Patents

Literature

142results about How to "Use thoroughly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing active carbon

The invention discloses a method for producing active carbon, comprising the following steps: grinding corn cobs and cornstalks into flocculent corn cob materials and flocculent cornstalk materials bya grinder respectively, evenly mixing and then sending the materials into a particle forming machine to be extruded into particle materials; placing the particle materials into a carbonization kiln to be carbonized to obtain carbonized materials; directly sending the carbonized materials into an activation kiln to be activated without cooling to obtain activated materials; grinding and grading the activated materials to obtain the finished product of active carbon. Wood gas discharged from the flue of the carbonization kiln is introduced into a heating chamber on the lower part of an activation chamber to be ignited for heating the activation kiln; high temperature flue gases generated by combustion of the wood gas are introduced into the flue on the upper part of the activation chamber for carrying out secondary heating on the activation kiln; the flue gases discharged from the flue on the upper part of the activation chamber are introduced out to serve as the heat sources of a steamboiler, and the high temperature steam generated by the steam boiler enters the activation chamber to activate the carbonized materials. The active carbon produced by the method is good in quality and low in cost.

Owner:XIFENG DENGYUN JIEGAN COMPREHENSIVE UTILIZATION DEV

Method for producing chicken manure fermented feed

InactiveCN101584375ALow viscosityHigh nutritional valueAnimal feeding stuffNutrient solutionMixed materials

The invention discloses a method for producing chicken manure fermented feed, which comprises the following steps that: fully mixing fresh chicken manure with a carrier, and sterilizing and cooling the mixture to obtain a mixed material for standby; mixing and dissolving food-grade glucose in water to obtain nutrient fluid; mixing bacteria solution of yeast with bacteria solution of lactobacillus to prepare mixed bacteria solution; fully mixing and sealing the prepared mixed material, nutrient fluid and mixed bacteria solution in a plastic bag for fermentation at a temperature of between 25 and 35 DEG C for 2 to 4 days to obtain a fermentation material; and drying the fermentation material prepared by the steps; and when the water content in the fermentation material is reduced below 10 percent, crushing the fermentation material to obtain a finished product of the chicken manure fermented feed. By the method, parasite ova and harmful bacteria contained in the raw chicken manure can be removed, and the chicken manure can be prepared into the feed with good palatability and rich nutrition.

Owner:辽宁曙光农牧集团有限公司

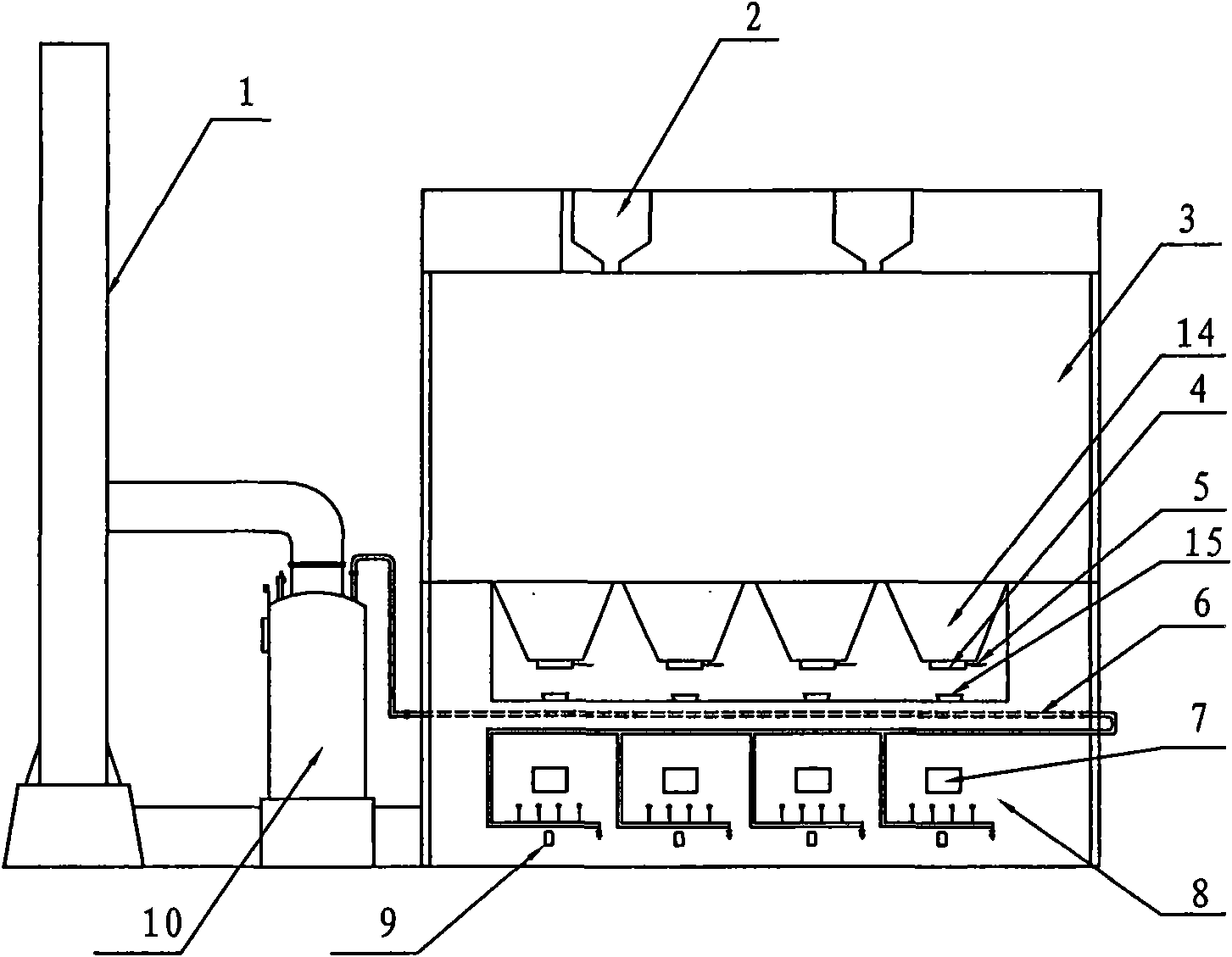

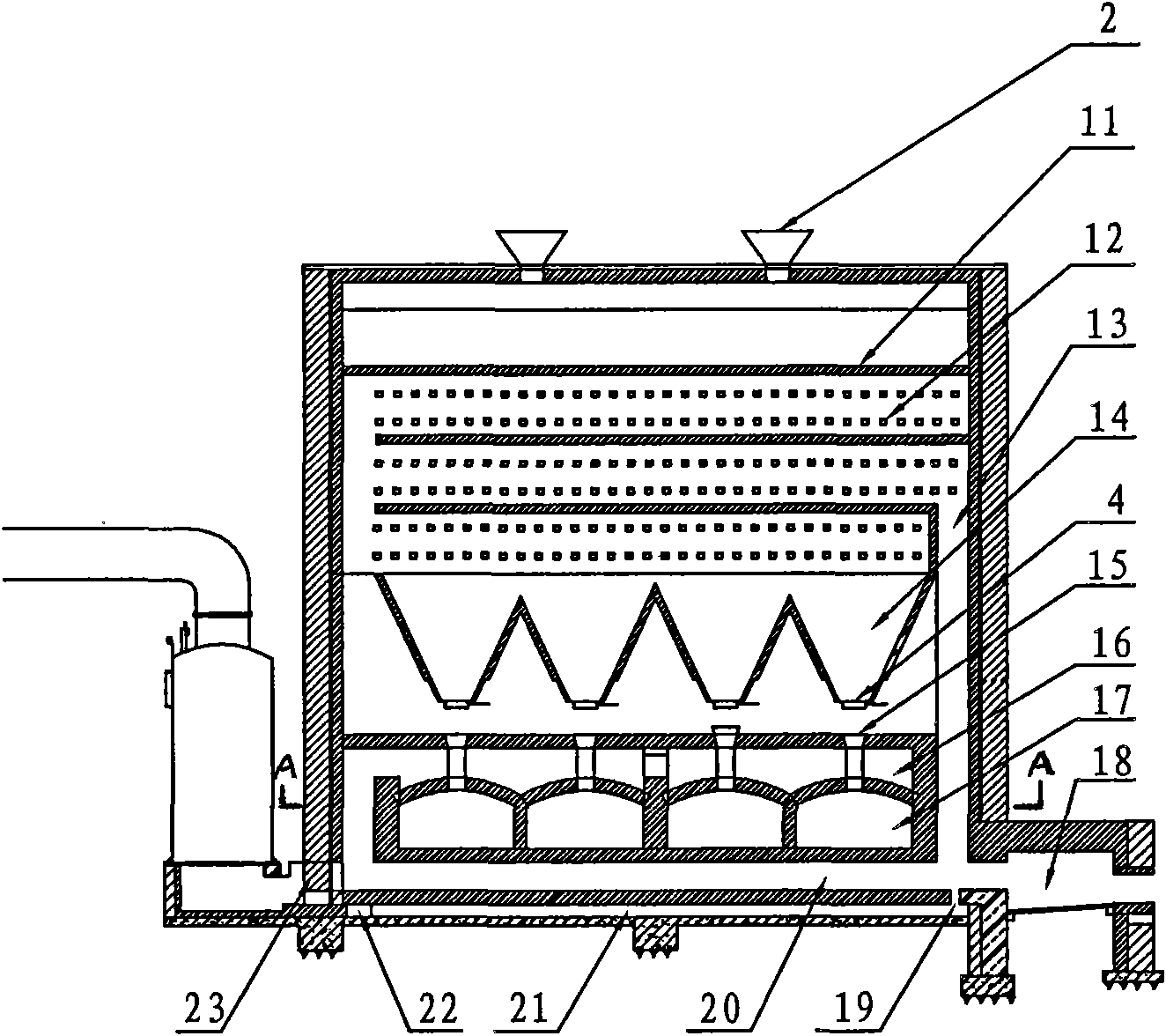

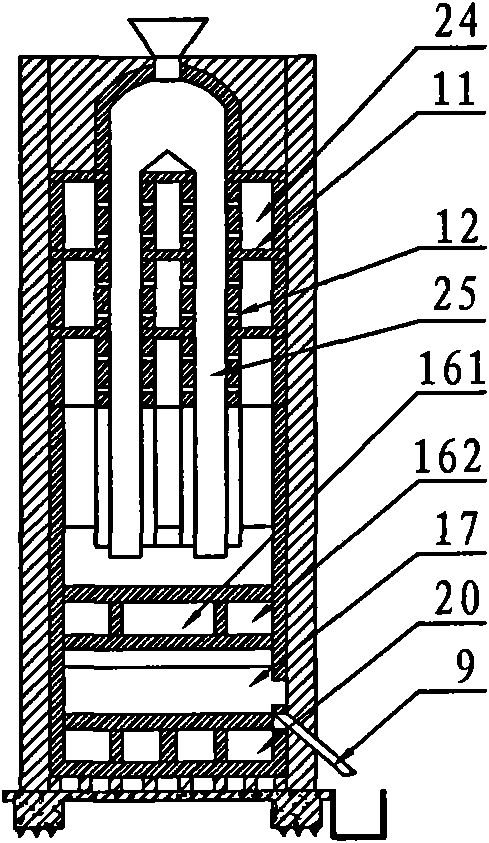

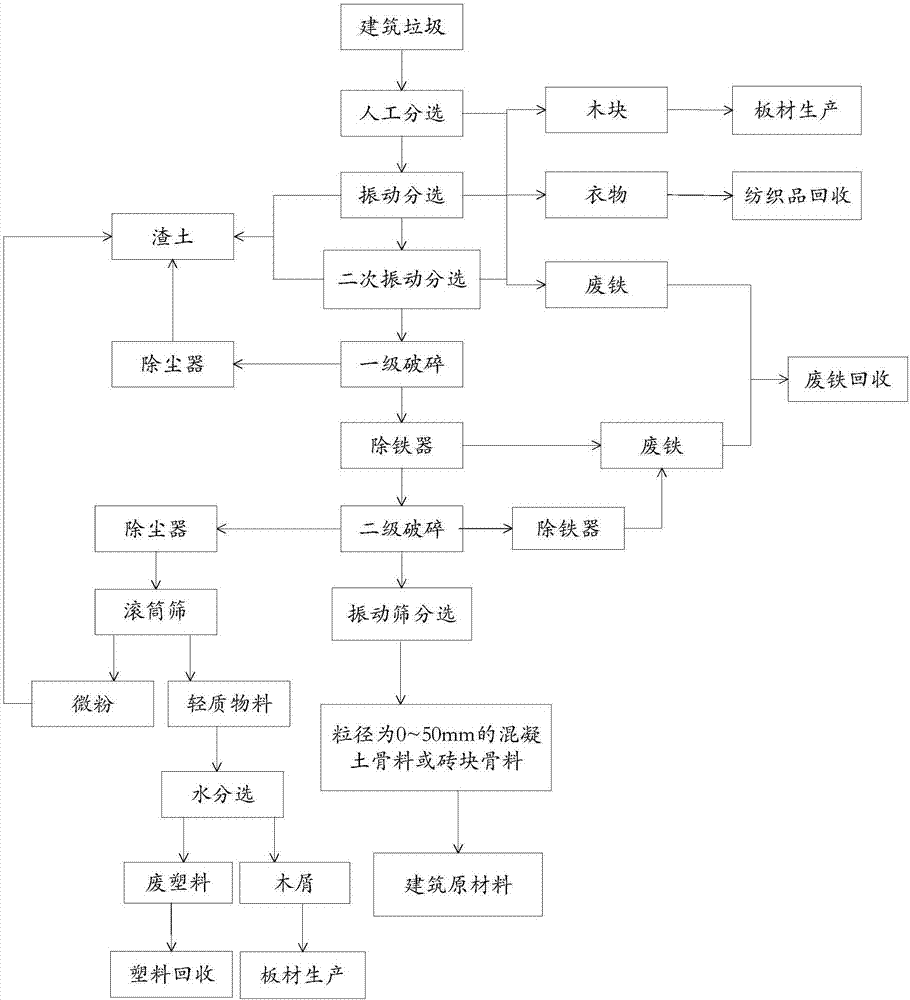

Method for recycling construction wastes

InactiveCN107377584AIncrease profitQuality improvementConstruction waste recoverySolid waste disposalEnvironmental resistancePrill

The invention discloses a method for recycling construction wastes. The method comprises the following steps: artificial sorting, vibratory sorting, primary crushing, iron removing, secondary crushing and sorting through a vibrating screen. According to the method for recycling the construction wastes, steps are reasonable and orderly, selected equipment is advanced, and the running cost is low. By the method, the sorting efficiency is high, a large quantity of recycled aggregates which are good in quality and are fine-grained can be produced, and the recycled aggregates which are produced by the method do not contain other impurities, and belong to high-quality recycled materials. Meanwhile, residue soil, scrap iron, clothes, wood blocks, plastics, micro-powder and the like in the construction wastes can further be recycled and are fully utilized, the construction wastes are sorted thoroughly, the utilization rate of raw materials is high, and therefore, the method has high benefit of environmental protection and marketization popularization prospect.

