Method for improving appearance quality of inertial porcelain ball

A technology of appearance quality and inert ceramic balls, which is applied in the field of new materials, can solve problems such as easy cracks and insufficient sphericity, and achieve the effects of reducing scrap rate, solving surface cracks, and reducing appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

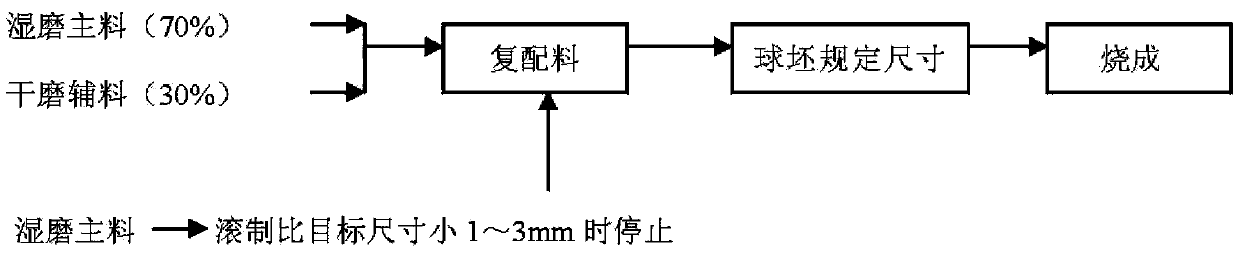

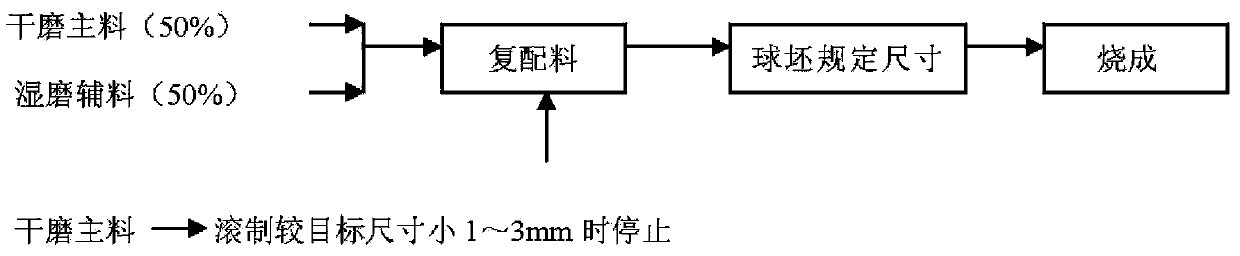

Method used

Image

Examples

Embodiment 1

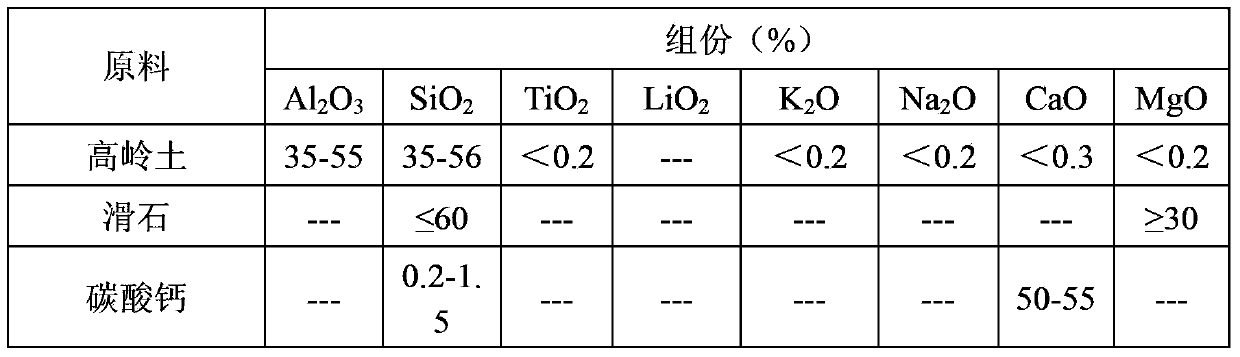

[0042] (1) Main ingredients (parts by weight): 88 parts of industrial alumina powder, 5 parts of kaolin; composite sintering aids (parts by weight): 2 parts of calcium carbonate, 2.5 parts of talc, 2.5 parts of spodumene, using wet ball milling process Ball milling: glass balls are used as the grinding medium, and the mass ratio of material: ball: water = 1:2.5:0.5.

[0043] (2) Auxiliary materials (parts by weight): 68 parts of industrial alumina powder, 20 parts of calcined alumina powder, 5 parts of kaolin; composite sintering aids (parts by weight): 2 parts of calcium carbonate, 2.5 parts of talc, 2.5 parts of spodumene ;

[0044](3) The auxiliary materials and composite sintering aids in step (2) are put into a continuous ball mill for dry grinding. The ball milling process parameters are as follows: use glass balls as the grinding medium, and the material ratio by mass: balls = 1:3, ball mill cylinder The length is 7.48m, the diameter of the cylinder is 1.5m, and the ou...

Embodiment 2

[0050] (1) Main ingredients (parts by weight): 89 parts of industrial alumina powder, 7 parts of kaolin; composite sintering aids (parts by weight): 2 parts of calcium carbonate, 1.5 parts of talc, 0.5 parts of spodumene; wet grinding by traditional technology . Glass ball stone is used as the grinding medium, and the mass ratio of material: ball: water = 1:3:0.5.

[0051] (2) Auxiliary materials (parts by weight): 69 parts of industrial alumina powder, 20 parts of calcined alumina powder, 7 parts of kaolin; composite sintering aids: 1 part of calcium carbonate, 1.5 parts of talc, 1.5 parts of spodumene;

[0052] (3) The auxiliary materials and composite sintering aids in step (2) are put into a continuous ball mill for dry grinding. The ball milling process parameters are as follows: use glass balls as the grinding medium, and the material ratio by mass: balls = 1:3, ball mill cylinder The length is 7.48m, the diameter of the cylinder is 1.5m, and the output is 2-3 tons per ...

Embodiment 3

[0058] (1) Main ingredients (parts by weight): 75 parts of industrial alumina powder, 21.5 parts of kaolin; composite sintering aids (parts by weight): 1 part of calcium carbonate, 1.5 parts of talc, 1 part of spodumene; dry grinding by traditional technology . Glass ball stone is used as the grinding medium, and the mass ratio of material:ball=1:2.8.

[0059] (2) Auxiliary materials (parts by weight): 65 parts of industrial alumina powder, 10 parts of calcined alumina powder, 20 parts of kaolin; composite sintering aids (parts by weight): 1.5 parts of calcium carbonate, 2.5 parts of talc, 1 part of spodumene ;

[0060] (3) The auxiliary materials and composite sintering aids in step (2) are put into a ball mill for wet grinding. The ball milling process parameters are as follows: use glass ball stone as the grinding medium, the cylinder length of the ball mill is 4.0m, the cylinder diameter is 3.0m, and the material: ball :Water=1:2.5:0.5, ball mill for 12h, load 15 tons of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| body length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com