Water jacket structure of diesel cylinder block

A technology for cylinder block and diesel engine, applied in the direction of cylinder, cylinder head, mechanical equipment, etc., can solve the problems affecting the reliability of the whole machine, uneven temperature of the cylinder block, difficult to clean sand, etc., to increase the oil cooling function, parts It is easier to control and avoid the effect of direct erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific drawings and embodiments.

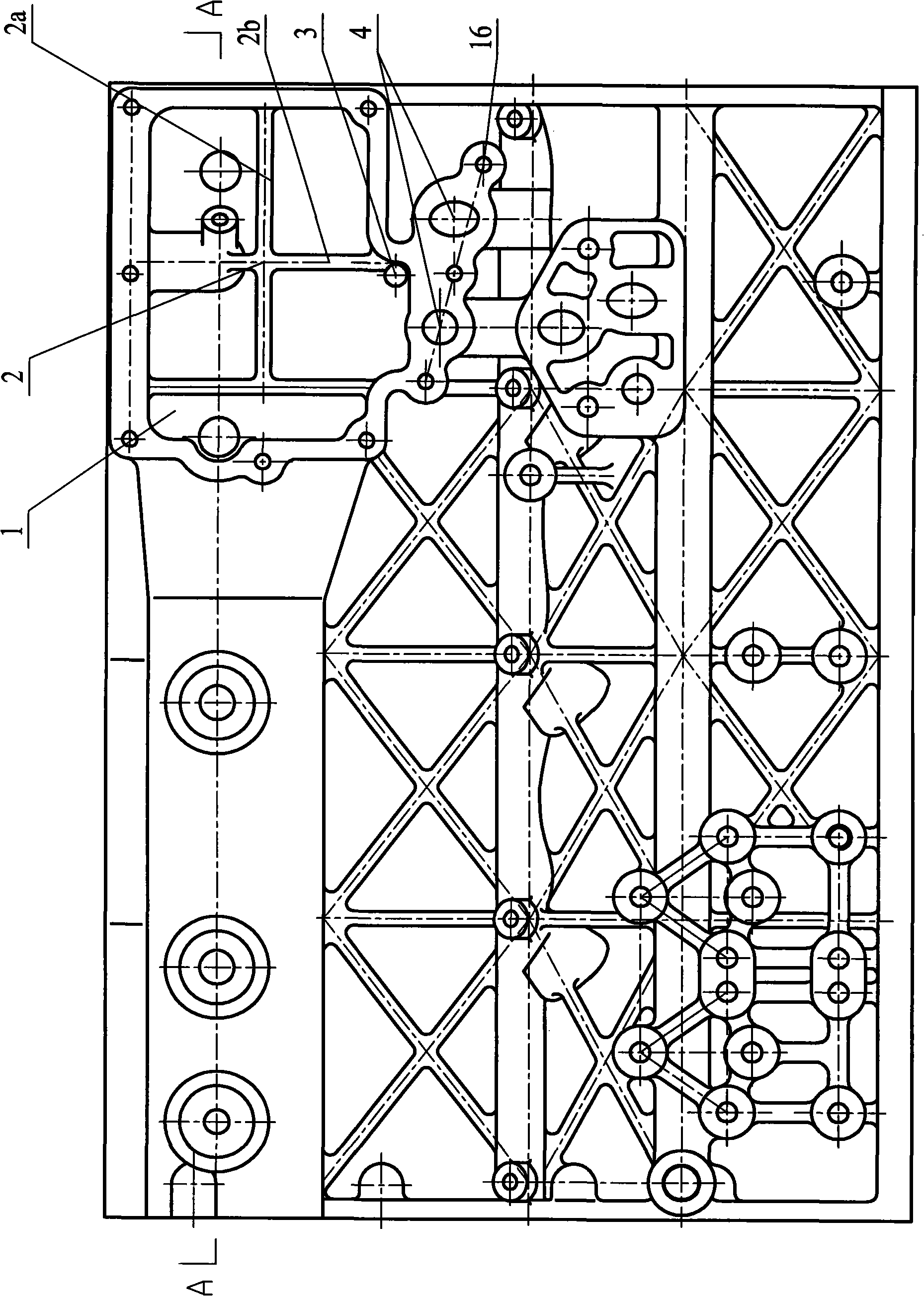

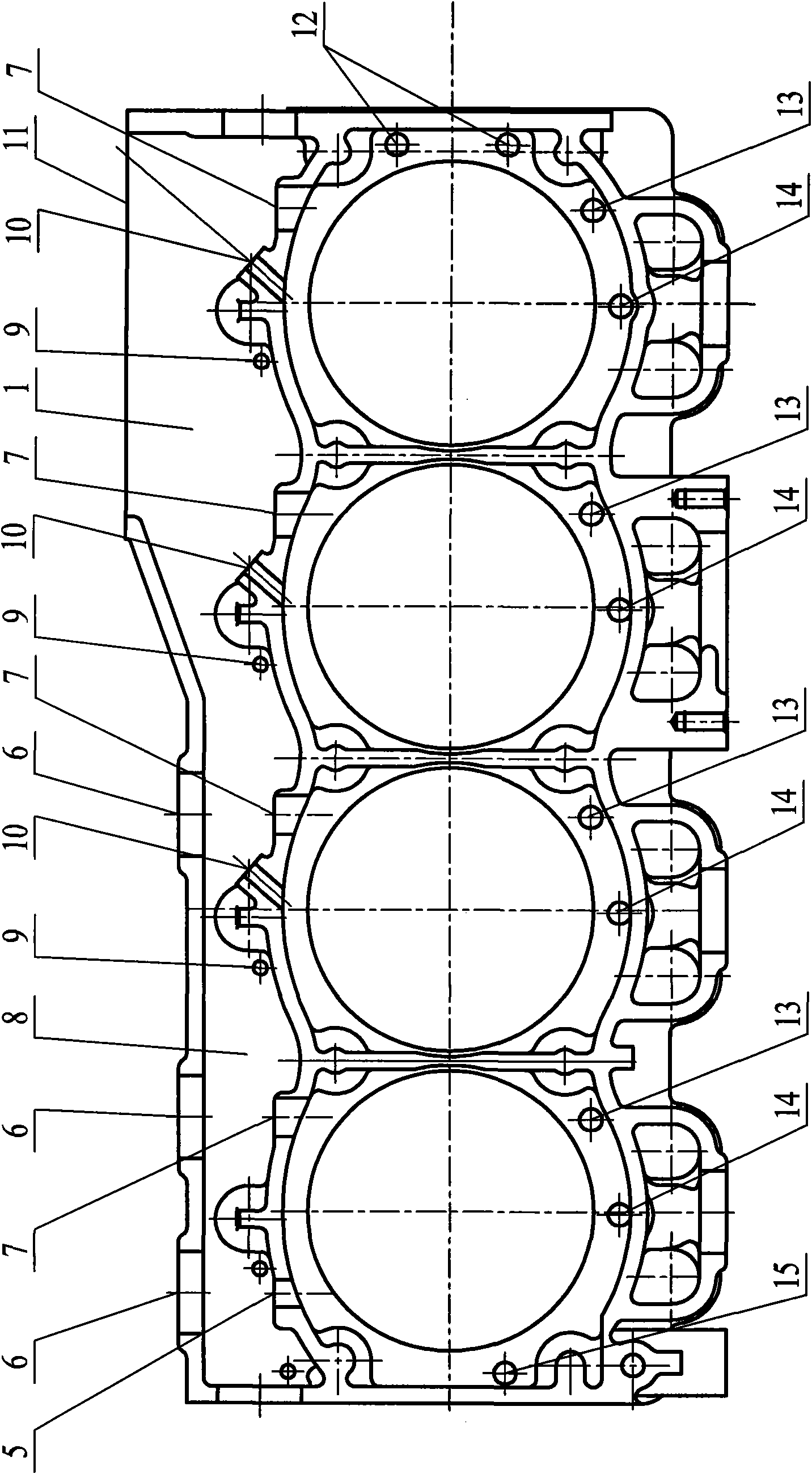

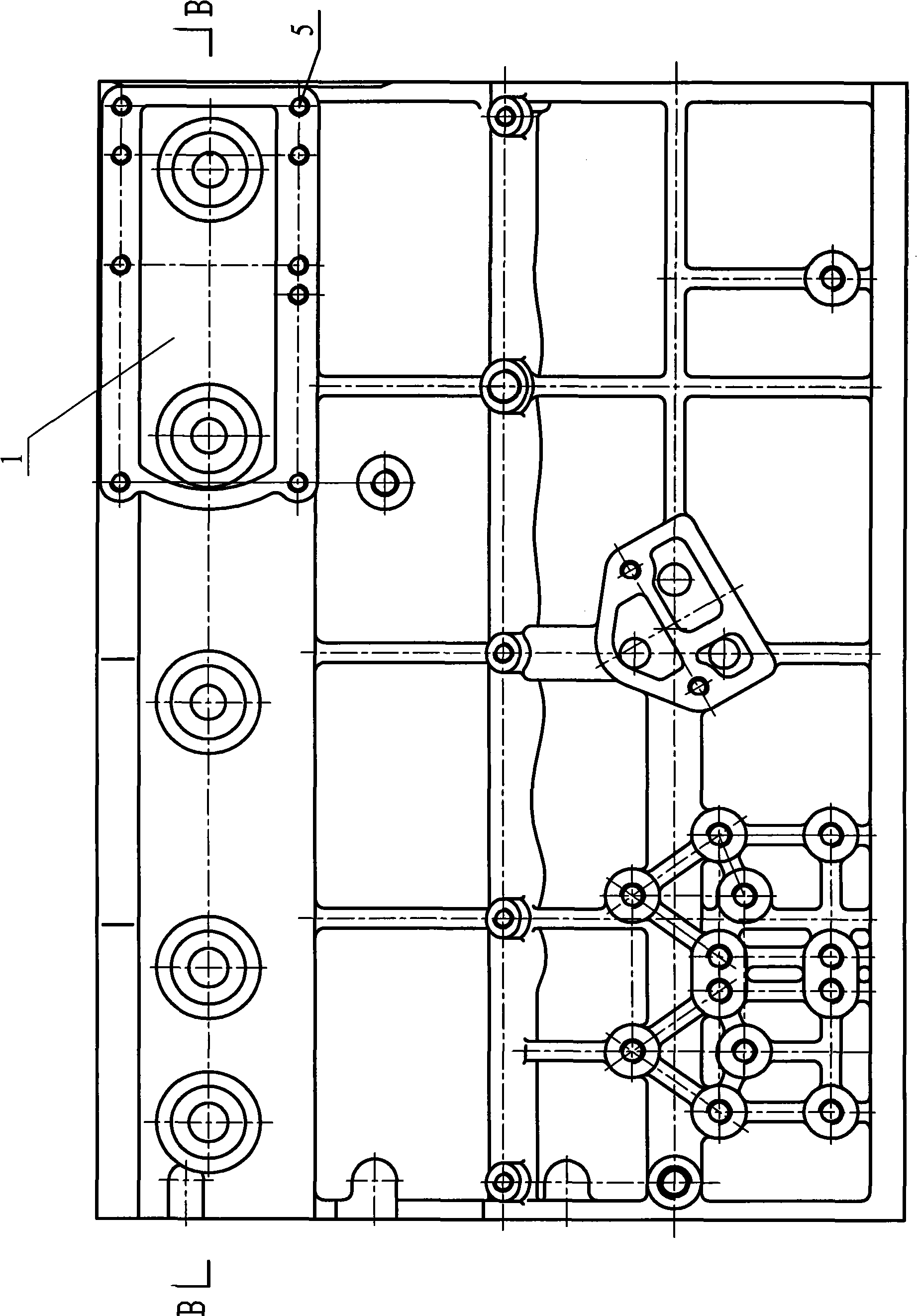

[0030] Such as figure 1 , figure 2 As shown, taking a diesel engine with a four-cylinder 2.0-2.5L Euro IV wet-type cylinder liner as an example, a horizontal water distribution channel 8 is arranged on the upper part of the intake side of the cylinder block, and the front end of the water distribution channel 8 is connected to a pump for pumping cooling water. water pump. The rear end of the water distribution channel 8 is provided with an oil cooler cavity 1 . A cylinder block water jacket is formed on the middle and upper part of the cylinder block, and the width of the cylinder block water jacket is 18-45mm. The distance between them is 10-70mm; the water jacket of the cylinder body includes four single-water jackets arranged side by side, and each single-water jacket is provided with a water inlet hole and a drain hole, and the water distribution chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com