Owner:赵长强

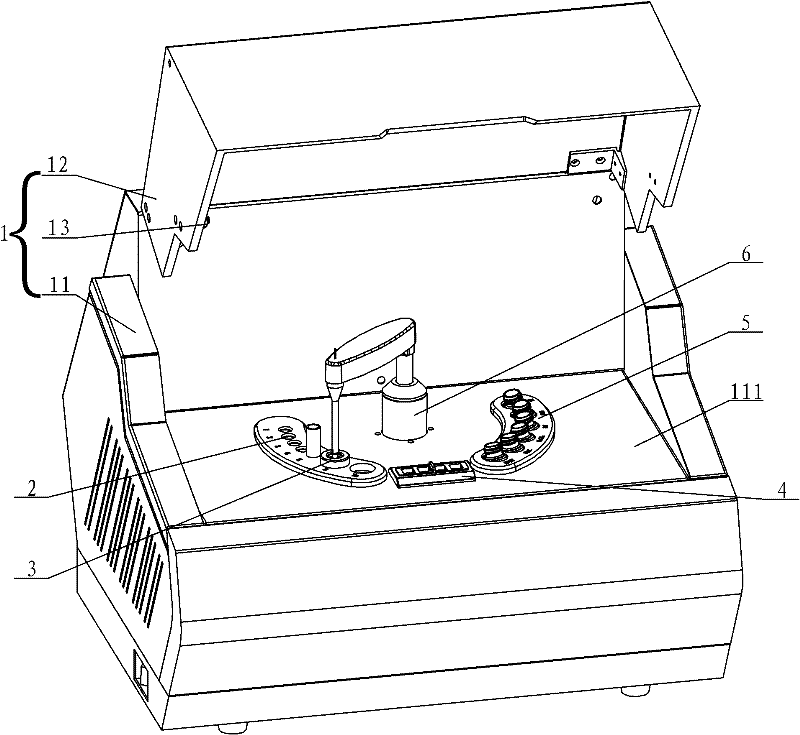

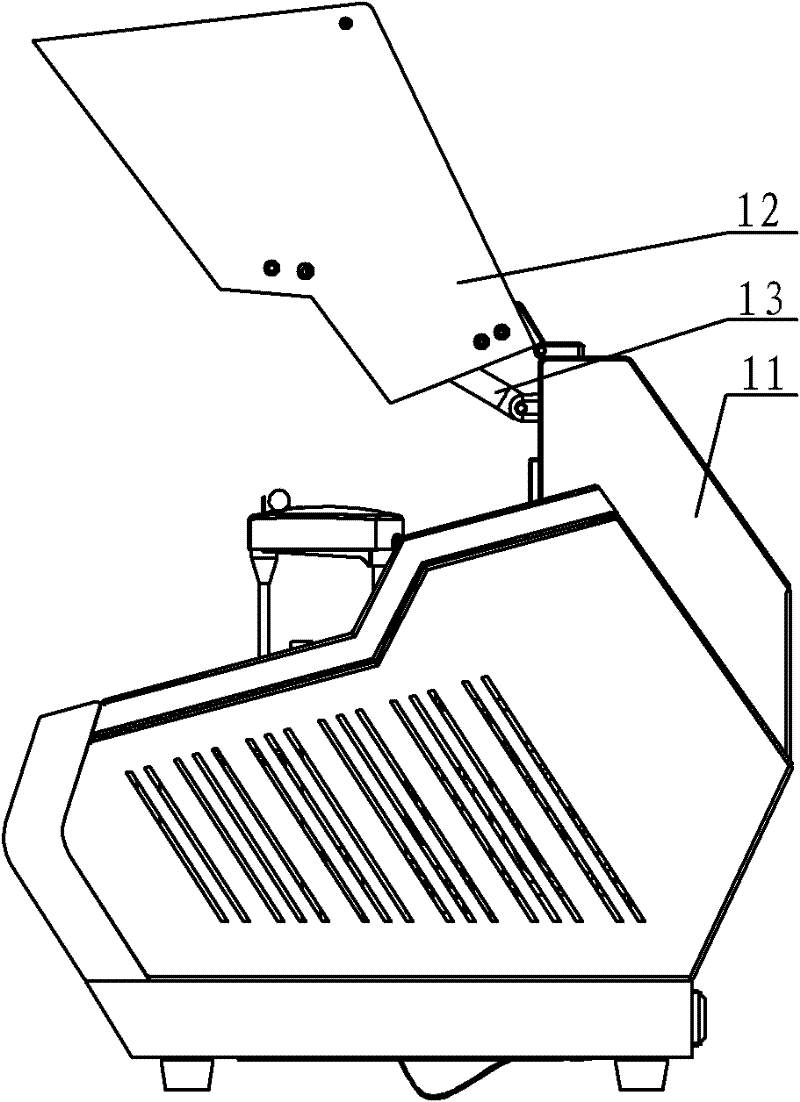

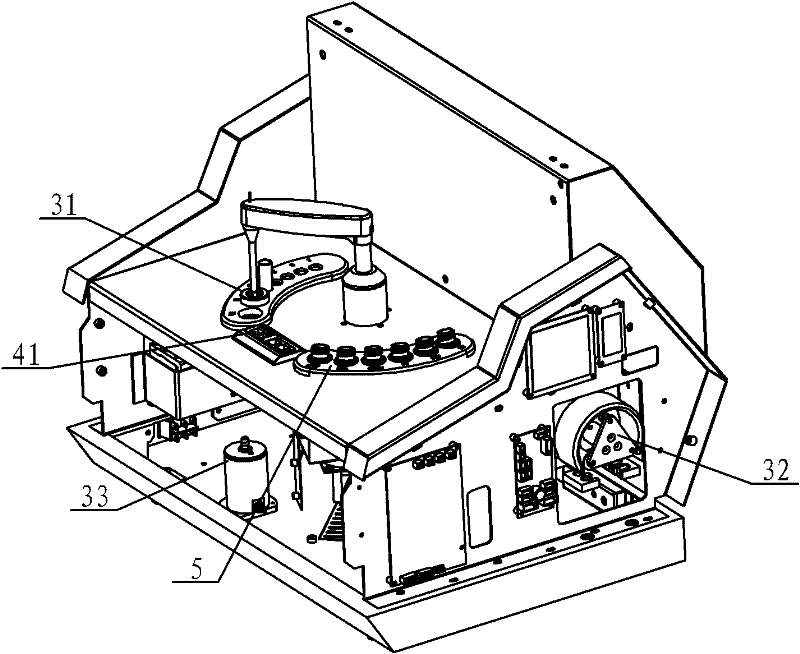

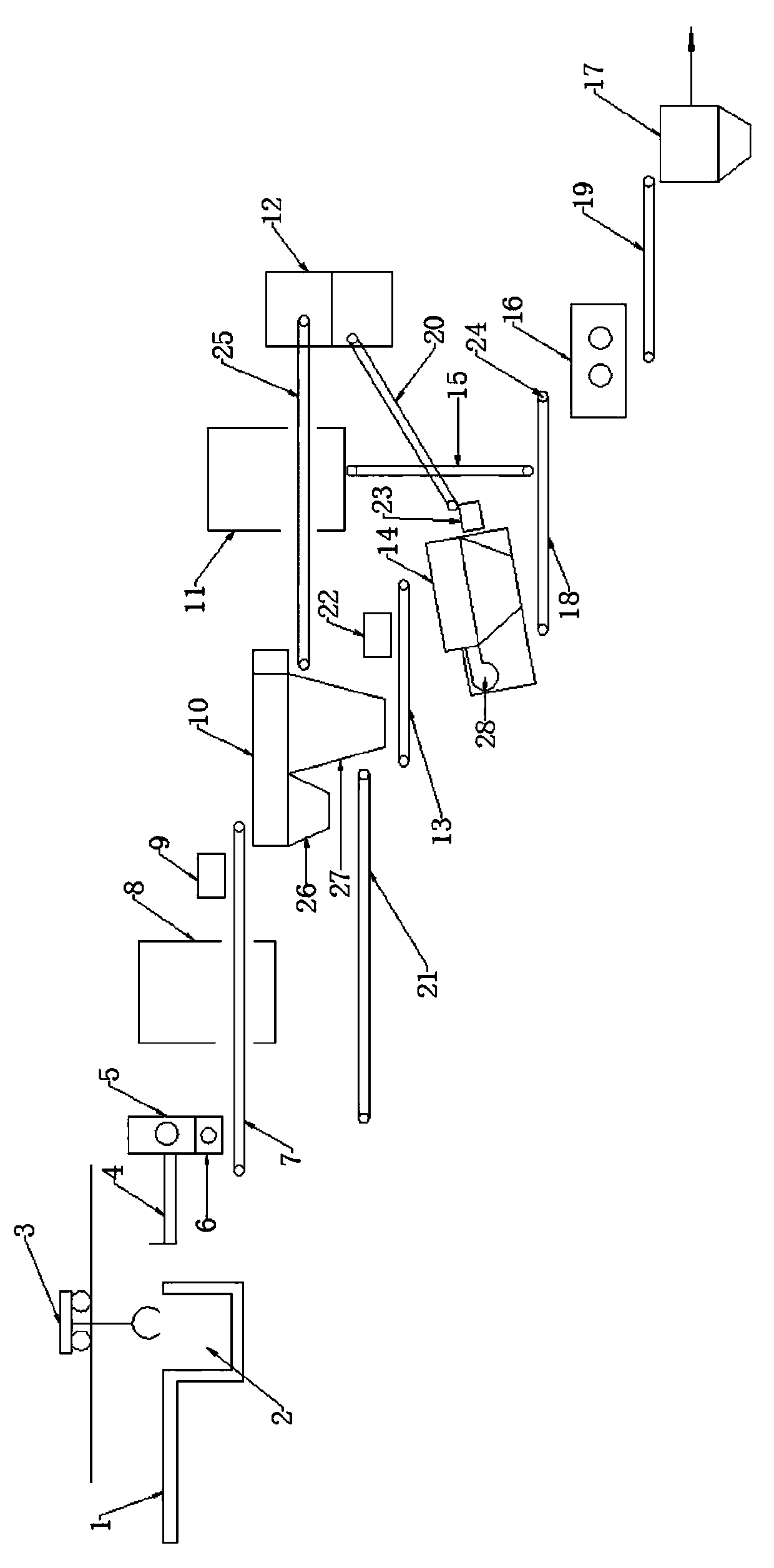

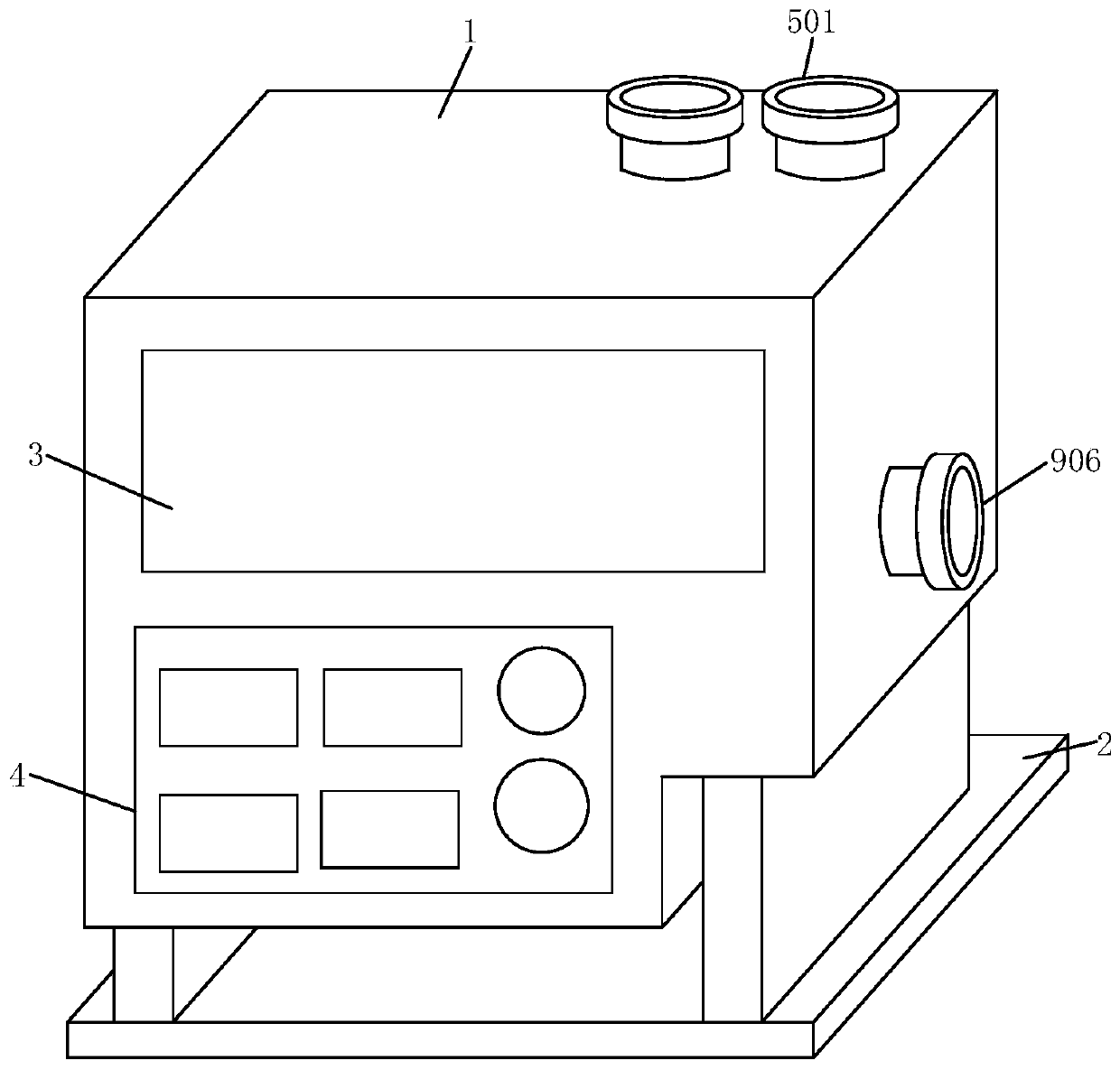

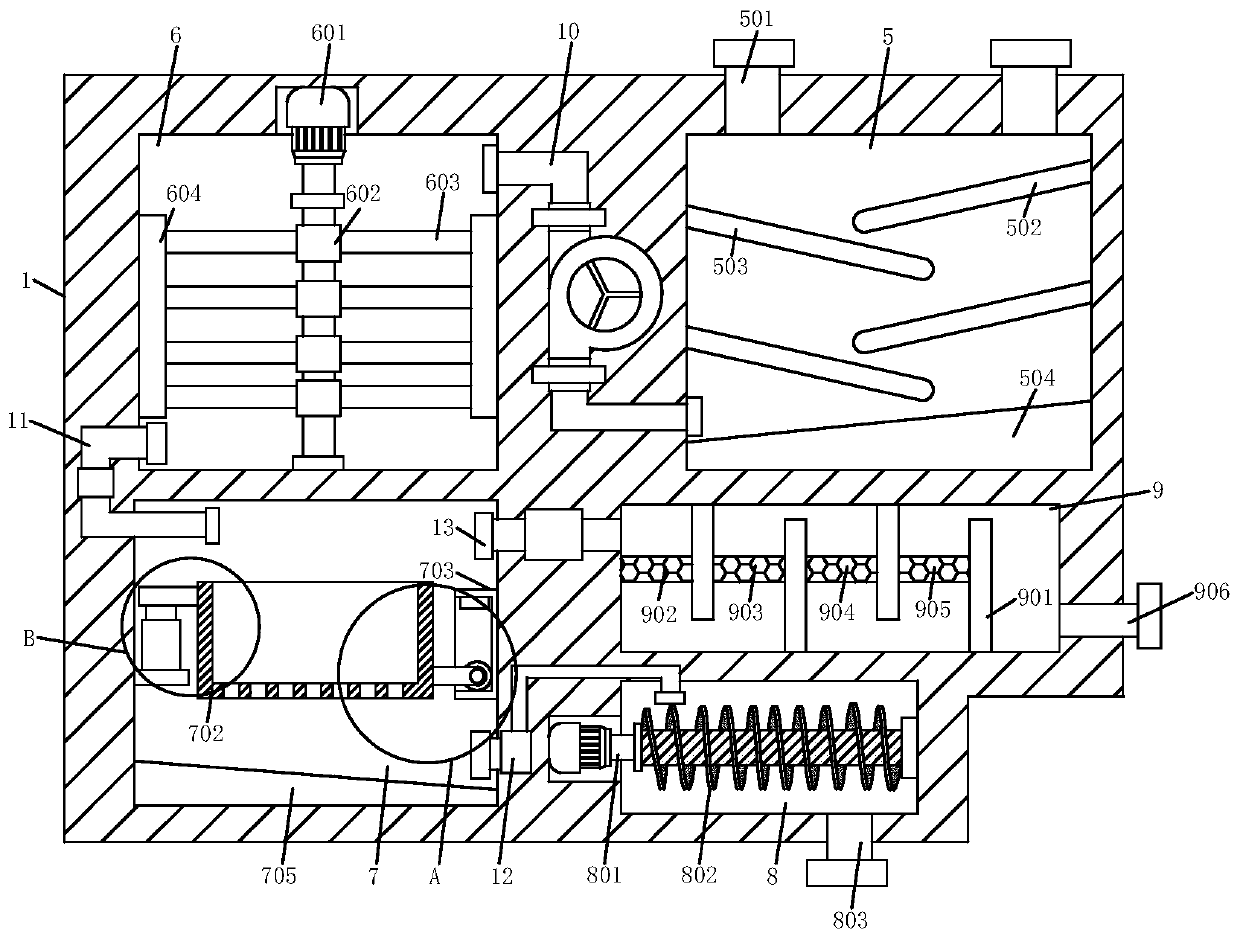

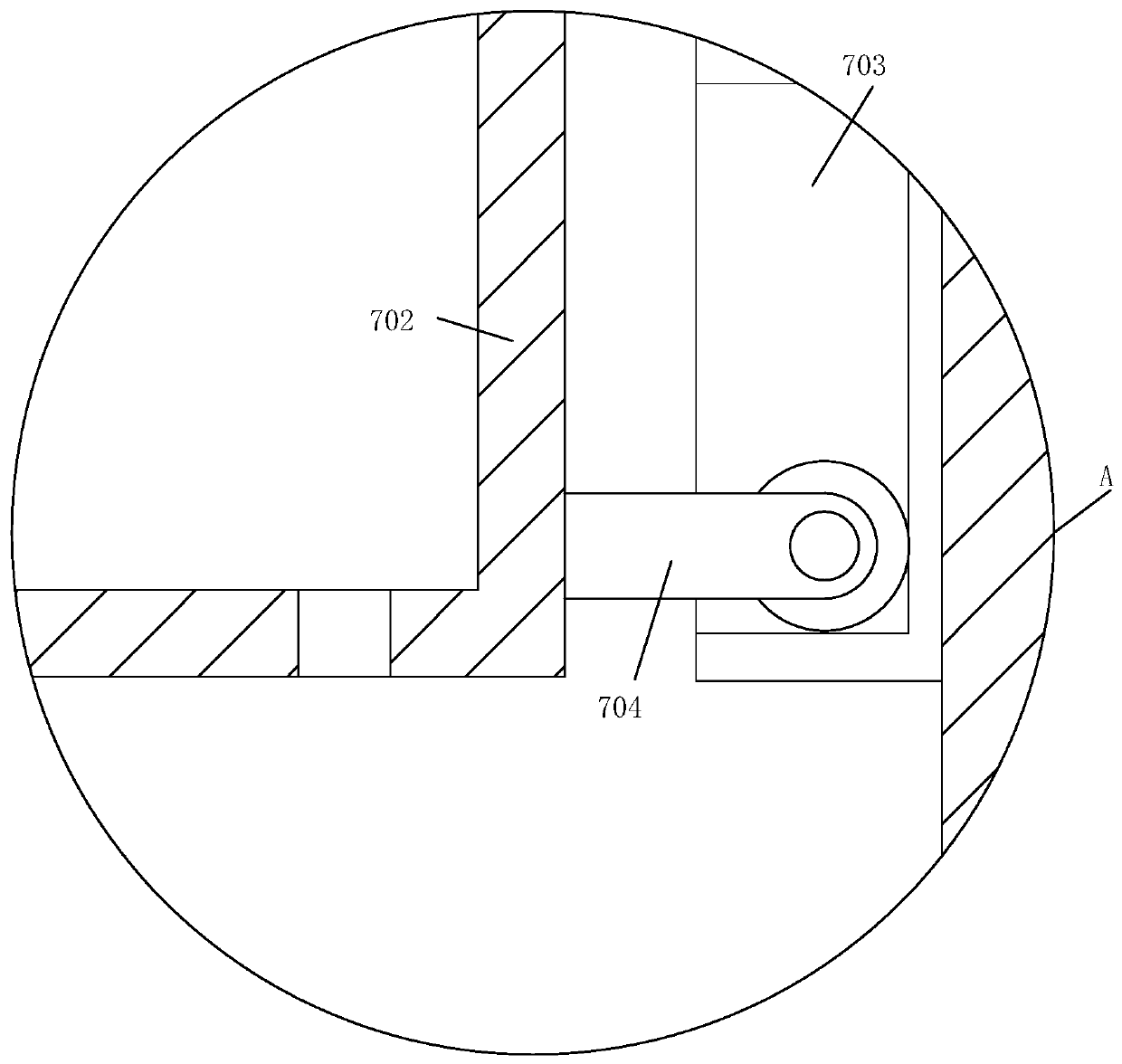

Rotary sample addition type fully-automatic blood coagulation tester

The invention discloses a rotary sample addition type fully-automatic blood coagulation tester. The tester which comprises a test system, a rotary sample addition system, an inclined reagent refrigeration system, a cleaning system and a cabinet is characterized in that the test system assembles four test channels which can simultaneously work; the rotary sample addition system comprises a rotary sample addition arm module, a sample addition probe module with constant temperature heating and liquid level probing functions, and a lead screw linear guide rail sample introduction control system; the inclined reagent refrigeration system which adopts an inclined mode to install a reagent bottle saves the reagent and avoids waste; and the cleaning system comprises an overflow type cleaning module and a double-channel peristaltic liquid charging and discharging system. The tester has the advantages of accurate test, accurate sample addition, reagent saving, long reagent preservation time, constant heating of the test system, high detection efficiency, simple operation, good cleaning effect, safe and efficient liquid discharge, and small noise.

