Preservative film for vegetables and fruits and production process of preservative film

A technology for plastic wrap, vegetables and fruits, applied in the field of plastic film, can solve problems such as the inability to guarantee the size, quantity and distribution of micropores, difficulties in the production process of microporous plastic wrap, limited tensile and tear strength, etc., and achieve good catalytic effect , Improve tensile and tear resistance, avoid static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

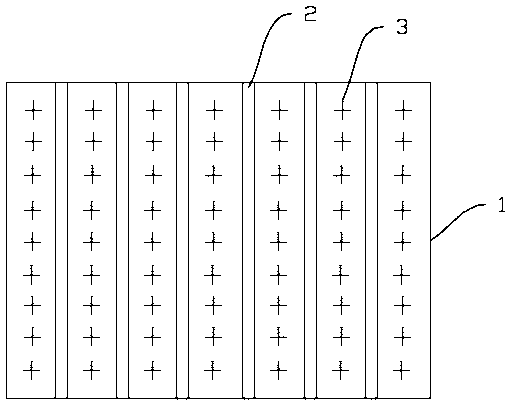

Image

Examples

Embodiment 1

[0039] First, put 50 parts of polytetrafluoroethylene particles, 10 parts of polyethylene particles, 10 parts of poly-p-phenylene terephthalamide particles, 2 parts of phosphite powder, and 1 part of sodium alginate powder into the reactor, and react The temperature of the kettle is controlled at 130°C, and the polytetrafluoroethylene particles, polyethylene particles, poly-p-phenylene terephthalamide particles, phosphite powder and sodium alginate powder are mixed to form a mixed raw material; then three Each part of the screw extruder was heated and preheated, the preheating temperature was 95°C, and the preheating time was 30 minutes; Extrusion process is carried out on the mixed raw materials at high temperature. The heating zone includes the fuselage, machine neck and machine head. The fuselage includes four heating zones. The temperature of the first zone is 170°C, and the temperature of the second zone is 180°C. , the temperature in the third zone is 185°C, the temperat...

Embodiment 2

[0041] First, put 55 parts of polytetrafluoroethylene particles, 15 parts of polyethylene particles, 15 parts of poly-p-phenylene terephthalamide particles, 2 parts of phosphite powder, and 1 part of sodium alginate powder into the reactor, and the reaction The temperature of the kettle is controlled at 130°C, and the polytetrafluoroethylene particles, polyethylene particles, poly-p-phenylene terephthalamide particles, phosphite powder and sodium alginate powder are mixed to form a mixed raw material; then three Each part of the screw extruder was heated and preheated, the preheating temperature was 95°C, and the preheating time was 30 minutes; Extrusion process is carried out on the mixed raw materials at high temperature. The heating zone includes the fuselage, machine neck and machine head. The fuselage includes four heating zones. The temperature of the first zone is 170°C, and the temperature of the second zone is 180°C. , the temperature in the third zone is 185°C, the t...

Embodiment 3

[0043] First, put 60 parts of polytetrafluoroethylene particles, 20 parts of polyethylene particles, 20 parts of poly-p-phenylene terephthalamide particles, 2 parts of phosphite powder, and 1 part of sodium alginate powder into the reactor, and react The temperature of the kettle is controlled at 130°C, and the polytetrafluoroethylene particles, polyethylene particles, poly-p-phenylene terephthalamide particles, phosphite powder and sodium alginate powder are mixed to form a mixed raw material; then three Each part of the screw extruder was heated and preheated, the preheating temperature was 95°C, and the preheating time was 30 minutes; Extrusion process is carried out on the mixed raw materials at high temperature. The heating zone includes the fuselage, machine neck and machine head. The fuselage includes four heating zones. The temperature of the first zone is 170°C, and the temperature of the second zone is 180°C. , the temperature in the third zone is 185°C, the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com