Filling mechanism for electronic cigarette tar atomized liquid

A technology of electronic cigarette oil and atomizing liquid, which is applied in the field of electronic cigarettes to achieve the effect of avoiding waste, good practical effect and thorough use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

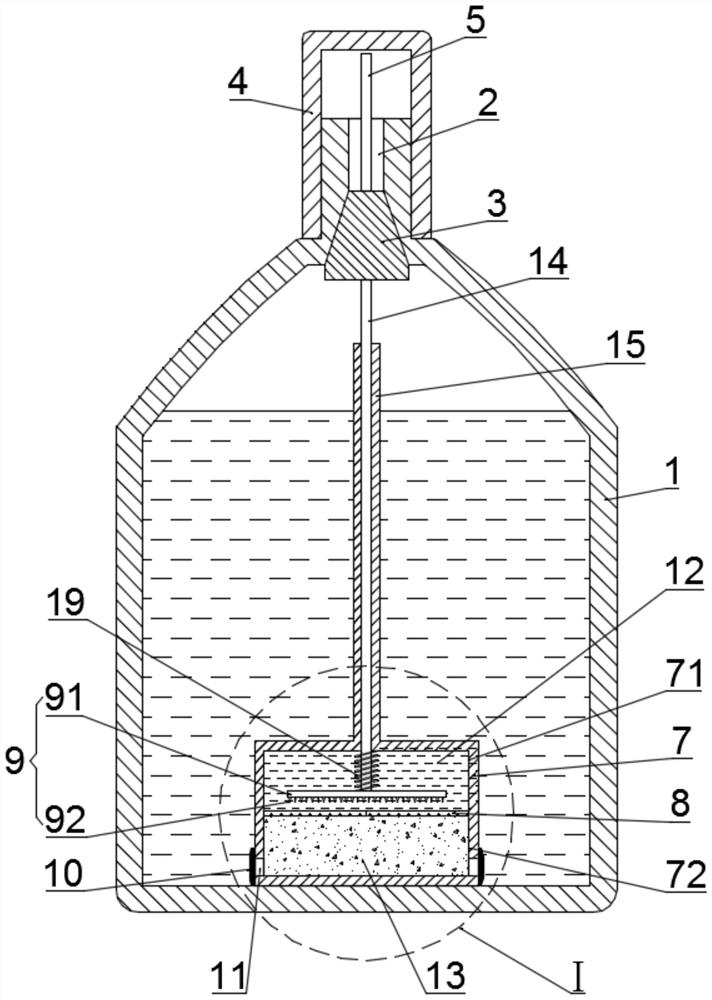

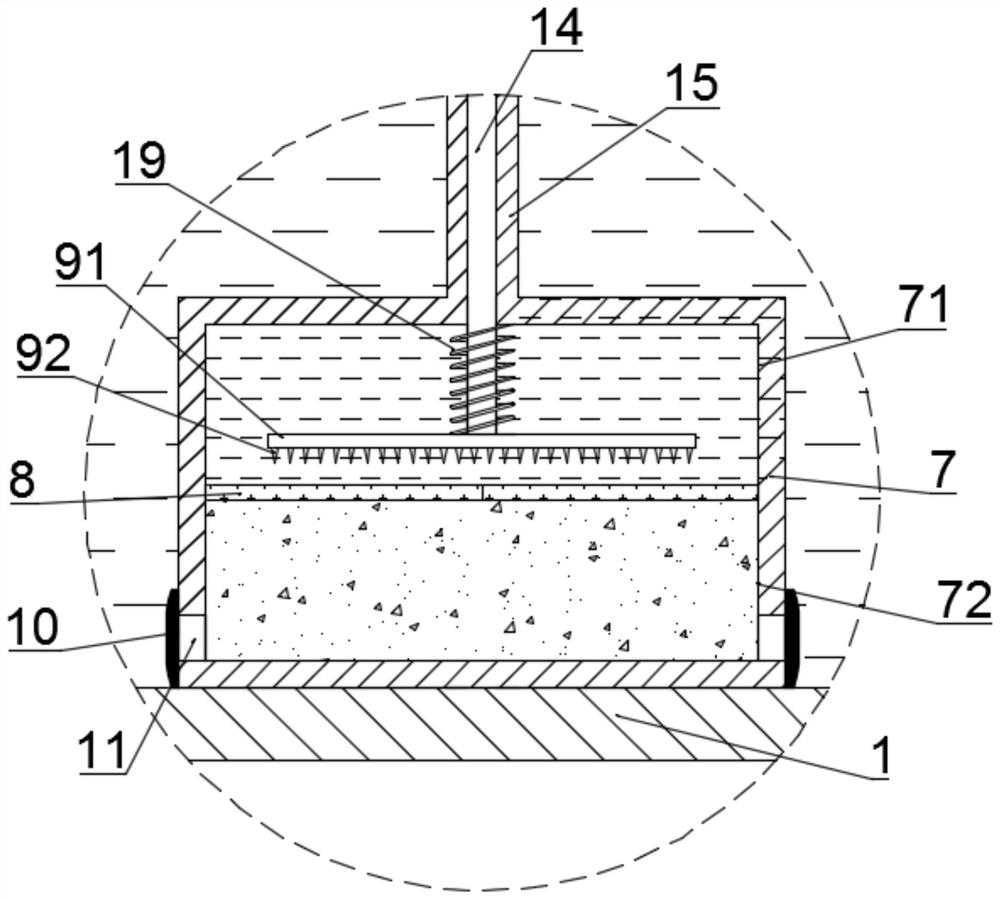

Embodiment 1

[0023] Such as figure 1 and 2 As shown in the figure, a filling mechanism for electronic cigarette oil atomization liquid includes a box body 1 for containing the smoke oil atomization liquid. The top of the box body 1 is provided with a liquid outlet 2, and the lower part of the liquid outlet 2 A first plug body 3 for blocking the liquid outlet 2 is provided. Preferably, the first plug body 3 has a shape with a narrow upper end and a wider lower end, so as to improve the blocking and sealing effect on the liquid outlet 2. The first plug body 3 The upper surface of the box body 1 is fixedly connected with a protruding rod 5 extending out of the liquid outlet 2, the lower part of the box body 1 is fixedly connected with a housing 7, and the interior of the housing 7 is fixed with a partition 8 horizontally. The sheet 8 is used to divide the interior of the housing 7 into an upper chamber 71 and a lower chamber 72, the upper chamber 71 and the lower chamber 72 are separately eq...

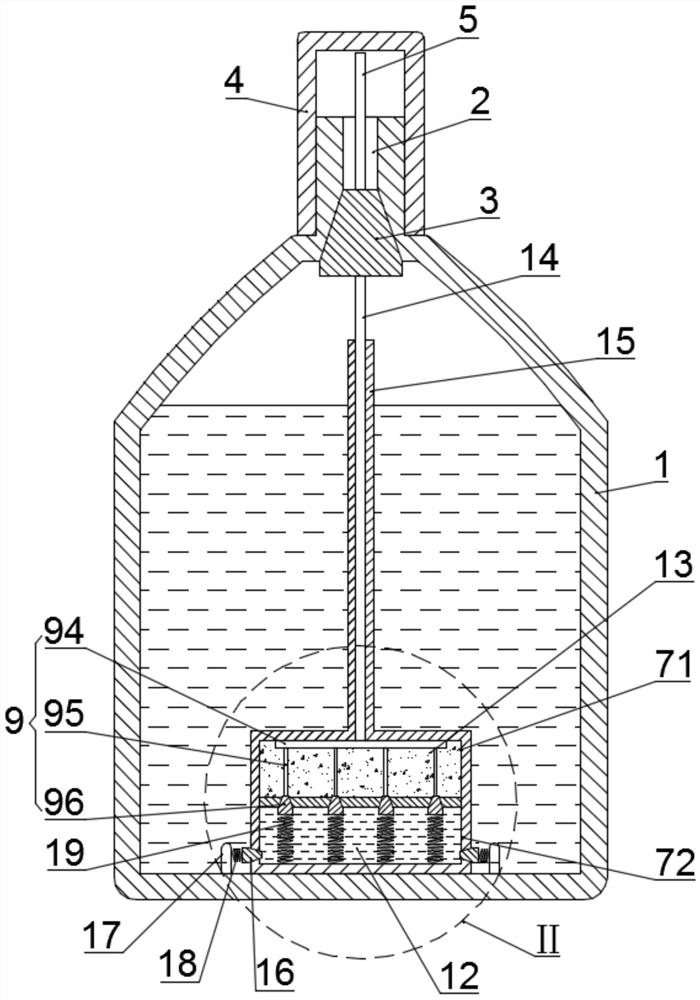

Embodiment 2

[0032] A filling mechanism for electronic cigarette oil atomization liquid, comprising a box body 1 for containing the smoke oil atomization liquid, the top of the box body 1 is provided with a liquid outlet 2, and the lower part of the liquid outlet 2 is provided with a Block the first plug