Owner:北京众驰伟业科技发展有限公司

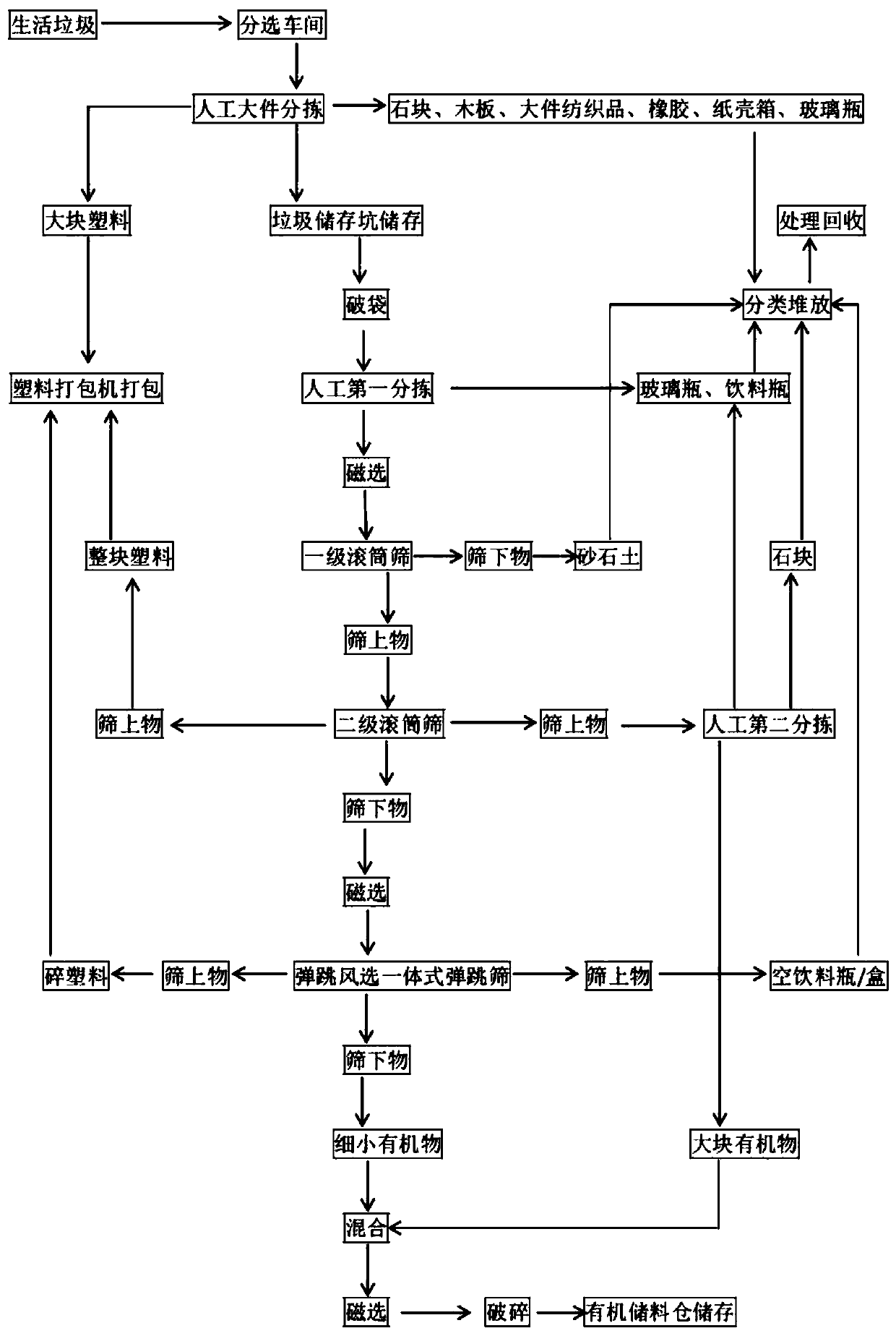

Household garbage sorting process and household garbage sorting system

PendingCN110170377AIncrease productivityConducive to utilization of fermentation resourcesSievingGas current separationPlastic packagingLitter

The invention discloses a household garbage sorting process. The household garbage sorting process comprises the steps of sequentially carrying out household garbage large piece sorting, household garbage bag breaking treatment, garbage primary sorting, garbage fine sorting, organic matter fine sorting and the like. The invention further discloses a household garbage sorting system, wherein the household garbage sorting system comprises a large piece sorting table, a garbage storage pit, a bag breaking machine, a first manual sorting chamber, a first magnetic separation device, a second-stagerotary screen, a second manual sorting chamber, an organic matter fine sorting system and a plastic packaging machine which are sequentially connected through a conveying device. According to the process and the system disclosed by the invention, the household garbage is separated according to the respective differences through the combination of a screening device and the manual sorting, so thatthe effective separation of the whole components of the garbage is realized; and meanwhile, the sorted organic matters are further subjected to fine sorting, the obtained organic matter raw materialsare high in purity, the organic matter productivity is increased, the subsequent organic matter fermentation resource utilization is facilitated, and the recyclable resources in the waste can be fullyrecycled.

Owner:JIANGSU YIJIN ENVIRONMENTAL PROTECTION TECH CO LTD

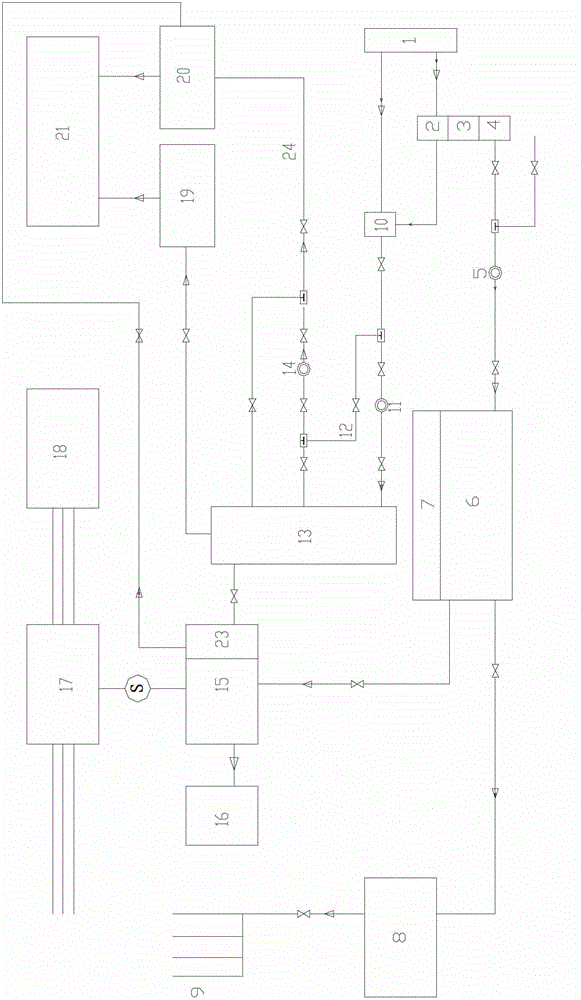

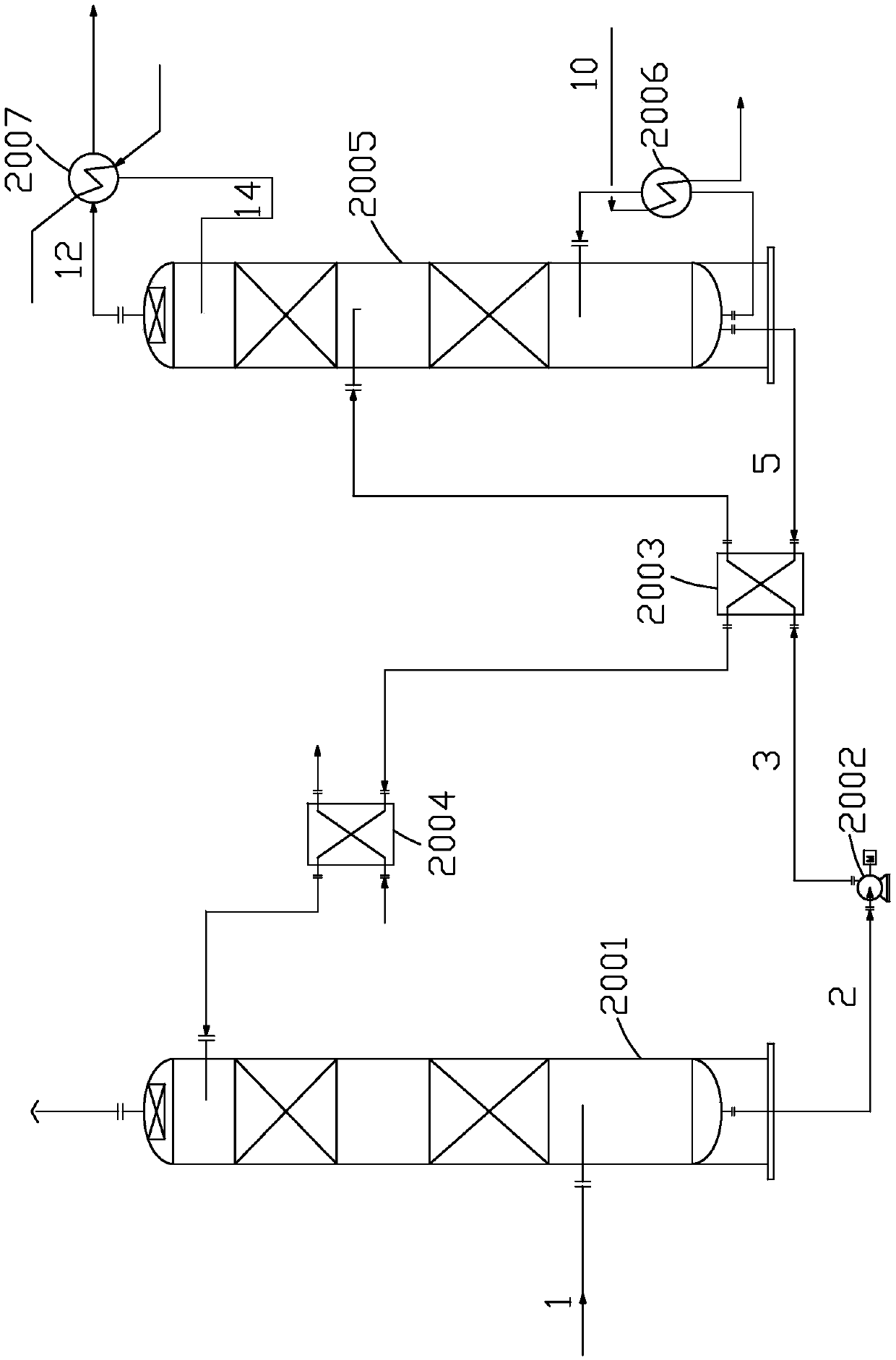

Breeding pollution discharge treatment system and treatment method thereof

ActiveCN102718355AUse thoroughlyEliminate bad effectsBio-organic fraction processingSludge treatment by de-watering/drying/thickeningLiquid wasteHigh concentration

The invention discloses a breeding pollution discharge treatment system and a treatment method thereof. The breeding pollution discharge treatment system comprises a primary solid-liquid separation apparatus, a liquid waste treatment system, a highly concentrated slurry treatment system, and an organic fertilizer processing system. In the invention, concentration-type separation is carried out on breeding waste according to commercial value. Anaerobic biogas treatment is carried out on low-concentration slagless liquid waste which can be then returned to farmland for utilization. Solid-liquid separation is carried out on the waste material of high-concentration slurries after anaerobic biogas treatment for producing high-concentration liquid and solid commercial fertilizers. The breeding pollution discharge treatment system can be constructed together with a farm and can be nearby used, and is suitable for the treatment of the breeding waste of large and medium-sized livestock such as cattle, sheep, pigs, and the like and organic garbage. Compared with the method of on-site discharge and transport treatment, the system and the method of the invention can realize more thorough waste utilization, can provide irrigation water and commercial fertilizer raw materials while proving biogas, can reduce breeding cost, and can eliminate adverse influence on surrounding environment caused by breeding pollution discharge.

Owner:福建欣彦环保科技有限公司

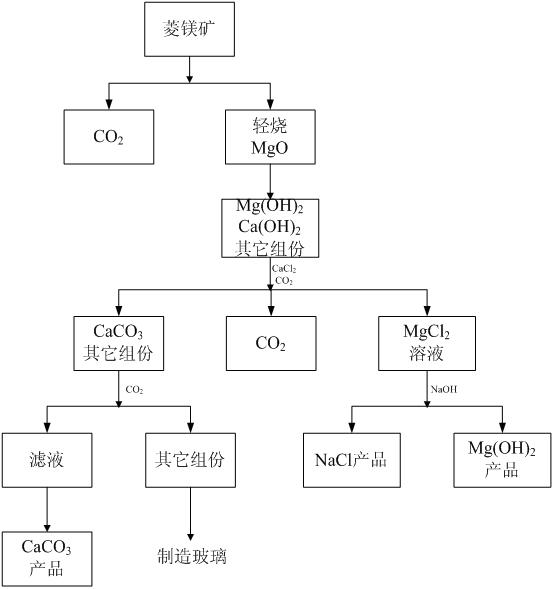

Magnesite carbonization method for producing magnesium hydroxide and calcium carbonate product

InactiveCN101987734AImprove carbonization efficiencyTake advantage ofCalcium/strontium/barium carbonatesMagnesium hydroxideCalcium carbonateEngineering

The invention discloses a magnesite carbonization method for producing magnesium hydroxide and a calcium carbonate product, and belongs to the technical field of inorganic chemical industry. The method comprises the following steps of: calcining and grinding magnesite, mixing with water, adding CaCl2 into pulp, introducing CO2 gas, and stirring and filtering to obtain a primary filter cake and primary filtrate; adding alkali into the filtrate, and stirring and filtering to obtain a secondary filter cake and secondary filtrate; performing spray drying on the secondary filter cake to obtain Mg(OH)2; drying the secondary filtrate to obtain NaCl; adding water into the primary filter cake, introducing CO2 gas, and stirring and filtering to obtain a third filter cake and third filtrate; performing spray drying on the third filtrate to obtain CaCO3; and filtering and drying the third filter cake to obtain a product serving as a raw material for producing glass for subsequent treatment. The CaCl2 is added in the carbonization reaction process, the carbonization efficiency is improved, high-purity magnesium hydroxide and calcium carbonate products are prepared, other useful components serve as raw materials for producing glass and is subsequently treated and utilized, the production process flow is simple, the equipment requirement is low, and after the treatment, other pollution is not generated.

Owner:LIAONING TECHNICAL UNIVERSITY

Modified vegetable fat and its application in erythromycin fermentation process

ActiveCN102732383AImprove utilization speedUse fastFatty acid chemical modificationFermentationBiotechnologyVegetable oil

The invention relates to a modified vegetable fat and its application in an erythromycin fermentation process. The modified vegetable fat is prepared by: mixing vegetable fat with water and lipase, with the water and the lipase respectively accounting for 20-50wt% and 0.1-0.5wt% of the vegetable fat, conducting heat preservation for 4-6 hours at PH of 5.5-8.5 and a temperature of 35-45DEG C, and carrying out standing and layering so as to obtain a fat layer, i.e. the modified vegetable fat, which has an enzymolysis rate of 30-60% and an acid value of 50-100mgKOH / g. In the invention, natural vegetable fat is modified, and lipase is utilized to make the fat in fermentation, the oil system is decomposed into mixed fat composed of free fatty acid, glycerol and monoglyceride or diglyceride andthe like, so that the fat residue in an erythromycin fermentation solution is reduced, the fat utilization speed is enhanced, and the oxygen consumption during fermentation is reduced, thus effectively improving the fermentation titer and reducing the fermentation cost.

