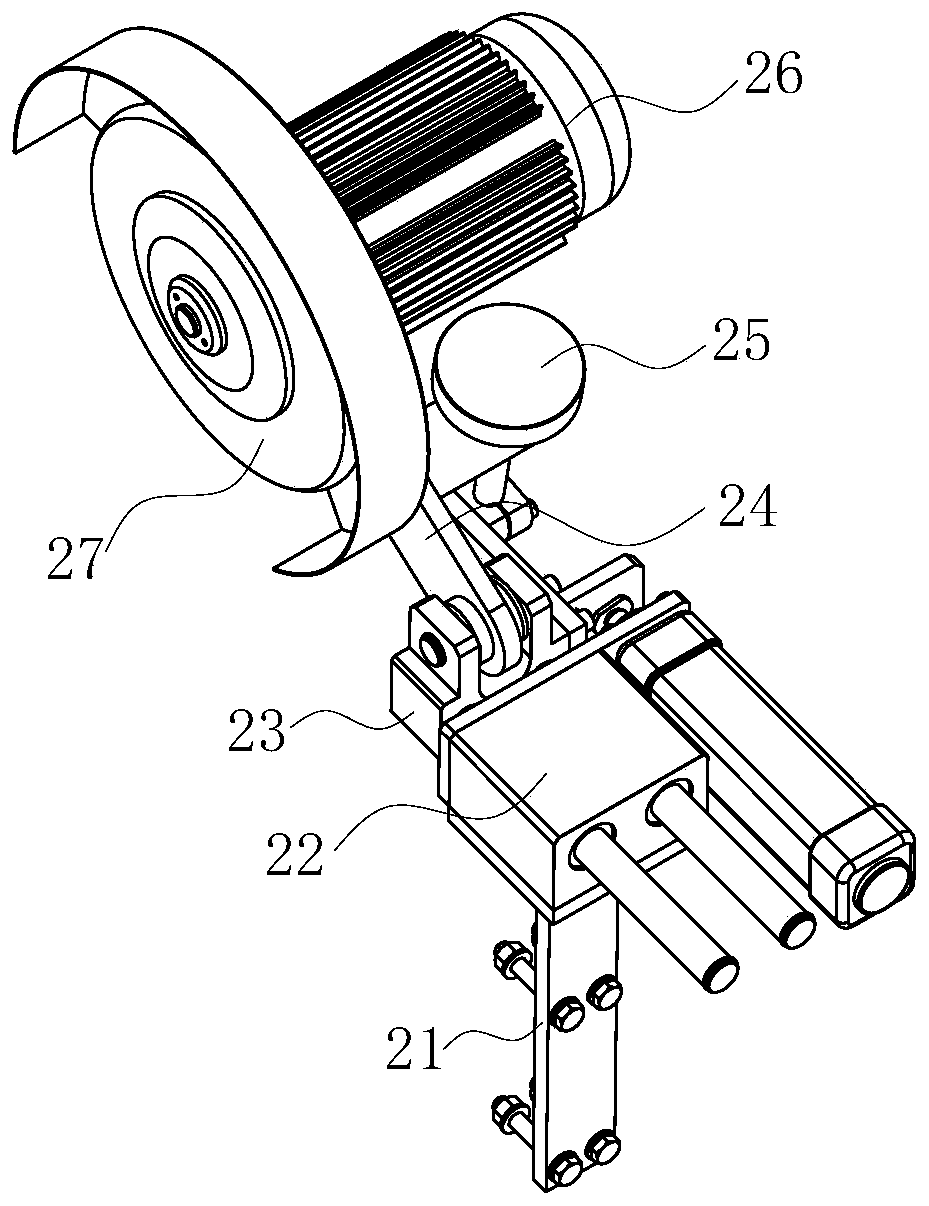

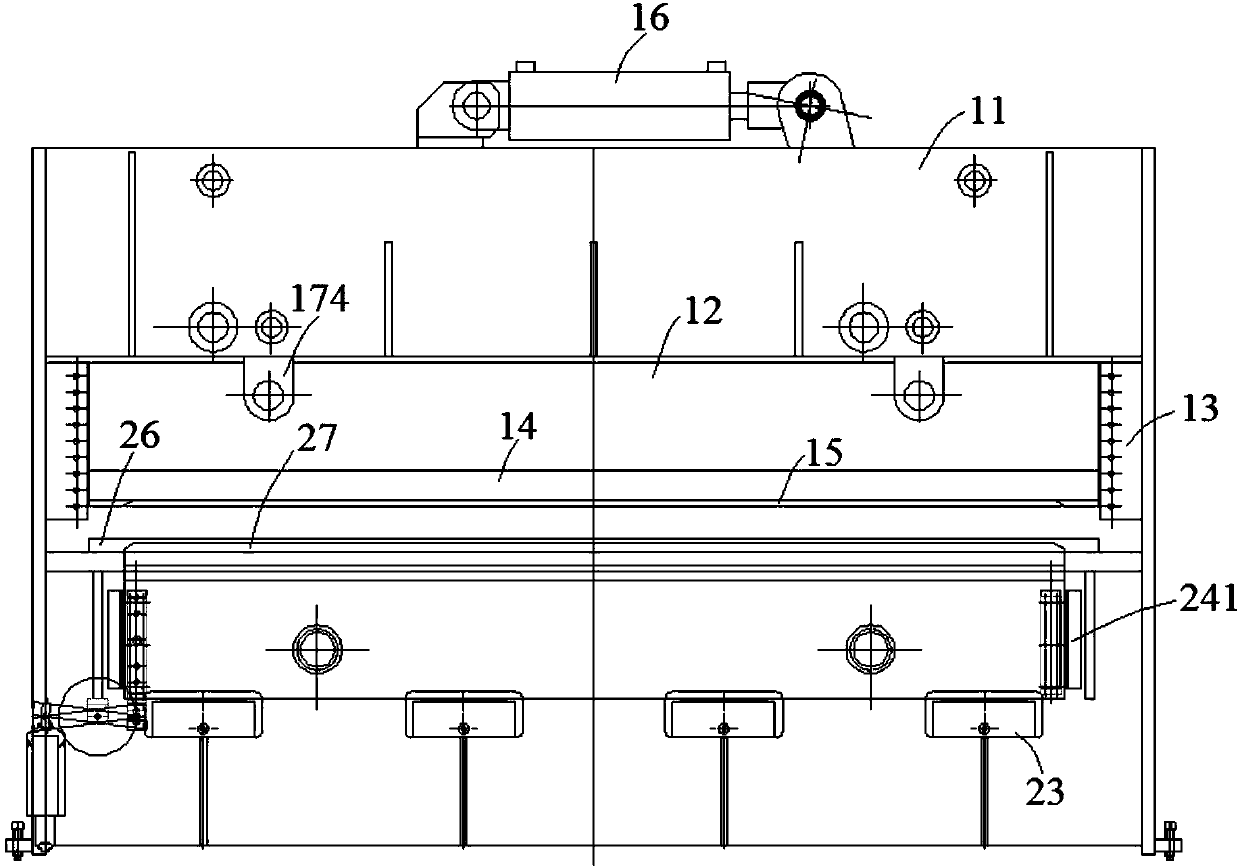

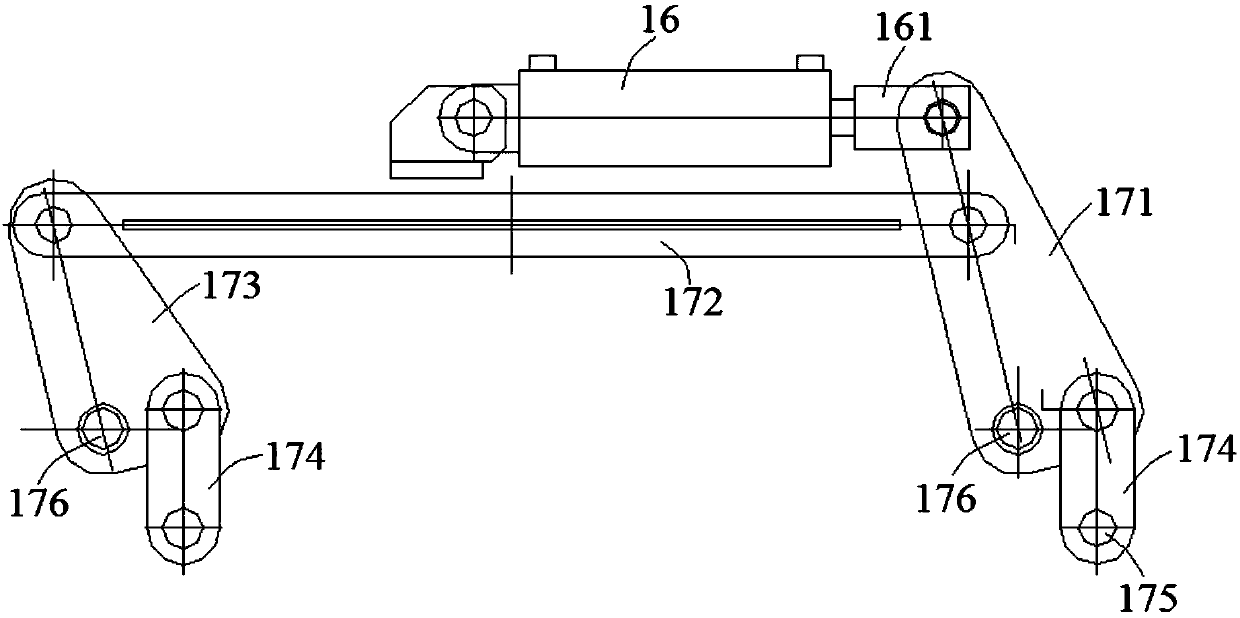

ActiveCN110524700AAffect regular cuttingAffect regularityMixing operation control apparatusAuxillary shaping apparatusFilling materialsCutting force

The invention belongs to the technical field of building materials, and particularly relates to a method for producing ALC plates in multiple lengths. The method comprises the following steps: processing raw materials; proportioning the raw materials; performing pulping; setting mold sizes; filling materials; standing still; overturning and cutting: separating the mold by an overturning machine, overturning a green body by 90 degrees, putting the green body into a steam-curing trolley, and removing a building block frame to form a complete green body; sending the green body into a green body cutting device through the steam-curing trolley, and carrying out regular cutting according to a preset size; carrying out autoclaved curing. Through matching of a sliding cutting mechanism and a greenbody limiting mechanism, the ALC wallboard green bodies with different lengths can be cut; meanwhile, the green body limiting mechanism can limit and fix the ALC wallboard green bodies, and the situation that when the cutting mechanism cuts the green bodies, the green bodies slide due to the cutting force or vibration force of the cutting mechanism, and then regular cutting of the ALC wallboard green bodies is affected is prevented.

