Comprehensive utilization method for low-grade magnesite

A magnesite and low-grade technology, which is applied in the field of comprehensive utilization of low-grade magnesite, can solve the problem of separation of useful components without magnesite, and achieve the effect of improving comprehensive utilization rate and full utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

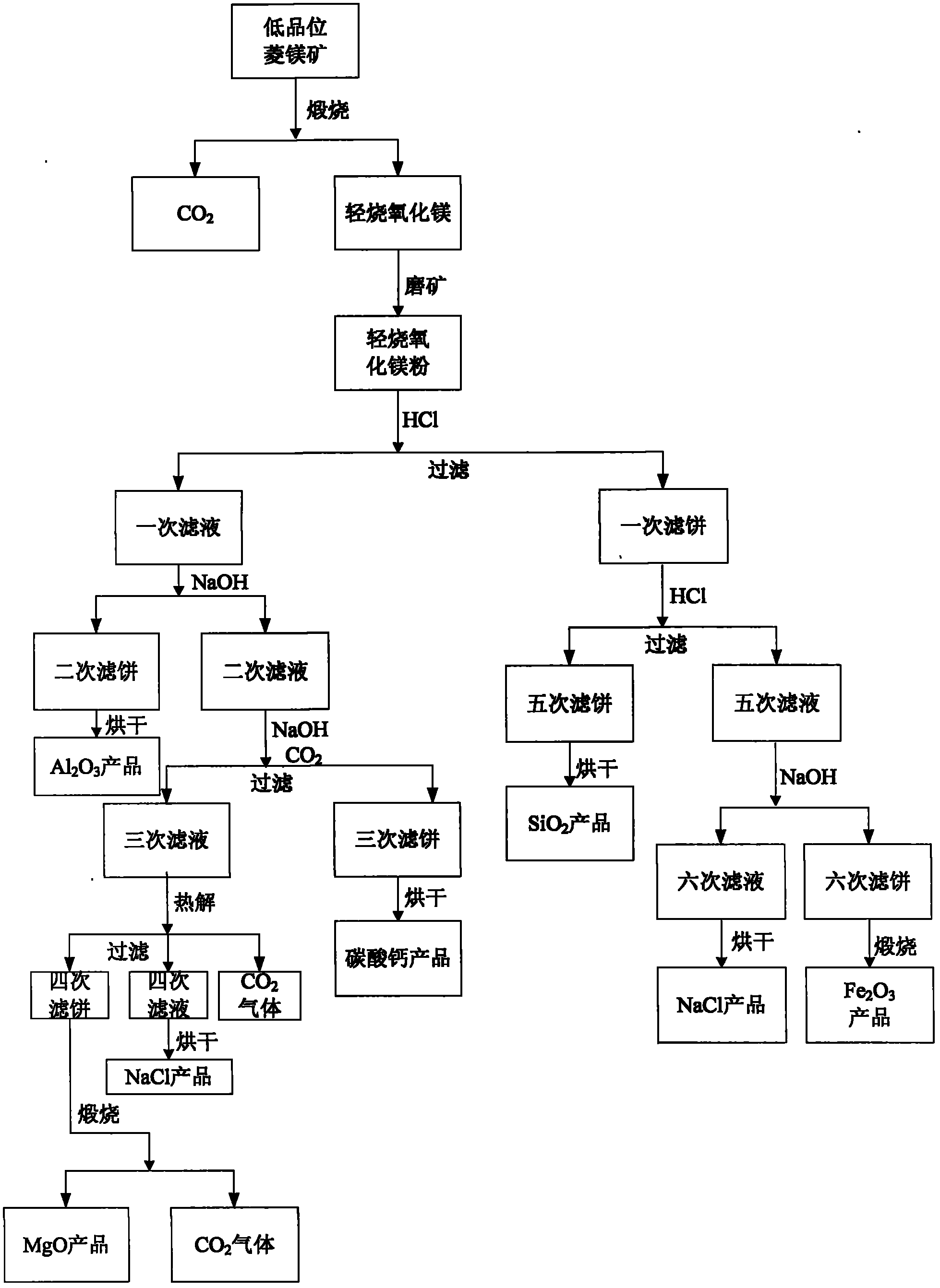

Image

Examples

Embodiment 1

[0040] The concentration of hydrochloric acid used in this embodiment is 0.2 mol / L, and the concentration of NaOH solution used is 0.1 mol / L.

[0041] Calcining low-grade magnesite in a muffle furnace at 900 °C for 3 h, the obtained CO 2 Gas recovery, the obtained light-burned magnesia is ground into -200 mesh light-burned magnesia powder; the light-burned magnesia powder is mixed with water and stirred evenly, and the mixing ratio is light-burned magnesia powder by weight: water=1: 4. Then add hydrochloric acid to adjust the pH of the mixture to 5 to obtain a slurry, filter the slurry to obtain a primary filter cake and a primary filtrate; add NaOH solution to the primary filtrate and stir evenly, the pH of the primary filtrate = 5, and then under stirring conditions Filtrate to obtain the secondary filter cake and secondary filtrate, and dry the secondary filter cake at 150°C to obtain Al 2 o 3 product; add NaOH solution to the secondary filtrate and stir evenly, while fee...

Embodiment 2

[0046] The concentration of hydrochloric acid used in this embodiment is 0.3 mol / L, and the concentration of NaOH solution used is 0.4 mol / L.

[0047] Calcining low-grade magnesite in a muffle furnace at 950 °C for 2.5 h, the 2 Gas recovery, the obtained light-burned magnesia is ground into -100 mesh light-burned magnesia powder; the light-burned magnesia powder is mixed with water and stirred evenly, and the mixing ratio is light-burned magnesia powder by weight: water=1: 2. Then add hydrochloric acid to adjust the pH=4 of the mixture to obtain a slurry, filter the slurry to obtain a primary filter cake and a primary filtrate; add NaOH solution to the primary filtrate and stir evenly, the pH of the primary filtrate=4, and then under stirring conditions Filtrate to obtain the secondary filter cake and secondary filtrate, and dry the secondary filter cake at 140°C to obtain Al 2 o 3 product; add NaOH solution to the secondary filtrate and stir evenly, while feeding CO 2 Gas,...

Embodiment 3

[0051] The hydrochloric acid concentration that adopts is 0.5mol / L, and the NaOH solution concentration that adopts is 0.2mol / L;

[0052] Calcining low-grade magnesite in a muffle furnace at 1000 °C for 2 h, the CO 2 Gas recovery, the obtained light-burned magnesia is ground into -300 mesh light-burned magnesia powder; the light-burned magnesia powder is mixed with water and stirred evenly, and the mixing ratio is light-burned magnesia powder by weight: water=1: 1, then add hydrochloric acid to adjust the pH=5 of the mixture to obtain a slurry, filter the slurry to obtain a primary filter cake and a primary filtrate; add NaOH solution to the primary filtrate and stir evenly, the pH of the primary filtrate=6, and then under stirring conditions Filtrate to obtain the secondary filter cake and secondary filtrate, and dry the secondary filter cake at 160°C to obtain Al 2 o 3 product; add NaOH solution to the secondary filtrate and stir evenly, while feeding CO 2 Gas, adjust the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com