Owner:NINGXIA QIYUAN PHARMA

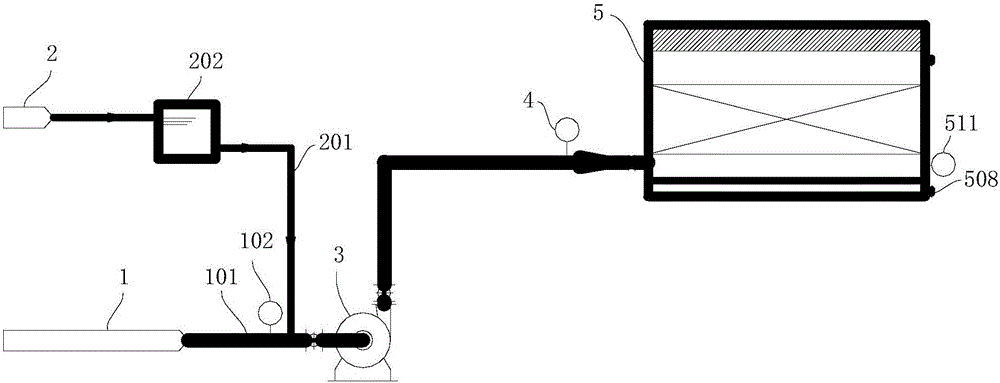

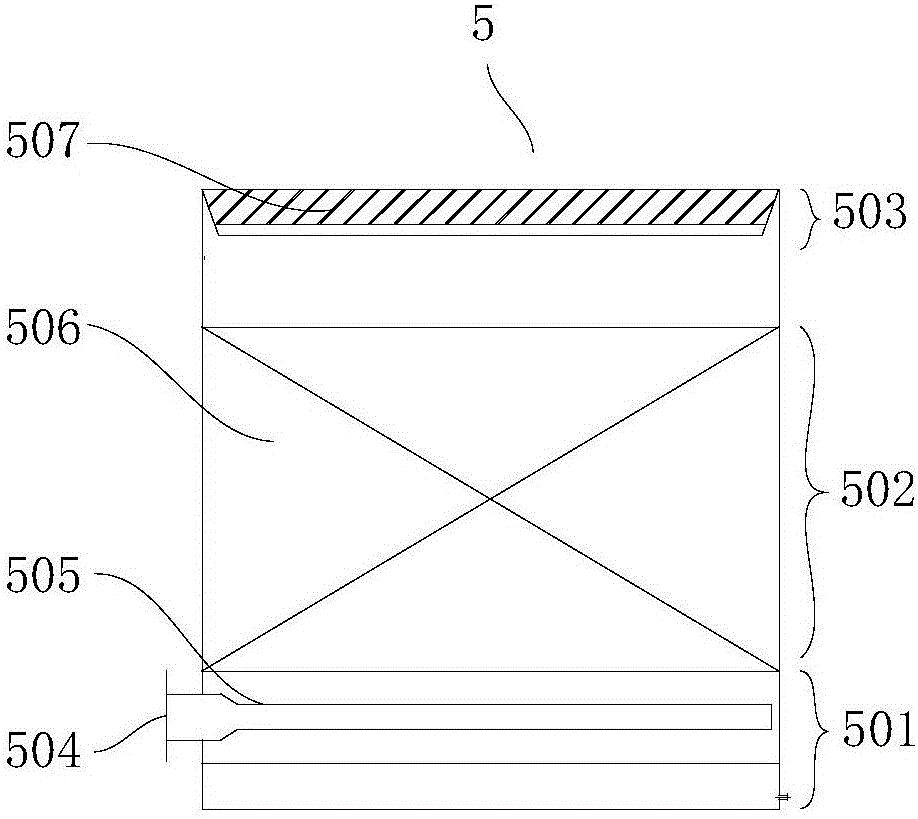

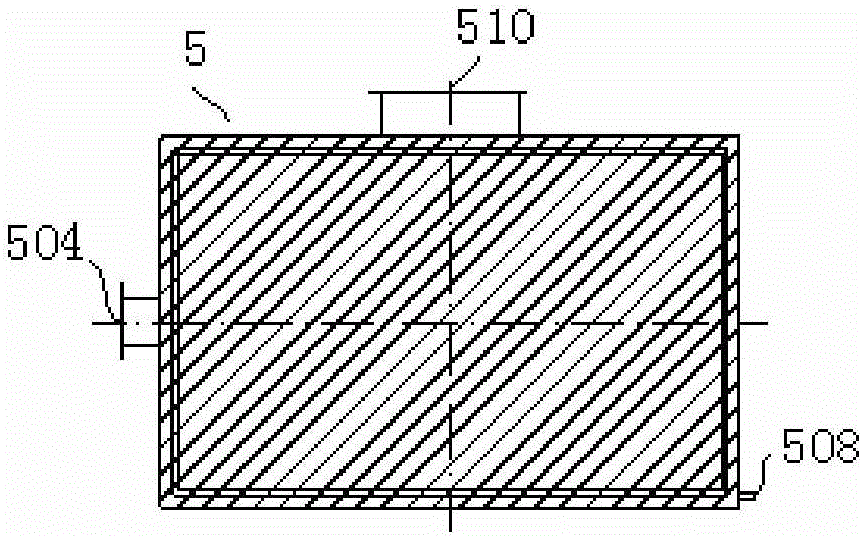

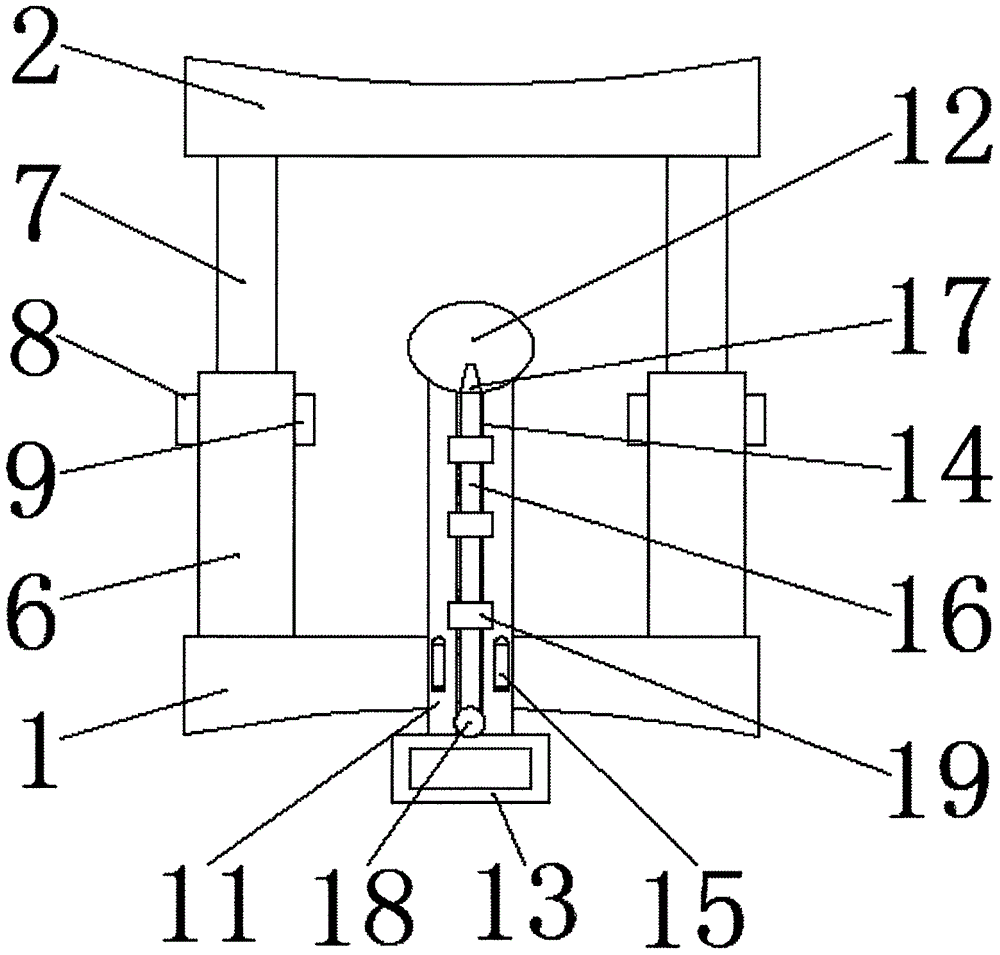

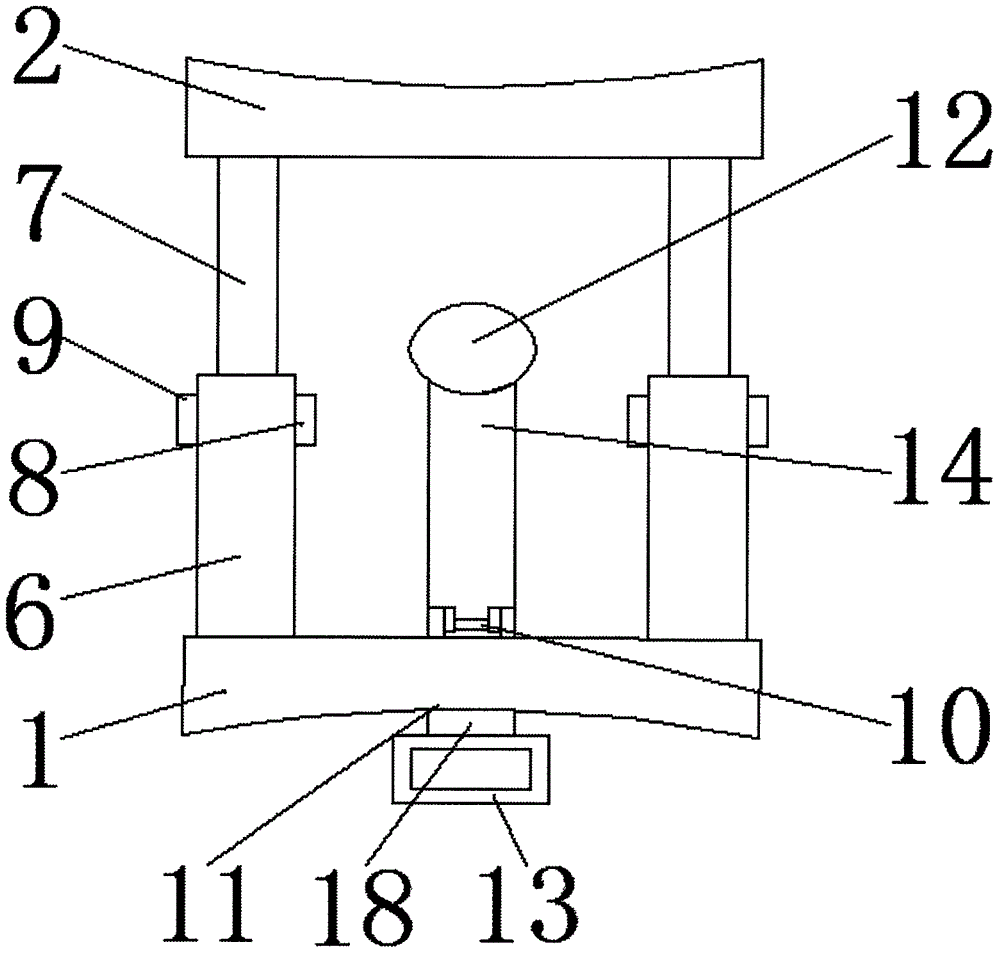

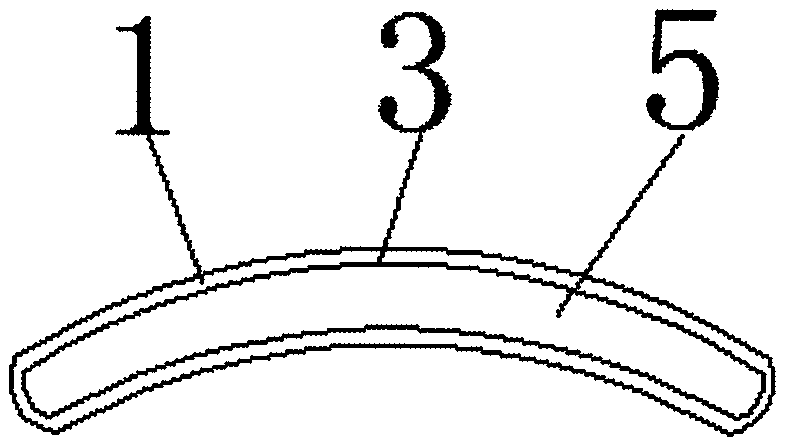

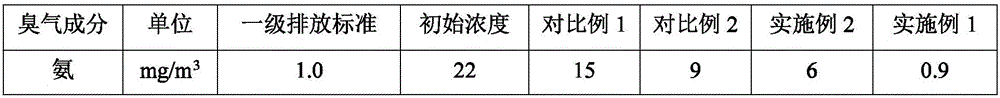

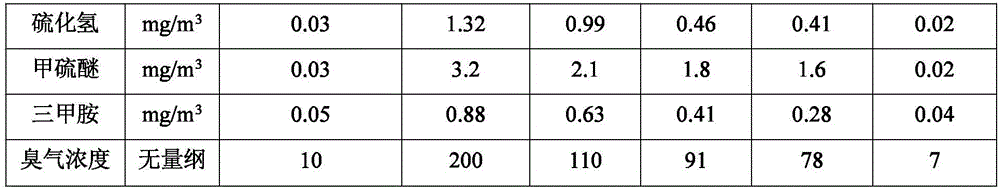

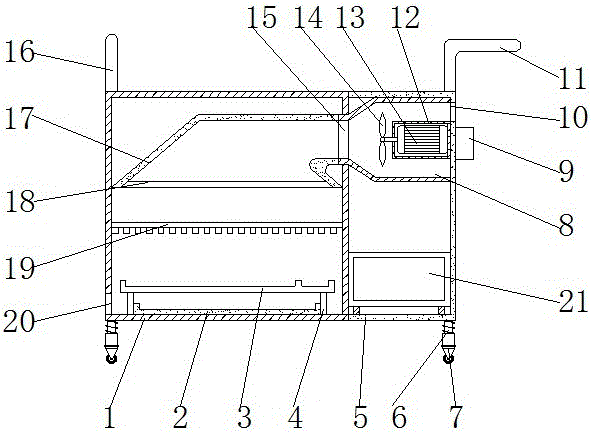

Biological combined synergistic deodorization process and device thereof

ActiveCN106178930AHigh affinityImprove film formationDispersed particle separationAir quality improvementEngineeringTherapeutic effect

The invention discloses a biological combined synergistic deodorization process and a device thereof. An odor source is humidified and sequentially subjected to microbial filler deodorization and soil deodorization by a two-stage deodorization process, and finally freely escape through the top of a soil deodorization system. The deodorization device comprises a deodorization box, an odor pipeline and a humidifying pipeline, one end of the odor pipeline is communicated with the odor source, the other end of the odor pipeline is connected to an air inlet of the deodorization box, a fan is arranged on the odor pipeline, the humidifying pipeline is parallelly connected onto a deodorization pipeline in front of the fan, connected with a humidifier and used for humidifying odor in the odor pipeline, an air distribution layer, a primary deodorization layer and a secondary deodorization layer are serially connected into the deodorization box, the air distribution layer is communicated with the air inlet, the primary deodorization layer is a microbial filler deodorization system, and the secondary deodorization layer is a soil deodorization system. The structure of a biological deodorization device is adjusted, biological deodorization process features are combined, the multi-stage deodorization system is used for synergistic deodorization, the treatment efficiency of the deodorization system is guaranteed, integration degree is high, and treatment effects are good.

Owner:HUNAN HENGKAI ENVIRONMENT TECH INVESTMENT CO LTD

Pediatric clinical oral examination device

The invention discloses a pediatric clinical oral examination device comprising a lower jaw support. An upper jaw support is arranged above the lower jaw support, the top of the lower jaw support is provided with a first supporting pipe, the upper jaw support is provided with a second supporting pipe, the top end of the first supporting pipe is connected to the bottom end of the second supporting pipe through a screw and a nut, the center of the top surface of the lower jaw support is connected to a tongue depressor through a pin joint device, and the upper surface of the tongue depressor is provided with a liquid collection groove provided with a thin glass tube inside. The upper and lower jaw supports are adopted to fix the oral cavity of a child, the oral examination is facilitated, oral cross infection is reduced, the thin glass tube and an air ball can be adopted to remove a small amount of sputum, the examination can be performed more thoroughly, the device can be used more conveniently, the practicality is high, and the examination effect is fine.

Owner:刘峰

Biological deodorization composition for odor removal, method for preparing filler by biological deodorization composition and application of biological deodorization composition

ActiveCN105833716AImprove adsorption capacitySustained and slow releaseGas treatmentDispersed particle separationSlagSludge

The invention discloses a biological deodorization composition for odor removal and further discloses application of the biological deodorization composition as deodorization filler for deodorization of gas or mist containing odor substances. The composition comprises composted sludge, charcoal, cement and blast furnace slag. By synergistic cooperation of the composted sludge and the charcoal which serves as a controlled-release carrier of composted sludge nutritive elements, the composted sludge nutritive elements can be released sustainably and slowly to achieve an engineering application effect of freeness of additional nutritive elements. In addition, the composted sludge and the charcoal are high in microbial affinity and conducive to microbial film colonization, and accordingly efficient adsorption and deodorization can be realized by microorganisms under sustainable feeding of the composted sludge and the charcoal. Furthermore, thorough utilization of the nutritive elements and organic matters in the composted sludge is realized, and environment friendliness and freeness of pollution are realized as well.

Owner:HUNAN HENGKAI ENVIRONMENT TECH INVESTMENT CO LTD

Preparation method of mesoporous potamogeton pectinatus adsorption material for heavy metal ions

InactiveCN106179248AImprove adsorption performanceIncrease profitOther chemical processesWater contaminantsPectinatusIon

The invention relates to a preparation method of a mesoporous potamogeton pectinatus adsorption material for heavy metal ions, and belongs to the field of adsorption material preparation. According to the invention, Potamogeton pectinatus stems are taken as raw materials, and soaked in water to enable deionized water enter into inner pores of the stems, and quickly frozen by liquid nitrogen to enable water in the pores of the stems frozen, inner apertures of the stems are widened to increase porosities by using an ice splitting effect, namely the principle that water freezes to increase volume, then adsorption sites of the stems are treated by methanol to be fully exposed, the number of active groups on the surfaces of the stems and in the inner pores is further increased through composite fermentation modification of hydroxycitric acid in a garcinia cambogia extracting solution and microorganisms in biogas liquid to increase the adsorption rate of the stems, finally freeze drying is carried out to obtain the adsorption material. The method disclosed by the invention not only changes surface properties of the potamogeton pectinatus stems, but also changes the internal structures of the stems to improve adsorption properties of the stems so as to facilitate more thorough adsorption, thus the adsorption material can be thoroughly utilized, and the utilization rate of the adsorption material is increased.