Owner:山东恒瑞新型建材有限公司

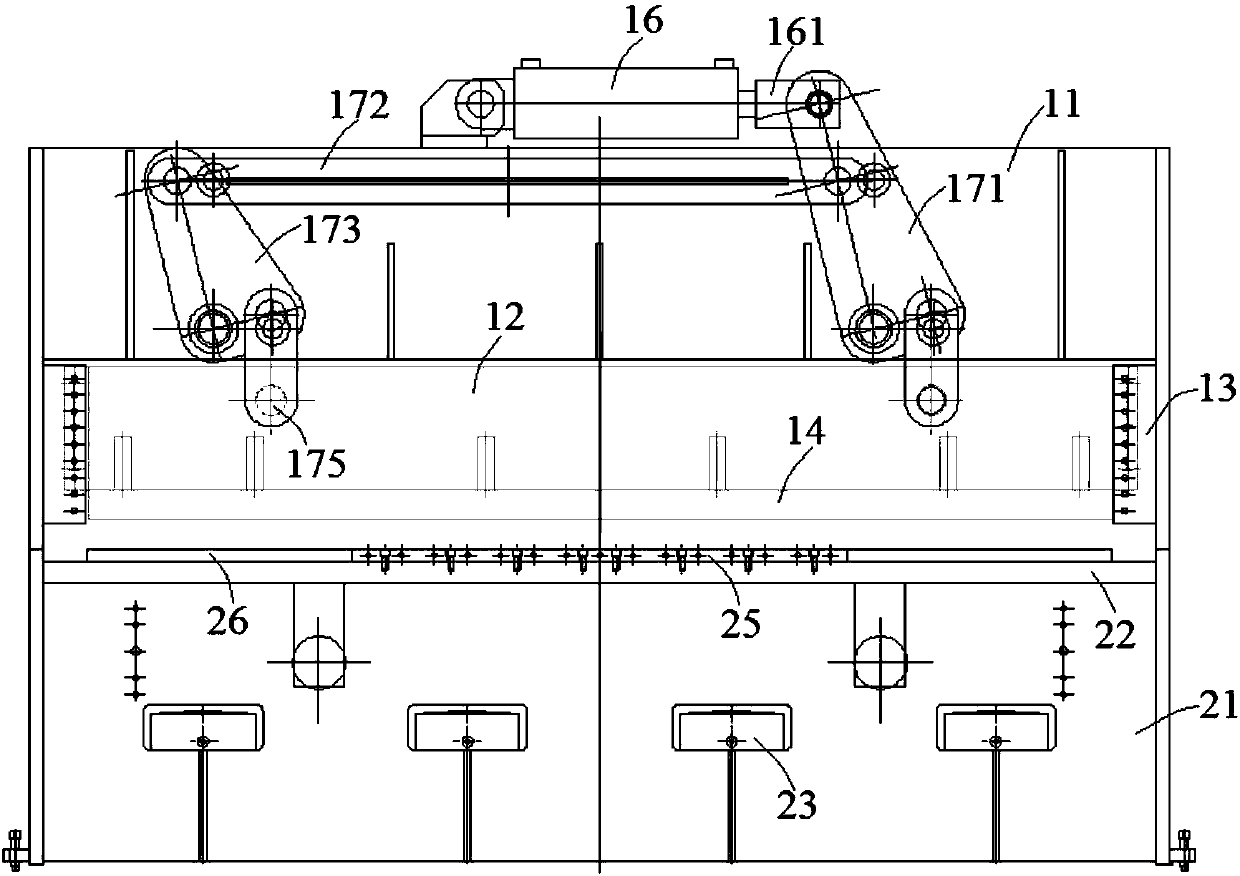

Low-cost container top plate hydraulic forming system

ActiveCN107931389AReduce financial burdenReduce procurement costsShaping toolsMetal-working feeding devicesEngineeringContainer tops

The invention discloses a low-cost container top plate hydraulic forming system and belongs to the field of hydraulic forming. The system comprises an upper box body, upper sliding blocks, upper molds, an upper main oil cylinder, a lower box body, lower main oil cylinders, lower sliding blocks and lower molds. The upper main oil cylinder is arranged at the upper part of the upper box body, and theupper sliding blocks are arranged at the lower part of the upper box body; the upper molds are fixed at the bottom of the upper sliding blocks, and a driving unit is arranged between the upper main oil cylinder and the upper sliding blocks; the upper main oil cylinder drives the upper sliding blocks to move in a vertical direction through the driving unit; and the lower sliding blocks are arranged in the lower box body, the lower portions of the lower sliding blocks are connected with the lower main oil cylinders, the upper portions of the lower sliding blocks are connected with the lower molds, and the lower main oil cylinders drive the lower sliding blocks to move in the vertical direction. The low-cost container top plate hydraulic forming system relates to a special machine designed for a container top plate structure, the cost of equipment purchasing is greatly reduced, and the economic burden of a small-and-medium-sized container top plate production enterprise is reduced.

Owner:安徽金大进重工机床有限公司

Clamp holder with elastic partition plate

InactiveCN105081860ASmooth motionAdjust the range of motionMetal working apparatusInlet valveAir chamber

The invention discloses a clamp holder with an elastic partition plate. The clamp holder with the elastic partition plate can clamp workpieces in various shapes and different sizes and comprises an air chamber wall and a guide base attached to the end face of the air chamber wall. A cavity is formed between the guide base and the air chamber wall. The elastic partition plate is arranged in the cavity and divides the cavity into an air chamber and a containing cavity. The air chamber wall is provided with an air inlet valve communicated with the air chamber. A guide hole is formed in the middle of the guide base. An installation base attached to the elastic partition plate is arranged in the containing cavity. The installation base is fixed to one end of a push rod. The push rod penetrates the guide hole. Reset springs are arranged at the positions, located between the installation base and the inner wall of the guide base, on the periphery of the push rod. Two L-shaped swing claws are arranged on the sides of the guide base. One end of each L-shaped swing claw is a clamping end for the workpieces, the middle of each L-shaped swing claw is hinged to the guide base, and the other end of each L-shaped swing claw is hinged to the other end of the push rod.

Owner:CHONGQING TENGHAN IND & TRADE

Opening frame structure and refrigerating device

ActiveCN107120908AImprove appearance qualityAffect appearance qualityDomestic cooling apparatusLighting and heating apparatusEngineeringInjection molding process

The invention provides an opening frame structure used for a refrigerating device. The refrigerating device comprises a box body. The opening frame structure is arranged at the opening end of the box body and comprises an appearance panel and a first reinforcing rib. A first side plate is arranged on the side, opposite to the outer portion of the box body, of the appearance panel. An arc protrusion is arranged at the position, at the connecting position of the first side plate and the appearance panel, on the outer surface of the appearance panel. The first reinforcing rib is arranged on the inner surface of the appearance panel, and a first insertion groove is formed by the first reinforcing rib and the first side plate. A transition section is arranged at the portion, between the connecting position of the first reinforcing rib and the appearance panel and the arc protrusion, on the outer surface of the appearance panel. The transition section covers the connecting position of the first reinforcing rib and the appearance panel. By means of the opening frame structure and the refrigerating device, due to the fact that the connecting position between the first reinforcing rib and the appearance panel is covered with the transition section, vision transfer can be caused, the problem that the connecting position shrunk in the injection molding process, and consequently the appearance panel is not attractive is effectively avoided, and the appearance quality of the opening frame structure is improved.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +2

