Patents

Literature

107results about How to "Drain clean" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

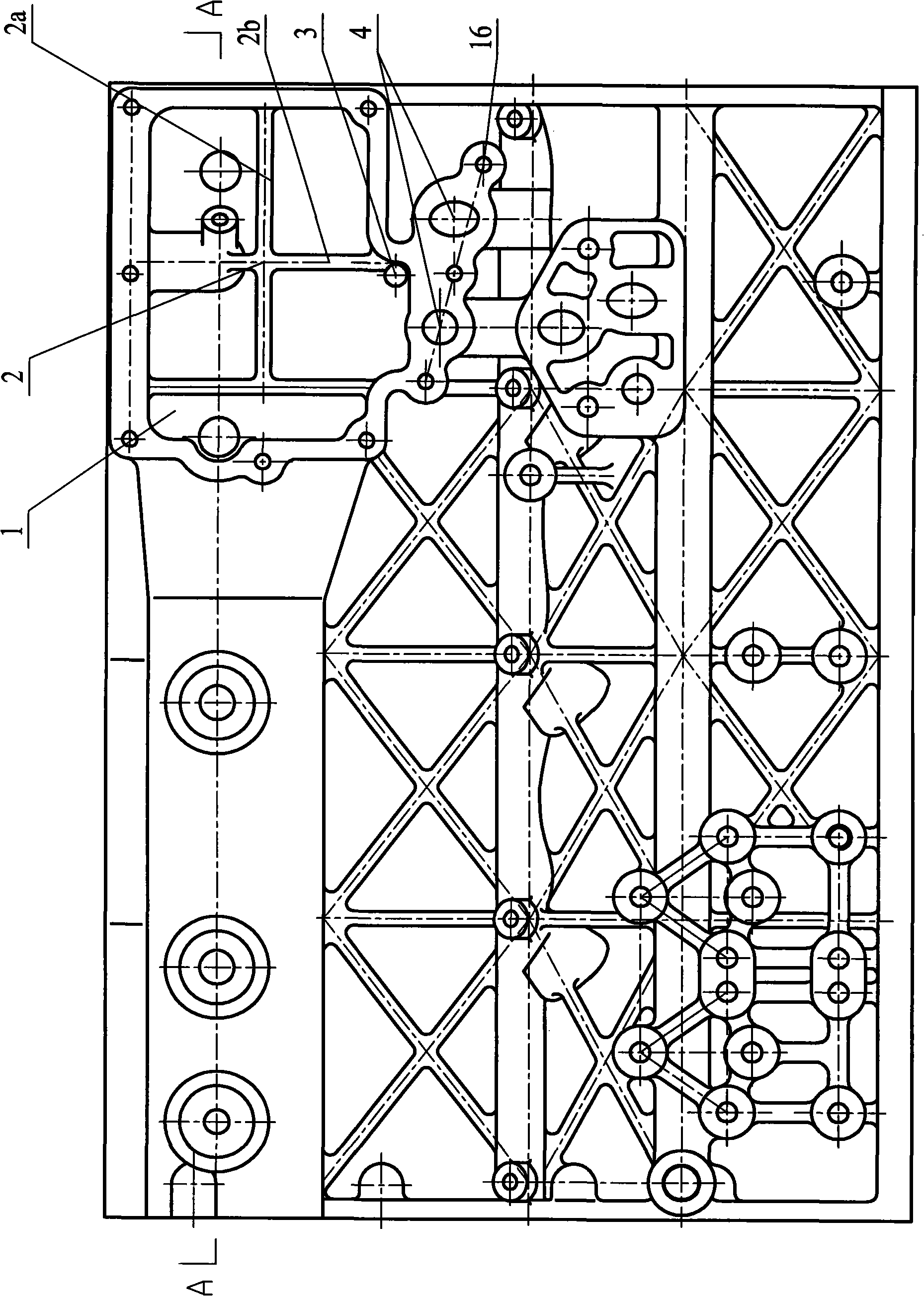

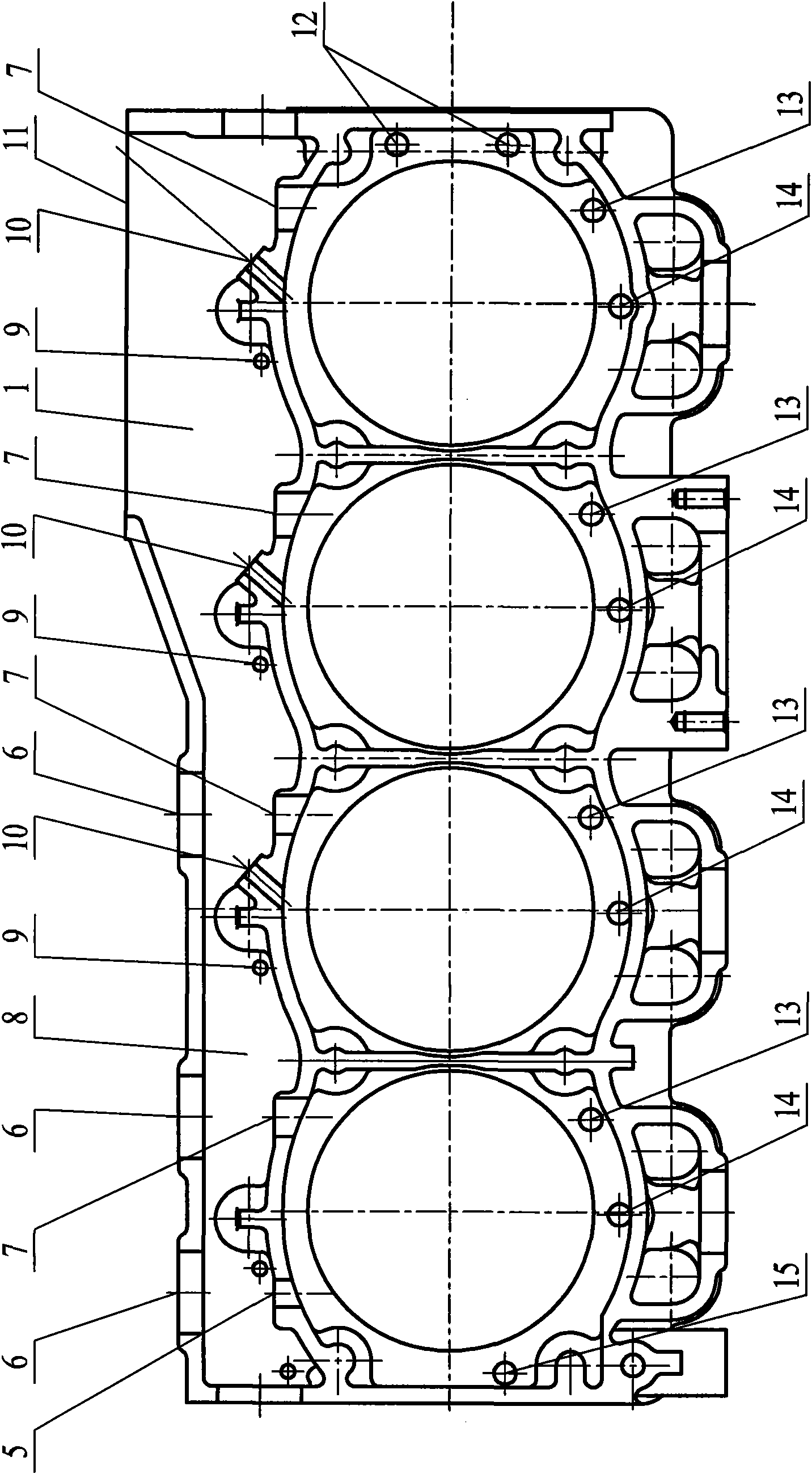

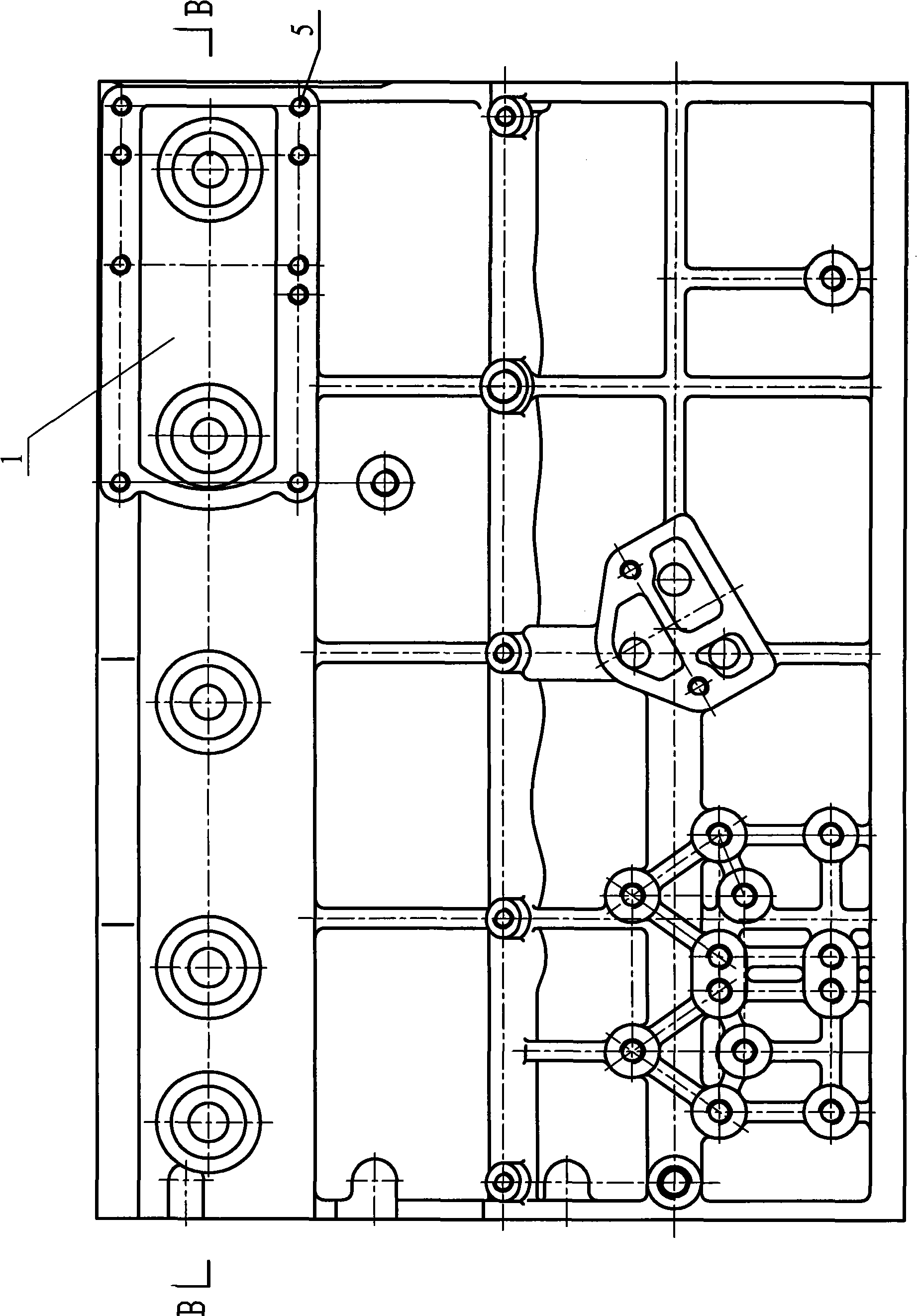

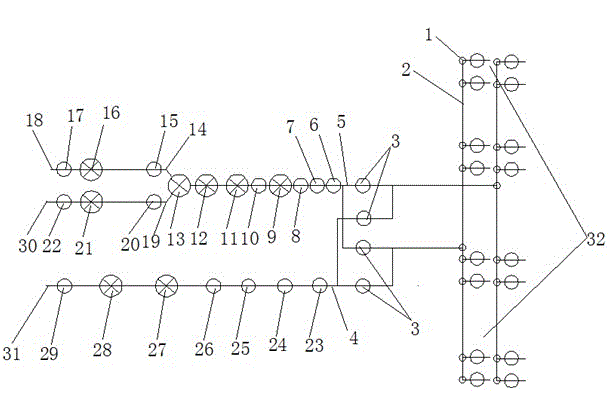

Water jacket structure of diesel cylinder block

InactiveCN101787936AAvoid cylinder liner deformationAvoid direct flushingCylinder headsCylindersCylinder blockEngineering

The invention relates to a water jacket structure of a diesel cylinder block. The upper portion of an intake side of the cylinder block is provided with a water distributing channel, the front end of which is connected with a water pump and the rear end of which is provided with an engine oil cooler cavity; a cylinder block water jacket is formed at the middle / upper portion of the cylinder block and comprises at least two transversely parallel single water jacket bodies, each of which is provided with an water intake hole and a water drainage hole, the water distributing channel is communicated with the interior of each of the single water jacket bodies through the water intake holes; the water intake hole on the first single water jacket body at the front end of the cylinder block water jacket comprises a front straight water intake hole and a rear straight water intake hole, the water intake holes on other single water jacket bodies each comprise a rear straight water intake hole, wherein all the single water jacket bodies are each provided with an oblique water intake hole except the first single water jacket body, the front straight water intake hole, the rear straight water intake hole and the oblique water intake hole are all tangential to the periphery of the single water jacket bodies. The water jacket structure, skillful and reasonable in structure, can effectively cool the cylinder block and the engine oil, increase the rigidity of the intake side of the cylinder block and lower noise.