Owner:吴迪

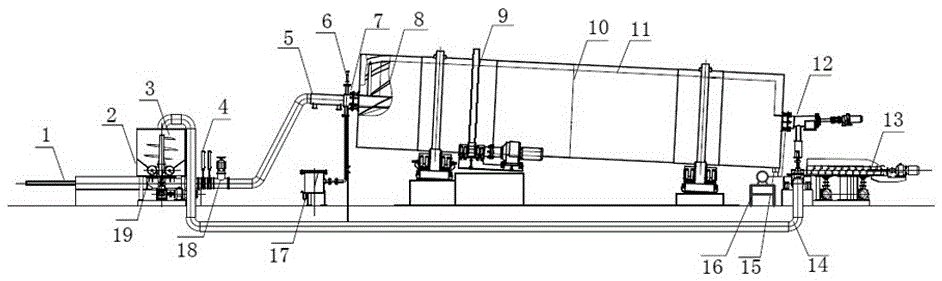

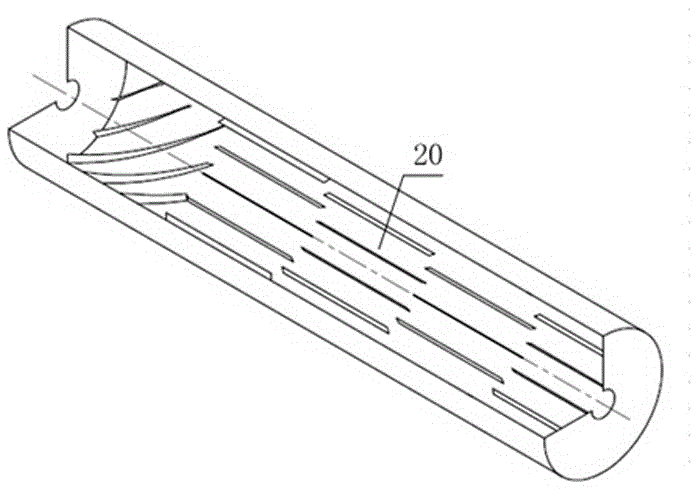

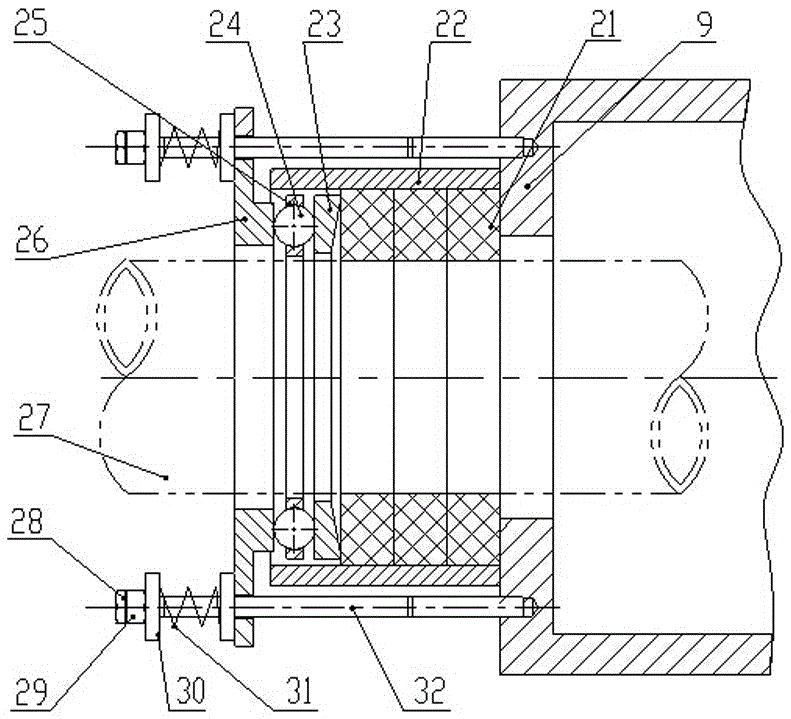

Continuous horizontal dry-process anaerobic fermentation system

InactiveCN105602843AImprove airtightnessRealize high-value utilizationBioreactor/fermenter combinationsBiological substance pretreatmentsRefluxAutomatic control

The invention provides a continuous horizontal dry-process anaerobic fermentation system, belonging to the technical field of fermentation plants. The continuous horizontal dry-process anaerobic fermentation system comprises a horizontal fermentation tank capable of rotating along the axis, wherein a biogas slurry reflux spray system is fixedly arranged in the fermentation tank; one end of the fermentation tank is a feed end, and the other end is a discharge end; the height of the feed end is greater than that of the discharge end; the feed end is connected with a mixing bin through a feed system; the feed end is provided with a biogas pipe; the discharge end is provided with a fermentation leftover discharge system; and a temperature measuring device is arranged inside the fermentation tank. Both ends of the obliquely-arranged horizontal fermentation tank are respectively connected with the automatic feed system and automatic discharge system, and the reflux spray system is arranged in the fermentation tank, thereby implementing continuous stable feed and discharge; and thus, the biogas slurry can implement circulating spray, and the marsh slag can implement circulating mixing. The continuous horizontal dry-process anaerobic fermentation system has the advantages of simple structure, reasonable design, high operation smoothness and low energy consumption, and can implement full-automatic control. The capacity aerogenesis rate is 1.0-1.5 m<3> / m<3>.d.

Owner:QINGDAO TIANREN ENVIRONMENT

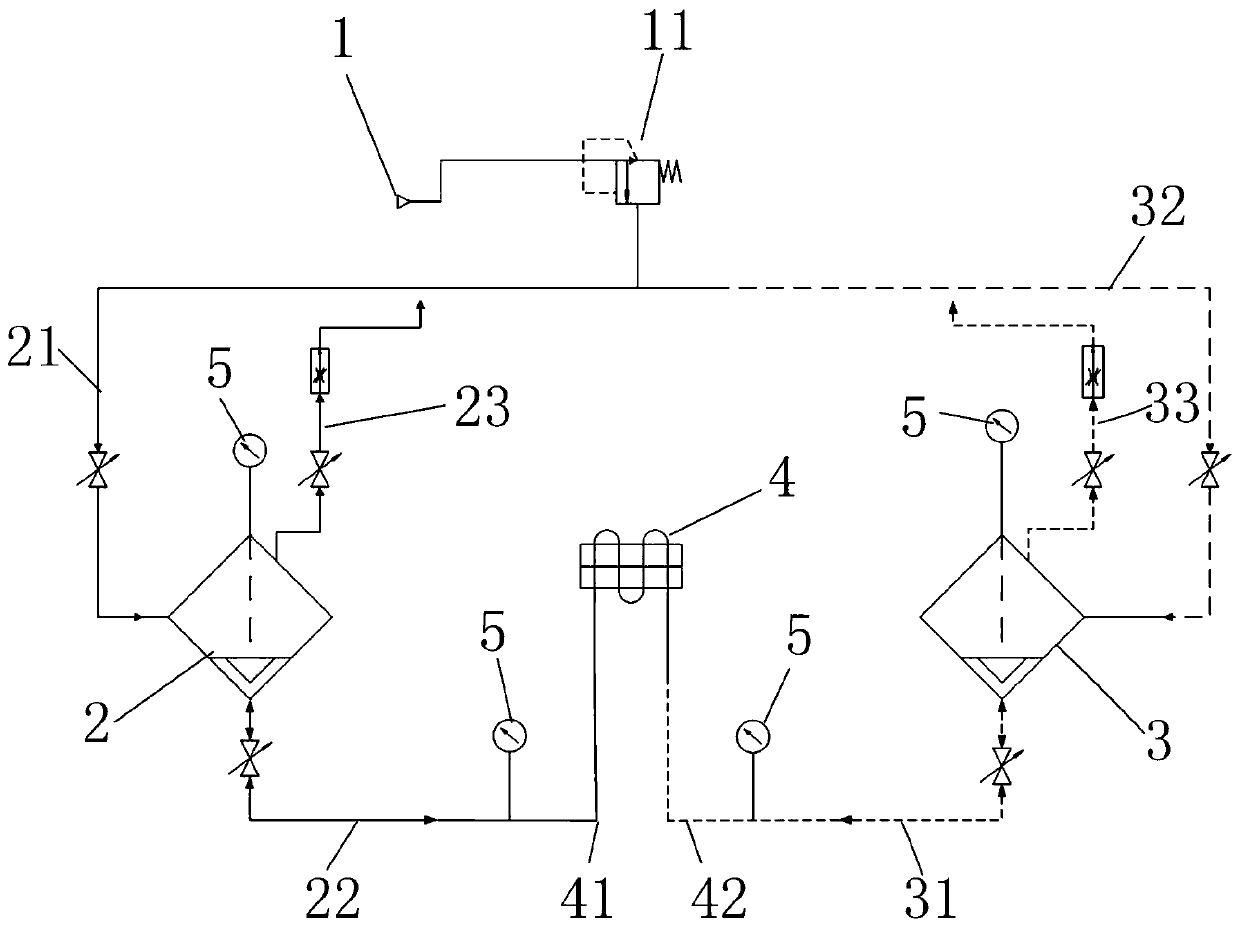

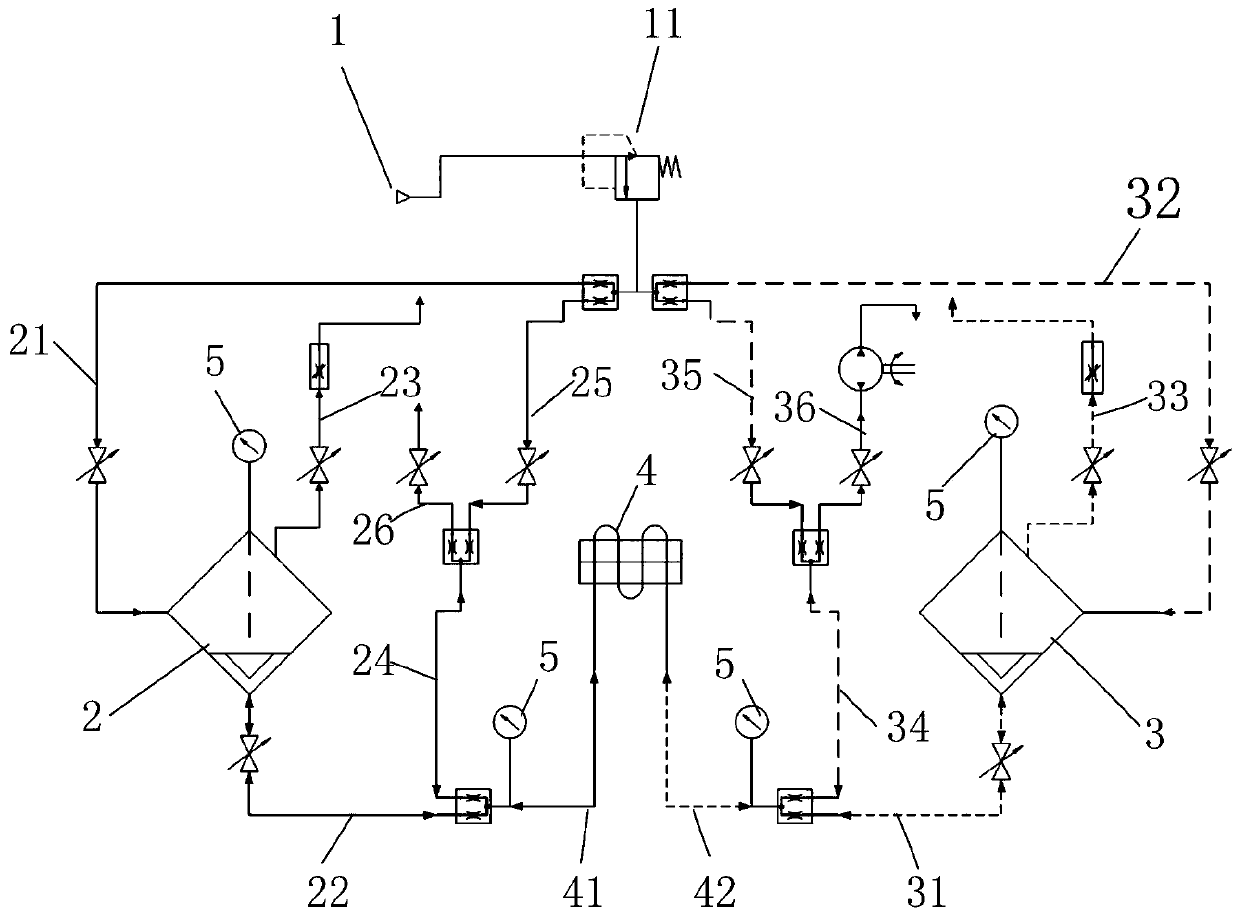

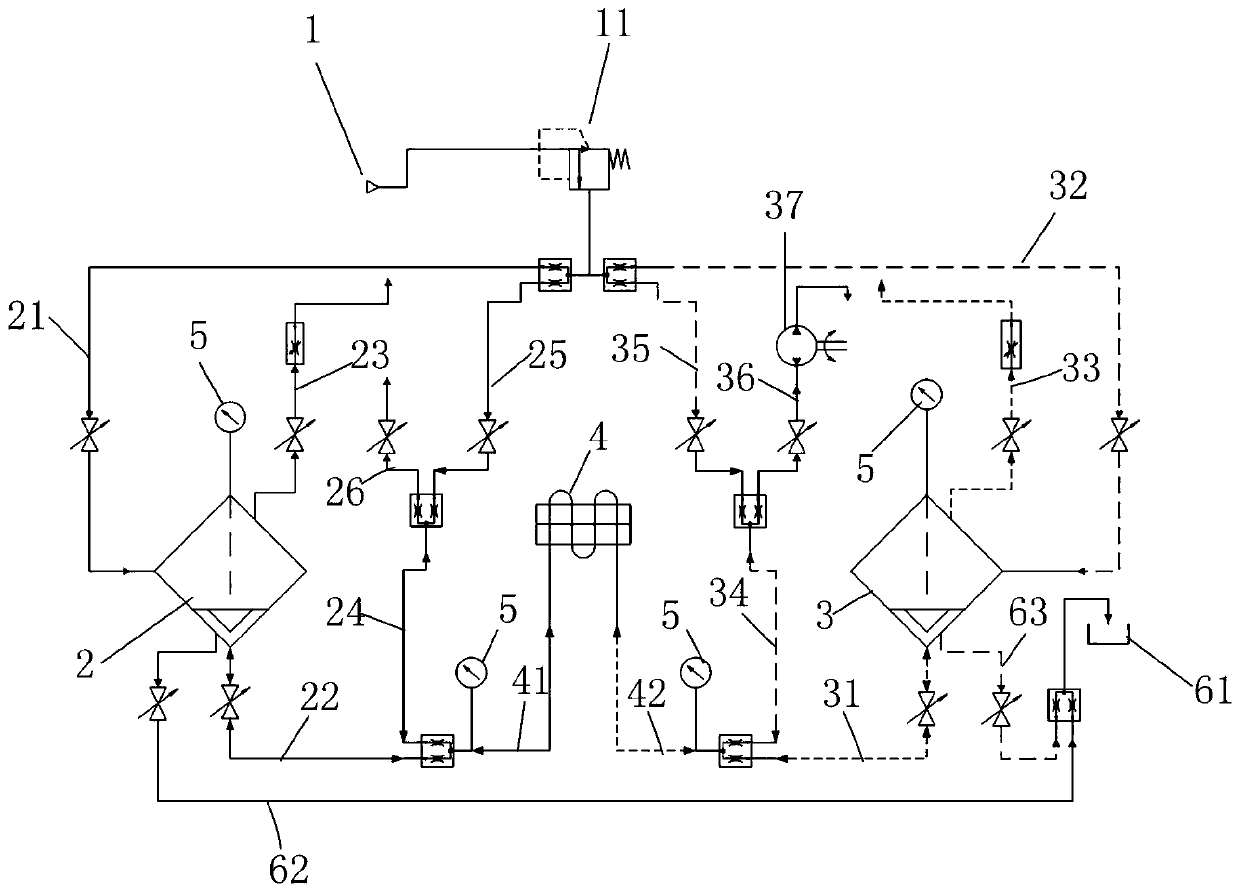

Multifunctional circulating cleaning system

PendingCN110420926ASolving Recycling ProblemsEasy to storeCleaning using liquidsVapor–liquid separatorSolenoid valve

The invention discloses a multifunctional circulating cleaning system used for two-way cleaning of a part to be cleaned. The multifunctional circulating cleaning system comprises a gas source, a firstgas-liquid separator for storing cleaning agents, a second gas-liquid separator for storing the cleaning agents, a first exhaust pipeline, a second exhaust pipeline, a pressure detecting device, a plurality of pipelines for connecting the components, solenoid valves arranged on the pipelines and controllers arranged on the pipelines. The gas source is used as power, the multiple pipelines and thesolenoid valves are used in cooperation to realize the reciprocating cycle type automatic cleaning process, the operation is simple, thorough cleaning can be achieved, batch cleaning work can be done, the problem of recycling of the cleaning agents is solved, the cleaning cost is effectively reduced, and the free-liquid residual cleaning is truly achieved.

Owner:蒋书印

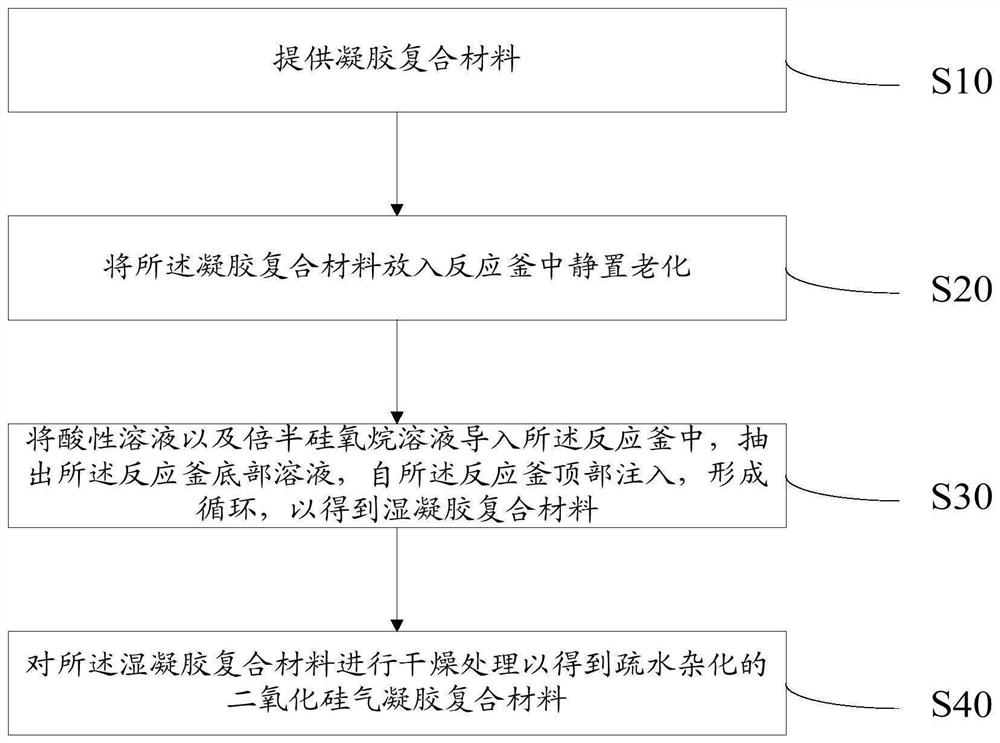

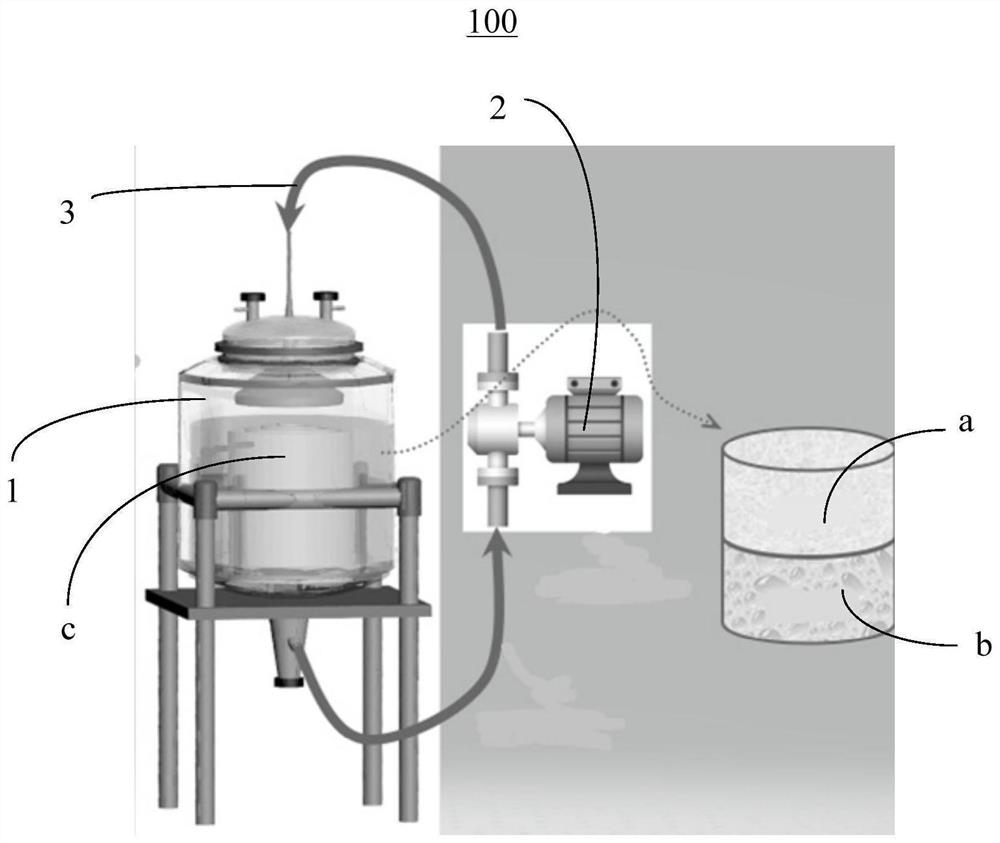

Preparation method of silicon dioxide aerogel composite material

ActiveCN113603452ATake advantage ofUse thoroughlyAerogel preparationColloidal chemistry detailsSelf-condensationSilicon oxide