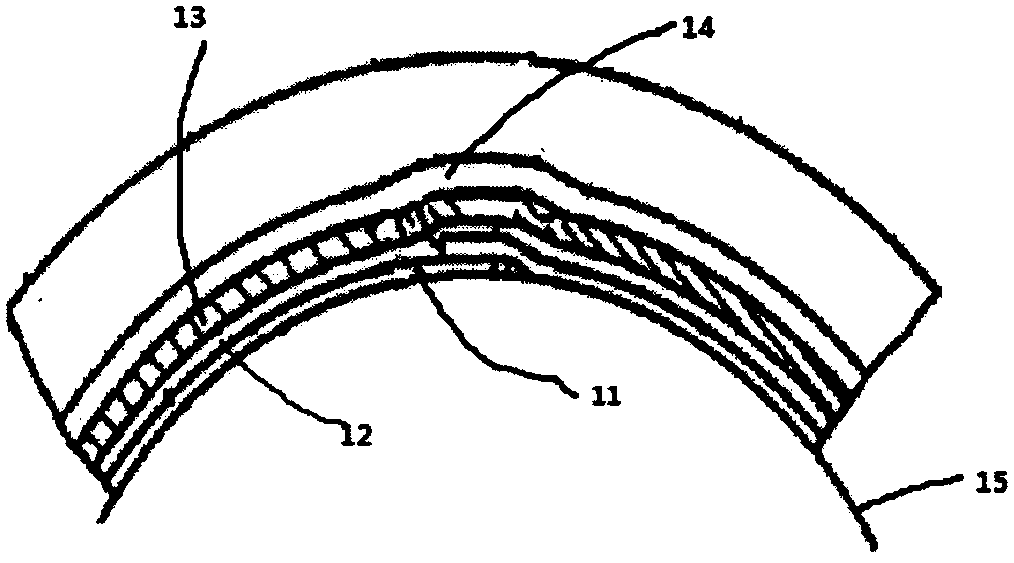

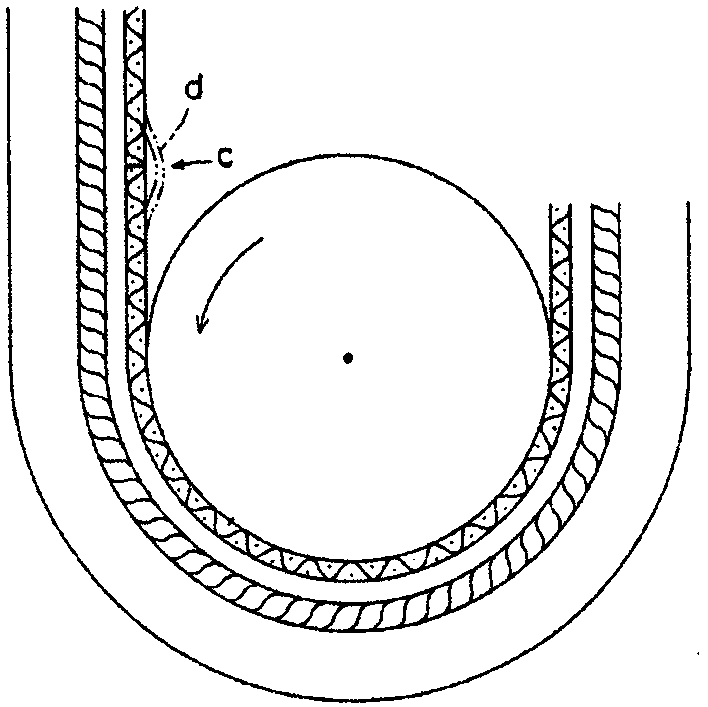

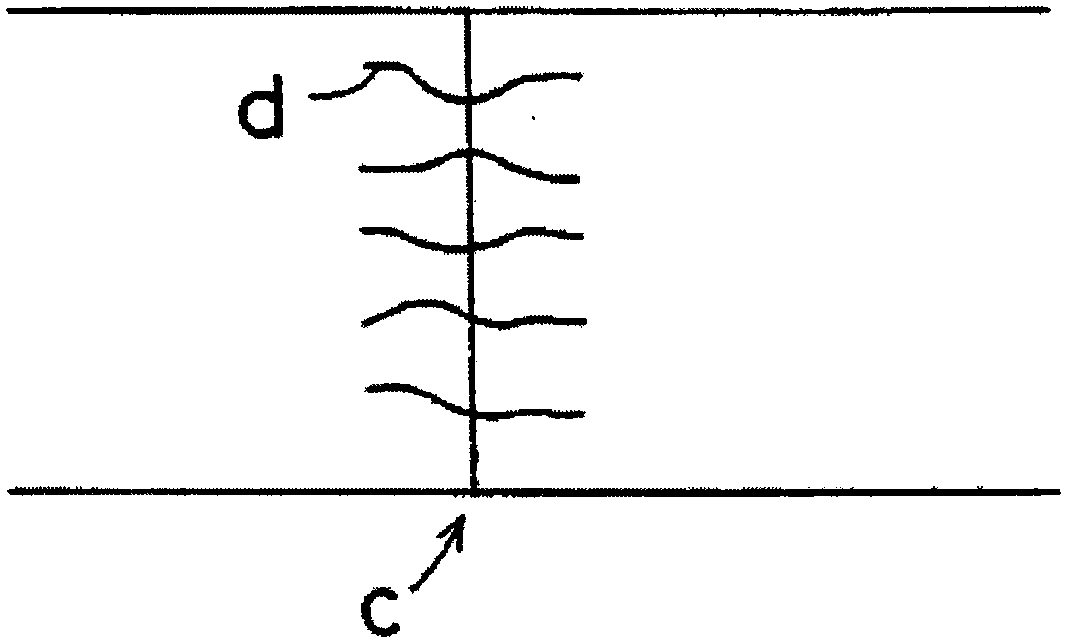

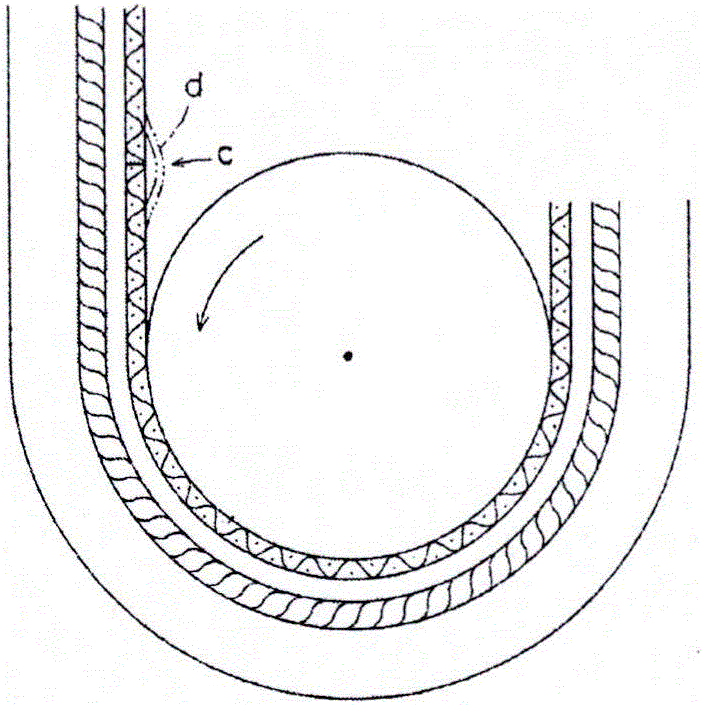

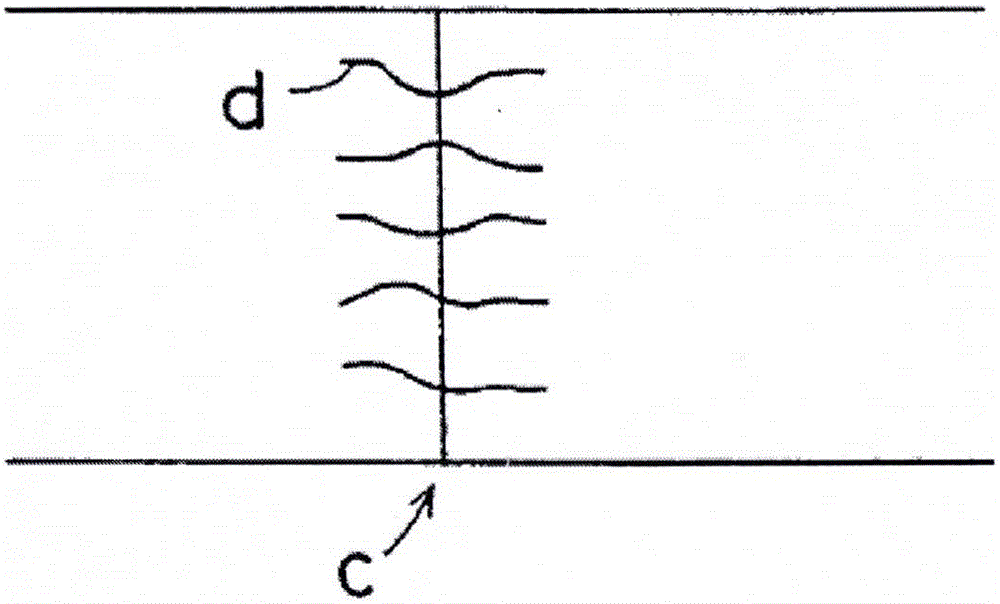

Transmission belt

The inventions provides a driving belt. A fabric layer covers on the back of the driving belt; the fabric layer is provided with a butt joint sewn by threads; the outer surface of the fabric layer is projecting pattern structure rubber, the threads are covered in the projecting pattern structure rubber. Compared with the traditional driving belt with fabric on the back, the driving belt with the structure has better appearance, and the noise is relieved further.