Owner:JIANGSU SIDA POWER MECHANICAL GROUP

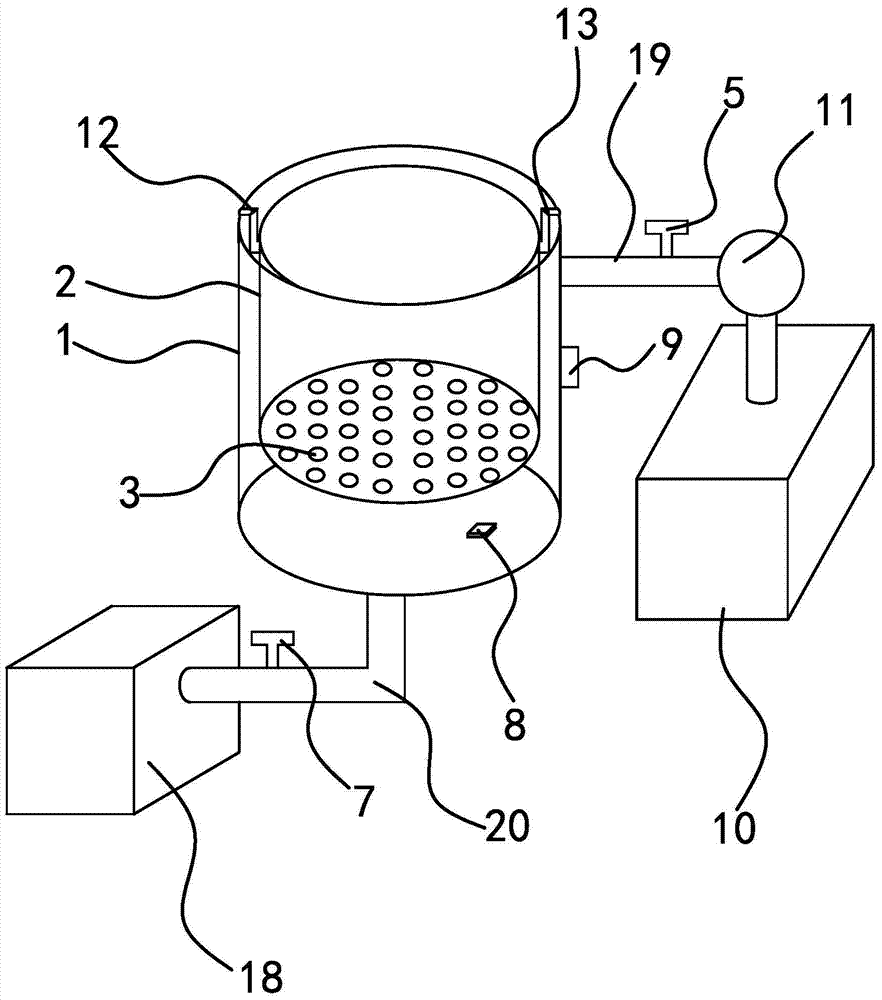

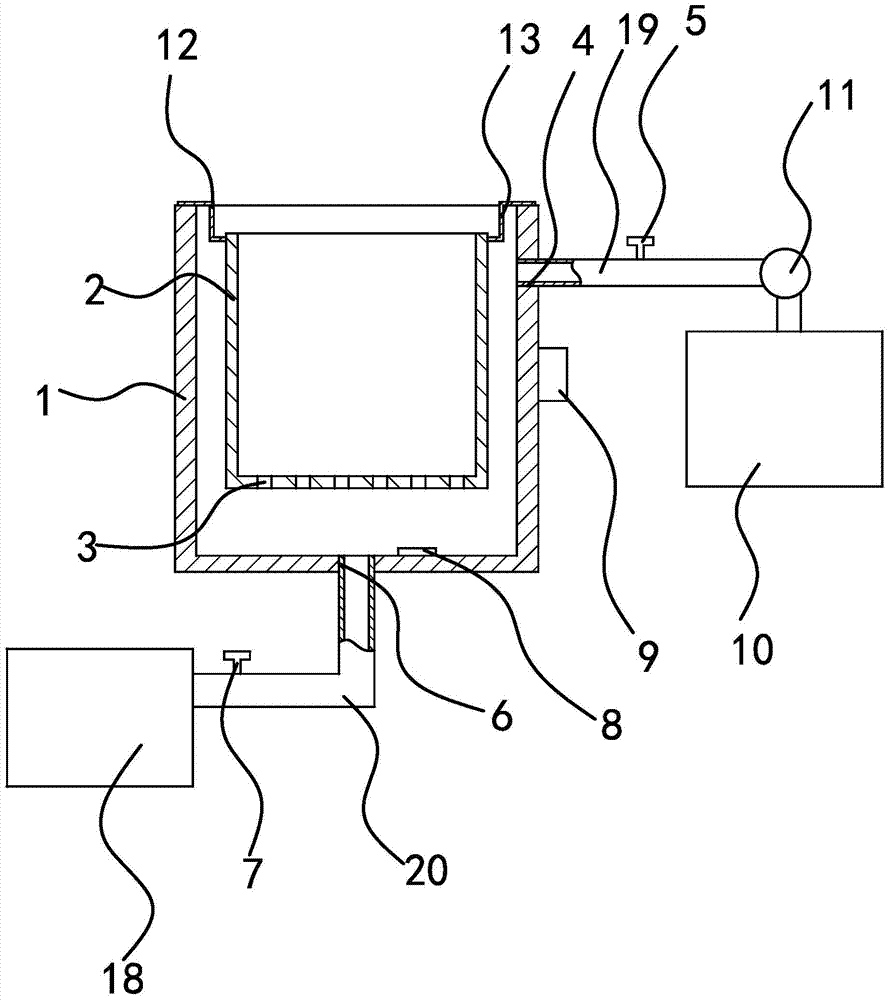

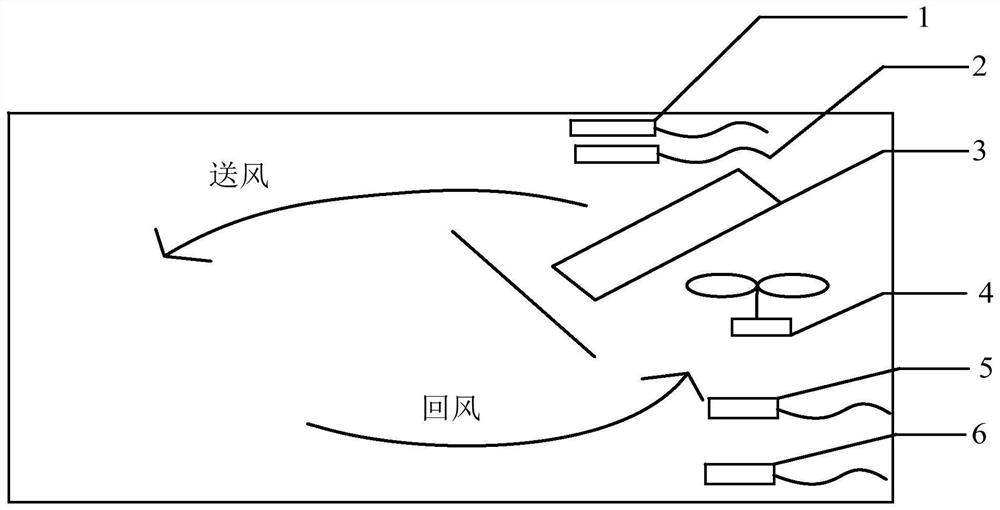

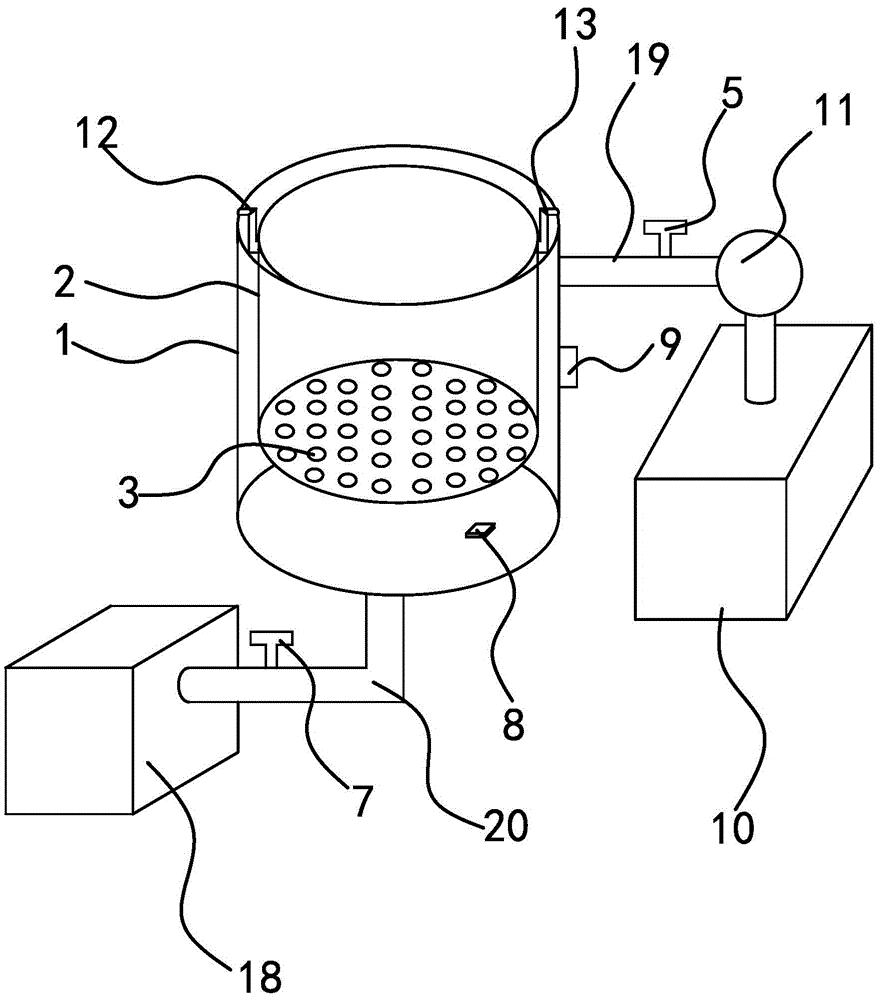

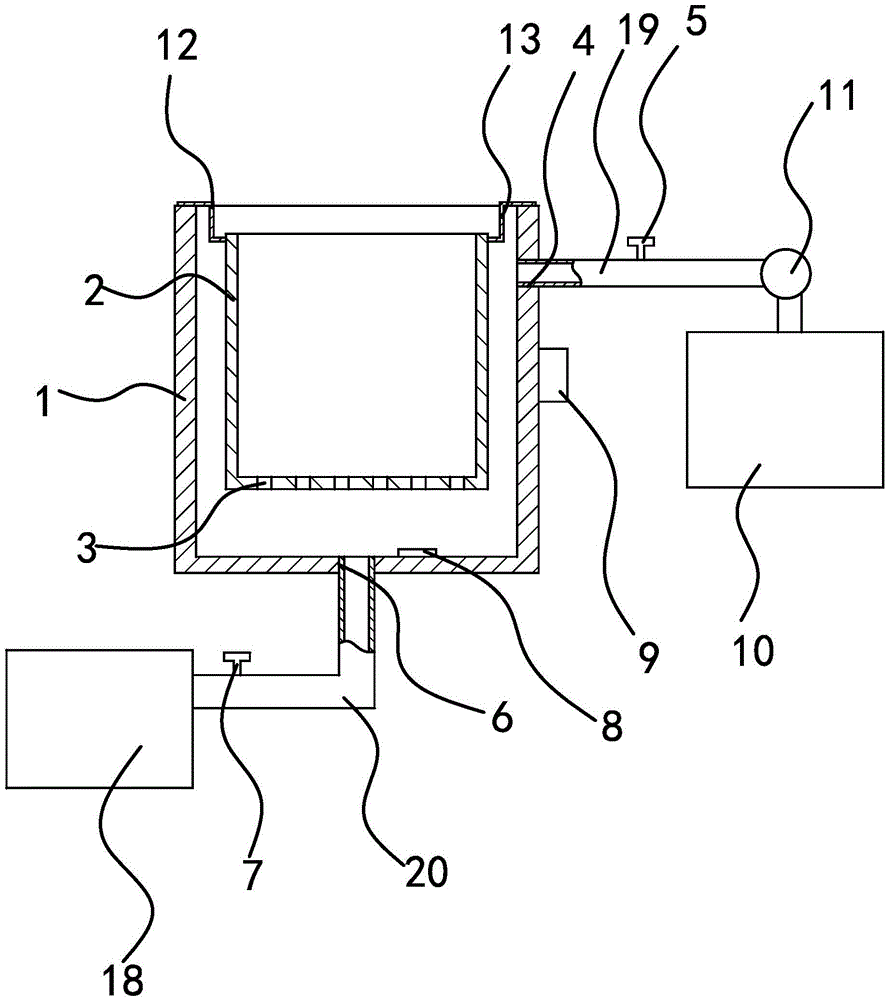

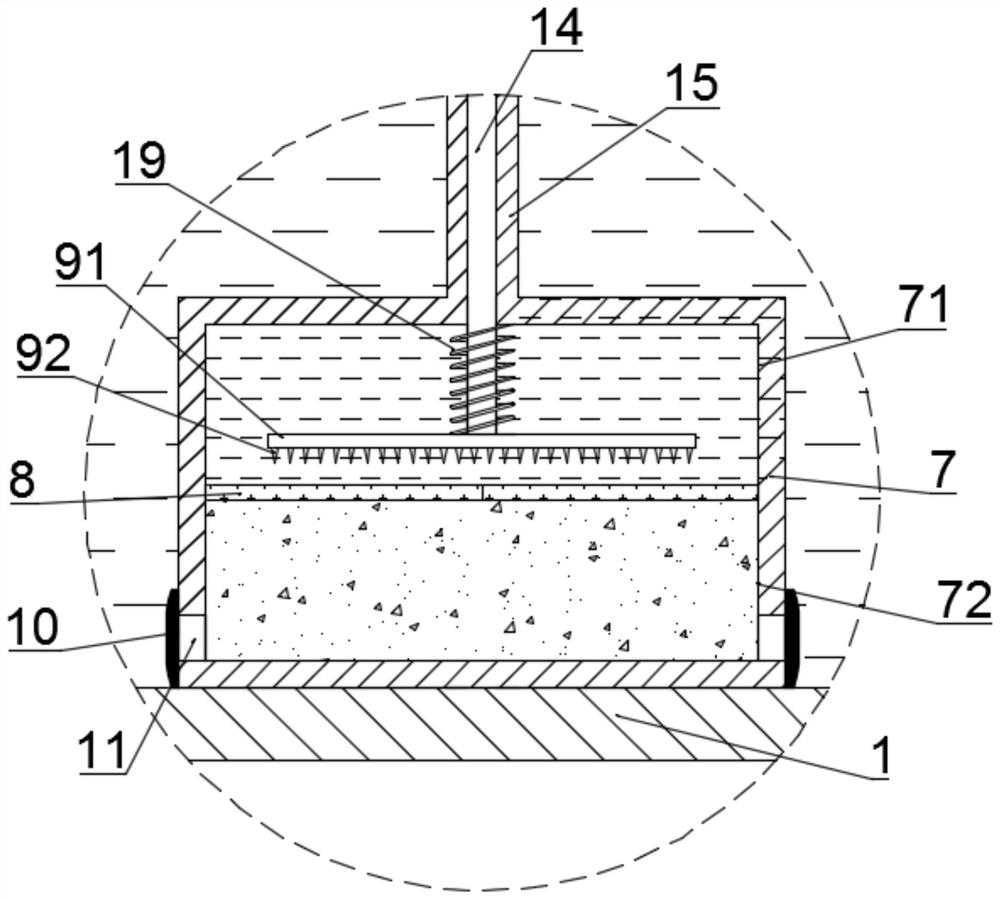

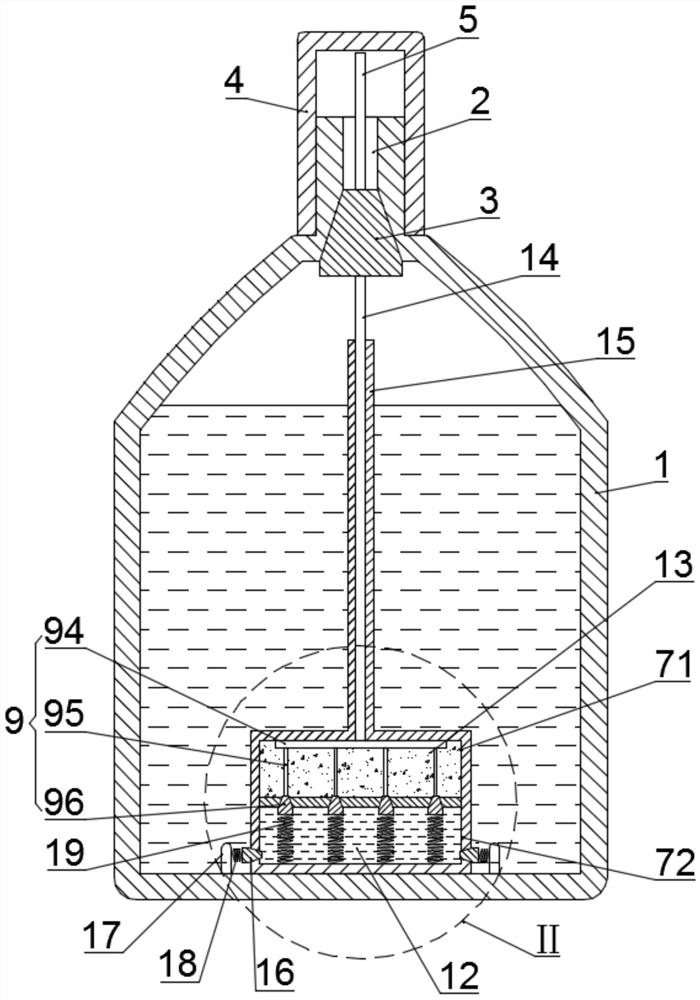

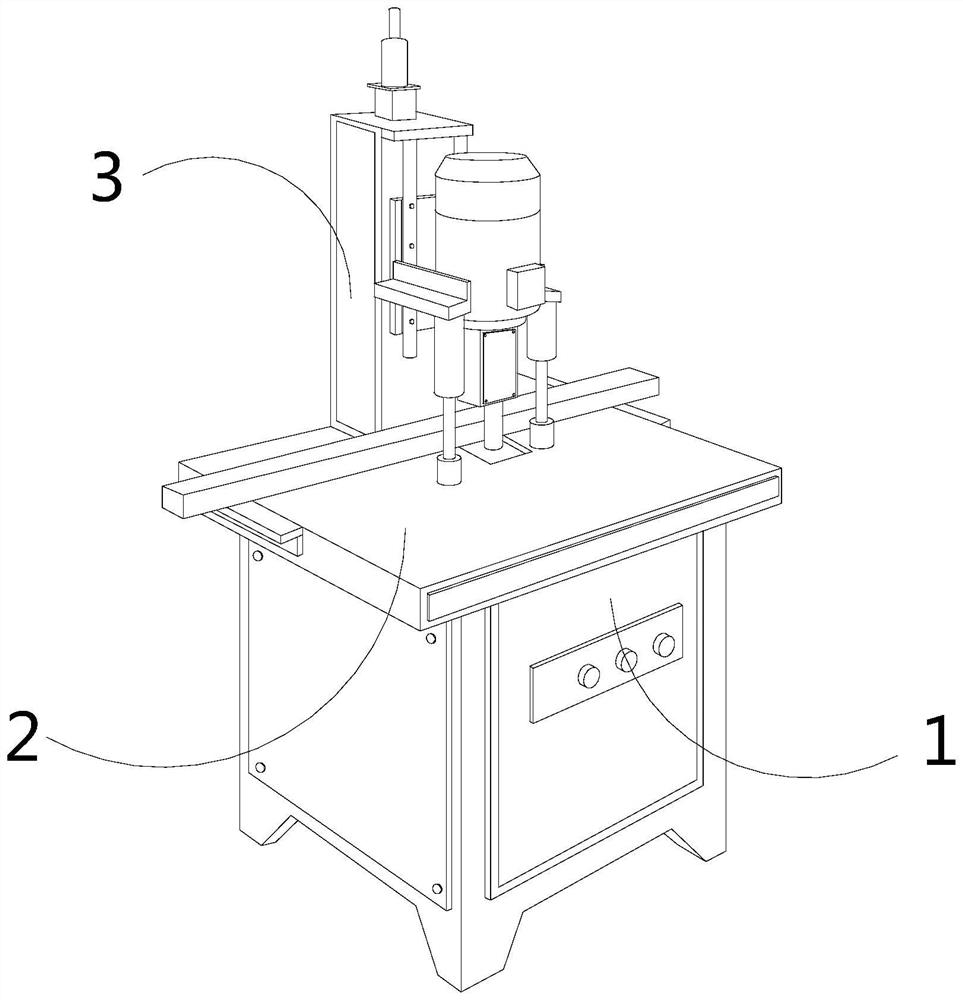

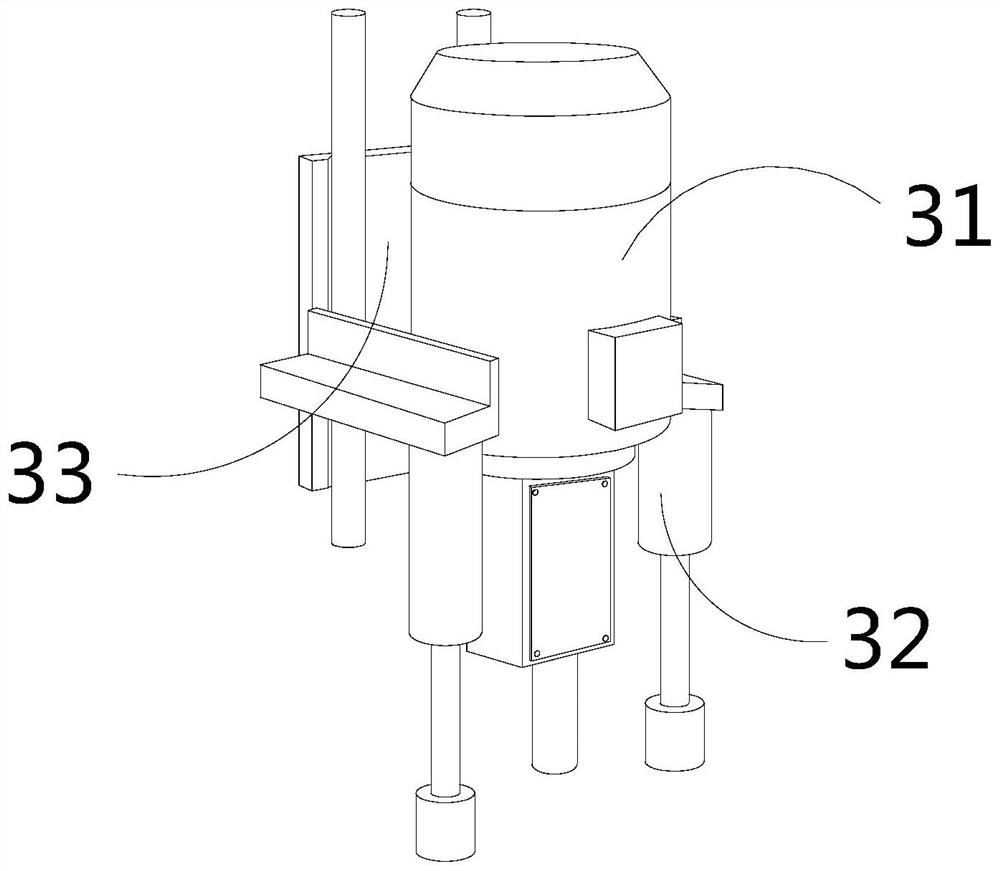

Micropore resin mold cleaning system

ActiveCN104646341AIncrease usageEasy dischargeCleaning using gasesCleaning using liquidsParticulatesWater circulation

The invention relates to a micropore resin mold cleaning system. According to the micropore resin mold cleaning system, a high-pressure high-strength cleaning method is adopted, so that tiny particulate matters in micropores can be completely cleaned; a method of circularly and alternately flushing with compressed air and water is adopted, so that various matters in the micropores can be completely cleaned; a filter device is adopted, so that the micropores are prevented from being blocked again. According to the micropore resin mold cleaning system, a design with a compressed air pipeline and a high-pressure water circulation pipeline is adopted, and the two pipelines are used for alternately flushing, so that particles in the micropores can be rapidly and completely discharged, the use frequency of a resin mold is increased and the production cost is lowered.

Owner:TANGSHAN MONOPY CERAMIC

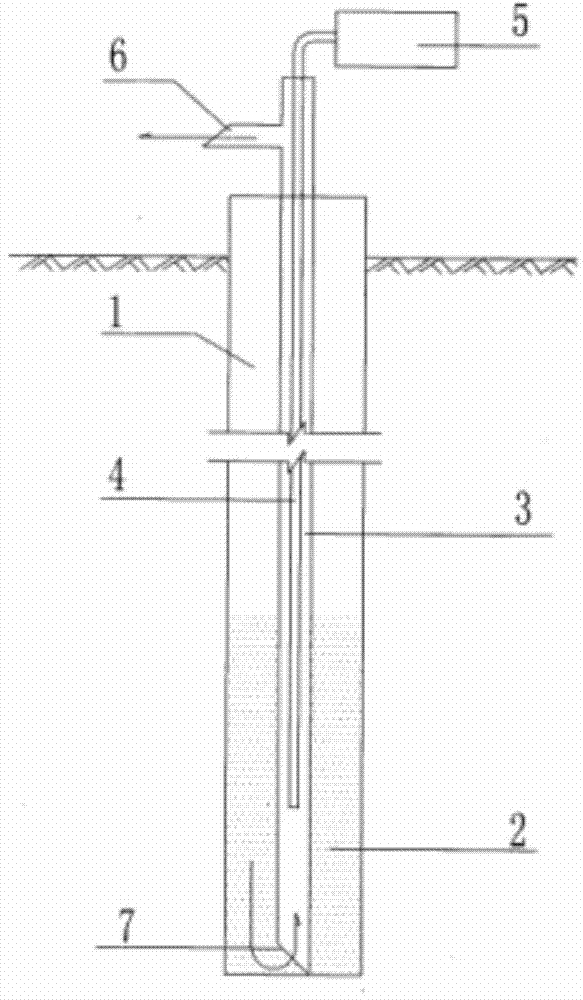

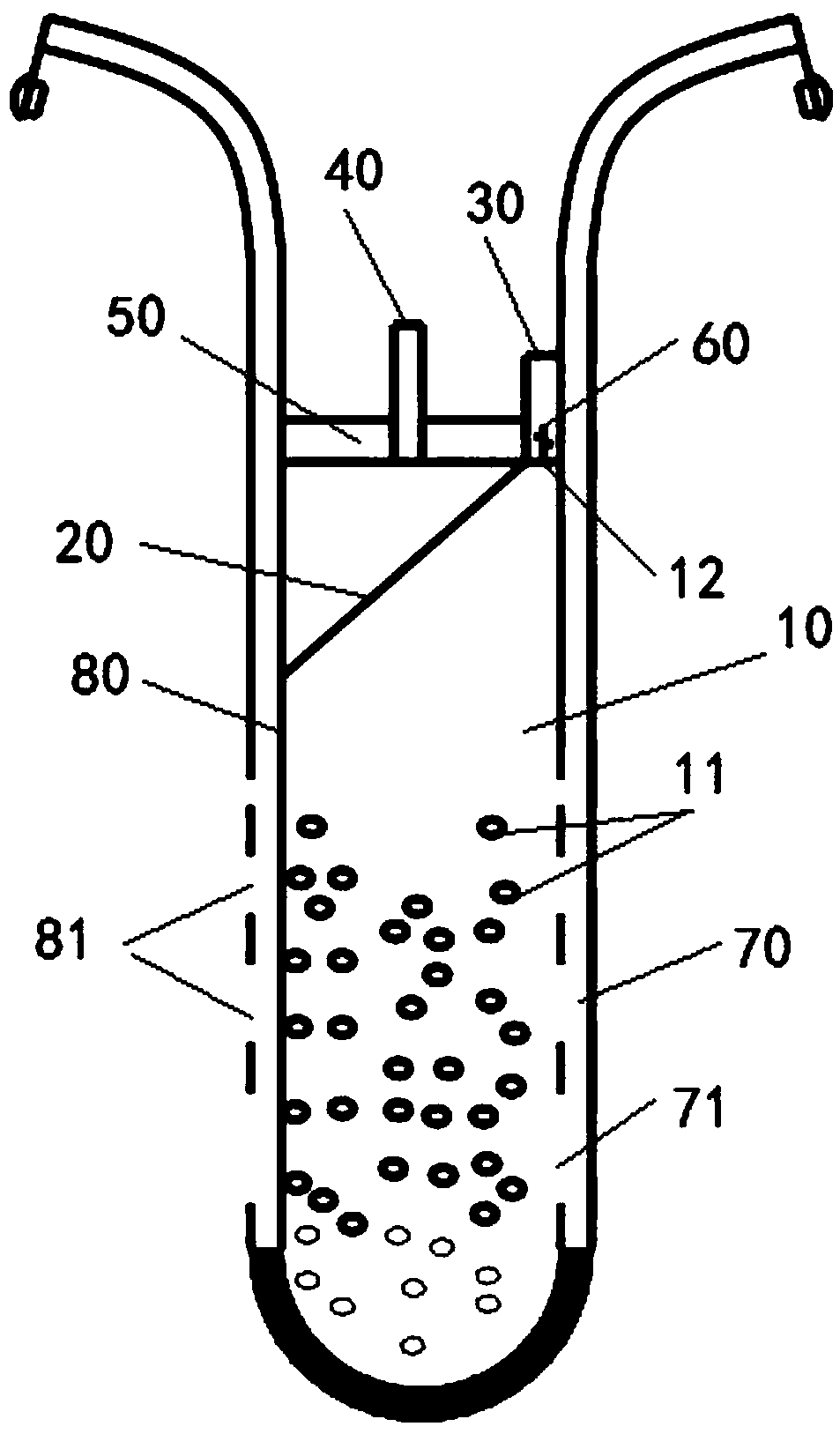

Surface precipitation deep well washing device

The invention relates to the technical field of construction, in particular to a surface precipitation deep well washing device. The surface precipitation deep well washing device comprises a well washing pipe, a high-pressure air hose and a blowing member. The blowing member is used for blowing high-pressure air to the high-pressure air hose, the high-pressure air in the high-pressure air hose moves upwards through a gap between the inner wall of the well washing pipe and the high-pressure air hose after passing through the bottom, meanwhile, well bottom sediment and water outside the well washing pipe are pushed to the head of the well to a certain height, then, the blowing member is turned off to stop blowing through an air supply pipe, and the blown sediment and water are quickly pushed upwards through the gap between the well washing pipe and the high-pressure air hose due to the siphon phenomenon and ejected out through a sediment discharge opening, so that the purpose of well bottom sediment removal is achieved. The surface precipitation deep well washing device is easy to assemble in site and operate and capable of well removing bottom sediment of a deep well to ensure the effective reduction of the water level of a tunnel.

Owner:CHINA RAILWAY 19 BUREAU GRP CO LTD

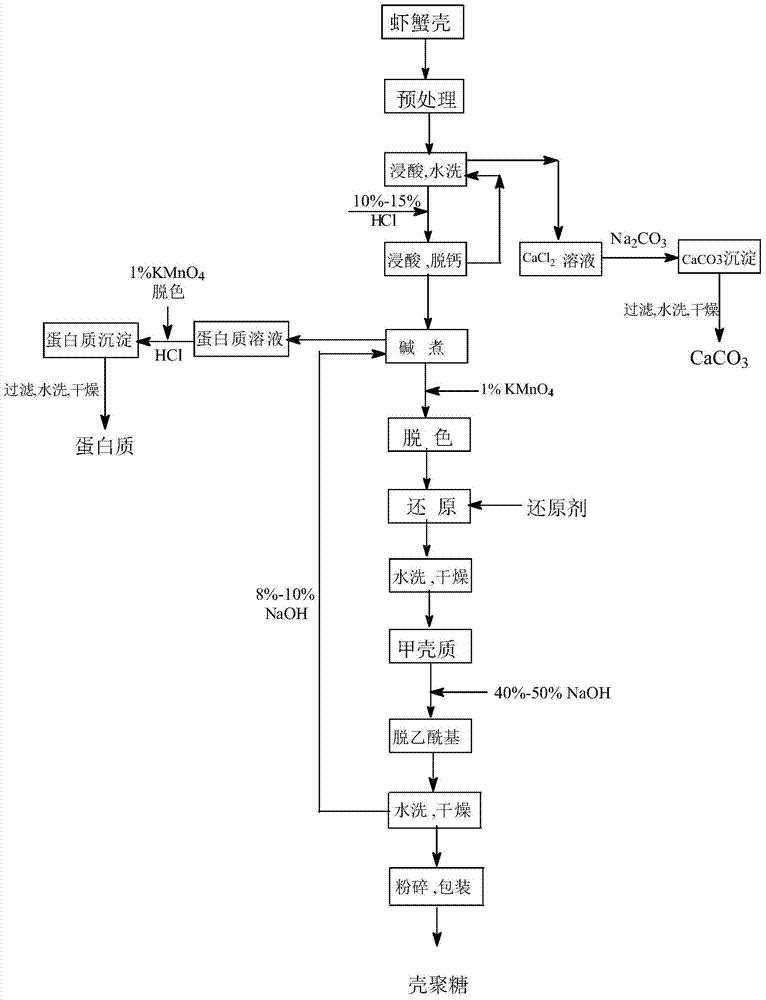

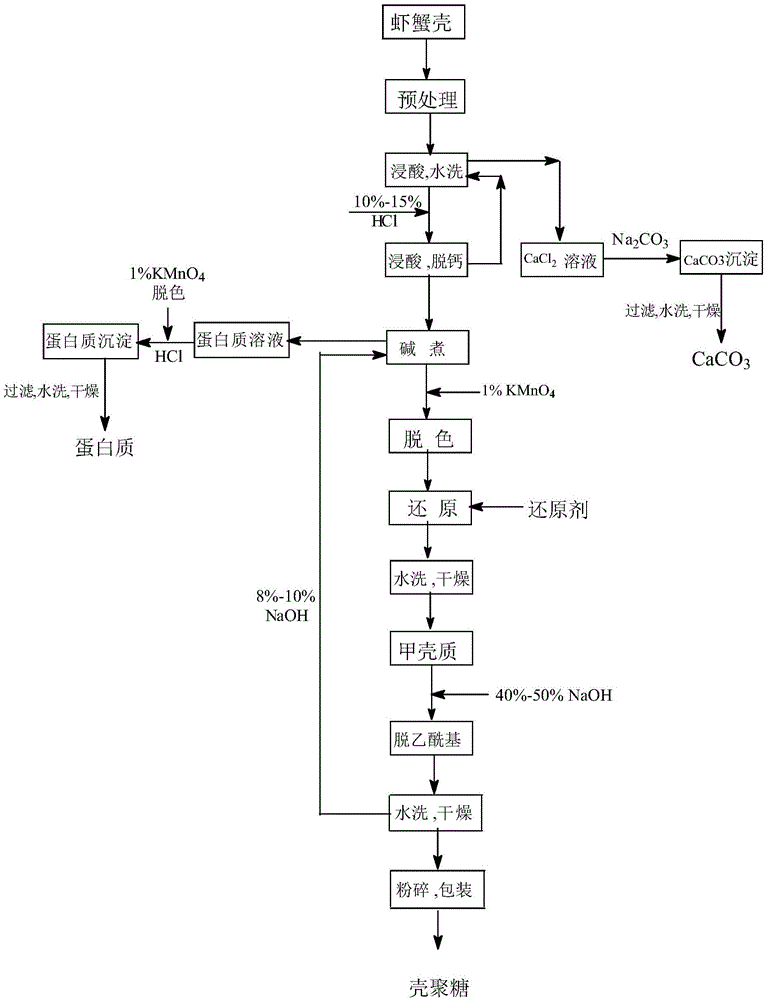

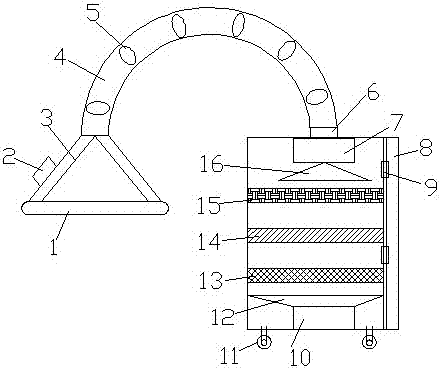

Preparation method of chitosan and immersion device for preparing chitosan

InactiveCN103665191AReduce manufacturing costComprehensive utilization of resourcesResource utilizationFiltration

The invention relates to a preparation method of chitosan, which comprises the following steps of: screening, purifying, dicing, washing and drying shrimp shells and crab shells, soaking with an appropriate amount of hydrochloric acid for 5-8h, after filtering, recovering a calcium chloride solution, collecting the preliminarily decalcified shrimp shells and crab shells, soaking with excessive hydrochloric acid, collecting the decalcified shrimp shells and crab shells, boiling with a sodium hydroxide solution, cooling, then filtering, recovering the sodium hydroxide solution after filtration, obtaining the shrimp shells and crab shells having protein removed, removing water, soaking with potassium permanganate, soaking a filtration product in a reducer solution after filtration till complete decoloration, washing with water, drying to form chitin, soaking the chitin with sodium hydroxide for 15-20 h at 80-100 DEG C, cooling, filtering, cleaning a filtration product, removing residual sodium hydroxide, drying, and grinding to form the chitosan. The preparation method realizes high resource utilization rate, low production cost and low environmental pollution by recycling materials.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

