Sewage waste residue recycling system of concrete mixing station and equipment thereof

A mixing plant and concrete technology, which is applied in the field of sewage and slag recycling system of concrete mixing plant and its equipment, can solve the problems that sewage cannot be sprayed evenly, the mixing time is prolonged, and it is easy to adhere and block, so as to achieve easy storage, transportation, and utilization. Complete, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

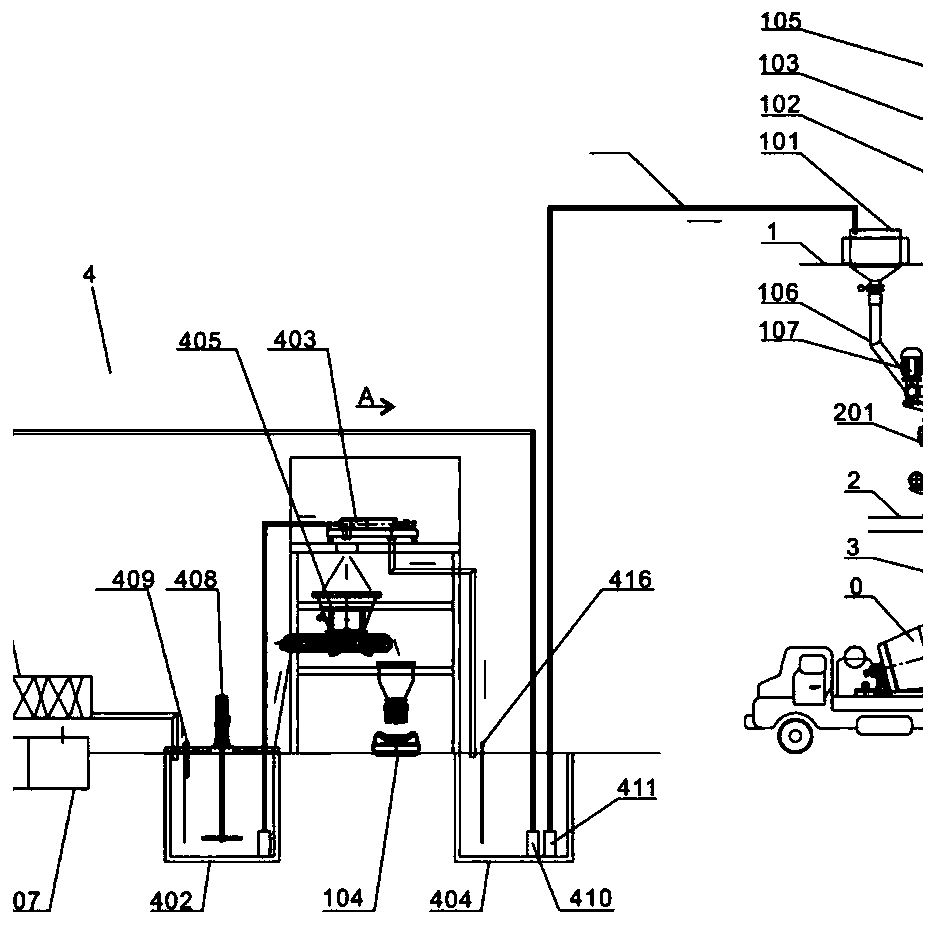

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] A system for recycling sewage and waste residue in a concrete mixing plant, which filters the slurry water separated by a sand-stone separator to obtain separated clear water and waste residue; the separated clear water is used for the production of the mixing plant or for concrete transport vehicles Tank washing; the waste slag is used in the production of the mixing station or returned to the slurry water for further mixing.

