Automatic chip discharging device for numerical control machine tool

A CNC machine tool and automatic discharge technology, which is used in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problem that the effect of chip removal is not very satisfactory, affects the health of the recipient, and the waste is not collected cleanly, etc. problems, to achieve the effect of preventing heat damage, preventing heat, and increasing attractiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

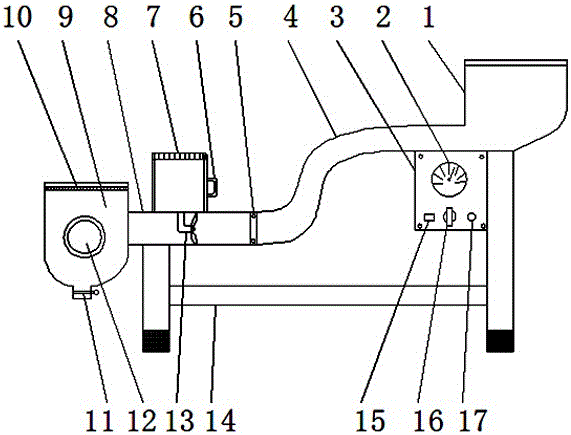

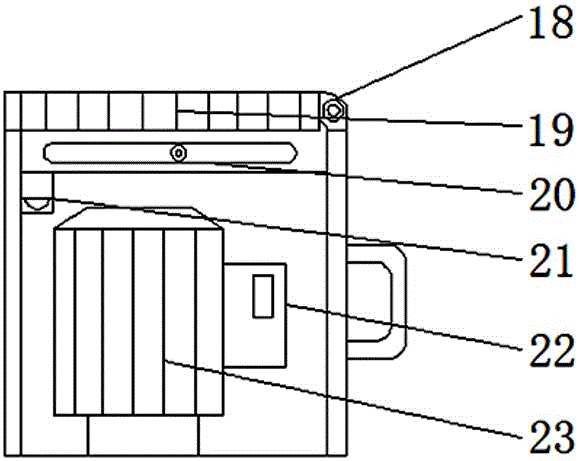

[0015] refer to Figure 1-2 , an automatic chip removal device for a CNC machine tool, comprising a control panel 3, an S-shaped pipe 4, a motor box 7, a straight pipe 8, a chip removal bin 9, a speed knob 16, a heat dissipation port 19 and a motor 23, and an S-shaped pipe 4 The chip removal interface 1 is installed on the right side, and a support frame 14 is installed under the chip removal interface 1. The S-shaped pipe 4 is connected with the straight pipe 8 through the connecting frame 5. A control panel 3 is installed below the S-shaped pipe 4. A speed knob 16 is installed on the surface of the panel 3, a tachometer 2 is installed above the speed knob 16, an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com