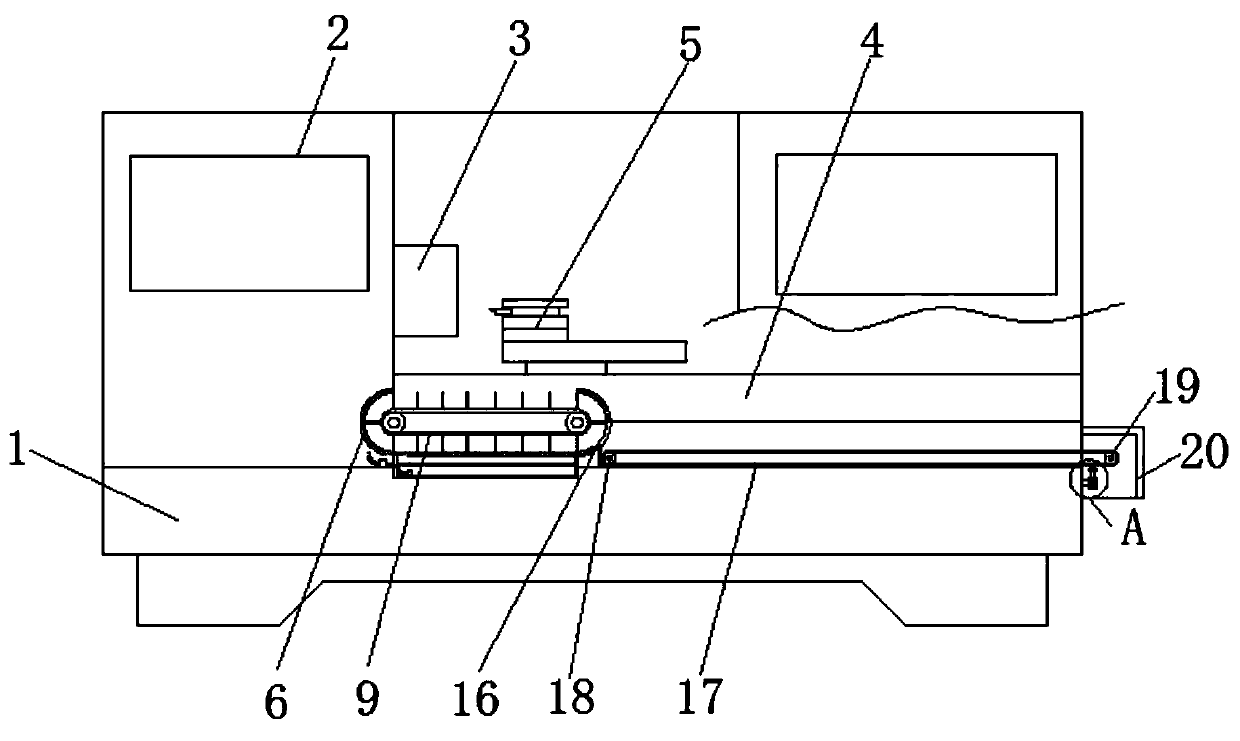

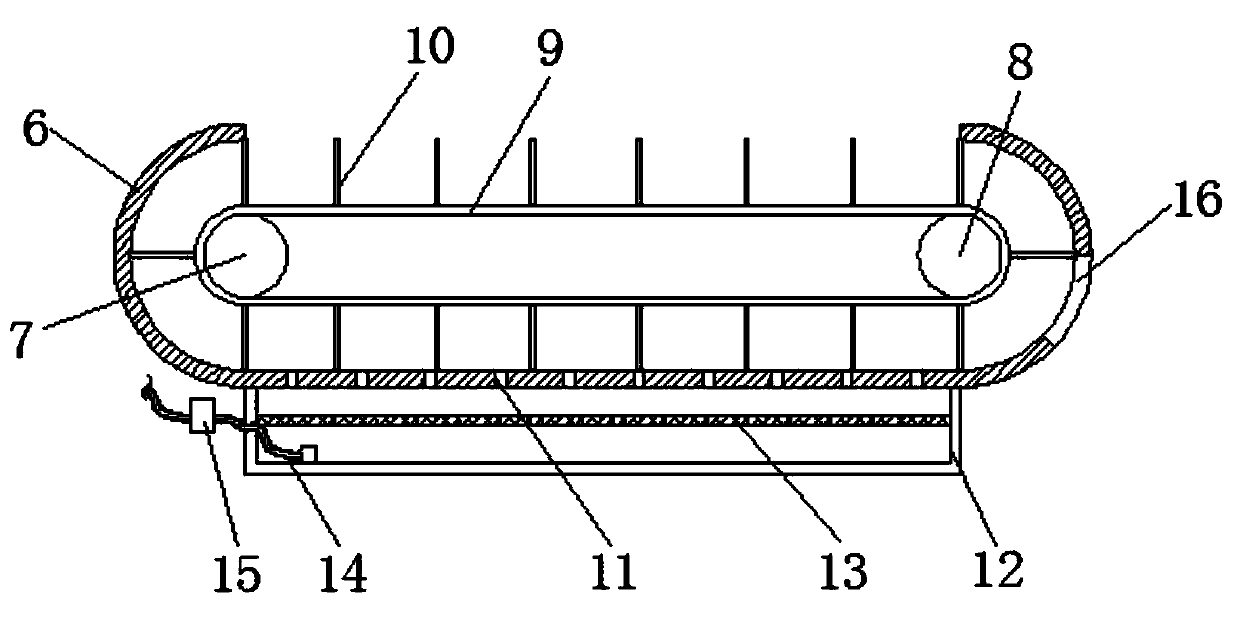

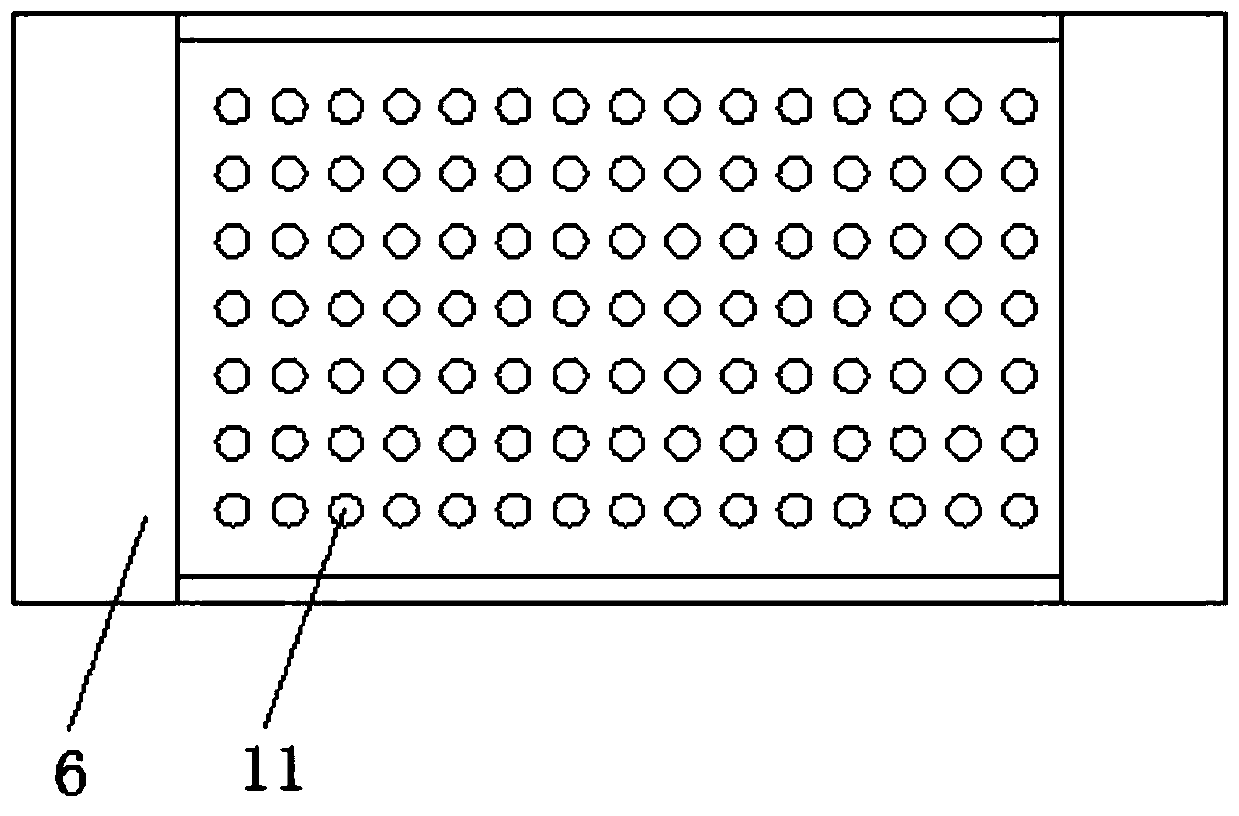

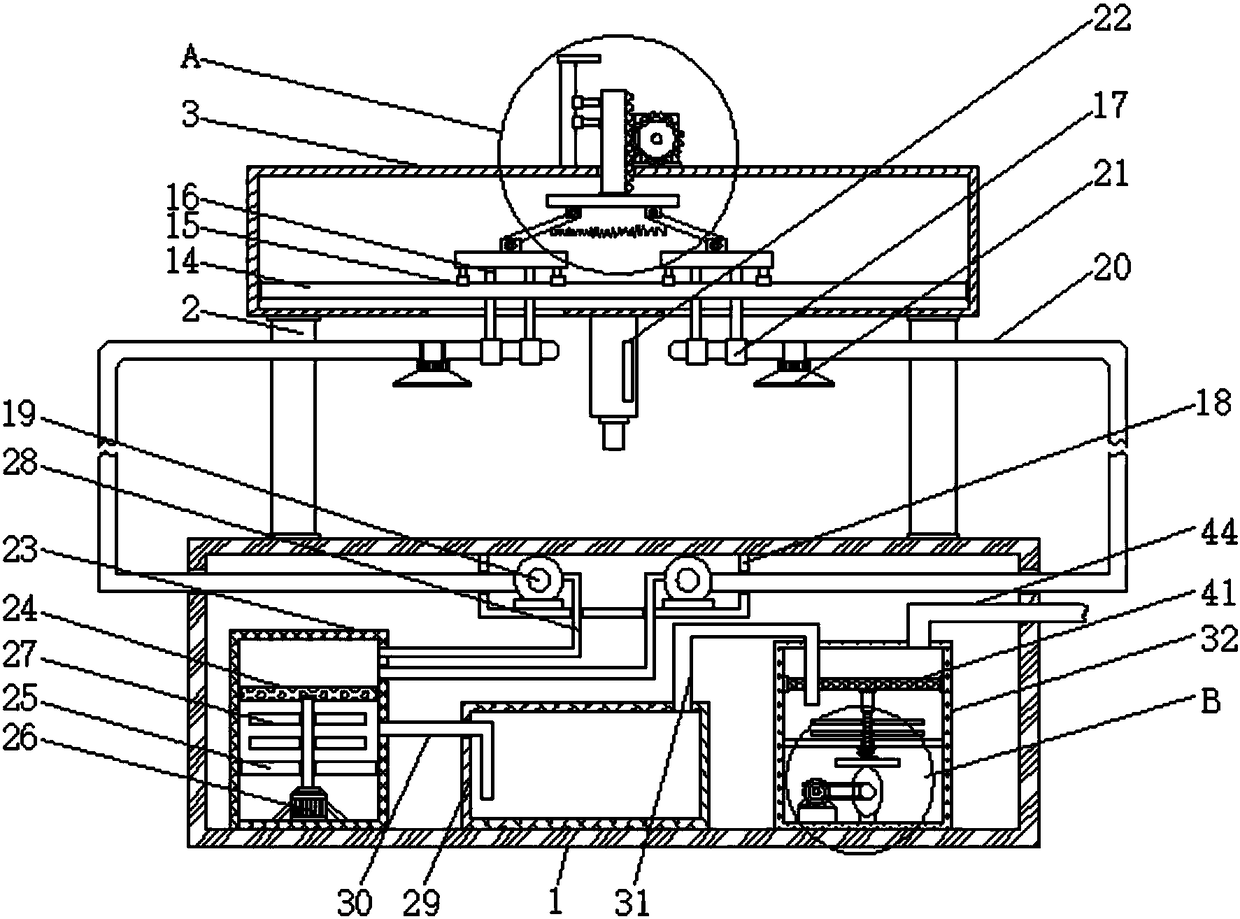

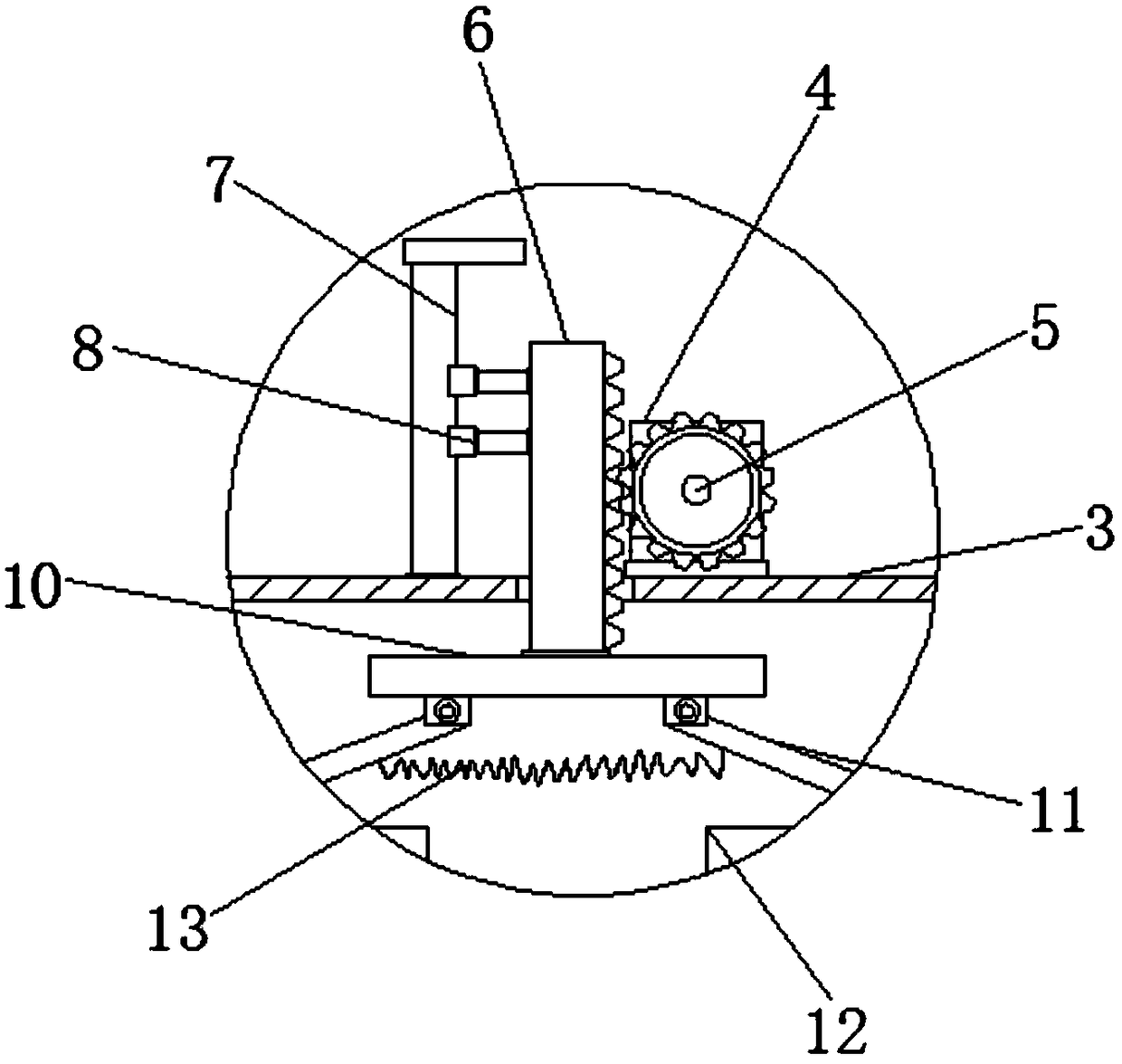

Conveyor belt principle-based scrap removal device for numerically controlled lathe

ActiveCN110977598AAvoid clutterAvoid pollutionMaintainance and safety accessoriesNumerical controlWorking environment

The invention belongs to the technical field of numerically-controlled machine tools and relates to a conveyor belt principle-based scrap removal device for a numerically controlled lathe. The conveyor belt principle-based scrap removal device for the numerically controlled lathe comprises a rack; the top of the rack is fixedly connected with a machining chamber; a clamp and movable guide rails are fixedly connected in the machining chamber; the tops of the movable guide rails are slidably connected with turning tool fixing seats; a waste scrap collecting box is fixedly connected between the movable guide rails; a first conveying wheel and a second conveying wheel are fixedly connected in the waste scrap collecting box; the exteriors of the first conveying wheel and the second conveying wheel are movably connected with a scrap removal belt; and the exterior of the scrap removal belt is fixedly connected with a scrapping plate. Through cooperative use of the waste scrap collecting box and a waste liquid collecting box, waste scraps and waste liquid can be collected; the waste scraps and the waste liquid are automatically separated, so that troubles in work are reduced; and the wastescrap collecting box collects the waste scraps, so that the scattered accumulation of the waste scraps is prevented, and therefore, the waste scraps are prevented from polluting the work environment,and the cleanliness of the work environment is guaranteed.

Owner:浙江欧鹰智能科技有限公司

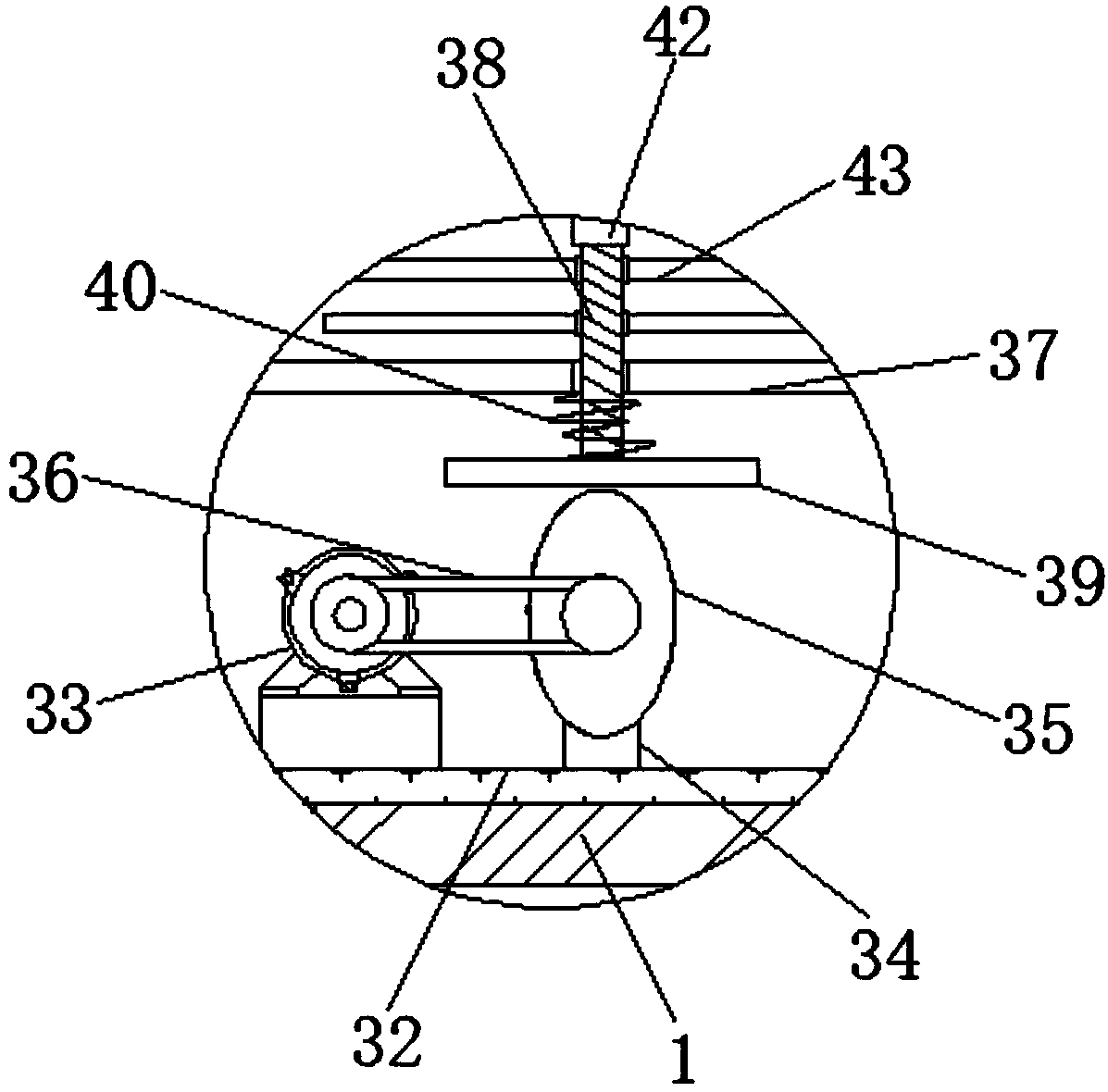

Welding device with welding fume removal function

InactiveCN108296683AHas the function of removing welding smokeEasy dischargeCombination devicesWelding/cutting auxillary devicesWelding fumePollution

The invention discloses a welding device with a welding fume removal function and relates to the technical field of welding equipment. The welding device with the welding fume removal function comprises a bottom box. Supporting columns are fixedly connected to the two sides of the top of the bottom box. A top box is fixedly connected to the top ends of the supporting columns. A first motor is fixedly connected to one side of the top of the top box. A gear is fixedly connected to one end of an output shaft of the first motor. A toothed plate is arranged on one side of the gear in an engaged mode. The bottom of the toothed plate penetrates through the top box and extends into the top box. A vertical plate is fixedly connected to the other side of the top of the top box. According to the welding device with the welding fume removal function, an inner box is fixedly connected to the top of the inner wall of the bottom box so that the quantity of fume discharged in the welding process is effectively reduced, and environment pollution caused by welding is relieved; and the supporting columns are fixedly connected to the two sides of the top of the bottom box, welding fume is sucked by two suction nozzles in a moving mode, and thus, pollution caused by welding fume can be effectively reduced.

