System and method for preparing titanium carbide from vanadium titano-magnetite comprehensively

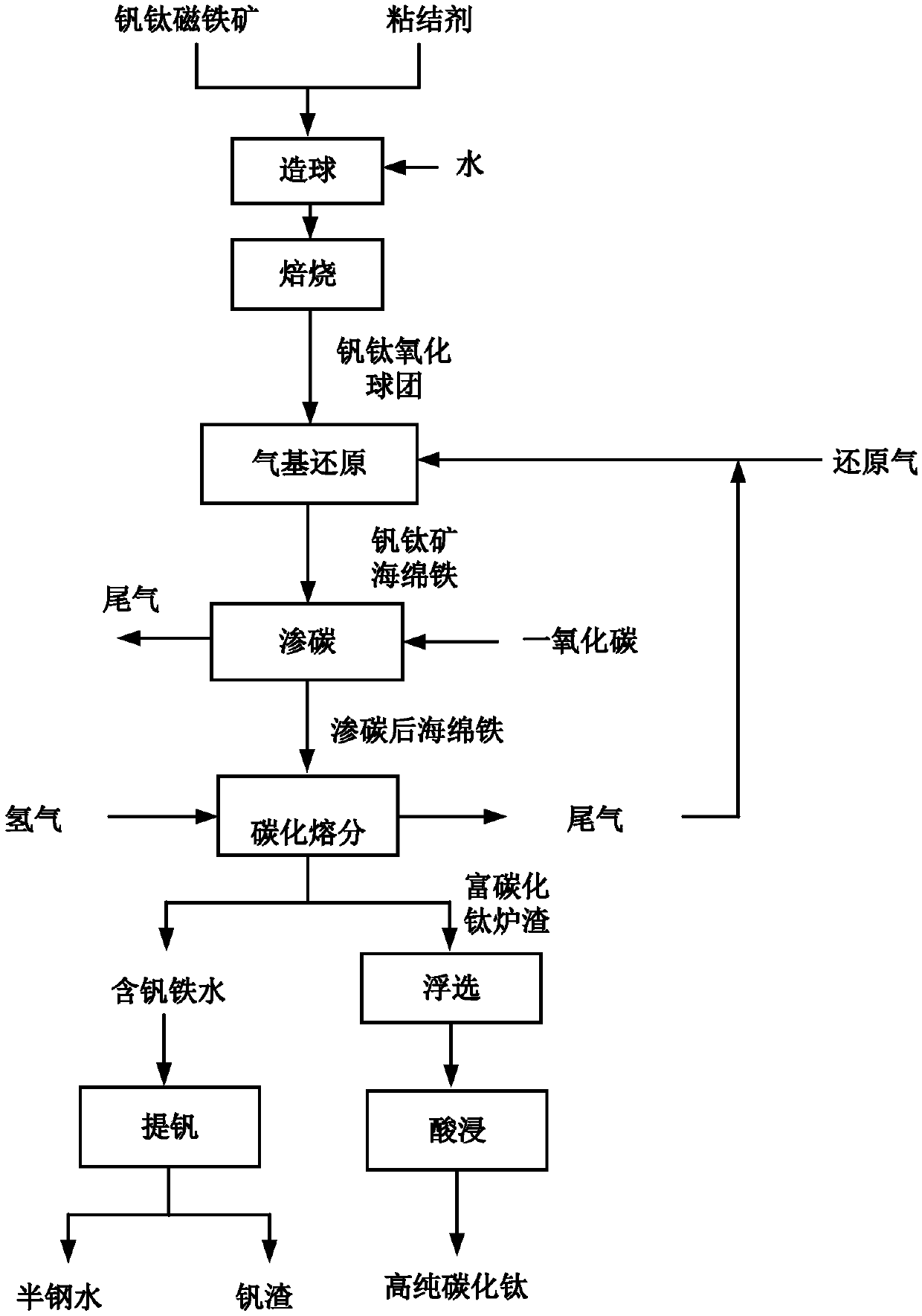

A technology of vanadium-titanium magnetite and titanium carbide is applied in the field of metallurgy, which can solve the problems of high energy consumption and incapability of resource utilization of titanium-containing blast furnace slag, and achieve the effects of high product value, increased added value and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] The present embodiment provides a kind of method for preparing titanium carbide, and concrete steps are as follows:

[0070] (11) The vanadium-titanium-magnetite, binder and water are mixed and pelletized in the pelletizing device at a mass ratio of 88:3:9 to obtain vanadium-titanium-magnetite pellets. The TF of the vanadium titanomagnetite is 59wt%, TiO 2 is 13wt%. The binder is sodium carboxymethyl cellulose.

[0071] (12) Roasting the vanadium-titanium-magnetite pellets in a roasting device after drying to obtain the vanadium-titanium-magnetite oxidized pellets with a porosity of 22%. The calcination temperature is 1250° C., and the calcination time is 20 minutes. The strength of the oxidized pellets was 1850N / piece.

[0072] (13) Using reducing gas containing methane to reduce vanadium-titanium magnetite oxidized pellets in the gas-based shaft furnace to obtain vanadium-titanium ore sponge iron, the reduction temperature is 1000°C. In the reducing gas, the meth...

Embodiment 2

[0080] The present embodiment provides a kind of method for preparing titanium carbide, and concrete steps are as follows:

[0081] (11) The vanadium-titanium magnetite, binder and water are mixed and pelletized in the pelletizing device at a mass ratio of 91:2:7 to obtain vanadium-titanium magnetite pellets. The TF of the vanadium-titanium magnetite is 61wt%, TiO 2 is 10wt%. The binder is sodium carboxymethyl cellulose.

[0082] (12) Roasting the vanadium-titanium-magnetite pellets in a roasting device after drying to obtain the vanadium-titanium-magnetite oxidized pellets with a porosity of 24%. The calcination temperature is 1250° C., and the calcination time is 20 minutes. The strength of the oxidized pellets was 1800N / piece.

[0083] (13) Using methane-containing reducing gas to reduce vanadium-titanium magnetite oxidized pellets in the gas-based shaft furnace to obtain vanadium-titanium magnetite sponge iron, the reduction temperature is 1050°C. In the reducing gas,...

Embodiment 3

[0091] The present embodiment provides a kind of method for preparing titanium carbide, and concrete steps are as follows:

[0092] (11) The vanadium-titanium magnetite, binder and water are mixed and pelletized in the pelletizing device at a mass ratio of 90:3:7 to obtain vanadium-titanium magnetite pellets. The TF of the vanadium titanomagnetite is 64wt%, TiO 2 is 7wt%. The binder is sodium carboxymethyl cellulose.

[0093] (12) Roasting the vanadium-titanium-magnetite pellets in a roasting device after drying to obtain the vanadium-titanium-magnetite oxidized pellets with a porosity of 21%. The calcination temperature is 1250° C., and the calcination time is 20 minutes. The strength of the oxidized pellets was 1900N / piece.

[0094] (13) Using methane-containing reducing gas to reduce vanadium-titanium magnetite oxidized pellets in the gas-based shaft furnace to obtain vanadium-titanium ore sponge iron, the reduction temperature is 1100°C. In the reducing gas, the metha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Purity | aaaaa | aaaaa |

| Purity | aaaaa | aaaaa |

| Purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com