A kind of preparation method of nano desulfurization gypsum artificial board

A technology for desulfurizing gypsum and wood-based panels, applied in the field of wood-based panels, can solve problems such as occupying land and polluting the environment, and achieve the effects of low cost, enhanced water resistance, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with specific examples.

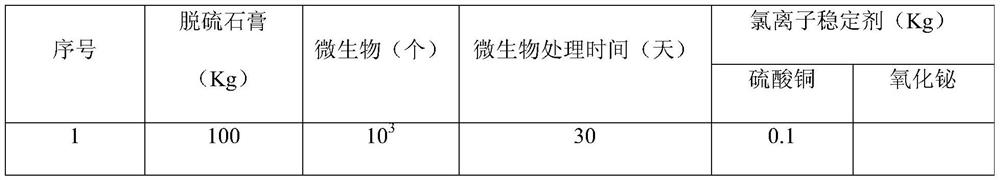

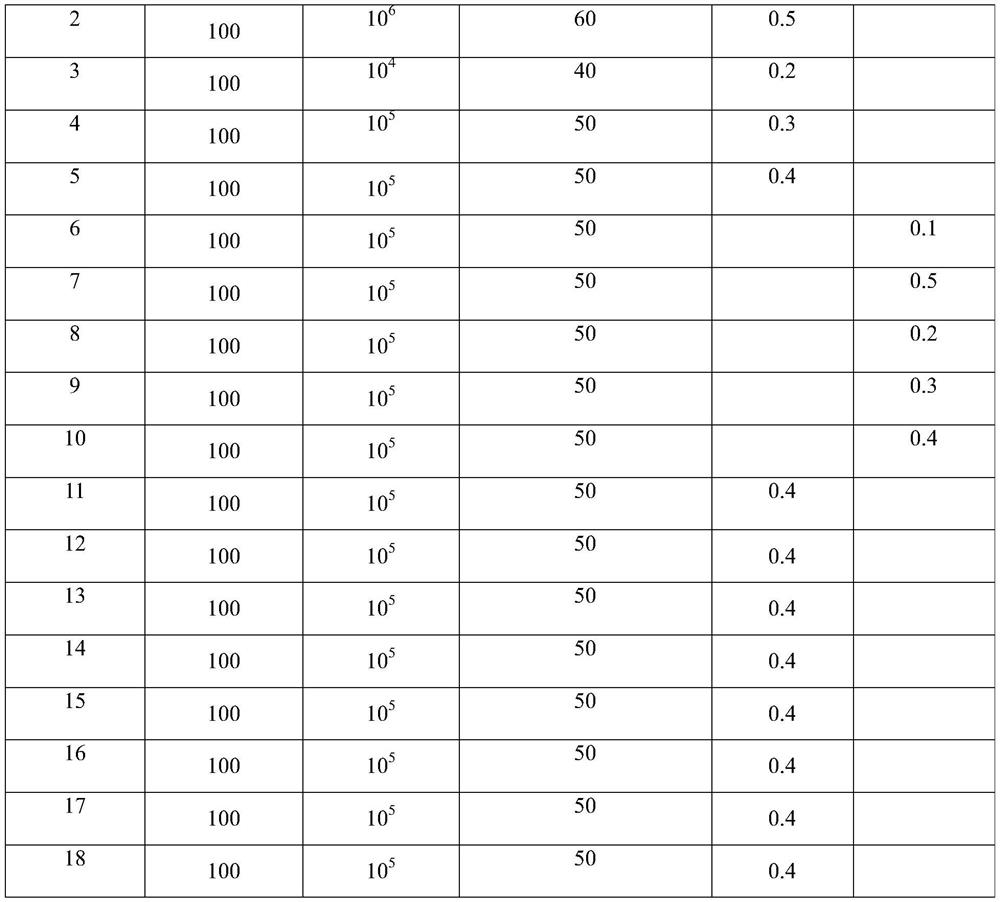

[0019] After adding microorganisms to the desulfurized gypsum, adding a chloride ion stabilizer to obtain pretreated desulfurized gypsum; recrystallizing the pretreated desulfurized gypsum to obtain spherical hemihydrate gypsum crystals. Table 1 lists 18 pretreatment examples numbered 1-18.

[0020] Table 1

[0021]

[0022]

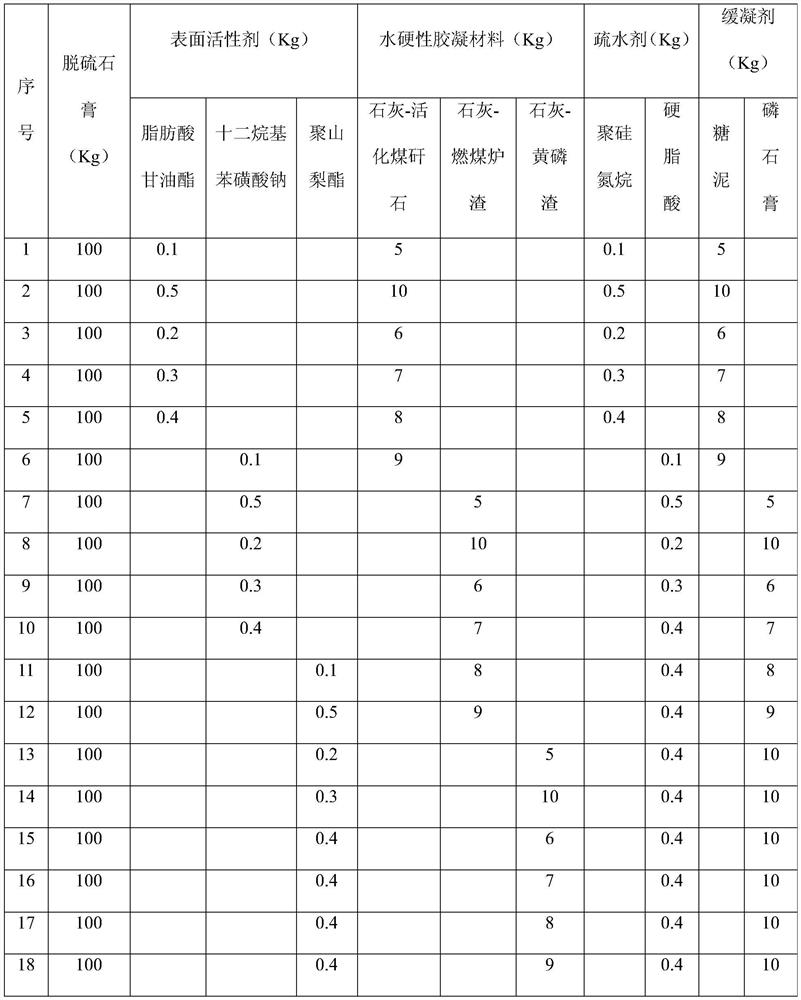

[0023] A surfactant, a hydraulic gelling material, a hydrophobic agent, and a setting retarder are added to the hemihydrate gypsum crystals, and the dry powder is obtained after mixing evenly. Table 2 lists 18 examples of dry powder formulations numbered 1-18.

[0024] Table 2,

[0025]

[0026] Add a solvent to the dry powder, stir evenly, pour it into a model covered with mesh cloth, and after curing in a curing room, demould to obtain a nano-desulfurized gypsum wood-based panel. Table 3 lists 18 examples of wood-based panel mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com