Owner:GATES UNITTA POWER TRANSMISSION (SUZHOU) LIMITED

Method of extracting and preparing mannose from pitaya stems

The invention provides a method of extracting and preparing mannose from pitaya stems, and belongs to the technical field of mannose preparation. The method includes the steps of pitaya stem preprocessing, polysaccharide extraction, polysaccharide deproteinization, polysaccharide decoloration, polysaccharide small-molecule impurity removal, polysaccharide alcohol precipitation and drying, mannoseoligosaccharide preparation, mannose transformation, high-purity mannose preparation, and the like. According to the method of extracting and preparing the mannose from the pitaya stems, pitaya by-products, namely the pitaya stems serve as a raw material, ultrahigh-pressure-assisted hot water extraction is adopted and combined with a modern enzymatic method to prepare pitaya stem polysaccharides,secondary extraction is conducted, and the extraction rate and utilization rate of crude pitaya stem polysaccharides are significantly increased. By adopting a modern bio-enzyme technology and a membrane separation technology, in combination with an organic solvent replacement crystallization method, a mannose crystal product with the purity of 90% or above is directly prepared simply through one-step crystallization without purification, thus, the technology is simple, and the mannose crystal product is easy to produce.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

Preservative film for vegetables and fruits and production process of preservative film

PendingCN107627704AImprove tensile propertiesImprove tear resistanceSynthetic resin layered productsFlat articlesEngineeringPhosphite ester

The invention provides a preservative film for vegetables and fruits. The preservative film comprises a film body, wherein the film body comprises at least three layers of structures and is longitudinally provided with at least one reinforcing bar, a plurality of incisions are formed in two sides of the reinforcing bar and penetrate through the film body; the film body contains the following raw materials in parts by weight: 50-60 parts of polytetrafluoroethylene particles, 50-60 parts of polypropylene particles, 10-20 parts of polyethylene particles, 10-20 parts of poly-p-phenylene terephthamide, 1-5 parts of phosphite ester powder and 1-5 parts of sodium alginate powder. The invention further provides a production process of the preservative film. The preservative film is formed by virtue of multi-layer coextrusion, a closed structure of the preservative film in the past is changed, the vegetables and the fruits in a package are in communication with external gas and moisture, and gas and moisture generated by the vegetables and the fruits are discharged, so that the preservation periods of the vegetables and the fruits are prolonged.

Owner:JIASHAN HENGYU PLASTIC

Storage and fresh-keeping method for fresh peanuts

InactiveCN110353040APrevent moisture lossSmell and Nutritional Value GuaranteedSeed preservation by freezing/coolingSeed preservation by dryingWater contentNutrient

The invention belongs to the technical field of food processing, and discloses a storage and fresh-keeping method for fresh peanuts. The method comprises the steps that fresh peanuts are sterilized; shells of the fresh peanuts are dried to control the water content of the shells of the fresh peanuts less than or equal to 8% and the water loss rate of peanut kernels less than or equal to 5%; the fresh peanuts are placed in an environment with a humidity larger than or equal to 85% and a temperature of 3-8 DEG C for storage. The method has the advantages that no food preservative needs to be adopted for preservative treatment of the fresh peanuts, which not only avoids toxicity hazards of chemical preservatives, but also the human health and environmental protection are facilitated; the color, flavor, taste and nutrient compositions of the peanuts themselves can also be effectively retained, inconvenience and troubles brought by a traditional process are solved, a big problem is solved for traditional delicious boiled peanuts, the needs of broad consumers are met, and the market application prospects are broad.

Owner:王清

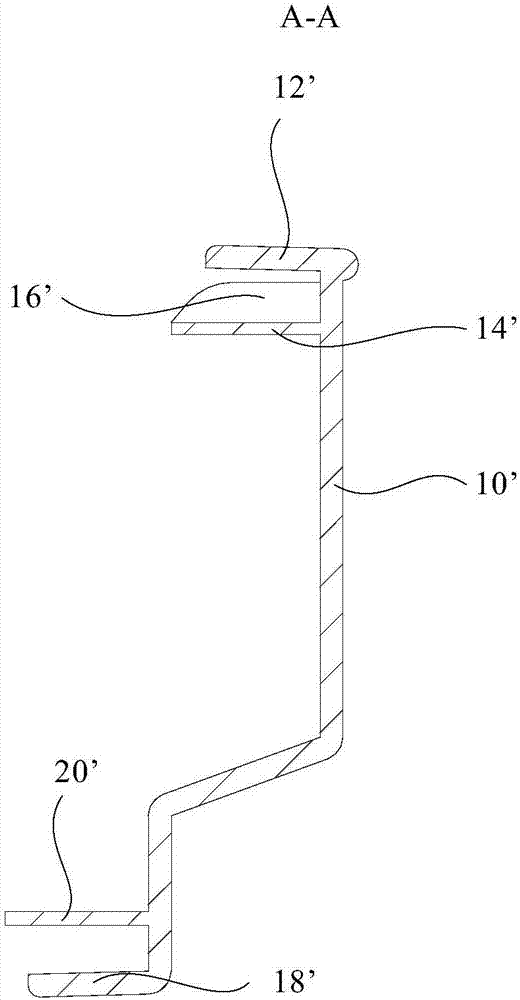

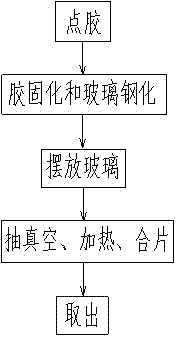

Manufacturing method and manufacturing equipment of vacuum glass

InactiveCN107540248AAffect appearance qualityHigh bonding strengthGlass tempering apparatusVitreous BodiesWarming process

The invention provides a manufacturing method and manufacturing equipment of vacuum glass. The manufacturing method comprises the following steps of A, glue dotting on a first glass sheet; B, glue curing and glass tempering; C, placing of the glass sheet; D, vacuum sucking, heating, and sheet closing; E, fetching out. The manufacturing method has the advantages that while the first glass is tempered, the glass powder glue, blocking glue and fulcrum glue are cured, and the glass tempering and the glue curing are simultaneously completed, so that the technology steps are simplified, the preparation time is shortened, and the adhering strength between the glass powder glue, the blocking glue as well as the fulcrum glue and the first glass is improved; by respectively arranging heating bodiesat the upper part and lower part, the heating speed of each glass body is favorably improved; the heat is transferred to the glass in a contact heating way, so that the heat loss is reduced, and the energy-saving effect is realized; the uniform change of temperature at each part of the glass sheet is favorably guaranteed in the heating process; by arranging the blocking glue, the influence to theappearance quality of the vacuum glass due to the flowing of the melting glass power glue to the interior in a tempering furnace is avoided.

