Wood veneer joint interface structure

A technology of interface structure and veneer, applied in building construction, covering/lining, construction, etc., can solve problems such as uneven splicing, and achieve the effect of solving uneven splicing, firm installation, and coordinated body effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

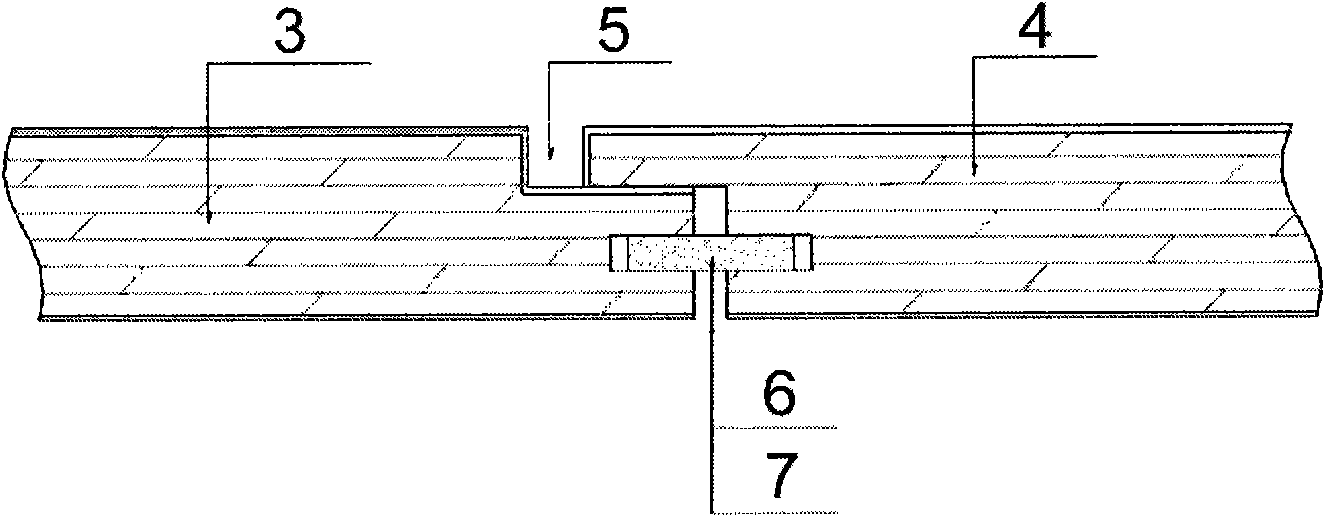

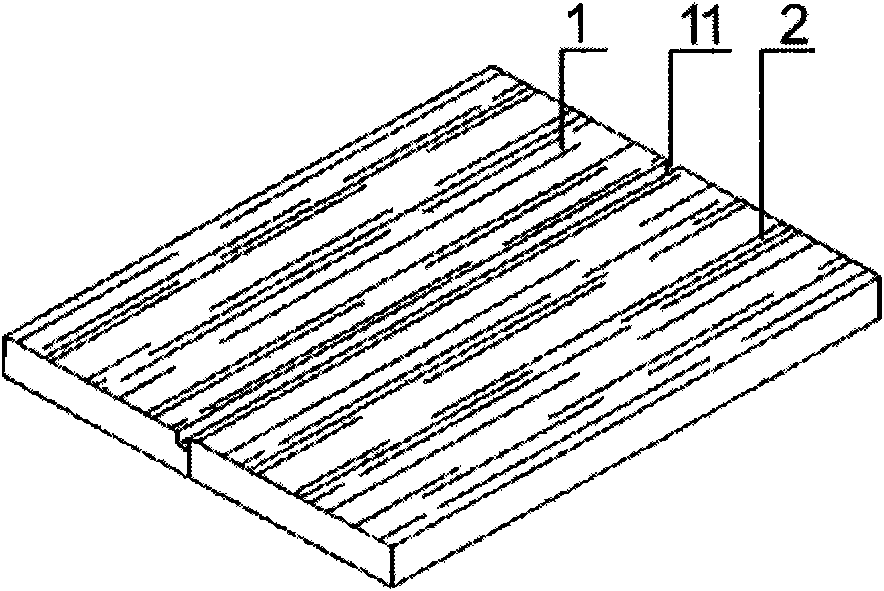

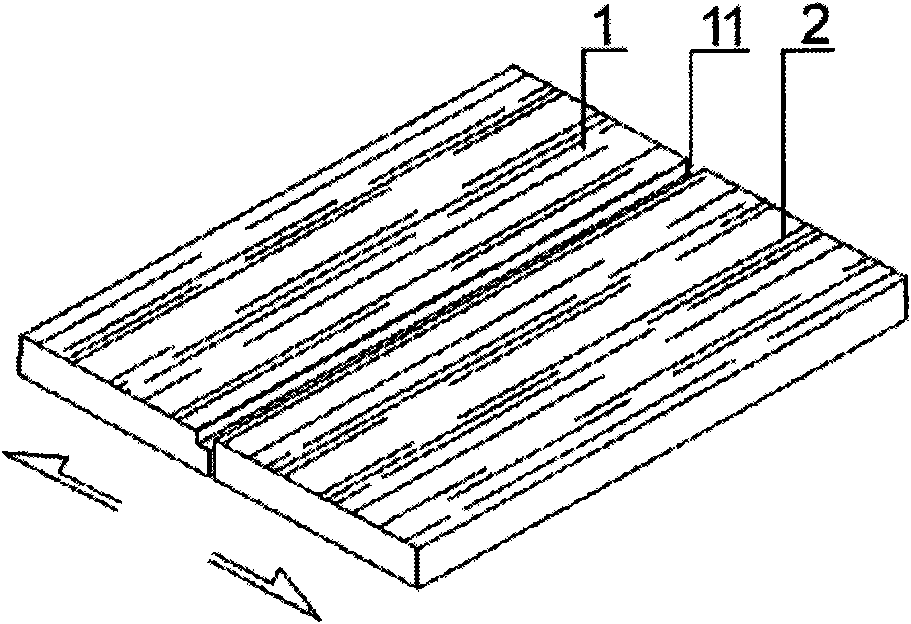

[0025] Example: such as figure 1 As shown, a joint joint structure of a wooden veneer, which includes a wooden veneer 1 3 and a wooden veneer 2 4 . The end face of the splicing of the wooden veneer 3 and the wooden veneer 2 4 is provided with a convex portion, and the wooden veneer 2 4 is correspondingly provided with a concave portion matching the convex portion, and the wooden veneer 3 and the wooden veneer 2 4 pass through the convex portion Staggered overlapping with the concave part.

[0026] A craft seam 5 is left between the wooden veneer 1 3 and the wooden veneer 2 4, and the craft seam 5 is located on the front of the wooden veneer. The bottom of the process seam 5 is the upper surface of the convex part of the wooden veneer-3. The upper surface of the convex part is the front coating layer of the veneer panel which coordinates with the overall decorative effect of the veneer panel. The upper surface of the convex part is pasted with a veneer, and the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com