Supercharged turbo expander

A booster turbine and expander technology, which is applied to mechanical equipment, engine components, machines/engines, etc., can solve problems such as low working efficiency, rough expansion wheel and booster wheel, and affecting the performance of the expander. The effect of thorough energy utilization, small shaft loss and simple structure

Inactive Publication Date: 2012-09-12

苏州制氧机股份有限公司

View PDF7 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

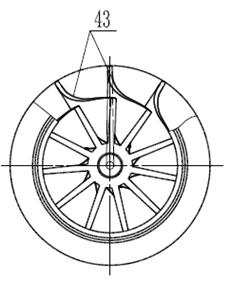

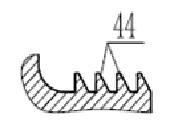

[0004] At present, the expansion wheel and the supercharging wheel used in the supercharged turbo expander are generally made of aluminum casting, and the expansion wheel and the supercharging wheel obtained in this way are relatively rough, which affects the performance of the entire expander

In addition, due to the shape of the blades of the current expansion wheel and supercharging wheel, the work efficiency is not very high.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

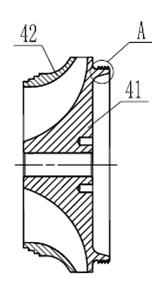

The invention provides a gas bearing supercharged turbo expander, including an intermediate shell body with a turbo volute being arranged on the left end of the intermediate shell body, a supercharger volute being arranged on the right end of the intermediate shell body, and a rotor being rotatably arranged inside the intermediate shell body, wherein an expansion wheel and a supercharging wheel are respectively arranged on both ends of the rotor, and two gas bearings sleeve on the rotor for supporting the expansion wheel and the supercharging wheel. The supercharged turbo expander provided in the invention has the advantages of simple structure, low shaft loss, low cost, high safety performance, reduced oil steam discharge in an oil bearing expander, and decreased environmental pollution, thereby establishing a milepost-type foundation for the development of the supercharged turbo expander.

Description

Technical field [0001] The invention relates to a supercharged turboexpander, in particular to a supercharged turboexpander using a gas bearing. Background technique [0002] The turbo-expander is a key unit necessary to obtain cold energy for air separation equipment, natural gas petroleum gas liquefaction separation equipment and cryogenic crushing equipment, and is the heart of ensuring the stable operation of the entire equipment. The main principle is to use a certain pressure of gas to perform adiabatic expansion in the turbo expander to do external work and consume the internal energy of the gas itself, so that the gas itself is strongly cooled to achieve the purpose of refrigeration. The energy output by the turbo expander is consumed by the coaxial compressor recovery or braking fan. [0003] The supercharged turboexpander includes a middle casing. The left end of the middle casing is equipped with a turbine volute, and the right end is installed with a supercharger volut...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F01D15/08F01D25/16F01D11/00F01D9/00F01D5/14F16C32/06F04D29/26

Inventor 徐友亮

Owner 苏州制氧机股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com