The invention discloses a preparation method of a silicon dioxide aerogel composite material. The preparation method comprises the following steps: S10, providing a gel composite material; s20, putting the gel composite material into a reaction kettle for standing and aging; s30, introducing an acid solution and a silsesquioxane solution into a reaction kettle,pumping the solution at the bottom of the reaction kettle out, and injecting the solution from the top of the reaction kettle to form circulation so as to obtain a modified wet gel composite material ; and s40, performing drying treatment on the wet gel composite material to obtain the hydrophobic hybrid silicon dioxide aerogel composite material. Due to the fact that the circulation process is conducted continuously, an active modifier is generated continuously, the active modifier makes full contact with the gel composite material from top to bottom, and the modification process is conducted fully, so that the gel compositematerial can be fully and efficiently modified. In addition, a large number of active modifiers generated in the modification process can be subjected to self condensation reaction when meeting water to generate silsesquioxane, and the generated silsesquioxane can participate in the next circular reaction process.

Owner:INST OF ADVANCED TECH UNIV OF SCI & TECH OF CHINA

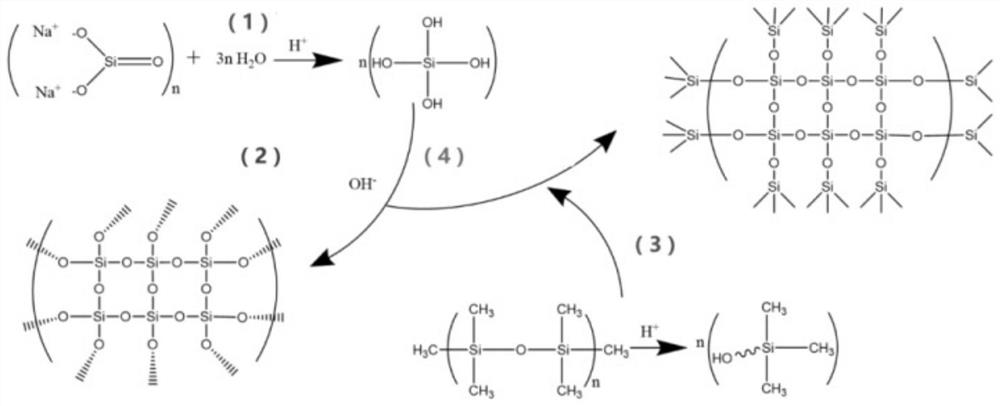

Disinfection device for surgical instruments in general surgery department

InactiveCN108787568AEasy to useUse thoroughlyLavatory sanitoryCleaning using liquidsInlet valveUv disinfection

The invention discloses a disinfection device for surgical instruments in the general surgery department. The disinfection device comprises a support frame, a shell body, a liquid storage box, a wasteliquid box, a placement frame, a rotary shaft, a drive motor, a high-pressure water pump, an electromagnetic liquid inlet valve, an electromagnetic liquid outlet valve, an ultraviolet disinfection lamp and a PLC, wherein the shell body is of a cavity structure with an open top end, a cover body capable of opening and sealing the shell body is hinged to the top of the shell body, the shell body isarranged in the support frame, and the liquid storage box, the waste liquid box and the drive motor are arranged at the bottom of the support frame separately; the ultraviolet disinfection lamp is further arranged on the bottom surface of the cover body; and the high-pressure water pump, the electromagnetic liquid inlet valve, the electromagnetic liquid outlet valve, the drive motor and the ultraviolet disinfection lamp are electrically connected with the PLC arranged in the support frame separately. The disinfection device is simple in structure, convenient to use, capable of ensuring the safety of the surgical instruments and the thoroughness of disinfection, capable of lowering the labor intensity of medical personnel and increasing the working efficiency, and great in popularization and use values.

Owner:马利

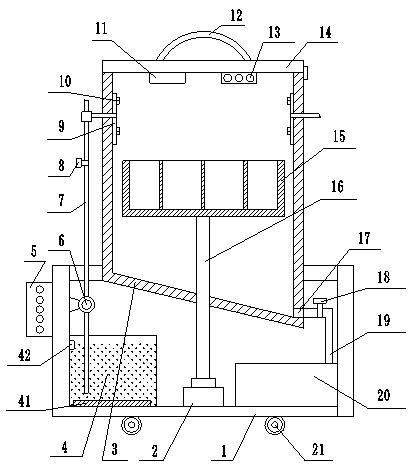

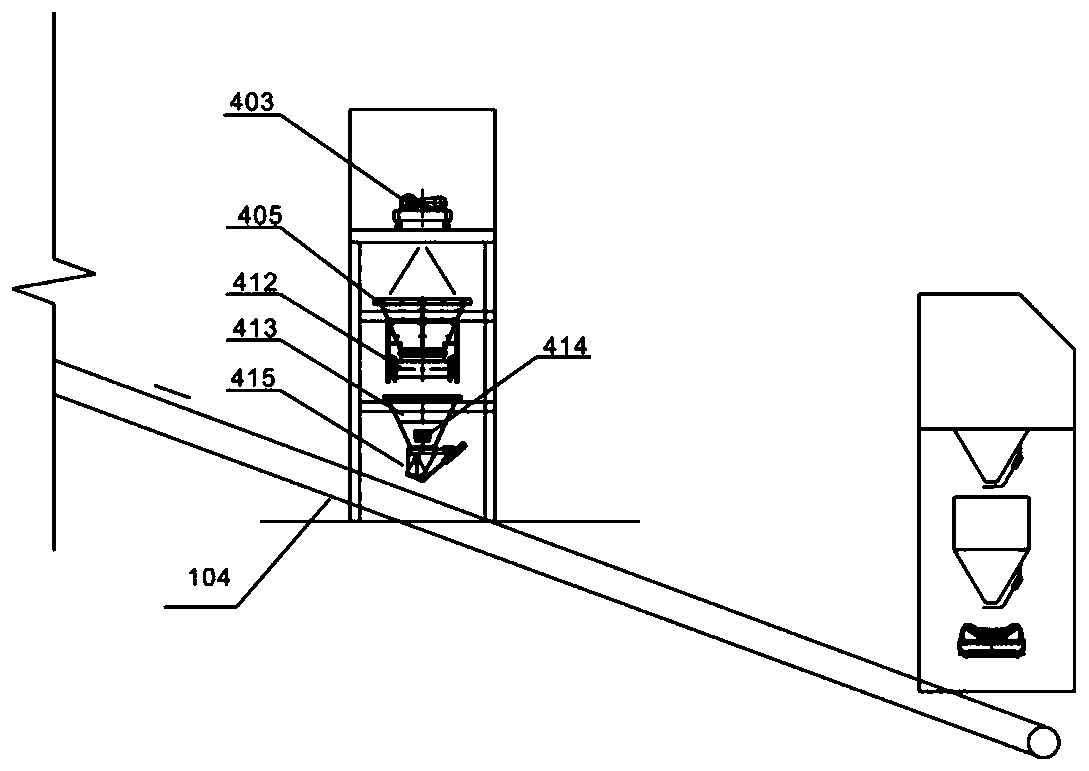

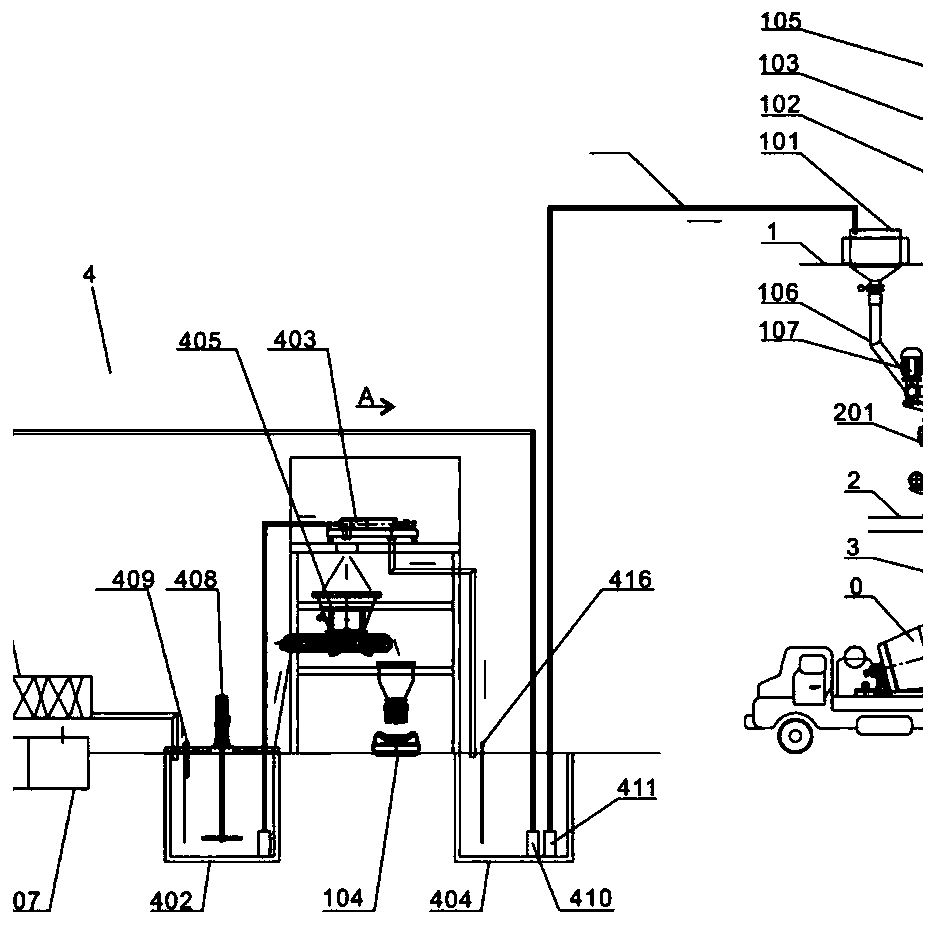

Sewage waste residue recycling system of concrete mixing station and equipment thereof

InactiveCN109968538AEfficient use ofNo stickingWater/sewage treatment by centrifugal separationTreatment involving filtrationWastewaterSewage

The invention provides a sewage waste residue recycling system of a concrete mixing station and equipment thereof. Mixed starch separated by a sand and stone separator is filtered to obtain separatedclean water and waste residues. The separated clean water is used for production of the stirring station or washing a tank of a concrete transport cart. The waste residues are used for production of the stirring station or are returned to the mixed starch to be uniformly stirred again. On the one hand, the damage of waste water to a stirring pond, a conveying pipeline and a pressurizing pump is reduced and on the other hand, an effect of cyclic utilization of the waste residues is promoted. Meanwhile, the freshness of the waste residues is ensured by means of the system and the equipment, so that the waste residues can be directly put into production for application, and therefore, the consumed time and cost for disposal of filter residues and filter cakes are saved.

Owner:ZHENGZHOU SANHE HYDRAULIC MACHINERY +4

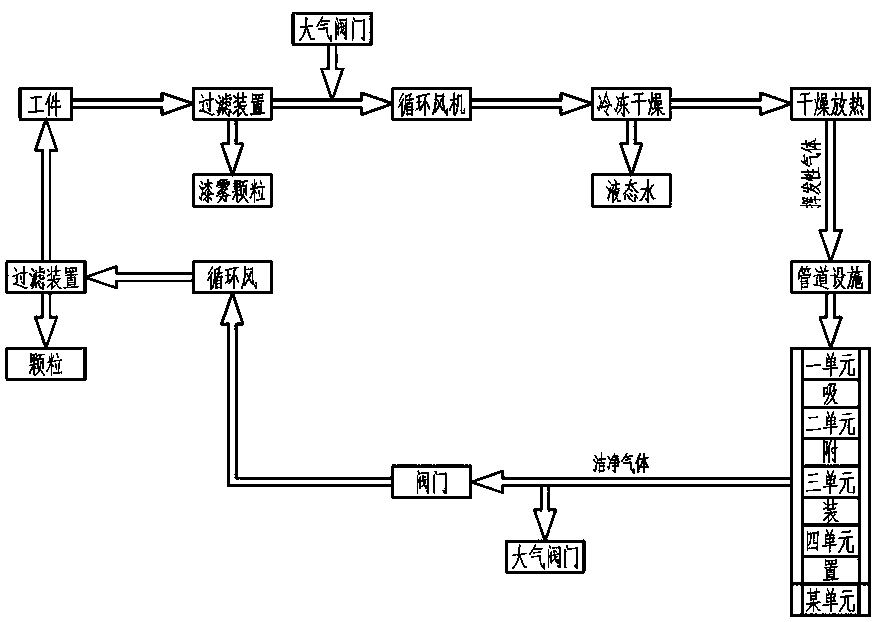

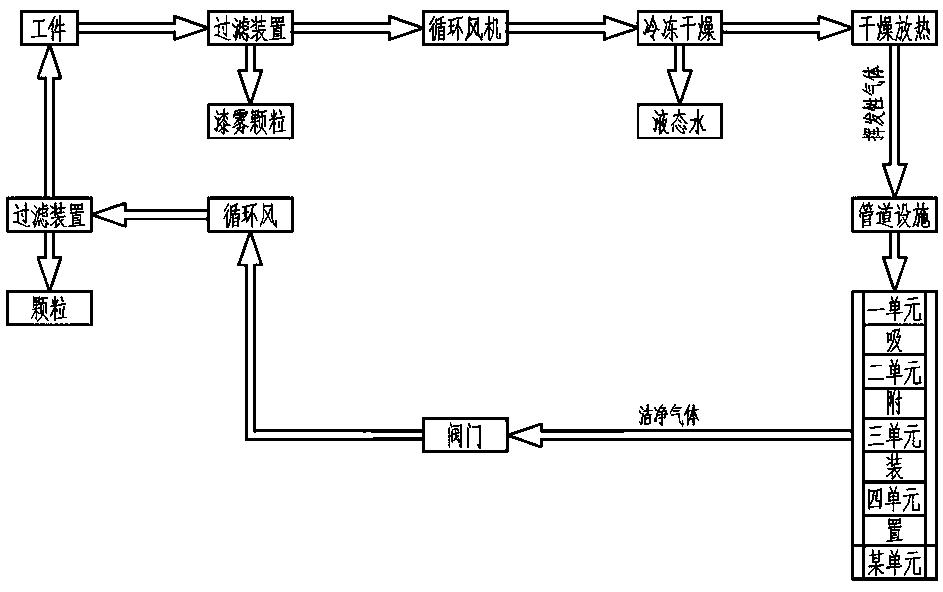

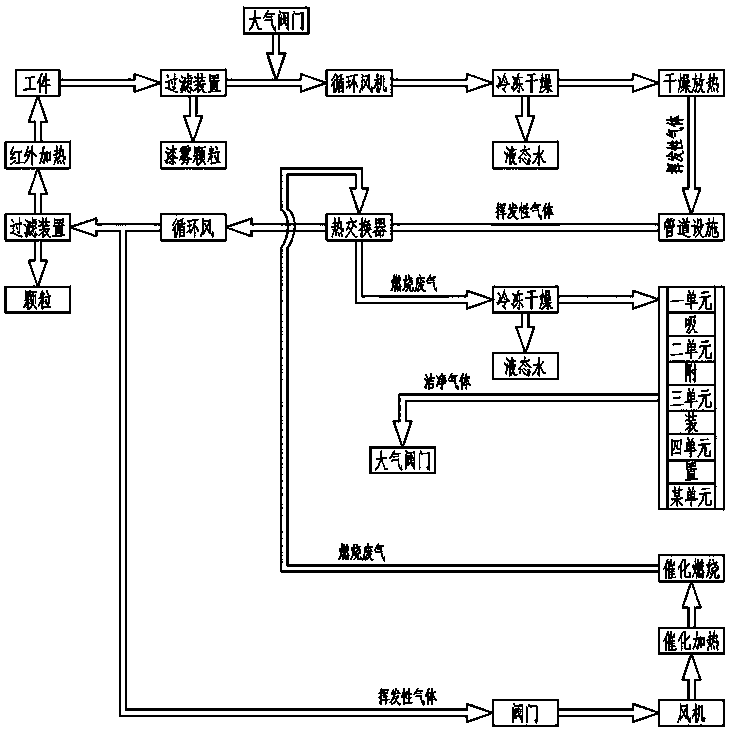

Energy-saving environment-friendly circulation type waste gas treatment method applied to paint spraying and paint baking process

ActiveCN108079738AAchieve recyclingAvoid affecting the painting and baking operation, or even polluting the workpieceGas treatmentDispersed particle filtrationHigh concentrationEnvironmental resistance

The invention discloses an energy-saving environment-friendly circulation type waste gas treatment method applied to a paint spraying and paint baking process. The method comprises the steps of paintspraying stage waste gas treatment, levelling stage waste gas treatment and drying stage waste gas treatment; during the drying stage waste gas treatment, after the levelling is completed, the operation enters the drying stage; waste gas in a drying chamber is taken away by gas exchange equipment; the taken waste gas is filtered and dried; the treated waste gas flows back into the drying chamber to form circulation airflow; when the concentration of organic volatile gas is high, and is lower than the lower explosive limit by 25 percent, a small part of high-concentration waste gas is extractedfrom the circulation airflow; heating and low-temperature catalytic oxidation are performed to form high-temperature combustion waste gas; after the high-temperature combustion waste gas and most circulation airflow are subjected to heat exchange, freeze drying and adsorption are performed; the waste gas is exhausted into atmosphere after reaching the standard. After the method is used, the wastegas can be thoroughly treated as much as possible; the discharging total quantity is reduced to the greatest degree; the resource utilization rate is improved; the effects of energy saving and environment protection are really achieved.

