Vertical type pouring manufacturing method of decorative gypsum board

A production method and gypsum board technology, which are applied to supply devices, manufacturing tools, etc., can solve the problems of low production efficiency, high labor intensity of workers, and high requirements for workers' technical level of operation, and achieve low production efficiency and high labor intensity of workers. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

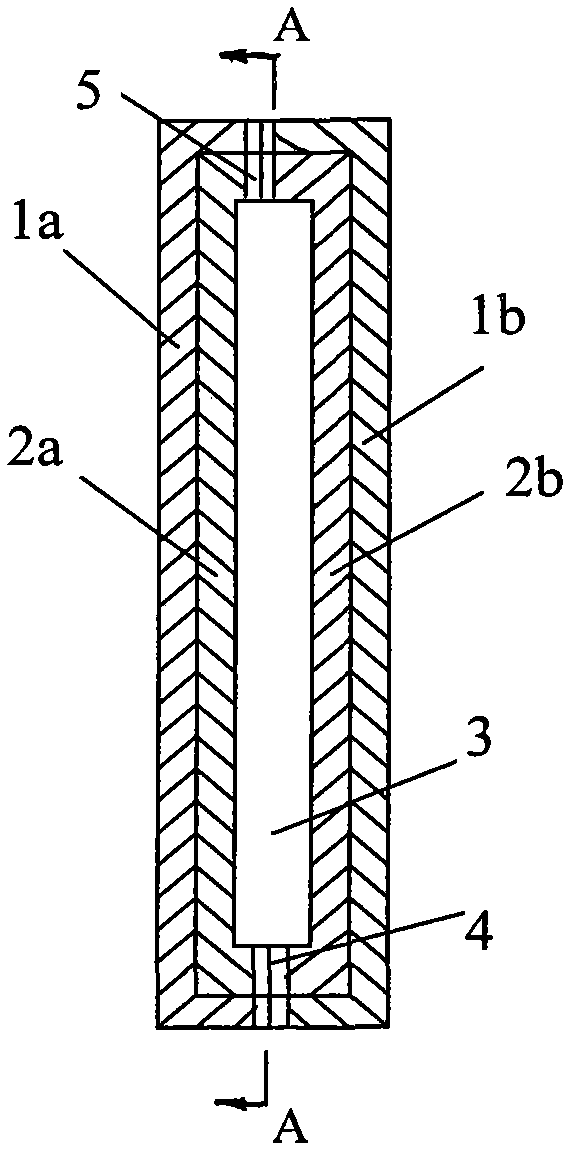

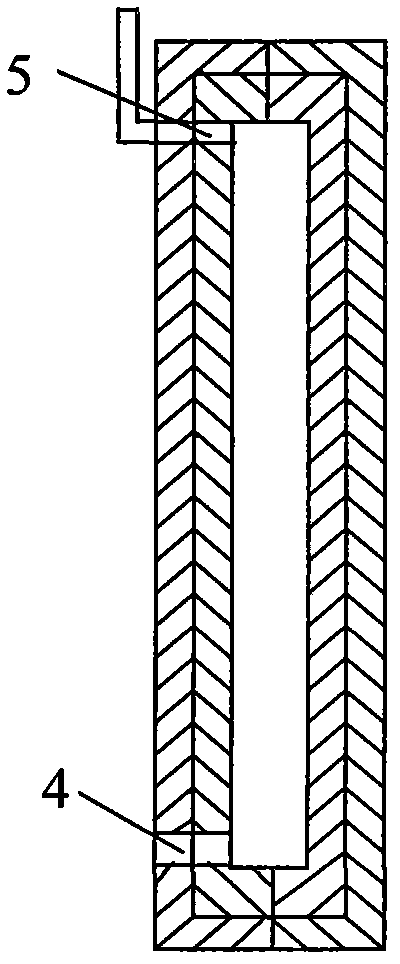

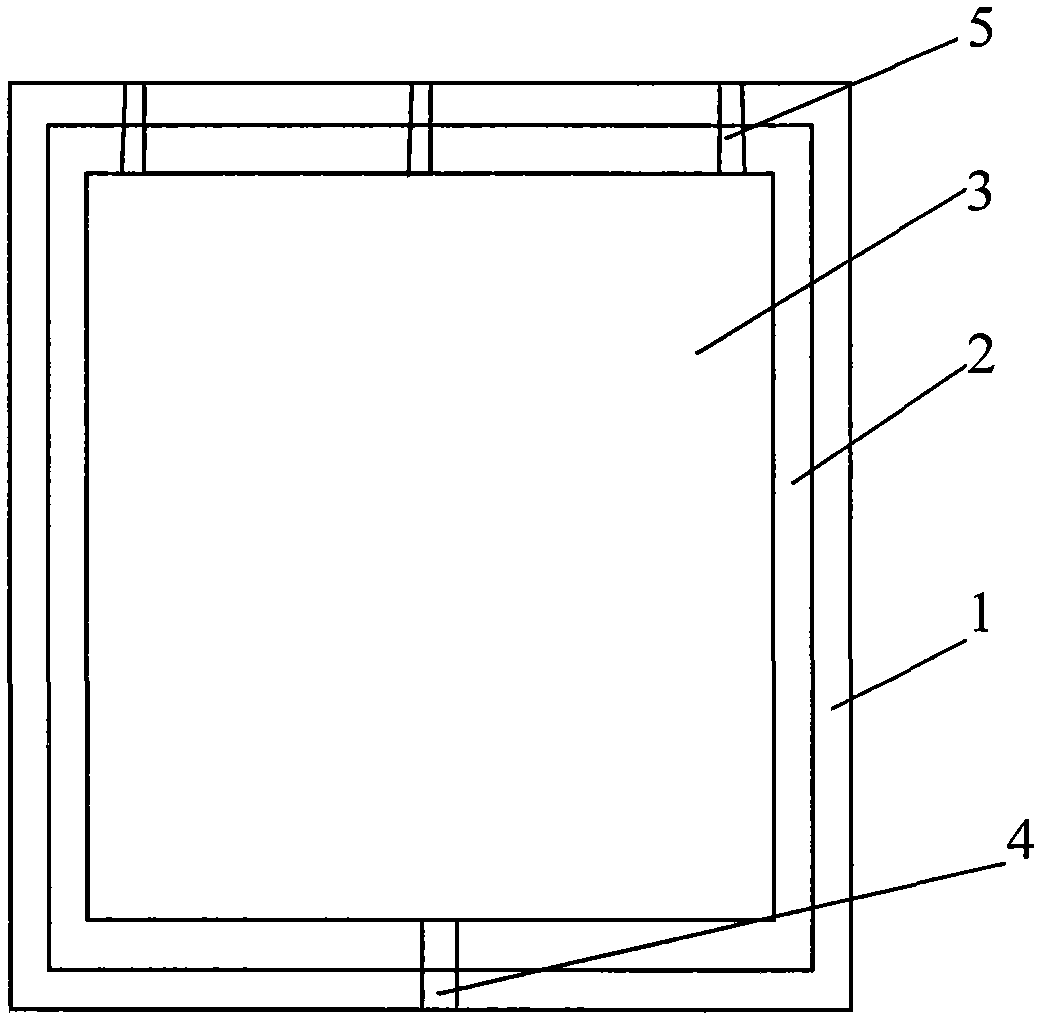

[0013] Such as figure 1 , figure 2 As shown, the method of the present invention uses an upright rigid outer mold and a flexible inner mold located in the outer mold. The bottom of the outer mold and the inner mold is provided with an injection port 4 leading to the cavity 3 of the inner mold, and the top of the outer mold and the inner mold is provided Exhaust hole 5 communicating with the inner cavity. The injection port can be as figure 1 As shown, it leads directly into the cavity from the bottom in the longitudinal direction, or it can be as figure 2 As shown, it leads to the bottom of the cavity along the transverse direction. The vent can be like figure 1 It is directly connected longitudinally to the top of the cavity as shown, or it can be as figure 2 Shown is connected laterally from the top of the cavity. The number of vent holes 5 can be 2 or more. In this embodiment, for example image 3 There are 3 exhaust holes shown. The outer mold is composed of a left hal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com