Driving belt

A technology of transmission belt and rubber layer, which is applied in the field of transmission belt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

[0025] The drive belt of the present invention is an example of a V-belt, but it is not limited thereto, it can also be a synchronous belt or a V-belt.

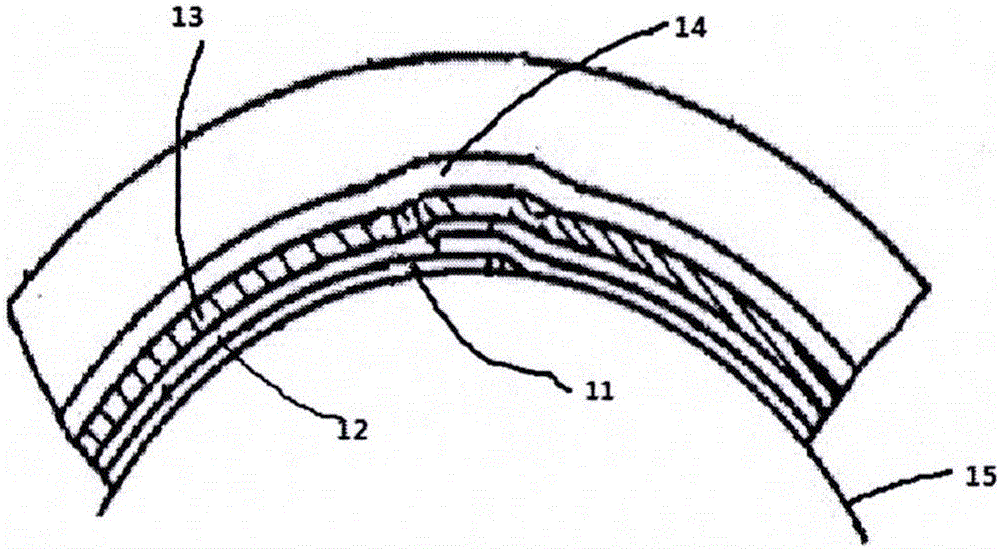

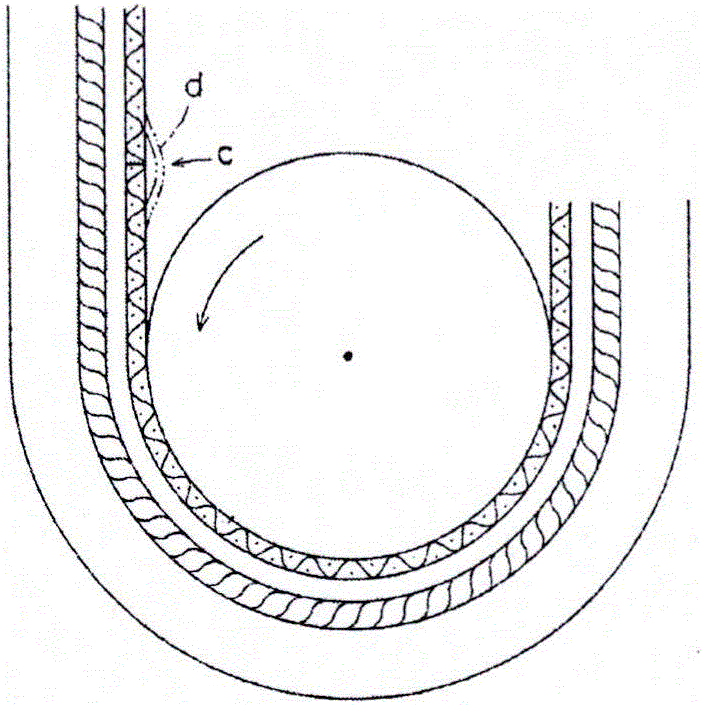

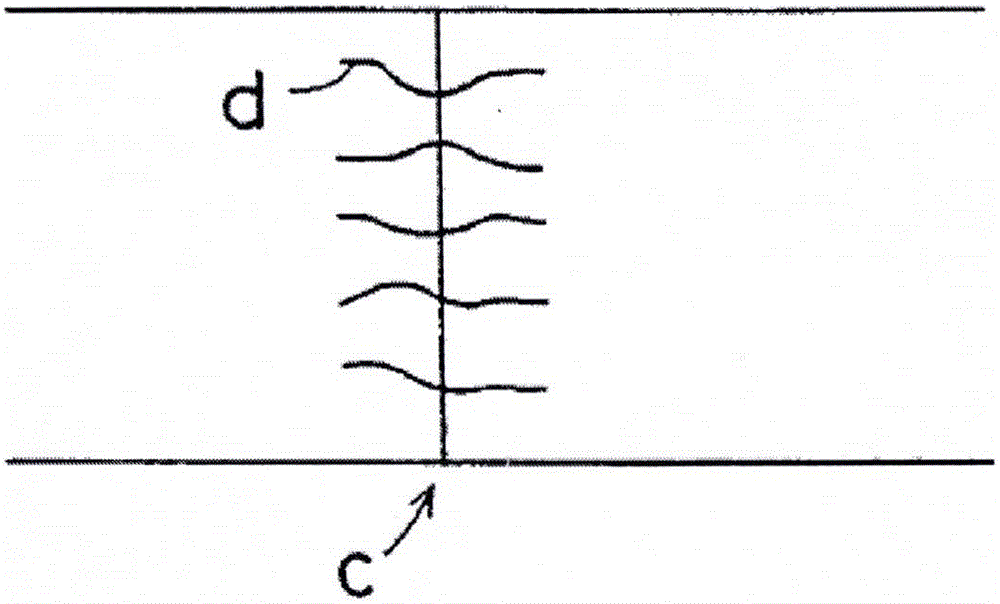

[0026] Such as Figure 4 The V-ribbed belt shown comprises a bottom rubber layer 1, an adhesive rubber layer 5, a tensile cord 2 embedded in the adhesive rubber layer and a back fabric layer 4 bonded to the back of the adhesive rubber layer 5, as image 3 As shown, the fabric layer has a butt joint c sewn with stitching d, and the bottom rubber layer 1 has at least one rib extending along the length of the belt.

[0027] The rubber of the bottom rubber layer and the adhesive rubber layer can be made of the same rubber or different rubbers, and the rubber layer can be made of, for example, hydrogenated nitrile rubber, chloroprene rubber, EPDM rubber, etc. in the prior art. Or several kinds o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com