Owner:沈小荣

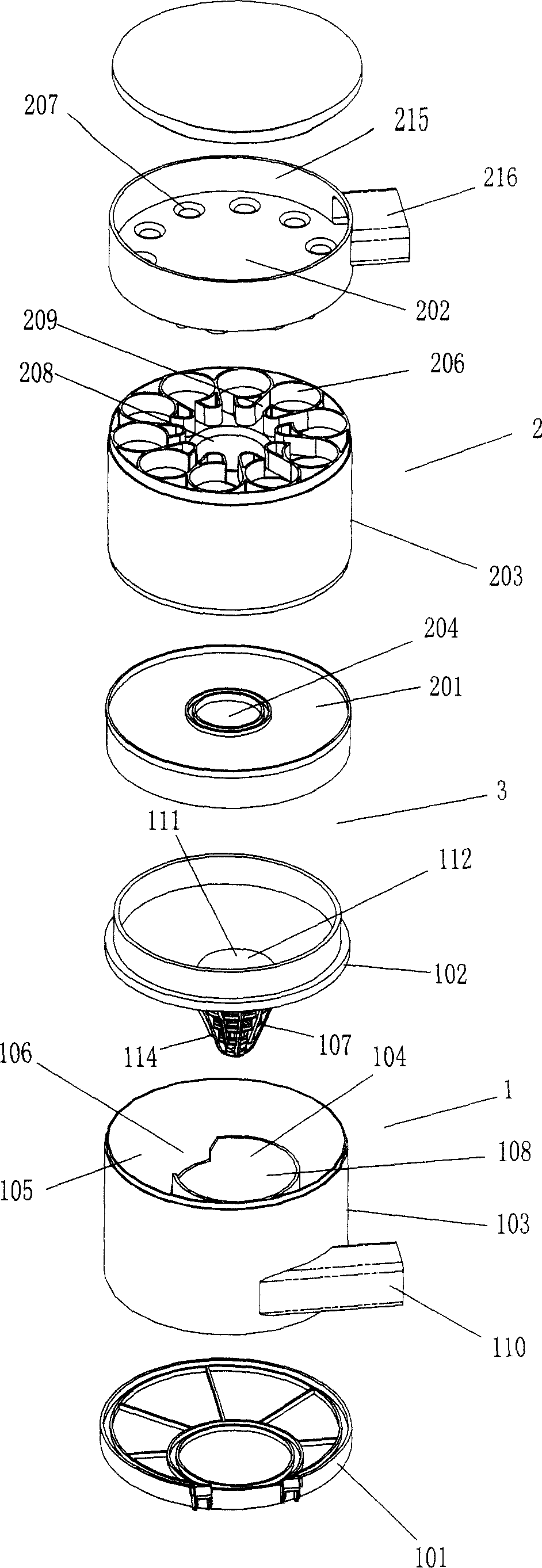

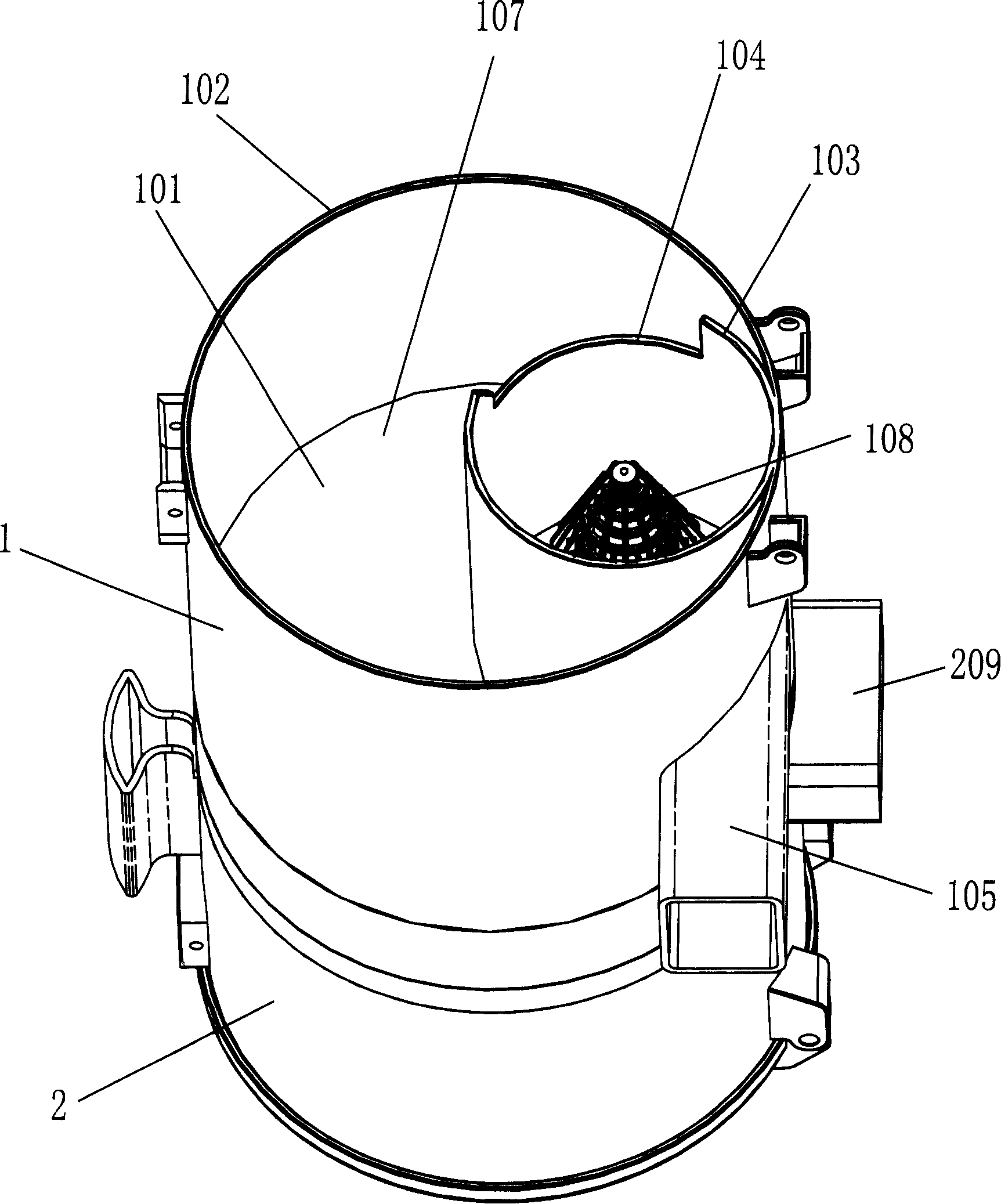

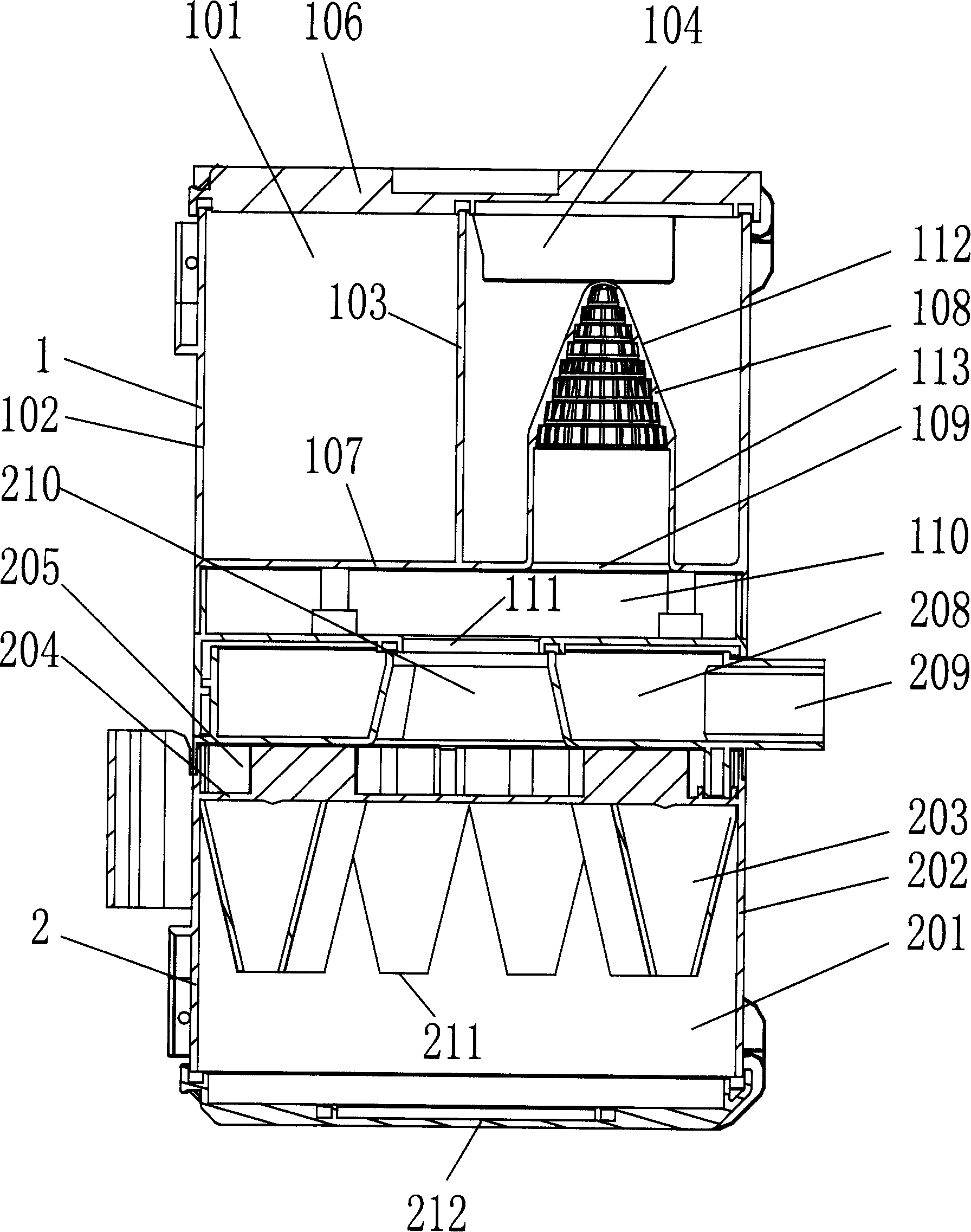

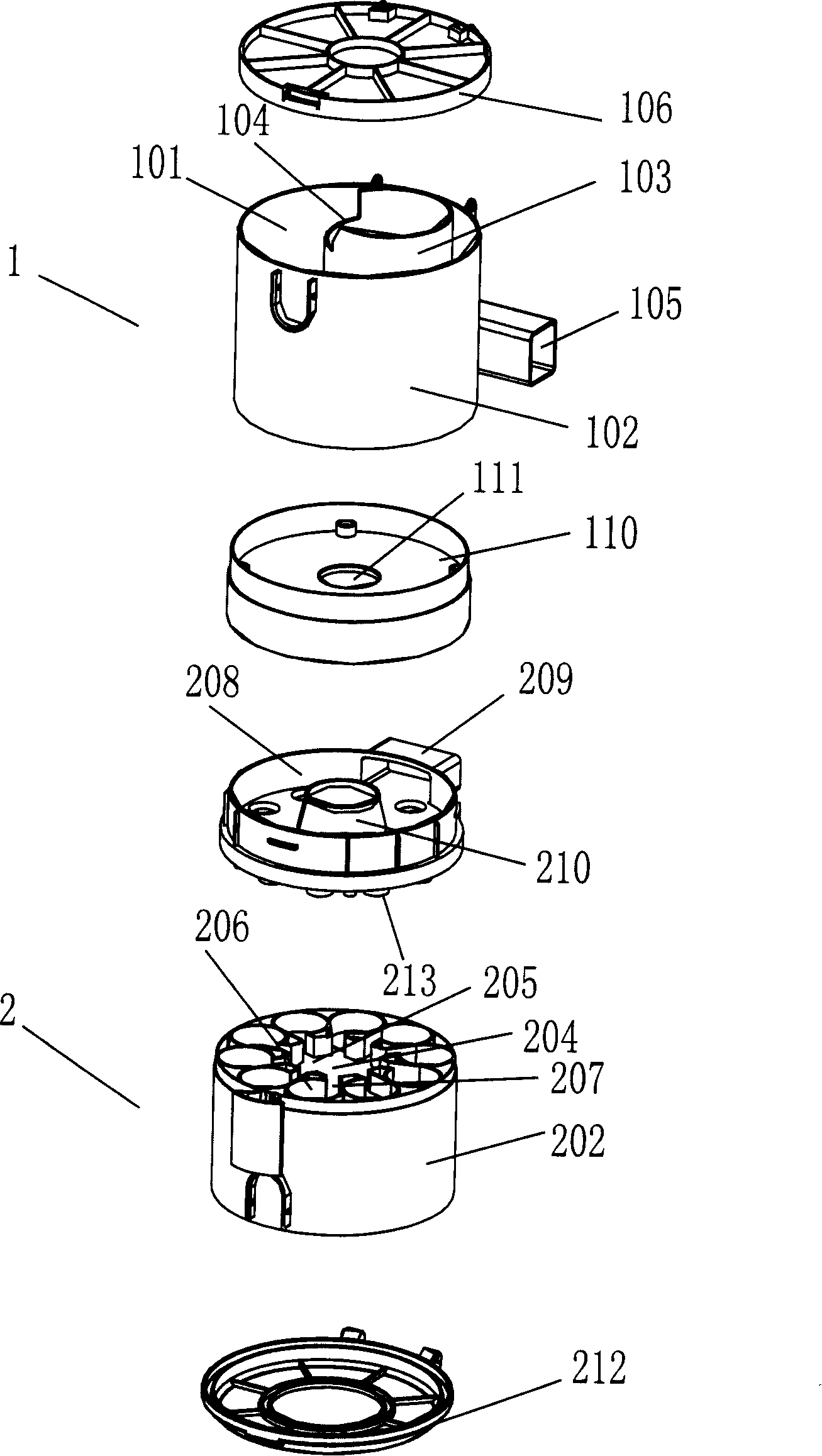

Dust removing device for vacuum cleaner

The invention discloses a dust removing device of a dust collector and comprises a level 1 cyclone and a level 2 cyclone. The level 2 cyclone is arranged above the level 1 cyclone; an air outlet of the level 1 cyclone is communicated with an air inlet of the level 2 cyclone; the level 1 cyclone and the level 2 cyclone are respectively provided with a separated dust chamber; the invention can thoroughly separate air from dust and leads the air exhausted by the dust collector to be more clean without a secondary pollution; the separated dust chamber respectively arranged in the level 1 cyclone and the level 2 cyclone can clean the ashes respectively and the users can use conveniently.

Owner:KINGCLEAN ELECTRIC

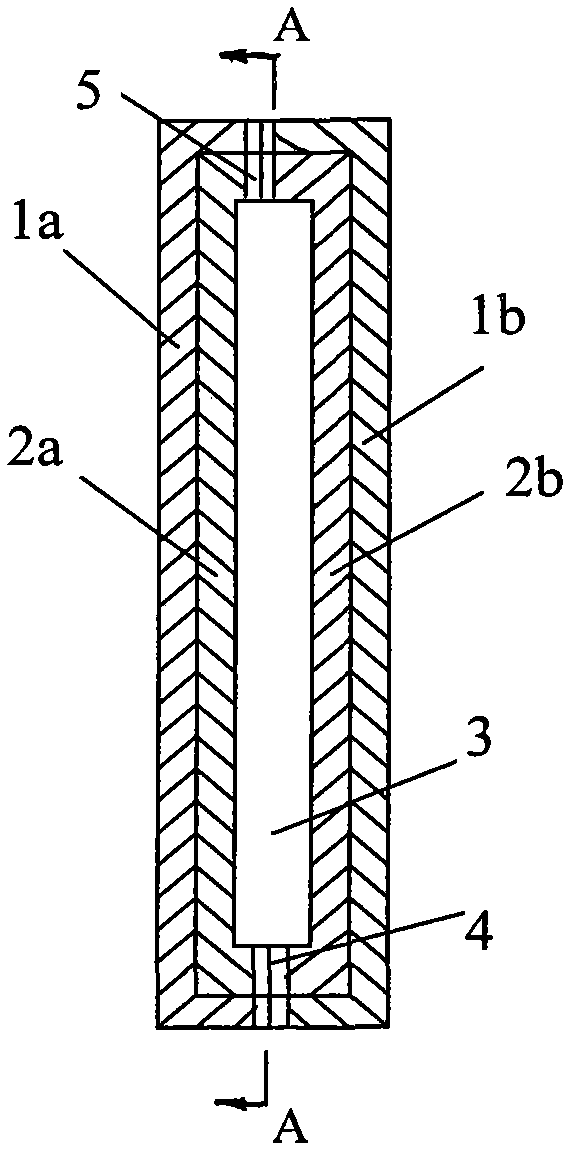

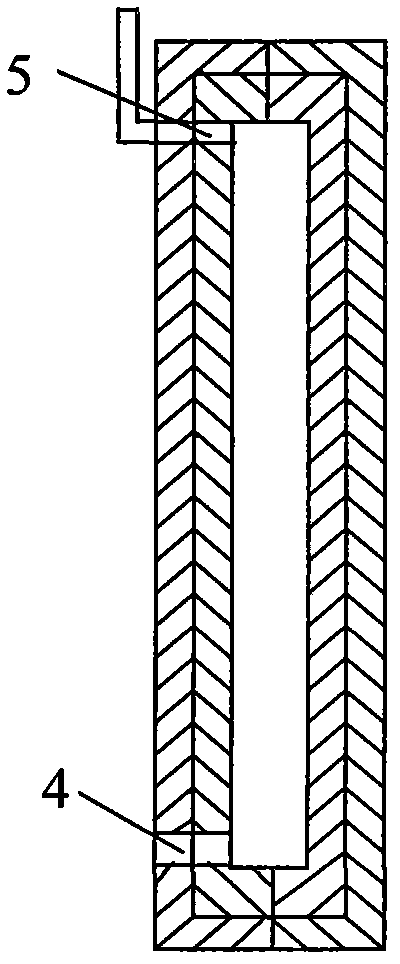

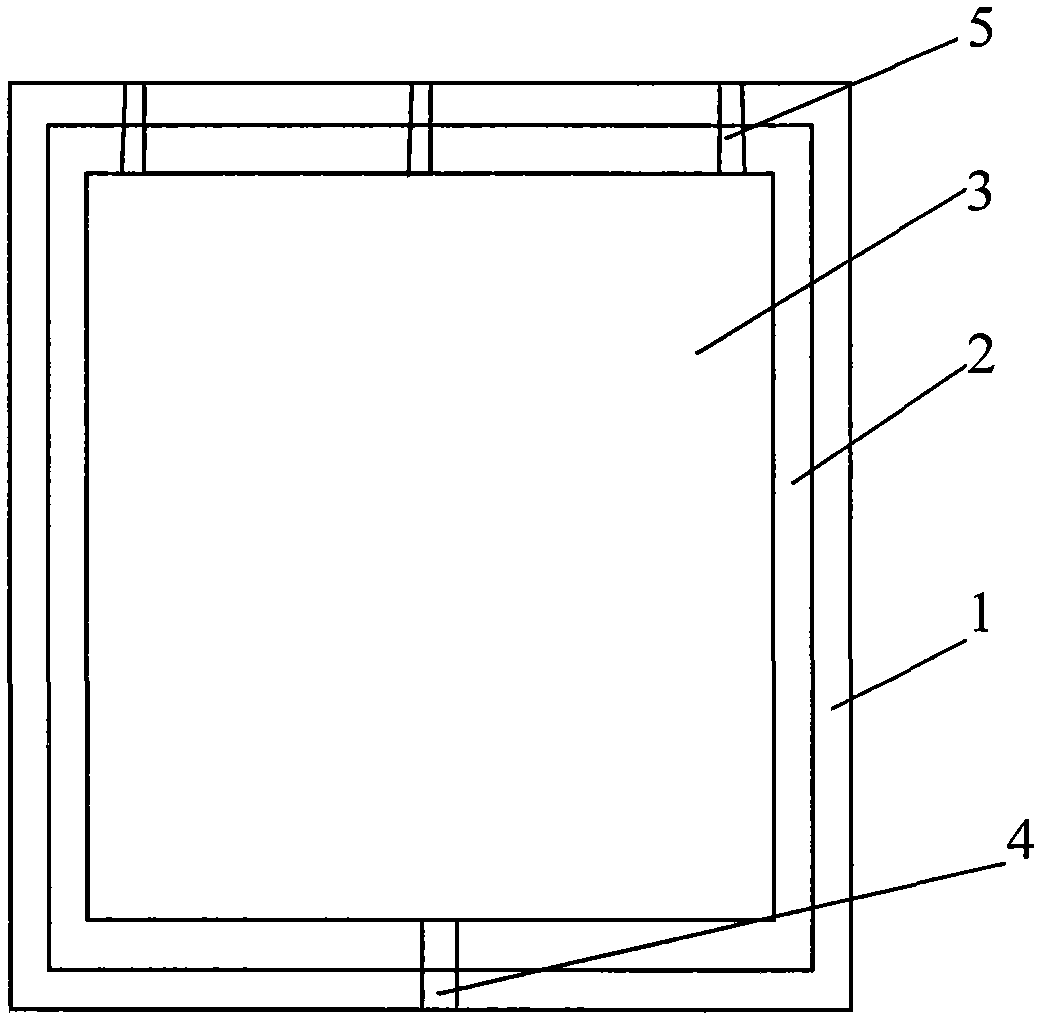

Vertical type pouring manufacturing method of decorative gypsum board

InactiveCN102380909AHigh dimensional accuracyReduce thicknessFeeding arrangmentsLeft halfInjection port

The invention relates to a vertical type pouring manufacturing method of a decorative gypsum board; a vertical rigid external mold and a flexible internal mold arranged in the external mold are adopted, injection ports (4) communicated to an inner cavity (3) of an internal mold are arranged at the bottoms of the external mold and the internal mold, air exhausts (5) communicated with the inner cavity are arranged at the tops of the external mold and the internal mold; the external mold is formed by a left half external mold (1a) and a right half external mold (1b) in an involution way; the internal mold is formed by a left half internal mold (2a) and a right half internal mold (2b) in the involution way; when in pouring, gypsum slurry is injected into the inner cavity through the injection ports until the inner cavity is full of the gypsum slurry; and after the gypsum slurry is solidified, the external mold is opened and the internal mold is taken down, so as to obtain a decorative gypsum board which is solidified and formed in the inner cavity. In the method, air bubbles can be effectively removed in the manufacturing process, so as to prevent air holes from being remained in the gypsum board; and a manufactured product has good quality, the mechanical and standard production can be realized and the production efficiency is high.

Owner:王志伟

Preparation method of rock wool

InactiveCN112299701ASolve the conditioning problemDrain cleanGlass making apparatusAlkali freeHeat energy

The invention discloses a preparation method of rock wool, and the method specifically comprises the following steps of: putting raw materials into a kiln, and performing melting and wire drawing to obtain rock wool; wherein the raw materials comprise 50-90wt% of hot melt slag, 5-30wt% of alkali-free glass waste wires and 2-30wt% of basalt. By means of the method, a large amount of alkali-free glass fiber waste silk solid waste can be utilized at present; and on the other hand, the problem of blending and hardening and tempering of mineral cotton produced by hot melt slag is solved. The threeraw materials almost have no silicate reaction during heating, so that the emission of carbon dioxide waste gas is greatly reduced. Due to the fact that the reaction amount is small and the emission amount of carbon dioxide is extremely small, heat energy consumption can be reduced, the heat utilization rate is increased, and fuel consumption is reduced.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Efficient medical anti-blockage drainage apparatus and using method thereof

ActiveCN108096653AEasy dischargeClean environmentClimate change adaptationCatheterSpiral bladeTissue fluid

The invention provides an efficient medical anti-blockage drainage apparatus and a using method thereof. The efficient medical anti-blockage drainage apparatus comprises a drainage tube, a blade-shaped filter screen, a negative-pressure tube, a mixing tube and a retaining loop, wherein a plurality of first through holes are kept in the sidewall of the drainage tube; the blade-shaped filter screenis arranged in the drainage tube; the blade-shaped filter screen is of a conical structure; a negative-pressure tube connecting port is defined by the conical part of the blade-shaped filter screen and the inner wall of the drainage tube; a spiral blade is arranged in the negative-pressure tube connecting port; the negative-pressure tube connecting port is connected to a negative-pressure device;the first through holes are located in the lower side of the blade-shaped filter screen; the spiral blade gets rotating when the negative-pressure device works; the mixing tube is connected to a nozzle of the drainage tube; via the mixing tube, flushing liquid or gas is flushed into the drainage tube; the negative-pressure tube and the mixing tube are fixed to the interior of the drainage tube viathe retaining loop; and air vents are kept in the retaining loop. According to the efficient medical anti-blockage drainage apparatus provided by the invention, the drainage tube is prevented from getting blocked in a using process; and complete drainage of polluted tissue fluid in a body cavity can be achieved.

Owner:张明凯

Dust-removing device for vacuum cleaner

The present invention discloses a dust-removing device of vacuum cleaner. It includes the communicated first-stage cyclone separator and second-stage cyclone separator. The described first-stage cyclone separator is positioned over the second-stage cyclone separator, said first-stage cyclone separator and second-stage cyclone separator respectively possess independent dust-collecting chamber. Said invention can more completely make the dust be separated from air and make the dust be separated from air and make the air discharged from vacuum cleaner be more clean and do not produce secondary pollution.