body 3 of the liquid outlet 2. Preferably, the first plug body 3 has a shape with a narrow upper end and a wider lower end, so as to improve the blocking and sealing effect on the liquid outlet 2. The upper surface of the first plug body 3 An extension rod 5 extending out of the liquid outlet 2 is fixedly connected, a housing 7 is fixedly connected to the bottom of the box body 1, and a separator 8 is fixedly arranged in the interior of the housing 7 horizontally, and the separator 8 is used for The interior of the housing 7 is divided into an upper chamber 71 and a lower chamber 72, the upper chamber 71 and the lower chamber 72 are separately equipped with the first reactant 12 and the sec...

Embodiment 3

[0042] A filling mechanism for electronic cigarette oil atomization liquid, comprising a box body 1 for containing the smoke oil atomization liquid, the top of the box body 1 is provided with a liquid outlet 2, and the lower part of the liquid outlet 2 is provided with a Block the first plug body 3 of the liquid outlet 2. Preferably, the first plug body 3 has a shape with a narrow upper end and a wider lower end, so as to improve the blocking and sealing effect on the liquid outlet 2. The upper surface of the first plug body 3 An extension rod 5 extending out of the liquid outlet 2 is fixedly connected, a housing 7 is fixedly connected to the bottom of the box body 1, and a separator 8 is fixedly arranged in the interior of the housing 7 horizontally, and the separator 8 is used for The interior of the housing 7 is divided into an upper chamber 71 and a lower chamber 72, the upper chamber 71 and the lower chamber 72 are separately equipped with the first reactant 12 and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com