Owner:张艳乡

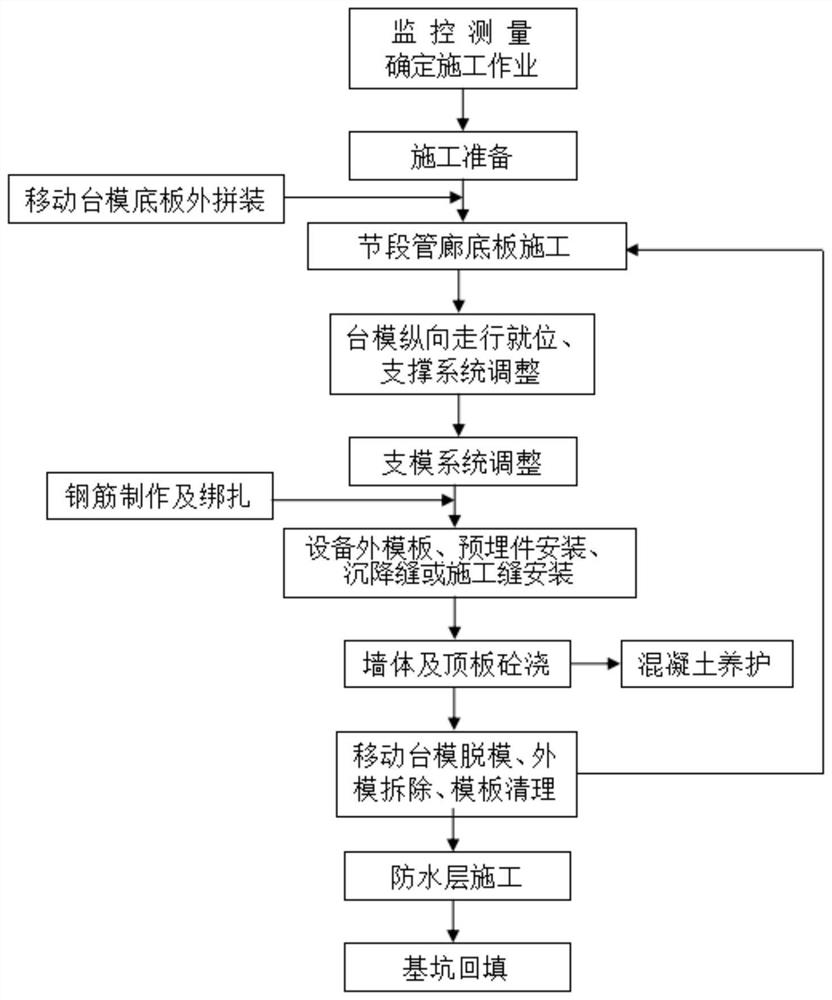

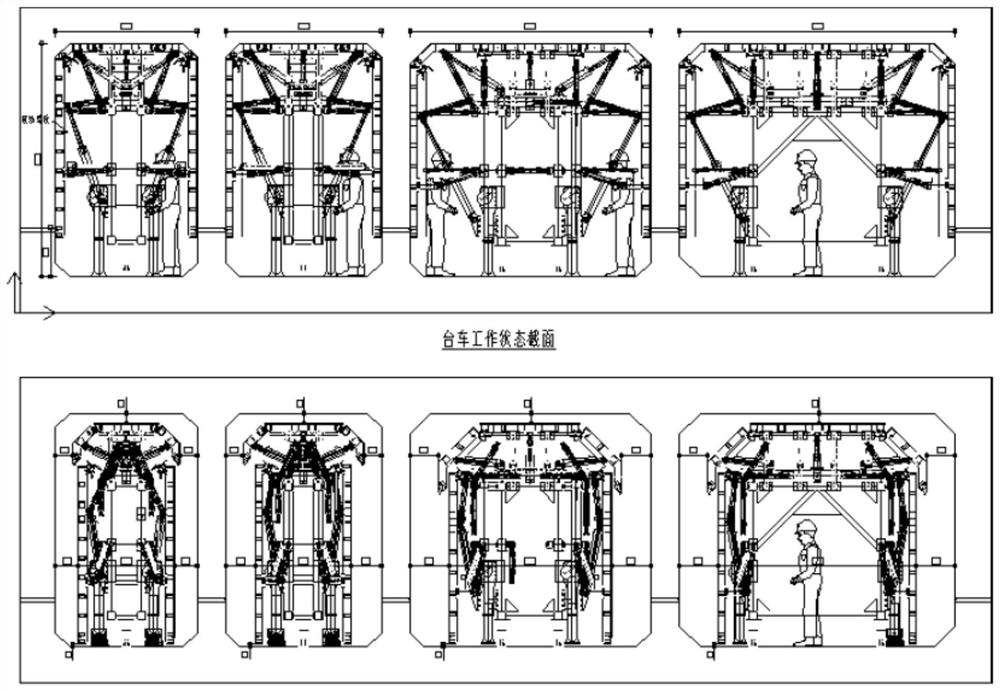

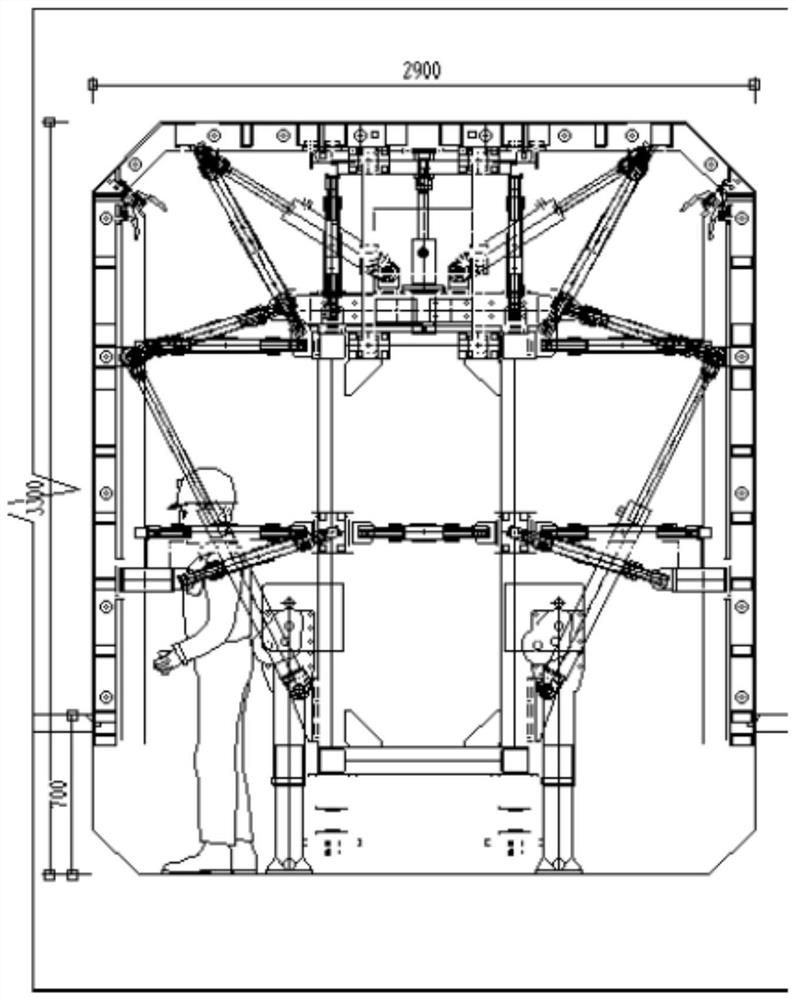

Open-cut cast-in-place underground comprehensive pipe gallery movable bench formwork integrated construction method

PendingCN114875969AImprove integrityImprove stabilityArtificial islandsProtective foundationSocial benefitsFalsework

The invention discloses an open-cut cast-in-place underground comprehensive pipe gallery movable bench formwork integrated construction method. The method comprises the following steps that S1, construction operation is determined through monitoring measurement; s2, construction preparation is conducted, and movable bench formwork bottom plates are externally spliced; s3, construction of a bottom plate of the segment pipe gallery; s4, a formwork system is adjusted, and steel bars are manufactured and bound; s5, an equipment outer formwork and an embedded part are installed, and a settlement joint or a construction joint is installed; s6, wall body and bottom plate concrete pouring is conducted, and concrete is cured; s7, the movable bench formwork is demolded, the outer formwork is dismantled, and the formwork is cleaned; step S8, constructing a waterproof layer; step S9, backfilling the foundation pit; by the adoption of the overall supporting and disassembling construction technology of the movable bench formwork, repeated assembling and disassembling of a top plate scaffold and a formwork are avoided, the effect is improved, the construction period is greatly shortened, and the method has obvious social benefits and economic benefits and has application and popularization value.

Owner:中铁大桥局第九工程有限公司

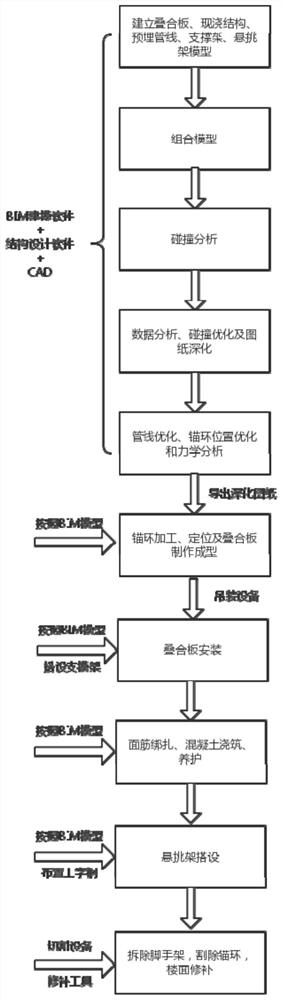

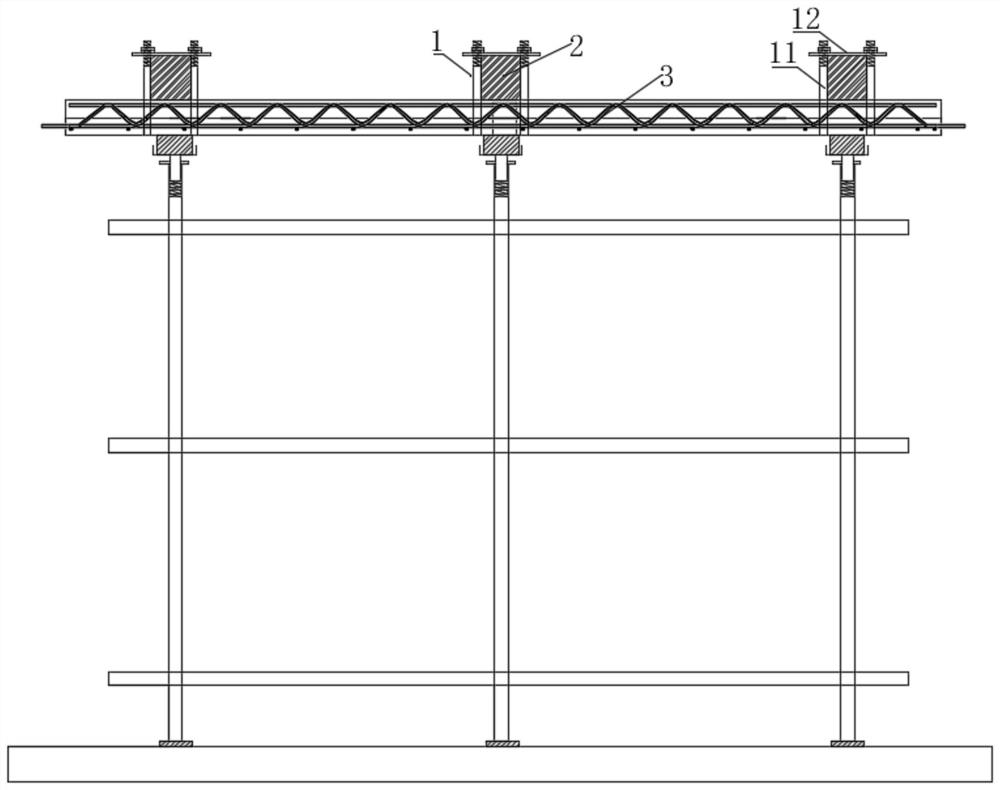

Laminated slab cantilever I-shaped steel construction method based on BIM (Building Information Modeling) technology

InactiveCN113216487AReduce structural safety hazardsAvoid collisionGeometric CADFloorsFloor slabCollision analysis

The invention relates to the field of construction engineering technology, and particularly discloses a laminated slab cantilever I-shaped steel construction method based on the BIM (Building Information Modeling) technology. The laminated slab cantilever I-shaped steel construction method based on the BIM technology specifically comprises the steps of establishing models; combining the models; performing collision analysis; according to the design scheme of a cantilever frame, calculating the stress of an anchor ring, and accurately placing the anchor ring to serve as a reference object of a laminated slab model; establishing a laminated slab supporting frame and a cast-in-place belt formwork model, optimizing the positions of vertical rods and supporting beams, enabling the vertical rods of the supporting frame at the anchor ring position to be arranged in an infilling mode, and achieving an jacking effect on a floor slab; performing data analysis and collision optimization; S5, processing, positioning, manufacturing and forming; mounting a laminated slab; binding upper side rebars, pouring concrete, and curing; and erecting the cantilever frame. According to laminated slab cantilever I-shaped steel construction method based on the BIM technology provided by the invention, collision with reinforcing steel bars, embedded pipelines and plate bottom keels can be effectively avoided, the construction efficiency is improved, and waste of manpower, financial resources and time is avoided.