Owner:KINGCLEAN ELECTRIC

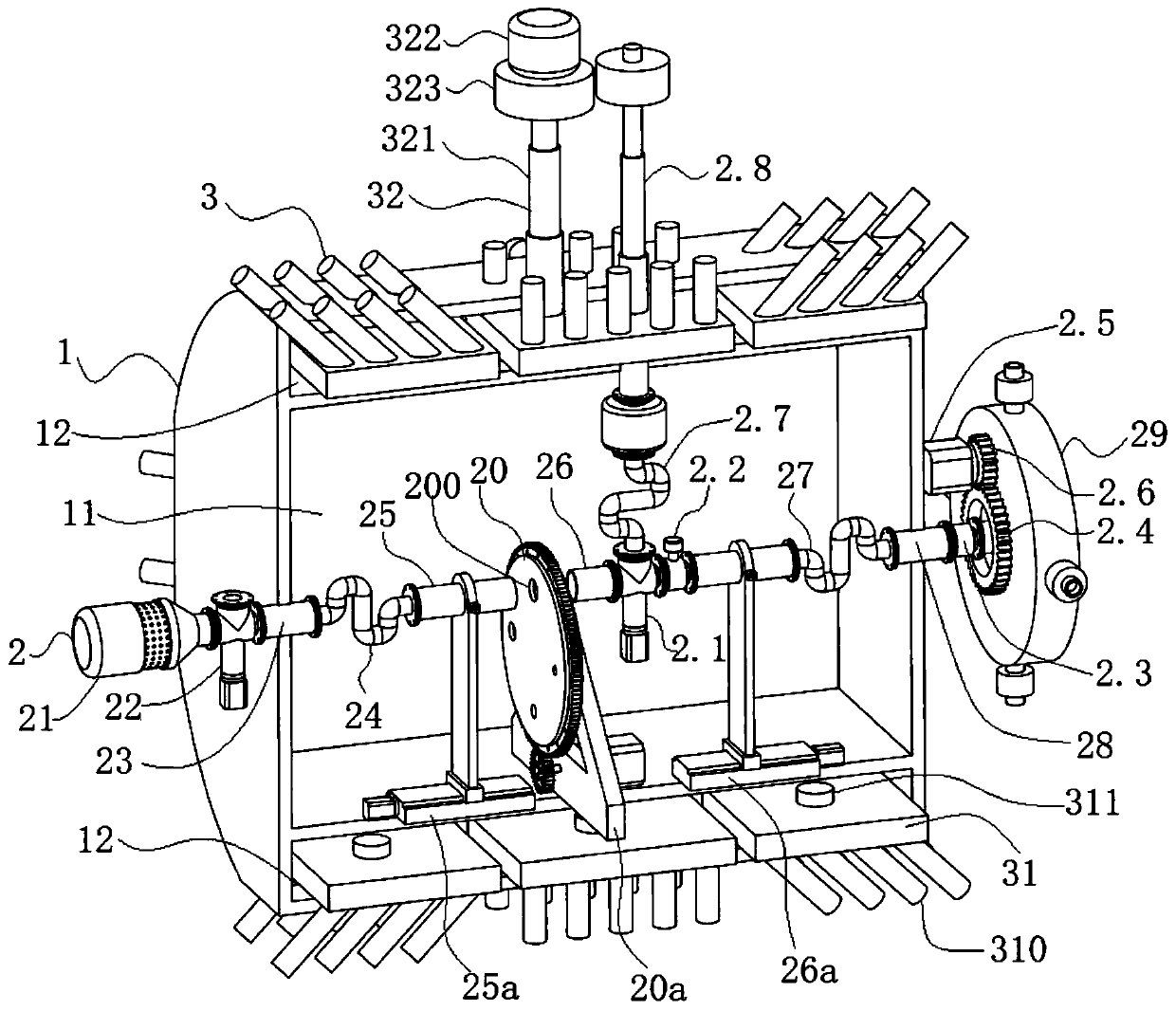

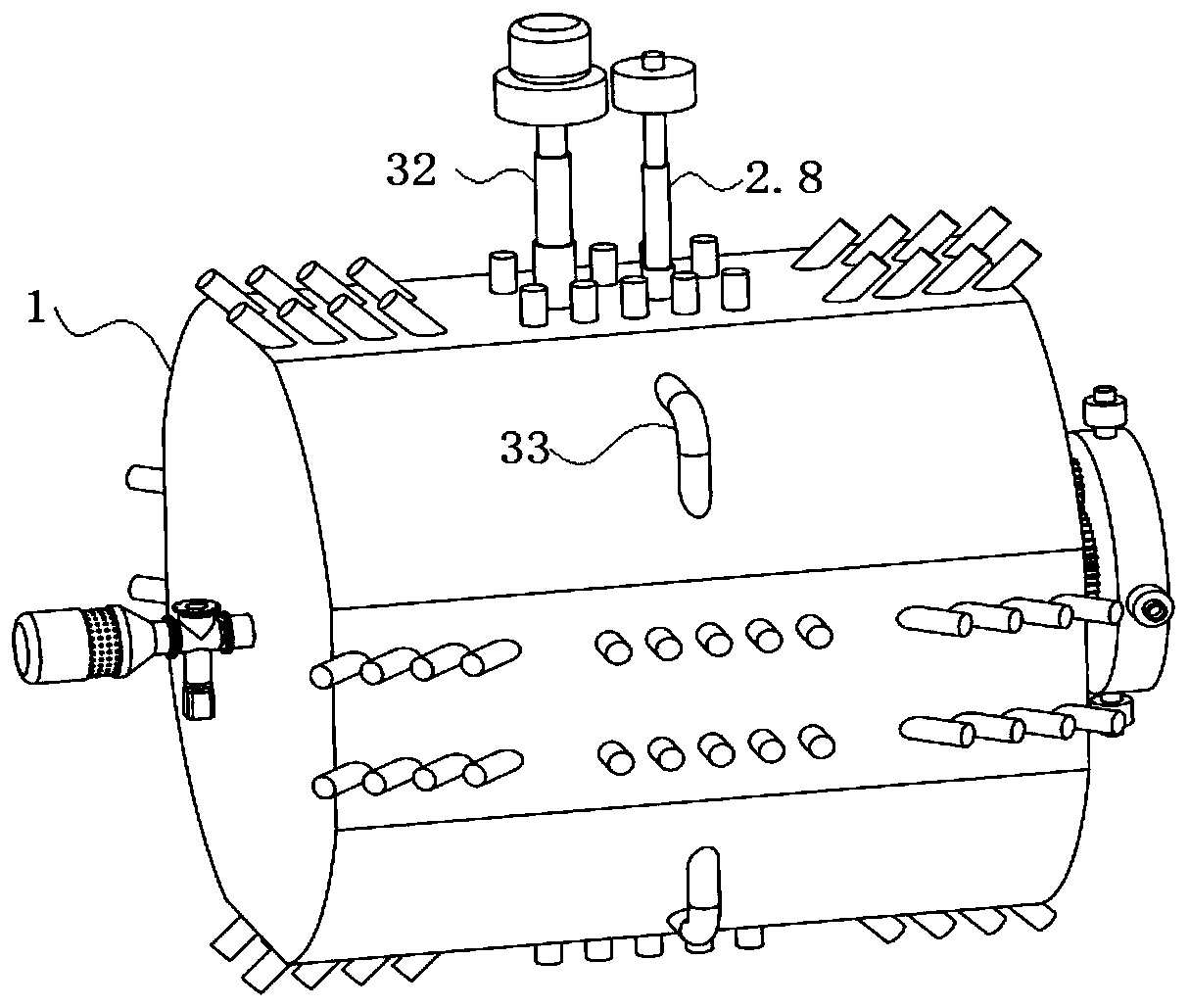

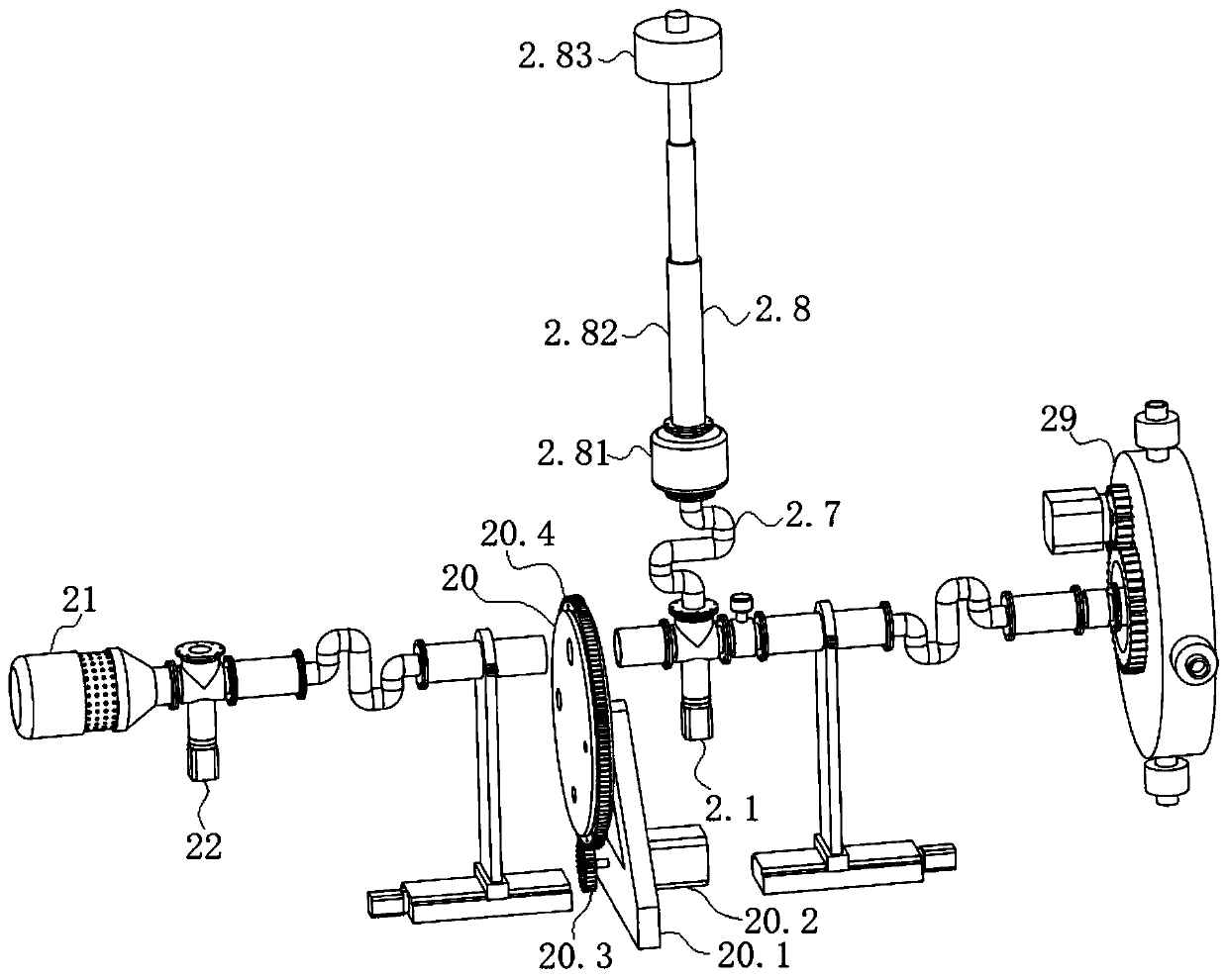

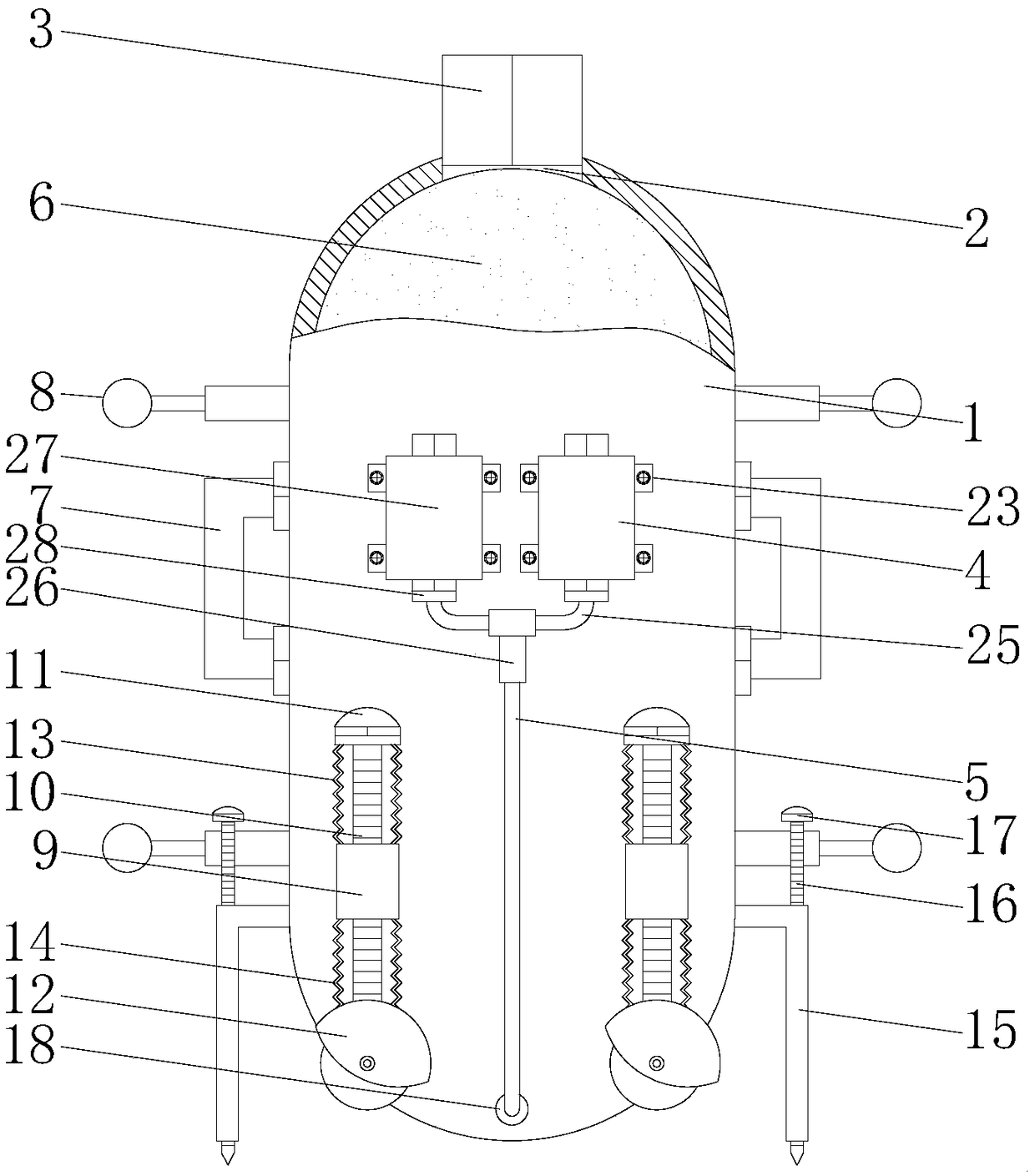

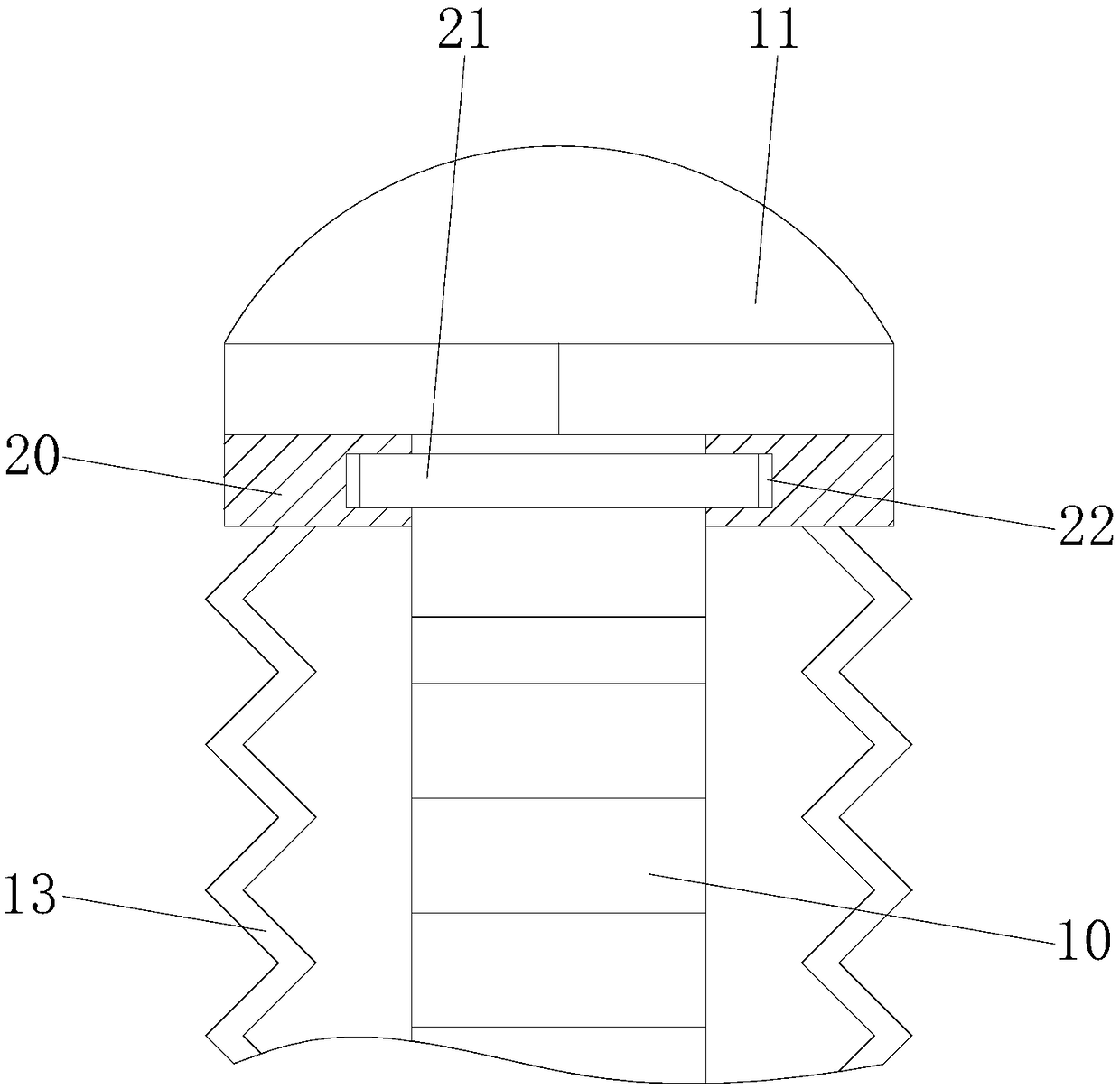

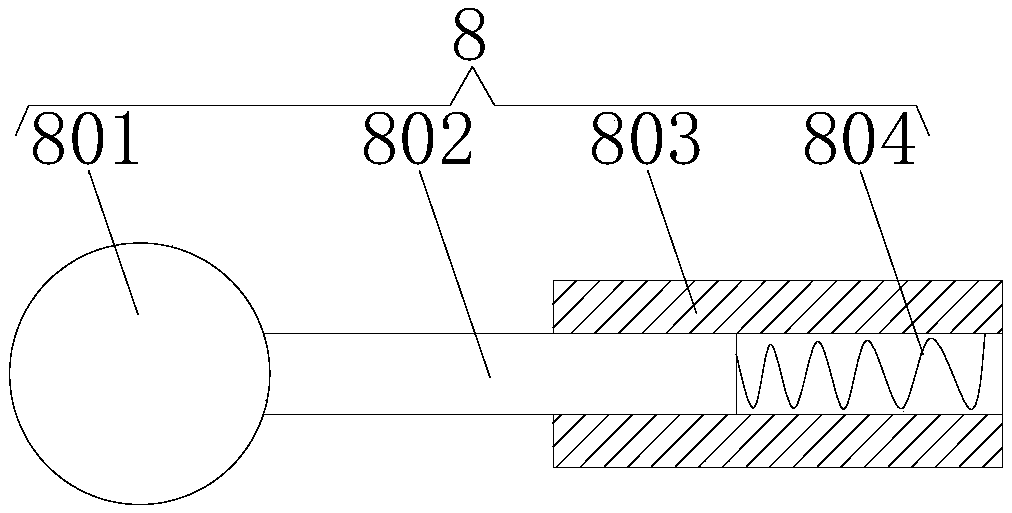

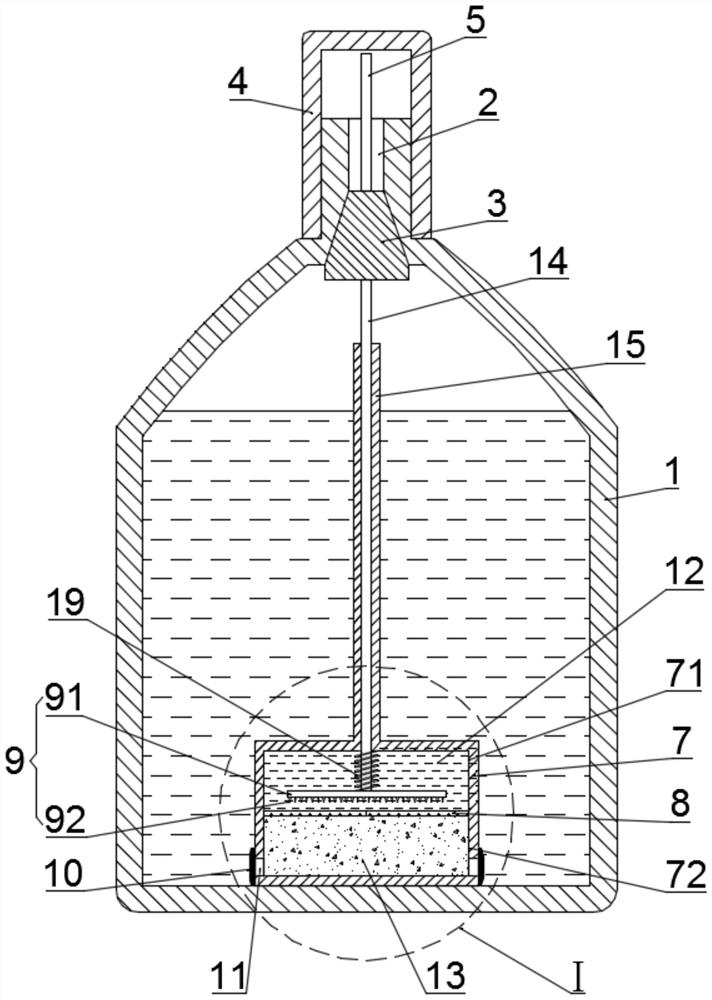

Creeping-type water quality sampling device for water quality detection and water quality sampling method

InactiveCN111595632AWide range of water quality samplingIncrease flexibilityWithdrawing sample devicesBuoysWater volumeSample water

The invention discloses a creeping-type water quality sampling device for water quality detection and a water quality sampling method. The creeping-type water quality sampling device comprises a shellbody, an adjustable water quality sampling device and a gas driving device, wherein the adjustable water quality sampling device and the gas driving device are both installed on the shell body, the adjustable water quality sampling device is used for sampling water, and the gas driving device is used for driving the whole creeping-type water quality sampling device to creep; the adjustable waterquality sampling device comprises a turntable group, a submersible pump, a first T-shaped three-way valve, a first interface guide pipe, a first metal snakelike hose, a first hard guide pipe, a secondhard guide pipe, a second metal snakelike hose, a second interface guide pipe and a sample water storage disc; and the gas driving device comprises gas distribution plates arranged in side bins, telescopic gas supply devices communicated with the side bins located at the top part of the shell body, and gas guide pipes communicating the adjacent side bins. The creeping-type water quality samplingdevice has the advantages of wide water quality sampling range, high flexibility, adjustable sampling water quantity and accurate sampling.

Owner:殷富新

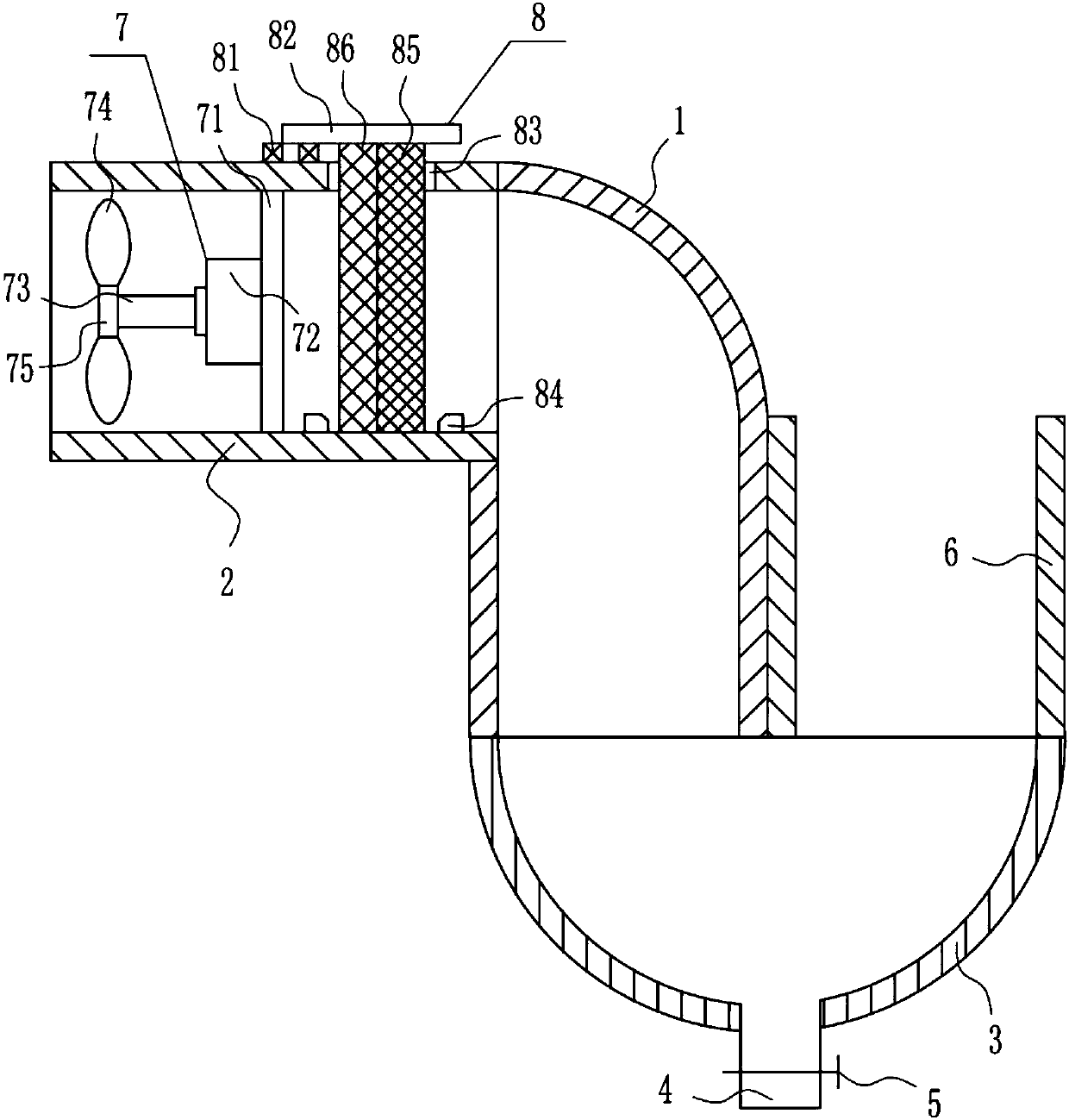

Air treatment device for metallurgical factory

InactiveCN108031223AGood effect of dust suppressionGood processing effectCombination devicesAir treatment

The invention relates to a treatment device, in particular to an air treatment device for a metallurgical factory, and aims to provide an air treatment device for the metallurgical factory, wherein the air treatment device can repeatedly treat and discharge air and cannot affect surrounding environments. In order to solve the technical problem, the air treatment device for the metallurgical factory comprises a bent pipe and the like. An air extractor is arranged on the inner left side of a pipeline, a filtering mechanism is arranged on the right inner side of the pipeline, the bent pipe is connected at the right end of the pipeline, the bent pipe is communicated with the inside of the pipeline, a hopper is mounted at the tail end of the bent pipe and communicated with the inside of the bent pipe, a pipe is connected with the right side of the top of the hopper and communicated with the inside of the hopper, and the outer left side surface of the pipe is connected with the lower portionof the outer right side of the bent pipe. According to the air treatment device, dust in the air can be removed, so that the air can be repeatedly treated and completely discharged, and the surrounding environments cannot be affected.

