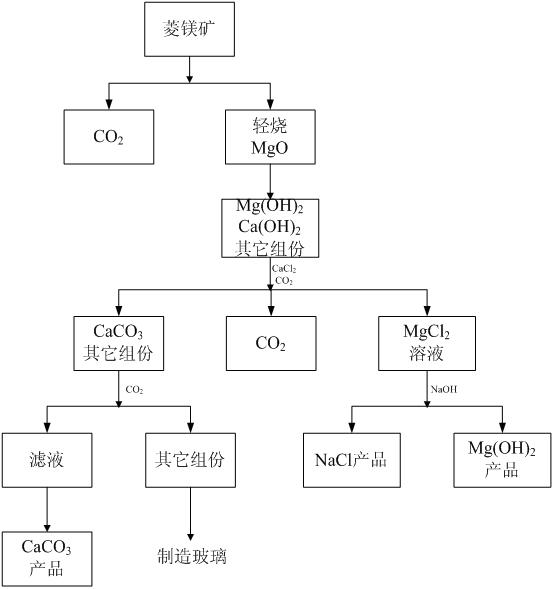

Magnesite carbonization method for producing magnesium hydroxide and calcium carbonate product

A technology of magnesium hydroxide and magnesite, applied in the direction of magnesium hydroxide, calcium carbonate/strontium/barium, etc., can solve the problems of low carbonization efficiency, low resource utilization efficiency, and small scale, so as to improve carbonization efficiency and comprehensive Utilization rate, fully utilized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The concentration of the NaOH solution used in this embodiment is 0.1 mol / L.

[0030] The magnesite is calcined in a muffle furnace at 900°C for 3 hours to obtain CO 2 After gas recovery, the obtained light burnt magnesia is ground into -200 mesh light burnt magnesia powder; the light burnt magnesia powder and water are mixed according to the weight ratio of light burnt magnesia powder: water=1:40 and stirred evenly, Hydrate at 80℃ for 3h to obtain a slurry; add lightly burned MgO powder:CaCl to the slurry in a weight ratio 2 =1:0.8 CaCl 2 Mix and stir evenly, the mixing ratio, and stir evenly, and at the same time pass in CO with a purity of 99% 2 Gas, reaction pressure is 0.5MPa, reaction temperature is 25℃, reaction time 2h , Then stir and filter to obtain the primary filter cake and the primary filtrate, add NaOH to the primary filtrate and stir evenly, adjust the pH of the primary filtrate to 8, then stir and filter to obtain the secondary filter cake and the secondary ...

Embodiment 2

[0034] The concentration of the NaOH solution used in this embodiment is 0.4 mol / L.

[0035] The low-grade magnesite is calcined in a muffle furnace at 950℃ for 2.5h to obtain CO 2 After gas recovery, the obtained light burned magnesia is ground into -100 mesh light burned magnesia powder; the light burned magnesia powder and water are mixed according to the weight ratio of light burned magnesia powder: water = 1:20 and stirred evenly, Hydrate at 90°C for 2.5 hours to obtain a slurry; add lightly burned MgO powder: CaCl to the slurry in a weight ratio 2 =1:0.9 Calcium chloride is mixed and stirred evenly, then CO with 99% purity by mass is introduced 2 Gas, reaction pressure is 0.3MPa, reaction temperature is 25℃, reaction time 3h , Then stir and filter to obtain the primary filter cake and the primary filtrate, add NaOH to the primary filtrate and stir evenly, adjust the pH of the primary filtrate to 9, then stir and filter to obtain the secondary filter cake and the secondary fil...

Embodiment 3

[0039] The concentration of the NaOH solution used in this embodiment is 0.2mol / L;

[0040] The magnesite is calcined in a muffle furnace at 1000°C for 2h to obtain CO 2 After gas recovery, the obtained light burned magnesia is milled into -300 mesh light burned magnesia powder; the light burned magnesia powder and water are mixed according to the weight ratio: water = 1:30 and stirred evenly, Hydrate at 100℃ for 2h to obtain a slurry; add lightly burned MgO powder:CaCl to the slurry in a weight ratio 2 =1:1.1 CaCl 2 After mixing and stirring, pass in CO with a purity of 99% 2 Gas, reaction pressure is 0.6MPa, reaction temperature is 25℃, reaction time 1.5h , Then stir and filter to obtain the primary filter cake and the primary filtrate, add NaOH to the primary filtrate and stir evenly, adjust the pH of the primary filtrate to 10, and then stir and filter to obtain the secondary filter cake and the secondary filtrate; press the secondary filter cake The weight ratio is configured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com