Waste incineration flue gas spraying deacidification tower

A technology of leaching deacidification tower and waste incineration, which is applied in gas treatment, dispersed particle separation, membrane technology and other directions, can solve the problems of increasing the volume of the spray tower, increasing the floor space, and increasing the cost of use, and achieves reliability and service life. The effect of improving cycle, improving cleanliness and good purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

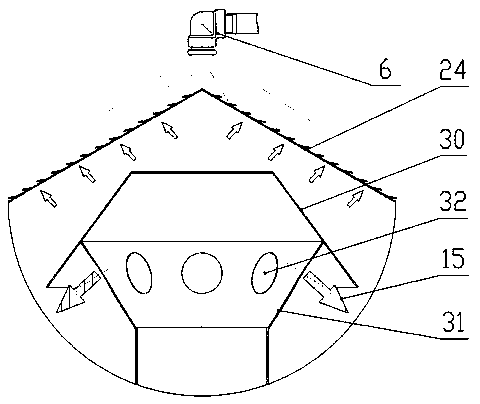

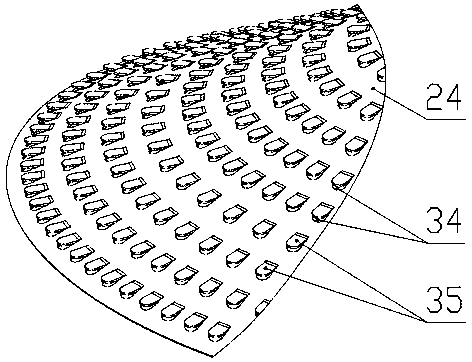

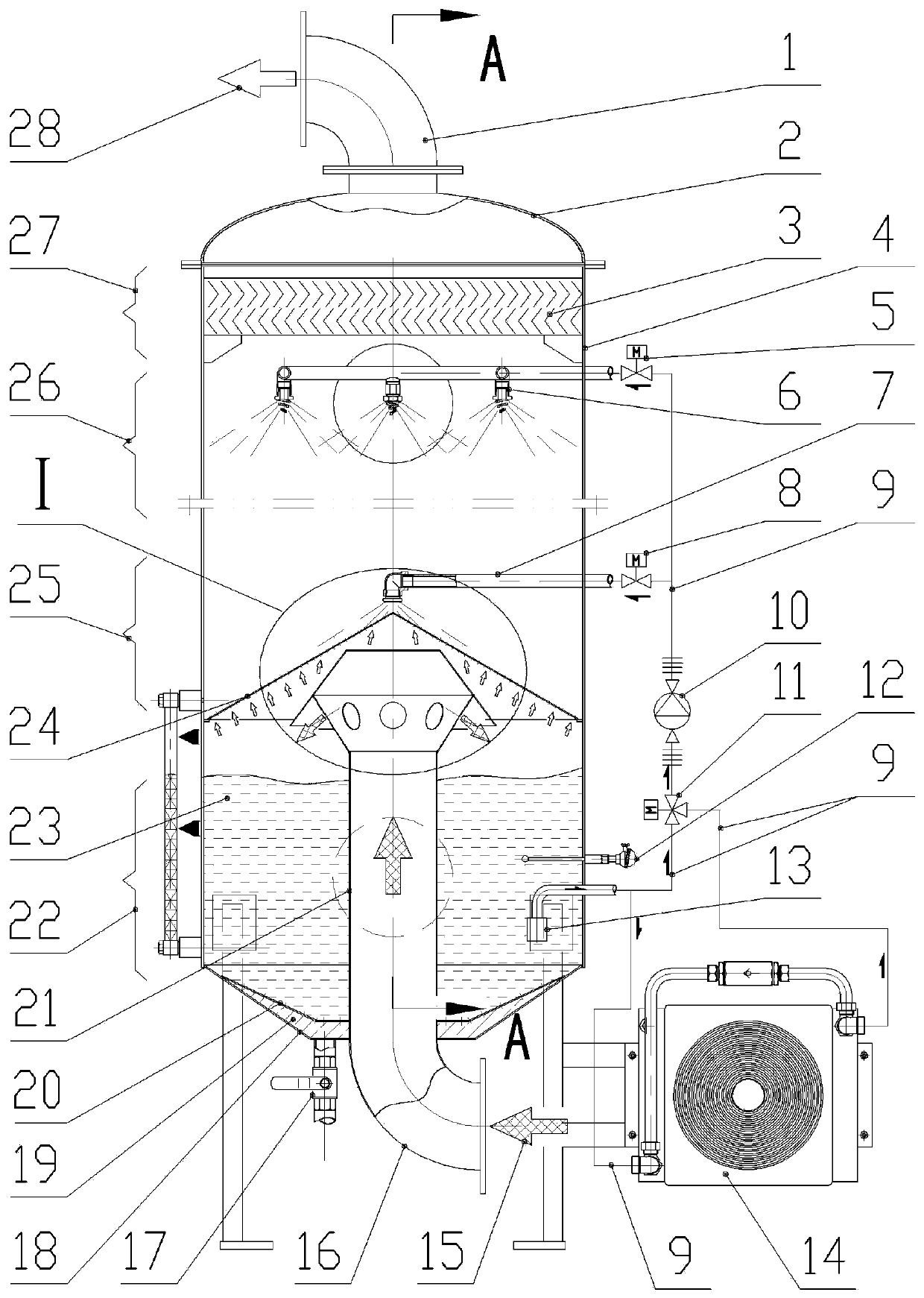

[0054] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of an embodiment of the structure of a garbage incineration flue gas spray deacidification tower provided by the present invention, combined with figure 2 , image 3 ,in, figure 2 for figure 1 A-A in the sectional view further shows the structure of the present invention; image 3 for figure 1 The partial enlarged view of the I place shows the structure of the foaming section (25) in the tower and the flow characteristics of the gas flow at this position.

[0055] The structure of the waste incineration flue gas spray deacidification tower includes a tower tube 4, the top of the tower tube 4 is provided with an upper head 2, the bottom is provided with a lower head 18, and the outside is provided with a spray pipe Road system 9; an exhaust pipe 1 is provided above the upper head 1, and an air intake pipe 16 is provided below the lower head 18;

[0056] The interior of the tower 4 is provid...

Embodiment 2

[0077] Such as Image 6 as shown, Image 6 It is a structural schematic diagram of another embodiment of the structure of a waste incineration flue gas spray deacidification tower provided by the present invention.

[0078] The differences between this embodiment and Embodiment 1 are:

[0079] 1) Structurally, the three-way valve 11 in Embodiment 1 is cancelled, and the spray liquid intake port 13 is directly connected to the spray pump 10; the tower 4 corresponding to the liquid storage area 22 is also provided with a cooling liquid intake Port 36 and liquid return port 39, the heat dissipation liquid intake port 36 and liquid return port 39 are all installed on the side wall of the tower tube 4, and pass through the side wall of the tower tube 4 to the outside and pass through the heat dissipation pipeline system 37 connected; the heat dissipation pipeline system 37 is provided with a heat dissipation pump 38 and a heat dissipation system 14 in series; that is, the spray p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com