Owner:王理

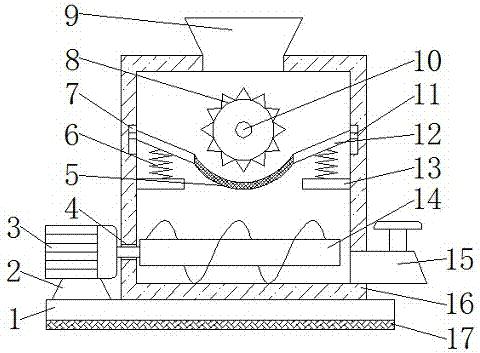

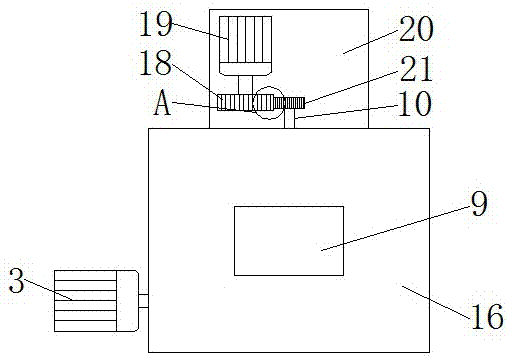

Pulverizing device for iron phosphate producing and processing

InactiveCN107243382AImprove crushing effectUse thoroughlyGrain treatmentsBiochemical engineeringPhosphate

The invention discloses a crushing device for ferric phosphate production and processing, comprising a base, a crushing box is fixedly connected to the top of the base, a second support plate is fixedly connected to the back surface of the crushing box, and the top of the second support plate The left side of the motor is fixedly connected with a second motor, and the output end of the second motor is fixedly connected with a master and a slave chainring. The present invention solves the existing problems by setting the first motor, the through hole, the filter screen, the crushing teeth, the rotating shaft, the swash plate, the crushing blade, the crushing box, the driving tooth disc, the second motor and the driven tooth disc. The crushing effect of the crushing device for production and processing of iron phosphate is poor. The crushing device for production and processing of iron phosphate has the advantages of good crushing effect, which makes the crushing of iron phosphate more thorough, reduces the workload of users, and improves the user's efficiency. The work efficiency speeds up the production progress of the next process, facilitates the use of users, and has a simple structure, which is worth popularizing.

Owner:王亚伟

Method for producing lipstatin by virtue of fermentation

InactiveCN104630301AUse thoroughlyFully utilizeMicroorganism based processesFermentationStreptomyces toxytriciniMixed fatty acid

The invention discloses a method for producing lipstatin by virtue of fermentation. The method comprises the following steps: preparing an inclined plane strain of streptomyces toxytricini, preparing shake flask seeds, preparing a seed solution, performing fermentation and cultivation, and adding linseed oil in a fed-batch mode after performing fermentation and cultivation for 50 hours, wherein calculated based on the volume of a fermentation canned material, the fed-batch rate of the linseed oil is 0.03-0.2L / h / t. The method disclosed by the invention can be controlled and operated more easily by only adding one substance namely the linseed oil in a fed-batch mode after performing fermentation and cultivation for 50 hours than by replenishing a mixture of linoleic acid and leucine as well as a mixture of mixed fatty acid and a leucine solution; on the premise of early fed-batch fermentation, the measures of further improving the fermentation yield, more completely utilizing a culture medium and cooling after fermenting for 130 hours can be controlled, bacterium decay can be delayed by virtue of cooling, the fermentation cycle can be prolonged by 20-30 hours, and the production titer time can be increased; and moreover, the culture medium can be used more fully and completely, the pressure of three-waste treatment can be reduced, and the method can be more environment-friendly.

Owner:HEBEI SHENGXUE DACHENG PHARMA

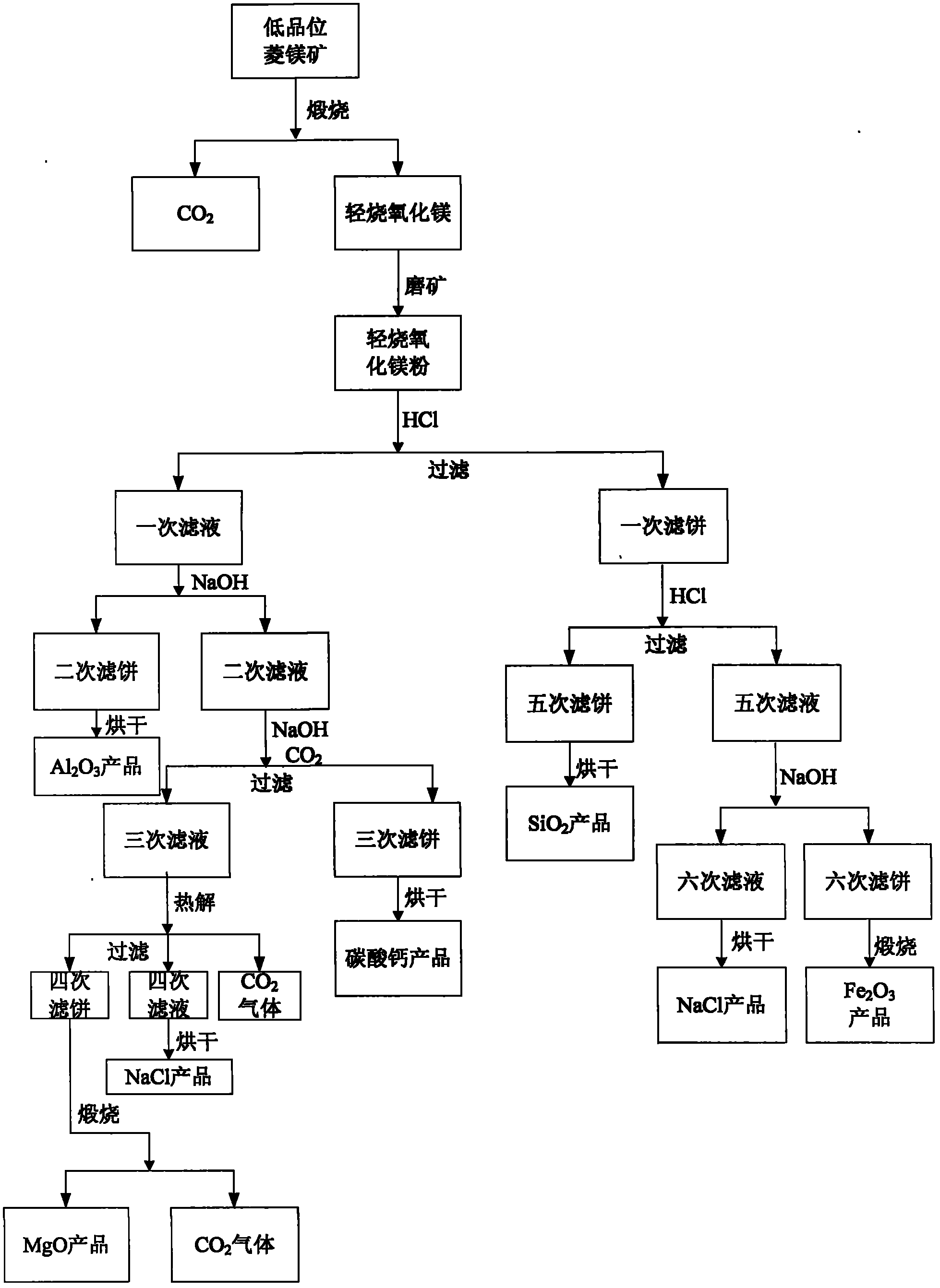

Comprehensive utilization method for low-grade magnesite

InactiveCN102115813ATake advantage ofImprove overall utilizationSilicon oxidesFerric oxidesChemistryZero emission

The invention relates to a comprehensive utilization method for low-grade magnesite, and belongs to the fields of mineral processing and environmental protection. The method comprises the following steps of: grinding MgO obtained by calcining the low-grade magnesite into powder, mixing with H2O, and filtering to obtain a primary filter cake and primary filtrate; adding alkali solution into the primary filtrate, and filtering to obtain a filter cake and filtrate; drying the filter cake to obtain Al2O3; adding NaOH solution into the filtrate and introducing CO2 gas to obtain a filter cake and filtrate; drying the filter cake to obtain CaCO3; heating and filtering the filtrate to obtain a filter cake and filtrate NaCl; calcining the filter cake to obtain the MgO; adding acid into the primary filter cake, filtering to obtain a filter cake and filtrate, and drying the filter cake to obtain SiO2; and adding the NaOH into the filtrate, filtering to obtain a filter cake and sexenary filtrate NaCl, and calcining the filter cake to obtain Fe2O3. Useful components in the magnesite are extracted and separated one by one, so that the zero emission of magnesite tailings is realized, the low-grade magnesite is more fully utilized, and the comprehensive utilization rate of mineral resources is improved.

Owner:LIAONING TECHNICAL UNIVERSITY

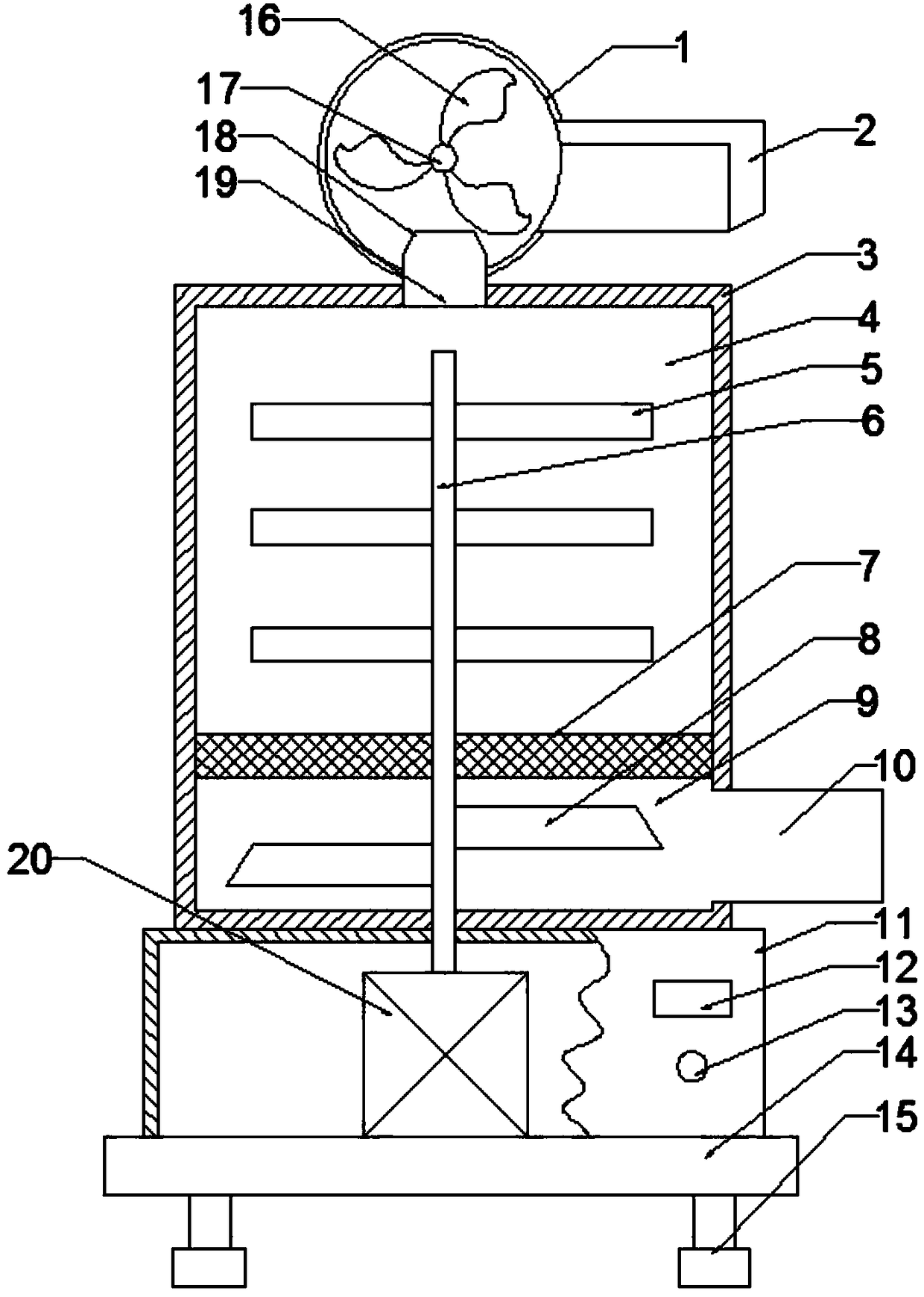

Agricultural straw pulverizer

The invention discloses an agricultural straw pulverizer. The agricultural straw pulverizer includes a feeding device and a pulverizing device; a preprocessing box is fixedly arranged at the center ofthe top of a box body, and the preprocessing box is communicated with the box body through a feed opening; a shearing arm is fixedly arranged on the inner wall of an inner cavity of the preprocessingbox; a filter net is fixedly arranged on the lower side of the inner cavity of the box body, the upper side of a filter net is provided with a pulverizing chamber, and the lower side of the filter net is provided with a discharge chamber; a discharge hole is formed in the right side of the box body, a motor box is fixedly arranged below the box body, the motor is fixedly arranged at the center ofthe inner cavity of the motor box, and an output shaft of the motor is connected with a pulverizing rotating shaft; a base is fixedly arranged below the motor box, and the lower end face of the baseis fixedly provided with a support device. The support device includes a support column and a foot, the support column is vertically arranged on the lower end face of the base, and the lower portion of the support column is provided with the foot. The agricultural straw pulverizer has the advantages of being simple in structure, convenient to use, thorough in pulverizing and stably supported.

Owner:刘桂珍

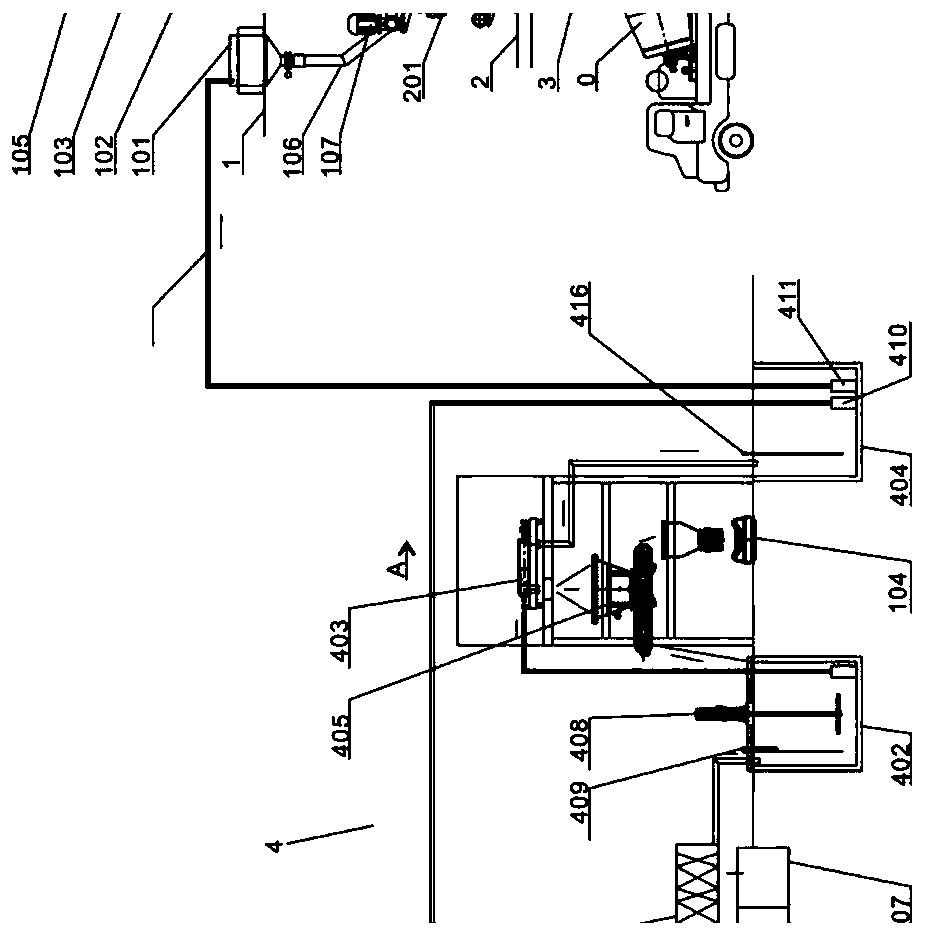

Electrolytic aluminum liquid preparation device

PendingCN110559940AUse thoroughlyAvoid stickingTransportation and packagingMixer accessoriesElectrolysisEngineering

The invention relates to the field of electrolytic aluminum, and more specifically relates to an electrolytic aluminum liquid preparation device. The electrolytic aluminum liquid preparation device comprises a box body; a placement base is fixedly installed at the bottom of the box body, an observation window and a control panel are fixedly installed on the front face of the box body, and the boxbody comprises a mixing cavity, a stirring cavity, a separation cavity, a discharging cavity, an air inlet cavity, a first water pump pipe, a control valve pipe, a second water pump pipe and an air pump pipe. According to the electrolytic aluminum liquid preparation device, the materials can be pre-mixed while being matched by utilizing the mixing cavity, so that subsequent workload is reduced effectively, and the working efficiency and the mixing effect are improved; the stirring cavity is adopted for matching to realize enhanced mixing of materials, so that the materials are mixed more uniformly; meanwhile, the inner wall of the stirring cavity is scraped through a scraping plate, adhesion of molten aluminum onto the inner wall of the stirring cavity is avoided, the molten aluminum in the stirring cavity is utilized more thoroughly, and the quality of the molten aluminum is guaranteed while the cost is saved.