Owner:王森杰

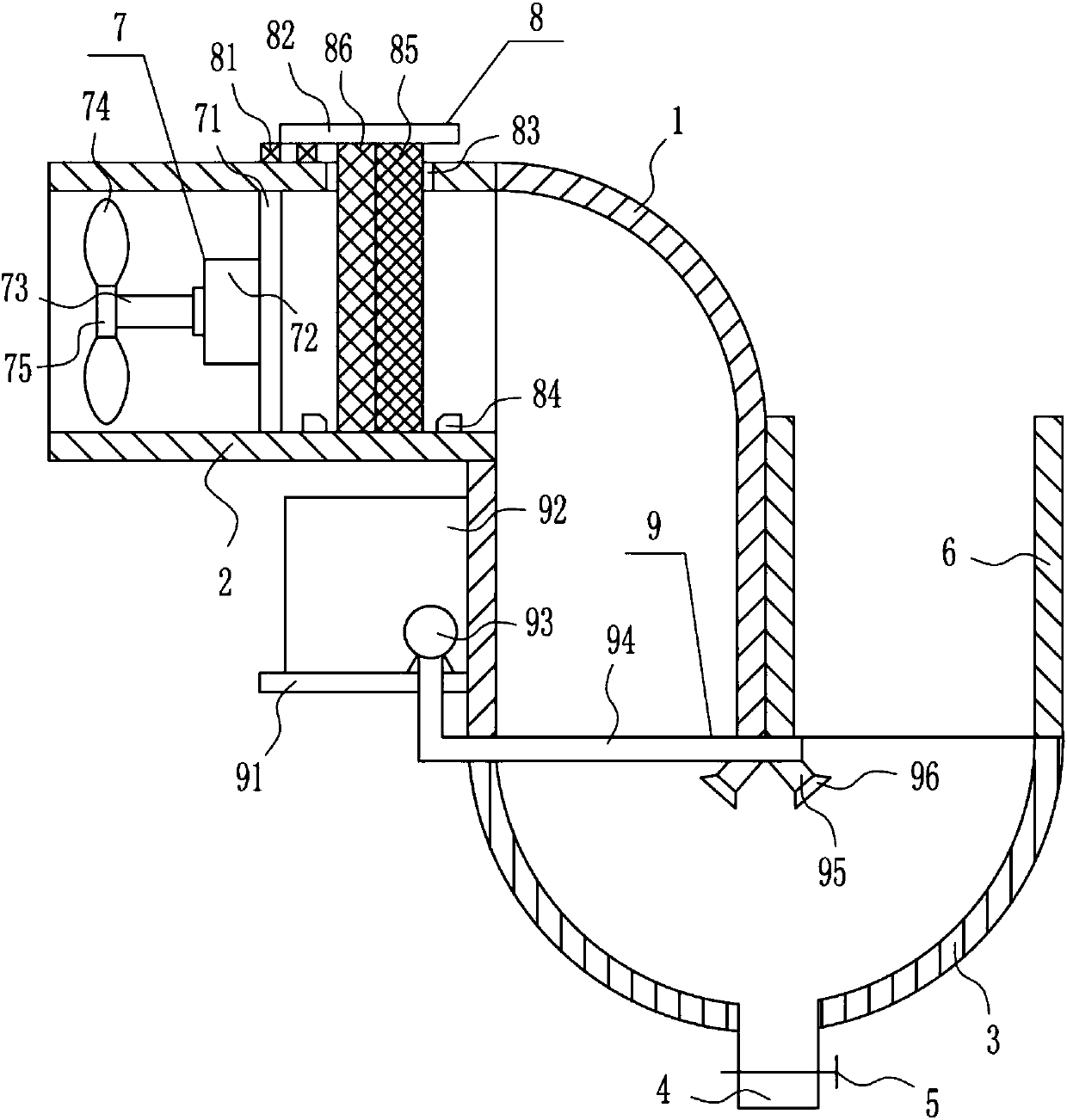

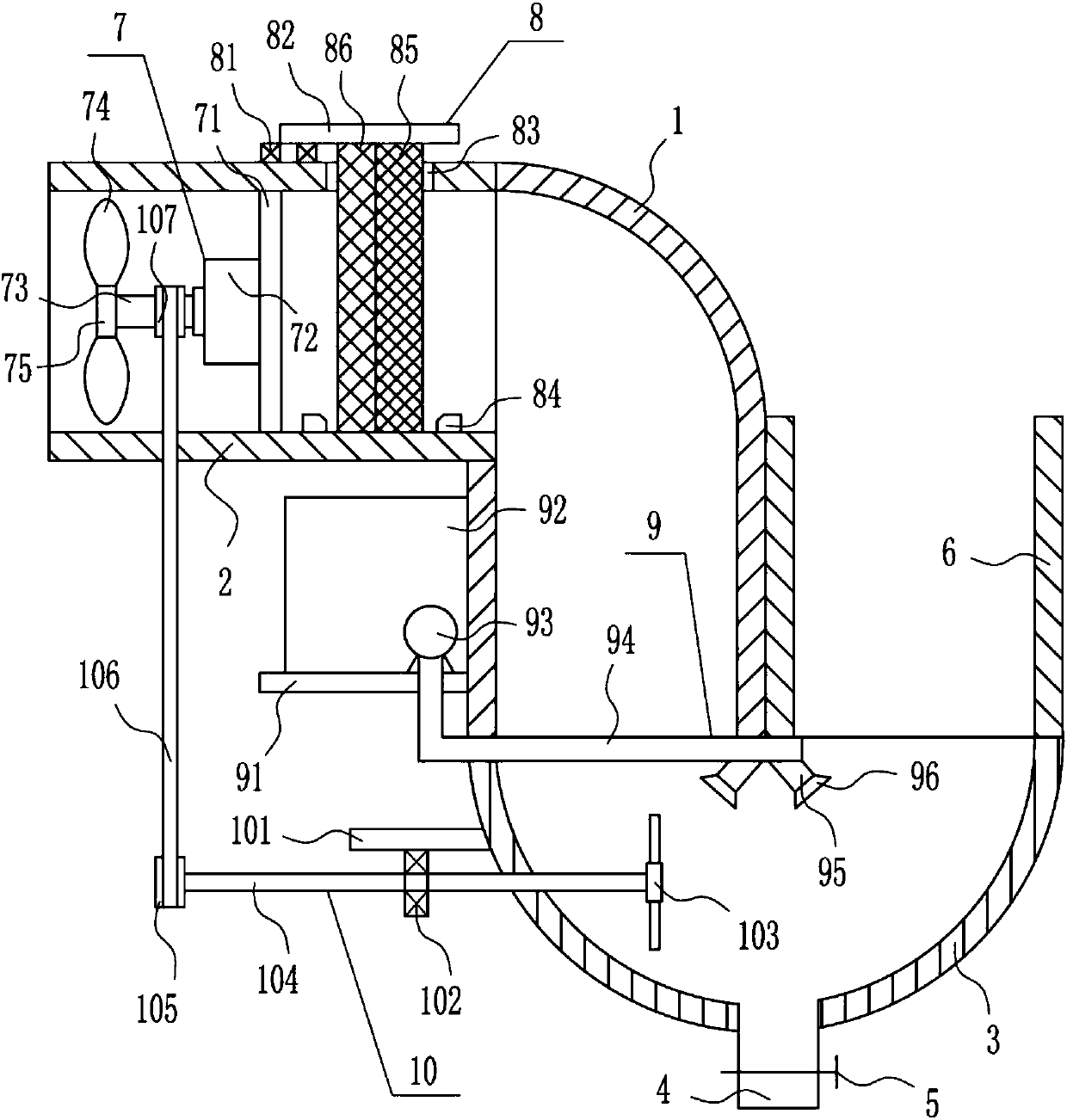

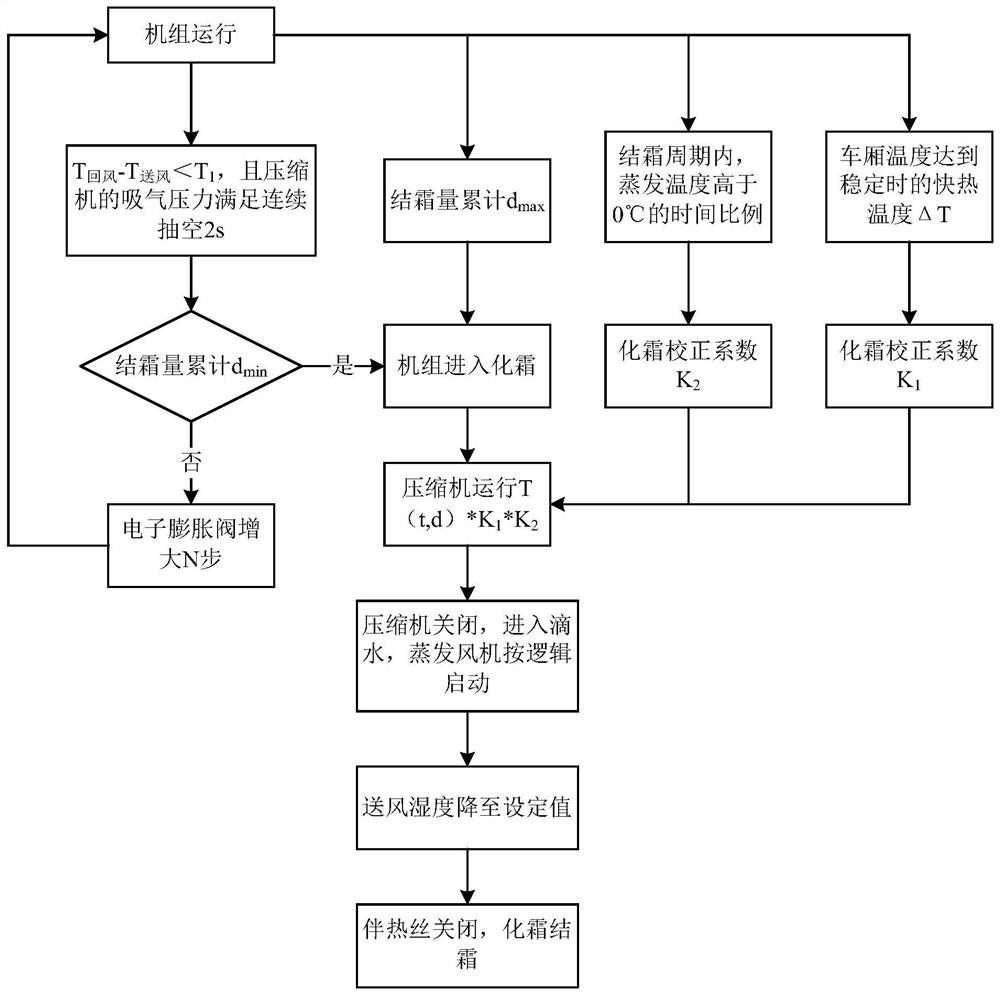

Defrosting control device and method of air conditioner and air conditioner

The invention discloses a defrosting control device and method of an air conditioner and the air conditioner. The device comprises an acquiring unit and a control unit, wherein the acquiring unit is configured to acquire the air inlet temperature, the air inlet humidity, the air outlet temperature and the air outlet humidity of the air conditioner; and the control unit is configured to determine the frosting amount of an evaporator of the air conditioner according to the air inlet temperature, the air inlet humidity, the air outlet temperature and the air outlet humidity, determine whether theair conditioner needs defrosting or not according to the air inlet temperature, the air outlet temperature and the frosting amount, control the air conditioner to enter the defrosting mode under thecondition that the air conditioner needs defrosting, and control the defrosting time of the air conditioner under the defrosting mode. According to the technical scheme, the judgment logic for the defrosting entering condition and the defrosting quitting condition during hot air bypass defrosting is intelligentized, so that different working conditions are adapted.

Owner:GREE ELECTRIC APPLIANCES INC

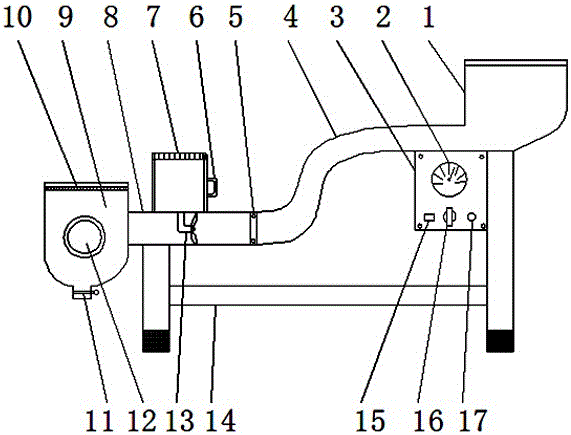

Automatic chip discharging device for numerical control machine tool

InactiveCN106217113AIncrease speedAvoid feverMaintainance and safety accessoriesNumerical controlSuction force

The invention discloses an automatic chip discharging device for a numerical control machine tool. The automatic chip discharging device comprises a control panel, an S-shaped pipeline, a motor box, a straight pipe, a chip discharging bin, a rotating speed rotary knob, a heat dissipation opening and a motor. A chip discharging connector is arranged on the right side of the S-shaped pipeline, and a supporting frame is arranged below the chip discharging connector. The S-shaped pipeline is connected with the straight pipe through a connecting frame. The control panel is arranged below the S-shaped pipeline. The rotating speed rotary knob is arranged on the surface of the control panel. A revolution meter is arranged above the rotating speed rotary knob. An indicator lamp is arranged on the right side of the rotating speed rotary knob. A power switch is arranged on the left side of the rotating speed rotary knob. The motor box is arranged above the straight pipe. A draught fan is arranged in the straight pipe. According to the automatic chip discharging device, a controller is arranged and can be used for adjusting the rotating speed of the motor, when large waste chips are encountered, the rotating speed of the motor can be increased, the suction force of the draught fan is made to be increased, and it is guaranteed that the waste chips are thoroughly discharged.

Owner:张民胜

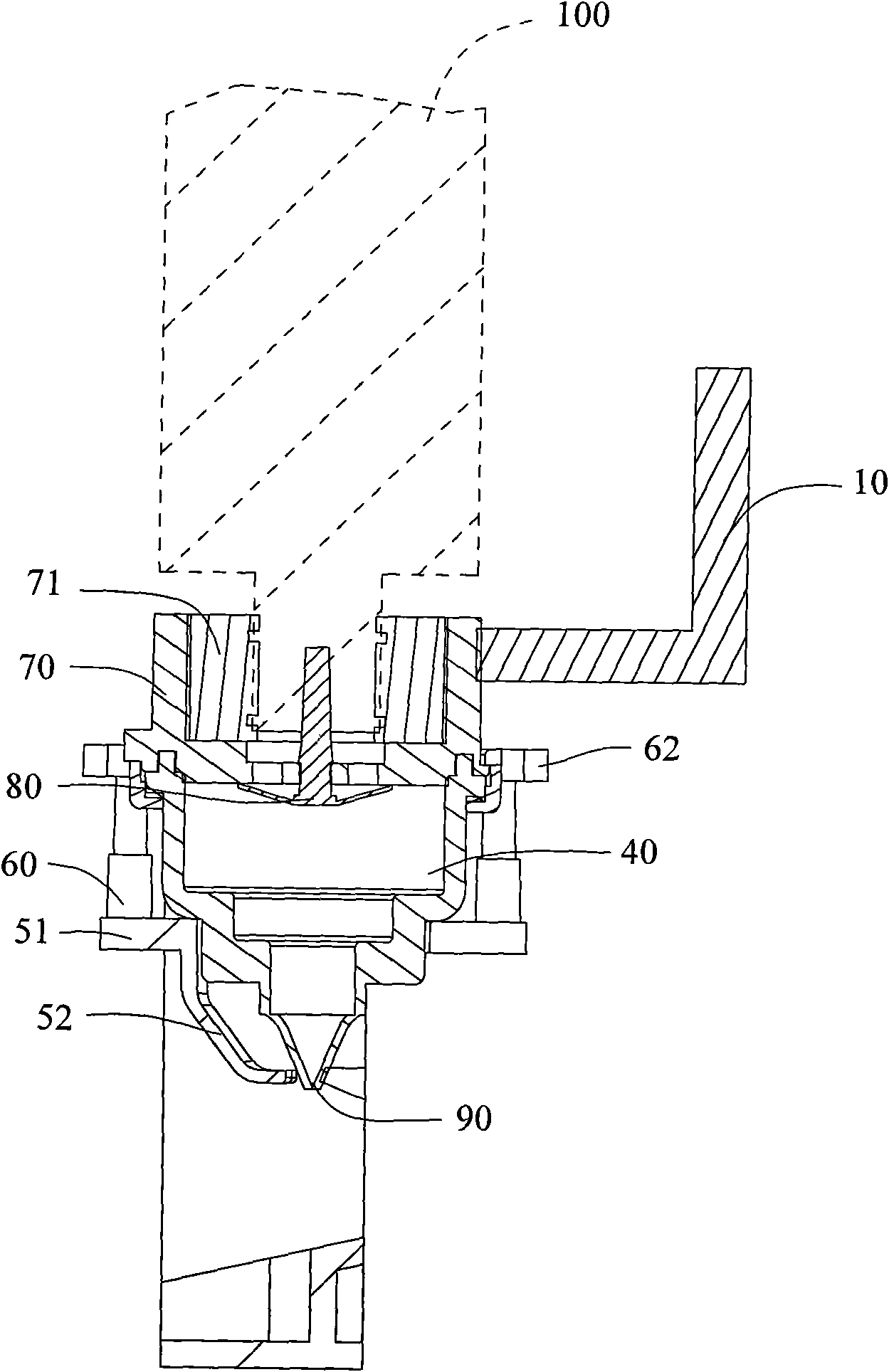

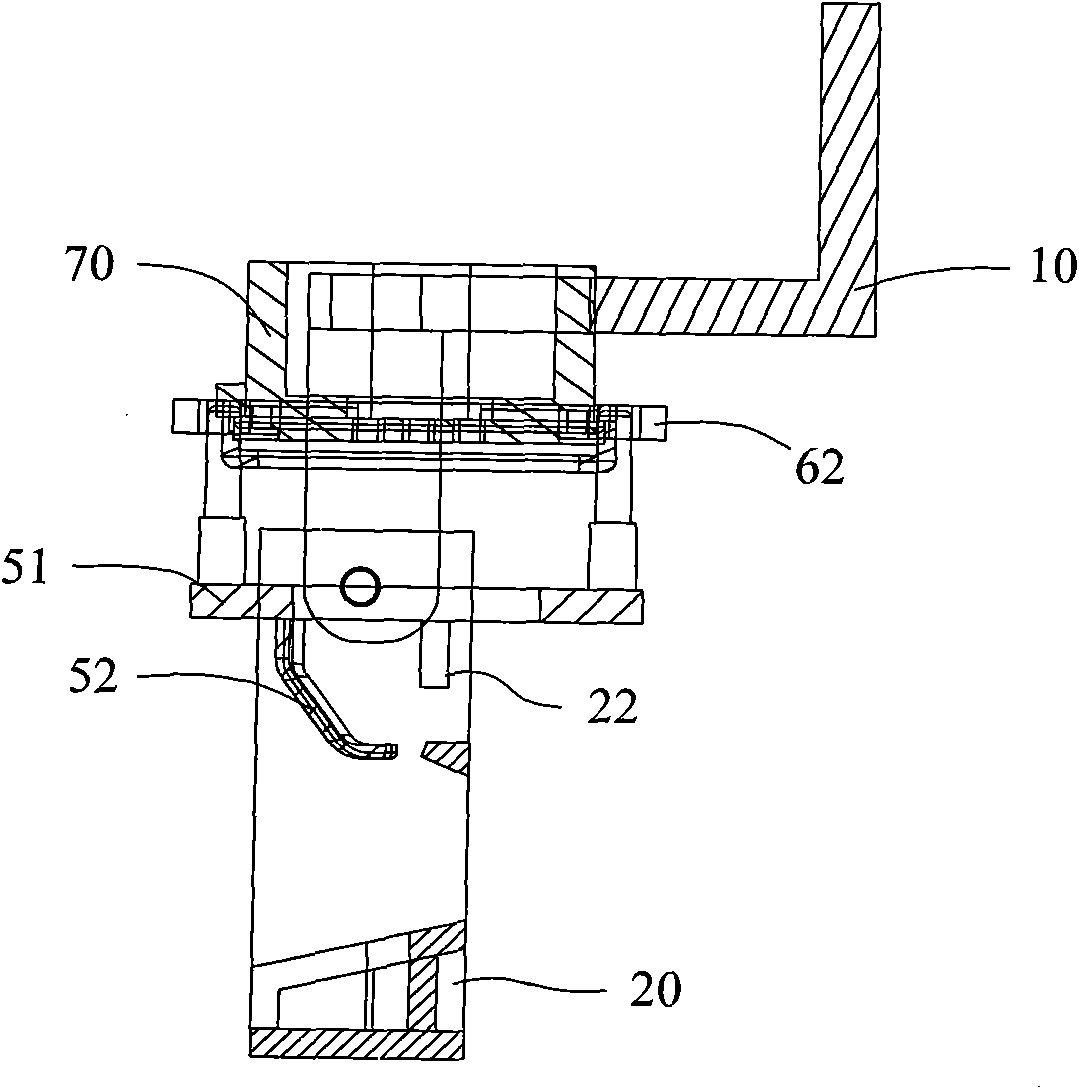

Fluid taking device

InactiveCN101665162AEasy to operateDrain cleanHolders and dispensersArticle unpackingFluid takingHand held

The invention relates to a fluid taking device which comprises a fixed machine frame, a swing stem connected under the fixed machine frame, an elastic storage compartment and a squeezing device, wherein the elastic storage compartment is arranged on the fixed machine frame and used for storing fluid substances, and the squeezing device is connected with the swing stem in a rotating way and used for squeezing the elastic storage compartment. The fluid taking device pertains to a device facilitating the taking of fluid substances. With one hand or one hand holding articles to push the swing stemof the device, the appropriate taking of the fluid substances can be realized. The device can be used conveniently and used as a convenient taking device for taking a certain amount of fluid substances in the bathroom field.

Owner:朱培畅

A kind of preparation method of chitosan and the immersion device of preparation chitosan

InactiveCN103665191BReduce manufacturing costComprehensive utilization of resourcesResource utilizationFiltration

The invention relates to a preparation method of chitosan, which comprises the following steps of: screening, purifying, dicing, washing and drying shrimp shells and crab shells, soaking with an appropriate amount of hydrochloric acid for 5-8h, after filtering, recovering a calcium chloride solution, collecting the preliminarily decalcified shrimp shells and crab shells, soaking with excessive hydrochloric acid, collecting the decalcified shrimp shells and crab shells, boiling with a sodium hydroxide solution, cooling, then filtering, recovering the sodium hydroxide solution after filtration, obtaining the shrimp shells and crab shells having protein removed, removing water, soaking with potassium permanganate, soaking a filtration product in a reducer solution after filtration till complete decoloration, washing with water, drying to form chitin, soaking the chitin with sodium hydroxide for 15-20 h at 80-100 DEG C, cooling, filtering, cleaning a filtration product, removing residual sodium hydroxide, drying, and grinding to form the chitosan. The preparation method realizes high resource utilization rate, low production cost and low environmental pollution by recycling materials.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

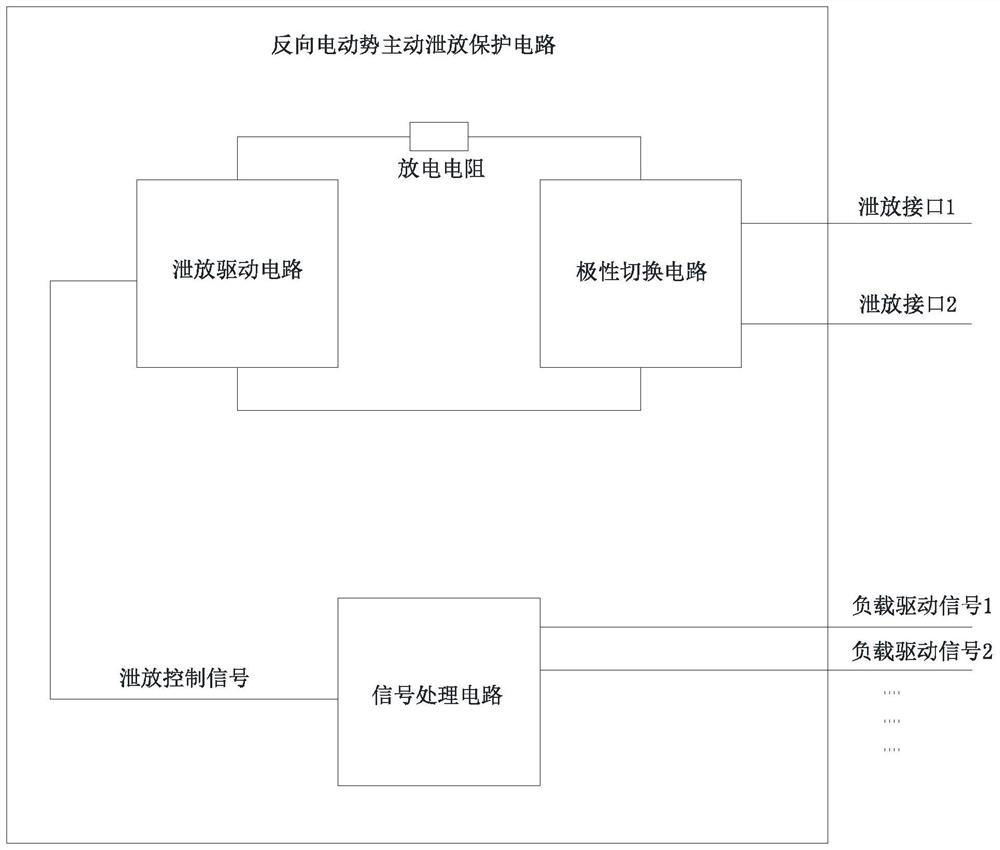

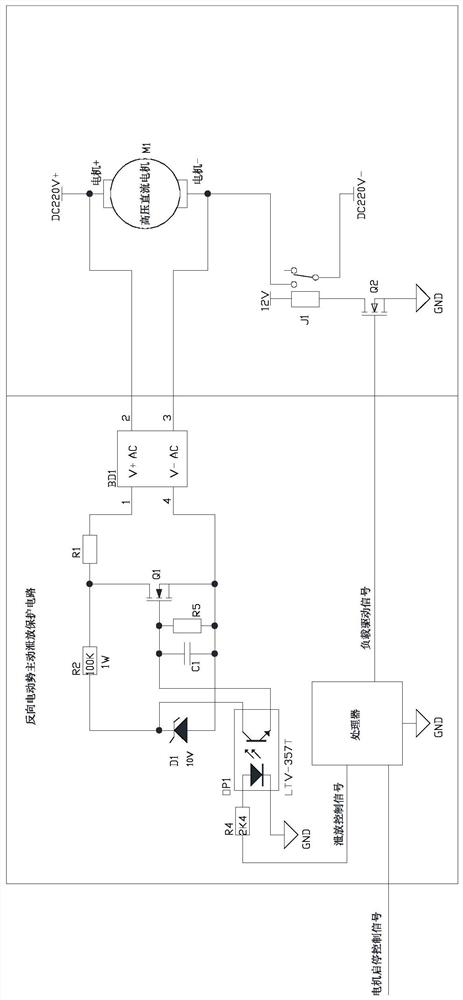

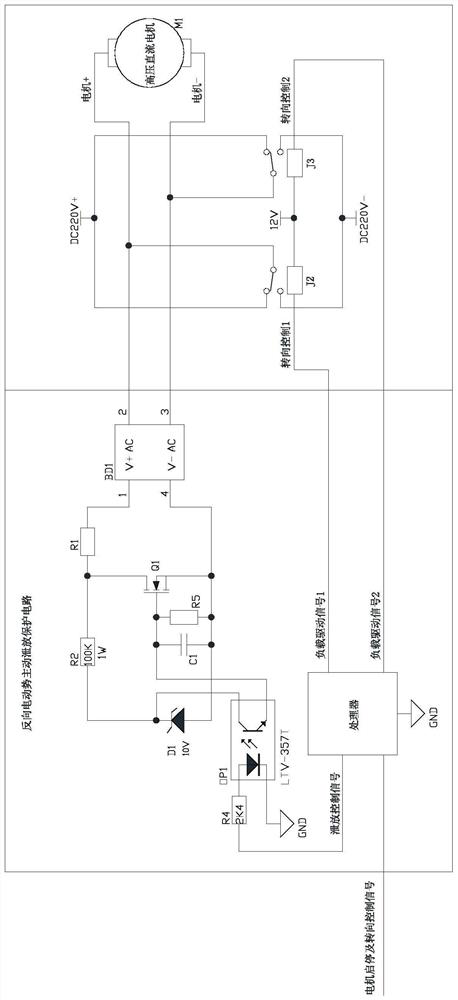

Reverse electromotive force active discharge protection circuit and active arc extinguishing method

PendingCN113285436AMeet actual needsSave installation spaceEmergency protective arrangements for limiting excess voltage/currentSignal processing circuitsControl signal

The invention relates to the field of direct current system protection, in particular to a reverse electromotive force active discharge protection circuit which comprises a signal processing circuit, a discharge driving circuit, a discharge resistor and a polarity switching circuit, wherein one end of the discharge resistor is electrically connected with the polarity switching circuit, the other end is electrically connected with the discharge driving circuit, the polarity switching circuit and the signal processing circuit are both electrically connected with the discharge driving circuit, the polarity switching circuit is provided with two discharge interfaces used for being connected in parallel with a direct-current load, and the signal processing circuit outputs a load driving signal used for controlling the direct-current load and a discharge control signal used for controlling the discharge driving circuit. The reverse electromotive force active discharge protection circuit provided by the invention can actively extinguish arc, and can solve the problem that a switch or a relay contact is damaged by reverse electromotive force generated by an inductive device. The invention further provides an active arc extinguishing method based on the reverse electromotive force active discharge protection circuit. The method deals with reverse electromotive forces that are harmful to the circuit in an active and advanced intervention manner.

Owner:浙江南晶电气有限公司

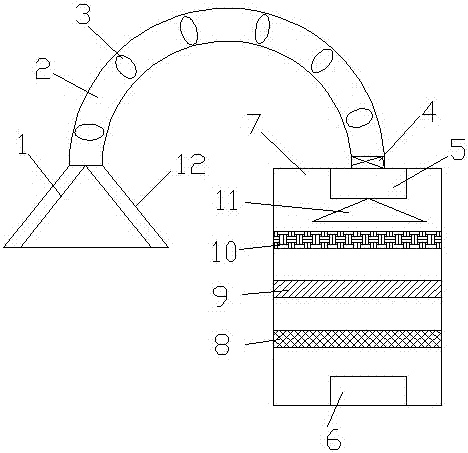

Smoke-free grill

PendingCN110123150AUniform temperatureNo smoke effectDispersed particle filtrationRoasting apparatusExhaust gas emissionsEngineering

The invention relates to a smoke-free grill, and belongs to the field of kitchen supplies. The smoke-free grill comprises a grill body, a grill body upper cover, a front door, a rotary hanging frame,a gas inlet inner pipe, an exhaust gas emission cylinder and a filtering part; one side of the grill body is provided with an opening for dishes to be placed on; the grill body upper cover is fixedlyconnected to the top of the grill body; the bottom of the grill body upper cover is provided with a first sliding groove, and the top of the front door is slidably formed in the first sliding groove;the rotary hanging frame is located in the grill body; one end of the gas inlet inner pipe is connected with the outer wall of the grill body; the exhaust gas emission cylinder fixedly sleeves the gasinlet inner pipe, and one end of the exhaust gas emission cylinder is connected with the grill body; the filtering part is fixedly arranged between the exhaust gas emission cylinder and the gas inletinner pipe. The smoke-free grill has the advantages that exhaust gas can be treated, and particles in the exhaust gas are filtered out, so that emitted exhaust gas does not contain the particles.