Owner:CHINA MCC5 GROUP CORP

Method for improving appearance quality of inertial porcelain ball

The invention discloses a method for improving appearance quality of an inertial porcelain ball, and belongs to the technical field of novel materials. The method disclosed by the invention divides conventional ball-billet rolling process into two stages, wherein in the first stage, ingredients are grinded by a dry method or a wet method to roll the ball-billet till the size of the ball-billet is 1-3mm smaller than target size; and in the second stage, powder compounded by dry and wet grinding is adopted, and based on the ball-billet formed in the first stage, auxiliary materials are added to prepare compound powder based on the dry or wet grinded powder, and a novel surface wrapping layer is formed by rolling. Practices show that the method can solve the problem of ball layering in production of the inertial ball by the wet method ball-milling process and surface blistering after calcining. The method solves the problem that the degree of sphericity of the product in production of the inertial ball by the wet method ball-milling process is insufficient, and cracks are easy to generate after calcining. In addition, detection shows that the integral physical property of the product is further improved while the appearance quality of the inertial porcelain ball is improved at the same time.

Owner:JINGANG NEW MATERIALS

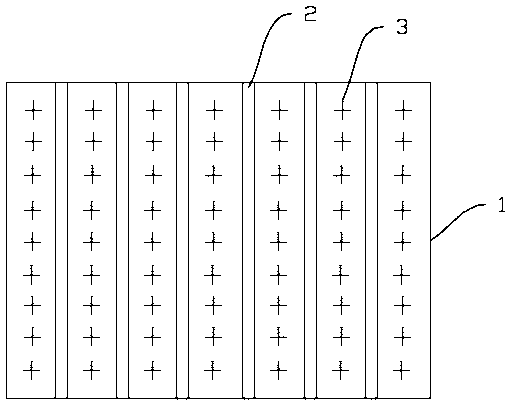

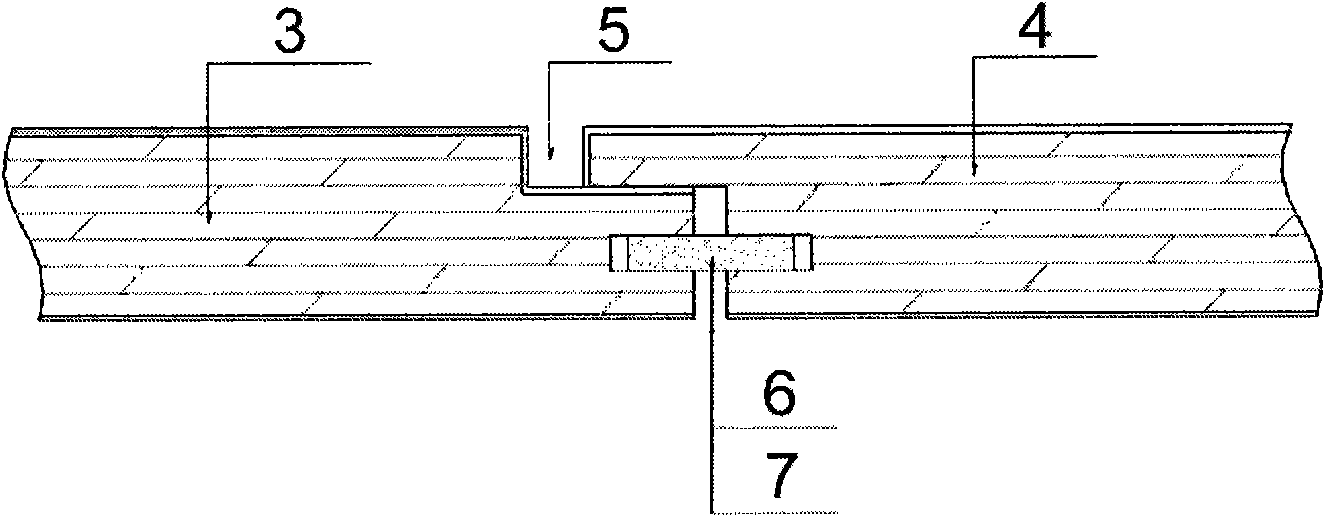

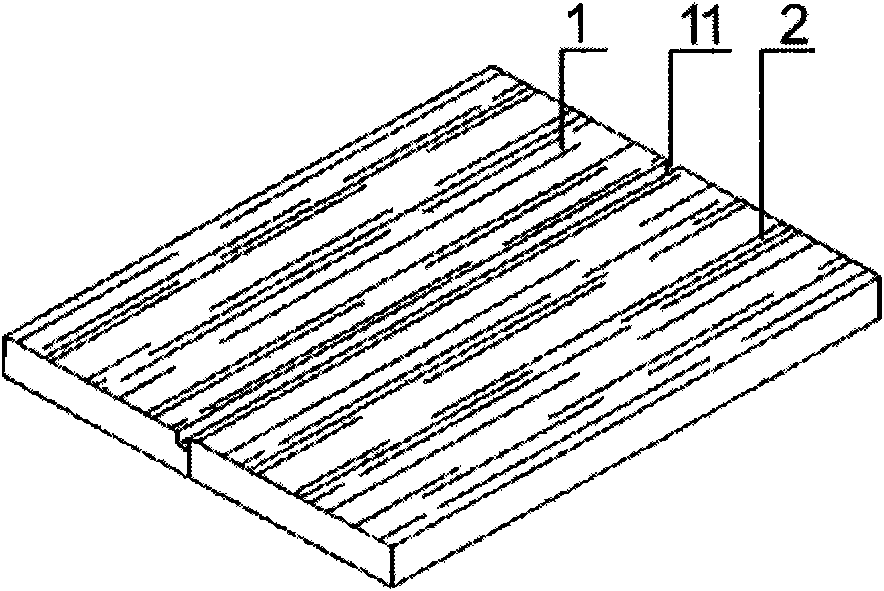

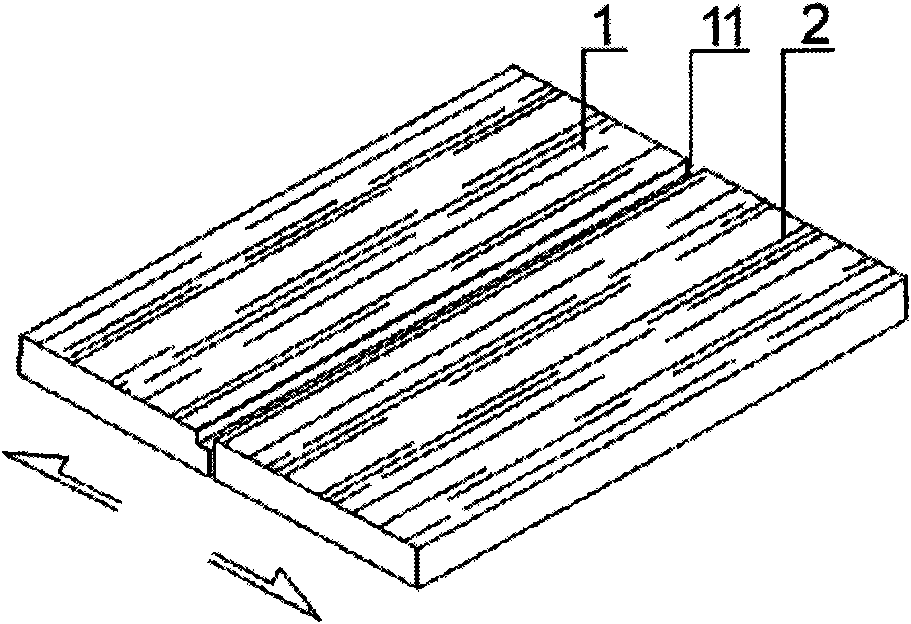

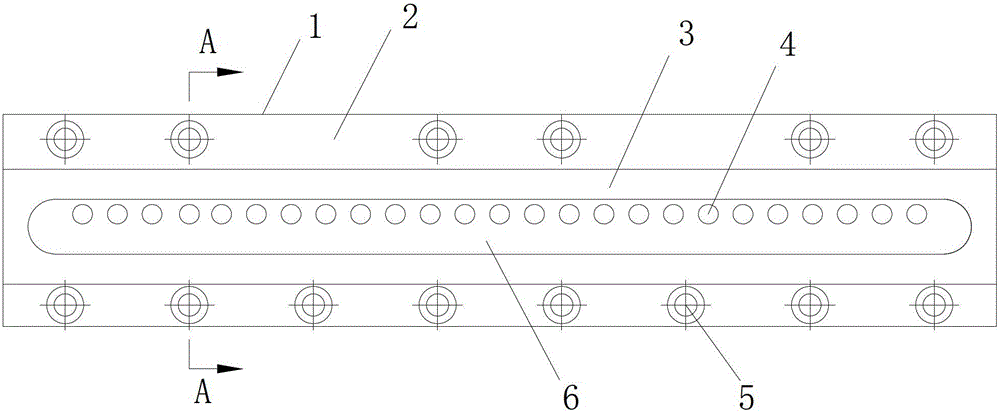

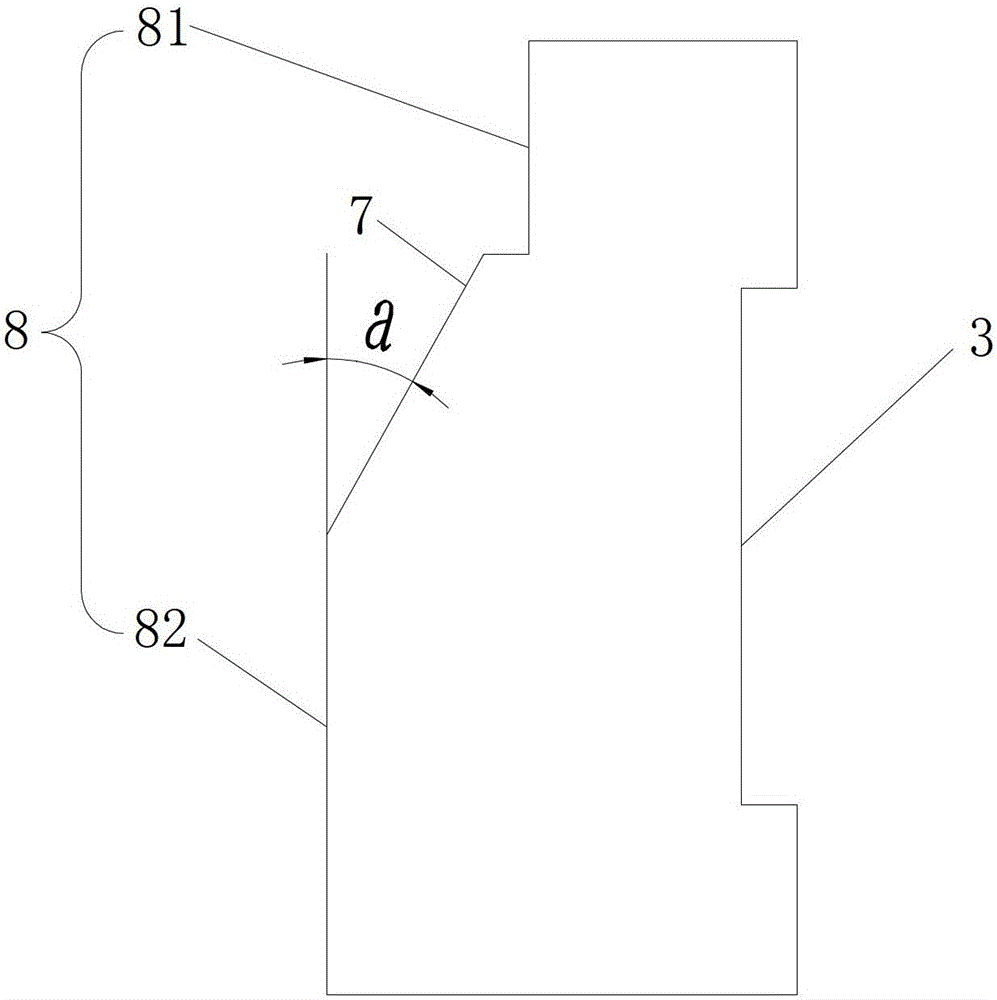

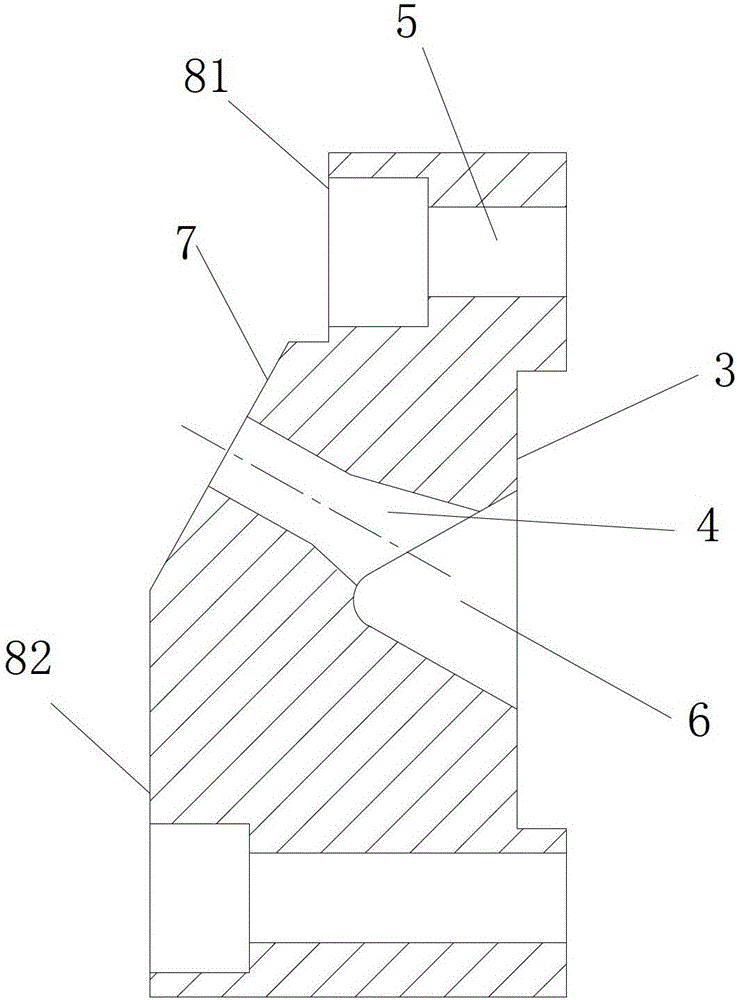

Wood veneer joint interface structure

ActiveCN102182285BAffect appearance qualitySolve the problem of uneven splicingCovering/liningsWood veneerPulp and paper industry

The invention discloses a wood veneer joint interface structure. The wood veneer joint interface structure comprises a wood veneer I (3) and a wood veneer II (4); the end face, jointed with the wood veneer II (4), of the wood veneer I (3) is provided with a convex part; the wood veneer II (4) is correspondingly provided with a concave part matched with the convex part; the wood veneer I (3) is lapped with the wood veneer II (4) by staggering the convex part and the concave part; a process seam (5) is reserved between the wood veneer I (3) and the wood veneer II (4); and the process seam (5) is positioned on the right side of the wood veneer. The wood veneer joint interface structure can effectively overcome open joint or bottom exposure of the wood veneers due to drying shrinkage, and caneffectively solve the quality problems of irregular joint and the like caused by warping deformation of the wood veneers so as to ensure integral appearance effects of the wood veneers.

