Injection mold for battery box shell of electric vehicle

A technology for electric vehicle batteries and injection molds, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of uneven contact between the top block and the box body, and difficulty in separating the punch and the battery box, so as to reduce water consumption. The effect of waste of resources, convenient demoulding and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

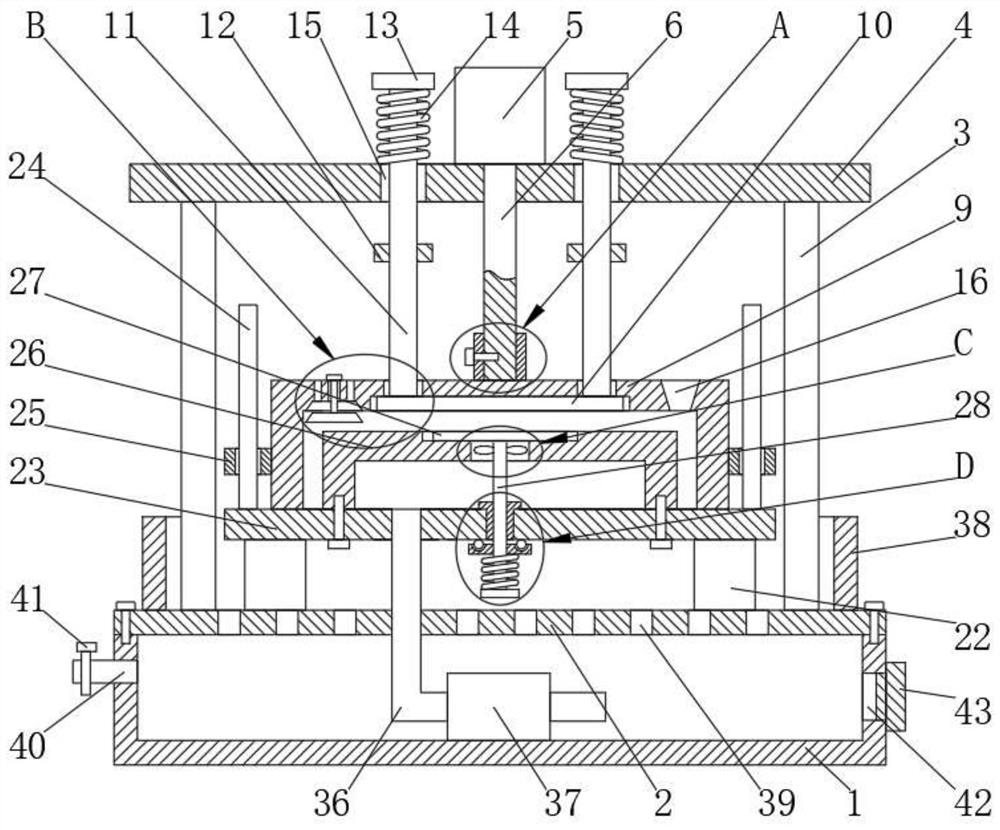

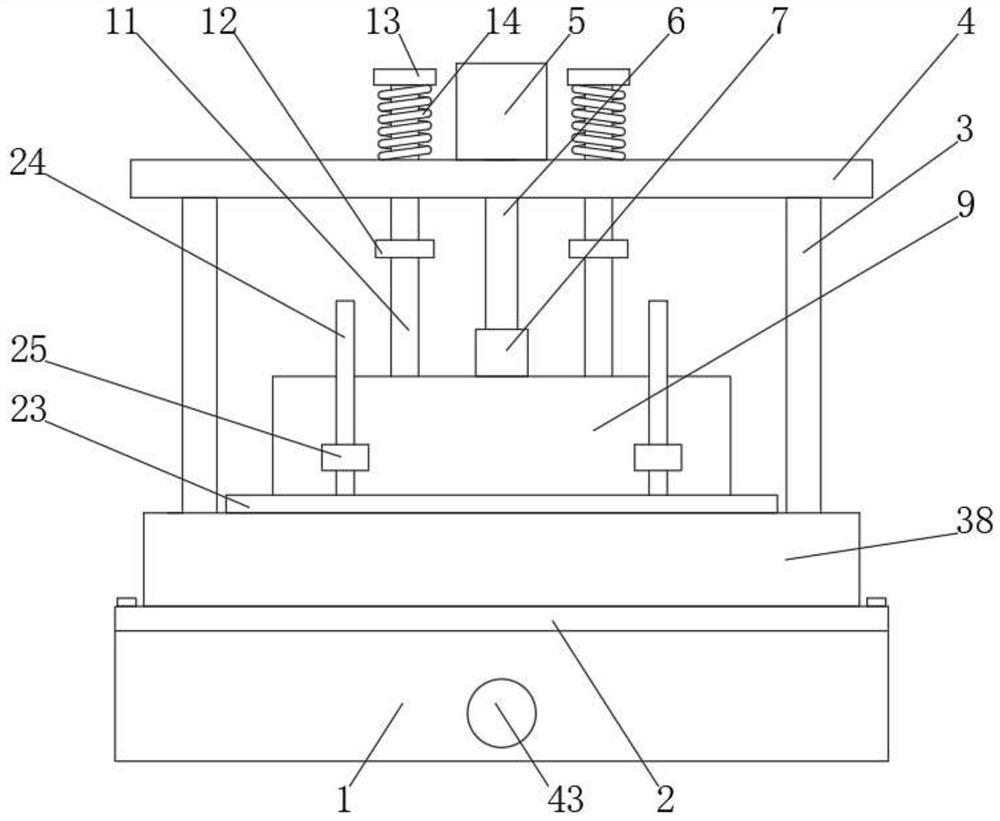

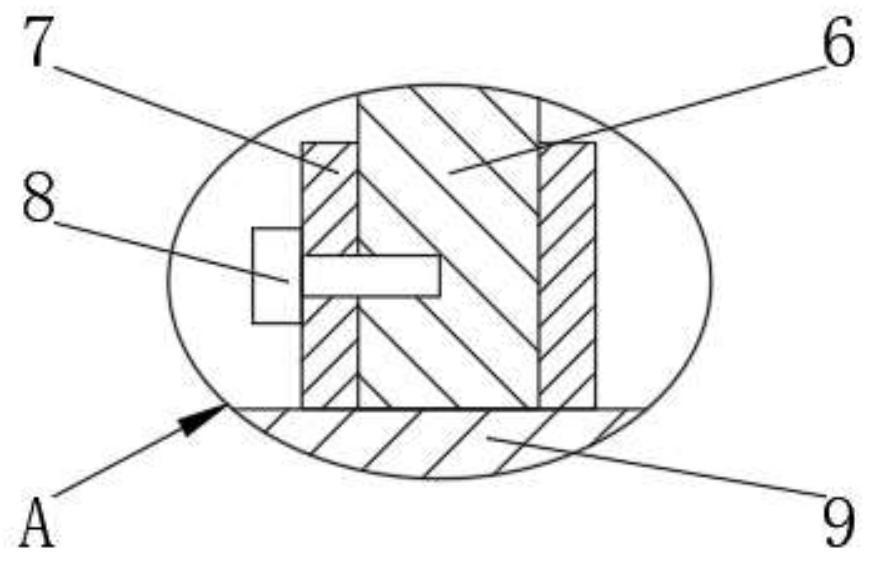

[0030] see Figure 1-6 , an injection mold for the electric vehicle battery box shell, including a water tank 1, the upper end of the water tank 1 is connected with a tank cover 2 by screws, the upper end of the tank cover 2 is welded with a support column 3, and the upper end of the support column 3 is welded with a mounting plate 4, and the installation The upper end of the plate 4 is fixedly equipped with a cylinder 5, the lower end of the cylinder 5 is provided with a cylinder rod 6, the installation plate 4 is slidingly sleeved with a cylinder rod 6, and the outer side of the lower end of the cylinder rod 6 is fixedly sleeved with a connecting sleeve 7, and the connecting sleeve 7 The upper die base 9 is welded at the lower end, the lower end of the upper die base 9 is slidingly connected with a pressure plate 10, the upper end of the pressure plate 10 is welded with a suspender 11, the upper die base 9 is slidingly sleeved with a suspender 11, and the outer fixing sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com