Owner:GUIZHOU MINZU UNIV

Grinding machine flue gas purifying method

InactiveCN106902580ADrain cleanEasy to monitor usageDispersed particle filtrationTransportation and packagingFlue gasProduct gas

The invention discloses a grinding machine flue gas purifying method. The flue gas purifying method comprises the following steps: 1) assembling a flue gas purifier; 2) removing dust particles in the flue gas through gluing; 3) filtering the particles in the flue gas; 4) dispersing wind speed; 5) filtering the particles in the flue gas; 6) removing smell in the flue gas; and 7) discharging clean gas. The gas purifying method can remove the dust and polluted gas during a polishing process by a grinding machine, can avoid the diffusion of dust and polluted gas in a workshop, and can protect the workshop environment.

Owner:SUZHOU YASIKE PRECISION CNC CO LTD

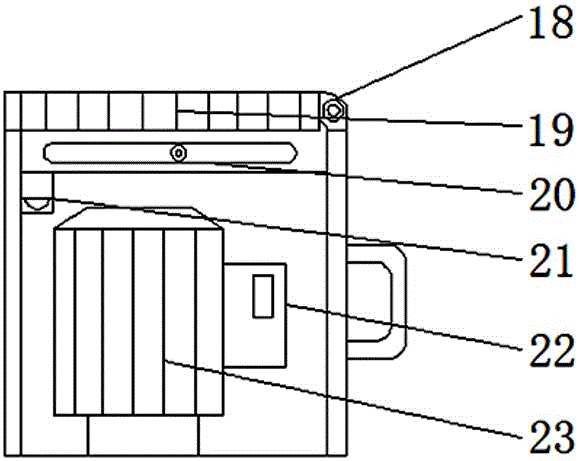

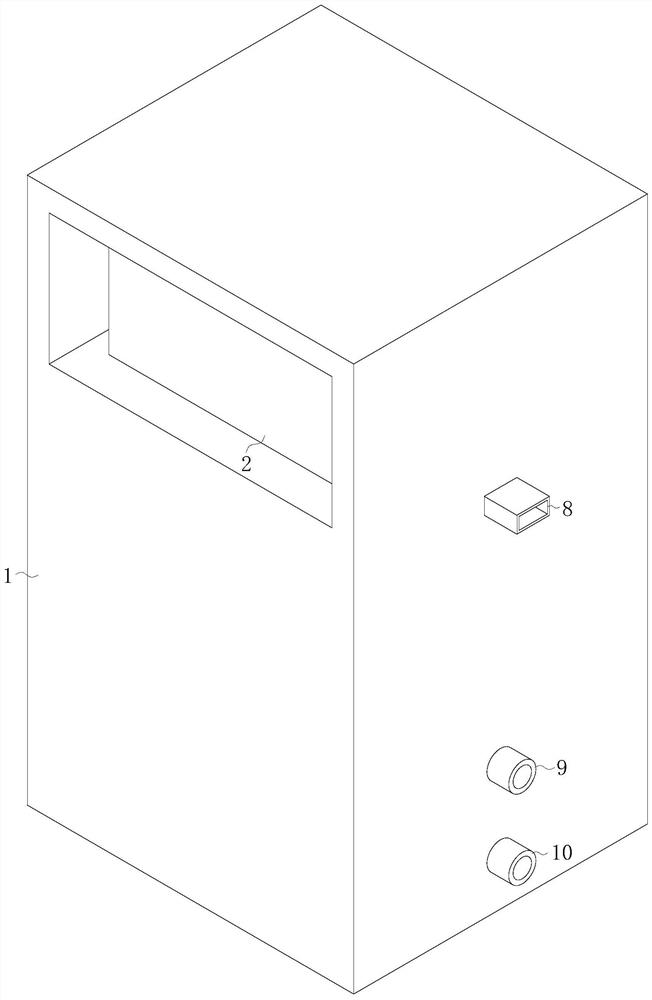

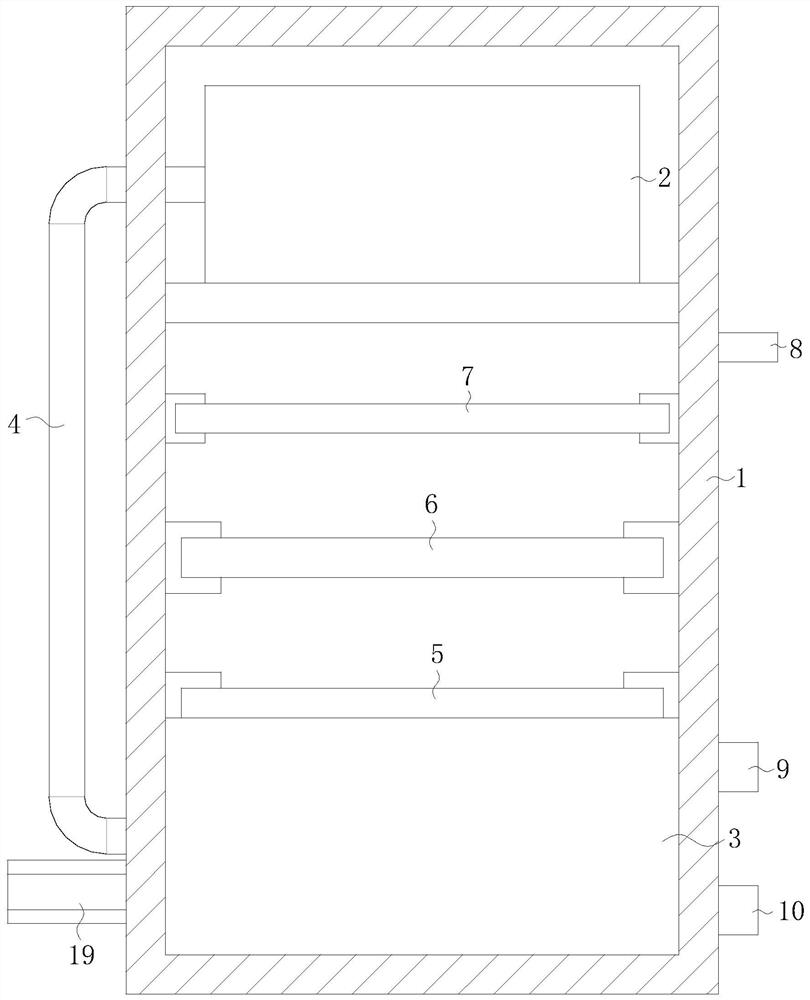

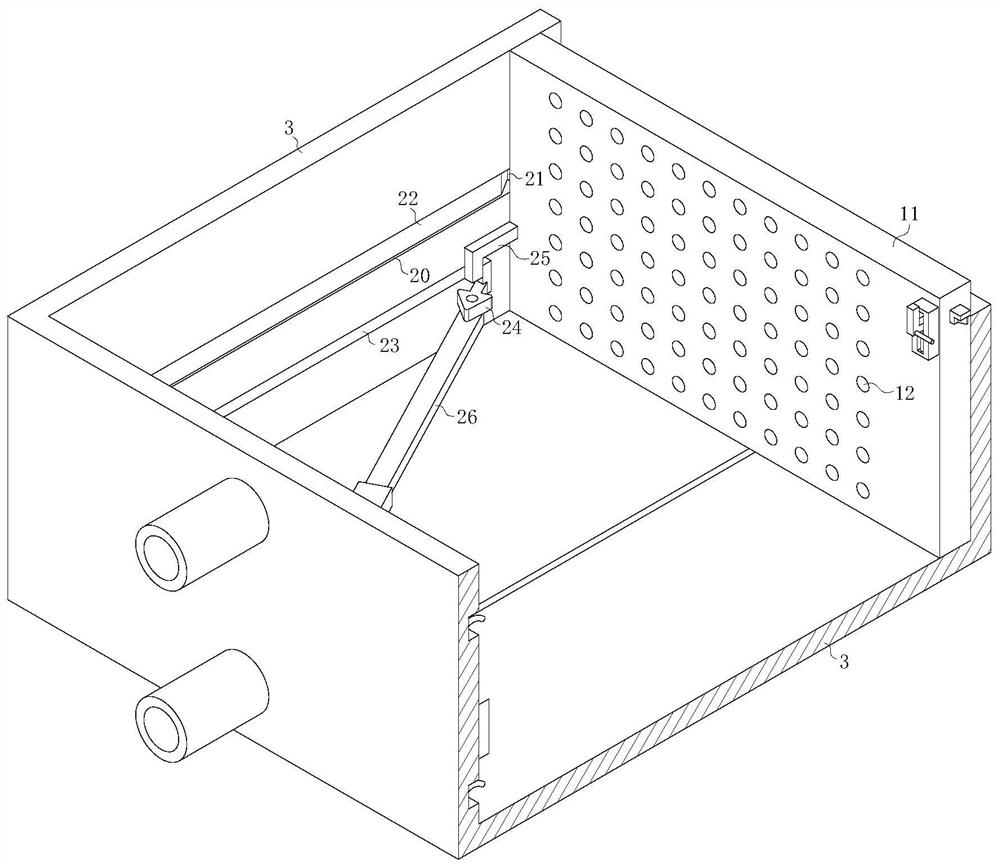

Waste gas treatment device applied to double-laser printer

ActiveCN113368642AImprove purification effectEasy dischargeCombination devicesDispersed particle filtrationComputer printingProcess engineering

The invention discloses a waste gas treatment device applied to a double-laser printer, and belongs to the technical field of printer technologies. The waste gas treatment device comprises a mounting box, the printer is fixedly arranged in the mounting box, a purification box is fixedly connected to the bottom of the inner wall of the mounting box, and a gas outlet pipeline is fixedly connected to a gas outlet of the printer; the bottom end of the gas outlet pipeline penetrates through the inner wall of the mounting box and is inserted into the purification box, a first-stage filter screen, a second-stage filter screen and a third-stage filter screen are fixedly connected to the inner wall of the mounting box, the first-stage filter screen, the second-stage filter screen and the third-stage filter screen are sequentially distributed from bottom to top, the first-stage filter screen covers the top surface of the purification box, and the second-stage filter screen covers the top surface of the purification box; and an exhaust port formed in the inner wall of the mounting box is formed above the third-stage filter screen. When a water source is replaced, waste gas cannot leak out of the water outlet pipe, and the waste gas can be purified more completely.

Owner:山东创瑞激光科技有限公司

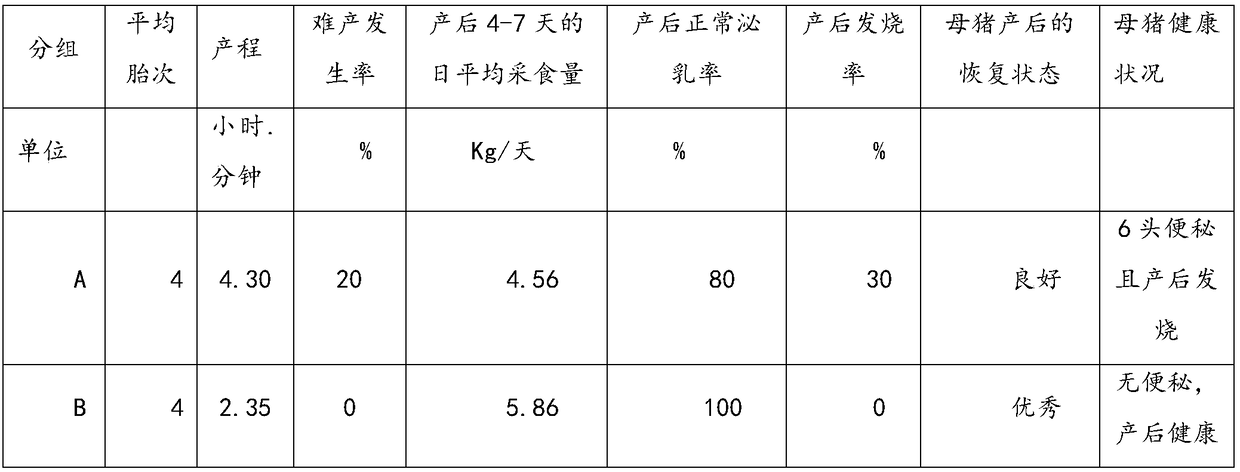

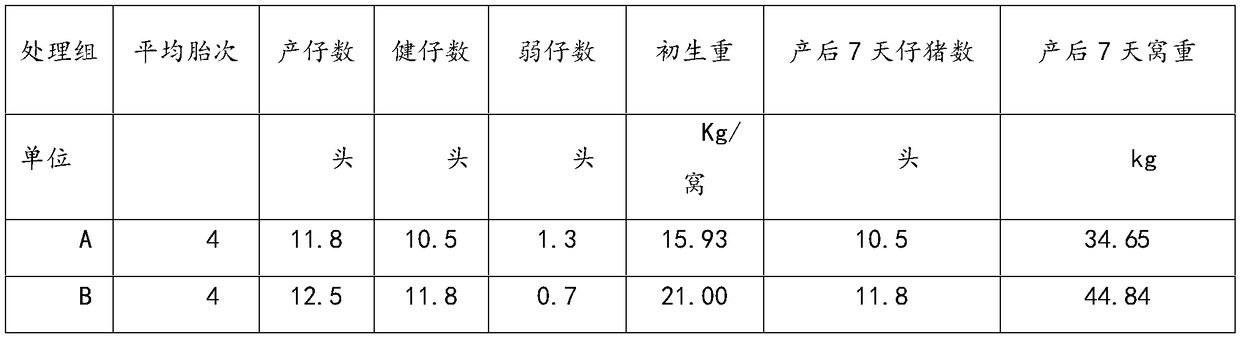

Latter half of gestation sow complete formula feed capable of preventing dystocia and feeding method thereof

ActiveCN109007391AImprove healthImprove biochemical efficiencyFood processingAnimal feeding stuffEthoxyquinCalcium

The invention relates to a latter half of gestation sow complete formula feed capable of preventing dystocia and a feeding method thereof. Every 1kg of complete formula feed is prepared from the following components by weight: 600-640g of corn, 120-150g of bean pulp, 60-80g of extruded soybeans, 15-30g of fermented soybean meal, 40-60g of fermented bran and fermented kelp residues, 10-20g of freshwater mussel powder subjected to enzymolysis, 15-25g of compound chyle fat powder, 20-40g of glucose, 0.3-0.35g of composite vitamin, 1.0-1.5g of composite organic trace element, 0.2-0.5g of pig complex enzyme, 1.0-1.5g of choline chloride, 2.5-3.5g of lysine, 0.3-0.4g of ethoxyquinoline, 3.0-4.5g of table salt, 12.5-14.5g of mountain flour, 6.5-7.5g of calcium hydrophosphate, 0.1-0.15g of phytase, 0.15g of protease and the balance of lentinus edodes powder. From improving the constitution of a latter half of gestation of sow, the latter half of gestation complete formula feed effectively solves problems such as tear spots, gum and raccoon eyes of the sow, increases the food intake of the sow, effectively solves the dystocia problem and the postpartum recovery problem, and remarkably improves the health condition and the production performance of the sows and piglets.

Owner:BEIJING CHALLENGE AGRI SCI & TECH CO LTD

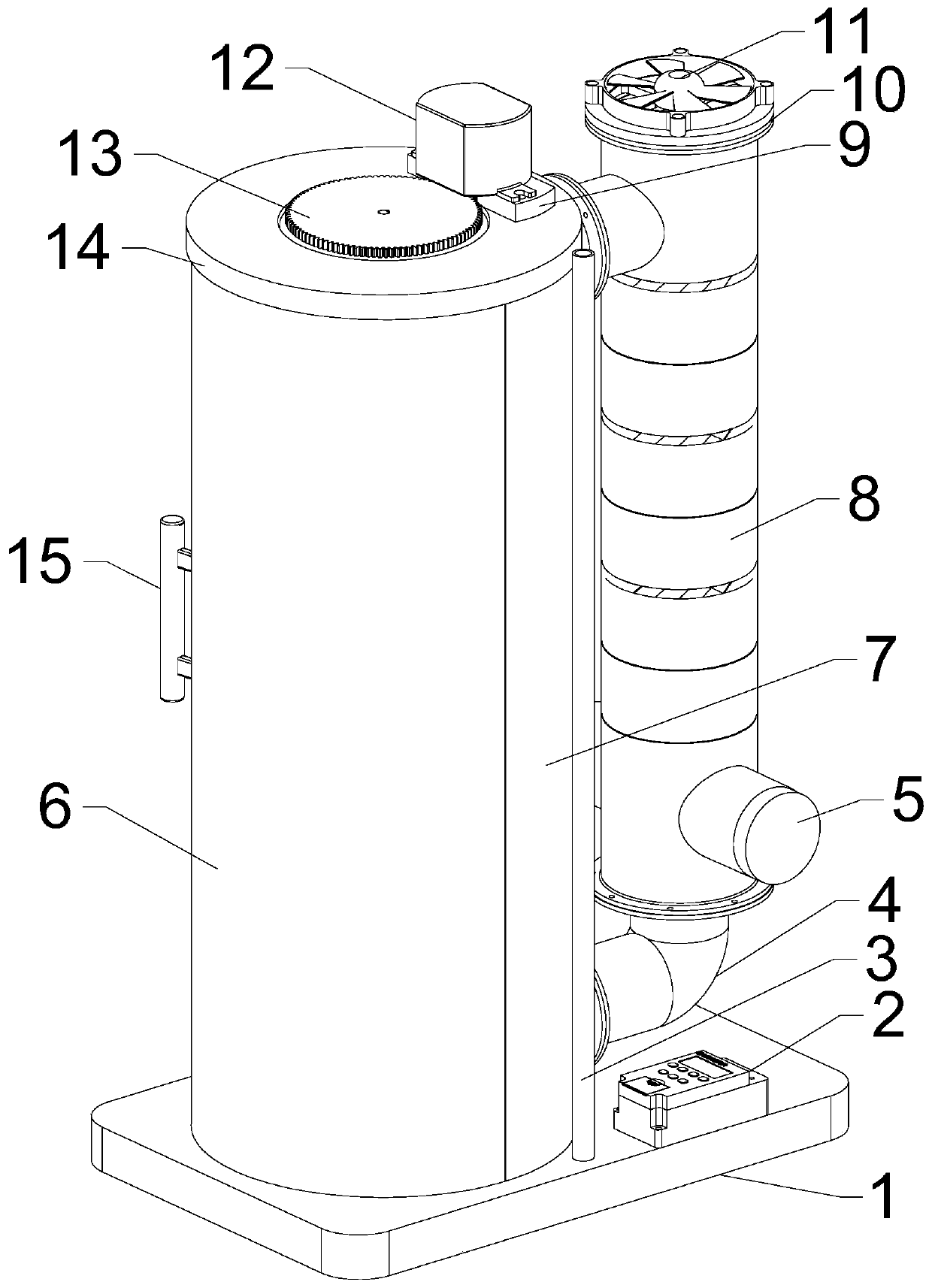

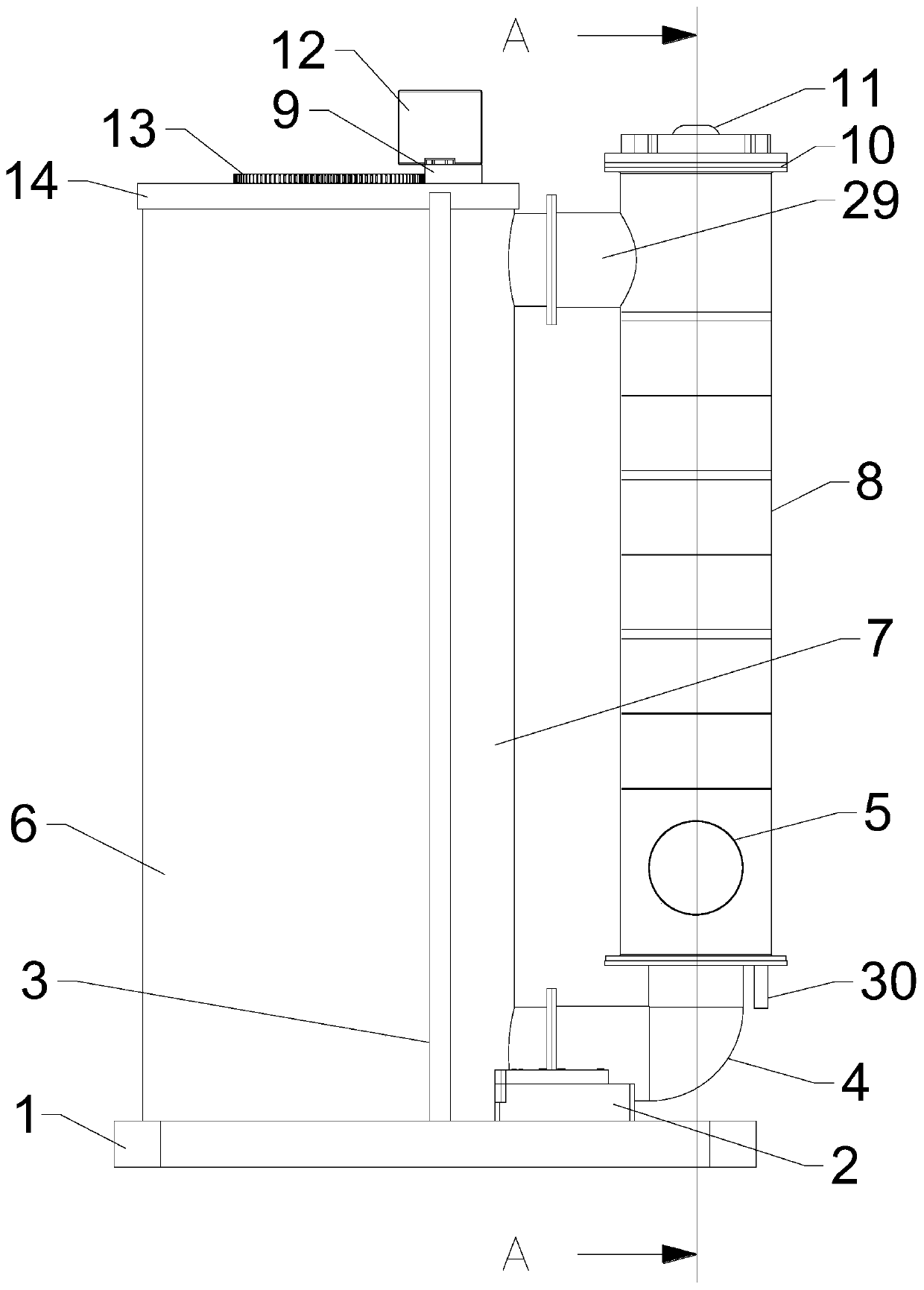

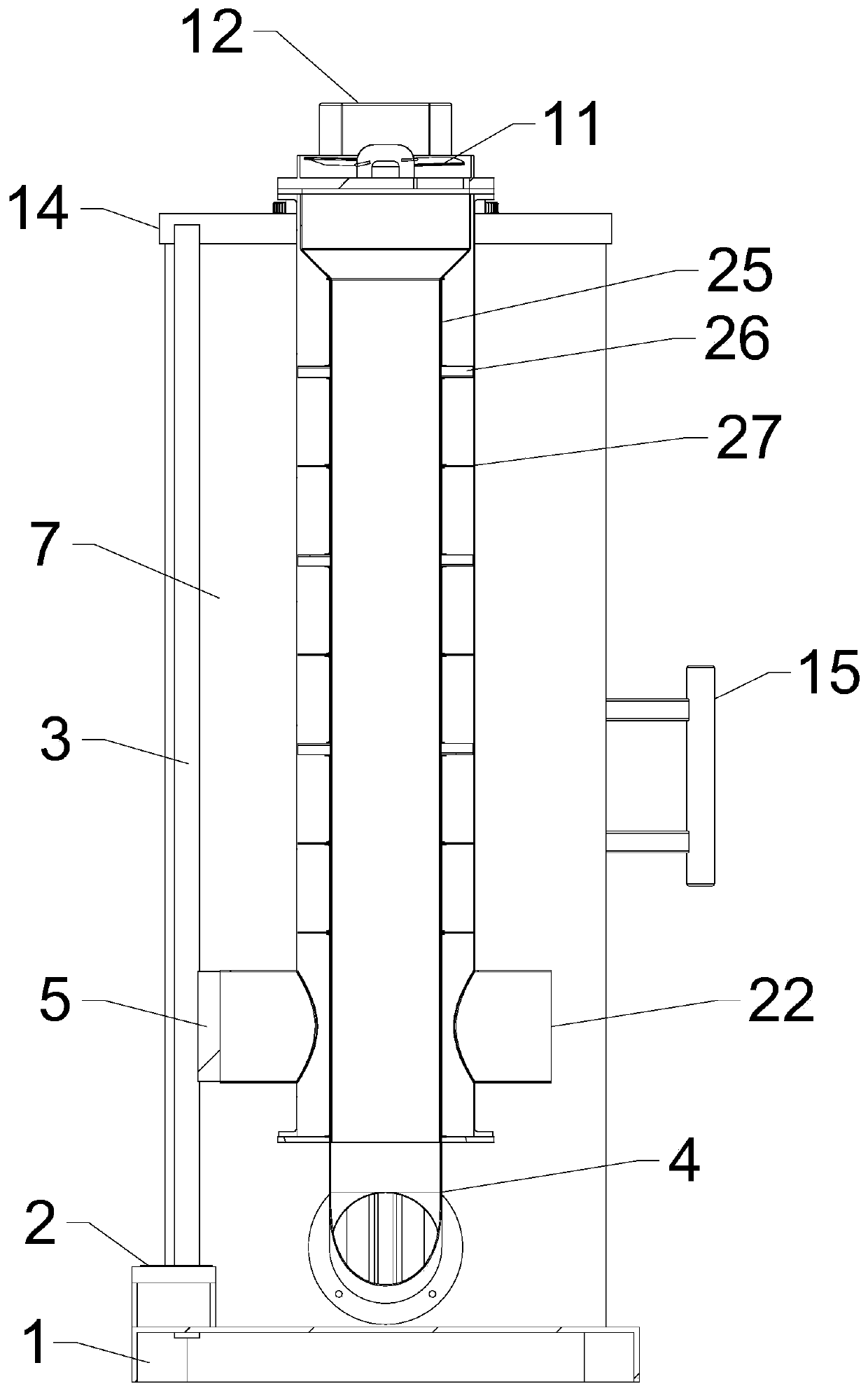

Flue gas cleaner for grinding machine

InactiveCN106880997ADrain cleanEasy to monitor usageCombination devicesDirt cleaningFlue gasActivated carbon filtration

The invention discloses a flue gas cleaner for a grinding machine. The flue gas cleaner comprises a dust collection cover, a flue gas pipe and a purification tank, wherein the dust collection cover is connected to the top of the purification tank through the flue gas pipe; an adhesive layer which is consistent with the dust collection cover in shape is arranged in the dust collection cover, and is in a mesh form; a plurality of filter cores are arranged in the flue gas pipe; a wind speed sensor is arranged at the connected end of the flue gas pipe and the purification tank; a first fan is arranged at the top of the inner side of the purification tank; an air inlet of the first fan communicates with the flue gas pipe; an air outlet of the first fan is provided with a wind dispersing cover; wind blown from the first fan is uniformly dispersed by the wind dispersing cover; a sponge filter layer, a filter felt and an activated carbon filter plate are sequentially arranged from top to bottom in the purification tank; and a second fan is arranged at the bottom in the purification tank. According to the flue gas cleaner, flying dust in the polishing process of the grinding machine and a pollution gas are absorbed by the dust collection cover, and the flying dust and the pollution gas are prevented from diffusing in a workshop, so that the workshop environment is protected.