Owner:GOLD MANTIS CONSTR DECORATION

A combined die

Owner:KINGFA SCI & TECH CO LTD +1

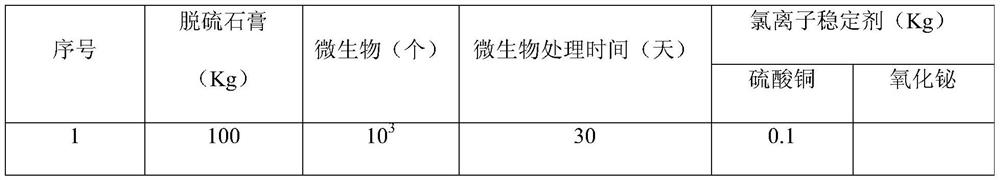

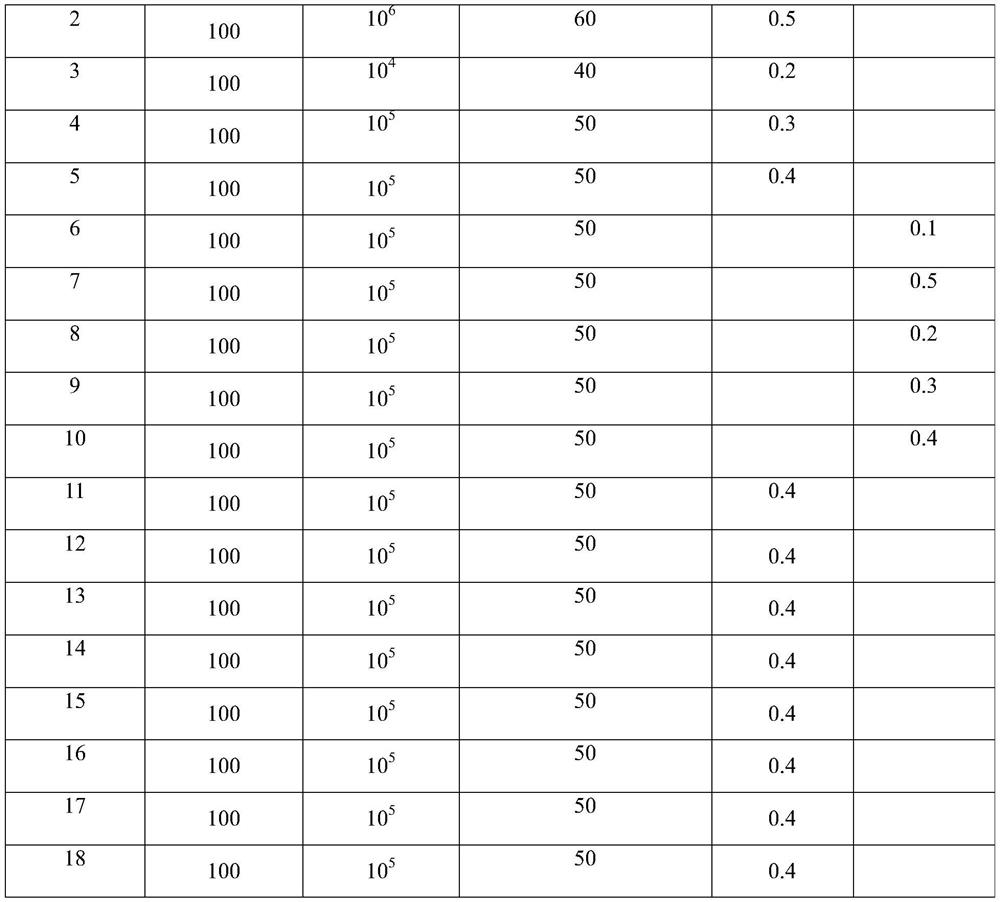

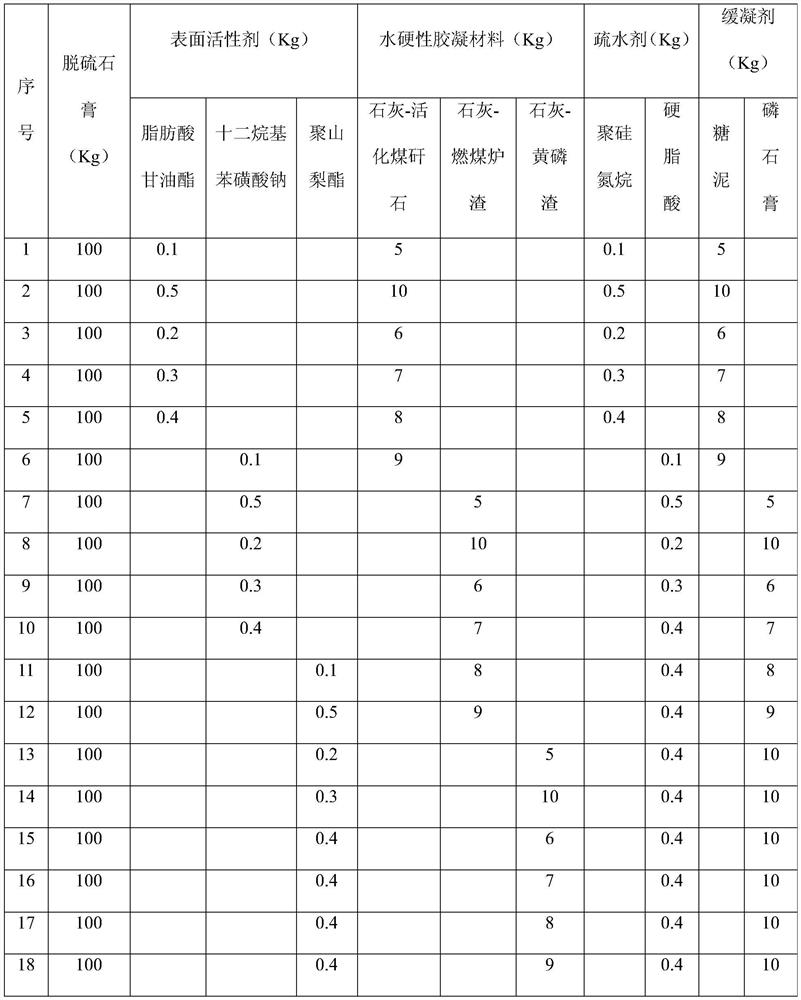

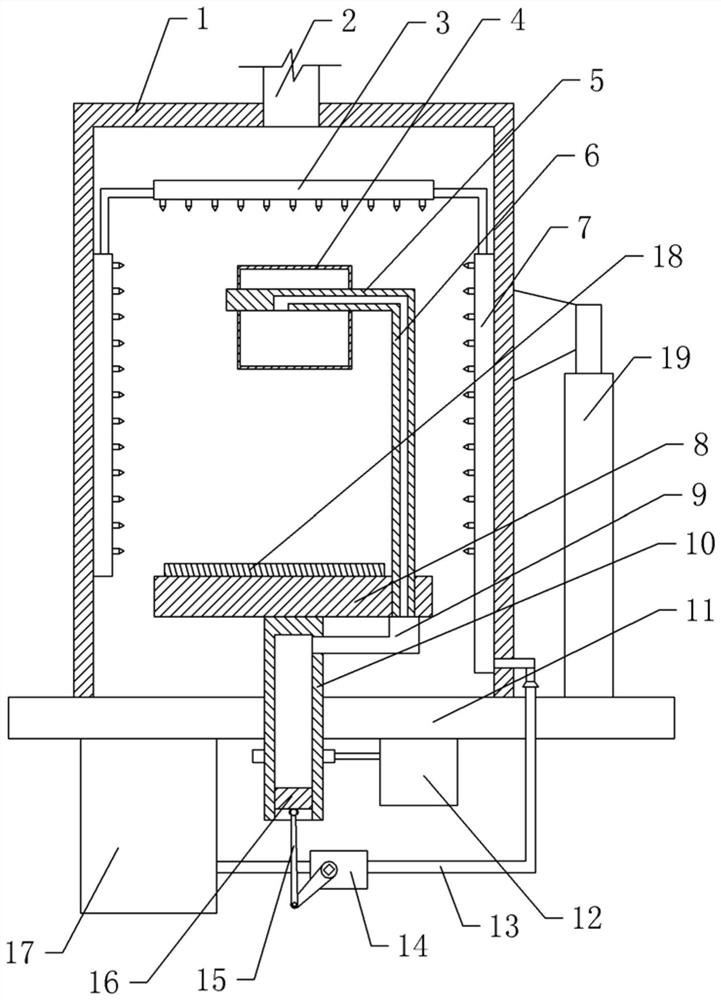

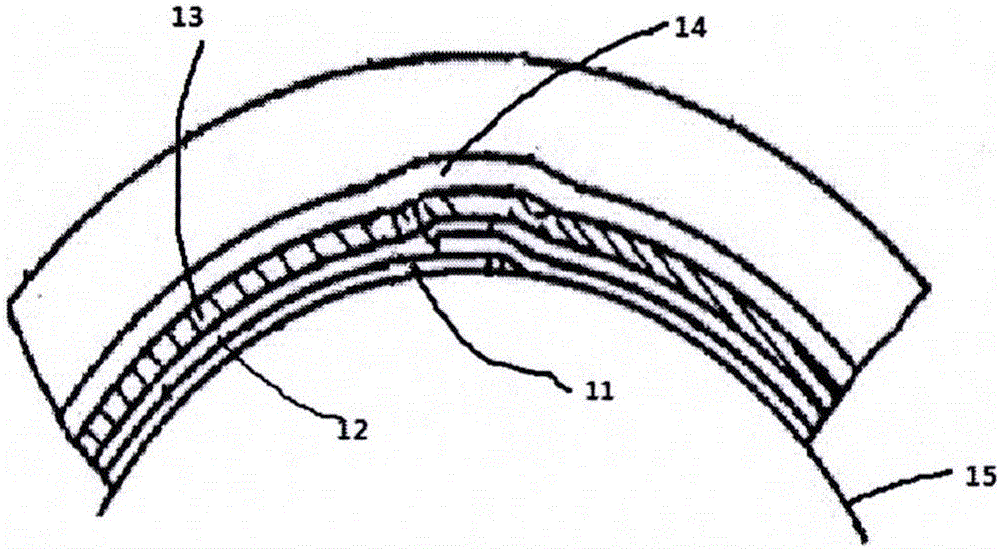

A kind of preparation method of nano desulfurization gypsum artificial board

The patent discloses a preparation method of a nano desulfurization gypsum artificial board. The method includes: 1) adding microorganisms to the desulfurization gypsum for treatment, and adding a chlorine ion stabilizer to prepare pretreated desulfurization gypsum; 2) recrystallizing the pretreated desulfurization gypsum to obtain quasi-spherical hemihydrate gypsum crystal; 3) adding a surfactant, a hydraulic cementing material, a water repellent agent, and a retarder to the hemihydrate gypsum crystal with uniform mixing to obtain dry powder; 4) adding a solvent to the dry powder, uniformly stirring the mixture, pouring the mixture into a mould in which a gridding cloth is laid; 5) maintaining the mixture in a maintenance chamber, and demolding the mixture to produce the nano desulfurization gypsum artificial board. The method utilizes industrial wastes and is high in product additional value.

Owner:新疆昌吉职业技术学院

The spray painting method of the desk

ActiveCN107999346BAffect appearance qualityPrevent sprayingLiquid surface applicatorsCoatingsWorking environmentElectric machinery

The invention belongs to the technical field of spraying methods, and particularly provides a painting method for a desk. The painting method for the desk comprises the following steps of A, injectingpaint; B, placing the desk on a rotary table; C, covering the desk with a cover body; D, closing a pressure relief valve, starting a negative-pressure fan to form negative pressure in the cover body,and expanding an elastic airbag to fill a storage cavity of the desk; E, driving the desk to rotate through the rotary table and painting the desk through a painting mechanism; F, stopping a motor, and then opening the pressure relief valve to increase the air pressure in the cover body; and G, stopping the negative-pressure fan, moving the cover body away, and taking down the desk from the rotary table. By adoption of the painting method for the desk, the problem that in the prior art, when a desk is painted, paint is likely to fly everywhere and consequentially affects the working environment is solved.

Owner:CHONGQING JIANLONG FURNITURE CO LTD

Driving belt

The inventions provides a driving belt. A fabric layer covers on the back of the driving belt; the fabric layer is provided with a butt joint sewn by threads; the outer surface of the fabric layer is projecting pattern structure rubber, the threads are covered in the projecting pattern structure rubber. Compared with the traditional driving belt with fabric on the back, the driving belt with the structure has better appearance, and the noise is relieved further.

Owner:GATES UNITTA POWER TRANSMISSION (SUZHOU) LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com