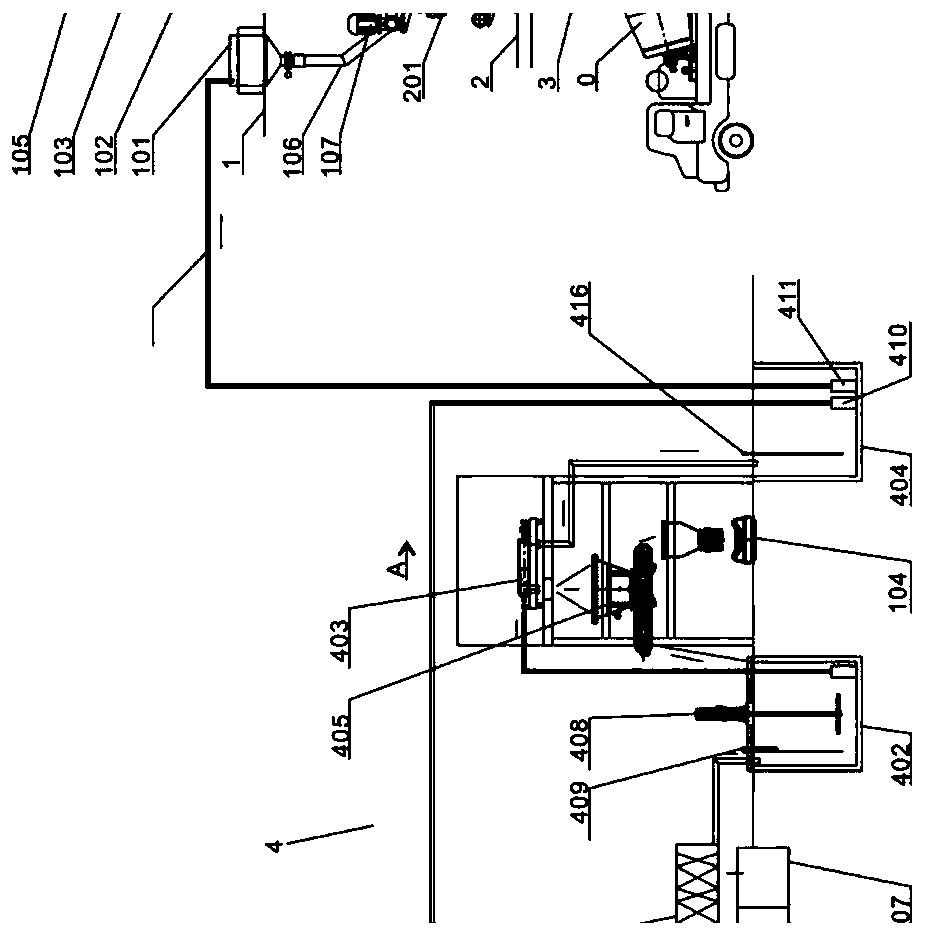

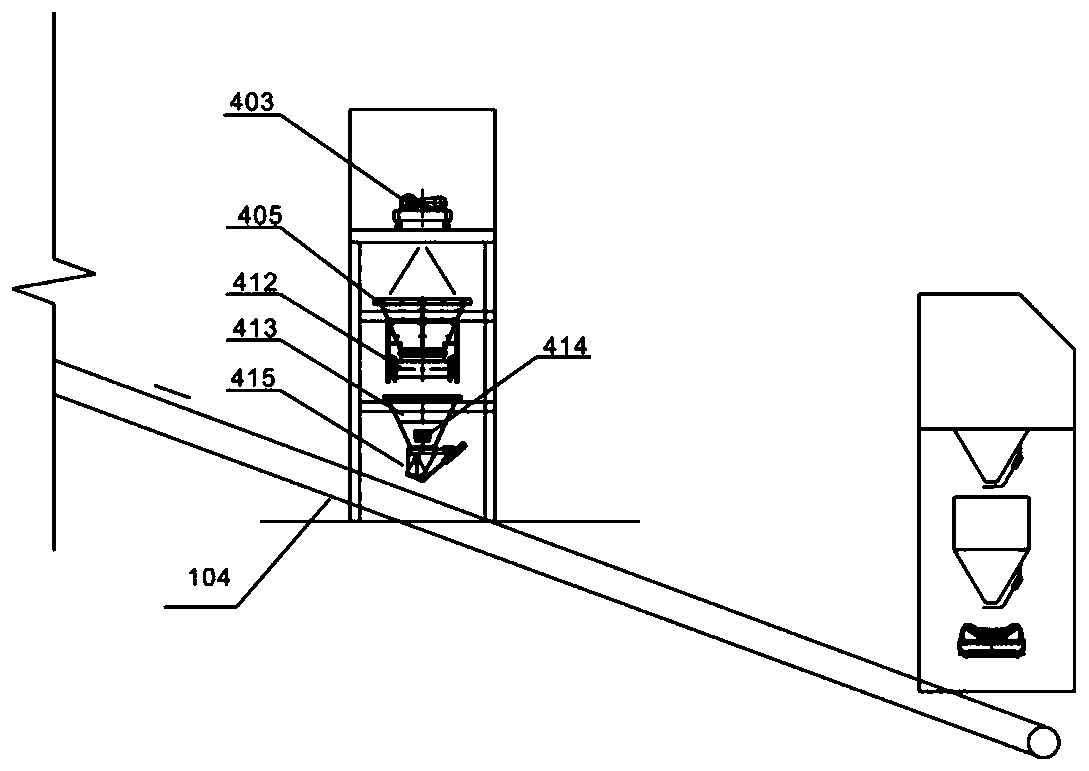

[0022] Such as figure 1 and figure 2 Shown is a concrete mixing plant sewage and waste residue recovery equipment, which mainly includes the concrete mixing plant body and corresponding recycling equipment.

[0023] The main body of the concrete batching plant includes a batching platform 1, a mixing layer platform 2 and a concrete hopper 3; the batching mainly includes three parts, which correspond to water, powder, and pre-stored ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com