Owner:SUZHOU YASIKE PRECISION CNC CO LTD

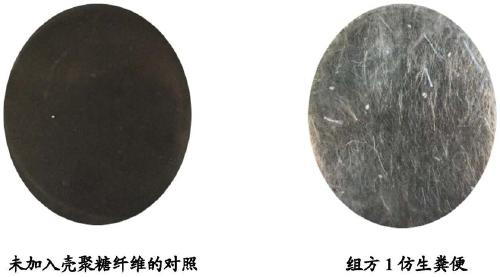

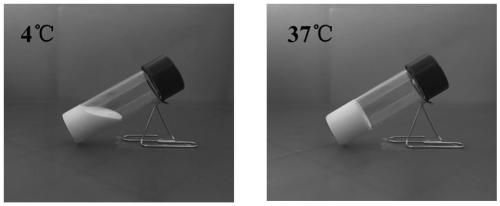

Bionic excrement and preparation method and application thereof

ActiveCN111437394AMake up for deficiencies in defecographyMake up for deficienciesX-ray constrast preparationsPharmaceutical non-active ingredientsHuman bodyLiquid state

The invention relates to the technical field of medical instruments, and discloses bionic excrement and a preparation method and application thereof. The bionic excrement comprises a temperature-sensitive material, a solvent and chitosan fibers. The temperature-sensitive bionic excrement is prepared by selecting proper materials, is in a flowable liquid state at a low temperature (below 25 DEG C),has a certain consistency, can be smoothly injected into the intestinal tract through an injector, is converted to be in a non-flowable gel state in the intestinal tract (36-39 DEG C) through a shortgelatinization process to completely lose flowability, and has the certain mechanical strength and surface roughness to stimulate the intestinal tract to produce awareness of defecation, so that a normal defecation process of the human body is simulated for discharging the excrement out of the body. Meanwhile, by adding a contrast agent, the bionic excrement is developed in the intestinal tract,X-ray radiography can be carried out after forming, and a radiography image is uniform and clear, so that the examination of a nidus area is assisted.

Owner:长春吉原生物科技有限公司

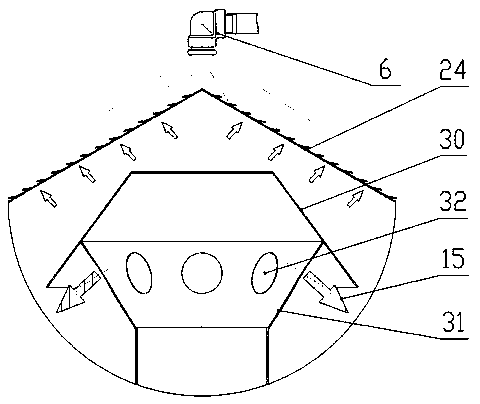

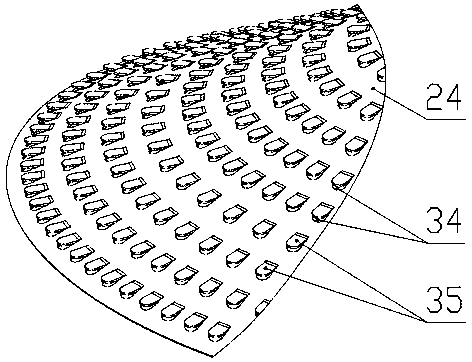

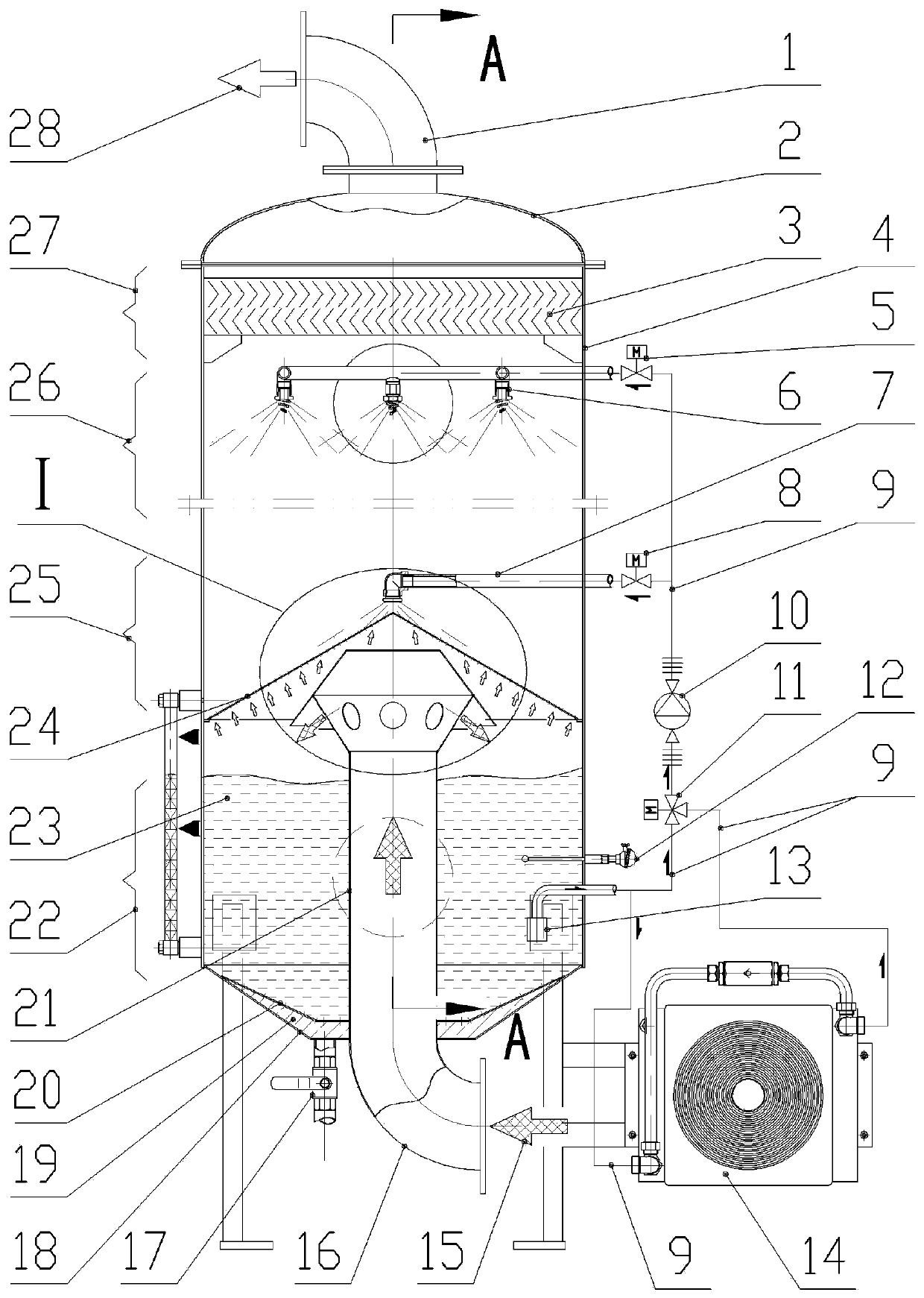

Waste incineration flue gas spraying deacidification tower

PendingCN111151113AGood purification effectLittle flow resistance lossGas treatmentDispersed particle separationDemisterEngineering

The invention discloses a waste incineration flue gas spraying deacidification tower. The top of a tower barrel is provided with an upper sealing head with an exhaust pipe, the bottom of the tower barrel is provided with a lower sealing head with an air inlet pipe, the side wall of the tower barrel is provided with a spraying liquid taking opening, and the exterior of the tower barrel is providedwith a spraying pipeline system; an ascending pipe communicated with the air inlet pipe is arranged in the tower barrel, an air distribution cone is arranged at the upper end of the ascending pipe, abaffling cap is arranged at the top of the air distribution cone, and a foam generation cover, a liquid distribution system, a defoaming system and a demister are sequentially arranged above the baffling cap from bottom to top. Flue gas flows in the tower from bottom to top, a purification liquid flows from top to bottom, when the flue gas and the purification liquid are in contact with each otherin the foam generation cover, foam is generated, the flue gas is promoted to be in full contact with the purification liquid, then the dynamic stability of the foam is maintained, and finally the flue gas is exhausted after being demisted. Compared with a common traditional spraying tower, the spraying deacidification tower provided by the invention is more suitable for waste incineration flue gas, has better purification effect and reliability, does not need to build a huge purification liquid treatment system, and has lower construction and operation costs.

Owner:云南净美环保科技有限公司

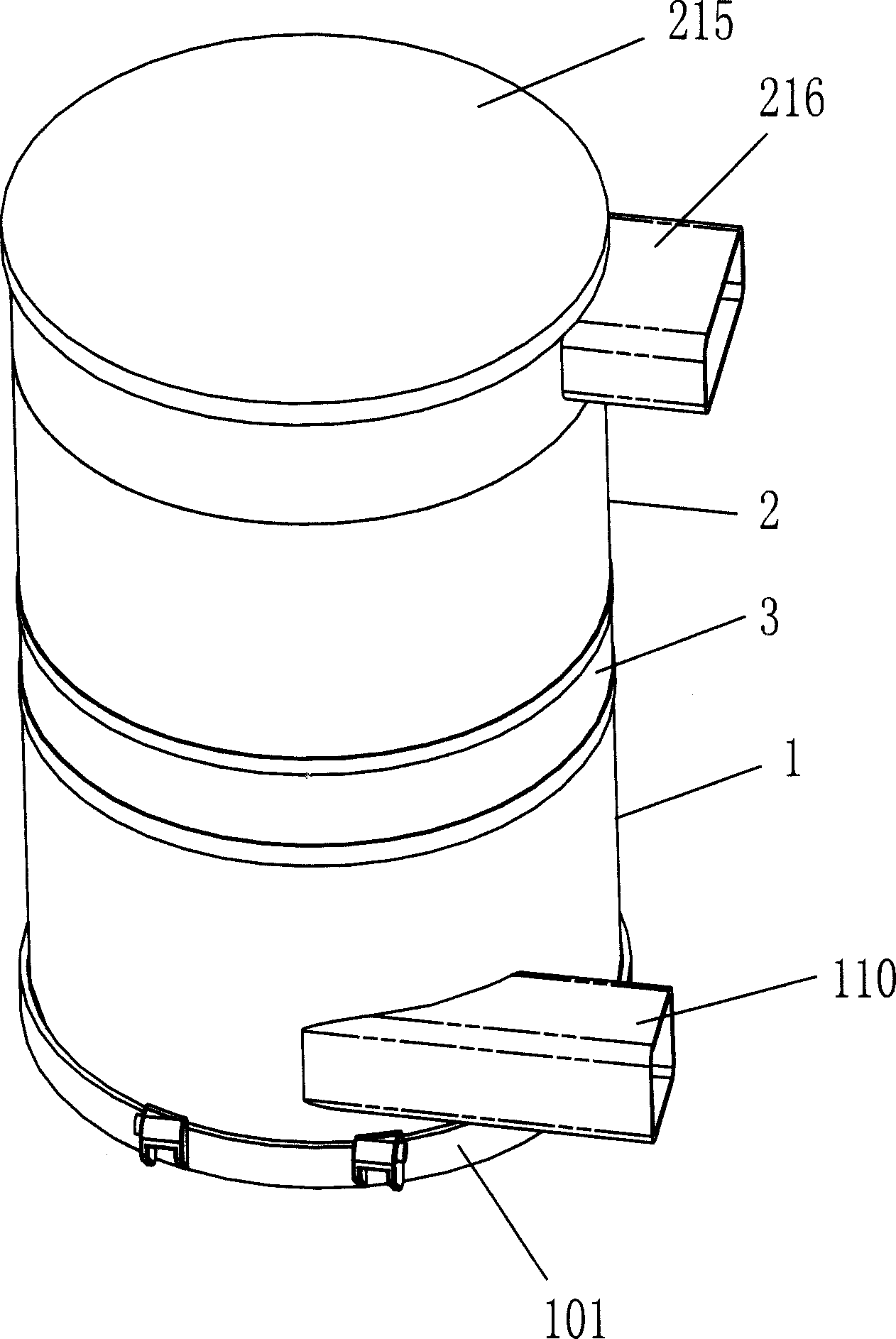

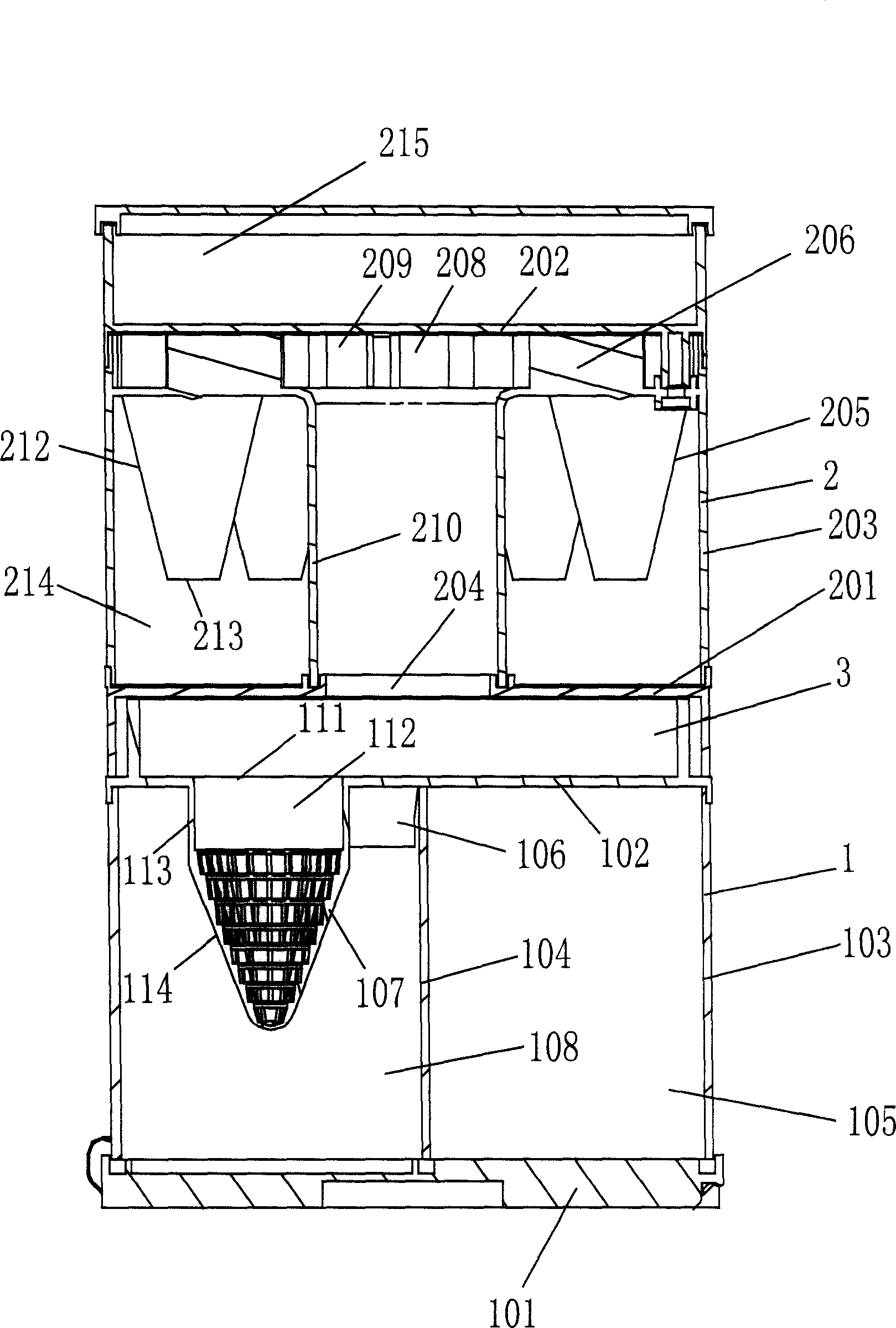

Gas storing device for carbon dioxide flooding

InactiveCN109442202APrevent movementGuaranteed stabilityVessel mounting detailsVessel geometry/arrangement/sizeCo2 floodingEngineering

The invention discloses a gas storing device for carbon dioxide flooding. The gas storing device comprises a gas storing tank, a carbon dioxide opening, a first valve, a first air pump, an air pipe, arubber air bag, handles, elastic buffer rods, rubber balls, moving rods, fixing sleeves, springs, ball nuts, first screw rods, first screwing blocks, moving trundles, first plastic soft sleeves, second plastic soft sleeves, supporting rods, second screw rods, second screwing blocks, a second valve, fixing blocks, rotating rings, fixing rings, annular grooves, fixing plates, threaded holes, shortpipes, a three-way pipe, second air pumps and one-way valves. The structure is rational. The device can be used for gas supply for carbon dioxide flooding in oil and gas field development. Through a moving structure, the gas storing tank can move on the ground. When moving is not required, the moving trundles are lifted and are not in contact with the ground, and a ground inserting structure is arranged in a matched mode. Stability during application of the gas storing tank is guaranteed, and moving is avoided.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Mud fish fry breeding method

ActiveCN109699534APrevent excessive growthAvoid pollutionClimate change adaptationAgricultural fishingWeatherfishGreenhouse

The invention discloses a mud fish fry breeding method. The method comprises the following steps of (1) injecting non-polluting water into a soilless breeding pond in a greenhouse, and putting in weeping willow branches; (2) 20-30 days after putting in the weeping willow branches, putting in mud fish fry and placing ricefield eels the next day. The method has the advantages of convenient materialobtaining, easy water quality regulation, convenient fishing, less mud fish pests and diseases, high fry survival rate and the like.

Owner:SHANGHAI ACAD OF AGRI SCI

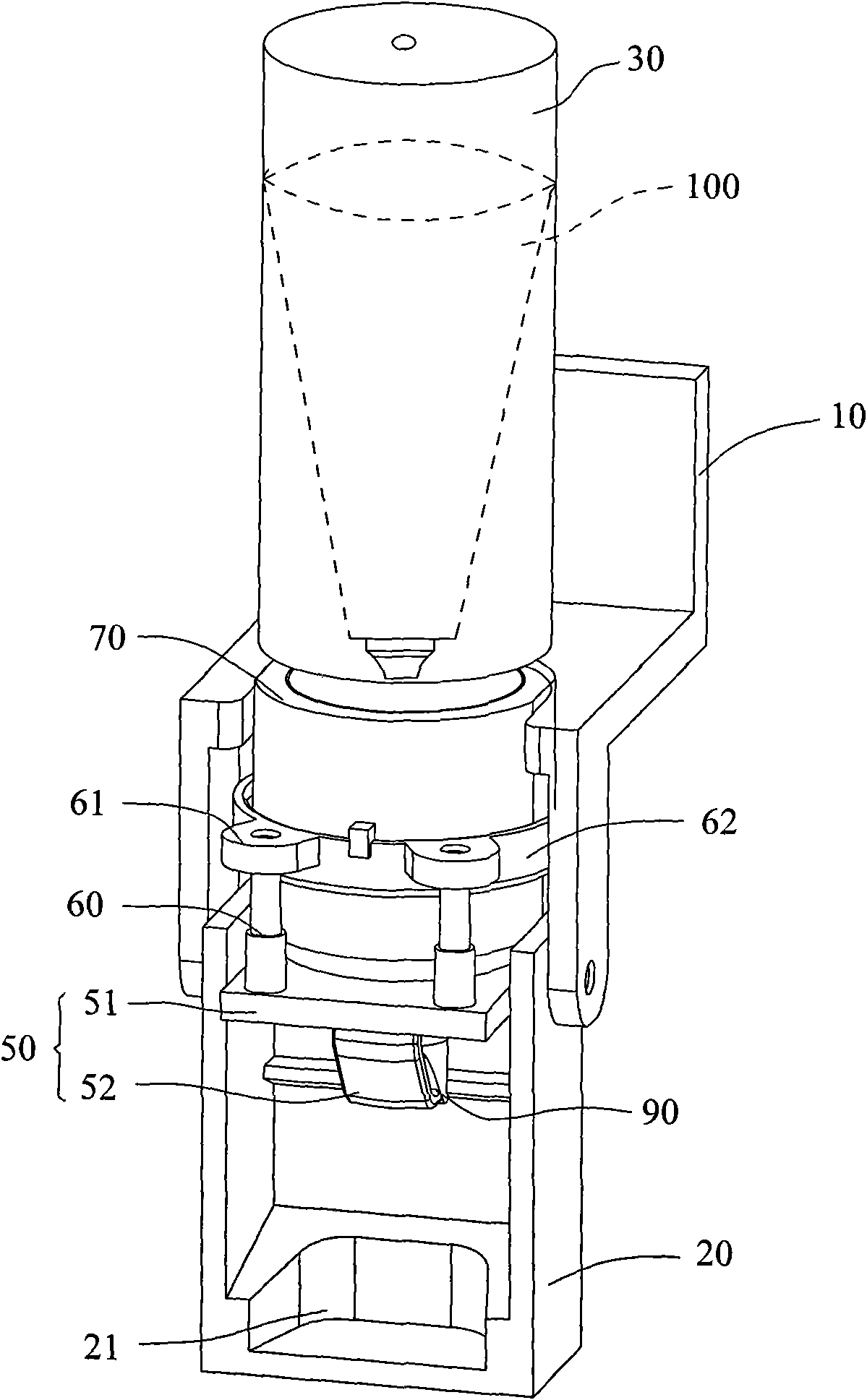

Filling mechanism for electronic cigarette tar atomized liquid

The invention provides a filling mechanism for electronic cigarette tar atomized liquid, and relates to the technical field of electronic cigarettes. The filling mechanism for the electronic cigarettetar atomized liquid comprises a box body used for containing the cigarette tar atomized liquid, wherein a liquid outlet is formed in the top of the box body, a first plug body used for blocking the liquid outlet is arranged on the lower portion of the liquid outlet, an extending rod extending out of the liquid outlet is fixedly connected to the upper surface of the first plug body, a shell is fixedly connected to the lower portion of the box body, and a partition piece is transversely and fixedly arranged in the shell. According to the invention, the cigarette tar atomized liquid can be usedthoroughly, and the waste is avoided. Moreover, the filling mechanism is particularly simple and convenient to use, the liquid outlet is automatically opened and non-toxic gas can be automatically generated in the box body by only inserting the extending rod into the electronic cigarette gun and arranging a series of linkage triggering structures, so that the gas pushes the cigarette tar atomizedliquid to be completely discharged, and the filling mechanism has a very good practical effect.

Owner:深圳市方盈电子科技有限公司

Plate punching and grinding device for intelligent manufacturing

PendingCN114473522AAvoid slight deviations in thicknessDrain cleanOther manufacturing equipments/toolsMaintainance and safety accessoriesPunchingSuction force

The plate punching and polishing device for intelligent manufacturing structurally comprises a base, an operation table and a machining frame, the bottom of the operation table is connected with the upper end of the base, the machining frame is fixedly embedded in the rear position of the upper end of the operation table, and the machining frame can downwards slide out along a second sealing rod along with the gravity of the machining frame after punching is completed through a telescopic block; the annular body rotates clockwise along with the punching head, so that the vibration block rapidly impacts the inner wall of the embedded groove towards the outer side along the embedded groove, vibration can be generated, dust on the bearing ring can be gathered at the edge side attaching position of the outer pipe and the bearing ring, and therefore the effect that a metal wafer which does not completely fall off after a plate is punched is achieved is achieved. Therefore, fine chippings on the bearing ring can be discharged to a metal wafer generated by punching when the telescopic block is extruded and contracted, and after the punching head stops rotating, the suction block can be attracted by a steel material at the rear end of the embedded groove to automatically reset.

Owner:张闽镛

Injection mold for battery box shell of electric vehicle

InactiveCN113334694AEasy to disengageReduce wasteDomestic articlesElectric-vehicle batteryElectrical battery

The invention belongs to the field of electric vehicles, and particularly relates to an injection mold for a battery box shell of an electric vehicle. The injection mold comprises a water tank, wherein the upper end of the water tank is connected with a box cover through screws; a support column is welded to the upper end of the box cover; a mounting plate is welded to the upper end of the support column; an air cylinder is fixedly mounted at the upper end of the mounting plate; an air cylinder rod is arranged at the lower end of the air cylinder, and the air cylinder rod is sleeved with the mounting plate in a sliding manner; a connecting sleeve fixedly sleeves the outer side of the lower end of the air cylinder rod; an upper mold base is welded to the lower end of the connecting sleeve; a pressing plate is connected to the lower end of the upper mold base in a sliding manner; and a hanging rod is welded to the upper end of the pressing plate, and the hanging rod is sleeved with the upper mold base in a sliding manner. A water pump is arranged at the lower end of a water inlet pipe, the water pump sucks water into a convex mold, the water enters the convex mold to jack up a top plate, the water is injected between a battery box and the convex mold for pressurization, and the battery box is separated from the convex mold, so that the battery box is separated from the convex mold more conveniently.

Owner:杨施旅

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com