Owner:臧龙

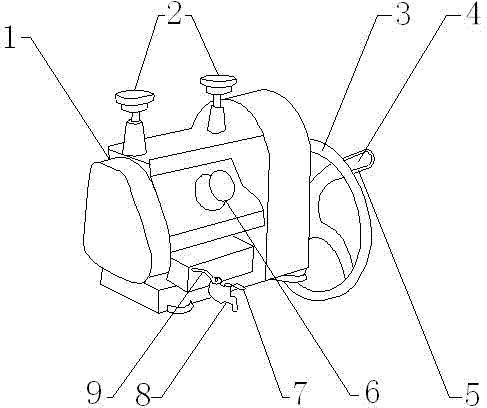

Manual cane crusher

InactiveCN103070597AUse thoroughlyEasy to operateStrainersJuice extraction from sugarcaneEngineeringCrusher

The invention discloses a manual cane crusher and relates to the field of food machinery. The manual cane crusher comprises a main machine; the upper middle part of the main machine is provided with a feeding hole; the lower part of the main machine is provided with a juice outlet; the side face of the main machine is provided with a rocking device; a rocking bar is arranged on the rocking device; and the main machine is provided with two rotating gears. The manual cane crusher is easy to operate, small in size and convenient to move, and is provided with two rotating gears, a proper gear can be selected according to the thickness and the size of cane and the condition of an operator, the manual cane crusher is suitable for all kinds of people, and the two gears are alternately used, so that the cane is utilized thoroughly.

Owner:SUZHOU MAIKE FOOD MACHINERY PLASTIC CEMENT

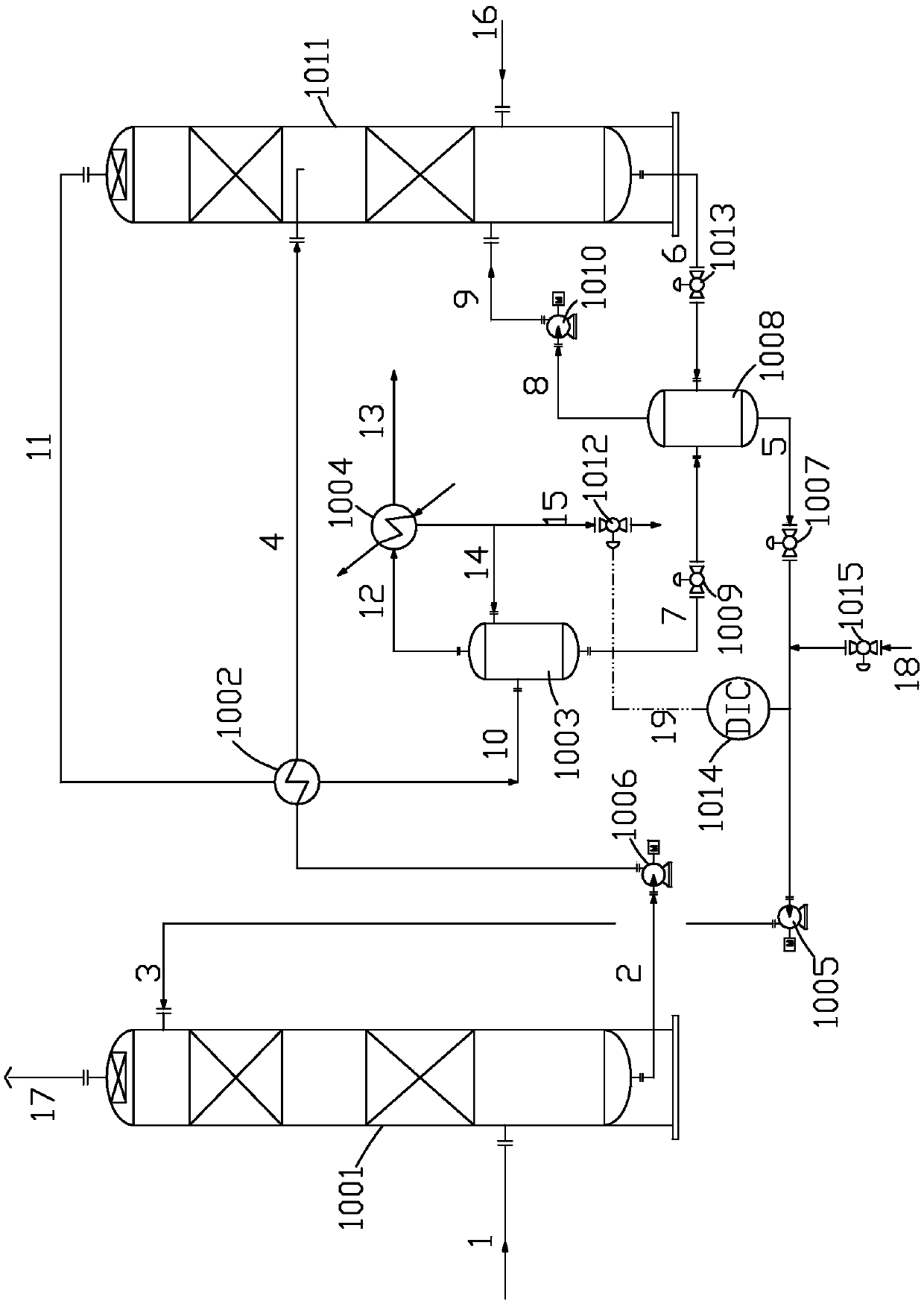

Device for capturing smoke and recovering carbon dioxide at low energy consumption and gas recovery process

ActiveCN107754568AWon't clogStable concentration controlGas treatmentDispersed particle separationDesorptionFlash-gas

The invention discloses a device for capturing smoke and recovering carbon dioxide at low energy consumption and a gas recovery process. The device comprises an absorption tower, a desorption tower, arich solution pump, a vacuum flasher, a gas stripping desorption device, a desorption tower top gas heat recovery device and an absorbent concentration regulation device, a barren solution pump is connected on the side surface of the top end of the absorption tower through a first barren solution pipe and is connected with the vacuum flasher through a second barren solution pipe, the desorption tower is connected with the rich solution pump through the desorption tower top gas heat recovery device, and the absorbent concentration regulation device is connected between the desorption tower topgas heat recovery device and the second barren solution pipe. The recovery process is as follows: a solvent absorbs the carbon dioxide in the smoke, a rich solution heater uses a regenerated gas to heat the absorbent, then the absorbent enters the desorption tower, a hot barren solution is flashed in vacuum after being mixed, the flash gas enters the desorption tower to implement gas stripping, and the carbon dioxide is desorbed. The device reduces the number of heat exchangers, the heat is thoroughly recovered, the problem that a barren and rich solution heat exchanger is often blocked and needs to be cleaned is solved, the heat utilization ratio is high, and the equipment investment is low.

Owner:沈建冲

Medical trolley with function of sterilizing

InactiveCN106473884AUse thoroughlyAvoid wastingNursing accommodationRadiationFan bladeMedical treatment

The invention discloses a medical trolley with a function of sterilizing. The medical trolley comprises a shell, a casing is fixedly connected to the right side of the shell, the top of the left side of the inner cavity of the casing is fixedly connected with an air collecting tube, a motor case is fixedly connected to the left side of the top of the casing and located in the inner cavity of the air collecting tube, the right side of the inner cavity of the motor case is fixedly connected with a motor, a rotating shaft of the motor penetrates the left side of the motor case and extends to the inner cavity of the air collecting tube, and fan blades sleeve one end, located in the inner cavity of the air collecting tube, of the rotating shaft of the motor. The medical trolley capable of sterilizing is provided with the motor, the fan blades and an ultraviolet radiator strip, wet medical instruments are placed on a tray, the air blown from an electric fan accelerates the drying of the medical instruments, an ultraviolet radiator sterilizes the medical instruments, a water receiving tray is arranged at the bottom of the tray, then the disinfectant dripping from the medical instrument drips into the water receiving tray, and the trolley is worthy of popularization.

Owner:林丽芳

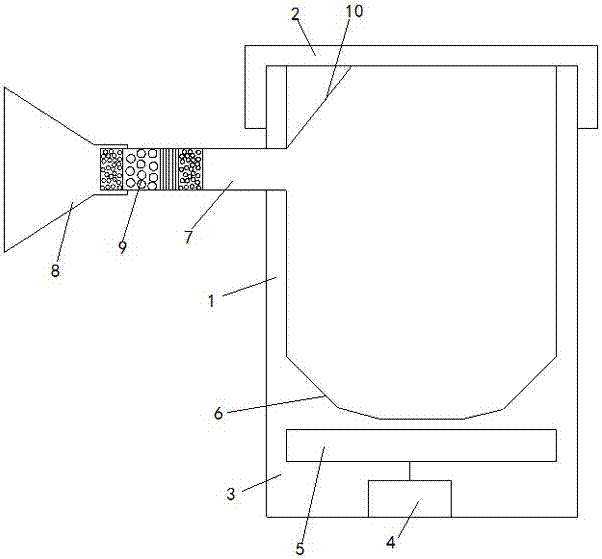

Medical ultrasonic atomizer

ActiveCN107029324AImprove water absorption efficiencyFast water absorptionSolid sorbent liquid separationMedical devicesUltrasonic generatorEngineering

The invention discloses a medical ultrasonic atomizer. The medical ultrasonic atomizer comprises a cup body (1), the top of the cup body (1) is provided with a cup cover (2), the bottom of the cup body (1) is provided with a base (3), the base (3) is internally provided with an ultrasonic generator (4), the ultrasonic generator (4) is connected with a crystal transducer (5), and the cup body (1) is connected with the base (3) through a sound transparent film (6); the side wall of the cup body (1) is connected with a nasal mask (8) through a connecting pipe (7), and the nasal mask (8) is movably connected with the connecting pipe (7); a plurality of layers of desiccants (9) are arranged in the connecting pipe (7), and filtering nets are movably arranged in the middle of each layer of desiccant and at the two ends of each layer of desiccant; a guide plate (10) is arranged in the cup body (1). According to the method, water removal efficiency of a liquid drug is high, and drying agents can be replaced, so that moisture can be avoided from entering the lung.

Owner:苏州雾联医疗科技有限公司

Novel alcohol-based liquid fuel and preparation method thereof

The invention relates to a novel alcohol-based liquid fuel with a high combustion heat value and no smoke and toxicity after combustion, which relates to the field of petrochemical fuels. The alcohol-based liquid fuel is composed of refined methanol, an igniting agent, a stabilizing agent, an anti-knock and a deodorant. The preparation method for the novel alcohol-based liquid fuel comprises the following steps: placing refined methanol in a container, adding the igniting agent and carrying out uniform mixing with stirring; then adding the deodorant and carrying out uniform mixing with stirring for 3 min; adding the anti-knock, carrying out uniform mixing with stirring for 5 min and then carrying out an immobility reaction for 10 min; adding the stabilizing agent and carrying out uniform mixing with stirring; and carrying out an immobility reaction in a storage tank for 24 h so as to prepare the novel alcohol-based liquid fuel. According to the invention, methanol used in the method can be converted from coal and the like, which provides a feasible approach for clean utilization of coal; production cost is low, and the method is simple and is favorable for large scale popularization and utilization; the fuel has a high heat value, as high as 25000 kJ / kg; and the fuel has the advantages of thorough gasification, full combustion, no smoke, no toxicity, no pollution to the environment, accordance with requirements of environmental protection, good anti-shock performance, safety in use and convenience in storage and transportation.

Owner:黄利

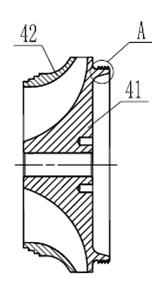

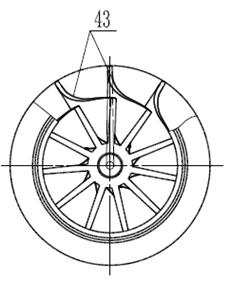

Supercharged turbo expander

InactiveCN102661174AReduce lossUse thoroughlyPump componentsBlade accessoriesEngineeringMechanical engineering

The invention provides a gas bearing supercharged turbo expander, including an intermediate shell body with a turbo volute being arranged on the left end of the intermediate shell body, a supercharger volute being arranged on the right end of the intermediate shell body, and a rotor being rotatably arranged inside the intermediate shell body, wherein an expansion wheel and a supercharging wheel are respectively arranged on both ends of the rotor, and two gas bearings sleeve on the rotor for supporting the expansion wheel and the supercharging wheel. The supercharged turbo expander provided in the invention has the advantages of simple structure, low shaft loss, low cost, high safety performance, reduced oil steam discharge in an oil bearing expander, and decreased environmental pollution, thereby establishing a milepost-type foundation for the development of the supercharged turbo expander.

Owner:苏州制氧机股份有限公司

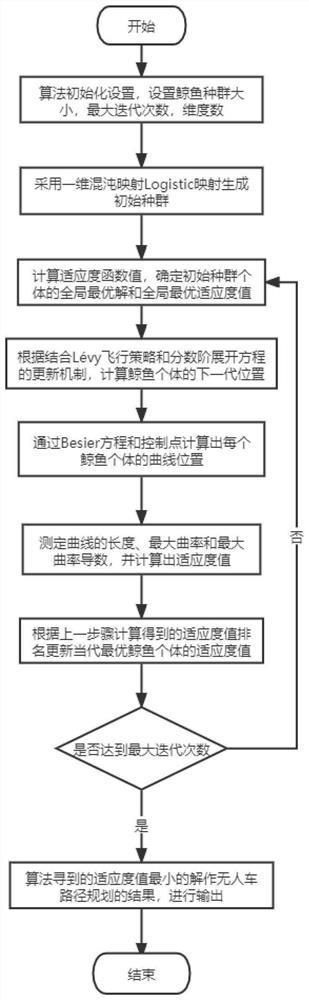

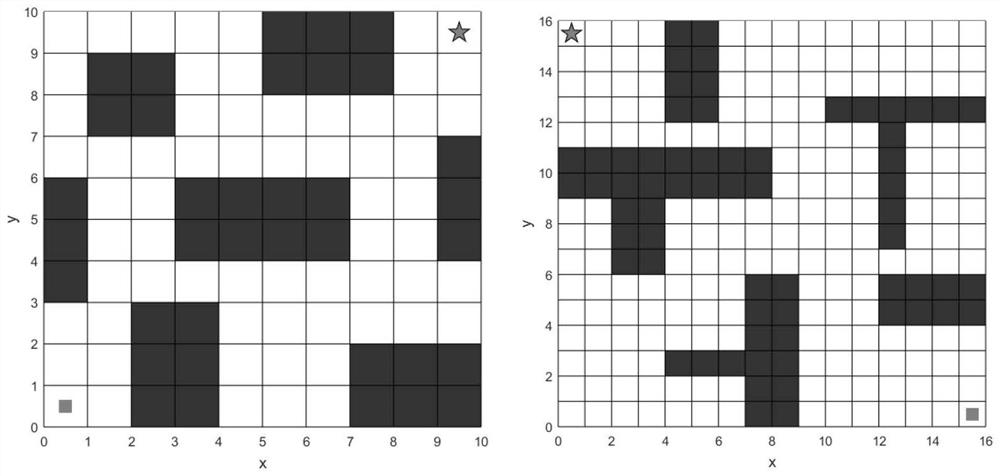

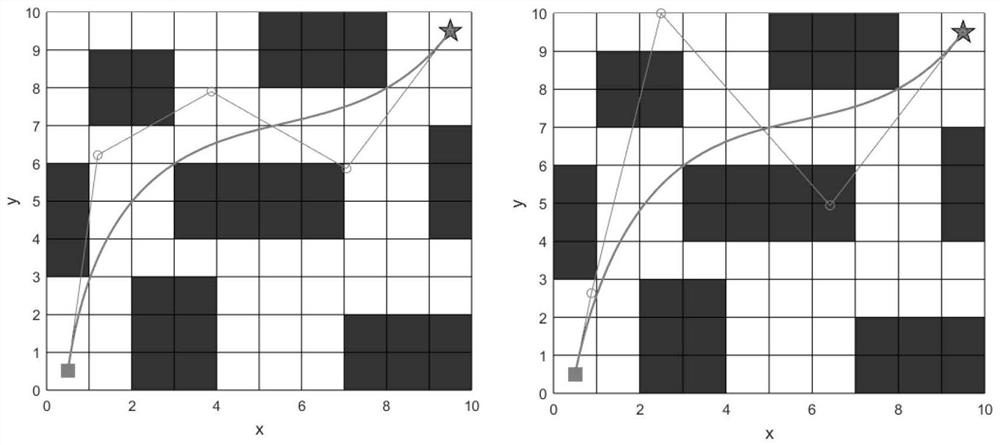

Smooth path planning method based on whale optimization algorithm

ActiveCN114489061AVerify superiorityImprove performanceInternal combustion piston enginesPosition/course control in two dimensionsLocal optimumPath length

According to the whale optimization algorithm-based smooth path planning method provided by the invention, the path length, the curvature and the curvature derivative in an improved WOA optimization curve path are adopted, and a good result is obtained. In the improved WOA algorithm, a Levy flight strategy is introduced to add local disturbance to the algorithm, the diversity of solutions is increased, and local optimum is avoided. And meanwhile, a fractional order expansion equation is introduced, so that each generation of whale individuals is influenced by the positions of the previous generations, and the search capability of the algorithm is further enhanced. In 23 reference functions, the performance of the improved WOA algorithm and other algorithms is tested and compared, and the superiority of the improved WOA algorithm is verified. Finally, analog simulation experiments are carried out in two different maps, a high-order Bezier curve is adopted in a smoothing method, and continuity of the path curvature is guaranteed. Compared with the existing other algorithms, the improved WOA algorithm has the advantages that the performance is obviously improved, and the operation time is shorter.

Owner:HUBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com